Abstract

Electrochemical impedance spectroscopy provides information on the steady state of an electrochemical redox reaction and its kinetics. For instance, impedance is a very useful technique to investigate kinetics in batteries, such as diffusion processes or charge-transfer reaction dynamics during battery operation. Here, we summarize procedures for conducting reliable impedance measurements on a battery system, including cell configurations, readiness of a system for impedance testing, validation of the data in an impedance spectrum, deconvolution of electrochemical processes based on the distribution of relaxation time and equivalent circuit fitting of the impedance spectrum. The aim of this paper is to discuss key parameters for accurate and repeatable impedance measurements of batteries.

Similar content being viewed by others

Introduction

Electrochemical impedance spectroscopy (EIS) or ac impedance is a very useful technique to investigate any electrochemical systems including electrochemical energy storage devices. Although ac impedance has been a traditional electrochemical analytical technique, it was only widely adopted during the past several decades, benefiting from the revolutionary advancements of fast computers, electronics, and computational algorithms. For example, with a digital frequency response analyzer and a Fourier transformation, a full frequency scan can be done within minutes. The advancement of electronics and computational technologies indeed contributed to the proliferations of ac impedance technique in the analysis of electrochemical systems. However, the automation of the processes and low-cost instrumentations have had an unexpected consequence on the electrochemical research—the causal use of the impedance technique. Unlike the traditional (ancient) technique with an ac Wheatstone bridge and an X-Y oscilloscope, a modern commercial impedance spectrometer can provide a set of so-called data and result plots for an electrochemical system not even at a steady state. In this perspective, we will comment on the right experiment procedures of conducting an ac impedance experiment on an electrochemical system and data modeling. Most of the comments and examples were based on our group’s research and the authors’ prior experience. For those readers who wish to gain in-depth knowledges on EIS, there are a few recent review articles on the subject1,2,3,4,5. See Box 1 for a basic summary of how EIS works, and for those readers who wish to gain in-depth knowledge on EIS, there are a few recent review articles on the subject 1–5.

ac impedance is a steady-state technique: preparation of an electrochemical system

One of the misconceptions about the EIS is that it is wrongly considered as a non-steady-state technique. The perturbation signal in a non-steady-state experiment is large enough to bring an electrochemical system far away from its initial steady-state. For example, when a battery is discharged at a large current, the electrochemical system is polarized to the Tafel region that is far away from the equilibrium state. An EIS experiment, however, is conducted at a steady state, which the small amplitude perturbation signals are superimposed on a steady-state potential. Since the amplitude of the excitation signals is so small, the electrode has never left the vicinity of the steady state. Unlike a non-steady-state experiment in which the polarization signal will inevitably cause irreversible changes to the electrochemical system, such irreversible modifications can be avoided in a steady-state experiment. The electrochemical properties of an electrode e.g., Li ion diffusion coefficient in a LiCoO2 electrode, are different at different depths of discharge (DoD). A good example is to measure the diffusion coefficient of Li0.5CoO2. One should first reduce the LiCoO2 to 50% DoD, rest the cell until a steady state (may not be completely thermodynamic equilibrium state) is reached, then conduct EIS. This is particularly important to a battery research, owing to the porous nature of the electrodes. It normally takes a long time for the battery to reach a steady state. It is critical to assure that the relaxation current (DC current) is substantially smaller than the current from the excitation, before an EIS can be conducted. Occasionally a 10 mV pulse (assuming the excitation amplitude is 10 mV) is applied to a system, the peak current is recorded. An EIS can be conducted on the battery when the current at open-circuit-voltage (OCV) decays to less than 10% of the peak current. When the excitation signals of the wide range of frequencies are applied, the interfacial processes of a wide range of time constant can be obtained without deviating from the initial steady state. Therefore, EIS is ideal for investigating kinetic parameters near a steady state of electrode because it bridges a steady state and transient states of various time constants.

Therefore, one should ensure that an electrochemical system is close to its equilibrium state before an impedance measurement is taken. The majority of ac impedance instruments and associated mathematical treatments are only applied to a linear system. As shown in Fig. 1, an electrochemical system is a non-linear system; for example, the current at an electrode/electrolyte interface is exponentially dependent on the potential (Tafel relation). The nonlinearities can substantially distort the response signal since they can manifest themselves through the production of harmonics of the excitation signal in the cell response. Such distortions can result in the misrepresentation and/or misinterpretation of the results during the modeling of the impedance results. The region near equilibrium or steady state (i = 0 mA/cm2) can be considered as a linear system. If an excitation signal is not high enough to polarize the electrochemical system into the Tafel region, the electrochemical system can be safely assumed and treated as a linear system. Generally, peak-to-peak amplitude of 10 mV is used in most of the cases.

