Abstract

Nervonic acid benefits the treatment of neurological diseases and the health of brain. In this study, we employed the oleaginous yeast Yarrowia lipolytica to overproduce nervonic acid oil by systematic metabolic engineering. First, the production of nervonic acid was dramatically improved by iterative expression of the genes ecoding β-ketoacyl-CoA synthase CgKCS, fatty acid elongase gELOVL6 and desaturase MaOLE2. Second, the biosynthesis of both nervonic acid and lipids were further enhanced by expression of glycerol-3-phosphate acyltransferases and diacylglycerol acyltransferases from Malania oleifera in endoplasmic reticulum (ER). Third, overexpression of a newly identified ER structure regulator gene YlINO2 led to a 39.3% increase in lipid production. Fourth, disruption of the AMP-activated S/T protein kinase gene SNF1 increased the ratio of nervonic acid to lignoceric acid by 61.6%. Next, pilot-scale fermentation using the strain YLNA9 exhibited a lipid titer of 96.7 g/L and a nervonic acid titer of 17.3 g/L (17.9% of total fatty acids), the highest reported titer to date. Finally, a proof-of-concept purification and separation of nervonic acid were performed and the purity of it reached 98.7%. This study suggested that oleaginous yeasts are attractive hosts for the cost-efficient production of nervonic acid and possibly other very long-chain fatty acids (VLCFAs).

Similar content being viewed by others

Introduction

Brain and neurological diseases affect nearly one in six of the world’s population according to the American Brain Foundation (www.americanbrainfoundation.org/). Nervonic acid (cis-15-tetracosenoic acid, C24:1 Δ15), an omega-9 very long-chain monounsaturated fatty acid (VLCMFA), is rich in the white matter and myelin sheath of human brain. More and more studies show that nervonic acid benefits neurological health1,2 and has therapeutic potential for adrenoleukodystrophy and multiple sclerosis3,4. Moreover, nervonic acid levels in specific tissues are associated with Alzheimer’s disease5, Parkinson’s disease6, cognition7, mood symptoms8,9, cardiovascular death10 and even obesity11.

The source of nervonic acid has attracted increasing interests due to its tremendous potentials for nutraceutical and pharmaceutical applications. Nervonic acid accounts for >40% of the total fatty acids (TFA) in seeds of the rare plant Malania oleifera and the herbaceous plants Tropaeolum speciosum and Cardamine graeca12,13,14,15. The oil extracted from Acer truncatum seeds containing about 5% of nervonic acid is sold as a nutraceutical in China16. Although a couple of plants have seeds rich in nervonic acid, supply of nervonic acid by these plants is expensive due to limitations of scale-up cultivation, climate-dependence, and harvesting cost17. Nervonic acid has also been identified in a few microalgae and filamentous fungi. The oleaginous microalgae Mychonastes afer HSO-3-1 and the filamentous fungal Mortierella capitata can synthesize nervonic acid accounting for 3.8% and 6.9% of the TFA, respectively18,19. However, the photoautotrophic microalgae M. afer produces low biomass and M. capitate is a rare fungus lacking genetic tools, which prevent them being used as cell factories for the production of nervonic acid20,21.

In recent years, the oleaginous yeast Yarrowia lipolytica has been used as a valuable host for the production of both lipid and nonlipid chemical products by metabolic engineering22,23,24,25,26. This yeast is generally regarded as safe (GRAS), grows fast, and has advantages in supply of acetyl-CoA and NADPH for anabolism27,28. The metabolic characteristic of Y. lipolytica makes it suitable for the production of fatty acids, such as polyunsaturated eicosapentaenoic acid (EPA)29, gamma-linolenic acid (GLA)30 and docosahexaenoic acid (DHA)31. Laudably, DuPont successfully synthesized EPA (C22:6, ω-3) from C18:1-acyl-CoA by elongation and desaturation in Y. lipolytica, and they commercialized EPA-rich oil for food and EPA-rich Y. lipolytica biomass for feed applications29,32. In the context, Y. lipolytica is expected to be an appropriate host for the production of nervonic acid.

The fatty acid profiles in triacylglycerol (TAG) produced by Y. lipolytica mainly consist of palmitic acid (C16:0), palmitoleic acid (C16:1, ω-7), oleic acid (C18:1, ω-9), and linoleic acid (C18:2, ω-6)33. Several aspects should be optimized for high-production of nervonic acid by Y. lipolytica. First, β-ketoacyl-CoA synthases (KCS) are among the key fatty acid elongation enzymes for synthesis of VLCMFA from C18:1-acyl-CoA. The substrate preference and specificity of KCS may differ in various hosts. For example, the KCS ACJ61777.1 (GenBank No. EU871787) identified in the biennial grass Lunaria annua used C22:1-acyl-CoA as substrate to synthesize nervonic acid when expressed in the Ethiopia mustard Brassica carinata34, while it elongated C18:1-acyl-CoA to produce mainly eicosenoic acid (C20:1, ω-9) and erucic acid (C22:1, ω-9, EA) when expressed in the yeast Rhodosporidium toruloides35. Second, most fatty acids exist in lipid forms in oleaginous microbes and therefore the selectivity of esterifying enzymes toward acyl-CoAs affects the fatty acid profiles in lipids. Third, subcellular engineering of the endoplasmic reticulum (ER) can improve the production of VLCMFA because esterification and elongation of long-chain fatty acids occur in ER36,37.

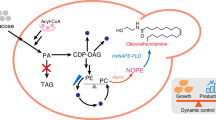

In this study, we employed the oleaginous yeast Y. lipolytica as a host to de novo synthesizing nervonic acid. The metabolic pathways for overproducing nervonic acid were designed and depicted in Fig. 1. High-level production of nervonic acid was achieved by multiplex engineering strategies. This study showed the potential of oleaginous yeasts used for cost-efficient production of nervonic acid and possibly other VLCFAs.

The solid line-box and the dotted line-box denote native pathways and heterologous pathways, respectively. The gray arrows represent competing pathways of the biosynthesis of nervonic acid. The dotted arrows show the hypothetical desaturation steps of fatty acids. FAE fatty acid elongases, KCS β-ketoacyl-CoA synthases.

Experimental

Strains and plasmids

The Y. lipolytica strains po1g (Yeastern Biotech, Taibei, Taiwan, China) and po1g-G3 were used as the hosts20. Yeast strains constructed in this study were listed in Supplementary Table 1. Plasmids (Supplementary Table 2) were constructed using Gibson assembly method and verified by DNA sequencing. Primers used were listed in Supplementary Data1. DNA sequences (Supplementary Table 3) of heterologous genes were codon-optimized and synthesized by Beijing Genomics Institute (BGI), China.

All plasmids constructed in this study were assembled via Gibson assembly. The plasmid backbones and DNA fragments were amplified using the KAPA HiFi HotStart PCR kit (Kapa Biosystems, Boston, USA) and the primers described in Supplementary Data 1. The assembly was performed at 50 °C for 1 h. The assembled mixture was used to transform the Escherichia coli Trans1-T1 component cells (TransGen Biotech, Beijing, China) for plasmid amplification. Positive clones were verified by colony PCR and DNA sequencing.

The Y. lipolytica native promoter TEFin was used in controlling the expression of the CgKCS gene from Cardamine graeca33. The organelle target signals KDEL for ER, SKL for peroxisome, and the CoxIV signal for mitochondria were fused with CgKCS26,38. To raise the copy numbers of CgKCS, three CgKCS-expressing cassettes were assembled together, resulting in a plasmid pYL-3sKCS (Supplementary Table 2). The expression of gELOVL6 and MaOLE2 was driven by the inducible promoter yat1 under oleaginous conditions29. To overexpress CgKCS, gELOVL6 and MaOLE2, the expression cassettes of the three genes were ligated together with backbone fragments, generating the plasmids pYL-3grDNA and pYL-3gD17 (Supplementary Table 2).

Expression of genes by homologous recombination were performed at the specific gene loci FAD2 (fatty acid desaturase 2), TGL4 (lipase 4), rDNA, GSY1 (glycogen synthase), SNF1 (AMP-activated S/T protein kinase), D17 and PEX10 (peroxisomal membrane protein) according to previous studies29,39,40. The plasmids pYL-rDNA-CgKCS, pYL-GSY1-CgKCS and pYL-SNF1-CgKCS were separately used to express one copy of CgKCS at the rDNA, GSY1 and SNF1 locus. The plasmids pYL-2gFAD2 and pYL-2gTGL4 were adopted to express two copies of CgKCS at the FAD2 locus and the TGL4 locus, respectively. The fusion protein of CgKCS and MaOLE2 in the plasmid pYL-D17-gMaOLE2 was expressed at the D17 locus. To express the GPATs and DGAT2s from M. oleifera, the plasmids pYL-PEX10-Mo-35, pYL-PEX10-Mo-49, pYL-PEX10-Mo-88 and pYL-PEX10-Mo-90 were constructed and the gene expression cassettes were inserted at the PEX10 locus. To express the putative regulators INO2 and INO4 of lipid synthesis, the plasmids pYL-PEX10-YlINO2 and pYL-PEX10-YlINO4 were constructed and the PEX10 locus was employed to accommodate the gene expression cassettes.

Culture media and conditions

YPD medium, containing 20 g/L glucose, 20 g/L peptone, and 10 g/L yeast extract, was used in regular cultivation of Y. lipolytica with rotary shaking at 250 rpm and 28 °C. YNB medium used for selection of genetic transformants was made with 20 g/L glucose, 1.7 g/L yeast nitrogen (without amino acids and ammonium sulfate) (Sangon Biotech, Shanghai, China), 5 g/L ammonium sulfate, and 0.69 g/L CSM-Ura or CSM-Leu (MP Biomedicals, Solon, OH).

