Abstract

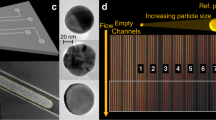

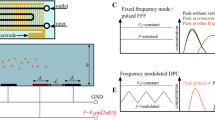

Solid catalysts are complex, multi-component materials with large interparticle heterogeneities that hamper statistically relevant in-depth catalyst characterization. Here we introduce an automated high-throughput screening and sorting method for catalyst particles. A droplet microreactor was developed for fluorescence-activated sorting of catalyst particles using dielectrophoresis. Fluid catalytic cracking (FCC) particles stained with styrene derivatives were analysed with the analytical platform developed and sorted based on catalytic activity. Highly active and low-to-moderately active catalyst particles were sorted using 4-fluorostyrene or 4-methoxystyrene as probe, respectively. FCC particles were encapsulated in liquid droplets, where fluorescent FCC particles activated the dielectrophoretic sorter and were sorted within 200 ms. Post-sorting analysis of 4-fluorostyrene-stained and sorted catalyst particles was done using fluorescence microscopy and micro-X-ray fluorescence. This confirmed that the sorted particles were the least deactivated and showed the highest acidity, while non-sorted particles contained more metal poisons.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Supplementary Videos 1–10 are included within the Supplementary information. Supplementary Videos 11–29 can be found in a data repository at https://doi.org/10.24435/materialscloud:em-r4. All data not added to the Supplementary Information or repository are available from the corresponding author on reasonable request.

References

Boudart, M. in Handbook of Heterogeneous Catalysis 2nd edn (eds Ertl, G. et al.) Ch. 1 (Wiley-VCH, 2008).

Hagen, J. Industrial Catalysis (Wiley-VCH, 2015).

Weckhuysen, B. M. Chemical imaging of spatial heterogeneities in catalytic solids at different length and time scales. Angew. Chem. Int. Ed. 48, 4910–4943 (2009).

Plessers, E. et al. Resolving interparticle heterogeneities in composition and hydrogenation performance between individual supported silver on silica catalysts. ACS Catal. 5, 6690–6695 (2015).

Buurmans, I. L. C. & Weckhuysen, B. M. Space and time as monitored by spectroscopy. Nat. Chem. 4, 873–886 (2012).

Sivaramakrishnan, M., Kothandan, R., Govindarajan, D. K., Meganathan, Y. & Kandaswamy, K. Active microfluidic systems for cell sorting and separation. Curr. Opin. Biomed. Eng. 13, 60–68 (2020).

Whitesides, G. M. The origins and the future of microfluidics. Nature 442, 368–373 (2006).

Auroux, P. A., Iossifidis, D., Reyes, D. R. & Manz, A. Micro total analysis systems. 2. Analytical standard operations and applications. Anal. Chem. 74, 2637–2652 (2002).

Reyes, D. R., Iossifidis, D., Auroux, P. A. & Manz, A. Micro total analysis systems. 1. Introduction, theory, and technology. Anal. Chem. 74, 2623–2636 (2002).

Jensen, K. F. Microchemical systems: status, challenges, and opportunities. AIChE J. 45, 2051–2054 (1999).

Yue, J., Schouten, J. C. & Nijhuis, T. A. Integration of microreactors with spectroscopic detection for online reaction monitoring and catalyst characterization. Ind. Eng. Chem. Res. 51, 14583–14609 (2012).

Pattekar, A. V. & Kothare, M. V. A microreactor for hydrogen production in micro fuel cell applications. J. Microelectromech. Syst. 13, 7–18 (2004).

Pennell, T. et al. Microfluidic chip to produce temperature jumps for electrophysiology. Anal. Chem. 80, 2447–2451 (2008).

Lin, J. L., Wu, M. H., Kuo, C. Y., Lee, K. D. & Shen, Y. L. Application of indium tin oxide (ITO)-based microheater chip with uniform thermal distribution for perfusion cell culture outside a cell incubator. Biomed. Microdevices 12, 389–398 (2010).

Crews, N., Wittwer, C., Palais, R. & Gale, B. Product differentiation during continuous-flow thermal gradient PCR. Lab Chip 8, 919–924 (2008).

Phatthanakun, R. et al. Fabrication and control of thin-film aluminum microheater and nickel temperature sensor. in Annual International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology 14–17 (IEEE ECTI-CON, 2011).

Miralles, V., Huerre, A., Malloggi, F. & Jullien, M.-C. A review of heating and temperature control in microfluidic systems: techniques and applications. Diagnostics 3, 33–67 (2013).

Chang, W.-Y. & Hsihe, Y.-S. Multilayer microheater based on glass substrate using MEMS technology. Microelectron. Eng. 149, 25–30 (2016).

Tiggelaar, R. M. et al. Fabrication of a high-temperature microreactor with integrated heater and sensor patterns on an ultrathin silicon membrane. Sens. Actuators A 119, 196–205 (2005).