The electrochemical polarization curve shows how the battery voltage shifting away from its OCV, which can be considered as its thermodynamic equilibrium voltage. The difference of a battery voltage during charge or discharge with its OCV is overpotential. ia and ic are the anodic and cathodic current density, respectively; α and β (= 1−α) are the charge transfer coefficient of anode and cathode, respectively; η is charge transfer overpotential; R is gas constant and F is Faraday constant.

The perturbation signal used in an ac impedance is commonly a sinuous voltage signal. The sinuous signal is applied to a system stabilized at a certain potential e. g. OCV, the response sinuous current response is measured. Rarely, the perturbation signal could be a low amplitude sinuous current signal. The signal is applied to a steady system in which the polarization current is zero. The response sinuous potential response is detected. Both techniques will not drive the electrochemical system out of the linear region. However, an impedance in galvanostatic mode is used by electrical engineers, in which a sinuous current signal is superimposed on a DC current and applied to the system. Unlike a linear circuitry consisting only of the electronic components, the DC polarization current can drive an electrochemical system into nonlinear Tafel region. Unless one is for the challenge of many more complex mathematical treatments, one should remain in the area of linear impedance. When an exciting signal manifests through a porous electrode, the interfacial concentration of reactants may not follow the same harmonics of the perturbation signal, which results in nonlinearity. It also takes a very long time for a porous electrode to reach a true steady state due to long relaxation time. The impact of the porosity on the system linearity is frequency-dependent. Unfortunately, porous electrodes are used in most of the battery systems. Therefore, it is crucial to ensure the linearity of the whole frequency range of an ac impedance measurement.

The quality of ac impedance data

As discussed above, the measurement, the interpretation and the simulation of an impedance spectrum are based on the assumption of linearity of the electrochemical system. Non-compliance that could result from even a small measurement noise could lead to the misinterpretations of electrochemical processes and inaccurate electrochemical parameters. Causality, linearity, stability and finiteness are used to warrant the compliance. Kramers–Kronig (K–K) relationship is normally used to vindicate the compliance of the impedance data. The K–K relationship was proposed by Kramers and Kronig for the analysis of optics6,7, and then was introduced by Bode in an electronic circuit analysis8. The non-compliant data points can be identified and removed from the impedance spectrum.

Figure 2 shows the K–K validation of two sets of impedance data9. The software used for the K–K validation was BioLogic EC-Lab (https://www.biologic.net/support-software/). Figure 2a shows the impedance spectrum of K–K compliance in the whole frequency range, while Fig. 2b shows that only the high frequency part of the spectrum is K-K compliance. The non-compliant data points of low frequency in Fig. 2b needed to be excluded from the subsequent data modeling and calculations.

K–K (Kramers–Kronig) compliance is needed to ensure the linearity of the electrochemical system. a K–K compliant; b K–K non-compliant; The equivalent model was used to calculate the impedance points outside the measured frequency range. (reprinted from ref. 9. Copyright © 2019, with permission from Elsevier).

Impedance data modeling and analysis

Ideally, one would analyze impedance data based on the mathematics derived from real electrochemical processes such as Fick’s laws, electrochemical absorption, Butler–Volmer relation, etc. The theoretical impedance functions can then be used to extract kinetic parameters. Due to the level of mathematics required for the proper analysis, almost all the impedance analysis was conducted with hard components based on equivalent electric circuits. Although the approach overlooks the capability of the EIS for the interpretation of electrochemical mechanisms and kinetics, it still yields much useful information, especially for the practical design of an electrode, a cell, and a battery pack. Even with the down-graded or simplified equivalent circuit modeling, researchers sometimes intend to use it lightly without careful considerations. The word equivalent in the equivalent circuit stands for the equivalent to the electrochemical processes. There is no such thing of one-kind-fits-all or a universal equivalent circuit. Similar to building a LEGO figure, one need to be familiar with each LEGO piece. Building an equivalent circuit, one needs to have a hypothesis of the overall electrochemical processes, the relations among those processes (series or parallel), and the physical and electrochemical meanings of each component – resistor, capacitor, and particularly CPE (constant phase element).

