Abstract

Wearable skin-contacting devices are extensively studied for their ability to provide convenient and safe health monitoring. A key aspect that controls their performance are the properties of the device electrodes. Optimizing electrode structure, and the materials they are made from, can improve device functionality. Here, we discuss the various properties required for optimal electrode performance, including mechanical, electrical, and biocompatible factors. To address these challenges, we consider alteration of electrode structure, the development of flexible or soft conductive materials, and the creation of hybrid structures. Additionally, the integration of artificial intelligence is proposed as a promising direction to achieve smart devices. As well as outlining essential characteristics for high-performance wearable skin devices we also offer insight into possible future applications.

Similar content being viewed by others

Introduction

Wearable electronics has been developed to improve public health by enabling health monitoring and diagnosis1,2. Skin-interfaced wearable electronics is a promising field due to its non-invasive and easily accessible nature3. These devices can be categorized based on their functions, including sensing vital signs or biomarkers4, and delivering stimuli to alert patients, both of which rely on electrodes5,6. Therefore, it is essential to investigate and establish optimal electrode conditions to ensure the effectiveness of wearable skin devices7.

This paper first discusses the essential characteristics that the electrodes of wearable skin devices should possess, including mechanical properties related to skin elasticity, electrical properties related to device performance, and biocompatibility requirements associated with the skin-electrode interface8,9. Due to the continuous changes in the shape of the skin caused by its high elasticity and low modulus, the electrodes need to exhibit high flexibility, adhesion, and the ability to conform to the shape of the skin10. However, conventional skin electrodes made of rigid materials exhibit relatively higher modulus, making it challenging to meet these requirements11,12. To address this limitation, various approaches for electrode structure have been developed, including the alteration of electrode structures, the development of new flexible and soft electrodes, and the creation of hybrid materials by combining various materials13. These structural methodologies guarantee the secure attachment of the electrodes to the skin, even in instances where the skin undergoes stretching or movement. Achieving the shape, flexibility, and elasticity of wearable skin devices not only extends their lifespan but also significantly enhances their effectiveness.

Furthermore, the utilization of artificial intelligence (AI)14,15 and hybrid functionalities16,17 is recently proposed as a promising direction for the application of wearable skin devices. AI can be employed to facilitate real-time assessment of the user’s physiological status by transmitting and analyzing biological signal data18,19. Additionally, consolidating various functions of wearable skin devices into a unified system can establish an integrated hybrid system within a single device.

Material requirements for wearable skin device electrode

The electrodes adopted in skin devices serve to interact with the skin and capture various electrical signals generated during this process. Moreover, they are utilized for stimulation purposes, including haptic feedback, electrical muscle stimulation, and neural stimulation. Depending on the type of the associated sensor or application, these electrodes can be designed in various forms. Specifically, the skin possesses various characteristics, and it is crucial to thoroughly consider these features when designing electrodes. One of the skin’s most prominent features is its remarkable elasticity, allowing relatively unrestricted contraction and expansion, with the ability to stretch up to around 50%20,21. The skin exhibits varying moduli across different regions, layers, or applied strain, with a wide range, from a few kPa to tens of MPa22. Additionally, the skin secretes sweat containing various biomarkers which can also be a hindrance to adhesion. The skin also presents a significant electrical resistance, typically in the range of 1000 to 100,000 Ω23. Furthermore, skin types can vary widely based on factors such as race, age, and health conditions24. The skin is susceptible to damage from external impacts, chemical contact, etc., which can increase the risk of infection and lead to inflammation. In addition, the skin has numerous microstructures, such as fingerprints and wrinkles, which hinder conformable contact.

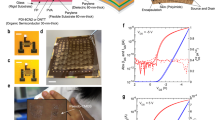

Therefore, the required characteristics of the electrode which has a skin-electrode interface can be categorized into mechanical properties, electrical properties, and biocompatibility25,26 (Fig. 1a, Table 1). Meeting characteristics in these three aspects is essential to create a fully functional skin device. Below we will describe each characteristic in detail.

a Skin device’s requirements (mechanical properties, electrical properties, and biocompatibility) and associated characteristics. b The occurrence of cracks with low stretchability and high stretchability. c Comparison of electrode-to-skin separation due to differences in adhesion. d Differences in void occurrence according to conformability. e Scanning electron microscope image of platinum nanowires (PtNWs) (Scale bar: 400 nm) (top) and Impedance of Au, Pt/Au, PtNW/Au electrodes with respect to frequency of applied signal (bottom). f Electromyography recordings for three subjects measured with poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) gel electrode (red) and conventional electrode (gray). e Reproduced with permission41. Copyright 2014 Springer Nature. f Reproduced with permission43. Copyright 2023 John Wiley and Sons.

Mechanical properties

Mechanical properties are the most fundamental characteristics of skin device electrodes. Due to the freely flexible nature of the skin, the skin device electrode must fit well with the skin and be securely attached. The electrodes must effectively interact with the skin despite disturbing factors such as body movement and sweat. In addition, from the perspective of the stimulation electrode, it must be designed to provide consistent and efficient stimulation.

Stretchability

First and foremost, the most crucial aspect to consider is stretchability. As the shape of the skin continuously changes with the wearer’s movements, a skin device must possess stretchable characteristics to accommodate these maneuvers27,28. However, materials commonly used for electrodes, such as metals, have a very high modulus posing limitations to exhibit stretchability (Fig. 1b). Typically, metals can experience fracture with deformations exceeding around 2%29. Poor stretchability leads to continuous degradation of the electrode due to the occurrence of these cracks. This can pose difficulty in stable signal acquisition or providing consistent electrical stimulation through the electrode.

Adhesion

The second consideration is adhesion, which is crucial for patient comfort and stable physiological monitoring. To effectively monitor physiological signals by attaching to the skin, the device must adhere to the skin for extensive periods without causing issues (Fig. 1c). Poor adhesion continuously decreases the electrode’s surface area for signal collection, disrupting consistent signal acquisition. This is also crucial for efficient stimulus delivery. When low adhesion leads to electrode separation, the decrease in contact area and increase in distance from the target tissue results in stimulus loss. Therefore, the electrode should be securely fixed to the skin, resisting displacement caused by the skin’s flexibility, movement, or external forces. To achieve this, materials capable of forming effective adhesion to the skin, combined with high electrical conductivity, must be employed.

Conformability

In addition, conformability to the skin is also critical. Conformability is not only important for stable attachment but also for providing comfort and enabling effective physiological monitoring (Fig. 1d). Electrodes with poor conformability can cause skin damage or apply excessive pressure. Low conformability induces the formation of numerous voids between the skin and the electrode. Therefore, excellent conformability, which reduces the voids, enables accurate and consistent data acquisition through close adherence to the skin surface. In addition, voids caused by low conformability significantly reduce the contact area of the electrode, leading to a substantial decrease in the efficiency of stimulus delivery. To achieve high skin conformability, the electrodes should be designed in a way that mimics the shape of the skin surface. Generally, conformability is increased by creating microstructures with low-modulus materials. Microstructures such as microprotrusions and microhairs can adapt to the skin, exhibiting very high conformability. Microstructures tailored to fit the skin surface can adhere stably to the skin, aligning well with its curvature and movements30,31.

As a result, skin device electrodes necessitate suitable mechanical properties. The attributes of the skin can vary depending on the area, hence, the properties suitable for each area must be applied accordingly. To meet these requirements, recent advancements have not only focused on materials but also incorporated structural approaches. These will be further explored in detail in the “Future Directions for Wearable Skin Device Materials” section.

Electrical characteristics

Electrical characteristics of the electrode are an essential component for efficient electrical stimulation and analysis of electrophysiological signals including electromyogram (EMG), and electroencephalogram (ECG)32,33,34. Although it is not a major consideration in electrochemical sensors, the electrical characteristic of an electrode is a critical factor determining device performance in electrical sensing35 and stimulating36. Typical electrical characteristics include impedance and signal-to-noise ratio (SNR) in the electrical interaction between skin and electrodes. This section describes factors influencing electrical characteristics and introduces novel materials exhibiting enhanced electrical performance.

Impedance

Skin impedance refers to the capacitive and resistive response of a certain skin region to an external application of electrical current37 or voltage38. A critical problem with conventional metal-based electrodes is that planar shaped electrode hinders conformal skin attachment and electrochemical reactions at the electronic skin (e-skin) interface result in electrode corrosion and high contact impedance.

