Abstract

Organic solvents are widely used in polymer synthesis, despite their use lengthening purification steps and generating chemical waste. All-dry synthesis techniques, such as initiated chemical vapour deposition polymerization, eliminate the use of solvents; however, only a narrow palette of material properties are accessible. Inspired by the principles of solvent engineering in solution synthesis, we report a strategy to broaden this palette by vapour phase complexing (namely, vapour phase solvation) mediated by hydrogen bonding. Broad ranges of polymer chain length, as well as the mechanical strength and variety of film surface morphology, are demonstrated using this strategy. We further achieve an unprecedented solvation modality; more specifically, interfacial solvation. The molecular interactions, locations of solvation and kinetics of the coupled solvation–adsorption–polymerization process are investigated using molecular dynamics simulations and experimental validation of a theoretical kinetics model. The strategy can be applied to various methacrylate and vinyl monomers. Solvation in all-dry polymerization offers a concept in polymer design and synthesis with improved environmental benignness, pointing to accelerated discovery of polymer thin films by simply introducing active solvents in the vapour phase.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All of the data needed to evaluate the conclusions in this paper are presented within the paper and its Supplementary Information. Source data are provided with this paper.

Code availability

NAMD is free and open-source code available at https://www.ks.uiuc.edu/Research/namd/. Data processing scripts are available upon request from the corresponding authors. The code for data processing can be found at https://doi.org/10.24435/materialscloud:1k-qd.

References

Coote, M. L., Davis, T. P., Klumperman, B. & Monteiro, M. J. A mechanistic perspective on solvent effects in free-radical copolymerization. J. Macromol. Sci. Polym. Rev. 38, 567–593 (1998).

Salehpour, S. & Dubé, M. A. The use of biodiesel as a green polymerization solvent at elevated temperatures. Polym. Int. 57, 854–862 (2008).

Wang, W. et al. Simultaneously improving controls over molecular weight and stereoregularity of poly(4-vinylpyridine) via a hydrogen bonding-facilitated controlled radical polymerization. Polymer 54, 3248–3253 (2013).

Oxana, S., Pascale, C. & Cunningham, M. F. Greener solvent systems for copper wire-mediated living radical polymerisation. Green Mater. 4, 104–114 (2016).

Wang, X., Shen, L. & An, Z. Dispersion polymerization in environmentally benign solvents via reversible deactivation radical polymerization. Prog. Polym. Sci. 83, 1–27 (2018).

Donadt, T. B. & Yang, R. Amphiphilic polymer thin films with enhanced resistance to biofilm formation at the solid–liquid–air interface. Adv. Mater. Interfaces 8, 2001791 (2021).

Gleason, K. K. Nanoscale control by chemically vapour-deposited polymers. Nat. Rev. Phys. 2, 347–364 (2020).

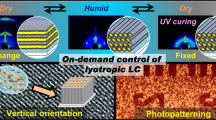

Cheng, K. C. K. et al. Templated nanofiber synthesis via chemical vapor polymerization into liquid crystalline films. Science 362, 804–808 (2018).

Yu, S. J. et al. Initiated chemical vapor deposition: a versatile tool for various device applications. Adv. Eng. Mater. 20, 1700622 (2018).

Moon, H. et al. Synthesis of ultrathin polymer insulating layers by initiated chemical vapour deposition for low-power soft electronics. Nat. Mater. 14, 628–635 (2015).

Sun, L. et al. Chemical vapour deposition. Nat. Rev. Methods Primers 1, 5 (2021).

McGaughey, A. L., Karandikar, P., Gupta, M. & Childress, A. E. Hydrophobicity versus pore size: polymer coatings to improve membrane wetting resistance for membrane distillation. ACS Appl. Polym. Mater. 2, 1256–1267 (2020).

Beauregard, N. et al. Enhancing iCVD modification of electrospun membranes for nembrane distillation using a 3D printed scaffold. Polymers 12, 2074 (2020).

Chen, Y. et al. Controlled flight of a microrobot powered by soft artificial muscles. Nature 575, 324–329 (2019).

Gleason, K. K. Controlled release utilizing initiated chemical vapor deposited (iCVD) of polymeric nanolayers. Front. Bioeng. Biotechnol. 9, 632753 (2021).

Bonnet, L. et al. Initiated-chemical vapor deposition of polymer thin films: unexpected two-regime growth. Macromol. Mater. Eng. 302, 1700315 (2017).

Bose, R. K. & Lau, K. K. S. Mechanical properties of ultrahigh molecular weight PHEMA hydrogels synthesized using initiated chemical vapor deposition. Biomacromolecules 11, 2116–2122 (2010).