One may read in the literature in which a semi-circle and slop line were shown in a Nyquist plot. In the discussion, a conclusion was reached that the process has an interfacial reaction with a parallel diffusion process. Without careful analysis, the conclusions could be misleading or simply not adequate. Let us investigate electrochemical processes in a cathode of Li-ion battery (LIB)and how they can be assembled in an equivalent circuit. Figure 3 illustrates all the possible electrochemical processes in the porous cathode of LIB. Like any electrochemical electrodes, three of four basic electrochemical processes are included—charge transfer, double layer and diffusion while electro-sorption is not applied or at least could be ignored.

This figure shows how the physical and electrochemical processes can be represented in a transmission line model. For example, a charge transfer process at the interface of active material particles can be represented by a resistor (RCT), Li diffusion processes inside active material and through CEI can be represented by Warburg resistors, Rw and RCEI. The CEI stands for possible surface interface on a cathode; Rs are resistor; Cdls are double-layer capacitor and U0 is applied voltage.

Charge transfer process occurs at the interface between the cathode active material particles and electrolyte. As long as the electrochemical reaction is kept near equilibrium condition, the charge transfer process is linear as shown in Fig. 1. Thus, the process can be represented by a resistor and follows the ohmic law.

It is reasonable to assume that the surface of all the active material particles has the same condition; if so, then the RCT (Ωm) should be the same. Through the equivalent circuit modeling, RCT can be determined, thus the exchange current of the reaction, i0.

In a porous cathode of LIB, the double layer can be on the surface of an active material particle and a conductive carbon particle. For a single active material particle, the charge transfer resistor, RCT is in parallel with its double-layer capacitor, while the double-layer capacitor on an adjunct carbon particle is in parallel with R/C unit as shown in Fig. 3. Since the conductive carbon used in a cathode is a minor component and its surface area is low (<100 m2g−1), the double-layer contribution from the conductive carbon is normally ignored. It is worth emphasizing that the double layer is established on all the surfaces in which electrochemical reaction occurs. Therefore, double-layer capacitance can be used to estimate the dynamic electrochemical accessible surface area—the physical surface of an electrode that can be used during a certain rate of operation1.

Mass transfer is arguably the most important and the most complex of all electrochemical processes. The diffusion rate determines the utilization of an active material, which is especially true at a high-rate operation. Diffusion acts like a courier transporting mass throughout the matrix of a porous electrode and moves the ions to and from an electrode and an electrolyte interface. Detailed discussions on mass transfer can be found in our previous review10. A Warburg impedance is used in an equivalent circuit to represent the diffusion process. The Warburg impedance can be derived directly from solving the partial differential equation of the Fick’s second law.

In classic electrochemistry, a system containing a solid flat electrode is immersed in a flooded electrolyte. A semi-infinite boundary condition (\({C}_{o}\left(\infty ,{t}\right)={C}_{0}^{0}\)) is used to solve the Fick’s partial differential equation. The semi-infinite assumption is always true since the length of a diffusion layer on a flat electrode is always orders of magnitude smaller than the size of an electrochemical cell of a flooded electrolyte. However, the semi-infinite boundary condition may not be met in a Li-ion cathode, especially under a low frequency excitation or a perturbation condition. Figure 4 shows the change of the concentration perturbation length under the excitation of various frequencies. The effective-diffusion-length (δ) stands for the physical space available for the diffusion to take place. Apparently, the higher the excitation frequency, the shorter the concentration perturbation length. Unlike the flat electrode in a large amount of flooded electrolytes in which δ can be the size of a beaker cell, the Li ion diffusion in a porous cathode happens in a primary particle of the active material, in a thin SEI (solid electrolyte interface) layer and in the pores within the porous electrode. Depending on the size of the primary particle, the diameter of the pore and the thinness of the SEI layer, the semi-infinite condition may not be applied. Hypothetically, if the thinness of the SEI layer is about the length of “a” shown in Fig. 4, a semi-infinite Warburg impedance should not be used in a low frequency region, but is appropriate to be used in a high frequency region. According to our experience, the “a” situation is the most common situation in a battery system. The boundary condition in such case is ∆C0 = 0 at x = δ. The detailed mathematics of solving the Fick’s second law and the expressions of the real and imaginary parts of the impedance can be found in refs. 1,11. The comparison of semi-infinite and infinite Warburg impedance was reported in refs. 12,13.

