Abstract

The coupling of micro- or nanomechanical resonators via a shared substrate is intensively exploited to built systems for fundamental studies and practical applications. So far, the focus has been on devices operating in the kHz regime with a spring-like coupling. At resonance frequencies above several 10 MHz, wave propagation in the solid substrate becomes relevant. The resonators act as sources for surface acoustic waves (SAWs), and it is unknown how this affects the coupling between them. Here, we present a model for MHz frequency resonators interacting by SAWs, which agrees well with finite element method simulations and recent experiments of coupled micro-pillars. In contrast to the well-known strain-induced spring-like coupling, the coupling via SAWs is not only dispersive but also dissipative. This can be exploited to realize high quality phonon cavities, an alternative to acoustic radiation shielding by, e.g. phononic crystals.

Similar content being viewed by others

Introduction

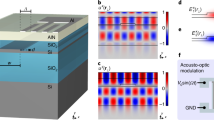

Two mechanical resonators mounted on the same substrate are considered coupled if the motion of one of the resonators affects the motion of the other resonator and vice versa. Such systems of coupled micro- or nanomechanical resonators are widely used in fundamental studies and practical applications. They are utilized to build highly precise mass sensors1,2,3, allow for the study of quantum-coherent coupling and entanglement between two distinct macroscopic mechanical objects4,5, and enable the investigation of collective dynamics6. In all of these cases, the considered resonance frequencies are in the kHz or low MHz regime and the coupling of the resonators is well understood. This is not the case at higher resonance frequencies in the order of several 10 MHz and above. At these frequencies, the wavelength of surface acoustic waves (SAWs) becomes much smaller than the usual dimensions of the resonators’ substrates, assuming a typical SAW velocity7,8 of around 3000 m/s. This allows coupling of the resonators by SAWs. An example of SAW-coupled resonators is illustrated in Fig. 1 by a pair of short micro-pillar resonators vibrating in the first bulk mode9, also known as compression mode10,11. Typical resonance frequencies of such pillar resonators are above 50 MHz. Short micro-pillar resonators are compatible with SAW devices11,12,13, and pillar-based phononic crystals and metamaterials are utilized to manipulate the propagation of SAWs10,14, including applications such as acoustic superlenses15, waveguides16,17, vibration attenuation13,18, mass sensing19 and phononic graphene20.

Schematic of the symmetric mode of two identical SAW-coupled pillar resonators for two different moments in time. The solid and dashed blue lines show the amplitude of the SAW emitted by each pillar along the y-direction. a At t0 the pillars' displacement is maximal and (b) minimal half a period T later. The pillar resonators vibrate in the first bulk/compression mode and emit SAWs, which exert an effective force FSAW on the other resonator.

In a lumped-element model, a substrate-mediated coupling is usually represented by a spring connecting two spring-mass systems9,21. In doing so, the interaction between the resonators is assumed to be instantaneous. This assumption is not valid if the resonators interact with SAWs. In this case, the coupling between the resonators has a delay. This is the propagation time of a SAW, which is created by one resonator22,23 and travels to the other. Delay-coupled systems have been studied before: two resonators mounted on a string24, two resonators coupled by a rod25, or the interaction of air bubbles in water26,27,28,29, for example. However, a radiative coupling by SAWs between three-dimensional micro- or nanomechanical resonators mounted on a semi-infinite substrate has not yet been investigated. A coupling function, analogous to the spring coupling model, is unknown and would be helpful to a deeper understanding of recent experiments of coupled micro-pillar resonators30.

Here, we propose a coupling function for SAW-coupled micro- or nanomechanical resonators. First, we consider a pair of identical and SAW-coupled pillar resonators. We analytically derive the eigenfrequencies and quality factors of the symmetric and antisymmetric modes of the pillars as a function of their distance, compare the results to finite element method (FEM) simulations and discuss the strength of the SAW coupling. For the FEM simulations, we considered the first bulk mode of the pillars, since it represents the most simple case. Second, we investigate the frequency response of two non-identical and SAW-coupled pillar resonators vibrating in the first bending mode and compare the results with recent experiments of coupled micro-pillar resonators30.

Results

SAW coupling model

The coupling by SAWs is schematically depicted in Fig. 1. Each of the resonators emits a SAW, which exerts an effective force FSAW on the other resonator. The origin of FSAW is the mechanical vibration of the resonators and the resulting forces exerted on the substrate surface. In a lumped-element model, the effective force exerted by the vibration of a single resonator with an effective mass m and a displacement z that drives the SAW mode of the substrate is given by

based on the principle of action and reaction. The dimensionless parameter g represents the coupling strength between the resonator’s vibrational mode and the SAW mode. We consider the displacement of the resonator in z-direction, since the pillars depicted in Fig. 1 vibrate in the first bulk mode, whose vibration direction is the z-direction. For example, if a bending mode in x-direction is considered, z is replaced by x, the displacement in x-direction.