Utilizing surface coatings and hydrogels to increase surface area and to ensure a stable ionic current flow mitigates these drawbacks and enhances electrode performance for both stimulating-type and sensing-type39,40. Kim et al. demonstrated a prosthetic skin device with platinum nanowires (PtNW) for conformal contact between the skin and electrode, showing low contact impedance due to the large surface area of the NWs compared to the planar metal electrode (Fig. 1e)41. Yang et al. investigated the variation of impedance depending on the conditions between the skin interface and the electrode42. They found that the semi-dry and wet electrodes with a large contact area presented a lower impedance than the dry electrodes due to the robust contact and the presence of an electrolyte. This suggests that the impedance depends on the contact area and conductivity between the electrode and the skin.

High-quality signal acquisition

The impedance between the electrode and skin influences the transmission quality of the electrophysiological signal or SNR. SNR determines whether the acquired signal is contaminated with external noise or other physiological signals. Signal quality deteriorates when the impedance at the skin-electrode interface is high and varies at the electrode sites. Therefore, the selection of electrode material with minimal skin-electrode impedance across the skin interface promotes effective current transfer and high-quality signal. Martinez et al. developed poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) based soft conductive polymer (CP) hydrogel reducing the contact impedance by nearly an order of magnitude compared to the conventional electrodes (Fig. 1f)43. The application of the fabricated CP improved the SNR by 2.1 dB in average as it supports conformal contact and enhanced conductivity. The integration of such a soft CP layer lowers the contact impedance, ultimately increasing the SNR value.

Biocompatibility

Biocompatibility is regarded as the most significant criterion for skin electronic devices to ensure safe application to the human epidermis44. Conventionally, biologically inert metals have been selected as electrode material. However, the recent research trend focuses on the combination of conductive materials with elastic material to overcome many on-skin scenarios such as dynamic stretching caused by body movement. In this section, novel biocompatible composite material, and alternate strategy to mitigate biocompatible risks are introduced.

Biocompatible material

Metals exhibiting corrosion resistance, and low biological response are regarded as inert in physiological environment45. The adoption of biocompatible metals, such as Au and Pt, in terms of tissue interaction and immune response has been widely favored. Although Cu and Ag have higher conductivity, the long-term use of these metals is not favored due to corrosion and cytotoxicity46. Other than attempts to utilize biologically inert metals, utilization of biocompatible stretchable polymer materials along with conductive nanoparticle exhibiting low cytotoxicity has been adopted to demonstrate novel electrode material retaining high conductivity and stretchability to improve the overall performance of the epidermal device without compromising biocompatibility. Yi et al. reported three-dimensional (3D) printed multilayer wearable pressure sensors using a conductive composite made of carbon nanotube (CNT) and polydimethylsiloxane47. The biocompatibility of CNT has been demonstrated as CNT does not influence osteoblast cell growth (Fig. 2a)48.

a Osteoblast cell proliferation measured with cell density over 7 days for glass substrate (black), 100 nm diameter carbon nanotube (CNT) with pyrolytic outer core (horizontal dash), 200 nm CNT with a pyrolytic outer core (white), 60 nm CNT without a pyrolytic outer core (vertical dash), and 125 nm CNT without a pyrolytic outer core (gray) b Schematic illustration and circuit diagram of capacitive coupling driven electrode with insulation layer. c, Electromyography signals measured through conventional gel electrode (blue), direct contact epidermal electrode (red), and capacitive epidermal electrode (green). d Real-time physiological stimuli detection of male adult subjects. e Breathability in skin electrode. f All nanofiber-based electrodes fabricated for high breathability. g photograph of ultrathin, transparent electronic skin (e-skin) device attached to the wrist. The Inset image is a magnified image of e-skin perfectly fitted to the wrinkles of the wrist. h Transmittance spectra of 3 μm thick e-skin device before and after healing. a Reproduced with permission48. Copyright 2002 Elsevier. b, c Reproduced with permission52. Copyright 2013 John Wiley and Sons. d Reproduced with permission53. Copyright 2019 American Chemical Society. f Reproduced with permission58. Copyright 2022 John Wiley and Sons. g, h Reproduced with permission62. Copyright 2022 Elsevier.

Electrode design

Electrode design is classified into capacitive and faradaic according to its operating mechanism. For faradaic electrodes, the electrode is in direct contact with tissue and charged particles travel across the electrode directly. Thus, the utilization of biocompatible material is essential, as the electrode is in direct contact with the tissue. However, capacitive electrodes encapsulate the metal electrodes with a biocompatible substrate, eliminating direct contact with the skin, unlike the faradaic electrodes. Due to the presence of a passivation layer, charges cannot transfer across the electrode in capacitive and charge transfer is conducted through capacitive coupling49. This approach not only prevents direct charge transport but also eliminates the risk of leakage between electronic components, ensuring enhanced biocompatibility for both sensing-type and stimulating-type wearable epidermal devices50. Xu et al. adopted capacitive coupling as an effective means of wound healing with non-contact electrical stimulation, enhancing collagen synthesis and angiogenesis51. Jeong et al. proposed a capacitive sensor-based electrophysiological signal measurement system, driven by capacitive coupling (Fig. 2b and c) capable of recording EMG signals equivalent to the standard electrode system52. These results suggest potential application to both stimulation and sensing skin devices (Fig. 2d)53.

Additional properties

In addition to these key characteristics, wearable skin devices may necessitate additional characteristics based on their intended use or specific circumstances. While not indispensable, these properties contribute to meeting specific requirements such as functionality, appearance, and dimensions. This part will specifically address the significance of breathability, transparency, size, and density in relation to skin devices.

Breathability

Breathability refers to the ability of the electrode to allow air to pass through. Mainly, breathability is a characteristic required for clothing that comes in contact with human skin, such as clothes and shoes54,55. This breathability is a characteristic applied to help the wearer feel comfortable and healthy, and it also can be applied to skin electrodes attached to the skin. The need for breathability in skin electrodes arises from the constant occurrence of sweat on the skin56. Materials with excellent breathability allow the dissipation of sweat between the skin and the electrode, facilitating the release of moisture to the external environment and supplying oxygen through air circulation (Fig. 2e). Particularly in humid and hot environments, these breathable materials help maintain an ideal interface between the electrode and the skin. Therefore, when using a skin device, breathability contributes to the preservation of skin health and the enhancement of device durability, allowing prolonged usage.

The breathability of the material itself is important, but even with non-breathable materials, it is possible to achieve high breathability through these microstructures and holes57. For example, applying metal nanomesh structures to electrodes achieves much better breathability than before application (Fig. 2f)58.

Transparency

Along with the mechanical properties that allow conformal attachment of the skin device to the epidermis, transparency is a crucial factor for acquiring imperceptible skin electronics59. Transparency can be achieved through either making electrode ultrathin or utilizing inherently conductive nanostructure composites to non-conductive transparent elastomers. Rather than introducing the use of conventional transparent electrode material such as indium tin oxide, we focus on discussing recent methods to achieve transparency for wearable skin electrode.

Transparency is defined as the transmittance of light. Transmittance is well described through Beer-Lambert Law expressed as T = exp(-αx), where T is the transmittance of light, α is the linear attenuation coefficient, x is the thickness of the material60,61. Thus, adopting material with a lower α-value or decreasing the thickness of the material increase the transmittance of light. Higher transmittance of light or minimized scattering and absorption of light ultimately leads to transparency. Based on this relationship between transparency and thickness, Liu et al. developed a few micrometers thick, self-healing e-skin by embedding PEDOT:PSS in self-healing elastomer composed of polytetramethylene ether glycol, hydrogenated 4,4’-methylenediphenyl diisocyanate and aliphatic disulfide bis(2-hydroxyethyl) disulfide62. Fabricated e-skin was 3 μm thick and perfectly attached to the wrinkles of the wrist (Fig. 2g). After healing, e-skin had no noticeable decrease in transmittance, showing average transmittance above 92% (Fig. 2h). Another approach to transparency can be made by embedding conductive nanoparticle which is smaller than the wavelength of visible light to transparent elastomers. Chen et al. designed a transparent e-skin by the combination of silver nanoparticles (AgNPs), citric acid, and polyvinyl alcohol63. Since AgNP has a size much smaller than the wavelength of visible light (390–780 nm), the fabricated e-skin device had transmittance over 93.2% in the visible light range. As such, transparency can be obtained by controlling the thickness of the material and integrating nanoparticles that are smaller than the wavelength of visible light. Transparency should be achieved for the practical application of imperceptible skin electronics, which ultimately enhances user convenience and experience.