Shake flask cultures were carried out using the fermentative medium composed of 150 g/L glucose, 6 g/L yeast nitrogen, and 12 g/L ammonium sulfate. A single colony was inoculated into 5 mL YNB medium and cultivated at 28 °C with shaking at 250 rpm for 24 h. Afterwards, 500 µL of the seed culture was inoculated into 5 mL fresh YNB medium and cultivated at 28 °C with shaking at 250 rpm for 24 h. Then, precultures were inoculated into 30 mL of fermentative medium in 250 mL shake flasks to an optical density (OD600) of 0.08 and incubated at 250 rpm and 28 °C for 144 h.

Bioreactor fermentation was carried out in a 50-L bioreactor (HND Bio-engineering Equipment, Jiangsu, China). The fermentative medium contained 150 g/L glucose, 6 g/L yeast extract, 12 g/L ammonium sulfate, 1.5 g/L MgSO4·7H2O, 6 g/L KH2PO4, 3 g/L Na2HPO4·12H2O, 3 mg/L CaCl2•2H2O, 1 mL/L trace metals stock (1000 ×), and 1 mL/L vitamins stock (1000 ×). One liter of trace metals stock contained 1 mg boric acid, 0.2 mg KI, 0.67 mg FeCl3•6H2O, 0.125 mg CuSO4•5H2O, 0.89 mg MnSO4•H2O, 0.48 mg Na2MoO4•2H2O, 1.42 mg ZnSO4•7H2O, 20 mg FeSO4•7H2O, and 0.73 mg CoCl2•6H2O. One liter of vitamins stock contained 0.05 mg biotin, 0.8 mg calcium pantothenate, 0.004 mg folic acid, 4 mg inositol, 0.8 mg niacin, 0.4 mg p-aminobenzoic acid, 0.8 mg pyridoxine HCl, 0.4 mg riboflavin, 1.5 mg thiamine HCl. The vitamins stock was sterilized by 0.22 µm hydrophilic filters. The strains used in fermentation were pre-cultivated in the medium containing 20 g/L glucose, 1.7 g/L yeast nitrogen (without amino acids and ammonium sulfate), 5 g/L ammonium sulfate, and 0.69 g/L CSM-Ura. Next, 2.3 L of the precultures were inoculated into the fermentative medium and cultivated at 28 °C. Oxygen was supplied in the form of filtered air via sparging rate of 20–80 L/min of air using agitation in 50–500 rpm range to maintain a dissolved oxygen level at 40% in 24 h and below 5% after 24 h. The pH of the cultures was constantly controlled at 5.5 using 12 mol/L NaOH. During the process of fermentation, glucose concentration was detected by an SBA-40D Biosensor (Shandong Academy of Sciences, China) every 12 h.

Extraction and quantification of lipid and protein

Total lipids were extracted using a previous procedure with minor modification41. Briefly, yeast cultures were collected by centrifugation and 0.3 g wet cells of each sample was used for lipid extraction. The wet cells were resuspended in 3 mL of 4 mol/L hydrochloric acid in glass tubes and shaken slightly for 1.5 h. Subsequently, the cells were boiled for 8 min and then were frozen at –20 °C for half an hour. Next, 6 mL of chloroform: methanol (1:1) was added to the tubes and centrifuged at 2,000 g for 10 min. The supernatant was transferred into a clean tube and 3 mL of 0.15% NaCl was added and then centrifuged. Finally, the supernatant was collected and dried using the blowing concentrator with nitrogen gas.

To detect the lipid content and composition by gas chromatography (GC), the extracted lipid was esterified by methanol to fatty acid methyl esters (FAMEs). The lipid was first incubated with 3.9 mL of methanol: sulfuric acid (98:2) at 85 °C for 3 h. Next, 1.5 mL of saturated NaCl was added and FAMEs were extracted through the addition of 1.5 mL hexane. The FAMEs were analyzed by an Agilent 7890B-GC equipped with a flame ionization detector and a capillary column HP-INNOWAX (30 m, 0.32 mm). 1 μL of sample was injected at 250 °C using helium as the carrier gas at a flow rate of 1 mL/min. The GC oven temperature was held at 140 °C for 1 min, and then ramped to 180 °C for 10 min at a speed of 10 °C/min, 210 °C for 4 min at a speed of 5 °C/min, and 250 °C for 4 min at a speed of 5 °C/min. FAMEs were identified and quantified using commercial FAME standards purchased from Sigma-Aldrich (Shanghai, China). The content of proteins was determined by the Kjeldahl method using the Kjeldahl instrument K9840 (Hanon Shandong Scientific Instruments Co., Ltd., Jinan, China).

Structural analysis and point mutation of AtADS2

To evaluate the substrate preference of AtADS2, the 3D structural model of AtADS2 was constructed by SWISS-MODEL server using mouse SCD (PDB ID: 4ymk) as the template42. Pictures of AtADS2 structures were generated with the program UCSF Chimera43. The docking of acyl-CoA into the binding pocket of AtADS2 was performed with the AutoDock Vina software44. The 3D structures of acyl-CoA and the minimized energy structures were constructed by BIOVIA Discovery Studio 4.5. Next, AutoDock Tools 1.5.4 was used to assign hydrogens, Gasteiger charges and rotatable bonds to acyl-CoA. A docking grid dimension was set to 64 Å × 70 Å × 64 Å and default values were used for other parameters. Based on molecular docking and characteristics of the binding pocket of AtADS2, some polar amino acids at the periphery of the binding pocket were replaced with non-polar amino acids (Supplementary Table 4). The AtADS2 mutant genes were expressed in the Y. lipolytica strain YLVL6 to estimate the substrate preference according to the fatty acid profiles.

Determination of the distribution of nervonic acid in TAG

The distribution of nervonic acid in triacylglycerol (TAG) was detected according to a previous publication45. Briefly, 10 mg of TAG and 3 mL of methanol was mixed with 10 mg of 1,3-specific lipase from Thermomyces lanuginose (Lipozyme TL IM; Novozymes, Bagsvaerd, Denmark) and shaken at 30 °C for 8 h. The hydrolytic products were separated by thin layer chromatography (TLC) on Partisil K6 Silica gel 60 plates (250 µm thickness, 20 × 20 cm; Merck) with developing solvent, hexane: diethyl ether: acetic acid (70:30:1, v/v). Lipids were visualized under UV light by brief exposure to iodine vapor. Then, the free fatty acids and 2-monoacylglycerols (2-MAGs) was converted to the corresponding methyl ester by incubating with 2% H2SO4-methanol solution at 85°C for 3 h. The compositions of the fatty acid methyl esters were analyzed by GC and GC-MS.

Illumina genome sequencing and bioinformatic analyses

The genome sequences of representative edited clones were sequenced by Illumina technique. Standard genome sequencing and standard bioinformatic analyses were provided by Oebiotech (Shanghai, China). The filtered reads were mapped to the reference genome Y. lipolytica CLIB89 (W29) (GenBank: GCA_001761485.1) using the BWA 0.7.16a software. The aligned sequence reads were visualized by Integrative Genomics Viewer (IGV).

Identification of DGAT2 and GPAT genes from M. oleifera

Putative acyltransferase DGAT and GPAT have been annotated in the genome of M. oleifera and transcriptomic analysis showed that two DGAT2 and two GPAT genes highly expressed in seeds at fast oil accumulation stage46. However, it is not clear whether these acyltransferases prefer esterifying C24:1-acyl-CoAs to generate nervonic acid lipids. In this study, the DGAT2 and GPAT genes in M. oleifera were identified by comparative sequence analysis. The amino acid sequence of DGAT2 (AEE78802.1) and GPAT (AAG23437.1) was used as a BLAST query against the M. oleifera genome database to retrieve gene homologs, which were used as candidates for identifying C24:1-acyl-CoAs preferred acyltransferases.

Identification of regulators of lipid synthesis in Y. lipolytica

To identify regulators for lipid synthesis in Y. lipolytica, the regulators INO2 (NP_010408.1) and INO4 (NP_014533.1) in the phospholipid biosynthesis of Saccharomyces cerevisiae were used as BLAST queries against the Y. lipolytica W29 genome (GCA_009372015.1) to retrieve the gene homologs. Homology modeling of the retrieved YlINO2 and YlINO4 from Y. lipolytica was performed using SWISS-MODEL server42. The bHLH ScINO2-ScINO4 transcription activation complex bound the promoter region (PDB ID: 7XQ5) and the structures of TFIIIB-TBP/Brf2/DNA and SANT domain of Bdp1 (PDB ID: 5N9G) in Protein Databank (PDB) were used as templates for homology modeling of YlINO4 and YlINO2, respectively. The predicted protein structures were visualized using PyMOL Molecular Graphics System (Version 1.7.0.0). Figures 2F, 6A, 7A, B and 8A were created by Figdraw (www.figdraw.com). Structure-based multiple sequence alignment of the bHLH transcription factors was carried out on the T-COOFFEE online service47.

A Expression of CgKCS in Y. lipolytica po1g. B The control strain po1g. C Expression of AtFAE1 in po1g. D Expression of BtFAE1 in po1g. E Co-expression of AtFAE1, BtFAE1 and CgKCS in po1g. F Diagram of fatty acid metabolism related to multiple organelles and subcellular localization of CgKCS. ACL, ATP-citrate lyase; ACC, acetyl-CoA carboxylase; CgKCS, β-ketoacyl-CoA synthase of C. graeca; FAS, fatty acid synthase; FFA, free fatty acids; PalCoA, palmitoyl-CoA. G The relative amount of nervonic acid content in the TFA produced by the strains expressing CgKCS and CgKCS fused with organelle targeting signals. Cultivations were carried out for 144 h at 250 rpm and 28 °C in flasks. Data are mean ± s.d. from three replicates. H Microscopic observation of the strains expressing the fused protein CgKCS-sfGFP for evaluating the location of CgKCS in Y. lipolytica. CgKCS-sfGFP exhibited both punctate and accumulated localization at the early stage of cultivation (36 h) and gathered in lipid droplets at lipid accumulation stage (60 h).