It is not the force Fs that directly acts on another resonator but the SAW created by Fs. Due to the propagation of the SAW, the force FSAW exerted by the SAW has a smaller amplitude and is phase-shifted compared to Fs. The change in the amplitude of FSAW corresponds to the change of the SAW amplitude and the phase shift is the difference in phase between the resonator and its emitted SAW at the site of the other resonator. Consequently, the force exerted on the other resonator by the emitted SAW is given by

with

where ASAW(d) and ϕSAW are the normalized (ASAW(0) = 1) amplitude and phase of the emitted SAW at the site of the other resonator, ϕR and ω are the phase and vibration frequency of the SAW-emitting resonator, t represents the time, cSAW is the velocity of the emitted SAW, and θ represents additional phase changes of the emitted SAW during its formation (see Supplementary Note 1 for details).

In Eq. (2), we do not give an explicit expression for the SAW amplitude, since the amplitude of a SAW emitted by a three-dimensional resonator mounted on a semi-infinite substrate strongly depends on the materials. Some substrate materials are anisotropic, such as single crystalline silicon or lithium niobate, so the intensity of the SAWs and, accordingly31, also their amplitude are a function of the propagation direction. This effect is known as phonon focusing32,33.

It is important to note that the presented model assumes linear elasticity and does not take into account non-linear effects. The model assumes further that the dimension of the resonator in the propagation direction of the SAW is small in comparison to the SAW wavelength λSAW. Beyond that, the model does not consider the propagation loss of the SAWs. Popular SAW substrates, such as lithium niobate or quartz, feature a propagation loss7,34 of less than 0.0031 dB/ λSAW at frequencies below 1 GHz. Such a loss is small in comparison to intensity changes of the SAW due to propagation in two dimensions.

Eigenfrequencies and quality factors of two identical and SAW-coupled resonators

In the following, we consider the symmetric and antisymmetric modes of two identical SAW-coupled resonators to investigate the effect of the SAW coupling on the modes’ eigenfrequencies and quality factors. Two SAW-coupled resonators exert the force FSAW on each other. For weak damping, this results in the following equations of motion

where indices 1 and 2 give the number of the resonator and ω0 = 2π f0 and Q0 are the eigenfrequency and quality factor of a single resonator, respectively. If the two resonators vibrate in a symmetric (+) or antisymmetric (−) mode, we can drop the indices, since the modes feature \({\ddot{z}}_{{{{{{{{\rm{1}}}}}}}}}=\pm {\ddot{z}}_{{{{{{{{\rm{2}}}}}}}}}\). The equations of motion of both resonators are then given by

Using the ansatz z = z0 ei ω t for the steady-state solution with complex amplitude z0 results in

with

and

By comparing Eq. (7) with the case of a single resonator, it becomes clear that ω± and Q± are the eigenfrequencies and quality factors of the symmetric (+) and antisymmetric (−) modes of the SAW-coupled resonators. In contrast to the spring-like coupling, the coupling by SAWs not only modulates the resonators’ eigenfrequencies (dispersive coupling) but also modulates their damping (dissipative coupling). Due to the dependency of Δϕ on the resonators’ vibration frequency, ω± is a function of itself. In the case of small modulations of the eigenfrequencies ω± ≈ ω0, the eigenfrequencies ω± can be approximated by using Δϕ(d, ω±) ≈ Δϕ(d, ω0). Furthermore, it is important to note that the SAWs are a part of the resonators’ radiation losses into the substrate, which are represented by Qrad. Hence, the coupling force FSAW can only modulate Qrad and not other damping mechanisms included in Q0. Consequently, the product Q0 g in Eq. (9) must be proportional to Q0/Qrad, which gives g ∝ 1/Qrad. This matches with the definition of g as the coupling strength between the resonators’ vibrational mode and the SAW mode.

