Abstract

Dehydration is an abundant and promising process in chemical, biochemical, and industrial fields. Dehydration methods can contribute to building a modern and sustainable society with minimal environmental impact. Breakthrough advances in the dehydrative SN1 reaction can be achieved through the discovery of new cationic indium catalysts. Here we show that the breakthrough advances in the dehydrative SN1 reaction can be achieved using the cationic indium catalysts. The dehydrative carbon–carbon bond formation of α-alkyl propargyl alcohols afforded a wide variety of α-aryl- and heteroaryl-propargyl compounds. Mechanistic investigations into this process revealed that the InCl3/AgClO4/Bu4NPF6/1,1’-binaphthol catalytic system generated a powerful cationic indium catalyst that could promote the dehydration of alcohols. Labile α-alkyl propargyl cations were found to self-condense, and the catalyst system efficiently regenerated propargyl cations for reaction with nucleophiles. This propargylation reaction directly proceeded from the corresponding alcohols under mild and open-air conditions and tolerated a broad scope of functional groups. Furthermore, a wide variety of nucleophiles, including aromatic and heteroaromatic compounds, phenols, alcohols, and sulfonamides, reacted with the corresponding cations to afford the propargyl compounds in good to high yields. Finally, the synthetic utility of this reaction was demonstrated by the synthesis of colchicine and allocolchicine analogues. The dehydration process could help create new compounds that were previously impossible to synthesize and is more eco-friendly and efficient than conventional methods.

Similar content being viewed by others

Introduction

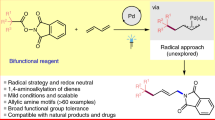

Dehydrating propargyl alcohols (prop-2-ynyl alcohols) is an excellent and straightforward method for generating propargyl (or propynylium) cations. The nucleophilic addition reactions of propargyl cations result in a diverse assortment of useful compounds, such as propargylic compounds1,2,3,4,5,6, allenic compounds7, α,β-unsaturated aldehydes and ketones8, carbocycles9, and heterocycles10, that can often include drugs and drug candidates11,12,13. Two breakthrough methods have been achieved in the field of dehydrative propargylation; the first method is the Nicholas reaction. It utilizes a propargyl cation that is stabilized by a dicarbonyl moiety14. The second method was reported by Nishibayashi, in which propargylation proceeds through a Ru-allenilidene complex15. While the Nicholas reaction successfully yields propargylated products with many nucleophiles and avoids the formation of allenes, the reaction requires stoichiometric amounts of cobaltoctacarbonyl as an alkyne protecting group. On the other hand, the dehydrative propargylation reaction catalysed by Ru inspired many research groups to develop transition metal-catalysed and Brønsted acid-catalysed dehydrative propargylation protocols16,17; however, most of these methods were limited to α-aryl- and heteroaryl-substituted propargyl alcohols, and α-alkyl-substituted propargyl alcohols were not suitable substrates. In general, nucleophilic substitution reactions of propargyl cations substituted with either aromatic and heteroaromatic groups at the α-position to the cationic centre or two alkyl substituents18,19. Therefore, direct dehydrative propargylation through α-alkyl-propargyl cations typically results in low product yields and many undesirable byproducts and complex reaction mixtures (Fig. 1a)20,21,22. The method utilizing a metal-allenylidene complex and/or protect the corresponding alcohol as a Boc23,24, aryl ester25, halide26,27, or phosphonate was used as the alternative route for the α-alkyl-substituted propargylation28,29. A direct Friedel–Crafts-type propargylation of alcohols using calcium trifluoroimidate/tetrabutylammonium hexafluorophosphate in dichloromethane (DCM) was recently reported; however, most of the substrates were tertiary alcohols30. Using imidazolium-based ionic liquids, a metal triflate-catalysed propargylation of secondary alcohols afforded propargylated arenes31; however, this reaction was accompanied by undesirable byproducts, such as dipropargylated products and ketones that were dehydrated to alkynes. The Ir–Sn3-catalysed propargylation of arenes using α,α-dialkylpropargyl alcohols was successfully reported; however, the reactions of secondary alcohols mostly resulted in the recovery of unreacted starting materials32,33.