Separation and purification of nervonic acid

Crude lipids extracted from cell sediment of the YLNA9 culture from 50 L-reactor were used to separate nervonic acid. The extracts were hydrolyzed in the solution of sodium hydroxide (pH 9.0) and ethanol at 80–85 °C with stirring for 3 h. When no stratification was observed with the naked eye, the saponification solution was acidified to pH 2.0 by sulfuric acid and heated to volatilize ethanol at 75 °C. Next, free fatty acids in the saponification solution were extracted by using n-hexane for three times, washed and dehydrated, and then evaporated. The extracts of free fatty acids were dissolved in n-hexane for purification analysis.

Silica gel column chromatography was used in preliminary purification of nervonic acid. Mobile phases consisting of n-hexane and ammonia (0.1%, 0.5%, or 10%) or acetic acid (0.5%, 1%, or 2%) were first evaluated by TLC on silica gel plates. Next, the extracts of free fatty acids were isolated by silica gel column (26×3.0 cm i.d.) using hexane containing 1% acetic acid as the elution buffer. The initial 75 mL eluent was discarded, and following 230 mL eluent was collected and concentrated by rotary evaporator. The residues were dissolved in 1 mL of methanol for further purification by preparative chromatography. The effusion mainly containing nervonic acid was determined and collected according to the HPLC spectrogram of nervonic acid standard. Next, the collection was dried under a gentle nitrogen flow, dissolved in methanol, and filtered through 0.22-μm nylon syringe filters for further separation by UHPLC (Ultra high performance liquid chromatography) (Thermo U3000) equipped with a UV detector through a C18 column Poroshell 120 EC-C18 (4.6 × 150 mm, 4 μm) (Agilent Technologies, Inc.). Mobile phase consisted of acetonitrile/methanol/0.4% acetic acid/ tetrahydrofuran (80:12:5:3, v/v/v/v). Twenty microliters of samples were automatically injected. A flow rate of 0.6 mL/min of the mobile phase was used.

The reagents methanol, acetonitrile, n-hexane, and tetrahydrofuran used in this study are all HPLC grade and purchased from Merck Co. Acetic acid, NaOH, ammonia, sulfuric acid, and ethanol are purchased from Sinopharm Chemical Ceagent Co., Ltd. (Shanghai, China). Nervonic acid, methyl cis-15-tetracosenoate, and ethyl 15-tetracosenoate (>99%) were purchased from Shanghai McLean Biochemical Technology Co., Ltd., China. Silica gel was provided by Qingdao Ocean Chemical Plant, China.

Transmission electron microscopy and fluorescence microscope

Yeast stock cells were inoculated into 5 mL YNB medium and cultivated at 28 °C with shaking at 250 rpm for 24 h. Afterwards, 300 µL of the cultures were grown for 24 h in 30 mL of YNB medium at 28 °C and 250 rpm. Collect the cells by centrifugation and fix them by 2.5% glutaraldehyde at room temperature for 2 h. Then, gently wash the fixed cells by 0.1 M phosphate buffer solution (PBS) at pH 7.4 for three times. Further fix the cells by 1% osmic acid solution for 1 h and then wash them with PBS for three times. Dehydration of the fixed cells by acetone at the concentrations of 30%, 50%, 70%, 80%, 90%, 95% and 100%. Next, the cells were infiltrated by acetone and resin at a ratio of 7:3 (v/v) for 5 h, 3:7 (v/v) for 5 h, and then embedded by pure resin for 12 h. The specimen was stained by 2% uranyl acetate for 15 min and lead citrate for 5 min, and observed using a transmission electron microscope (FEI Tecnai G2 Spirit, OR, USA). To observe the intracellular lipid droplets, the yeast cells were stained with Nile red and observed by a fluorescence microscope (OLYMPUS BX35, Tokyo).

Prediction and visualization of transmembrane segments in CgKCS and MaOLE2

The transmembrane segments (TMS) of CgKCS and MaOLE2 embedded in ER were predicted using matching apparent free energy differences (ΔG prediction server v1.0) via the Sec61 translocon48. The anticipated TMS with ΔG ≤ 1.5 kcal/mol were considered to TMS49. For membrane protein topology visualization, the PROTTER online servers was used50. Structure homology modeling of MaOLE2 was carried out using the SWISS-MODEL online servers42. The three-dimensional structure of a mouse stearoyl-CoA desaturase (PBD ID: 4YMK) in PDB was used as the template for homology modeling of MaOLE2. Three-dimensional structures modeling of CgKCS was carried out using I-TASSER unified platform51. The predicted protein structures were visualized using the program UCSF Chimera43 and PyMOL Molecular Graphics System (Version 1.7.0.0).

Statistics and reproducibility

All quantitative data are represented as the mean ± SE. Statistically significant differences between each engineered Y. lipolytica strains were denoted *P < 0.05, **P < 0.01 (two-tailed Student’s t-test).

Results

Nervonic acid synthesis by fatty acid elongation

The KCS, one of the fatty acid elongase (FAE) components, is considered the rate-limiting enzyme for VLCFAs synthesis52. We expressed the codon-optimized CgKCS gene from C. graeca in the Y. lipolytica strain po1g and achieved production of nervonic acid accounting for 1.4% of total fatty acids (TFA) in the strain YL-CgKCS (Fig. 2A). The strain po1g cannot synthesize eicosenoic acid (C20:1) and EA (C22:1), so it is considered that C18:1-acyl-CoA was used as the substrate of CgKCS in YL-CgKCS (Fig. 2B). The fatty acid elongases AtFAE1 in Arabidopsis thaliana and BtFAE1 in Brassica tournefortii prefer extending oleic acid to eicosenoic acid and EA, respectively53,54,55. Protein topology prediction showed that AtFAE1, BtFAE1 and CgKCS have extremely similar transmembrane structures (Supplementary Fig. 1A–E).

To test whether C20:1-acyl-CoA and C22:1-acyl-CoA can be used as substrates for KCS to produce nervonic acid, the genes AtFAE1 and BtFAE1 were expressed in Y. lipolytica. As expected, expression of AtFAE1 and BtFAE1 resulted in the production of eicosenoic acid (4.4% of the TFA) in YL-AtFAE1 and EA (5.4% of the TFA) in YL-BtFAE1 (Fig. 2C, D). The expression of BtFAE1 also led to the production of a small amount of nervonic acid (0.47% of the TFA; Fig. 2D). Multisequence alignment showed that the catalytic residues in CgKCS, AtFAE1 and BtFAE1 are extremely conservative (Supplementary Fig. 1F), while structural modeling indicated that the size of substrate-binding regions were consistent with the preference of them to different acyl-CoAs (Supplementary Fig. 2). Nevertheless, the strain YL-3FAEs co-expressing of AtFAE1, BtFAE1 and CgKCS did not improve the production of nervonic acid (Fig. 2E), indicating that CgKCS may not be able to effectively use C20:1-acyl-CoA and C22:1-acyl-CoA as substrates in Y. lipolytica.

The biosynthesis of fatty acids is functionally partitioned in multiple cellular compartments, including the cytosol, mitochondria, ER, peroxisome, and lipid droplets26,56,57. We next investigated whether CgKCS expression in specific subcellular organelles could help direct acyl-CoA toward the formation of nervonic acid (Fig. 2F). Mitochondria was included in the subcellular localization tests because of mitochondrial FAS found in yeast and the interaction between mitochondria associated member and ER58,59. Expression of CgKCS or CgKCS fused with ER, peroxisomal or mitochondria signals led to similar production of nervonic acid (1.1%-1.3% of the TFA). Co-expression of CgKCS fused with ER and peroxisome signals resulted in an increase of nervonic acid to 2.9% of the TFA (Fig. 2G). Because expression of CgKCS without additional target signals allowed production of nervonic acid and CgKCS is a transmembrane protein (Supplementary Fig. 1A), we speculated that CgKCS may contain inherent signals for organelles localization in Y. lipolytica. To assess this speculation, we fused CgKCS to a superfolder GFP gene (sfGFP)60. CgKCS-sfGFP exhibited both punctate and accumulated localization in the early stage of cultivation and targeted in lipid droplets in the lipid accumulation stage (Fig. 2H). This observation indicates that CgKCS can target multiple cellular organelles in Y. lipolytica, including ER and lipid droplets. Given the effectiveness of both original CgKCS and CgKCS fusing with additional target signals, we employed combinatorial patterns to express these genes to further improve nervonic acid production.

Evaluation of nervonic acid synthesis by desaturation

Theoretically, nervonic acid could be synthesized from both C18:1-acyl-CoA and C18:0-acyl-CoA by expression of KCS and desaturases (Fig. 1). However, few fatty acid desaturases with VLCFA activities have been identified. To the best of our knowledge, the acyl-coenzyme A desaturase-like protein AtADS2 in A. thaliana and the Δ15 desaturase from Mortierella alpina were able to catalyze C24:0-acyl-CoA to synthesize nervonic acid61,62. We expressed the AtADS2 gene in the strain YL-3FAEs due to the TFA of this strain containing 7% lignoceric acid (C24:0) (Supplementary Fig. 3A). Determination of the fatty acids in the AtADS2-overexpresed strains showed that nervonic acid was nearly undetected while oleic acid improved from 26% to 54% in TFA (Supplementary Fig. 3A, B), suggesting that AtADS2 desaturated C18:0-acyl-CoA by Δ9-desaturase activity. This finding is in contrast to expressing AtADS2 in S. cerevisiae, in which AtADS2 presented Δ15-desaturase activity leading to nervonic acid production from C24:0-acyl-CoA61.