FEM model

To test the proposed SAW coupling model, we performed FEM simulations of a pair of coupled pillar resonators, which are mounted on a semi-infinite substrate and vibrate in the first bulk mode, as schematically depicted in Fig. 1. We simulated the eigenfrequencies and quality factors of the symmetric and antisymmetric modes of the pillars as a function of the spacing between them. The pillars had a diameter of 4 μm and a height of 6 μm. Their Young’s modulus, mass density, and Poisson’s ratio were E = 4.88 GPa, ρ = 1183 kg/m3, and ν = 0.22, similar to the material properties of SU-8 resist. No intrinsic damping was considered since the focus was on the modulation of the radiation losses into the substrate. The substrate was modelled as a half-sphere and partitioned into an outer and an inner part. The outer part was defined as a perfectly matched layer (PML) mimicking an infinitive large substrate. The substrate’s material was lithium niobate (LiNbO3) with a 127.86∘ Y-cut orientation. The pillars were placed along a line perpendicular to the crystallographic X-axis (geometric y-direction). Along the line, Rayleigh-type SAWs emitted by a point source propagate with a velocity35,36,37 of around cSAW = 3664 m/s. Simulations of a single pillar show that the pillars emit Rayleigh waves (see Supplementary Note 2). The symmetry of the LiNbO3 crystal38 allowed for reducing the simulated domain to half of the considered domain. The geometry and the used mesh are shown in Fig. 2. Further details of the FEM simulations are given in the Methods section.

SAW model vs. FEM simulations

To compare the proposed SAW coupling model with the FEM simulations, we determined g by fitting Eq. (8) to the simulated eigenfrequencies first, then plotted Eqs. (8) and (9) together with the simulated eigenfrequencies and quality factors. For the fitting and plotting, we exploited the small modulation of the eigenfrequencies, as discussed above. In addition to the normalized SAW amplitude ASAW, we also determined the phase difference Δϕ by a FEM simulation of a single pillar resonator. Along a line in y-direction on the surface, we determined the displacement in z-direction uz of an SAW emitted by the single pillar and calculated the absolute value ∣uz∣ ∝ ASAW and the phase \({{\phi }_{u}}_{{{{{{{{\rm{z}}}}}}}}}={\phi }_{{{{{{{{\rm{SAW}}}}}}}}}\). We chose the displacement in z-direction, since the pillars vibrate in z-direction. Based on ϕSAW and Eq. (3), we calculated then Δϕ, with ϕR determined at the central point on top of the single pillar. The results of the single pillar FEM simulation are given in Supplementary Note 2.

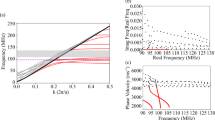

The simulated eigenfrequencies f± and quality factors Q± of the symmetric and antisymmetric mode of the two pillar resonators are plotted in Fig. 3 as a function of the pillars’ separation distance. The distances between the pillars range from 0.3 to 10.5 λSAW/2. In comparison, coupled beams or cantilevers3,5,21 in the frequency regime around 100 kHz usually have a separation distance in the order of 10−3 λSAW/2, assuming a typical SAW velocity7,8 of around 3000 m/s. The eigenfrequencies f± and quality factors Q± of both modes are periodically modulated with increasing distance d. The modulations of f± and Q± are phase-shifted by π/2, which implies that the coupling between the pillars is purely dispersive at the maxima and minima of f± and purely dissipative at its zeros. The results of the FEM simulations are in excellent agreement with the proposed SAW coupling model, as can be seen in Fig. 3 by the red lines.

a, b Eigenfrequencies and (c), (d) quality factors of the symmetric and antisymmetric modes as a function of the distance d between the pillars. The grey lines mark the properties f0 = 84.18 MHz and Q0 = 208 of a single pillar resonator. The red lines are plots of Eqs. (8) and (9) for g = 0.027 and exploiting ω± ≈ ω0. The insets illustrate schematically the mode of vibration of the pillars. The black dashed lines represent the height of the pillars for no displacement.

With increasing distance d, the amplitude of the modulations of f± and Q± decreases, since the amplitude of the emitted SAWs decreases with increasing propagation distance. The huge difference in the modulation strength between Q+ and Q− at small distances d becomes clear by considering the limiting case d → 0 and pillarradius → 0, which is discussed in the following. The quality factor is defined as the ratio between the energy stored and energy lost during one cycle at resonance9. In the antisymmetric case, the pillars behave as a non-radiating source39,40,41. No power is emitted due to destructive interference of the emitted waves, which results in Q− → ∞. In the symmetric case, the two pillars emit four times the power emitted by a single pillar due to constructive interference31 and store together twice the total energy, which yields Q+/Q0 = 0.5. The discussed limiting case shows that the dissipative coupling can also be interpreted as a result of wave interference, which explains the difference in the modulation strength of the quality factors and the eigenfrequencies. Only a small fraction of the waves emitted by one resonator reaches the other resonator directly. In comparison, the interference affects all waves emitted by the pillars.

In addition to the presented FEM simulations, we simulated the second bending mode of the discussed pillar pair and a typical thin cantilever geometry vibrating in the first bending mode. The results are given in Supplementary Notes 3 and 4 and are in excellent agreement with the SAW coupling model.

