Abstract

Bicyclic peptides exhibit improved metabolic stabilities and target specificities when compared to their linear or mono-cyclic counterparts; however, efficient and straightforward synthesis remains challenging due to their intricate architectures. Here, we present a highly selective and operationally simple one-pot chemoenzymatic tandem cyclization approach to synthesize bicyclic peptides with small to medium ring sizes. Penicillin-binding protein-type thioesterases (PBP-type TEs) efficiently cyclized azide/alkyne-containing peptides in a head-to-tail manner. Successive copper (I)-catalyzed azide-alkyne cycloaddition generated bicyclic peptides in one-pot, thus omitting the purification of monocyclic intermediates. This chemoenzymatic strategy enabled the facile synthesis of bicyclic peptides bearing hexa-, octa-, and undecapeptidyl head-to-tail cyclic scaffolds.

Similar content being viewed by others

Introduction

Macrocyclization of a peptide backbone reduces its conformational flexibility, thus potentially improving the metabolic stability, membrane permeability, and target specificity1,2,3. Although numerous chemical methodologies have been invented, macrolactamization has remained challenging as it inherently competes with the oligomerizing side reaction4. Enzyme utilization is a promising alternative to the chemical methodologies, as enzymes efficiently catalyze chemo- and regiospecific cyclization under mild conditions5. However, extensively studied biocatalysts derived from ribosomal pathways such as sortase A6,7, trypsin8, asparaginyl endopeptidases like butelase-I9 and OaAEP1b10, and subtilisin variants like Omniligase-I and others11,12,13 are generally limited to cyclizing peptides longer than ten amino acid residues, and thus smaller peptides, which potentially exhibit better bioavailability14 and less immunogenicity15, are beyond the scope of these biocatalysts. There are several enzyme families that can cyclize substantially shorter peptides. These include the subtilisin-like proteases in cyanobactin biosynthesis like PatG16, and the type-I thioesterase domains in non-ribosomal peptide biosynthetic pathways like TycC-TE17. Their distinctive properties make them intriguing biocatalysts; however, they suffer from narrow substrate scopes16,18, requirements for peculiar recognition sequences19, or low catalytic efficiencies20.

Penicillin-binding protein-type thioesterases (PBP-type TEs) have emerged as a promising family of peptide cyclases21,22,23,24,25,26,27,28,29,30. PBP-type TEs efficiently cyclize peptides, preferentially those with fewer than ten residues, although they also tolerate substantially larger substrates28. PBP-type TEs catalyze head-to-tail cyclization in the biosynthesis of cyclic non-ribosomal peptides (cyclic NRPs). Since the identification of the first PBP-type TE, SurE21, several homologous enzymes such as PenA27, WolJ28,31, and Ulm1629 with alternative substrate scopes have been identified from actinobacteria. Although PBP-type TEs require non-peptidyl leaving groups, which must be installed at the C-terminus of linear substrates, we have established a solid phase peptide synthesis (SPPS)-based method that enables rapid access to the substrate peptides with a C-terminal ethylene glycol (EG) leaving group28. The method yields the EG-embedded peptides with sufficient purities to be readily cyclized by PBP-type TEs after cleavage from the solid phase, thus circumventing the laborious purification of intermediates and streamlining the procedures28. Notably, the enzymatic cyclization generally exhibits high reaction efficiency and yields pure cyclic products, thereby opening the possibility for direct post-cyclization modification.

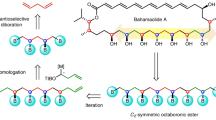

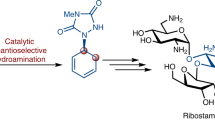

Several natural and synthetic bioactive cyclic peptides possess additional linkages within their macrocyclic scaffolds32,33. The linkages confer improved metabolic stability and target specificity due to the enhanced conformational rigidity, compared to their linear or monocyclic counterparts34,35,36. Due to their enormous potential as chemical probes and therapeutics, numerous chemical methodologies for synthesizing and screening bicyclic or multicyclic peptides have been developed35,36,37,38, such as those involving thioether formation33. Enzymes have occasionally been employed in the synthesis of multicyclic peptides9,39,40,41,42, however, smaller ring scaffolds has remained beyond the scope of enzymatic methodologies despite of their remarkable potential as therapeutics that has been demonstrated through several natural and synthetic precedents43,44,45,46,47 (Fig. 1).