The diffusion length becomes longer as the excitation frequency becomes lower. Since at low frequency, an ion has longer time to diffusion on one direction. ΔC the change of concentration. (reprinted from ref. 1. Copyright © 2018, with permission from John Wiley and Sons).

Warburg impedance, both semi-infinite and infinite, does not represent the diffusion in a distributed porous diffusion matrix well, even if there is no occurrence of charge transfer or faraday reactions, e.g., in an ideal double-layer capacitor. Warburg impedance is only applied to a continuous medium in which the boundary conditions are used to solve Fick’s second law. As shown in Fig. 3, owing to the ionic diffusion within the pores of different sizes, a non-continuous medium, the accessibility of the physical pore surface is not uniform. Only a small fraction of available surface, the surface of large pores, can become accessible at a high-rate operation or at a high frequency modulation. There are no electrochemical reactions or double layers occurring on the surface of fine pores, owing to the fact that the mass-transfer in those fine pores is slower than the polarization rate. Those fine pores can only be electrochemically accessed at a very low rate.

The same issue applies to a thick electrode; only the fraction of the electrode close to the separator participates in the reaction at a high rate while the portion of the electrode closest to the current collector remains unreacted. Qu discharged a D-size primary alkaline cell at various rate to the end-point voltage of 0.8 V. The discharged cells were immediately frozen in liquid nitrogen to stop any further chemical and physical reactions in the cell. After the frozen cell was sliced with a diamond saw, the MnO2 cathode samples were taken from different locations of the thick cathode. The oxidation state of Mn was determined through a Coulometric titration. It was found that at high rate (5 A) discharge, the Mn at the separator was over-discharged close to 2+ oxidation state; the Mn at the can was at 4+ oxidation state. While discharged at low rate (250 mA), the MnO2 in the cathode was evenly reduced to about 2.6+ oxidation state. A transmission line as shown in Fig. 5 proposed by Levie is normally used to simulate the distributed phenomenon of a non-continuous and porous medium14,15,16. The mathematical equations of the transmission line have the similar forms as the diffusion equation since the process taking place in an RC circuit may be treated as the electronic diffusion into a semi-infinite medium.

a Without charge transfer and b with charge transfer process. c Illustration of porosity-gradient design of thick electrode and d estimation of the penetration depth at different frequencies. This figure demonstrates how the transmission line equivalent circuit is used to represent a porous electrode with difference pore structure and related depth of electrochemical asscessibility. (reprinted from ref. 10. Copyright © 2021, with permission from John Wiley and Sons).

As shown in Fig. 5b, each RC unit that includes RCT. RW and CDL, represents an active cathode surface in the porous electrode matrix. Ideally, the number of RC units (n) in the transmission line model, which simulate the electrochemical reaction occurring on the 1/n of the total pore surface, should be infinite to represent the complete picture of a porous electrode. Each RC unit, thus 1/n of the pore surface, has different time constants. In other words, not all the surfaces can become electrochemically accessed at the same time. With the transmission line model shown in Fig. 5, one can estimate the electrochemical accessible surface area or the depth of electrochemical accessibility of a porous electrode.

Figure 5 shows the simulation of the electrochemical accessibility of a thick electrode with porosity-gradient design10. It is clearly demonstrated in Fig. 5d that 100% of the electrode surface can participate in an electrochemical reaction under very low rate (0.01 Hz). As the rate increased, the percentage of the physical surface area (for example, measured by N2 absorption isotherm) in which the electrochemical reaction took please decreased substantially. Based on our experience, only less than 50% of the electrode surface can be utilized for an electrode of thickness around 200 μm at a medium rate.

Although the details are kept as trade secrets, it has been a continuous effort in the battery industry to improve and optimize the electrode fabrication processes to enhance the percentage of electrochemical accessibility at high-rate conditions, for example, by particle matching, pore creation, pressure application17,18,19, etc. The EIS has been used as a tool for new product development, trouble shooting and competitive analysis in the battery industry for a long time20.