Developing a direct SN1-like propargylation under mild reaction conditions34 using readily available propargyl alcohols is a meaningful challenge from the standpoint of reactant compatibility. Many reactant (i.e., secondary alcohols) and nucleophile (arenes, alcohols, thiols, and amides) combinations are incompatible when functional groups are present, such as esters, amides, cyano, and nitro groups. These functional groups are typically found in drugs and drug candidates11,12,35,36,37. Despite the efforts of many researchers in this field, no practical process has been established for the dehydrative propargylation of α-alkyl-substituted secondary propargyl alcohols38. During our efforts in this field39,40,41,42,43, we have developed a powerful metal catalyst to generate α-alkyl-substituted propargyl cations from secondary alcohols and discovered a cationic indium-catalysed SN1-propargylation of secondary alcohols (Fig. 1, this work). A new catalytic SN1 process for α-alkyl-substituted propargyl alcohol was achieved using a unique highly oxophilic indium cation. This method could enable new possibilities for many chemical, environmental, industrial, and pharmaceutical applications. Here, we report delightful news and pioneering work involving cationic indium catalysts.

Results

Screening for reaction condition

We first examined the propargylation reaction using 1-phenylpent-1-yn-3-ol (1a) and 1,2,3-trimethoxybenzene (TMB) as the coupling partners. Ytterbium triflate was selected as the first Lewis acid for dehydrative propargylation. The reaction of 1a at room temperature did not proceed; however, the reaction under reflux in nitromethane afforded 1,2,3-trimethoxy-4-(1-phenylpent-1-yn-3-yl)benzene (2a) in 37% yield accompanied by many other byproducts (Entry 1, Table 1). To improve the yield of 2a, various Lewis acids were screened, and the results are shown in entries 2–10. The reactions using ytterbium trifluoroimidate, boron trifluoride etherate, titanium tetrachloride, aluminium trichloride, and copper triflate were not effective for dehydrative propargylation despite the use of tetrabutylammonium hexafluorophosphate as a good counter anion for the carbocations (entries 2–8). To our great delight, the reaction catalysed by indium trichloride under reflux conditions afforded 2a in 59% yield (entry 9). We next attempted to use conditions milder and reduce byproduct formation, such as ethers from self-condensation of the alcohol and Meyer–Schuster rearrangement products (such as α,β-unsaturated ketones). The use of tetrabutylammonium hexafluorophosphate clearly accelerated the propargylations (entry 10); however, the reaction failed to complete at room temperature (25 °C). The use of the cocatalyst silver perchlorate dramatically improved the reaction conditions to afford 2a in good yield (entry 11). This result was somewhat predictable according to previous reports by Corey and May groups38,44,45. To investigate our catalysts and the previous cationic indium catalysts, we performed the experiments shown in entries 12–14. As in previously published work, we performed reactions catalysed by both InCl2+ SbF6− and InI2+ SbF6− through in situ generation from indium halides and silver hexafluorophosphate in DCM or nitromethane. However, the reaction in DCM produced product 2a in only 27% with 54% recovery of starting material 1a. The reaction in nitromethane did not go to completion, even with prolonged reaction times, i.e., an overnight reaction. Therefore, we continued the screening study by exploring the equivalents of catalyst and additives used. The propargylation of TMB under our conditions using two equivalents of silver perchlorate to indium chloride provided 2a in 87% yield (entry 15). Furthermore, self-condensation ether 3a was not detected in the presence of 1,1’-binaphtol (entry 16). These observations inspired us to hypothesize that the unstable cationic intermediates could self-condense (ether formation) and regenerate the active intermediates to yield product 2a. Indium bromide also accelerated the reaction to give 2a at room temperature, and cationic indium bromide was also effective for this propargylation (entries 17–18). The reactions conducted at 25 °C were better than the reactions conducted at reflux. As shown in entries 19–20, the reaction with 1.5 equivalents of TMB was tolerated. We further optimized the reaction and screened the addition of cofactors for this propargylation. Utilizing HMPA or N,N-dimethyl formamide (DMF) did not result in a major breakthrough (entries 21–23). Changing the counter ions of both silver salts and indium salts did not improve yields (entries 24–26). Although it was necessary to heat the reaction, the indium catalyst loading could be reduced to 5 mol%.