Herein we report a chemoenzymatic approach to synthesizing bicyclic scaffolds based on small to medium head-to-tail cyclic peptides. We sequentially performed the PBP-type TE-mediated cyclization and the copper(I)-catalyzed azide-alkyne cycloaddition (CuAAC)48,49 in a one-pot manner (Fig. 2a). This tandem cyclization approach facilitated rapid access to the constrained bicyclic scaffolds based on small- to medium-sized head-to-tail cyclic peptides.

a Schematic representation of the previous28 and present work. b Cyclic peptides used as models for chemoenzymatic bicyclization. c Synthetic scheme for the bicyclic analogs of surugamide B (8a, 8b). Yields were determined by HPLC. d HPLC analysis of SurE-mediated cyclization using 6a and 6b as substrates. e HPLC analysis of reaction mixtures after CuAAC. Enzymatic reaction mixtures were directly subjected to CuAAC.

Results and discussion

First, we assessed the compatibility of the enzymatic cyclization with peptide substrates bearing clickable functionalities (i.e., azide and alkyne groups) (Fig. 2c). To this end, we substituted L-Ile3 and L-Ile6 of the seco-surugamide B sequence with an azide-containing residue L-Dab(N3) and an alkyne-containing residue L-propargylglycine (L-Pra), respectively, to give 6a. Variant 6b, bearing L-Lys(N3) instead of L-Dab(N3), was also designed to investigate the impact of the length of the azide-containing side-chain upon CuAAC. The conventional DIC/Oxyma-mediated Fmoc-based SPPS was performed using the EG-preloaded solid support 4 to afford 5a/5b. Peptides were cleaved and deprotected by treatment with TFA/i-Pr3SiH/H2O ( = 95:2.5:2.5) to give the ethylene glycol (EG)-embedded peptides 6a/6b. Next, 5 mol% of SurE was mixed with 6a/6b and incubated at 30 °C for 2 h. This resulted in the quantitative conversion of 6a/6b to their monocyclic counterparts 7a/7b, with no detectable accumulation of hydrolyzed products (Fig. 2d), showing the perfect compatibility of SurE with clickable functionalities. The enzymatic reaction mixtures were directly subjected to CuAAC by adding CuSO4 and L-ascorbic acid and then incubated for twelve hours at room temperature. The LC-MS analysis showed the efficient conversion of 7a/7b to the new compounds 8a/8b, with identical m/z values but distinct column retention times (Fig. 2e). MS/MS analysis of 8a/8b showed the disappearance of the fragment ions containing azide/alkyne groups and the generation of fragment ions consistent with the substructures containing a 1,4-disubstituted 1,2,3-triazole moiety (Fig. S1), indicating the successful intramolecular CuAAC. The structures of 8a/8b were finally confirmed by comparison with the authentic standards, which were synthesized via chemical head-to-tail cyclization followed by CuAAC (Fig. S2). Taken together, the bicyclic analogs of surugamide B 8a/8b were successfully synthesized in a one-pot manner from the linear peptides by sequentially performing two site-selective cyclizations: the PBP-type TE-mediated cyclization followed by CuAAC.