Structural analysis of AtADS2 by SWISS-MODEL server showed that the three-dimensional structure of AtADS2 is highly similar to that of mouse stearoyl-CoA desaturase (mSCD, PDB ID:4ymk)63. Like typical SCDs, cross-sections of the AtADS2 surface have a tunnel-like substrate binding pocket, which determines the chain length of acyl-CoA substrates (Supplementary Fig. 3C). Compared with C18:0-acyl-CoA, C24:0-acyl-CoA has a longer hydrophobic hydrocarbon chain that cannot effectively combine with the binding pocket. We explored improving the substrate preference of AtADS2 toward C24:0-acyl-CoA by modifying amino acids around the pocket to enhance its hydrophobicity (Supplementary Table 3). Unexpectedly, the content of nervonic acid decreased in all mutants, while the content of oleic acid increased from 36% to above 47% in TFA along with a slight increase of eicosenoic acid (Supplementary Fig. 3D). Since AtADS2 and the mutants tested here prefer desaturating C18:0-acyl-CoA to produce oleic acid in Y. lipolytica, the strategy of desaturation of C24:0-acyl-CoA for the production of nervonic acid was given up in this study.

Modulation of endogenous pathways improved nervonic acid production

Palmitoleic acid is an omega-7 fatty acid that cannot be used as the substrate for producing the omega-9 nervonic acid (Fig. 1). With the overexpression of CgKCS, palmitoleic acid increased significantly, from 13.5% to 27.3% of the TFA (Fig. 2A, B). We assumed that expression of C16/C18 FAEs that prefer to convert C16:0-acyl-CoA to C18:0-acyl-CoA together with Δ9 desaturases with high substrate preference for C18:0-acyl-CoA should decrease the synthesis of palmitoleic acid and increase the C18:1-acyl-CoA precursor for nervonic acid production (Fig. 1).

We next evaluated the substrate preference of heterologous FAEs for C16:0-acyl-CoA and fatty acid desaturases for C18:0-acyl-CoA in vivo (Supplementary Table 5). The goat ELOVL6 (gELOVL6)64, rat ELO2 (rELO2)65, and CpLCE1 from Cryptosporidium parvum66 were chosen according to previous reports about the high elongation preference of them toward C16:0-acyl-CoA. The tested fatty acid desaturases included OLE2 from Mortierella alpine (MaOLE2)67, FAT6 from Caenorhabditis elegans (CeFAT6)68, and D9DMB from Cunninghamella echinulata69. All the genes were optimized according to the codon usage bias of Y. lipolytica.

Expression of CeFAT6 and rELO2 in Y. lipolytica po1g increased the content of linoleic acid from 21.6% in TFA to 36.4% and 41.7%, respectively. In contrast, expression of MaOLE2 or gELOVL6 in po1g led to an effective increase of oleic acid from 36.3% in TFA to >50% along with a decrease of palmitoleic acid from 12.1% in TFA to below 8.4% (Fig. 3A, B). Because CgKCS prefers using C18:0-acyl-CoA as the substrate for nervonic acid synthesis, MaOLE2 and gELOVL6 were employed in constructing nervonic acid overproducing strains. Expression of gELOVL6 in the CgKCS-overexpressing strain YL-3CgK decreased the contents of palmitoleic acid and palmitic acid in TFA by 7.5% and 57.2% in the strain YL-3CgKE, respectively. Meanwhile, nervonic acid increased from 3.3% to 13.2% of the TFA in YL-3CgKE (Fig. 3C). Furthermore, expressing an additional copy of each of gELOVL6 and MaOLE2 in YL-3CgKE reduced palmitoleic acid by 40.5% and increased nervonic acid to 15.9% of the TFA in YL-3CgKEM, (Fig. 3C). A maximum nervonic acid titer of 0.34 g/L was achieved in flask cultures. These results confirmed the effectiveness of expression of gELOVL6 and MaOLE2 to decrease palmitoleic acid and improve the precursor for nervonic acid production in Y. lipolytica. The distribution of nervonic acid in TAG was then detected by hydrolysis using a 1,3-specific lipase as well as TLC and GC-MS analysis. The results indicated that nervonic acid produced by the engineered Y. lipolytica localized at sn-1 and sn-3 positions in TAG (Fig. 3D).

A Expression of genes encoding C16:0-acyl-CoA-specific FAEs. B Expression of genes encoding C18:0-acyl-CoA-specific fatty acid desaturases. C Co-expression of gELOVL6, MaOLE2, and CgKCS. YL-3CgK, the CgKCS overexpressing strain; YL-3CgKE, expression of gELOVL6 in YL-3CgK; YL-3CgKEM, expressing an additional copy of each of gELOVL6 and MaOLE2 in YL-3CgKE. D Determination of the distribution of nervonic acid in TAG by hydrolysis using a 1,3-specific lipase as well as TLC and GC-MS analysis. Cultivations were carried out for 144 h at 250 rpm and 28 °C in flasks. Data are mean ± s.d. from three replicates. Statistical analysis was performed by two-way ANOVA and Tukey’s multiple comparison test.

Construction of nervonic acid overproduction strains by homologous recombination in lipid-overproduction strains

Although the nervonic acid content in TFA reached 15.9% in the strain YL-3CgKEM, the lipid titer was only 2.1 g/L in flask cultures. To improve the titer of both nervonic acid and lipids, we iteratively overexpressed CgKCS, gELOVL6 and MaOLE2 in the lipid-overproduction strain po1g-G320 by both random integration and homologous recombination (Fig. 4A). Six copies of CgKCS were expressed by random genome insertion to generate the strain YLVL6, which produced 0.69 g/L of nervonic acid (6.5% of the TFA) in flask (Fig. 4B, C). However, further expression of additional copies of CgKCS by random genetic integration without clearly improving nervonic acid production in YLVL9 (Supplementary Fig. 4A, B). Genome resequencing revealed that the additional CgKCS expression cassettes eliminated the expression of previous CgKCS by recombination with their TEF1 promoters (Supplementary Fig. 4C). Thus, we next adopted homologous recombination to overexpress heterologous genes at given loci. Simultaneous expression of CgKCS, gELOVL6 and MaOLE2 at the ribosomal DNA loci of YLVL6 generated the strain YLVL7, in which the content and titer of nervonic acid reached 10.0% of the TFA and 1.46 g/L in flask cultures, respectively (Fig. 4B, C). Additional expression of CgKCS, gELOVL6 and MaOLE2 at the D17 locus40 increased nervonic acid to 11.8% of the TFA and 1.71 g/L in the strain YLVL8 (Fig. 4B, C). Next, double CgKCS expression cassettes were co-expressed at the fatty acid desaturase-2 (FAD2) gene locus in YLVL8, producing the strain YLVL10. Disruption of FAD2 led to a decrease of lipid production, from 14.5 g/L in YLNA8 to 11.6 g/L in YLVL10, with a slight increase of the nervonic acid titer, from 1.71 g/L to 1.76 g/L as nervonic acid content increased to 15.2% from 11.8% of the TFA (Fig. 4B–D). The strain YLVL10 produced VLCFAs at 3.74 g/L as high as 25-folds of that in the initial strain po1g-G3 in flasks (Fig. 4E). The content of VLCFAs in YLVL10 was 32.3% of the TFA (Fig. 4F). The ratio of nervonic acid and lignoceric acid to the total VLCFAs reached 47.1% and 38.2%, respectively.

A Schematic diagram showing the construction of YLVL strains. The overexpressed genes are indicated by red symbol. The red numbers in parentheses represented the gene copies more than one on plasmids. The green italics symbol denotes genes integrated into the genomes by random integration or homologous recombination. The results of lipid and VLCFAs biosynthesis in the strains YLVL3, 6, 7, 8 and 10, including the fatty acid profiles (B), the titer of lipid and nervonic acid (C), the fatty acid composition in YLVL10 detected by gas chromatography (D), the titer of LCFAs and VLCFAs (E), and the fraction of LCFAs and VLCFAs (F). The yeasts were cultured for 144 h at 250 rpm and 28 °C in flasks. Data are mean ± s.d. from three replicates. Statistically significant differences between each engineered Y. lipolytica strains were denoted *P < 0.05, **P < 0.01 (two-tailed Student’s t-test).

Meanwhile, we constructed a series of YLNA strains (YLNA1 to 7), in which all overexpressed genes were integrated into the genome of po1g-G3 by homologous recombination (Fig. 5A–E). In the strain YLNA7, seven copies of CgKCS were expressed at the genomic loci of rDNA, FAD2, TGL4, GSY1 and SNF1. In this study, two copies of CgKCS were expressed at FAD229 gene locus, producing strain YLNA3. Strain YLNA3 had nervonic acid content up to 10.79% (per TFA), while linoleic acid content showed no significant difference between YLNA1 and YLNA3 (Fig. 5C). Afterwards, double CgKCS expression cassettes were co-expressed at the TGL4 gene locus29, while disruption of TGL4 led to a slight but insignificant decrease in lipid production (Fig. 5C, D). One CgKCS expression cassette was then co-expressed at GSY129 to obtain the YLNA6 strain. Next, one copy of the CgKCS was overexpressed at SNF1 to obtain the YLNA7 strain. The nervonic acid titer in YLNA7 was significantly higher than that in YLNA6. (Fig. 5D). A nervonic acid titer of 2.60 g/L were achieved in YLNA7 (Fig. 5A and C), which was apparently higher than the 1.76 g/L achieved in YLVL10. Interestingly, the ratio of nervonic acid to lignoceric acid (C24:0) increased from 1.38 in YLNA6 to 2.23 in YLNA7 by disruption of the AMP-activated S/T protein kinase SNF129 and the overexpression of additional copy of CgKCS by random genomic integration (Fig. 5B, C), which facilitates the purification of nervonic acid. The ratio of nervonic acid to lignoceric acid in YLNA7 was also significantly higher than that in YLVL10 (2.23 vs 1.23).