Substrate scope

With the optimized reaction conditions in hand, we next explored the generality of the dehydrative propargylation of 3-alkyl-1-arylpropyn-3-ols. The results are shown in Fig. 2. This propargylation displayed a remarkable scope with respect to reactants. The bulky i-butyl and t-butyl alcohols 1b-c reacted with TMB to yield 4-propargyl-1,2,3-trimethoxybenzenes 2b-c, accompanied by a small amount of (5)-propargylated 2b-c. Cycloalkyl-substituted propargyl alcohols 1d-g regioselectively provided adducts 2d-g in good to excellent yields. We next examined the substituent effects on the alkyne terminus of the reactants in this propargylation. The reaction of 1-(p-tolyl)octyn-3-ol (1 h) with TMB successfully yielded 2h. Reactions with m- and o-tolyl derivatives 1i and 1j resulted in similar yields of the p-tolyl derivative 2h. Aryl substituents, including the electron-donating methoxy group and the bulky 2,4,6-trimethyl phenyl group, were well tolerated, and the corresponding TMBs 2k, 2l, 2m, and 2n were obtained in almost satisfactory yields. This propargylation exhibited good compatibility with functional groups in respect to the reactants. A diverse array of propargyl alcohols 1o–1u with a variety of electron-withdrawing groups (such as 2- and 4-fluoro-, 2,4-difluoro-, 4- and 3-chloro-, 2,4-dichloro-, and 4-bromo) on the benzene ring at the alkyne terminus were also tolerated. Since we successfully obtained a wide variety of propargylated products 2o–2u, we also examined the reactions of other alcohols bearing an aromatic substituent at the alkyne terminus. The alcohols bearing aromatic substituents with o- and m-trifluoromethyl-, p-ethoxycarbonyl-, o-, m-, p-cyano-, and m-nitro-groups afforded the products 2v-2z and 2α-2γ in good yields. However, the reaction of p-nitrophenyl derivative 1β resulted in low product yields. Both dodec-5-yn-4-ol (1δ) and tetracos-13-yn-12-ol (1ε) are classified as α,γ-dialkylpropargyl alcohols, and their reactions with TMB afforded 4-propargylated 1,2,3-trimethoxybenzenes in low yields. Since the aromatic substituents on the alkyne terminus are much more important when demonstrating this process, which is consistent with the reaction proceeding via a cationic SN1 process. In our previous work on the SN1-propargylation reaction39,40,41,42,43, an organosulfur substituent at the alkyne terminus was very important for stabilizing intermediate propargylic cations. Similarly, the aromatic groups on the alkyne terminus are also electron-donating substituents. We next performed propargylation with cycloalkanols and a dialkylated alcohol. The propargylation of cyclohexanol succeeded in forming trimethoxyphenylated 2η in high yield; however, cyclopentanol gave undesirable products, such as cyclopentene 4ζ. Unfortunately, the reactions of both cyclooctanol 1θ and 3-ethylpent-1-yn-3-ol 1ι gave cyclooctene 4θ and indene 5ι, respectively. These results show that our dehydrative propargylation is more suitable for secondary propargyl alcohols and not tertiary alcohols, in contrast to previously reported methods30,32. Recently, May and colleagues reported the gallium-catalyzed direct substitution of propargyl alcohols with aryl boronic acids, which describes that the SN1 reaction on the quaternary carbon centers seems to have the similar issue as ours38. We further challenged the reaction of α-aryl propargyl alcohols by employing electron-withdrawing effects on the α-aromatic substituents to the hydroxy group. These alcohols are difficult substrates in a Friedel–Crafts-type reaction. The reactions of p-, m-, and o-nitrophenyl analogues afforded 4-propargyl-1,2,3-trimethoxybenzenes 2κ, 2λ, 2μ, 2ν, and 2ξ in high yields. Both trifluoromethyl- and p-acetylaminophenyl alcohols 1ν and 1ξ provided adducts 2ν and 2ξ. Although acetamide and ester functional groups are usually coordinated with metal and organic catalysts, the Friedel–Crafts-type reactions with substrates bearing these groups provided products 2x and 2ξ without any catalyst inhibition. We next explored the scalability of propargylation. When the 3-gram scale reaction using 1a was performed with TMB, the equivalents of indium chloride and silver perchlorate were reduced, and product 2a was obtained in 94% isolated yield.