Lau, K. K. S. & Gleason, K. K. Initiated chemical vapor deposition (iCVD) of poly(alkyl acrylates): a kinetic model. Macromolecules 39, 3695–3703 (2006).

Chen, X. & Anthamatten, M. Solvent-assisted dewetting during chemical vapor deposition. Langmuir 25, 11555–11562 (2009).

Tao, R. & Anthamatten, M. Porous polymers by controlling phase separation during vapor deposition polymerization. Macromol. Rapid Commun. 34, 1755–1760 (2013).

De Luna, M. M., Karandikar, P. & Gupta, M. Interactions between polymers and liquids during initiated chemical vapor deposition onto liquid substrates. Mol. Syst. Des. Eng. 5, 15–21 (2020).

Wu, H. et al. Hydrogen bonding promoting the controlled radical polymerization of 2-vinyl pyridine: supramonomer for better control. Polym. Chem. 6, 2620–2625 (2015).

Wang, W. et al. Favorable hydrogen bonding in room-temperature Cu(0)-mediated controlled radical polymerization of 4-vinylpyridine. Polym. Chem. 3, 2731–2734 (2012).

Shafi, H. Z., Khan, Z., Yang, R. & Gleason, K. K. Surface modification of reverse osmosis membranes with zwitterionic coating for improved resistance to fouling. Desalination 362, 93–103 (2015).

Yang, R., Jang, H., Stocker, R. & Gleason, K. K. Synergistic prevention of biofouling in seawater desalination by zwitterionic surfaces and low-level chlorination. Adv. Mater. 26, 1711–1718 (2014).

Petruczok, C. D., Yang, R. & Gleason, K. K. Controllable cross-linking of vapor-deposited polymer thin films and impact on material properties. Macromolecules 46, 1832–1840 (2013).

Lau, K. K. S. & Gleason, K. K. Initiated chemical vapor deposition (iCVD) of poly(alkyl acrylates): an experimental study. Macromolecules 39, 3688–3694 (2006).

Lee, B. et al. Initiated chemical vapor deposition of thermoresponsive poly(N-vinylcaprolactam) thin films for cell sheet engineering. Acta Biomater. 9, 7691–7698 (2013).

Rudin, A. & Choi, P. in The Elements of Polymer Science & Engineering 3rd edn (eds Rudin, A. & Choi, P.) 341–389 (Academic Press, 2013).

Khlyustova, A. & Yang, R. Initiated chemical vapor deposition kinetics of poly(4-aminostyrene). Front. Bioeng. Biotechnol. 9, 670541 (2021).

Yao, F., Liu, Q., Zhang, Z. & Zhu, X. RAFT polymerization of styrene and maleimide in the presence of fluoroalcohol: hydrogen bonding effects with classical alternating copolymerization as reference. Polymers 9, 89 (2017).

Rumrill, S. M., Agarwal, V. & Lau, K. K. S. Conformal growth of ultrathin hydrophilic coatings on hydrophobic surfaces using initiated chemical vapor deposition. Langmuir 37, 7751–7759 (2021).

Franklin, T., Streever, D. L. & Yang, R. Versatile and rapid synthesis of polymer nanodomes via template- and solvent-free condensed droplet polymerization. Chem. Mater. 34, 5960–5970 (2022).

Larson, J. W., Clair, R. L. & McMahon, T. B. Bimolecular production of proton bound dimers in the gas phase. A low pressure ion cyclotron resonance technique for examination of solvent exchange equilibria and determination of single molecule solvation energetics. Can. J. Chem. 60, 542–544 (1982).

Izadi, Z., Tabrizchi, M. & Farrokhpour, H. Thermodynamic study of proton-bond dimers formation in atmospheric pressure: an experimental and theoretical study. J. Chem. Thermodyn. 63, 17–23 (2013).

Socha, O. & Dračínský, M. Dimerization of acetic acid in the gas phase—NMR experiments and quantum-chemical calculations. Molecules 25, 2150 (2020).

Pei, K., Li, Y. & Li, H. Hydrogen-bonding interaction between acetic acid and pyridine 1:1 complex. J. Mol. Struct. 660, 113–118 (2003).

Ranke, W. & Weiss, W. Adsorption and thermal decomposition of ethylbenzene and styrene on Pt(111) studied by UPS and XPS. Surf. Sci. 465, 317–330 (2000).

Driver, M. D., Williamson, M. J., Cook, J. L. & Hunter, C. A. Functional group interaction profiles: a general treatment of solvent effects on non-covalent interactions. Chem. Sci. 11, 4456–4466 (2020).