In the above discussions, the terms of a high-rate operation and a high frequency modulation were used interchangeably. It is worth mentioning that the impedance signals (a set of amplitudes and phase angles of the component sinusoids) in the frequency-domain can be converted into current densities in the time domain using a Fourier transformation1. Theoretically, an impedance spectrum can be converted into a set of polarizations at various current densities through the Fourier transformation and an inverse Fourier transformation can convert a potential decay curve to an impedance spectrum. Of course, special attention needs to be paid when converting a potential decay to an impedance making sure the linearity of the system, as shown in Fig. 1.

As the proliferation of nano-materials in the recent years, nano becomes a new buzzword in battery publication. The physical or geometric surface area of a solid is inversely related to the particle size of the material. However, it is only true to unpacked powders. In a battery electrode, primary particles (nano-powder) stick together owing to the surface energy forming secondary particles. The secondary particle would be in low micron size. Pores are constructed in those aggregated particles. The distribution of pore diameter or pore size depends on the shape, size, and packing of the primary particles. Generally, the smaller the primary particles, the lower the pore diameter would be. It is worth to pointing out that the electrochemical accessible surface area of a porous electrode is much low than its geometric surface area. Such discrepancy is more profound at a high rate operation. However, blending with micron size primary particles, nano-size materials are always good players for the engineering of an electrolyte porosity.

An electrochemical test cell—2-electrode vs. 3-electrode cell

The electrochemical processes on one particular electrode are studied in classic electrochemistry. The electrode under investigation is called working-electrode (WE). In order to make sure that all the changes in an electrochemical cell are ascribable to the WE, a three-electrode setup with a reference electrode (RE) is normally used. The makeup of an RE is constant and the electrode is maintained at an electrochemical equilibrium state throughout the experiment. No appreciable current can be allowed to pass through the RE, otherwise, a polarization would occur, resulting in a potential shift. Therefore, in a three-electrode system, one observes or controls the potential of the WE with respect to the RE. As shown in Fig. 6, the polarization current flows between the WE and an auxiliary electrode called a counter-electrode. In a three-electrode system, the electrochemical properties of the CE do not affect the behavior of the working electrode, whose sole purpose is to facilitate the current flow.

However, two-electrode cells are increasingly reported in the study of batteries. In a two-electrode cell, the polarizations of both electrodes are included in the electrochemical data such as an impedance spectrum. Unless proven otherwise, one cannot assume the electrochemical results from a two-electrode system are ascribable to either the cathode or the anode.

It is a very useful technique to implant RE in a battery cell. Barnard et al. investigated the impedance characteristics of undischarged primary alkaline cells by inserting Zn reference electrodes at different locations21. The contribution to the total impedance from the individual cell components and interfaces were de-convoluted, such as the impedance contributions from the cathode-can assembly, the anode-separator etc. The concept is demonstrated in Fig. 6. The impedance between the WE and the RE includes not only the impedance of the WE, but also the impedance between the WE and the RE (not including the impedance of the RE). The situation can be analog to the measurement of the voltages of a variable resistor where a current is passing through (Fig. 6). For instance, if two reference probes are implanted on both sides of a separator, the impedance between the cathode and each reference is measured, the difference of the two impedances is the separator impedance.

Special attention should be paid when a RE is implanted in a full battery cell22. First, all the RE should reach an equilibrium state before the measurement is taken. In the study of a LIB, a Li metal is normally used as RE. One should not be worried about the SEI or passive layer formed on the surface of Li reference, as long as the Li can reach and maintain its equilibrium state with the electrolyte. Second, the potentiostat and/or impedance spectrometer used for the measurement must have a high input impedance. Thus, only a negligible current pass through the RE and the polarization of the reference electrode can be ignored. Consequently, the RE potential remains constant and is equal to its equilibrium potential (open-circuit potential). Putting it in perspective, a high-end electrochemical workstation, e.g., AutoLab PGSTAT302N, has one tera ohms input impedance, while an affordable one has the input impedance in the range of mega ohms to giga ohms (1teraohm = 103 gigaohm = 106 megaohm). Last but not least, the size of a reference probe should be substantially smaller than the investigated electrodes; otherwise, a part of the solution current path between the cathode and the anode is blocked, in which nonuniform current distribution would arise at the electrode surface. The phenomenon is called shielding. As illustrated in Fig. 6, a RE senses the local potential. For instance, if a Lukin capillary was used, the potential at the tip of the capillary was sensed; if a plate or wire was used as a RE, then the average potential at the vicinity of the RE was sensed. Therefore, one should consider how a RE is placed in the cell so the desired information can be extracted strategically.