Limitations

The delightful results obtained in the cationic propargylation using a variety of propargyl alcohols encouraged us to further investigate the cationic indium-catalysed propargylation reaction using other nucleophiles to TMB (Fig. 3). The reaction of 1a with toluene resulted in a mixture of isomers, 4- and 5-propargylic toluene 6a, in good yields. The reaction of 1a with a nucleophilic anisole afforded adduct 6b in excellent yield; however, cumene was not suitable for the propargylation reaction because the product was unstable. The propargylation of disubstituted benzenes p-xylene and p-dimethoxybenzene exclusively produced propargylated products 6c and 6d, respectively. Bulky aromatics, such as benzo[d][1, 3]dioxole and mesitylene, were tolerated. Heteroaromatic compounds, such as 2,5-dimethylthiophene, benzo[b]thiophene, benzo[b]furan, and 2-methylthiophene, were also good nucleophiles in this process; however, neither pyrroles nor indoles were suitable nucleophiles for this propargylation reaction.

When we performed the reaction with phenols, C–C bond formation occurred without any C–O bond formation to afford propargylated phenols 6k–6s. The reactions with alcohols underwent C–O bond formation to yield alkyl propargyl ethers 8a–8k under reflux conditions. Both mercaptans and sulfonamides were suitable for this propargylation reaction.

Mechanistic studies

To elucidate the reaction mechanism of propargylation, our next objective was to identify intermediates along the reaction pathway. Initially, we conducted experiments using chiral propargylic alcohols46,47 in combination with TMB, as depicted in Fig. 4a, b. The reaction between (R)-alcohol 1a and TMB proceeded for 1.5 h under typical reaction conditions involving indium chloride and silver perchlorate in the presence of tetrabutylammonium hexafluorophosphate in nitromethane. Interestingly, this reaction was not influenced by the stereochemistry of the alcohol, yielding (rac)-2a. Notably, the enantioselectivity of 2a was quite low, with a ratio of R:S = 49:51 (Fig. 4a). Similarly, the reaction of (S)-1a with TMB resulted in comparable outcomes, with a 68% yield and a ratio of R:S = 51:49 (Fig. 4b). These findings suggest that the alcohols react with cationic indium catalysts to generate a classical propargylic cation during the substitution reaction, indicating that the propargylation proceeds via the SN1 process (Fig. 4c). While the cationic indium exhibited significant Lewis acidity in this propargylation38, we sought to further investigate the rates of product formation to confirm the formation of a classical cation. In time course experiments, we discovered an alternative route from ethers to the final products (Fig. 4d). These experiments involved monitoring the 19F NMR of the reaction of 1o using a 12 mol% catalyst in nitromethane-d3, which was optimized specifically for the time course experiments. The results, which are depicted in graph in Fig. 4f (detailed information in SI)24, illustrate the concentrations of alcohol 1o, product 2o, and ether 3o at various stages of the optimized reaction. The decrease in 1o concentration and formation of 2o are represented by circular and square lines, while the changing concentration of ether 3o is depicted by the triangular line. Notably, the formation of ether 3o was detected at all stages of the reactions. During the screening of substrate 1a with TMB, we observed significant formation of ether 3a in the early stages of the reaction. We hypothesized that these self-condensation events leading to the formation of ethers could protect the labile propargyl cations and regenerate them from the ethers as the reaction progressed. To verify this hypothesis, we isolated ether 3a and subjected it to TMB under indium-catalysed propargylation conditions, as shown in Fig. 4e. Remarkably, product 2a was obtained with a 45% yield. This outcome indicates that the unstable α-alkyl-propargyl cations can react with nucleophiles, and the self-condensed ethers can regenerate α-alkyl-propargyl cations under the reaction conditions when less nucleophilic substrates are employed.

Corey and colleagues previously reported that the diiodoindium(III) cation InI2+, which is a π-acid, could not be isolated as hexafluoroantimonate or B-[C6H3-3,5-(CF3)2]4 (BARF) salts because it was difficult to remove silver iodide from the resulting precipitates (AgI and InI2+SbF6−). However, they did confirm the presence of the indium(+) cation through single X-ray analysis of InI2(Phen)2+I−44. In our own attempts to obtain suitable crystals for X-ray analysis from the reaction between indium chloride and silver perchlorate, the obtained powders were hygroscopic and not appropriate for this analysis. Moreover, the 1H NMR studies about the indium catalysts in nitromethane-d3 were examined; however, we could not identify the cationic indium species. We are now investigating in obtaining the catalysts as crystalline.