Strength of the SAW coupling

A feature of major interest in the context of coupled micro- and nanomechanical resonators is the strength of the coupling. A distinction is typically made between the weak and the strong coupling regime. In the weak coupling regime the energy stored in one resonator dissipates before it is transferred to the other resonator, whereas in the strong coupling regime the resonators exchange energy and the dynamics of the coupled resonators are governed by the motion of both resonators42. For spring-like coupled resonators the strength of the coupling can be estimated by the ratio (f− − f+)/(f0/Q0), since f− − f+ is proportional to the energy exchange rate between the resonators and f0/Q0 is proportional to the energy dissipation rate of the system42. This approach can not be used for SAW-coupled resonators, since the quality factor of the resonators is a function of the time t due to the dissipative part of the coupling. To get an impression of the strength of the coupling between the two pillar resonators, we considered the dynamics of two pillar resonators separated by d = 0.3 λSAW/2 in comparison with two spring-coupled resonators at the threshold of the strong coupling regime. In detail, we calculated the displacements of the resonators as a function of time by numerically solving the equations of motion of each system for the following complex initial conditions

where z0 is a complex amplitude. At t = 0, both resonators are at rest, but resonator 1 is displaced. We chose \({\dot{z}}_{1}(t=0)\) such that the displacement and the velocity of resonator 1 are phase-shifted by π/2, and that its maximal kinetic energy equals its maximal potential energy.

The equations of motion of two SAW-coupled resonators are given by Eqs. (4) and (5). For weak damping, the equations of motion of two identical spring-coupled resonators are given by

where ωc is the coupling rate. We numerically solved both systems for the following parameter values

The given values of ω0, Q0, ASAW(d) and Δϕ(d, ω) originate from the FEM simulations discussed above, whereby ASAW(d) and Δϕ(d, ω) were evaluated at d = 0.3 λSAW/2. The value of g was determined by fitting of Eq. (8) to the simulated eigenfrequncies of two pillar resonators, as discussed above, and the value of the coupling rate ωc results in (f− − f+)/(f0/Q0) = 1, which is the definition of the threshold of the strong coupling regime for spring-coupled resonators6,9. Further details of the numerical calculations are given in the Methods section.

The calculated amplitudes of the resonators and their phase relationships are depicted in Fig. 4. It can be seen that the two systems exhibit different dynamics. The spring-coupled resonators exchange their total energy Etot ∝ ∣zi∣2 back and forth and vibrate with a phase difference of 90∘, as shown in Fig. 4a, c. In contrast, the pillar resonators vibrate antisymmetrically after a transient time and only transfer energy until both pillars have the same total energy, as shown in Fig. 4b, c. The reason for the different dynamics is the dissipative part of the SAW coupling. In contrast to the spring-coupled resonators, the pillar resonators maximize their quality factor, which is displayed by the exponentially decaying lines in Fig. 4a, b. Based on the FEM simulations discussed above, two pillar resonators, which are separated by d = 0.3 λSAW/2 and vibrate in the antisymmetric mode, have a quality factor of Q− = 1455 instead of Q0 = 208. By comparing the amplitudes ∣z2∣ of both systems, it can be seen that the second pillar resonator has a larger maximum amplitude than the second spring-coupled resonator. Consequently, the ratio of the energy exchange rate to the energy dissipation rate is larger for the SAW-coupled pillar resonators than for the spring-coupled resonators. Since the spring-coupled resonators are at the threshold of the strong coupling regime, the pillar resonators are strongly coupled. It is important to note that the pillar resonators’ damping is dominated by radiation losses into the substrate. If this were not the case, the coupling would be weaker.

The spring-coupled resonators are at the threshold of the strong coupling regime and the SAW-coupled pillar resonators are separated by d = 0.3 λSAW/2. a Amplitudes of the two spring-coupled resonators and (b) the two SAW-coupled pillar resonators as a function of time t. A single spring-coupled resonator has the same eigenfrequency f0 = 84.18 MHz and quality factor Q0 = 208 as a single pillar resonator. The grey lines show the amplitude decay of a single pillar resonator and of two antisymmetrically vibrating pillar resonators separated by d = 0.3 λSAW/2. In the latter case, the finite element method simulations discussed above gave f− = 84.27 MHz and Q− = 1145. In both graphs, we reduced the amount of data points for the sake of clarity. c Phase difference between the displacements of the two spring-coupled and the two SAW-coupled pillar resonators.