Zaki, M. I., Hasan, M. A., Al-Sagheer, F. A. & Pasupulety, L. In situ FTIR spectra of pyridine adsorbed on SiO2–Al2O3, TiO2, ZrO2 and CeO2: general considerations for the identification of acid sites on surfaces of finely divided metal oxides. Colloids Surf. A 190, 261–274 (2001).

Fowkes, F. M. Role of acid–base interfacial bonding in adhesion. J. Adhes. Sci. Technol. 1, 7–27 (1987).

Colomer, I., Chamberlain, A. E. R., Haughey, M. B. & Donohoe, T. J. Hexafluoroisopropanol as a highly versatile solvent. Nat. Rev. Chem. 1, 0088 (2017).

Wang, W., Zhang, Z., Zhu, J., Zhou, N. & Zhu, X. Single electron transfer-living radical polymerization of methyl methacrylate in fluoroalcohol: dual control over molecular weight and tacticity. J. Polym. Sci. A Polym. Chem. 47, 6316–6327 (2009).

Miura, Y. et al. Synthesis of well-defined syndiotactic poly(methyl methacrylate) with low-temperature atom transfer radical polymerization in fluoroalcohol. J. Polym. Sci. A Polym. Chem. 44, 1436–1446 (2006).

Phillips, J. C. et al. Scalable molecular dynamics on CPU and GPU architectures with NAMD. J. Chem. Phys. 153, 044130 (2020).

Huang, J. & MacKerell, A. D. Jr CHARMM36 all-atom additive protein force field: validation based on comparison to NMR data. J. Comput. Chem. 34, 2135–2145 (2013).

Hanwell, M. D. et al. Avogadro: an advanced semantic chemical editor, visualization, and analysis platform. J. Cheminformatics 4, 17 (2012).

Vanommeslaeghe, K. et al. CHARMM general force field: a force field for drug-like molecules compatible with the CHARMM all-atom additive biological force fields. J. Comput. Chem. 31, 671–690 (2010).

Heinz, H., Lin, T.-J., Kishore Mishra, R. & Emami, F. S. Thermodynamically consistent force fields for the assembly of inorganic, organic, and biological nanostructures: the INTERFACE force field. Langmuir 29, 1754–1765 (2013).

Martínez, L., Andrade, R., Birgin, E. G. & Martínez, J. M. PACKMOL: a package for building initial configurations for molecular dynamics simulations. J. Comput. Chem. 30, 2157–2164 (2009).

Humphrey, W., Dalke, A. & Schulten, K. VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Abraham, M. J. et al. GROMACS: high performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 1–2, 19–25 (2015).

Acknowledgements

This work was supported by the US National Science Foundation (NSF) Faculty Early Career Development Program (grant number CMMI-2144171) to R.Y. It was also sponsored by the US Department of the Navy Office of Naval Research under ONR award N00014-20-1-2418 to R.Y. and the Fleming Scholarship to P.C. J.Y. acknowledges support from the NSF under award EFMA-2223785 and the computational resources provided by the NSF Extreme Science and Engineering Discovery Environment program under award TG-BIO210063. The analytical methods involved the use of the Cornell Center for Materials Research shared facilities, which are supported through the NSF Materials Research Science and Engineering Centers program (grant number DMR-1719875). We thank Y. Cheng for helpful discussions on the gel permeation chromatography data analysis.

Author information

Authors and Affiliations

Contributions

P.C., R.Y., J.Y., Z.Z., Z.R. and S.P.B. designed the research and experiments. P.C. and Z.Z. conducted the depositions and characterizations. J.Y. conducted the all-atom molecular dynamics simulation. Z.R. and S.P.B. supported the nanoindentation experiments. P.C., R.Y. and J.Y. performed the data analysis. P.C. and R.Y. drafted the manuscript. All authors provided critical feedback on the experimental design and data analysis and reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Kenneth Lau and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Alison Stoddart, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended Data

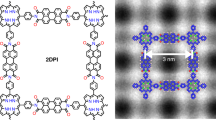

Extended Data Fig. 1 Characterization of the monomer-solvent interactions and the resulting polymer.

(a) Nuclear magnetic resonance (NMR) spectra of 4VP, HFIP, and their mixture, indicating the hydrogen bonding between 4VP and HFIP; (b) Fourier-transform infrared spectroscopy (FTIR) spectra of p4VP deposited using Ar, EtOH, HFIP, and AcOH as the vapor solvent, demonstrating that solvation engineering does not affect the polymer chemistry; (c) X-ray photoelectron spectroscopy (XPS) survey scans of p4VP deposited using Ar or HFIP as the vapor solvent; (d) The polydispersity index (PDI) of the p4VP deposited under various Pmonomer/Psat using Ar or HFIP as the vapor solvent.