Distribution of relaxation times (DRT) analysis

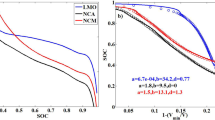

Although reference implementation is a very useful diagnostic tool, it is a destructive method. Sometimes, the implementation of a RE is technically challenging, e.g., to insert a reference into a jelly-roll cell. Theoretically, a generalized circuit of a continuous distribution of RC units in the space of relaxation of time can be used to represent any electrochemical impedances regardless of the electrochemical nature23,24. A relaxation of time is the time that a system takes in returning to the steady state after a perturbation. Therefore, the shorter the relaxation of time, the better the reaction kinetics are. For instance, the relaxation of time is short for an electrochemical reaction with a higher exchange current. In order to deconvolute the polarization effects overlapping in a frequency domain (impedance spectrum), an impedance spectrum can be transformed to the distribution of relaxation of time in time domain, by Fourier transformation or fitting into the generalized circuit21,25. In a DRT analysis, the impedance is fitted without prior assumptions of the physical and electrochemical processes. Therefore, each process can be distributed along the change of the relaxation times that represents the rate constants of the corresponding processes. Figure 7 shows physical and electrochemical processes in the corresponding frequency and time domain. The DRT method has attracted increasing attention in the field of electrochemical energy storage research because of its capability of detangling and deconvoluting the polarizations of various processes that otherwise overlap each other in an impedance spectrum. If coupled with the implementation of a reference probe, the kinetics of a cathode and an anode can be investigated in detail. Figure 8 shows the result of an impedance study of a LIB with a wide temperature electrolyte in comparison with a control electrolyte26. A Li reference electrode was implemented in a face-to-face single layer pouch cell. The impedance of cathode vs. reference; anode vs. reference and cell (cathode vs. anode) were measured after formation, after 50 cycles and after 100 cycles. As demonstrated in Fig. 8, the rate constants (relaxation times) and the polarization resistance (relaxation amplitudes, the integration of the corresponding peaks) of each physical and electrochemical process from the impedance spectrum are de-convoluted along the relaxation time. Figure 3 shows the complete equivalent circuit of a Li-ion cathode. Fitting an impedance spectrum to the complete equivalent circuit is time consuming and cumbersome. Practically, one builds a simplified equivalent circuit based on the educated speculation; such an approach works well for simple electrochemical systems. Owing to the distributed nature of a porous electrode used in a battery system, significant electrochemical processes may vary in the different frequency ranges. DRT can be used to identify dominant electrochemical processes at different frequency range by de-convoluting them along with relaxation of time. Equivalent circuits can then be built accordingly.

This diagram shows the kinetics and their time constants of various electrochemical and physical processes in a battery. The kinds of electrochemical techniques are also recommended for the investigation of the different processes. (reprinted from ref. 24. open access under the Creative Commons Attribution License).

a Baseline anode, b improved anode, c baseline cathode, d improved cathode, e baseline whole cell, f improved whole cell. (Reprinted from ref. 26. Copyright © 2022, with permission from Elsevier).

Solid state batteries have aroused a lot of attentions recently. The basic principles of EIS are also applied to all solid-state batteries. One unique feature of an all solid-state battery which results from the nature of a solid electrolyte is the charge carriers of the solid-state electrolyte. Unlike a liquid electrolyte, in which the electric current between electrodes is carried by ionic species, there may be electronic conductivity in a solid-state electrolyte. Although it is small, the electronic conductivity is responsible to the detrimental leakage current, which is equivalent to connect a large resistor between the cathode and anode. Theoretically, an electronic conductivity and ionic conductivity can be easily separated using both DC and AC27. Experimentally it is hard to get a reproducible measurement. A simple ac impedance measurement and fitting using a carefully designed electrochemical cell can be advantageous27. During the impedance measurements, an ion-blocking or electron-blocking or a redox electrode can be used. Ion-blocking electrodes can be metals e.g., Pt and Au or pyrolytic graphite, an ion-blocking electrode is inert and doesn’t facilitate charge transfer at the interface. Electron-blocking electrodes are high ionic conductivity materials with negligible electronic conductivity. Therefore, the only ionic conductivity is measured. If a redox electrode is used e.g., Li metal, then both ionic and electronic conductivity are included in the impedance measurement.