Frequency response of two non-identical and SAW-coupled resonators

The motivation to consider the frequency response of two SAW-coupled resonators is to further test the proposed SAW coupling model by comparison to recent experiments30. Raguin et al. drove a pair of coupled micro-pillar resonators by an incident SAW and measured the frequency response of the pillars by laser scanning heterodyne interferometry. A schematic of the sample is shown in Fig. 5a. A SAW is created by an interdigital transducer, travels towards the pillars and drives the first bending mode of the pillars, which is illustrated in Fig. 5b.

a Schematic top view on the sample illustrating the orientation of the pillar pair regarding the incident SAW. The SAW is created by an interdigital transducer (IDT) and the pillars vibrate in the first bending mode. The distance between the pillars is d = 5.9 μm. b Schematic side view of a single pillar illustrating the pillars' motion (first bending mode). c Experimental frequency response of the pillar pair measured by laser scanning heterodyne interferometry. The experimental data are taken from Raguin et al.30. The solid lines result from a fit of Eq. (15) to the experimental data.

In the following, we assume that the pillars bend along the x-direction and consider non-identical resonators since identically fabricated resonators usually are not identical due to fabrication limitations. For example, Raguin et al.30 give an uncertainty of 3–4% on the dimensions of their fabricated micro-pillars. Consequently, it is probable that the pillars of a pair have slightly different eigenfrequencies ω1 ≠ ω2 and quality factors Q1 ≠ Q2, which result in the following equations of motion

where FD is the force applied on the pillars by the incident SAW. It is important to have in mind that FD ≠ FSAW. FSAW is the force exerted on each pillar by the SAW emitted by the other pillar. Applying the ansatz for the steady-state solution to Eqs. (13) and (14), as discussed above, gives the frequency response of the two resonators

with

and the normalized frequency response of a single resonator

where the indices n, m ∈ {1, 2} give the number of the resonator. From Eq. (15) it can be seen that the frequency response of the SAW-coupled resonators is given by the frequency response of the single resonators modified by Cn.

SAW model vs. experiments

To compare the SAW coupling model with the discussed experiment30, we fitted Eq. (15) to the measured frequency responses. We first determined the normalized SAW amplitude ASAW and the phase difference Δϕ by a FEM simulation of a single pillar with identical dimensions and material properties as used by Raguin et al.30. In detail, the pillar had a diameter of 4.4 μm and a height of 4 μm. Its Young’s modulus, mass density, and Poisson’s ratio were given by E = 130 GPa, ρ = 104 kg/m3, and ν = 0.38, respectively. In comparison to the FEM simulations of the first bulk mode, we adjusted a boundary condition and the mesh around the base of the pillar, as described in Supplementary Note 3, and changed the cut of the LiNbO3 substrate to a Y-cut, according to the substrate used by Raguin et al.30. Furthermore, we determined ASAW and Δϕ on the displacement in x-direction and not z-direction, since the pillar vibrates in a bending mode in x-direction. The result of the FEM simulation was

where ASAW(d) and Δϕ(d, ω) were evaluated for the distance d = 5.9 μm. The simulated eigenfrequency and quality factor of the single pillar fit well with the experimental results of Raguin et al.30, who measured an eigenfrequency of f0 = 70.54 MHz and a quality factor of around Q0 ≈ 34.

When we fitted Eq. (15) to the experimentally measured frequency responses, we used ASAW determined by the FEM simulation of a single pillar and made the following assumptions. First, we set m1 = m2, since the difference in mass between the identical fabricated micro-pillars is small. Second, we assume Q1 = Q2 = Q0, since Benchabane et al.11 showed that the quality factor of the micro-pillars only changes slightly with small variations in their dimensions. Third, we set Δϕ(d, ω) = 0.61, the value which we determined by the FEM simulation of a single pillar since the SAW wavelength changes less than 10% in the applied frequency range relative to f0. The fitting of Eq. (15) to the experimental data of Raguin et al.30 gave

The calculated quality factor is in perfect agreement with the FEM simulation of the single pillar, which gave the identical quality factor. The measured and calculated frequency responses are shown in Fig. 5c. Each pillar shows two resonances: One resonance around 67 MHz and the other around 71 MHz. These frequencies are close to the eigenfrequencies f1 and f2 of the single pillars, which we determined by the fitting of Eq. (15). Hence, the difference in dimension of the pillars is the main reason for the frequency difference of the coupled pillars and not the dispersive coupling. In the case of identical pillars, the given value of g would result in a significant frequency difference of a few MHz of the pillars’ symmetric and antisymmetric modes.