Electrode size and density

In skin devices, the size and density of electrodes play crucial roles in ensuring both the efficacy of the device and the comfort of the user. The size of electrodes in skin devices is a critical parameter that directly influences the contact area with the skin. A larger electrode surface area often allows for better signal acquisition and distribution64. However, excessively large electrodes may lead to discomfort and restrict the flexibility of the device, particularly in areas with complex anatomical structures. Electrode density refers to the number of electrodes per unit area on the skin. The appropriate density is essential for achieving high-resolution data and improving the accuracy of signal detection. A higher electrode density is beneficial for applications that require detailed and precise data, such as in medical diagnostics or monitoring specific physiological parameters65. However, the density should be optimized to avoid excessive crowding of electrodes, which could result in discomfort, skin irritation, or limitations in the device’s flexibility. Therefore, it is important to appropriately balance electrode size and density depending on the purpose of the device.

In order to effectively utilize skin devices, various physical, chemical, electrical, and biological characteristics mentioned above must be satisfied. A diverse range of research is being conducted to achieve this, including methods such as combining various materials to form composite materials or utilizing the structure of the electrodes to address these challenges.

Future directions for wearable skin device materials

The connection between human physiology and technology is undergoing rapid transformation with the advancement of wearable skin devices. They seamlessly integrate with our bodies, by achieving the requirements of mechanical properties such as flexibility and stretchability. In particular, stretchability is a crucial factor in determining a device’s capacity to conform to the skin’s stretching66. There are two primary strategies for achieving stretchability in a device: one involves material innovation through the use of soft materials from the outset67, combining the cost of stretchability, or integrating stretchable materials68; the other involves structural design, which entails imparting a unique mechanical structure to a non-stretchable material or modifying the material’s structure to absorb stresses and strains applied to the device, thereby preventing material failure and enhancing durability69. At the forefront of this revolution lies the pursuit of advanced materials that have the potential to redefine the interface between the skin and devices including these approaches. This section explores future directions for materials utilized in wearable skin devices, with a particular focus on three key developments: (1) innovations in structural design, (2) advancements in flexible and soft electrode materials, and (3) synthesis of hybrid materials.

Integrating conformity with structural approaches

The structural approach is easily accessible because it utilizes conventional solid-state metals, commonly used in electronic devices, offering broad potential for conformal integration into wearable devices.

Mesh, wavy network architectures

Mesh and wave-structured electrodes represent a significant advancement in the design of skin devices, offering enhanced flexibility and conformity to the contours of the skin70. These structures drive their functionality from their distinctive physical geometries. Mesh electrodes, characterized by their network-like design, allow for ample air and moisture exchange between the skin and the environment, thereby reducing irritation and improving wearability over extended periods. This mesh structure also provides mechanical flexibility, enabling the electrode to conform to the skin’s surface without compromising its electrical connectivity (Fig. 3a).

a Optical image of a wavy network embedded in a soft elastomer, conformally attached to the thumb (Scale bars, 1 cm). Inset: Exploded view schematic illustration. b Freestanding van der Waals thin film (VDWTF) consisting of staggering 2D nanosheets (Left: Schematic to compare before and after stretching, Right: SEM, TEM image). c Schematic illustration of the polyacrylonitrile nanofiber films/MXene pressure sensor’s functional layer. d Schematic diagram of an e-skin with 16 flexible self-sensing actuators in a coil structure that transmits tactile data wirelessly and bidirectionally. e Photographs of a flexible trilayer coil electrode in a self-sensing actuator (Scale bar, 5 mm). f Optical Images of island-bridge (IB) structure under (i) Relaxed, (ii) Bent, (iii) Pinched states, and (iv) skin-mounted in the pinched state (Scale bars, 5 mm). g Photograph of the electrochemical device-based Ag-liquid metal island-bridge structure attached to the skin for sensing and energy applications. h Optical image of porous thermoplastic polyurethane (TPU) film dip-coated silver nanowires (AgNWs). a Reproduced under terms of the CC-BY license70. Copyright 2015 The Authors, published by Springer Nature. b Reproduced with permission72. Copyright 2022 American Association for the Advancement of Science. c Reproduced with permession77. Copyright 2022 John Wiley and Sons. d, e Reproduced under terms of the CC-BY license78. Copyright 2022 The Authors, published by American Association for the Advancement of Science. f, g Reproduced with permission79. Copyright 2020 John Wiley and Sons. h Reproduced with permission81. Copyright 2020 American Chemical Society.

Wave-structured electrodes, on the other hand, employ a serpentine or wavy pattern, providing intrinsic stretchability to the device71. This design enables the electrodes to accommodate the natural movements of the skin, including stretching, bending, and twisting, while ensuring consistent contact and electrical performance. The wavy configuration allows the electrodes to stretch and compress without inducing significant stress on the rigid solid-state metal electrodes, thereby maintaining the integrity and functionality of the electronic components embedded within the skin device. These innovative designs mark a leap forward in the development of skin-compatible electronic devices, offering a blend of comfort, durability, and efficiency.

Staggered nanosheet structure

Staggered nanosheet structures consist of nanosheets crossed with each other, creating a wide area plane-plane van der Waals (VDW) interface. These interfaces allow adjacent nanosheets to slide or rotate relative to each other to accommodate local structural disturbances and reduce cracks and deformation, thereby ensuring structural integrity. Yan et al. developed a free-standing VDW thin film (VDWTF) composed of two-dimensional (2D) nanosheets (Fig. 3b)72. The bond-free VDW features between parallax nanosheets allow sliding and rotational freedom to ensure mechanical flexibility, stretchability, and malleability. This structure forms a bond-free VDW and an isometric interface on the surface terrain, serving as an adaptable and breathable electronic membrane.

3D patterned interwoven structure

A 3D interwoven structure has been used to overcome the limitations of deformation in a 2D plane73,74,75,76. This structure, designed with a skin-like pattern suitable for long-term wearing, demonstrates outstanding sensing capabilities in low-pressure environments, such as airflow, due to its vertical multilayer configuration at both macro- and micro-scales. It offers commendable mechanical properties and can achieve superior electrical and composite characteristics through the incorporation of conductive materials. Liu et al. developed a highly sensitive wearable pressure sensor by utilizing the interwoven structure of its 3D pattern (Fig. 3c)77. By combining MXene with polyacrylonitrile blowing spinning nanofiber film, increased porosity was achieved, allowing for larger deformation spaces and heightened sensitivity to micro-movements.

Coiled structure

Coil-structured electrodes are mainly used as antenna electrodes that are integrated into the skin and receive or transmit electrical signals. This structure can be designed to be flexible and function as an electromagnetic-based device, enabling non-contact touch communication through wireless self-sensing. Li et al. reported a flexible actuator consisting of a trilayer flexible coil structure that can provide integrated functionality for both haptic feedback and self-sensing (Fig. 3d)78. When the flexible self-sensing actuator is dynamically pressed, electrical signals by electromagnetic induction are generated regarding external pressing speed and distance between the magnet and the coil. The entire coiled structure of the actuator was flexible and could conform to the skin while maintaining stable mechanical properties (Fig. 3e).

Island-bridge structure

The island-bridge (IB) structure offers great potential for fabricating stretchable and stable flexible electronics. This structure consists of several individual rigid “island” compartments connected by highly stretchable serpentine-bridge interconnections. As the device parts are usually located on the island, they undergo negligible deformation during deformation as the stress is well dispersed around them (i.e., stretchable parts), providing stable device performances. Silva et al. introduced a novel strategy for all-printed IB electrochemical devices based on stress-enduring eutectic indium gallium particles-containing silver inks (Fig. 3f)79. When the external force deforms the structure, the strain is effectively dispersed around the electrode “islands” and accommodated by the interconnecting silver-liquid metal (Ag-LM)-based “bridges”. This highly conductive hyperelastic structure could withstand mechanical deformations at 800% strain without degradation of mechanical and electrical properties, indicating its potential applications for body-interfaced sensing and energy applications (Fig. 3g).

Hollow/porous structure

The porous structure can enhance the vapor permeability of epidermal electronics and ensure a conformal fit to the skin. In recent research, these structured human–machine interfaces reduce the likelihood of skin irritation and allergic reactions with gas-permeable, ultrathin, stretchable materials80. Zhou et al. presented stretchable porous electrodes using a porous thermoplastic polyurethane (TPU) film embedded with silver nanowires (AgNWs) (Fig. 3h)81. These conductive nanostructures exhibit higher stiffness than the case without AgNWs, due to the formation of stronger and denser bonds between TPU film and AgNWs. The electrode can make conformal contact with the skin, enabling high-quality electrophysiological sensing for long-term wearable applications. These structured epidermal electronics have been used for a wide range of skin-mountable biopotential sensing and textile-integrated touch sensing.