We next attempted to apply this method to peptides with different ring sizes (Fig. 3). As a model for bicyclization, we chose the cyclic hexapeptide wollamide B1 (Fig. 2b), a synthetic analog of the naturally occurring cyclic peptide wollamide B, with improved antituberculosis activity50. Previous work demonstrated that WolJ, another member of the PBP-type TEs, efficiently cyclizes the wollamide B1 sequence28, making it a feasible target for benchmarking the present synthetic method. An analog of seco-wollamide B1 (9a), which possesses L-Pra in the 1st position and L-Dab(N3) at the 5th position, was synthesized from Fmoc-D-Arg(Pbf)-4. To determine the effect of the distance between the alkyne/azide residues in intramolecular CuAAC, we also synthesized the seco-wollamide B1 analog (9b) with L-Pra in the 4th position and L-Dab(N3) at the 5th position. In the in vitro enzymatic reactions, WolJ successfully cyclized both 9a and 9b and gave their monocyclic counterparts 10a and 10b, respectively, showing its broad substrate tolerance (Fig. S3). As a result of successive CuAAC, both 10a and 10b were converted to the bicyclic scaffolds 11a and 11b. The conversions were significantly more efficient for 11b: 10a to 11a in 15% whereas 10b to 11b in 58%. The decreased conversion for 10a could be rationalized by the conformational rigidity of the hexapeptide: When using two residues in the (i, i + 2) positions as in 10a, the rigid peptide backbone would prevent two clickable moieties from being in proximal space. A larger and flexible cyclic scaffold would be more amenable for CuAAC, as in the case of 8a/8b, in which the click residues are separated by two residues, yet the intramolecular CuAAC proceeded efficiently (Fig. 2d, e). Overall, although we observed certain limitations on the bridging position, these results showed that the tandem cyclization method is compatible with the hexapeptidyl bicyclic scaffold.

We next investigated the impact of reversing the cyclization processes (i.e., CuAAC followed by enzymatic reactions). To this end, octapeptide 6b and hexapeptides 9a/9b were subjected to CuAAC to give triazole-containing monocyclic peptides, 7b’, 10a’, and 10b’, respectively. When subjected to enzymatic reactions, distinct outcomes were observed. The triazole-octapeptide 7b’ remained intact after the incubation with SurE (Fig. S4), showing that it is unable to form peptide-O-enzyme complex. In the case of the triazole-hexapeptide 10a’, it underwent quantitative hydrolysis of the EG leaving group by WolJ (Fig. S5). The pre-cyclized peptides 7b’ and 10a’ were disfavored probably due to their reduced flexibilities, preventing them from adopting conformations suitable for enzyme recognition. On the other hand, the hexapeptide 10b’ with cross-link between adjacent residues was cyclized to the bicyclic peptide 11b in 43% conversion (Fig. S6), suggesting that the adjacent cross-linking had less impact on enzyme recognition. Although the conversion remains low compared to the linear substrate 9b (65% conversion), this is the first demonstration of PBP-type TE-mediated cyclization on a pre-cyclized substrate. Overall, these investigations indicated that constructing bicyclic scaffolds is more feasible when enzymatic cyclization is performed first, followed by CuAAC, rather than in the reverse order.

Having established the feasibility of performing chemoenzymatic tandem cyclization with natural product-based peptide substrates originally associated with PBP-type TEs, the next goal was to synthesize a variant of a biologically active bicyclic peptide that originated from random discovery methods, such as phage display. To this end, we selected BC1 (3) as the target for synthesis (Fig. 2b). BC1 is an undecapeptidyl head-to-tail cyclic peptide bridged by an amide linkage between L-lysine and L-aspartate. BC1 selectively binds to the Src homology 2 (SH2) domain of growth-factor-bound protein 2 (Grb2), a well-established target for breast and other cancers34. To synthesize BC1 analogs, namely BC1-triazole (14), via the tandem cyclization method, the following points were considered: (i) The amide bridge was substituted with its bioisostere 1,4-disubstituted 1,2,3-triazole to enable the intramolecular bridging via CuAAC at the final step of synthesis. (ii) BC1 solely consists of L-amino acids and glycines, thus conflicting with the diligent requirement of the native SurE-mediated cyclization for the D-amino acid at the C-terminus of the substrate21. In previous work, we manipulated the specificity of SurE by mutating a single residue in the substrate binding pocket and generated the SurEG235L variant that efficiently cyclizes peptides with glycine at their C-termini28. Accordingly, we set the enzymatic ring-closing site between glycine and L-methionine and designed an undecapeptidyl linear precursor (12), and employed the SurEG235L variant for cyclization (Fig. 3). Compound 12 was synthesized from Fmoc-Gly-4 with 86% efficiency in 21 steps. The SurEG235L variant efficiently cyclized 12 to give 13 (74% conversion) (Fig. S7). Successive CuAAC afforded 14 in one-pot (90% conversion from 13) (Fig. 3 and S7). A variant 12’ with swapped alkyne/azide positions was converted to bicyclic peptide 14’ with decreased conversion, which may be attributed to a conformational difference affecting the second CuAAC (Fig. S8).