Beyond that, it can be seen in Fig. 5c that the resonances around 67 MHz and 71 MHz differ in their quality factors. We estimated the quality factor of the main resonance of each pillar by fitting the frequency response of a single resonator, which is given by Eq. (17) multiplied by an amplitude. We determined a quality factor of around 30 for the main peak around 67 MHz and a quality factor of around 110 for the main peak around 71 MHz. Such a difference in the quality factor of more than a factor of 3 is unexpected for the identically fabricated micro-pillars, as discussed above. It is more plausible to assume that the difference in the quality factors has its origin in the coupling of the pillars. However, the usually used spring coupling model can not explain such a modification of the quality factors, since the spring-like coupling is purely dispersive. In contrast, the SAW coupling model is able to explain it and describes the experimental data well. The micro-pillars are separated by d < 0.3 λSAW/2, which is the minimal distance between the two identical resonators discussed above. Based on Fig. 3, this means that the pillars show a decreased quality factor in case of a symmetric vibration and an increased quality factor in case of an antisymmetric vibration. Raguin et al.30 showed that the pillars vibrate symmetrically around 67 MHz and antisymmetrically around 71 MHz.

Conclusions

In conclusion, our results indicate that the coupling between MHz frequency resonators can significantly differ from the usually assumed and purely dispersive spring-like coupling. The coupling via SAWs is not only dispersive but also dissipative. This makes our results important for all fields working with micro- or nanomechanical resonators with resonance frequencies in the MHz regime and above, for instance, NEMS/MEMS and acoustic metamaterials. In MEMS and NEMS, a major approach to increase the devices’ sensitivity is to shrink the sizes of the mechanical resonators, which shifts their resonance frequencies from the kHz to the MHz regime43,44,45. Furthermore, for quantum applications at room temperature, a high Qf-product is needed46,47. The dissipative coupling opens up a new possibility to reduce acoustic radiation losses via the substrate by positioning two or more resonators at certain distances. In comparison to acoustic radiation shielding with phononic crystals48,49,50, phonon cavities based on dissipative coupling are accessible by external SAWs and, thereby, allow to perform quantum acoustics experiments between a SAW51 and coupled mechanical resonators.

Pillar-based metamaterials are built on the local resonances of the pillar resonators10. Hence, the exact knowledge of the pillars’ resonance frequencies and quality factors is of great importance for the design of metamaterials, e.g., for the effective guidance16,17 or attenuation13,18 of acoustic waves with a known frequency. Our results give insights into the coupling of the individual pillar resonators and the resulting impact on their resonance frequencies and quality factors.

Methods

Details of the FEM simulations

The FEM simulations were carried out with COMSOL Multiphysics (Version 5.4) using the Modules AC/DC (Electrostatics) and Structural Mechanics (Solid Mechancis, Piezoelectricity). An unstructured tetrahedral mesh was used for the pillars with a maximum element size of an eighth of the pillars’ diameter. A swept mesh was utilized for the PML and an unstructured tetrahedral mesh for the inner part of the substrate. The latter had a maximum element size of an eighth of the SAW wavelength λSAW up to a distance of λSAW to the surface, which is approximately the penetration depth of a SAW7. For elements deeper in the substrate, the maximum element size was reduced by a factor of two. In Solid Mechanics, quadratic serendipity elements were used as Lagrange elements were used in Electrostatics. We performed an eigenfrequency study to calculate the eigenfrequencies and quality factors of the symmetric and antisymmetric modes for different distances d between the pillars and in the simulation of a single pillar resonator.

To minimize the memory requirements and the solution time, we reduced the simulated domain to half of the considered domain by using the following symmetric boundary condition

where u is the displacement vector and n is the unit normal vector of the considered sectional plane. In our case, this is the yz-plane, as shown in Fig. 2. The yz-plane lies in a plane of mirror symmetry of the lithium niobate substrate38, and a pillar resonator made out of an isotropic material shows no displacement in x-direction at any point in the yz-plane when vibrating in the first bulk mode in the limit of small vibrational amplitudes9,52.

Details of the numerical calculations

The numerical calculations were carried out in Matlab 2020a. We converted the second-order differential equations to first-order differential equations and solved the first-order differential equations by the function ode45 using a stepzise of Δt = 25/f0, and a relative and absolute error tolerance of 10−6 and 10−8, respectively.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Code availability

The codes used in this study are available from the corresponding author upon reasonable request.

References

Spletzer, M., Raman, A., Wu, A. Q., Xu, X. & Reifenberger, R. Ultrasensitive mass sensing using mode localization in coupled microcantilevers. Appl. Phys. Lett. 88, 1–3 (2006).

Gil-Santos, E. et al. Mass sensing based on deterministic and stochastic responses of elastically coupled nanocantilevers. Nano Lett. 9, 4122–4127 (2009).