Fabrication methods for stretchable structures

Mesh, wavy, and coiled structures can be patterned on a thin polymer film using a conventional photolithography method. As this method is well-known, forming these structures is considered the most accessible and facile method to form stretchable structures82,83,84. However, efforts to create stretchable structures using materials that cannot be photolithographically patterned have also been extensively studied. Low-dimension structures such as nanosheets can be made into flexible films through spin coating and printing. VDWTFs are suitable for bioelectronic membranes that mechanically match the skin by staggering 2D nanosheets through spin coating. The nanosheet ink for VDWTFs was fabricated by an intercalation-exfoliation process. Exfoliation of 2D VDW solids, such as MoS2 and Bi2Se3 crystal, mainly uses electrochemical molecular intercalation chemistry methods85,86. 2D bulk crystals and graphite rods are used as the cathode and anode, and then the electrochemical potential is applied.

3D patterned interwoven structure in micro/nanofibers is achieved by the blowing spinning technology that has been developed and evolved from both melt blasting and electrospinning. Melt blowing is a long-standing method that extrudes a polymer melt through a small nozzle surrounded by high-velocity heated gas. Electrospinning is a technology that fabricates nanofibers by applying an electric charge to a nozzle containing a polymer solution to overcome surface tension. Blowing spinning is a highly scalable technology in which the polymer solution in the inner chamber is sprayed by a parallel flow of high-pressure gas in the outer chamber87. The pressure difference between the extruded polymer’s outer and inner layers causes the solvent to evaporate from the stretched polymer, leading to the rapid formation of micro/nanofibers. These micro/nanofibers fabricated by using this technology overlap to create complex conductive paths to form a conductive 3D patterned interwoven structure.

To form the IB structure, various methods are used to sequentially integrate the rigid “island-like” structural layer and the soft “bridge-like” structural layer. In the case of 3D printing, it usually involves the printing of dielectric ink and elastic conductive ink, respectively. For example, the structural layer can be screen printed via a metal stencil onto a layer of thermoplastic elastomer (TPE), such as styrene-ethylene-butylene-styrene and cured in a convection oven. Then, the IB structure can be printed with the stretchable composite ink on the top of this TPE layer and also cured. This fabrication strategy can be applied to a wide range of flexible inks and substrates.

When fabricating porous polymer films, they are mainly produced using the breath figure method88,89. It is a self-assembly method in which a polymer solution is cast onto a solid substrate, and then water droplets condense to form a honeycomb-shaped microscale polymer pattern. Porous structured electronics can then be manufactured by filling conductive particles into a flexible porous film using a dip coating method. This enables the formation of conductive paths that closely adhere to the soft, porous elastomer platform, maintaining the inherent conductivity of the particles while also conforming to the softness of the elastomer platform.

Flexible and soft electrode materials

Flexible and soft materials are essential for the effective integration of irregular, soft electronic systems, and skin. The term “flexible” denotes the ability to be bent without breaking, while “soft” refers to being easily impressionable or moldable without resistance. The degree of flexibility can vary depending on how the material is fabricated, and softness can vary depending on how the material is synthesized. These material characteristics are utilized in electrodes and substrates, contributing to the advancement of wearable skin devices90.

Recent advances in flexible materials for skin electronics include low-dimensional conductive materials such as graphene, CNTs, MXene, and silver nanowires. They exhibit potential as promising candidates for skin electronic materials as they exhibit could have nanometer-scale thinness that enables high flexibility. Carbon-based materials, such as graphene and CNT, are a representative and most widely studied low-dimensional conductive materials for skin electronics. Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, exhibits exceptional electrical conductivity, flexibility, and strength91,92,93. Its thinness and high surface area make it an excellent choice for skin-mounted sensors, as it minimally interferes with skin movement and functionality. Also, its biocompatibility ensures that it does not irritate the skin, making it suitable for long-term wearable applications. Its ability to efficiently conduct heat and electricity allows for the development of skin electronics with superior thermal management and signal transmission capabilities. As gas permeability and water permeability are also an important characteristic for skin electronics efforts have been made to enhance these properties in graphene skin electrodes. Sun et al. developed a porous graphene and sugar-templated elastomer sponges to enhance its permeability (Fig. 4a)94. By exposing the laser to localized regions of polyimide (PI), a photothermal process occurred, converting the exposed PI regions to porous graphene. By integrating them into porous silicone sponge substrate, the electrode showed high water-vapor permeability (≈18 mg cm−2 h−1). CNTs have been instrumental in advancing skin electronics due to their remarkable electrical properties and mechanical strength95,96. CNTs are essentially rolled-up sheets of graphene, forming tubes that can be single-walled or multi-walled. They are known for their high aspect ratio, which significantly contributes to their flexibility and stretchability. This makes them ideal for integrating into skin-like electronic devices that require conformity and resilience. CNT-based skin electronics can be used for a range of applications, from health monitoring to interactive interfaces, providing reliable performance even under mechanical deformation97. AgNWs, known for their excellent conductivity and flexibility, are another critical material in skin electronics. These nanowires can form conductive networks when embedded in flexible substrates, providing a balance between electrical conductivity and mechanical flexibility. Their unique aspect ratio and surface properties allow them to form percolating networks at low filler loadings, maintaining the overall flexibility of the composite material. Silver nanowire-based skin electronics are particularly useful in applications requiring transparent conductive films. Liu et al. developed a AgNW composite electrode by combining two layers, a layer with AgNWs randomly oriented on the polydimethylsiloxane (PDMS) surface and CNT-PDMS composite layer (Fig. 4b)98. This composite electrode showed self-adhesive characteristics as well as continuous monitoring of ECG signals from the skin for 8 days.

a SEM images of silicone elastomer sponge and porous graphene. b SEM image of the carbon nanotube (CNT)-adhesive polydimethylsiloxane (PDMS)/silver nanowire/PDMS structure of composite electrode. c Photographic image of the device treated with positive electroic fieldser. d Photographic image of the conformal interface between stretchable poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) device conformally attached to the wrist. e Schematics that the sensing layers are either encapsulated or exposed outside by arranging in a layer-by-layer assembly based on polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene (SEBS) layer. f Schematic illustration of skin interface between skin and PEDOT:PSS with graphene layer. g Chemical structures of PEDOT:PSS, hybridized with graphene, sodium dodecyl sulfate, and bis(trifluoromethane) sulfonimide lithium salt. a Reproduced with permission94. Copyright 2018 John Wiley and Sons. b Reproduced with permission98. Copyright 2016 Elsevier. c Reproduced with permission105. Copyright 2023 John Wiley and Sons. d Reproduced with permission107. Copyright 2022 The American Association for the Advancement of Science. e Reproduced under terms of the CC-BY license110. Copyright 2022 The Authors, published by Springer Nature. f, g Reproduced under terms of the CC-BY license111. Copyright 2021 The Authors, published by Springer Nature.

MXene is a class of two-dimensional inorganic compounds, which recently emerged as a promising material in skin electronics99,100. MXenes are derived from bulk MAX phases by selective etching, resulting in layers that are a few atoms thick. They offer metallic conductivity and hydrophilic surfaces, which are beneficial for applications requiring rapid electron transfer and compatibility with biological environments101. MXenes can be processed into flexible and conductive films or coatings, suitable for skin-attachable devices that require high electrical performance and comfort.

Together, these low-dimensional materials are revolutionizing the field of skin electronics. By leveraging the unique properties of them, researchers and engineers are developing devices that are not only highly functional but also comfortable and unobtrusive for the wearer. From health monitoring skin patches to interactive wearable technology, these materials are opening new frontiers in e-skin applications, promising a future where electronics seamlessly integrate with the human body.

As shown above, over the past decade, the development of electrodes for skin devices has been particularly focused on flexibility using thin materials and various fabrication technologies. However, flexible electronics cannot be considered as soft. Given that softness is a key property for the seamless integration with the soft and delicate tissue, several approaches to develop intrinsically soft electrodes have also been developed.