A Schematic diagram showing the construction of YLNA strains by expressing the genes CgKCS, MaOLE2, YlINO2 and MoGPAT-88 at multiple genomic loci. The overexpressed genes are indicated by blue symbol. The blue numbers in parentheses represented the gene copies more than one on plasmids. The green italics symbol denotes genes integrated into the genomes by homologous recombination. B Comparison of the production of nervonic acid and lignoceric acid in YLNA9, YLNA10 and YLVL10. The results of lipid and VLCFAs biosynthesis in the strains YLNA1, 3, and 5 to 10, including the fatty acid profiles (C), the titer of lipid and nervonic acid (D), the fatty acid composition in YLNA10 detected by gas chromatography (E). The yeasts were cultured for 144 h at 250 rpm and 28 °C in flasks. For YLNA1-YLNA6 in (C, D), n = 3; For YLNA7-YLNA10 in (C, D), n = 2. Statistically significant differences between each engineered Y. lipolytica strains were denoted *P < 0.05, **P < 0.01 (two-tailed Student’s t-test).

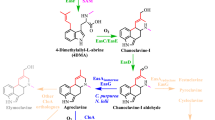

Since the fatty acid desaturase MaOLE2 prefers to desaturate C18:0-acyl-CoA to generate C18:1-acyl-CoA as the substrate of CgKCS for nervonic acid biosynthesis, it is hypothesized that the proximity of MaOLE2 and CgKCS in ER benefits the production of nervonic acid (Fig. 6A). Protein transmembrane prediction showed that MaOLE2 has five transmembrane helices (TM1–TM5) arranged in a trumpet-like shape (Fig. 6B, D). The dimetal (Zn2+) catalytic activity sites locate in two helical turns toward the cytoplasm (Fig. 6B). CgKCS has two transmembrane segments (TM1 and TM2) at the N-terminal (Fig. 6C, E). When the transmembrane regions were removed, the truncated CgKCS maintained only a weak elongation ability (Supplementary Fig. 5). Based on the structure information, a flexibility glycine linker (GGGGGGGGGG) was used to fuse the C-terminal of MaOLE2 with the N-terminal of CgKCS. The fusion protein was expressed at the D17 locus in YLNA7, producing the strain YLNA8. The nervonic acid content in YLNA8 (17.3%) was slightly higher than YLNA7 (16.5%) (Fig. 5C, D). The ratio of nervonic acid to lignoceric acid in YLNA8 also increased from 2.23 to 2.27 (Fig. 6F, G).

A Schematic diagram showing the physical locations of MaOLE2 and CgKCS in ER. B Three-dimensional architecture of MaOLE2. The red spheres represent the catalytic site of zinc ions. C Three-dimensional architecture of CgKCS. D Five transmembrane domains in MaOLE2 are organized in a two-dimensional topology. E Two transmembrane domains in CgKCS are organized in a two-dimensional topology. F Comparison of the fatty acid composition between YLNA7 and YLNA8. G Comparison of the production of nervonic acid and lignoceric acid in YLNA7, YLNA8 and YLVL10.

Expansion of ER enhancing lipid and nervonic acid production

The INO2/INO4 transcription factor complex has been demonstrated to activate phospholipid biosynthesis and ER structural alteration in S. cerevisiae (Fig. 7A, B)70. Over-expression of INO2 and INO4 improved the production of terpenoids, 3-hydroxypropionic acid, ethanol and lycopene by expanding the ER size or enhancing cellular stress response in S. cerevisiae36,37,71. However, the homologs of INO2/INO4 have not been identified in Y. lipolytica.

A Schematic diagram showing the functions of INO2. B The regulatory network of the INO2/INO4 complex. PA, lipidphosphatidic acid; PI, phosphatidylinositol; PS, phosphatidylserine; PE, phosphatidylethanolamine; PC, phosphatidylcholine. C Three-dimensional architecture showing the combination of YlINO2 with DNA. D Structure-based multiple sequence alignment of bHLH transcription factors. Sc, S. cerevisiae; Yl, Y. lipolytica. The star symbol above the red boxes indicates the conserved residues. E Comparison of DCW, and the titer of lipid and nervonic acid in the CK strain YLNA8 and the strains YlINO2 (YLNA9) and YlINO4. F The cell growth and glucose consuming in the CK strain YLNA8 and YlINO2 (YLNA9). Data are mean ± s.d. from three replicates. G The content of lipid and protein in CK (YLNA8) and YlINO2 (YLNA9). H Comparison of fatty acid composition in CK (YLNA8) and YlINO2 (YLNA9).

To recognize the ER regulatory factors in Y. lipolytica, a putative inositol-3-phosphate synthase YlINO1 (NC 006068.1) was first identified by two-sequence alignment. The YlINO1 was confirmed by prediction of the interaction between ScINO2/INO4 and the YlINO1 promoter by using the software JASPAR2020 (Supplementary Fig. 6A), indicating Y. lipolytica having INO2/INO4 complex. YlINO1 and ScINO1 (NC 001142.9) showed a sequence identity of 67.2% (Supplementary Fig. 6B). Subsequently, putative ER regulators YlINO2 (GenBank No. AOW01275.1) and YlINO4 (GenBank No. AOW06291.1) were identified by homology analysis in the genome of Y. lipolytica. In the GenBank database, YlINO2 was annotated as a hypothetical protein with no specific function, whereas YlINO4 was annotated as a ScINO4-like protein. YlINO4 shared a sequence identity of 37.3% with ScINO4 and they had similar three-dimensional structure (Supplementary Fig. 7A–C). The sequence similarity between templet (Bdp1) and YlINO2 is only 15.2% (Fig. 7C). Structure-based multi-sequence alignment showed that the putative YlINO2/INO4 and the Sc INO2/INO4 shared the same essential amino acids for DNA recognition (Fig. 7D, Supplementary Fig. 7D–G), indicating that YlINO2/YlINO4 is ER transcription factors.

Next, the putative YlINO2 and YlINO4 were separately expressed at the PEX10 locus39 in YLNA8. Overexpression of YlINO4 did not result in clear changes in the production of lipid and nervonic acid (Fig. 7E). Overexpression of YlINO2 resulted in a 39.3% increase in lipid production from 15.2 g/L in YLNA8 to 21.1 g/L in YLNA9, as well as a significant increase in biomass from 28.0 g/L to 36.6 g/L (Fig. 7E). The rate of sugar consumption speeded up quickly from 48 h that resulted in rapid increases in the biomass and lipid titer in YLNA9 expressing YlINO2 (Fig. 7F). A lipid content of 59.5% in the DCW and a nervonic acid content of 16.5% in TFA were achieved in YLNA9 (Fig. 7G, H). The titer of nervonic acid increased by 18.2% from 2.96 g/L to 3.5 g/L in YLNA9 (Fig. 7E). The nervonic acid was confirmed by GC-MS (Supplementary Fig. 8). The ER membrane expansion was observed in the YlINO2 overexpressed strains YLNA9 by transmission electron microscopy (Supplementary Fig. 9), further indicated that YlINO2 is an ER structure regulator.

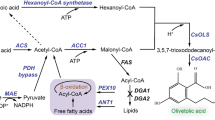

Engineering the esterification of C24:1-acyl-CoAs

The biosynthesis of TAG from fatty acyl-CoA and glycerol-3-phosphate requires glycerol-3-phosphate acyltransferases (GPAT), lysophospholipid acyltransferases (LPAT), phosphatidic acid phosphatase (PAP), and diacylglycerol acyltransferases (DGAT) (Fig. 8A). Most fatty acids exist in the lipid forms of TAG. Once C16-acyl-CoAs and C18-acyl-CoAs are esterified to form lipids, they cannot be elongated to C24:1-acyl-CoAs for the synthesis of nervonic acid. So, esterified enzymes with substrate preference for C24:1-acyl-CoAs rather than C16-acyl-CoAs or C18-acyl-CoAs are expected to improve the production of nervonic acid. In view of the seeds of M. oleifera rich in nervonic acid12, DGAT and GPAT genes in this plant were systematically evaluated to identify C24:1-acyl-CoAs preferred ones.

A The biosynthesis of TAG in ER catalyzed by GPAT, LPAT, PAP and DGAT. G3P glycerol 3-phosphate, GPAT glycerol-3-phosphate acyltransferase, LPAT lysophosphlipid acyltransferase, PAP phosphatidic acid phosphatase, DGAT diacylglycerol acyltransferase. Phylogenetic trees of the acyltransferases GPAT (B) and DGAT2 (C) from M. oleifera constructed by the Neighbor-Joining method using the software MEGA11. The titer of lipid and nervonic acid in the acyltransferases overexpressed strains (D). The fatty acid composition in GPAT (E) and DGAT2 (F) overexpressed strains.

Eight putative GPATs and ten putative DGAT2s sequences were extracted from the M. oleifera genome by homologous sequence analysis (Fig. 8B, C). Further functional prediction using UniPort in NCBI indicated that two GPATs (GenBank No. oleifera 006088 and 006090) and two DGAT2s (GenBank No. oleifera 010035 and 015949) possibly prefer to esterify C24:1-acyl-CoAs. Both GPAT sequences 006088 and 006090 showed a sequence identity of above 55% compared with the GPAT AAG23437.1 in A. thaliana. The sequence identity of DGAT2 010035 and 015949 to the DGAT2 AEE78802.1 in A. thaliana was 25.4% and 37.8%, respectively. Separated expression of the four putative acyltransferases at the PEX10 locus in YLNA8 increased the lipid titer by 22.1% (strain MoGPAT-88), 18.8% (strain MoGPAT-90), 15.6% (strain MoDGAT2-35) and 17.2% (strain MoDGAT2-49), respectively (Fig. 8D). A highest nervonic acid titer of 3.36 g/L was achieved in MoGPAT-88 (entitled YLNA10), which is 28.1% higher than that in the strain YLNA8 (Fig. 8D). The content of nervonic acid in TFA improved from 17.3% to 18.0% in YLNA10 (Fig. 8D–F). The ratio of nervonic acid to lignoceric acid in YLNA10 increased to 3.5 from 2.27 in YLNA8.