Stassi, S. et al. Large-scale parallelization of nanomechanical mass spectrometry with weakly-coupled resonators. Nat. Commun. 10, 1–11 (2019).

Kotler, S. et al. Direct observation of deterministic macroscopic entanglement. Science 372, 622–625 (2021).

Okamoto, H. et al. Coherent phonon manipulation in coupled mechanical resonators. Nat. Phys. 9, 480–484 (2013).

Doster, J., Hoenl, S., Lorenz, H., Paulitschke, P. & Weig, E. M. Collective dynamics of strain-coupled nanomechanical pillar resonators. Nat. Commun. 10, 1–5 (2019).

Morgan, D. Surface Acoustic Wave Filters, 2nd edn. (Elsevier Ltd., 2007).

Fu, Y. Q. et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 89, 31–91 (2017).

Schmid, S., Villanueva, L. G. & Roukes, M. L. Fundamentals of Nanomechanical Resonators (Springer, 2016).

Jin, Y. et al. Physics of surface vibrational resonances: pillared phononic crystals, metamaterials, and metasurfaces. Rep. Prog. Phys. 84, 1–51 (2021).

Benchabane, S. et al. Surface-wave coupling to single phononic subwavelength resonators. Phys. Rev. Appl. 8, 1–7 (2017).

Benchabane, S. et al. Nonlinear coupling of phononic resonators induced by surface acoustic waves. Phys. Rev. Appl. 16, 1–9 (2021).

Achaoui, Y., Khelif, A., Benchabane, S., Robert, L. & Laude, V. Experimental observation of locally-resonant and Bragg band gaps for surface guided waves in a phononic crystal of pillars. Phys. Rev. B 83, 1–5 (2011).

Liu, Y. et al. Autler-townes splitting and acoustically induced transparency based on love waves interacting with a pillared metasurface. Phys. Rev. Appl. 11, 1–13 (2019).

Rupin, M., Catheline, S. & Roux, P. Super-resolution experiments on Lamb waves using a single emitter. Appl. Phys. Lett. 106, 1–5 (2015).

Pennec, Y. et al. Phonon transport and waveguiding in a phononic crystal made up of cylindrical dots on a thin homogeneous plate. Phys. Rev. B 80, 1–7 (2009).

Oudich, M., Assouar, M. B. & Hou, Z. Propagation of acoustic waves and waveguiding in a two-dimensional locally resonant phononic crystal plate. Appl. Phys. Lett. 97, 1–3 (2010).

Colombi, A., Roux, P., Guenneau, S., Gueguen, P. & Craster, R. V. Forests as a natural seismic metamaterial: Rayleigh wave bandgaps induced by local resonances. Sci. Rep. 6, 1–7 (2016).

Bonhomme, J. et al. Love waves dispersion by phononic pillars for nano-particle mass sensing. Appl. Phys. Lett. 114, 1–5 (2019).

Torrent, D., Mayou, D. & Sánchez-Dehesa, J. Elastic analog of graphene: Dirac cones and edge states for flexural waves in thin plates. Phys. Rev. B 87, 1–8 (2013).

Gil-Santos, E., Ramos, D., Pini, V., Calleja, M. & Tamayo, J. Exponential tuning of the coupling constant of coupled microcantilevers by modifying their separation. Appl. Phys. Lett. 98, 1–3 (2011).

Berte, R. et al. Acoustic far-field hypersonic surface wave detection with single plasmonic nanoantennas. Phys. Rev. Lett. 121, 1–6 (2018).

Jin, Y. et al. Pillar-type acoustic metasurface. Phys. Rev. B 96, 1–8 (2017).

Lepri, S. & Pikovsky, A. Nonreciprocal wave scattering on nonlinear string-coupled oscillators. Chaos 24, 1–9 (2014).

Edelman, K. & Gendelman, O. V. Dynamics of self-excited oscillators with neutral delay coupling. Nonlinear Dyn. 72, 683–694 (2013).

Feuillade, C. Scattering from collective modes of air bubbles in water and the physical mechanism of superresonances. J. Acoust. Soc. Am. 98, 1178–1190 (1995).

Ooi, A., Nikolovska, A. & Manasseh, R. Analysis of time delay effects on a linear bubble chain system. J. Acoust. Soc. Am. 124, 815–826 (2008).

Feuillade, C. Acoustically coupled gas bubbles in fluids: time-domain phenomena. J. Acoust. Soc. Am. 109, 2606–2615 (2001).

Doinikov, A. A., Manasseh, R. & Ooi, A. Time delays in coupled multibubble systems (L). J. Acoust. Soc. Am. 117, 47–50 (2005).