CPs or hydrogels exhibit distinct advantages as interfacial electrode materials, including elevated specific capacity, exceptional electrochemical activity, favorable mechanical properties, and noteworthy biocompatibility102. Therefore, they have notable applications in skin bioelectronics, as demonstrated by Li et al.’s development of a durable conductive hydrogel electrode with breakage-resistant capacity through an effective enforcement method of solvent exchange103. They also show promise due to their capability to add adhesion property during the synthetic process104. Yang et al. developed a polyaspartic acid-modified dopamine/ethyl-based ionic liquid hydrogel as stimulation/recording device that can regulate its adhesion characteristic with a simple electric field treatment (Fig. 4c)105. Ten et al. developed a self-adhesive conductive polymer (SACP) composite for soft electronics by doping the rigid and non-stick PEDOT:PSS composites with a biocompatible supramolecular solvent (SMS)106. SACPs are prepared by mixing and drying a mixture containing SMS (i.e., citric acid and cyclodextrin), an elastic polymer network (poly (vinyl alcohol) crosslinked by glutaraldehyde), and a conductive polymer (PEDOT:PSS). Jiang et al. developed a biocompatible and stretchable CP with high conductivity and high crack-onset strain in a physiological environment107. Also, by crosslinking moiety (methacrylate) for photopatterning, this CP could be photopatterned enabling its facile patterning process as electronics. Due to its high stretchability and direct photopatternability, this CP could conformally adhere to the skin as well as other biological interfaces (Fig. 4d).

Despite their exceptional flexibility, CPs exhibit relatively low electrical conductivity compared to traditional electrode materials (i.e., metals). On the other side, Gallium-based liquid metals (Ga-based LMs) possess comparable softness with electrical conductivity similar to conventional solid-state metal electrodes108. They are also biocompatible, making them a promising material candidate for soft and flexible skin devices. Kim et al. reported a liquid metal-based ECG electrode capable of achieving conformal contact with the skin and producing a high SNR of the ECG peak109.

Advancements in substrates are also conducted along with the studies conducted on electrode materials to minimize the mismatch of mechanical properties between them. Zhang et al. presented an innovative approach using an ultrathin (143 µm) and highly elastic polystyrene-block-poly (ethylene-ran-butylene)-block-polystyrene (SEBS) material to develop a stretchable multifunctional sensor (Fig. 4e)110. SEBS, characterized by stretchability, elastic recovery, and cycling stability, possesses thinness that enables layer-by-layer assembly to produce multiple sensors.

Hybrid formation of materials

As previously demonstrated, there has historically been a trade-off in electrode materials: increased softness often leads to reduced electrical conductivity, and vice versa. To address this issue, one strategic solution is the creation of hybrid materials. Over the past decade, the term “hybrid” has been applied to approaches that combine hard inorganic materials, known for their excellent electrical properties, with soft elastomeric materials to achieve conformal attachment to the skin70. The resulting hard/soft composites displayed a wide range of deterministic and precisely controllable mechanical properties. Recently, directly mixing two flexible materials with high conductivity is getting attention to significantly enhance both electrical and mechanical characteristics. An example of this approach is the combination of PEDOT:PSS with graphene. Zhao et al. developed a ~100 nm ultra-thin dry epidermal electrode that could conformably adhere to skin and accurately measure electrophysiological signals with low sheet resistance (~24 Ω sq−1, 4142 S cm−1), high transparency, and mechano-electrical stability (Fig. 4f and g)111. The enhanced optoelectronic performance was due to the synergistic effect between graphene and PEDOT:PSS, which induced a high degree of molecular ordering on PEDOT and charge transfer on graphene by strong π-π interaction.

It is evident that the materials used will have a significant impact on the development of skin-interactive devices. By advancing flexible and soft electrode materials, we are ushering in a new era of devices that seamlessly integrate with the human body, while remaining unobtrusive and long-term functionality. Through the integration of structural innovations, we ensure that these devices not only conform to our skin but also adapt to its changes and movements. Furthermore, the emergence of hybrid materials is opening up new possibilities that bridge the realms of organic and inorganic, soft and hard, and durable and flexible. sensitivity, and responsiveness to the wearer’s needs. The properties of the wearable skin devices employing flexible, soft and hybrid materials as detailed in this section are outlined in Table 2.

Prospects for expanded applications of wearable skin devices

As previously mentioned, wearable skin devices are currently under development, featuring flexible electrodes and substrates to the skin to fulfill their mechanical needs. The advancement of wearable skin device technology is not only progressing in terms of manufacturing but also ushering in a new era of potential applications112. This section provides an introductory overview of the conventional methods for detecting biological signals, ES, and drug delivery113,114. Moreover, this section delves into the innovative applications of these devices in hybrid systems, which possess the ability to perform multiple functions within a single115. Furthermore, the integration of AI promises to significantly enhance the performance of wearable skin devices. By utilizing machine learning and deep learning methods, these devices can process information through artificial neural networks, mirroring the functioning of human neurons116,117,118. This technological advancement is paving the way for the future of personalized smart wearable skin devices.

Basic wearable skin device functions

Skin devices are commonly utilized for the detection of physical and chemical bio-signals, as well as the stimulation of the skin and muscle tissues in the body. Sensors can be classified into physical sensors119,120,121, which measure the body’s physical deformation, and chemical sensors122, which analyze the composition of body fluids123. Physical sensors, including mechanical124, temperature125, and electrophysiological sensors33, monitor body movements, heart rate, temperature, and other physiological activities by tracking changes in resistance and capacitance126,127,128. Yamamoto et al. developed a stable gel-less adhesive electrical sensing device, which incorporates a temperature sensor and an ECG sensor (Fig. 5a)129. This device is capable of monitoring health conditions by detecting ECG signals and skin temperature when attached to the skin. Chemical sensors are employed to detect concentrations of electrolytes, ions, and molecules in body fluids, such as sweat and interstitial fluid130. Electrochemical sensors, mainly using enzymes, aptamers, and antibodies, are used to detect target chemicals by variations in current, pH, or color upon reaction71,131,132. Kim et al. introduced a tattoo-based skin device for chemical sensing, which measures alcohol concentration in sweat through iontophoresis (Fig. 5b)133. The device showed the ability to detect ethanol within the range of 0 mM to 36 mM, as indicated by its chronoamperometric response (Fig. 5c). The calibration curve exhibited a high level of linearity, with a correlation coefficient (R2) of 0.993 (Fig. 5c inset). Stimulation devices are classified into ES, chemical stimulation, and others. Electric stimulators are employed for therapeutic purposes in activating wound healing or muscle activity by applying electric current to the skin134,135. In addition, electrical stimulators can be used in the form of textile devices to provide tactile sensations through electrical signals or vibrations136,137. Furthermore, chemical stimulation is also utilized for therapeutic applications by means of transdermal drug delivery, wherein drugs are loaded into the device138. The system, type, and mechanism according to the application of wearable skin device are summarized in Table 3.

a Photograph of the skin device containing a temperature sensor and electrocardiogram (ECG) sensor. b Photograph of tattoo-based skin device for alcohol sensing. c Amperometric response of the alcohol sensor to increasing ethanol from 0 mM to 36 mM (a-m). Inset: Calibration curve of the alcohol sensor. (slope: 0.362 ± 0.009 μA mM−1; intercept: 1.810 ± 0.170 μA; correlation coefficient: R2 = 0.993; n = 3). d Photograph of the skin device attached to the forearm (left) and under stretching (right). e Photograph of the stretchable wearable patch. (Scale bar, 1 cm). f Quantitative analysis of wound closure in four rat groups with a 35 mm diameter wound: the control group, drug group, electrical stimulation group, and combination group. g Schematic diagram of the control system of the smart glove. h Schematic illustration of rapid situation learning (RSL) process using transfer learning. a Reproduced with permission129. Copyright 2017 John Wiley and Sons. b, c Reproduced with permission133. Copyright 2016 America Chemical Society. d Reproduced with permission136. Copyright 2016 John Wiley and Sons. e, f Reproduced under terms of the CC BY 4.0 license139. Copyright 2023 The Authors, published by American Association for the Advancement of Science. g Reproduced under terms of the CC BY 4.0 license145. Copyright 2020 The authors, published by John Wiley and Sons. h Reproduced under terms of the CC BY 4.0 license146. Copyright 2020 The Authors, published by American Association for the Advancement of Science.

Performing hybrid functions

Previously, the functionality of wearable skin devices has been limited to performing either sensing or stimulating functions. However, there is a growing trend in the development of multifunctional devices capable of both sensing and stimulation for improved efficiency.