Production of nervonic acid by two-stage fed-batch bioreactor

The fermentative medium and conditions were optimized in flasks and a 3-L reactor. In oleaginous yeast and algae, the C/N ratio is critical for lipid accumulation62. In Y. lipolytica, nitrogen limitation (high C/N ratio media) is commonly used to induce the accumulation of intracellular lipids72. Growth slows down as nitrogen becomes limited, and the influx of carbon is subsequently utilized mostly for the production of lipids62. Central composite design (CCD) and response surface methodology were used to optimize the concentrations of glucose and nitrogen sources (yeast extract and ammonium sulfate) in flasks using strain YLVL3 (Supplementary Table 6 and 7). In two rounds of optimization experiments, the medium containing 150 g/L glucose, 6 g/L yeast extract, and 12 g/L ammonium sulfate exhibited optimal lipid production (Supplementary Fig. 10), with lipid and nervonic acid titer that were 2.9-fold and 6.7-fold the levels obtained in the control media, respectively (Supplementary Fig. 10). The strain YLVL6 was also cultivated by fed-batch fermentation in the 3-L bioreactor and the feeding medium composition was evaluated for maximal lipid production. The results showed that feeding glucose and ammonium sulfate with a C/N molar ratio of 100:1 during fermentation resulted in an 84.6% increase in lipid titer (41.4 g/L) compared to that achieved by feeding solely glucose (Supplementary Fig. 11A). The lipid titer was further improved to 43.7 g/L by controlling the dissolved oxygen level at 20% up to 24 h and below 5% after 24 h, and the biomass reached 159.2 g/L at 120 h (Supplementary Fig. 11B). Under the optimized conditions, a nervonic acid titer of 4.2 g/L was achieved by 120 h for strain YLVL6 in the 3-L reactor.

On the basis of the optimized fermentation medium and conditions, pilot-scale fermentation in 50-L reactor was separately performed using the strains YLVL10 and YLNA9 (Fig. 9A–C). Lipid and nervonic acid synthesized constantly by YLVL10 in 192 h during the fermentation process (Fig. 9C). A VLCFAs titer of 24.0 g/L was obtained in YLVL10 at 192 h, which consisted of behenic acid (C22:0) 1.6 g/L, EA (C22:1) 2.2 g/L, lignoceric acid (C24:0) 10.0 g/L and nervonic acid (C24:1) 10.2 g/L (Fig. 9B). Lipid and nervonic acid synthesized constantly by YLNA9 in 216 h (Fig. 9C). The fastest lipid production in YLNA9 happened between 48 h and 72 h which was earlier than that of 72 h to 96 h in YLVL10, and the highest yield during this period in both YLNA9 and YLVL10 reached 0.267 g lipid /g glucose (98% of the maximum theoretical yield). A largest lipid titer of 96.7 g/L and a lipid content of 52.1% to DCW were achieved in YLNA9 (Fig. 9C, Supplementary Fig. 12). The titer of nervonic acid and VLCFAs in YLNA9 reached 17.3 g/L (17.9% of the TFA) and 28.2 g/L (29.2% of the TFA), respectively (Fig. 9C), as far as we known, both of which were the highest reported levels35,73. The productivity of nervonic acid is 0.135 g·L−1·h−1.

Separation and purification of nervonic acid

Both nervonic acid and lignoceric acid have 24 carbons and the positions of them in GC spectrums are close (Fig. 5B). Separation of nervonic acid from lignoceric acid and other fatty acid components was explored. The lipids produced by the strain YLNA-9 in 50-L reactor were extracted and saponified to release free fatty acids. The standards of methyl cis-15-tetracosenoate and ethyl 15-tetracosenoate were used to estimate saponification conditions. The recoveries of methyl cis-15-tetracosenoate and ethyl 15-tetracosenoate reached 93.38 ± 6.20 % and 101.71 ± 10.53%, respectively, indicating the feasibility of the processes used in this study.

After saponification, silica gel column chromatography was used to separate nervonic acid in view of the weak polarity of it. Mobile phases consisting of n-hexane and ammonia or acetic acid were first evaluated on TLC. The results showed that using the solutions containing n-hexane and acetic acid or 0.5% ammonia successfully presented nervonic acid (Supplementary Fig. 13). Particularly, the mobile phase consisting of n-hexane and 1% acetic acid exhibited best separation efficiency and product purity and was used in silica gel column chromatography. Furthermore, discarding 75 mL of initial eluent and collecting 230 mL of subsequent eluent resulted in maximum recovery of nervonic acid. Next, the products purified by silica gel column chromatography were further separated by a C18 column using UHPLC and the eluent containing nervonic acid was collected according to the elution time of nervonic acid standard. Nervonic acid was verified by HPLC-MS/MS and the purity of the nervonic acid solution reached 98.7% (m/m) determined by HPLC (Supplementary Fig. 14). Thus, these processes successfully separated nervonic acid from lignoceric acid and other fatty acid components.

Discussion

The number of lipid structures collected in the LIPID MAPS® Structure Database (LMSD) exceeds 47, 000 so far. Many lipids have similar structures except the chain length of fatty acids because of the non-specificity of elongation and esterification reactions toward fatty acid units. Therefore, evaluation of fatty acid elongases and esterifying enzymes is crucial for producing tailored fatty acid species74,75.To synthesize VLCFAs, KCS is among the key enzymes used for lengthening fatty acid chains52. Here, we found that CgKCS prefers to directly convert C18:1-acyl-CoA to C24:1-acyl-CoA by three rounds of two-carbon addition in the yeast Y. lipolytica. Meanwhile, increase of C20:1-acyl-CoA and C22:1-acyl-CoA by expression of AtFAE1 and BtFAE1 did not help CgKCS to produce more C24:1-acyl-CoA and nervonic acid. In contrast, expression of CgKCS in R. toruloides led to approximately equal amount of EA (C22:1) and nervonic acid35. In addition, some KCSs prefers using C22:1-acyl-CoA as substrate to synthesize nervonic acid in plants34. Accordingly, we concluded that the products of KCSs depend on both enzyme specificity and the hosts, and therefore, both aspects should be seriously considered when VLCFAs are produced by metabolic engineering.

In oleaginous prokaryotes and eukaryotes, most acyl-CoAs are incorporated onto glycerol-3-phosphate (G3P) to generate TAGs as a form of energy storage. TAG biosynthesis is an evolutionarily conserved process, while acyltransferases GPAT and DGAT involved in the synthesis of TAGs do not possess rigid substrate specificity toward acyl-CoAs76,77. Acyltransferases with similar amino acid sequences can exhibit completely different acyl-donor specificities78. In the nervonic acid producing plant M. oleifera, GPAT and DGAT genes have been identified, which exhibited apparently differential transcript levels in seeds46. In this study, we demonstrated that expression of the GPAT Maole_006088.T1 encoding gene in Y. lipolytica effectively improved the titer and content of nervonic acid. This result indicated that regulating esterification specificity is also a strategy to overproduce tailored fatty acid species, while this strategy has not received enough attention.

Lipids play a vital function in the physiology of cells and lipid metabolism correlates with various organelles in eukaryotes26,56,57. The organelle ER is particularly critical in the elongation and desaturation of fatty acids and lipid formation. Biosynthesis of fatty acids require enzymes being targeted on ER. Here, we identified a hypothetical protein YlINO2 (AOW01275.1) in Y. lipolytica, which is possibly a counterpart of S. cerevisiae INO2. Overexpression of YlINO2 apparently improved the titer of both TAG and nervonic acid in Y. lipolytica, highlighting the significance of ER engineering for the production of lipids and tailored fatty acids (Table 1).

Some VLCFAs and VLCFA derived products have been utilized as lubricants, detergents, cosmetics and pharmaceuticals, such as EA, docosanol, and wax esters79,80,81. Microbial production of VLCFAs from renewable feedstocks presents a promising alternative route to sourcing these materials from plant oils or the petrochemical industry82,83.

In this study, we engineered the oleaginous yeast Y. lipolytica to produce the VLCUFA nervonic acid and achieved the highest reported titer to date, 17.3 g/L in a 50-L bioreactor, indicating a bright prospect for commercial use. Notably, a nervonic acid titer of 13.5 g/L in 5-L bioreactor73 was reported closely before this study posted on bioRxiv. In contrast to unsaturated fatty acids and long-chain saturated fatty acids, very long-chain saturated fatty acids (VLSFAs) have received limited attention. Interestingly, recent studies reported that arachidic acid (20: 0), behenic acid (22: 0), and lignoceric acid (24: 0) need to be distinguished from other saturated fatty acids for their potential health benefits in reducing risks of diabetes, heart disease mortality and aging84,85,86. Here, we engineered Y. lipolytica to produce the VLCFAs at 28.2 g/L in a 50-L bioreactor, indicating this oleaginous yeast is a superior host for the production of valuable VLCFAs.