Overall, PBP-type TE-mediated cyclization followed by CuAAC generated bicyclic scaffolds based on head-to-tail cyclic peptides with six, eight, and eleven amino acid residues. The results demonstrated that the appropriate choices of cyclases and cyclization positions enable facile access to bicyclic peptides, including BC1 analogs, which are unrelated to PBP-type TEs in terms of their origins. The presented chemoenzymatic tandem cyclization approach will potentially accelerate the construction of compound libraries with highly constrained bicyclic peptides based on smaller ring sizes. The full compatibility between PBP-type TE-mediated cyclization and CuAAC provides valuable opportunities for post-cyclization modifications, which are not limited to bicyclization but also include intermolecular coupling with diverse molecules such as cyclic peptides, glycosides, or biologics.

Methods

General remarks

1H and 13C NMR spectra were recorded on a JEOL ECZ500 (500 MHz for 1H NMR) or a JEOL ECZ400 (400 MHz for 1H NMR) spectrometers. Chemical shifts are denoted in δ (ppm) relative to residual solvent peaks as internal standard (DMSO-d6, 1H δ 2.50, 13C δ 39.5). ESI-MS spectra were measured by a Thermo Scientific Exactive mass spectrometer or a SHIMADZU LCMS-2050 spectrometer. Optical rotations were recorded on a JASCO P-1030 polarimeter. High-performance liquid chromatography (HPLC) experiments were performed with a SHIMADZU HPLC system equipped with a LC-20AD intelligent pump. MS/MS analysis was performed with amaZon SL-NPC (Bruker Daltonics) using helium gas with an amplitude value 1.0 V. The chemical structures of enzyme substrates and enzymatic reaction products are analyzed by MS/MS (Supplementary data 1) and/or NMR (Supplementary data 2). All reagents were used as supplied unless otherwise noted.

Preparation of the peptide cyclases

Expression plasmids for SurE, WolJ, and SurEG235L, were constructed previously (Table S1)21,28. 50 μg/ml kanamycin was used for the selection of E. coli host harboring pET28a-based SurE and SurEG235L expression plasmids, whereas 200 μg/ml ampicillin was used for the selection of E. coli host harboring pColdII-based WolJ expression plasmids. A single colony of E. coli host was inoculated into 10 mL of 2xYT media (1.6% Bacto tryptone, 1.0% Bact yeast extract, 0.5% NaCl) containing an appropriate antibiotic and was cultured at 37 °C overnight as seed culture. 2.0 mL of cultural broth was transferred to 200 mL of 2xYT media containing an appropriate antibiotic and cultured at 37 °C for three hours. The broth was cooled on ice and 0.1 mM of isopropyl-β-D-thiogalactopyranoside (IPTG) was added to induce the expression of recombinant enzymes. E. coli was cultured at 16 °C for overnight. Cells were harvested by centrifugation with 3500 × g for 10 min at 4 °C and washed with wash buffer (20 mM Tris-HCl pH 8.0, 150 mM NaCl). Cells were resuspended into lysis buffer (20 mM Tris-HCl pH 8.0, 150 mM NaCl, 20 mM imidazole pH 8.0), then successfully homogenized by sonication. Cell debris was precipitated by centrifugation with 20,630 × g for 20 min at 4 °C, then the supernatant was subjected to Ni-NTA His-Bind® resin (Merck Millipore), which was equilibrated by lysis buffer (20 mM Tris-HCl pH 8.0, 150 mM NaCl, 20 mM imidazole pH 8.0). The column was washed with additional lysis buffer, then eluted with elution buffer (20 mM Tris-HCl pH 8.0, 150 mM NaCl, 500 mM imidazole pH 8.0). Imidazole was removed by an Amicon Ultra 0.5 ml filter (Merck Millipore). The concentrations of proteins were measured using a Bio-Rad protein assay kit (Bio-Rad).

Chemical synthesis

The details of the chemical synthesis of compounds (Table S2) are described in the Supplementary methods.