Tiggelaar, R. M. et al. Thermal and mechanical analysis of a microreactor for high temperature catalytic gas phase reactions. Sens. Actuators A 112, 267–277 (2004).

Tiggelaar, R. M. et al. Fabrication and characterization of high-temperature microreactors with thin film heater and sensor patterns in silicon nitride tubes. Lab Chip 5, 326–336 (2005).

Casadevall, X. Droplet microfluidics: recent developments and future applications. Chem. Commun. 47, 1936–1942 (2011).

Kaminski, S. T. S. & Garstecki, P. As featured in: multistep chemical and biological assays. Chem. Soc. Rev. 46, 6210–6226 (2017).

Teh, S., Lin, R., Hung, L. & Lee, A. P. Droplet microfluidics. Lab Chip 8, 198–220 (2008).

Wen, N. et al. Development of droplet microfluidics enabling high-throughput single-cell analysis. Molecules 21, 881 (2016).

Baret, J. C. et al. Fluorescence-activated droplet sorting (FADS): efficient microfluidic cell sorting based on enzymatic activity. Lab Chip 9, 1850–1858 (2009).

Cerqueira, H. S., Caeiro, G., Costa, L. & Ribeiro, F. R. Deactivation of FCC catalysts. J. Mol. Catal. A 292, 1–13 (2008).

Vogt, E. T. C. & Weckhuysen, B. M. Fluid catalytic cracking: recent developments on the grand old lady of zeolite catalysis. Chem. Soc. Rev. 44, 7342–7370 (2015).

Letzsch, W. in Handbook of Petroleum Processing Vol. 1 (ed. Treese, S. A.) 262–312 (Springer, 2015).

Sadeghbeigi, R. Fluid Catalytic Cracking Handbook (Elsevier, 2012).

Biswas, J. & Maxwell, I. E. Recent process- and catalyst-related developments in fluid catalytic cracking. Appl. Catal. 63, 197–258 (1990).

Komvokis, V., Tan, L. X. L., Clough, M., Pan, S. S. & Yilmaz, B. in Zeolites in Sustainable Chemistry (eds Xiao, F.-S. & Meng, X.) 271–297 (Springer, 2016).

Wise, A. M. et al. Nanoscale chemical imaging of an individual catalyst particle with soft X‑ray ptychography. ACS Catal. 6, 2178–2181 (2016).

de Winter, D. A. M., Meirer, F. & Weckhuysen, B. M. FIB-SEM tomography probes the mesoscale pore space of an individual catalytic cracking particle. ACS Catal. 6, 3158–3167 (2016).

Mitchell, B. I. R. Metal contamination of cracking catalysts. Ind. Eng. Chem. Prod. Res. Dev. 19, 209–213 (1980).

Meirer, F. et al. Life and death of a single catalytic cracking particle. Sci. Adv. 1, e1400199 (2015).

Meirer, F. et al. Mapping metals incorporation of a whole single catalyst particle using element specific X-ray nanotomography. J. Am. Chem. Soc. 137, 102–105 (2015).

Meirer, F. et al. Agglutination of single catalyst particles during fluid catalytic cracking as observed by X-ray nanotomography. Chem. Commun. 51, 8097–8100 (2015).

Kalirai, S., Boesenberg, U., Falkenberg, G., Meirer, F. & Weckhuysen, B. M. X-ray fluorescence tomography of aged fluid-catalytic-cracking catalyst particles reveals insight into metal deposition processes. ChemCatChem 7, 3674–3682 (2015).

Liu, Y., Meirer, F., Krest, C. M., Webb, S. & Weckhuysen, B. M. Relating structure and composition with accessibility of a single catalyst particle using correlative 3-dimensional micro-spectroscopy. Nat. Commun. 7, 12634 (2016).

Ihli, J. et al. Localization and speciation of iron impurities within a fluid catalytic cracking catalyst. Angew. Chem. Int. Ed. 56, 14031–14035 (2017).

Ihli, J. et al. A three-dimensional view of structural changes caused by deactivation of fluid catalytic cracking catalysts. Nat. Commun. 8, 809 (2017).

Mathieu, Y., Corma, A., Echard, M. & Bories, M. Single and combined Fluidized Catalytic Cracking (FCC) catalyst deactivation by iron and calcium metal-organic contaminants. Appl. Catal. A 469, 451–465 (2014).

Karreman, M. A. et al. Probing the different life stages of a fluid catalytic cracking particle with integrated laser and electron microscopy. Chem. Eur. J. 19, 3846–3859 (2013).

Buurmans, I. L. C. et al. Catalytic activity in individual cracking catalyst particles imaged throughout different life stages by selective staining. Nat. Chem. 3, 862–867 (2011).

Dyrkacz, G. R., Ruscic, L., Marshall, C. L. & Reagan, W. Separation and characterization of FCC catalysts using density gradient separation. Energy Fuels 71, 849–854 (2000).