Extended Data Fig. 2 Thin film morphology of p4VP deposited with and without a vapor solvent.

(a) and (b) Optical images of Si wafers coated by p4VP thin films, deposited at (a) P4VP = 417 mTorr (with Pmonomer/Psat = 1.01), and (b) P4VP = 208 mTorr and PHFIP = 208 mTorr (with Pmonomer/Psat = 0.21). The DR and Mn were 18.8 nm min-1 and 27.5 kDa, respectively for the film shown on the left, and 20.4 nm min-1 and 44 kDa, respectively for the film shown on the right. (c) Atomic force microscopy (AFM) images of p4VP thin films deposited using Ar (left) and different PHFIP (the three panels on the right); (d) and (e) Scanning electron microscope (SEM) images of 200-nm p4VP thin films deposited on Si wafer in the presence of Ar (b) or HFIP (c).

Extended Data Fig. 3 Demonstration of vapor solvation by reduced chamber pressure during co-flow of monomer and solvents.

Chamber pressure as a function of time when co-flowing 4VP with a non-solvent (Ar) or different vapor solvents (EtOH, AcOH, HFIP) into the vacuum chamber at specified flow rates.

Extended Data Fig. 4 Deposition kinetics of 4VP without a vapor solvent.

(a) The deposition rate of 4VP as a function of Pmonomer/Psat. Error bars represent standard deviations (N = 3); (b) The interaction energy between 4VP and Ar.

Extended Data Fig. 5 Film shrinkage upon applying vacuum at the end of a deposition for different vapor solvents.

Film shrinkage of p4VP deposited using AcOH and HFIP as the vapor solvent, respectively, under different solvent partial pressures. The Pmonomer/Psat and stage temperature were fixed at 0.09 and 27°C, respectively.

Extended Data Fig. 6 MD simulation results of the solvation by EtOH.

The interaction energy during the complexing-adsorption process of the 4VP-EtOH system based on MD simulation.

Extended Data Fig. 7 Independence of the vapor solvation and its effect on deposition kinetics from the underlying substrate.

(a) water contact angles of four different substrates: Si wafer, that is, SiO2, a carbon-coated substrate, a gold-coated substrate, and a pPFDA-coated substrate; (b) the comparison of water contact angles and deposition rates on the four substrates; depositions were performed using the following conditions: 4VP (1.5 sccm) + HFIP (1.5 sccm) + TBPO (0.6 sccm), and a total pressure of 500 mTorr. Error bars represent standard deviations (N = 10).

Extended Data Fig. 8 Independence of the morphology of the thin films deposited with a vapor solvent from the underlying substrate.

AFM images of p4VP films deposited on different substrates. (Si wafer, that is, SiO2, C sputtered on Si wafer, Au sputtered on wafer, pPFDA deposited on Si wafer). The depositions were performed using the following conditions: 4VP (1.5 sccm) + HFIP (1.5 sccm) + TBPO (0.6 sccm), and a total pressure of 500 mTorr.

Extended Data Fig. 9 A schematic illustration of the approach employed to derive the complex desorption enthalpy.

The elemental steps used to deconstruct the desorption of the molecular complex, in which the red arrow indicates the process of interest (that is, molecular complex desorption), and the blue arrows indicate the elemental steps

Extended Data Fig. 10 Understanding the acceleration rate and the effects of stage temperature, Ts, and solvent partial pressure PHFIP or PAcOH.

(a, d) Regression of the acceleration rates versus the synthesis conditions, that is, Ts and PHFIP or AcOH (to obtain the apparent activation energies and rate constants), where the orange dots in (a) denote the data obtained using HFIP and those in (d) denote the data obtained using AcOH. (b, e) Corresponding contour plots of the acceleration rate surface with the conditions that gave rise to the same acceleration rate connected by a contour line. (c, f) Linear correlation between the predicted acceleration rate and the values measured experimentally for HFIP and AcOH.

Supplementary information

Supplementary Information

Supplementary discussion.

Source data

Source Data Fig. 1

Source data for Fig. 1.

Source Data Fig. 2

Source data for Fig. 2.

Source Data Fig. 3

Source data for Fig. 3.

Source Data Fig. 4

Source data for Fig. 4.

Source Data Fig. 5

Source data for Fig. 5.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, P., Zhang, Z., Rouse, Z. et al. Engineering solvation in initiated chemical vapour deposition for control over polymerization kinetics and material properties. Nat. Synth 2, 373–383 (2023). https://doi.org/10.1038/s44160-023-00242-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44160-023-00242-5