Enzymatic peptide cyclization

Enzymatic cyclization was initiated by adding 20 μM of enzymes (i.e., SurE, WolJ, or SurEG235L mutant) to 100 μL of reaction mixtures containing 20 mM Tris-HCl (pH 8.0) and 400 μM substrate peptides. Reaction mixtures were incubated at 30 °C for 3 h for cyclizing 6a/6b. Reaction mixtures were incubated at 30 °C overnight for cyclizing other substrates. Reactions were directly subjected to CuAAC as described below.

Copper(I)-catalyzed cycloaddition (CuAAC)

CuAAC was performed by directly adding 2 mM of CuSO4⋅5H2O and 2 mM of L-ascorbic acid into the enzymatic reaction mixtures. Mixtures were incubated at 30 °C overnight, and then subjected to downstream analysis.

HPLC analysis of enzymatic reaction

Samples were diluted 10-fold with methanol, then centrifuged at 20,630 × g for 10 min. Resultant supernatants were subjected to the Shimadzu HPLC system coupled with mass spectroscopy (LCMS-2050) operated in positive mode. Samples were separated by a reversed-phase column COSMOSIL 5C18-MS-II 2.0 × 150 mm column (nacalai tesque). H2O + 0.1% formic acid and acetonitrile + 0.1% formic acid were used as mobile phases A and B, respectively. Samples were eluted with a gradient mode of 10 to 90% for mobile phase B over 10 min with a flow rate of 0.4 ml/min.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

References

Muttenthaler, M., King, G. F., Adams, D. J. & Alewood, P. F. Trends in peptide drug discovery. Nat. Rev. Drug Discov. 20, 309–325 (2021).

Zorzi, A., Deyle, K. & Heinis, C. Cyclic peptide therapeutics: past, present and future. Curr. Opin. Chem. Biol. 38, 24–29 (2017).

Zhang, H. & Chen, S. Cyclic peptide drugs approved in the last two decades (2001-2021). RSC Chem. Biol. 3, 18–31 (2022).

White, C. J. & Yudin, A. K. Contemporary strategies for peptide macrocyclization. Nat. Chem. 3, 509–524 (2011).

Schmidt, M., Toplak, A., Quaedflieg, P. J. L. M., van Maarseveen, J. H. & Nuijens, T. Enzyme-catalyzed peptide cyclization. Drug Discov. Today Technol. 26, 11–16 (2017).

Jia, X. et al. Semienzymatic cyclization of disulfide-rich peptides using Sortase A. J. Biol. Chem. 289, 6627–6638 (2014).

Stanger, K. et al. Backbone cyclization of a recombinant cystine-knot peptide by engineered Sortase A. FEBS Lett. 588, 4487–4496 (2014).

Thongyoo, P., Roqué-Rosell, N., Leatherbarrow, R. J. & Tate, E. W. Chemical and biomimetic total syntheses of natural and engineered MCoTI cyclotides. Org. Biomol. Chem. 6, 1462–1470 (2008).

Nguyen, G. K. et al. Butelase 1 is an Asx-specific ligase enabling peptide macrocyclization and synthesis. Nat. Chem. Biol. 10, 732–738 (2014).

Harris, K. S. et al. Efficient backbone cyclization of linear peptides by a recombinant asparaginyl endopeptidase. Nat. Commun. 18, 10199 (2015).

Nuijens, T. et al. Chemo-enzymatic peptide synthesis (CEPS) using omniligases and selective peptiligases efficient biocatalysts for assembling linear and cyclic peptides and protein conjugates. Chem. Today 34, 16–19 (2016).

Nuijens, T. et al. Engineering a diverse ligase toolbox for peptide segment condensation. Adv. Synth. Catal. 358, 4041–4048 (2016).

Weeks, A. M. & Wells, J. A. Subtiligase-catalyzed peptide ligation. Chem. Rev. 120, 3127–3160 (2020).

Nielsen, D. S. et al. Orally absorbed cyclic peptides. Chem. Rev. 117, 8094–8128 (2017).

Morrison, C. Constrained peptides’ time to shine? Nat. Rev. Drug Discov. 17, 531–533 (2018).

McIntosh, J. A. et al. Circular logic: nonribosomal peptide-like macrocyclization with a ribosomal peptide catalyst. J. Am. Chem. Soc. 132, 15499–15501 (2010).

Trauger, J. W. et al. Peptide cyclization catalysed by the thioesterase domain of tyrocidine synthetase. Nature 14, 215–218 (2000).