Solsona, M. et al. Magnetophoretic sorting of single catalyst particles. Angew. Chem. Int. Ed. 57, 10589–10594 (2018).

Gambino, M. et al. Nickel poisoning of a cracking catalyst unravelled by single particle X‐ray fluorescence‐diffraction-absorption tomography. Angew. Chem. Int. Ed. 59, 3922–3927 (2019).

Aramburo, L. R. et al. Styrene oligomerization as a molecular probe reaction for Brønsted acidity at the nanoscale. Phys. Chem. Chem. Phys. 14, 6967–6973 (2012).

Stavitski, E., Kox, M. H. F. & Weckhuysen, B. M. Revealing shape selectivity and catalytic activity trends within the pores of H-ZSM-5 crystals by time- and space-resolved optical and fluorescence microspectroscopy. Chem. Eur. J. 13, 7057–7065 (2007).

Leamon, J. H., Link, D. R., Egholm, M. & Rothberg, J. M. Overview: methods and applications for droplet compartmentalization of biology. Nat. Methods 3, 541–543 (2006).

Wolff, A. et al. Integrating advanced functionality in a microfabricated high-throughput fluorescent-activated cell sorter. Lab Chip 3, 22–27 (2003).

Huh, D. et al. Gravity-driven microfluidic particle sorting device with hydrodynamic separation amplification. Anal. Chem. 79, 1369–1376 (2007).

Xi, H.-D. et al. Active droplet sorting in microfluidics: a review. Lab Chip 17, 751–771 (2017).

Fiedler, S., Shirley, S. G., Schnelle, T. & Fuhr, G. Dielectrophoretic sorting of particles and cells in a microsystem. Anal. Chem. 70, 1909–1915 (1998).

Basu, A. S. Droplet morphometry and velocimetry (DMV): a video processing software for time-resolved, label-free tracking of droplet parameters. Lab Chip 13, 1892–1901 (2013).

Nieuwelink, A.-E. et al. Single particle essays to determine heterogeneities within fluid catalytic cracking catalysts. Chem. Eur. J. 26, 8546–8554 (2020).

Kerssens, M. M. et al. Photo-spectroscopy of mixtures of catalyst particles reveals their age and type. Faraday Discuss. 188, 69–79 (2016).

Agresti, J. J. et al. Ultra-high throughput screening in drop-based microfluidics for directed evolution. Proc. Natl Acad. Sci. USA 107, 4004–4009 (2010).

Van Den Brink, F. T. G. et al. A minaturized push–pull-perfusion probe for few-second sampling of neurotransmittors in the mouse brain. Lab Chip 19, 1332–1343 (2019).

Acknowledgements

This work was supported by the Netherlands Center for Multiscale Catalytic Energy Conversion, an NWO gravitation programme funded by the Ministry of Education, Culture and Science of the government of the Netherlands. We thank L. I. Segerink and K. Groothuis-Oudshoorn (both University of Twente, UT) for help with SPSS analysis. We thank F. Meirer (Utrecht University, UU) for scientific discussions and help regarding µXRF data analysis. We thank T. Hartman (UU) for the graphical abstract.

Author information

Authors and Affiliations

Contributions

This work is based on a collaboration between the BIOS Lab on a Chip group (UT) and the Inorganic Chemistry and Catalysis group (UU). A.-E.N., J.C.V. and M.O. conceptualized the microreactor and proof-of-principle reaction used in this work and carried out experiments. J.C.V. developed and fabricated the microreactors with help from J.G.B. and R.M.T. A.-E.N. performed ex situ post-sorting analysis. A.v.d.B., M.O. and B.M.W. conceptualized the idea of using microreactor technology for catalyst screening.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Catalysis thanks the anonymous reviewers for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–14, Methods, Discussion, Tables 1–7 and Videos 1–29.

Supplementary Video 1

Illustrative video of fluorescence-based DEP sorting of catalyst particles.

Supplementary Video 2

Video showing droplet manipulation using a.c. DEP.

Supplementary Video 3

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 4

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 5

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 6

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 7

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 8

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 9

Video related to the sorting results in Supplementary Table 6.

Supplementary Video 10

Video related to the sorting results in Supplementary Table 6.

Rights and permissions

About this article

Cite this article

Nieuwelink, AE., Vollenbroek, J.C., Tiggelaar, R.M. et al. High-throughput activity screening and sorting of single catalyst particles with a droplet microreactor using dielectrophoresis. Nat Catal 4, 1070–1079 (2021). https://doi.org/10.1038/s41929-021-00718-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-021-00718-7

This article is cited by

-

Accelerated discovery of molecular nanojunction photocatalysts for hydrogen evolution by using automated screening and flow synthesis

Nature Synthesis (2024)

-

Droplet microreactor for high-throughput fluorescence-based measurements of single catalyst particle acidity

Microsystems & Nanoengineering (2023)