Xu et al. introduced a transcutaneous haptic device with densely arranged electrodes for both tactile stimulation and electrophysiological sensing (Fig. 5d)136. The device, composed of an ultra-thin polyimide film and Au electrodes, demonstrated strong adherence to the skin even under stretching irritation. This device not only replicates tactile stimulation but also enables the physical sensing of bio-signals by integrating a temperature sensor, EMG sensor, and strain sensor.

In addition, Sani et al. created a patch device that electronically stimulates tissue regeneration to promote wound healing, while also wirelessly and continuously monitoring the physiological state of the wound area through a sensor array (Fig. 5e)139. Monitoring the chemical composition and temperature of wound exudate is crucial throughout the healing process, as temperature is linked to the degree of infection, pH reflects the healing state, and uric acid concentration indicates wound severity. Therefore, the authors incorporated sensors into the patch device and conducted wireless monitoring. Additionally, the wearable patch can provide a combined treatment for chronic wounds by releasing drugs from an electroactive hydrogel layer and applying electrical stimulation under an exogenic electric field. Both are regulated by a pair of voltage-modulated electrodes. The healing progress in wounds was analyzed in four groups, including a control group, a drug group, an electrical stimulation group, and a combination group, utilizing Zucker diabetic fatty rats as test subjects (Fig. 5f). When comparing the degree of wound healing after 3 and 14 days of treatment, it is evident that the rate of wound closure is notably higher in the treated group compared to the untreated control group. Moreover, the electrical stimulation group and the combination group exhibited a higher closure rate than the control group after 14 days, indicating that electrical stimulation has a positive effect on wound healing. A wearable skin device with hybrid functionality has been developed, which can monitor the wound healing process while simultaneously applying electrical therapy and drug delivery.

Wearable skin devices with artificial intelligence

Wearable skin devices, used for sensing or stimulating, have faced challenges in rapidly processing large volumes of data due to the complexity of the human body and the various signals involved. To overcome this limitation, recent research has actively incorporated AI technology into wearable skin devices, thereby enhancing their ability to handle complex data more effectively140,141,142,143. This integration not only allows for the direct measurement of signals but also facilitates their transmission and external reception. Machine learning technology enables these devices to learn from and recognize data patterns, leading to more effective feedback mechanisms. Deep learning technology can directly extract patterns from signal data, which aids in accumulating big data and results in more detailed and accurate information. By employing AI technology designed for data accumulation, it becomes feasible to improve the capacity to process more intricate and precise information. Furthermore, this advancement extends to the realm of virtual reality (VR), where these devices can identify emotions and movements, enabling their practical implementation as feedback in real-world applications144.

Wen et al. introduced a glove interface featuring a superhydrophobic triboelectric fiber sensor (Fig. 5g)145. This sensor is classified as a physical sensor used to monitor human movement by generating voltage peaks for triboelectric output. The acquired human motion data is promptly processed in real-time through Python using the developed glove interface. Subsequently, commands are transmitted to the virtual hand based on three distinct signal patterns via Transmission Control Protocol/Internet Protocol communication. Consequently, the glove demonstrated the ability to discern different gestures utilizing machine learning technology. Based on the glove’s voltage output relative to the degree of finger bending, the glove executes commands for holding, loading, and shooting the gun, ensuring the accurate real-time implementation of these motions. These findings indicate that highly precise VR/augmented reality (AR) control can be effectively deployed and utilized in diverse skin device applications. Kim et al. devised a method to detect finger movements utilizing a deep learning sensor attached to the skin surface and simulate a hand with similar characteristics in VR (Fig. 5h)146. This sensor is a physical sensor that detects changes in resistance when moving with a laser-induced crack structure. It has the capability to interpret intricate finger movements in real-time through rapid situation learning (RSL) and is engineered to consistently capture five finger motions irrespective of wrist positioning. The RSL system assimilates data derived from hand movements and transfers the parameters of the long short-term memory network to a novel hand model. The process of automatically processing virtual hand gestures to detect movements over time is facilitated. Consequently, this RSL system expedites the acquisition of new signals by only retraining the mapping function based on the sensor values obtained. The integration of AI technology into wearable skin devices is progressing in a sophisticated manner, focusing not only on data acquisition through signal sensing and motion but also on the transmission and reception of this data to the external environment, as well as the generation of new movements through learned processes. While the current application is limited to a specific body part, expanding its use to other areas requires a detailed biomechanical analysis of the human body. Furthermore, when the feedback system based on AI and wireless platform technology is activated, it will be possible to establish a personalized remote real-time system, enabling the development of a smart system based on wearable skin devices.

In this section, we review the prospect of wearable skin devices that can detect bio-signals or deliver stimuli for electrical application, drug delivery, or tactile reproduction. By integrating these functions, wearable skin devices have been expanded multifunctionally, allowing for simultaneous diagnosis and therapeutic treatment. Moreover, the skin devices integrate AI technology to measure and exchange signal data with the external environment, learning from the perceived data to offer feedback. These multifunctional wearable devices with AI technology will facilitate the design of complex systems for monitoring and treating diseases, provide wireless tactile sensation, and establish a human-machine interface platform that individuals can use in various situations.

Conclusion

Electrodes in wearable skin devices must adhere to mechanical, electrical, and biocompatibility standards to ensure stable operation, consistent skin contact, and long-term use. Traditional metal electrodes with very high modulus struggle to withstand skin movement, prompting the development of stretchable structural electrodes such as mesh or staggered designs. Furthermore, progress has been made in manufacturing wearable skin devices and hybrid materials using flexible and soft materials.

These materials include excellent conductivity, high transparency, mechanical deformability, robust flexibility, chemical stability, moisture resistance, and smooth surface. As previously mentioned, given that certain properties involve trade-offs, it is essential to analyze them from various material and structural perspectives. The next research stage for wearable skin devices involves individually identifying the mechanical, electrical, and biocompatibility requirements and enhancing the essential functions of electrodes according to the intended use.

The future of wearable skin devices is anticipated to advance significantly through innovations in electrode technology, AI integration, and the development of hybrid functionalities, promising to revolutionize healthcare by providing more accessible, accurate, and versatile tools for health monitoring and disease treatment. Furthermore, the exploration of hybrid functionalities, integrating sensing, stimulating, and drug delivery into integrated systems, presents an exciting frontier. This approach not only streamlines device usage but also opens avenues for comprehensive diagnosis, treatment, and alert functions within a singular device.

References

Seo, H. et al. Smart contact lenses as wearable ophthalmic devices for disease monitoring and health management. Chem. Rev. 123, 11488–11558 (2023). An detailed examination of the process by which abnormal signals are detected within the human body through the utilization of diverse biosensors.

Iqbal, S. M. A., Mahgoub, I., Du, E., Leavitt, M. A. & Asghar, W. Advances in healthcare wearable devices. Npj Flex. Electron. 5, 1–14 (2021).

Yun, S. M. et al. Recent advances in wearable devices for non-invasive sensing. Appl. Sci. 11, 1235 (2021).

Wang, M. et al. A wearable electrochemical biosensor for the monitoring of metabolites and nutrients. Nat. Biomed. Eng. 6, 1225–1235 (2022).

Shull, P. B. & Damian, D. D. Haptic wearables as sensory replacement, sensory augmentation and trainer—a review. J. Neuroeng. Rehabil. 12, 59 (2015).

Kar, A. et al. Wearable and implantable devices for drug delivery: applications and challenges. Biomaterials 283, 121435 (2022).

Ates, H. C. et al. End-to-end design of wearable sensors. Nat. Rev. Mater. 7, 887–907 (2022).

Kim, S. et al. Materials and structural designs for neural interfaces. ACS Appl. Electron. Mater. 5, 1926–1946 (2023). An overview of encompassing wearable devices, along with an analysis of the mechanical characteristics of the human skin.

Kim, M. et al. Emerging bio-interfacing wearable devices for signal monitoring: overview of the mechanisms and diverse sensor designs to target distinct physiological bio-parameters. Adv. Sens. Res. 2, 2200049 (2023).

Wu, Y., Li, Y., Tao, Y., Sun, L. & Yu, C. Recent advances in the material design for intelligent wearable devices. Mater. Chem. Front. 7, 3278–3297 (2023).

Mostafavi Yazdi, S. J. & Baqersad, J. Mechanical modeling and characterization of human skin: a review. J. Biomech. 130, 110864 (2022). An overview of the structural configuration of neural interfaces.

Yuk, H., Lu, B. & Zhao, X. Hydrogel bioelectronics. Chem. Soc. Rev. 48, 1642–1667 (2019). A precise and comprehensive description of the necessary properties and operational mechanisms required for devices involved in sensing and stimulation.