Kohli, R. M. et al. Generality of peptide cyclization catalyzed by isolated thioesterase domains of nonribosomal peptide synthetases. Biochemistry 40, 7099–7108 (2001).

Oueis, E., Stevenson, H., Jaspars, M., Westwood, N. J. & Naismith, J. H. Bypassing the proline/thiazoline requirement of the macrocyclase PatG. Chem. Commun. 53, 12274–12277 (2017).

Sarkar, S., Gu, W. & Schmidt, E. W. Expanding the chemical space of synthetic cyclic peptides using a promiscuous macrocyclase from prenylagaramide biosynthesis. ACS Catal. 10, 7146–7153 (2020).

Kuranaga, T. et al. Total synthesis of the nonribosomal peptide surugamide B and identification of a new offloading cyclase family. Angew. Chem., Int. Ed. 57, 9447–9451 (2018).

Matsuda, K., Kuranaga, T. & Wakimoto, T. A new cyclase family catalyzing head-to-tail macrolactamization of non-ribosomal peptides. J. Synth. Org. Chem. Jpn. 77, 1106–1115 (2019).

Matsuda, K. et al. SurE is a trans-acting thioesterase cyclizing two distinct non-ribosomal peptides. Org. Biomol. Chem. 17, 1058–1061 (2019).

Zhou, Y. et al. Investigation of penicillin binding protein (PBP)-like peptide cyclase and hydrolase in surugamide non-ribosomal peptide biosynthesis. Cell Chem. Biol. 26, 737–744 (2019).

Thankachan, D. et al. A trans-acting cyclase offloading strategy for nonribosomal peptide synthetases. ACS Chem. Biol. 14, 845–849 (2019).

Matsuda, K. et al. Heterochiral coupling in non-ribosomal peptide macrolactamization. Nat. Catal. 3, 507–515 (2020).

Matsuda, K., Fujita, K. & Wakimoto, T. PenA, a penicillin-binding protein-type thioesterase specialized for small peptide cyclization. J. Ind. Microbiol. Biotechnol. 48, kuab023 (2021).

Kobayashi, M., Fujita, K., Matsuda, K. & Wakimoto, T. Streamlined chemoenzymatic synthesis of cyclic peptides by non-ribosomal peptide cyclases. J. Am. Chem. Soc. 145, 3270–3275 (2023).

Budimir, Z. L. et al. Biocatalytic cyclization of small macrolactams by a penicillin-binding protein-type thioesterase. Nat. Chem. Biol. 20, 120–128 (2024).

Fazal, A., Wheeler, J., Webb, M. E. & Seipke, R. F. The N-terminal substrate specificity of the SurE peptide cyclase. Org. Biomol. Chem. 20, 7232–7235 (2022).

Booth, T. J. et al. Bifurcation drives the evolution of assembly-line biosynthesis. Nat. Commun. 13, 3498 (2022).

Thombare, V. J. & Hutton, C. A. Bridged bicyclic peptides: structure and function. Pept. Sci. 110, e24057 (2018).

Ullrich, S. & Nitsche, C. Bicyclic peptides: paving the road for therapeutics of the future. Pept. Sci. 116, e24326 (2024).

Quartararo, J. S., Wu, P. & Kritzer, J. A. Peptide bicycles that inhibit the Grb2 SH2 domain. Chembiochem 13, 1490–1496 (2012).

Bartoloni, M. et al. Bridged bicyclic peptides as potential drug scaffolds: synthesis, structure, protein binding and stability. Chem. Sci. 6, 5473–5490 (2015).

Rhodes, C. A. & Pei, D. Bicyclic peptides as next-generation therapeutics. Chem. Eur. J. 23, 12690–12703 (2017).

Teixido, M. et al. Bicyclic homodetic peptide libraries: comparison of synthetic strategies for their solid-phase synthesis. J. Comb. Chem. 5, 760–768 (2003).

Bartoloni, M. et al. Expanding the accessible chemical space by solid phase synthesis of bicyclic homodetic peptides. Chem. Commun. 47, 12634–12636 (2011).

Schmidt, M. et al. Omniligase-1: A powerful tool for peptide head-to-tail cyclization. Adv. Synth. Catal. 359, 2050 (2017).