Raguin, L. et al. Dipole states and coherent interaction in surface-acoustic-wave coupled phononic resonators. Nat. Commun. 10, 1–8 (2019).

Miles, R. N. Physical Approach to Enginnering Acoustics (Springer, 2020).

Kolomenskii, A. A. & Maznev, A. Phonon-focusing effect with laser-generated ultrasonic surface waves. Phys. Rev. B 48, 502–508 (1993).

Taylor, B., Maris, H. J. & Elbaum, C. Phonon focusing in solids. Phys. Rev. Lett. 23, 416–419 (1969).

Slobodnik, A. J. Surface acoustic waves and SAW materials. Proc. IEEE 64, 581–595 (1976).

Kovacs, G., Anhorn, M., Engan, H., Visintini, G. & Ruppel, C. Improved material constants for LiNbO/sub 3/ and LiTaO/sub 3/. IEEE Symp. Ultrason. 1, 435–438 (1990).

Holm, A., Stürzer, Q., Xu, Y. & Weigel, R. Investigation of surface acoustic waves on LiNbO3, quartz, and LiTaO3 by laser probing. Microelectron. Eng. 31, 123–127 (1996).

Laude, V. et al. Subwavelength focusing of surface acoustic waves generated by an annular interdigital transducer. Appl. Phys. Lett. 92, 1–3 (2008).

Weis, R. S. & Gaylord, T. K. Lithium niobate: summary of physical properties and crystal structure. Appl. Phys. A 37, 191–203 (1985).

Berry, M., Foley, J. T., Gbur, G. & Wolf, E. Nonpropagating string excitations. Am. J. Phys. 66, 121–123 (1998).

Gbur, G., Foley, J. T. & Wolf, E. Nonpropagating string excitations—finite length and damped strings. Wave Motion 30, 125–134 (1999).

Miroshnichenko, A. E. et al. Nonradiating anapole modes in dielectric nanoparticles. Nat. Commun. 6, 1–8 (2015).

Rodriguez, S. R. K. Classical and quantum distinctions between weak and strong coupling. Eur. J. Phys. 37, 1–15 (2016).

Yang, Y. T., Callegari, C., Feng, X. L., Ekinci, K. L. & Roukes, M. L. Zeptogram-scale nanomechanical mass sensing. Nano Lett. 6, 583–586 (2006).

Li, M., Tang, H. X. & Roukes, M. L. Ultra-sensitive NEMS-based cantilevers for sensing, scanned probe and very high-frequency applications. Nat. Nanotechnol. 2, 114–120 (2007).

Dominguez-Medina, S. et al. Neutral mass spectrometry of virus capsids above 100 megadaltons with nanomechanical resonators. Science 362, 918–922 (2018).

Tsaturyan, Y., Barg, A., Polzik, E. S. & Schliesser, A. Ultracoherent nanomechanical resonators via soft clamping and dissipation dilution. Nat. Nanotechnol. 12, 776–783 (2017).

Norte, R. A., Moura, J. P. & Gröblacher, S. Mechanical resonators for quantum optomechanics experiments at room temperature. Phys. Rev. Lett. 116, 1–6 (2016).

Chan, J. et al. Laser cooling of a nanomechanical oscillator into its quantum ground state. Nature 478, 89–92 (2011).

Arrangoiz-Arriola, P. et al. Resolving the energy levels of a nanomechanical oscillator. Nature 571, 537–540 (2019).

Riedinger, R. et al. Non-classical correlations between single photons and phonons from a mechanical oscillator. Nature 530, 313–316 (2016).

Gustafsson, M. V. et al. Propagating phonons coupled to an artificial atom. Science 346, 207–211 (2014).

Weaver, W., Timoshenko, S. & Young, D. Vibration Problems in Engineering, 5th edn. (Wiley, 1990).

Acknowledgements

We thank A.L. Gesing for his support with the FEM simulations as well as R. West, M. Piller and N. Luhmann for many fruitful discussions. This work is supported by the European Research Council under the European Unions Horizon 2020 research and innovation program (Grant Agreement-716087-PLASMECS).

Author information

Authors and Affiliations

Contributions

H.K. developed the SAW coupling model with the support from D.P., performed the FEM simulations and the numerical calculations including the data analysis and compared the model to the discussed experiment. H.K. wrote the paper with input from all authors. The project was supervised by S.S..

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Physics thanks Amal Hajjaj and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kähler, H., Platz, D. & Schmid, S. Surface acoustic wave coupling between micromechanical resonators. Commun Phys 5, 118 (2022). https://doi.org/10.1038/s42005-022-00895-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42005-022-00895-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.