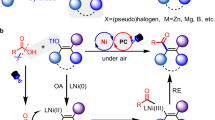

Based on the experimental findings, we proposed a plausible mechanism for the cationic indium-catalysed reaction of α-alkyl-propargyl alcohols with nucleophiles (Fig. 5). In organic solvents, indium trihalide 9 reacts with silver perchlorate to form, leading to the formation of the cationic indium 10. Nitromethane likely plays an important role in further activating the cationic indium, which causes some of the cationic indium to transform into the nitoromethane-coordinated indium 10. When either 1,1’-binaphthol or the substrate, propargyl alcohol 11, is present in the system, the cationic indium catalyst converts into the binaphthol-ligated structure 12 or intermediate 13. Dehydration of 13 results in the formation of propargyl cation 14, which subsequently reacts with nucleophiles (H-Nu:) to yield adduct 16. Tetrabutylammonium hexafluorophosphate plays a crucial role in deprotonating 16 and regenerating the cationic indium. Specifically, tetrabutylammonium hexafluorophosphate 18 regenerates indium catalyst 10 by trapping the hydroxy anion of 15. The self-condensation of cation 14 with 11 produces ether 20, while indium catalyst 10 can reactivate ether 20 into cation 14 and propargyloxy indium 13. In this study, the reaction predominantly proceeded via the SN1 process. However, the proposed reaction mechanism suggests that asymmetric propargylation could be achieved with chiral ammonium salts or chiral phosphorus ligands. Consequently, our current focus is investigating the direct asymmetric propargylation reaction (Fig. 6).

Finally, we applied this reaction to the production of drug candidates. Colchicine and allocolchicine analogues are valuable targets for cancer therapy36. We examined the preparation of suitable propargyl alcohol 21 using 5-ethynyl-1,2,3-trimethoxybenzene (22) and propanal. The key Friedel–Crafts-type arylation of 22 with TMB successfully provided 1,2,3-trimethoxy-4-(1-(3,4,5-trimethoxyphenyl)pent-1-yn-3-yl)benzene (23) in good yield48. Hydrogenation and oxidative cyclization with iodosobenzene diacetate/boron trifluoride diethyl ether afforded a unique allocolchicinoide (25) and 7-ethyl-1,2,3,10,11-pentamethoxy-6,7-dihydro-5H-dibenzo[b,g]oxocine (26), respectively. Successive treatment with potassium tert-butoxide of 6k yielded trimethoxyphenylmethylbenzofuran (27),49 which has a similar structure to Perkinson’s disease50,51.

Conclusion

We have established that the SN1-type propargylation of secondary aliphatic propargyl alcohols proceeds through a cationic indium-catalysed reaction pathway. This reaction with 1,2,3-trimethoxybenzene proceeds at room temperature under ambient air conditions to exclusively produce a wide variety of 4- and 5-propargylbenzenes in high yields. The reaction displays a remarkable nucleophile substrate scope, including mono-, di-, tri-substituted aromatic compounds, heteroaromatic compounds, phenols, alcohols, alkane-thiols, aryl-thiols, and sulfonamides. The reported cationic indium catalyst was also effective for propargyl alcohols that contain an electron-withdrawing (nitro, trifluoromethyl, chloro, methoxycarbonyl, acetylamino) aromatic group α-position to the hydroxyl. NMR studies indicated that the catalyst possessed a unique cationic indium nitromethanate structure, and the highly hygroscopic and oxophilic nature of the cationic indium complex was disclosed in this report. This cationic indium catalyst eliminates a challenge in propargylation chemistry; has new applications in several fields, including organic, material, and pharmaceutical chemistry; and contributes to building a modern and sustainable society with minimal environmental impacts.

Methods (Supplementary Methods in the SI)

General procedure for the synthesis of 3

Typical experimental procedure: to a nitromethane (1.50 mL) solution of 1 (0.312 mmol) and 1,2,3-trimethoxybenzene (157 mg, 0.936 mmol), and tetrabutylammonium hexafluorophosphate (24.0 mg, 0.0624 mmol), 1,1’-binaphthol (17.6 mg, 0.0624 mmol) were added silver perchlorate (16.2 mg, 0.156 mmol) and indium trichloride (13.8 mg, 0.0624 mmol). The reaction mixture was stirred at room temperature for 30 min and then the almost same procedure as entry 1 was performed. The residue was purified by preparative TLC on silica gel eluting with AcOEt-n-hexane (1:40) to give 2 in good to high yields.