Richelle, G. J. J. et al. A one-pot “triple-C” multicyclization methodology for the synthesis of highly constrained isomerically pure tetracyclic peptides. ChemBioChem 19, 1934–1938 (2018).

Schmidt, M. et al. Efficient enzymatic cyclization of disulfide-rich peptides by using peptide ligases. ChemBioChem 20, 1524–1529 (2019).

Streefkerk, D. E. et al. Synthesis of constrained tetracyclic peptides by consecutive CEPS, CLIPS, and oxime ligation. Org. Lett. 21, 2095–2100 (2019).

VanderMolen, K. M., McCulloch, W., Pearce, C. J. & Oberlies, N. H. Romidepsin (Istodax, NSC 630176, FR901228, FK228, depsipeptide): a natural product recently approved for cutaneous T-cell lymphoma. J. Antibiot. 64, 525–531 (2011).

Jolad, S. D. et al. Bouvardin and deoxybouvardin, antitumor cyclic hexapeptides from Bouvardia ternifolia (Rubiaceae). J. Am. Chem. Soc. 99, 8040–8044 (1977).

Block, S. S., Stephens, R. L., Barreto, A. & Murrill, W. A. Chemical identification of the Amanita toxin in mushrooms. Science 121, 505–506 (1955).

Maggi, C. A. et al. MEN 10,627, a novel polycyclic peptide antagonist of tachykinin NK2 receptors. J. Pharmacol. Exp. Ther. 271, 1489–1500 (1994).

Veber, D. F. et al. Highly active cyclic and bicyclic somatostatin analogues of reduced ring size. Nature 280, 512–514 (1979).

Tornøe, C. W., Christensen, C. & Meldal, M. Peptidotriazoles on solid phase: [1,2,3]-triazoles by regiospecific copper(i)-catalyzed 1,3-dipolar cycloadditions of terminal alkynes to azides. J. Org. Chem. 67, 3057–3064 (2002).

Rostovtsev, V. V., Green, L. G., Fokin, V. V. & Sharpless, K. B. A stepwise huisgen cycloaddition process: copper(I)-catalyzed regioselective “ligation” of azides and terminal alkynes. Angew. Chem. Int. Ed. Engl. 41, 2596–2599 (2002).

Khalil, Z. G. et al. Structure-activity relationships of wollamide cyclic hexapeptides with activity against drug-resistant and intracellular Mycobacterium tuberculosis. Antimicrob. Agents Chemother. 63, e01773–18 (2019).

Acknowledgements

This work was partly supported by Hokkaido University, Global Facility Center (GFC), Pharma Science Open Unit (PSOU), funded by MEXT under “Support Program for Implementation of New Equipment Sharing System”, Global Station for Biosurfaces and Drug Discovery, a project of Global Institution for Collaborative Research and Education in Hokkaido University, the Asahi Glass Foundation, the Naito Foundation, the Uehara Memorial Foundation, the Sumitomo Foundation−Grant for Basic Science Research Projects, Daiichi Sankyo Foundation of Life Science, Japan Foundation for Applied Enzymology, TERUMO Life Science Foundation, the Japan Agency for Medical Research and Development (AMED Grant Numbers JP23ak0101163, JP23ama121039, JP23gm1610007), Grants-in-Aid from the Ministry of Education, Culture, Sports, Science and Technology (MEXT), the Japan Science and Technology Agency (JST Grant Numbers ACT-X JPMJAX201F and A-STEP JPMJTR20US), JSPS KAKENHI (Grant numbers JP16H06448, JP18H02581, JP19K16390, JP21H02635, JP22K15302, JP22H05128, JP22J13818 and JP23K17410).

Author information

Authors and Affiliations

Contributions

M.K., K.M. and T.W. designed the whole experiment. M.K. and N.O. performed experiments and data analysis. All authors contributed to writing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks Julien Tailhades and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kobayashi, M., Onozawa, N., Matsuda, K. et al. Chemoenzymatic tandem cyclization for the facile synthesis of bicyclic peptides. Commun Chem 7, 67 (2024). https://doi.org/10.1038/s42004-024-01147-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-024-01147-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.