Conclusion

In conclusion, this study engineered the oleaginous yeast Y. lipolytica to produce nervonic acid at a highest titer of 17.3 g/L reported to date by multi-level metabolic engineering. Enhancing the carbon flux toward fatty acid elongation efficiently improved the production of nervonic acid and total VLCFAs. Overexpression of the newly identified ER structure regulator YlINO2 resulted in a 39.3% increase in lipid production. Proof-of-concept purification and separation of nervonic acid generated a purity of 98.7%. These results showed a bright prospect for the production of nervonic acid and VLCFAs by oleaginous yeasts.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The authors declare that the data supporting the findings of this study are available within the Article and its Supplementary Information files. The source data for the graphs are available in Supplementary Data 2. Plasmids were deposited in Addgene (83442).

References

Dhobale, M. V., Wadhwani, N., Mehendale, S. S., Pisal, H. R. & Joshi, S. R. Reduced levels of placental long chain polyunsaturated fatty acids in preterm deliveries. Prostaglandins Leukot. Essent. Fat. Acids 85, 149–153 (2011).

Li, Q., Chen, J., Yu, X. & Gao, J. M. A mini review of nervonic acid: source, production, and biological functions. Food Chem. 301, 125286 (2019).

Lewkowicz, N. et al. Naturally occurring nervonic acid ester improves myelin synthesis by human oligodendrocytes. Cells 8, 786 (2019).

Terluk, M. R. et al. Nervonic acid attenuates accumulation of very long-chain fatty acids and is a potential therapy for Adrenoleukodystrophy. Neurotherapeutics 19, 1007–1017 (2022).

Astarita, G. et al. Elevated stearoyl-CoA desaturase in brains of patients with Alzheimer’s disease. PLoS One 6, e24777 (2011).

Hu, D., Cui, Y. & Zhang, J. Nervonic acid ameliorates motor disorder in mice with Parkinson’s Disease. Neurochem. J. 15, 317–324 (2021).

Song, W. et al. Cognitive improvement effect of nervonic acid and essential fatty acids on rats ingesting acer truncatum Bunge seed oil revealed by lipidomics approach. Food Funct. 13, 2475–2490 (2022).

Kageyama, Y. et al. Nervonic acid level in cerebrospinal fluid is a candidate biomarker for depressive and manic symptoms: a pilot study. Brain Behav. 11, 02075 (2021).

Kageyama, Y. et al. Plasma nervonic acid Is a potential biomarker for major depressive disorder: a pilot study. Int. J. Neuropsychopharmacol. 21, 207–215 (2018).

Delgado, G. E. et al. Individual omega-9 monounsaturated fatty acids and mortality-The Ludwigshafen Risk and Cardiovascular Health Study. J. Clin. Lipidol. 11, 126–135 (2017).

Keppley, L. J. W. et al. Nervonic acid limits weight gain in a mouse model of diet-induced obesity. FASEB J. 34, 15314–15326 (2020).

Chivandi, E., Davidson, B. C. & Erlwanger, K. H. A comparison of the lipid and fatty acid profiles from the kernels of the fruit (nuts) of Ximenia caffra and Ricinodendron rautanenii from Zimbabwe. Ind. Crops Prod. 27, 29–32 (2008).

Li, X. et al. Biomass, Biofuels and Bioproducts. Algal Res. 43, 101619 (2019)..

Liu, F. et al. 1-Aminocyclopropane-1-Carboxylate deaminase-producing plant growth-promoting rhizobacteria improve drought stress tolerance in grapevine (Vitis vinifera L). Front. Plant Sci. 12, 706990 (2021).

Tang, T. F. et al. Constituents of the essential oil and fatty acid from Malania oleifera. Ind. Crops Prod. 43, 1–5 (2013).

Qiao, Q., Xue, W. & Feng, Z. Variability of seed oil content, fatty acid composition, and nervonic acid content in <em>Acer truncatum</em>, native to 14 regions of China. Grasas Y Aceites 69, 274 (2018).

Fan, Y., Meng, H. M., Hu, G.-R. & Li, F. Biosynthesis of nervonic acid and perspectives for its production by microalgae and other microorganisms. Appl. Microbiol. Biotechnol. 102, 3027–3035 (2018).

Umemoto, H. et al. Fermentative production of nervonic acid by Mortierella capitata RD000969. J. Oleo Sci. 63, 671–679 (2014).

Yuan, C. et al. Mychonastes afer HSO-3-1 as a potential new source of biodiesel. Biotechnol. Biofuel 4, 47 (2011).

Li, J. X. et al. Disrupting a phospholipase A(2) gene increasing lipid accumulation in the oleaginous yeast Yarrowia lipolytica. J. Appl. Microbiol. 130, 100–108 (2021).

Xu, F. et al. Latitudinal adaptation and genetic insights into the origins of Cannabis sativa L. Front. Plant Sci. 9, 506 (2018).

Holkenbrink, C. et al. Production of moth sex pheromones for pest control by yeast fermentation. Metab. Eng. 62, 312–321 (2020).

Luo, Z. et al. Enhancing isoprenoid synthesis in Yarrowia lipolytica by expressing the isopentenol utilization pathway and modulating intracellular hydrophobicity. Metab. Eng. 61, 344–351 (2020).

Muhammad, A., Feng, X., Rasool, A., Sun, W. & Li, C. Production of plant natural products through engineered Yarrowia lipolytica. Biotechnol. Adv. 43, 107555 (2020). 107555.

Qiao, K., Wasylenko, T. M., Zhou, K., Xu, P. & Stephanopoulos, G. Lipid production in Yarrowia lipolytica is maximized by engineering cytosolic redox metabolism. Nat. Biotechnol. 35, 173–177 (2017).

Xu, P., Qiao, K., Ahn, W. S. & Stephanopoulos, G. Engineering Yarrowia lipolytica as a platform for synthesis of drop-in transportation fuels and oleochemicals. Proc. Natl Acad. Sci. USA 113, 10848–10853 (2016).

Abdel Mawgoud, A. M. et al. Metabolic engineering in the host Yarrowia lipolytica. Metab. Eng. 50, 192–208 (2018).

Miller, K. K. & Alper, H. S. Yarrowia lipolytica: more than an oleaginous workhorse. Appl. Microbiol. Biotechnol. 103, 9251–9262 (2019).

Xue, Z. et al. Production of omega-3 eicosapentaenoic acid by metabolic engineering of Yarrowia lipolytica. Nat. Biotechnol. 31, 734–740 (2013).

Sun, M. L. et al. Engineering Yarrowia lipolytica for efficient γ-linolenic acid production. Biochem. Eng. J. 117, 172–180 (2017).

Gemperlein, K. et al. Polyunsaturated fatty acid production by Yarrowia lipolytica employing designed myxobacterial PUFA synthases. Nat. Commun. 10, 4055 (2019).

Xie, D., Jackson, E. N. & Zhu, Q. Sustainable source of omega-3 eicosapentaenoic acid from metabolically engineered Yarrowia lipolytica: from fundamental research to commercial production. Appl. Microbiol. Biotechnol. 99, 1599–1610 (2015).

Tai, M. & Stephanopoulos, G. Engineering the push and pull of lipid biosynthesis in oleaginous yeast Yarrowia lipolytica for biofuel production. Metab. Eng. 15, 1–9 (2013).

Guo, Y. et al. Increase in nervonic acid content in transformed yeast and transgenic plants by introduction of a Lunaria annua L. 3-ketoacyl-CoA synthase (KCS) gene. Plant Mol. Biol. 69, 565–575 (2009).

Fillet, S. et al. Engineering Rhodosporidium toruloides for the production of very long-chain monounsaturated fatty acid-rich oils. Appl. Microbiol. Biotechnol. 101, 7271–7280 (2017).

Chen, Y. et al. The ACEII recombinant Trichoderma reesei QM9414 strains with enhanced xylanase production and its applications in production of xylitol from tree barks. Microb. Cell Factories 15, 215 (2016).

Kim, J.-E. et al. Tailoring the Saccharomyces cerevisiae endoplasmic reticulum for functional assembly of terpene synthesis pathway. Metab. Eng. 56, 50–59 (2019).

Avalos, J. L., Fink, G. R. & Stephanopoulos, G. Compartmentalization of metabolic pathways in yeast mitochondria improves the production of branched-chain alcohols. Nat. Biotechnol. 31, 335–341 (2013).

Lazar, Z., Liu, N. & Stephanopoulos, G. Holistic approaches in lipid production by Yarrowia lipolytica. Trends Biotechnol. 36, 1157–1170 (2018).

Schwartz, C., Shabbir Hussain, M., Frogue, K., Blenner, M. & Wheeldon, I. Standardized markerless gene integration for pathway engineering in Yarrowia lipolytica. ACS Synth. Biol. 6, 402–409 (2017).

Xiao, A., Jiang, X., Ni, H., Yang, Q. & Cai, H. Study on the relationship between intracellular metabolites and astaxanthin accumulation during Phaffia rhodozyma fermentation. Electron. J. Biotechnol. 18, 148–153 (2015).

Waterhouse, A. et al. SWISS-MODEL: Homology modelling of protein structures and complexes. Nucleic Acids Res. 46, 296–303 (2018).

Pettersen, E. F. et al. UCSF Chimera-a visualization system for exploratory research and analysis. J. Comput. Chem. 25, 1605–1612 (2004).

Trott, O. & Olson, A. J. AutoDock Vina: improving the speed and accuracy of docking with a new scoring function, efficient optimization, and multithreading. J. Comput. Chem. 31, 455–461 (2010).

Fan, Y., Yuan, C., Jin, Y., Hu, G.-R. & Li, F. L. Activation of interleukin-1β release by the classical swine fever virus is dependent on the NLRP3 inflammasome, which affects virus growth in monocytes. Algal Res. Biomass Biofuel Bioprod. 31, 225–231 (2018).

Yang, T. et al. The walnut transcription factor JrGRAS2 contributes to high temperature stress tolerance involving in Dof transcriptional regulation and HSP protein expression. BMC Plant Biol. 18, 367 (2018).