Outlook

EIS has been used for many decades. The proliferations of the EIS application, especially its application in energy storages occurred in the past decade. The revolutionary advancements in computers and electronics have made EIS analysis very easy and reduced the cost of EIS instruments drastically. Historically, an AC Wheatstone bridge was used for impedance measurement. It took an experienced electrochemist hour to measure the impedance at one frequency, especially at a low frequency. Now, even relatively affordable electrochemical workstations come with a built-in impedance spectrometer. Instead of running each frequency individually, the multiple-frequency excitation can be multiplexed and superimposed on a bias DC signal. With the help of Fourier transformation and digital frequency response analyzer, all frequency can be measured simultaneously with automatic output of real and complex spectra. Now an EIS measurement can be done by pushing the enter key on the keyboard. The advancements of the technology have made the powerful EIS technique widely available not only to electrochemists but also to professionals in the areas of material study, engineering, production quality control etc. Like every advancement in technology, there are always negative impacts. Here are two major issues found in many publications.

-

As mentioned earlier, EIS is a steady-state technique. The electrochemical system must be at an equilibrium state or at least the DC signal must be substantially smaller than the responding ac signals, when the impedance is measured. Almost all the electrodes used in energy storage are porous and the relaxation time is long. Using a modern impedance spectrometer, a set of impedance results can be produced. Even if the system is far from its equilibrium state, the obtained spectrum could be non-reproducible and misleading.

-

There is a clear trend of using EIS very casually and lightly in energy storage research. Due to the increasing convenience and affordability of the instrument, researchers just feel the pressure to have a Nyquist plot in the manuscript. Without a careful conduction of the experiments, validating the impedance data points frequency by frequency, establishing equivalent circuits, fitting the experimental data based on the equivalent circuit, and error analysis, the results can be at the very least useless or even misleading.

EIS is a powerful technique in electrochemical studies. It bridges the steady state and transient state so the kinetics of an electrode can be investigated at different stages of discharge or recharge. We hope it can be rightfully used to maximize the potential of the technique. We hope this discussion can provide a useful starting point for researchers in energy storage area, especially those who are not professional electrochemists.

The last but not the least, impedance techniques covered in this paper are for the investigation of electrochemical processes in a battery. In industries, impedance is also used as diagnostic tool for the state-of-health and state-of-charge. Those could be a single frequency impedance or discrete multi-frequency impedance. Since a large excitation signal is normally applied, the response would be non-linear. Most of the simulation models are semi-empirical and mostly proprietary.

References

Qu, D. et al. Electrochemical impedance and its applications in energy-storage systems. Small Methods 2, 1700342 (2018).

Chang, B.-Y. & Park, S.-M. Electrochemical impedance spectroscopy. Annu. Rev. Anal. Chem. 3, 207–229 (2010).

Meddings, N. et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 480, 228742 (2020).

Mc Carthy, K., Gullapalli, H., Ryan, K. M. & Kennedy, T. Review—Use of impedance spectroscopy for the estimation of Li-ion battery state of charge, state of health and internal temperature. J. Electrochem. Soc. 168, 080517 (2021).

Fan, C., O’Regan, K., Li, L., Kendrick, E. & Widanage, W. D. Frequency domain non-linear characterization and analysis of lithium-ion battery electrodes. J. Energy Storage 36, 102371 (2021).

Kramers, H. A. Die dispersion und absorption von Röntgenstrahlen. Phys. Z. 30, 522–523 (1929).

de L Kronig, R. On the theory of dispersion of X-rays. J. Opt. Soc. Am. 12, 547–557 (1926).

Bode, H. W. Network Analysis and Feedback Amplifier Design (Van Nostrand, 1945).

Qu, H. et al. Application of ac impedance as diagnostic tool—Low temperature electrolyte for a Li-ion battery. Electrochim. Acta 322, 134755 (2019).

Ji, W., Qu, H., Zhang, X., Zheng, D. & Qu, D. Electrode architecture design to promote charge-transport kinetic in high-loading and high-energy lithium-based batteries. Small Methods 5, 2100518 (2021).

Dawson, J. L. & John, D. G. Diffusion impedance—An extended general analysis. J. Electroanal. Chem. Interf. Electrochem. 110, 37–47 (1980).