Saber, D. & Abd El-Aziz, K. Advanced materials used in wearable health care devices and medical textiles in the battle against coronavirus (COVID-19): a review. J. Ind. Text. 51, 246S–271S (2022).

Seng, K. P., Ang, L.-M., Peter, E. & Mmonyi, A. Machine learning and AI technologies for smart wearables. Electronics 12, 1509 (2023). An exploration of the potential integration of intelligent wearable devices with artificial intelligence technology.

McGinnis, R. S. et al. A machine learning approach for gait speed estimation using skin-mounted wearable sensors: From healthy controls to individuals with multiple sclerosis. PLoS ONE 12, e0178366 (2017).

Huang, Z. et al. Recent advances in skin-like wearable sensors: sensor design, health monitoring, and intelligent auxiliary. Sens. Diagn. 1, 686–708 (2022).

Xu, K., Lu, Y. & Takei, K. Multifunctional skin-inspired flexible sensor systems for wearable electronics. Adv. Mater. Technol. 4, 1800628 (2019).

Sabry, F., Eltaras, T., Labda, W., Alzoubi, K. & Malluhi, Q. Machine learning for healthcare wearable devices: the big picture. J. Healthc. Eng. 2022, 4653923 (2022).

Kim, J., Cha, E. & Park, J.-U. Recent advances in smart contact lenses. Adv. Mater. Technol. 5, 1900728 (2020).

Kalra, A. & Lowe, A. Mechanical behaviour of skin: a review. J. Mater. Sci. Eng. 5 (2016).

Chen, S. et al. Mechanically and biologically skin-like elastomers for bio-integrated electronics. Nat. Commun. 11, 1107 (2020). Soft and flexible skin-like elastomer materials resembling human skin, suitable for integration into bioelectronic systems.

Wei, J. C. J. et al. Allometric scaling of skin thickness, elasticity, viscoelasticity to mass for micro-medical device translation: from mice, rats, rabbits, pigs to humans. Sci. Rep. 7, 15885 (2017).

Fish, R. M. & Geddes, L. A. Conduction of electrical current to and through the human body: a review. Eplasty 9, e44 (2009).

Dąbrowska, A. K. et al. The relationship between skin function, barrier properties, and body-dependent factors. Ski. Res. Technol. 24, 165–174 (2018).

Min, J. et al. Skin-interfaced wearable sweat sensors for precision medicine. Chem. Rev. 123, 5049–5138 (2023).

Liu, Y., Pharr, M. & Salvatore, G. A. Lab-on-skin: a review of flexible and stretchable electronics for wearable health monitoring. ACS Nano 11, 9614–9635 (2017).

Kim, K. et al. Nanomaterial-based stretchable and transparent electrodes. J. Inf. Disp. 17, 131–141 (2016).

Lee, M.-S., Kim, J., Park, J. & Park, J.-U. Studies on the mechanical stretchability of transparent conductive film based on graphene-metal nanowire structures. Nanoscale Res. Lett. 10, 27 (2015).

Lacour, S. P., Wagner, S., Huang, Z. & Suo, Z. Stretchable gold conductors on elastomeric substrates. Appl. Phys. Lett. 82, 2404–2406 (2003).

Kim, D. W. et al. Conformably skin-adherent piezoelectric patch with bioinspired hierarchically arrayed microsuckers enables physical energy amplification. ACS Energy Lett. 7, 1820–1827 (2022).

Ershad, F. et al. Ultra-conformal drawn-on-skin electronics for multifunctional motion artifact-free sensing and point-of-care treatment. Nat. Commun. 11, 3823 (2020).

Kwon, Y. W., Jun, Y. S., Park, Y.-G., Jang, J. & Park, J.-U. Recent advances in electronic devices for monitoring and modulation of brain. Nano Res. 14, 3070–3095 (2021).

Chung, W. G. et al. Recent advances in electrophysiological recording platforms for brain and heart organoids. Adv. NanoBiomed Res. 2, 2200081 (2022).

Wu, H. et al. Materials, devices, and systems of on-skin electrodes for electrophysiological monitoring and human–machine interfaces. Adv. Sci. 8, 2001938 (2021).

Ku, M., Hwang, J. C., Oh, B. & Park, J.-U. Smart sensing systems using wearable optoelectronics. Adv. Intell. Syst. 2, 1900144 (2020).

Keef, C. V. et al. Virtual texture generated using elastomeric conductive block copolymer in a wireless multimodal haptic glove. Adv. Intell. Syst. 2, 2000018 (2020).

Coston, A. F. & Li, J. K.-J. Transdermal drug delivery: a comparative analysis of skin impedance models and parameters. Proc. 25th Annu. Int. Conf. IEEE Eng. Med. Biol. Soc. IEEE Cat No03CH37439 2982–2985 (2003).

Bora, D. J. & Dasgupta, R. Estimation of skin impedance models with experimental data and a proposed model for human skin impedance. IET Syst. Biol. 14, 230–240 (2020).

Shaner, S. W. et al. Skin stimulation and recording: moving towards metal-free electrodes. Biosens. Bioelectron. X 11, 100143 (2022).

Oh, S.-J. et al. Newly designed Cu/Cu10Sn3 core/shell nanoparticles for liquid phase-photonic sintered copper electrodes: large-area, low-cost transparent flexible electronics. Chem. Mater. 28, 4714–4723 (2016).

Kim, J. et al. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 5, 5747 (2014).

Yang, L. et al. Insight into the contact impedance between the electrode and the skin surface for electrophysical recordings. ACS Omega 7, 13906–13912 (2022).

Roubert Martinez, S., Le Floch, P., Liu, J. & Howe, R. D. Pure conducting polymer hydrogels increase signal-to-noise of cutaneous electrodes by lowering skin interface impedance. Adv. Healthc. Mater. 12, 2202661 (2023).

Cao, J., Li, X., Liu, Y., Zhu, G. & Li, R.-W. Liquid metal-based electronics for on-skin healthcare. Biosensors 13, 84 (2023).

Bandyopadhyay, A., Mitra, I., Goodman, S. B., Kumar, M. & Bose, S. Improving biocompatibility for next generation of metallic implants. Prog. Mater. Sci. 133, 101053 (2023).

Salaie, R. N., Besinis, A., Le, H., Tredwin, C. & Handy, R. D. The biocompatibility of silver and nanohydroxyapatite coatings on titanium dental implants with human primary osteoblast cells. Mater. Sci. Eng. C 107, 110210 (2020).

Yi, Q. et al. All-3D-printed, flexible, and hybrid wearable bioelectronic tactile sensors using biocompatible nanocomposites for health monitoring. Adv. Mater. Technol. 7, 2101034 (2022).

Elias, K. L., Price, R. L. & Webster, T. J. Enhanced functions of osteoblasts on nanometer diameter carbon fibers. Biomaterials 23, 3279–3287 (2002).

Brummer, S. B., Robblee, L. S. & Hambrecht, F. T. Criteria for selecting electrodes for electrical stimulation: theoretical and practical considerations. Ann. N. Y. Acad. Sci. 405, 159–171 (1983).

Ianov, A. I., Kawamoto, H. & Sankai, Y. Development of a capacitive coupling electrode for bioelectrical signal measurements and assistive device use. in 2012. ICME Int. Conf. Complex Med. Eng. (CME) 593, 598 (2012).

Xu, J. et al. Non-contact electrical stimulation as an effective means to promote wound healing. Bioelectrochemistry 146, 108108 (2022).

Jeong, J.-W. et al. Capacitive epidermal electronics for electrically safe, long-term electrophysiological measurements. Adv. Healthc. Mater. 3, 642–648 (2014).

Qiu, J. et al. Rapid-response, low detection limit, and high-sensitivity capacitive flexible tactile sensor based on three-dimensional porous dielectric layer for wearable electronic skin. ACS Appl. Mater. Interfaces 11, 40716–40725 (2019).

Hoon Hong, S. et al. Multifunctional breathable electronic devices for smart wearable healthcare applications. Chem. Eng. J. 476, 146559 (2023).

Hunter, L. & Fan, J. In Engineering Apparel Fabrics and Garments (eds. Fan, J. & Hunter, L.) 283–308 (Woodhead Publishing, 2009).

Yang, Y. et al. Breathable electronic skins for daily physiological signal monitoring. Nano-Micro Lett. 14, 161 (2022).

Li, Z. et al. All-fiber structured electronic skin with high elasticity and breathability. Adv. Funct. Mater. 30, 1908411 (2020).