Notredame, C., Higgins, D. G. & Heringa, J. T-Coffee: A novel method for fast and accurate multiple sequence alignment. J. Mol. Biol. 302, 205–217 (2000).

Hessa, T. et al. Molecular code for transmembrane-helix recognition by the Sec61 translocon. Nature 450, 1026–1030 (2007).

Ojemalm, K., Botelho, S. C., Studle, C. & von Heijne, G. Quantitative analysis of SecYEG-mediated insertion of transmembrane α-helices into the bacterial inner membrane. J. Mol. Biol. 425, 2813–2822 (2013).

Omasits, U., Ahrens, C. H., Mueller, S. & Wollscheid, B. Protter: interactive protein feature visualization and integration with experimental proteomic data. Bioinformatics 30, 884–886 (2014).

Yang, J. et al. The I-TASSER Suite: protein structure and function prediction. Nat. Methods 12, 7–8 (2015).

Huai, D., Zhang, Y., Zhang, C., Cahoon, E. B. & Zhou, Y. Combinatorial effects of fatty acid elongase enzymes on nervonic acid production in camelina sativa. PLoS One 10, 0131755 (2015).

Singh, B. K., Bala, M. & Rai, P. K. Fatty acid composition and seed meal characteristics of Brassica and Allied Genera. Natl Acad. Sci. Lett. India 37, 219–226 (2014).

Sun, X. et al. Correction: Genetic diversity and population structure of rice pathogen ustilaginoidea virens in China. PLoS One 8, 12 (2013).

Trenkamp, S., Martin, W. & Tietjen, K. Specific and differential inhibition of very-long-chain fatty acid elongases from Arabidopsis thaliana by different herbicides. Proc. Natl Acad. Sci. USA 101, 11903–11908 (2004).

Kerner, J. & Hoppel, C. Fatty acid import into mitochondria. Biochim. Et. Biophys. Acta. Mol. Cell Biol. Lipids 1486, 1–17 (2000).

Yang, K. et al. Subcellular engineering of lipase dependent pathways directed towards lipid related organelles for highly effectively compartmentalized biosynthesis of triacylglycerol derived products in Yarrowia lipolytica. Metab. Eng. 55, 231–238 (2019).

Hiltunen, J. K. et al. Mitochondrial fatty acid synthesis type II: more than just fatty acids. J. Biol. Chem. 284, 9011–9015 (2009).

Malina, C., Larsson, C. & Nielsen, J. Yeast mitochondria: An overview of mitochondrial biology and the potential of mitochondrial systems biology. FEMS Yeast Res. 18, foy040 (2018).

Pedelacq, J. D., Cabantous, S., Tran, T., Terwilliger, T. C. & Waldo, G. S. Engineering and characterization of a superfolder green fluorescent protein. Nat. Biotechnol. 24, 79–88 (2006).

Smith, M. A. et al. Involvement of Arabidopsis ACYL-COENZYME A DESATURASE-LIKE2 (At2g31360) in the biosynthesis of the very-long-chain monounsaturated fatty acid components of membrane lipids. Plant Physiol. 161, 81–96 (2013).

Beopoulos, A. et al. Yarrowia lipolytica as a model for bio-oil production. Prog. Lipid Res. 48, 375–387 (2009).

Bai, Y. et al. X-ray structure of a mammalian stearoyl-CoA desaturase. Nature 524, 252–256 (2015).

Shi, H. B. et al. Fatty acid elongase 6 plays a role in the synthesis of long-chain fatty acids in goat mammary epithelial cells. J. Dairy Sci. 100, 4987–4995 (2017).

Yazawa, H., Kamisaka, Y., Kimura, K., Yamaoka, M. & Uemura, H. Efficient accumulation of oleic acid in Saccharomyces cerevisiae caused by expression of rat elongase 2 gene (rELO2) and its contribution to tolerance to alcohols. Appl. Microbiol. Biotechnol. 91, 1593–1600 (2011).

Frltzler, J. M., Millership, J. J. & Zhu, G. Cryptosporidium parvumlong-chain fatty acid elongase. Eukaryot. Cell 6, 2018–2028 (2007).

Wongwathanarat, P. et al. Two fatty acid delta9-desaturase genes, ole1 and ole2, from Mortierella alpina complement the yeast ole1 mutation. Microbiol. SGM 145, 2939–2946 (1999).

Watts, J. L. & Browse, J. A palmitoyl-CoA-specific delta9 fatty acid desaturase from Caenorhabditis elegans. Biochem. Biophys. Res. Commun. 272, 263–269 (2000).

Wan, X., Liang, Z., Gong, Y., Zhang, Y. & Jiang, M. Characterization of three Δ9-fatty acid desaturases with distinct substrate specificity from an oleaginous fungus Cunninghamella echinulata. Mol. Biol. Rep. 40, 4483–4489 (2013).

Schwank, S., Hoffmann, B. & Schuller, H. J. Influence of gene dosage and autoregulation of the regulatory genes INO2 and INO4 on inositol/choline-repressible gene transcription in the yeast Saccharomyces cerevisiae. Curr. Genet. 31, 462–468 (1997).

Fang, T. et al. Chromatin remodeling complexes are involvesd in the regulation of ethanol production during static fermentation in budding yeast. Genomics 112, 1674–1679 (2020).

Back, A., Rossignol, T., Krier, F., Nicaud, J. M. & Dhulster, P. High-throughput fermentation screening for the yeast Yarrowia lipolytica with real-time monitoring of biomass and lipid production. Microb. Cell Factories 15, 147 (2016). 147.

Wang, K., Lin, L., Wei, P., Ledesma-Amaro, R. & Ji, X.-J. Combining orthogonal plant and non-plant fatty acid biosynthesis pathways for efficient production of microbial oil enriched in nervonic acid in Yarrowia lipolytica Bioresour. Technol. 378, 129012 (2023).

Wang, Q. et al. Manipulating fatty-acid profile at unit chain-length resolution in the model industrial oleaginous microalgae Nannochloropsis. Metab. Eng. 66, 157–166 (2021).

Xin, Y. et al. Biosynthesis of triacylglycerol molecules with a tailored PUFA profile in industrial microalgae. Mol. Plant 12, 474–488 (2019).

Koerbes, A. P., Kulcheski, F. R., Margis, R., Margis-Pinheiro, M. & Turchetto Zolet, A. C. Molecular evolution of the lysophosphatidic acid acyltransferase (LPAAT) gene family. Mol. Phylogenet. Evol. 96, 55–69 (2016).

Liu, Q., Siloto, R. M. P., Lehner, R., Stone, S. J. & Weselake, R. J. Acyl-CoA:diacylglycerol acyltransferase: molecular biology, biochemistry and biotechnology. Prog. Lipid Res. 51, 350–377 (2012).

Jeppson, S., Mattisson, H., Demski, K. & Lager, I. A predicted transmembrane region in plant diacylglycerol acyltransferase 2 regulates specificity toward very-long-chain acyl-CoAs. J. Biol. Chem. 295, 15398–15406 (2020).

Gao, Q. et al. Yarrowia lipolytica as a metabolic engineering platform for the production of very-long-chain wax esters. J. Agric. Food Chem. 68, 10730–10740 (2020).

Taylor, D. C. et al. Biofuel Bioprod. Biorefin. 4, 538–561 (2010).

Yu, T. et al. Metabolic engineering of Saccharomyces cerevisiae for production of very long chain fatty acid-derived chemicals. Nat. Commun. 8, 14956 (2017).

Xu, Q. et al. Biotechnology in future food lipids: opportunities and challenges. Annu. Rev. Food Sci. Technol. 14, 225–246 (2023).

Phung, N. V., et al. Nervonic acid and its sphingolipids: Biological functions and potential food applications. Crit. Rev. Food Sci. Nutr. 28, 1–20 (2023).

Fretts, A. M. et al. Plasma ceramide species are associated with diabetes risk in participants of the strong heart study. J. Nutr. 150, 1214–1222 (2020).

Jensen, P. N. et al. Plasma ceramides and sphingomyelins in relation to atrial fibrillation risk: the cardiovascular health study. J. Am. Heart Assoc. 9, 012853 (2020).

Lemaitre, R. N. & King, I. B. Very long-chain saturated fatty acids and diabetes and cardiovascular disease. Curr. Opin. Lipidol. 33, 76–82 (2022).

Acknowledgements

This work was funded by National Key R&D Program of China (2022YFC2106200 and 2022YFE0207100), Shandong Energy Institute (SEI I202136), and Zhejiang Zhenyuan Biotech Co., LTD, China (Y86101190B).

Author information

Authors and Affiliations

Contributions

S.W., F.L. and W.F. conceived the project. S.W. and F.L. designed the experiments. H.M., H.S., X.H., P.S. and Z.M. constructed the engineered strains. H.S., C.Y., and Y.C. performed bioreactor fermentation. Z.S. and Y.F. performed the separation and purification experiments. S.W., H.S. and H.M. analyzed the data. S.W. and H.S. wrote the manuscript. S.W. and F.L. reviewed and edited the manuscript. All authors approved the final version.

Corresponding authors

Ethics declarations

Competing interests

The authors declare competing financial interests: S.W., F.L. and W.F. have filed patent applications on this work through Qingdao Institute of Bioenergy and Bioprocess Technology, CAS and Zhejiang Zhenyuan Biotech Co., LTD, China. S.W., F.L. and W.F. have commercial interests in Zhejiang Zhenyuan Biotech Co., LTD.

Peer review

Peer review information

Communications Biology thanks Xiao-Jun Ji and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Tobias Goris. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Su, H., Shi, P., Shen, Z. et al. High-level production of nervonic acid in the oleaginous yeast Yarrowia lipolytica by systematic metabolic engineering. Commun Biol 6, 1125 (2023). https://doi.org/10.1038/s42003-023-05502-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42003-023-05502-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.