Data availability

Pdf files (see Supplementary Data 1): Experimental details are included in Supplementary Data 1 (NMR Charts), all NMR data of new compounds and the other materials. All data generated and analyzed during this study are included in this article, its Supplementary Information, and also available from the authors upon reasonable request.

References

Nicholas, K. M. Chemistry and synthetic utility of cobalt-complexed propargyl cations. Acc. Chem. Res. 20, 207–214 (1987).

Teobald, B. J. The Nicholas reaction: the use of dicobalt hexancarbonyl-stabilised propargylic cations in synthesis. Tetrahedron 58, 4133–4170 (2002).

Müller, T. J. J. Stereoselective propargylations with transition-metal-stabilized propargyl cations. Eur. J. Org. Chem. 2021–2033 (2001).

Detz, R., Hiemstra, H., van Maarseveen, J. H. Catalyzed propargylic substitution. Eur. J. Org. Chem., 6263–6276 (2009).

Müller, T. J. & Netz, A. SN1 reactions with planar chiral (arene)Cr(CO)3-substituted α-propargyl cations—regio- and stereoselective additions to novel ambient electrophiles. Tetrahedron Lett. 40, 3145–3148 (1999).

Sanz, R., Miguel, D., Matínez, A., Álvarez-Gutiérrez, J. M. & Roddríguez, F. Brönsted acid catalyzed propargylation of 1,3-dicarbonyl derivatives. Synthesis of tetrasubstituted furans. Org. Lett. 9, 727–730 (2007).

Qian, H., Huang, D., Bi, Y., Yan, G. 2-Propargyl alcohols in organic synthesis. Adv. Synth. Catal. 361, 3240–3280 (2019).

Swaminathan, S. & Narayanan, K. V. The Rupe and Meyer-Schuster rearrangements. Chem. Rev. 71, 429–438 (1971).

Magnus, P. et al. Synthesis of protected (±)-Calicheamicinone derivative by sequential introduction of functionality into the bicyclo[7.3.1]enediyne core structure. J. Am. Chem. Soc. 119, 6739–6748 (1997).

Jia-Jie, W., Zhu, Y. & Zhan, Z.-P. The synthesis of aromatic heterocycles from propargylic compounds. Asian J. Org. Chem. 1, 108–129 (2012).

Frey, K. M., Georgiev, I., Donald, B. R. & Anderson, A. C. Predicting resistance mutations using protein design algorithms. Proc Natl Acad Sci USA 107, 13707–13712 (2010).

Song, J. et al. The discovery of quinoline derivatives, as NF-κB inducing kinase (NIK) inhibitors with anti-inflammatory effects in vitor, low toxicities against T cell growth. Bioorg. Med. Chem. 29, 115856 (2021).

Keshipeddy, S., Reeve, S. M., Anderson, A. C. & Wright, D. L. Nonracemic antifolates stereoselectively recruit alternate cofactors and overcome resistance in S. aureus. J. Am. Chem. Soc. 137, 8983–8990 (2015).

Lockwood, R. F., Nicholas, K. M., Transition metal-stabilized carbenium ions as synthetic intermediates. I. [(alkynyl)cobalt hexacarbonyl] carbenium ions as propargylating agents. Tetrahedron Lett. 4163–4166 (1977).

Nishibayashi, Y., Wakiji, I. & Hidai, M. Novel propargylic substitution reactions catalyzed by thiolate-bridged direthenium complexes via allenylidene intermediates. J. Am. Chem. Soc. 122, 11019–11020 (2000).

Miyake, Y., Uemura, S. & Nishibayashi, Y. Catalytic propargylic substitution reactions. ChemCatChem 1, 342–356 (2009).

Estopiñá-Durán, S. & Taylor, J. E. Brönsted acid-catalyzed dehydrative substitution reactions of alcohols. Chem. Eur J. 26, 106–120 (2021).

Downey, C. W., Confair, D. N., Liu, Y., Heafner, E. D. One-Pot Enol Silane Formation-Alkylation of Ketones with Propargyl Carboxylates Promoted by Trimethylsilyl Trifluoromethanesulfonate. J. Org. Chem. 83, 12931–12938 (2018).