Yang, X. et al. All-nanofiber-based janus epidermal electrode with directional sweat permeability for artifact-free biopotential monitoring. Small 18, 2106477 (2022).

Won, P. et al. Stretchable and transparent kirigami conductor of nanowire percolation network for electronic skin applications. Nano Lett. 19, 6087–6096 (2019).

Shiraishi, T. & Watanabe, I. Thickness dependence of light transmittance, translucency and opalescence of a ceria-stabilized zirconia/alumina nanocomposite for dental applications. Dent. Mater. 32, 660–667 (2016).

Chen, H. et al. Thickness dependence of optical transmittance of transparent wood: chemical modification effects. ACS Appl. Mater. Interfaces 11, 35451–35457 (2019).

Liu, R. et al. Ultrathin, transparent, and robust self-healing electronic skins for tactile and non-contact sensing. Nano Energy 95, 107056 (2022).

Chen, L. et al. Flexible and transparent electronic skin sensor with sensing capabilities for pressure, temperature, and humidity. ACS Appl. Mater. Interfaces 15, 24923–24932 (2023).

Turi, Z. et al. When size matters: large electrodes induce greater stimulation-related cutaneous discomfort than smaller electrodes at equivalent current density. Brain Stimul. Basic Transl. Clin. Res. Neuromodulation 7, 460–467 (2014).

Merletti, R., Holobar, A. & Farina, D. In Encyclopedia of Biomedical Engineering (ed. Narayan, R.) 95–111 (Elsevier, Oxford, 2019).

Wang, S., Oh, J. Y., Xu, J., Tran, H. & Bao, Z. Skin-inspired electronics: an emerging paradigm. Acc. Chem. Res. 51, 1033–1045 (2018).

Zhou, Z., Zhang, H., Liu, J. & Huang, W. Flexible electronics from intrinsically soft materials. Giant 6, 100051 (2021).

Li, H., Ma, Y. & Huang, Y. Material innovation and mechanics design for substrates and encapsulation of flexible electronics: a review. Mater. Horiz. 8, 383–400 (2021).

La, T.-G. & Le, L. H. Flexible and wearable ultrasound device for medical applications: a review on materials, structural designs, and current challenges. Adv. Mater. Technol. 7, 2100798 (2022).

Jang, K.-I. et al. Soft network composite materials with deterministic and bio-inspired designs. Nat. Commun. 6, 6566 (2015).

Song, H. et al. Wireless non-invasive monitoring of cholesterol using a smart contact lens. Adv. Sci. 9, 2203597 (2022).

Yan, Z. et al. Highly stretchable van der Waals thin films for adaptable and breathable electronic membranes. Science 375, 852–859 (2022).

Park, Y.-G. et al. High-resolution 3D printing for electronics. Adv. Sci. 9, 2104623 (2022).

Jang, J. et al. 3D heterogeneous device arrays for multiplexed sensing platforms using transfer of perovskites. Adv. Mater. 33, 2101093 (2021).

Cho, Y. H., Park, Y.-G., Kim, S. & Park, J.-U. 3D electrodes for bioelectronics. Adv. Mater. 33, 2005805 (2021).

Park, J., Hwang, J. C., Kim, G. G. & Park, J.-U. Flexible electronics based on one-dimensional and two-dimensional hybrid nanomaterials. InfoMat 2, 33–56 (2020).

Liu, Y. et al. Highly sensitive wearable pressure sensor over a wide sensing range enabled by the skin surface-like 3d patterned interwoven structure. Adv. Mater. Technol. 7, 2200504 (2022).

Li, D. et al. Touch IoT enabled by wireless self-sensing and haptic-reproducing electronic skin. Sci. Adv. 8, eade2450 (2022). Explanation of the amalgamation of wearable devices for sensing and haptic stimulation with emerging AI-Internet of Things technologies.

Silva, C. A. et al. Liquid metal based island-bridge architectures for all printed stretchable electrochemical devices. Adv. Funct. Mater. 30, 2002041 (2020).

Lu, Y. et al. Stretchable graphene–hydrogel interfaces for wearable and implantable bioelectronics. Nat. Electron. 7, 51–65 (2024).

Zhou, W. et al. Gas-permeable, ultrathin, stretchable epidermal electronics with porous electrodes. ACS Nano 14, 5798–5805 (2020).

Iguchi, S., Mitsubayashi, K., Uehara, T. & Ogawa, M. A wearable oxygen sensor for transcutaneous blood gas monitoring at the conjunctiva. Sens. Actuators B Chem. 108, 733–737 (2005).

Shi, J. et al. Thermal and UV light adaptive polyurethane elastomers for photolithography-transfer printing of flexible circuits. Mater. Horiz. 9, 3070–3077 (2022).

Bathaei, M. J. et al. Photolithography-based microfabrication of biodegradable flexible and stretchable sensors. Adv. Mater. 35, 2207081 (2023).

Lin, Z. et al. Solution-processable 2D semiconductors for high-performance large-area electronics. Nature 562, 254–258 (2018).

Lin, Z., Huang, Y. & Duan, X. Van der Waals thin-film electronics. Nat. Electron. 2, 378–388 (2019).

Dadol, G. C. et al. Solution blow spinning (SBS) and SBS-spun nanofibers: Materials, methods, and applications. Mater. Today Commun. 25, 101656 (2020).

Bai, H., Du, C., Zhang, A. & Li, L. Breath figure arrays: unconventional fabrications, functionalizations, and applications. Angew. Chem. Int. Ed. 52, 12240–12255 (2013).

Zhang, A., Bai, H. & Li, L. Breath figure: a nature-inspired preparation method for ordered porous films. Chem. Rev. 115, 9801–9868 (2015).

Park, J. et al. Flexible transparent conductive films with high performance and reliability using hybrid structures of continuous metal nanofiber networks for flexible optoelectronics. ACS Appl. Mater. Interfaces 9, 20299–20305 (2017).

Geim, A. K. Graphene: status and prospects. Science 324, 1530–1534 (2009).

Miao, P. et al. Graphene nanostructure-based tactile sensors for electronic skin applications. Nano-Micro Lett. 11, 71 (2019).

Qiao, Y. et al. Multilayer graphene epidermal electronic skin. ACS Nano 12, 8839–8846 (2018).

Sun, B. et al. Gas-permeable, multifunctional on-skin electronics based on laser-induced porous graphene and sugar-templated elastomer sponges. Adv. Mater. 30, 1804327 (2018).

Popov, V. N. Carbon nanotubes: properties and application. Mater. Sci. Eng. R. Rep. 43, 61–102 (2004).

Chi, M., Zhao, J., Dong, Y. & Wang, X. Flexible carbon nanotube-based polymer electrode for long-term electrocardiographic recording. Materials 12, 971 (2019).

Hossain, M. M., Li, B. M., Sennik, B., Jur, J. S. & Bradford, P. D. Adhesive free, conformable and washable carbon nanotube fabric electrodes for biosensing. Npj Flex. Electron. 6, 1–9 (2022).

Liu, B., Luo, Z., Zhang, W., Tu, Q. & Jin, X. Silver nanowire-composite electrodes for long-term electrocardiogram measurements. Sens. Actuators Phys. 247, 459–464 (2016).

Lyu, B. et al. Large-area MXene electrode array for flexible electronics. ACS Nano 13, 11392–11400 (2019).

Xu, J., Shim, J., Park, J.-H. & Lee, S. MXene electrode for the integration of WSe2 and MoS2 field effect transistors. Adv. Funct. Mater. 26, 5328–5334 (2016).

Alhabeb, M. et al. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 29, 7633–7644 (2017).

Yang, G. et al. Adhesive and hydrophobic bilayer hydrogel enabled on-skin biosensors for high-fidelity classification of human emotion. Adv. Funct. Mater. 32, 2200457 (2022).

Li, R. et al. Breakage-resistant hydrogel electrode enables ultrahigh mechanical reliability for triboelectric nanogenerators. Chem. Eng. J. 454, 140261 (2023).

Zhang, C. et al. Highly adhesive and self-healing γ-PGA/PEDOT:PSS conductive hydrogels enabled by multiple hydrogen bonding for wearable electronics. Nano Energy 95, 106991 (2022).

Yang, G. et al. Tunable hydrogel electronics for diagnosis of peripheral neuropathy. Adv. Mater. https://doi.org/10.1002/adma.202308831 (2023).

Tan, P. et al. Solution-processable, soft, self-adhesive, and conductive polymer composites for soft electronics. Nat. Commun. 13, 358 (2022).