Qu, D. Application of a.c. impedance technique to the study of the proton diffusion process in the porous MnO2 electrode. Electrochim. Acta 48, 1675–1684 (2003).

Qu, D. The study of the proton diffusion process in the porous MnO2 electrode. Electrochim. Acta 49, 657–665 (2004).

de Levie, R. On porous electrodes in electrolyte solutions: I. Capacitance effects. Electrochim. Acta 8, 751–780 (1963).

de Levie, R. On porous electrodes in electrolyte solutions—IV. Electrochim. Acta 9, 1231–1245 (1964).

de Levie, R. Advances in Electrochemistry and Electrochemical Engineering (Wiley-Interscience, 1967).

Qu, D. High discharge rate alkaline battery. US6960409B2 (2005).

Qu, D. Investigation of the porosity of electrolytic manganese dioxide and its performance as alkaline cathode material. J. Power Sources 156, 692–699 (2006).

Gourdin, G., Meehan, A., Jiang, T., Smith, P. & Qu., D. Investigation of the impact of stacking pressure on a double-layer supercapacitor. J. Power Sources 196, 523–529 (2011).

Qu, D. The ac impedance studies for porous MnO2 cathode by means of modified transmission line model. J. Power Sources 102, 270–276 (2001).

Barnard, R., Baugh, L. M. & Randell, C. F. The impedance of alkaline manganese cells and their relationship to cell performance. I. Interpretation of the basic impedance spectrum. J. Appl. Electrochem. 17, 165–173 (1987).

Bard, A. J. & Faulkner, L. R. Electrochemical Methods, Fundamentals and Applications 2nd edn (John Wiley & Sons, Inc., 2001).

Ivers-Tiffee, E. & Weber, A. Evaluation of electrochemical impedance spectra by the distribution of relaxation times. J. Ceram. Soc. Japan 125, 193–201 (2017).

Danzer, M. A. Generalized distribution of relaxation times analysis for the characterization of impedance spectra. Batteries 5, 53 (2019).

Smirnova, A. L., Ellwood, K. R. & Crosbie, G. M. Application of Fourier-based transforms to impedance spectra of small-diameter tubular solid oxide fuel cells. J. Electrochem. Soc. 148, A610–A615 (2001).

Qu, H., Zhang, X., Ji, W., Zheng, D. & Qu, D. Impedance investigation of the high temperature performance of the solid-electrolyte-interface of a wide temperature electrolyte. J. Colloid Interface Sci. 608, 3079–3086 (2022).

Huggins, R. A. Simple method to determine electronic and ionic components of the conductivity in mixed conductors. Ionics 8, 300–312 (2002).

Author information

Authors and Affiliations

Contributions

D.Q.: Conceptualization, manuscript structuring, and writing the first draft. W.J.: Contributing to conceptualization, reviewing and editing the manuscript, and graphing artworks. H.Q.: Participating, writing and editing, and obtaining copyright permission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Min Hong and the other, anonymous, reviewers for their contribution to the peer review of this work. Primary Handling Editors: Jie Xiao and John Plummer. Peer reviewer reports are available

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Qu, D., Ji, W. & Qu, H. Probing process kinetics in batteries with electrochemical impedance spectroscopy. Commun Mater 3, 61 (2022). https://doi.org/10.1038/s43246-022-00284-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-022-00284-w

This article is cited by

-

Balancing resistor-based online electrochemical impedance spectroscopy in battery systems: opportunities and limitations

Communications Engineering (2024)

-

Preparation and electrochemical performances for silicon-carbon ternary anode materials with artificial graphite as conductive skeleton

Journal of Solid State Electrochemistry (2024)

-

Effect of brain-like shape polypyrrole nanomaterial on the capacitance and stability enhancements of β-Ni(OH)2 two-symmetric electrodes supercapacitor

Journal of Materials Science: Materials in Electronics (2023)

-

Dumbbell-like shape Fe2O3/poly-2-aminothiophenol nanocomposite for two-symmetric electrode supercapacitor application

Journal of Materials Science: Materials in Electronics (2023)

-

Effect of Polypyrrole on the Capacitance Enhancement of the Spherical ZnS–ZnO/g-C3N4 Nanocomposite for Supercapacitor Applications

Journal of Inorganic and Organometallic Polymers and Materials (2023)