Kuhn, O., Rau, D. & Mayer, H. How electrophilic are cobalt carbonyl stabilized propargylium ions ? J. Am. Chem. Soc. 120, 900–907 (1998).

Mayr, H. & Schutz, F. Addition and cycloaddition reactions of allenyl cations with various cycloalka-1,3-dienes. Tetrahedron Lett. 22, 925–928 (1981).

Mayr, H., Seitz, B. & Haberstadt-Kausch, I. K. Stepwise [2+2] and [3+2] “cycloaddition” reactions of allenyl cations with olefins. J. Org. Chem. 46, 1041–1043 (1981).

Mayr, H. & Klein, H. Additions- und cycloadditionsreaktionen von allenyl-kationen mit acyclischen 1,3-dienen. Chem. Ber. 115, 3528–3546 (1982).

Chang, X., Zhang, J., Peng, L. & Guo, C. Collective synthesis of acetylenic pharmaceuticals via enantioselective nickel/Lewis acid-catalyzed propargylic alkylation. Nat. Commun. 12, 299–317 (2021).

Li, R.-Z., Liu, D.-Q. & Niu, D. Asymmetric O-propargylation of secondary aliphatic alcohls. Nat. Catal. 3, 672–680 (2020).

Oelke, A. J., Sun, J. & Fu, G. C. Nickel-catalyzed enantioselective cross-couplings of racemic secondary electrophiles that bear an oxygen leaving group. J. Am. Chem. Soc. 134, 2966–2969 (2012).

Hamel, J.-D., Beaudoin, M. & Paquin, J.-F. Hydrogen-bond-promoted Friedel-Crafts reaction of secondary propargyl fluorides: preparation of 1-alkyl-1-aryl-2-alkynes. Synlett 28, 2823–2828 (2017).

Jiang, S.-P. et al. Copper-Catalyzed Enantioconvergent Radical Suzuki-Miyaura C(sp3)-C(sp2) Cross-Coupling. J. Am. Chem. Soc. 142, 19652–19659 (2020).

Kobayashi, Y. et al. α-and γ-Regiocontrol and enantiospecificity in the copper-catalyzed substitution reaction of propargylic phosphonates with Grignard reagents. Chem. Eur. J. 27, 3779–3785 (2021).

Yu, Y.-B., Luo, Z.-J. & Zhang, X. Copper-catalyzed direct propargylation of polyfluoroarenes with secondary propargyl phosphonates. Org. Lett. 20, 2125–2126 (2018).

Niggenmann, M. & Meel, M. Calcium-catalyzed Friedel-Crafts alkylation at room temperature. Angew. Chem. Int. Ed. 49, 3684–3687 (2010).

Aridoss, G., Sarca, V. D., Ponder, J. F. Jr., Crowe, J. & Laali, K. K. Electrophilic chemistry of propargylic alcohols in imidazolium ionic liquids: propargylation of arenes and synthesis of propargylic ethers catalyzed by metallic triflates [Bi(OTf)3, Sc(OTf)3, Yb(OTf)3], TfOH, or B(C6F5)3. Org. Biomol. Chem. 9, 2518–2529 (2011).

Maity, A. K., Chatterjee, P. N. & Roy, S. Multimetallic Ir-Sn3-catalyzed substitution reaction of π-activated alcohols with carbon and heteroatom nucleophiles. Tetrahedron 69, 942–956 (2013).

Donald, C. P., Boylan, A., Nguyen, T. N., Chen, P.-A. & May, J. A. Quaternary and tertiary carbon centers synthesized via gallium-catalyzed direct substitution of unfunctionalized propargylic alcohols with boronic acids. Org. Lett. 24, 6767–6771 (2022).

Reddy, C. R., Jithender, E., Krishna, G., Reddy, G. V. & Jagadeesh, B. A novel acid-catalyzed C5-alkylation of oxindoles using alcohols. Org. Biomol. Chem. 9, 3940–3947 (2011).

Lippert, J. W. III Vascular disrupting agents. Bioorg. Med. Chem. 15, 605–615 (2007).

Sitnikov, N. S. et al. Synthesis of indole-derived allocolchicine congeners exhibiting pronounced anti-proliferative and apoptosis-inducing properties. Med. Chem. Commun. 6, 2158–2162 (2015).

Takubo, K. et al. Diversity oriented synthesis of allocolchicinoids with fluoro and/or oxygen substituent(s) on the C-ring from a single common intermediate. Eur. J. Org. Chem. 1562–1576 (2016).

Roy, R. & Saha, S. Scope and advances in the catalytic propargylic substitution reaction. RSC Adv. 8, 31129–31193 (2018).

Yoshimatsu, M., Shimizu, H., Kataoka, T. A reaction of γ-chalcogen-substituted prop-2-ynyl cations with mild nucleophiles. J. Chem. Soc. Chem. Commun. 149–150 (1995).

Yoshimatsu, M., Yamada, H., Shimizu, H., Kataoka, T. A novel synthesis of (Z)-enynes and (Z)-enediynes from prop-2-ynyl alcohols. J. Chem. Soc. Chem. Commun. 2107–2108 (1994).

Yoshimatsu, M., Naito, M., Kawahigashi, M., Shimizu, H. & Kataoka, T. Meyer-Schuster rearrangement of γ-sulfur-substituted propargyl alcohols: a convenient synthesis of α,β-unsaturated thioesters. J. Org. Chem. 60, 4798–4802 (1995).

Yoshimatsu, M., Ohtani, T., Matsuda, S., Yamamoto, T. & Sawa, A. Scandium-catalyzed carbon-carbon bond-forming reactions of 3-sulfanyl- and 3-selanylpropargyl alcohols. Org. Lett. 10, 4251–4254 (2008).

Yoshimatsu, M., Ohta, K. & Takahashi, N. Propargyl hydrazides: synthesis and conversion into pyrazoles through hydroamination. Chem. Eur. J. 18, 15602–15606 (2012).

Surendra, K. & Corey, E. J. Diiodoindium(III) cation, InI2+, a potent yneophile. Generation and application to cationic cyclization by selective π-activation of C≡C. J. Am. Chem. Soc. 136, 10918–10920 (2014).

Michelet, B. et al. Dibromoindium(III) cations as a π-Lewis acid: characterization of [IPr·InBr2][SbF6] and its catalytic activity towards alkynes and alkenes. Chem. Commun. 51, 7401–7404 (2015).

Garbacz, M. & Stecko, S. The synthesis of chiral allyl carbamates via Merger of photoredox and nickel catalysis. Adv. Synth. Catal. 362, 3213–3222 (2020).

Kikuchi, J., Takano, K., Ota, Y., Umemiya, S. & Terada, M. Chem. Eur. J. 26, 11124–11128 (2020).

Gracheva, I. A. et al. Synthesis and cytostatic properties of polyfunctionalized furanoallocolchicinoids. Eur. J. Med. Chem. 126, 432–443 (2017).

Xu, X., Liu, J., Liang, L., Li, H. & Li, Y. Iron-catalyzed regioselective hydroarylation of C≡C triple bonds: efficient synthesis of 2H-1-benzopyran derivatives. Adv. Synth. Catal. 351, 2599–2604 (2009).

Ghinet, A. et al. Eaton’s reagent-mediated comino π-cationic arylations of aromatic carboxylic acids to lasi-red polymethoxylated polycyclic activities as tubulin polymerization inhibitors. Chem. Eur. J. 20, 10117–10130 (2014).

Subair, T., Soremekun, O. S., Olotu, F. A. & Soliman, M. E. S. Therpeutic path to double knockout: investigating the selective dual-inhibitory mechanisms of adenosine receptors A1 and A2 by a novel methoxy-substituted benzofuran derivative in the treatment of Parkinson’s disease. Cell Biochem. Biophys. 79, 25–36 (2021).

Acknowledgements

We acknowledged the support of Amano Enzyme Japan Co. for giving the lipase CL Amano (LCLR0651901IMR), the support of KISHIDA Chemical Co., Ltd.

Author information

Authors and Affiliations

Contributions

M.Y. conceived and designed this project, M.Y., H.G., R.S., K.I., H.W. and M.K. conducted the experimental works. Y.S. conducted HPLC analysis. All authors discussed the results and drafted the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declared no competing interests.

Peer review

Peer review information

Communications Chemistry thanks James Taylor and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yoshimatsu, M., Goto, H., Saito, R. et al. Cationic indium catalysis as a powerful tool for generating α-alkyl propargyl cations for SN1 reactions. Commun Chem 6, 279 (2023). https://doi.org/10.1038/s42004-023-01048-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-023-01048-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.