Abstract

Copper-zinc-alumina catalysts are used industrially for methanol synthesis from feedstock containing carbon monoxide and carbon dioxide. The high performance of the catalyst stems from synergies that develop between its components. This important catalytic system has been investigated with a myriad of approaches, however, no comprehensive agreement on the fundamental source of its high activity has been reached. One potential source of disagreement is the considerable variation in pressure used in studies to understand a process that is performed industrially at pressures above 20 bar. Here, by systematically studying the catalyst state during temperature-programmed reduction and under carbon dioxide hydrogenation with in situ and operando X-ray absorption spectroscopy over four orders of magnitude in pressure, we show how the state and evolution of the catalyst is defined by its environment. The structure of the catalyst shows a strong pressure dependence, especially below 1 bar. As pressure gaps are a general problem in catalysis, these observations have wide-ranging ramifications.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article (and its Supplementary Information files) or can be obtained from the authors on reasonable request.

References

Topsøe, H. Developments in operando studies and in situ characterization of heterogeneous catalysts. J. Catal. 216, 155–164 (2003).

Behrens, M. et al. The active site of methanol synthesis over Cu/ZnO/Al2O3 industrial catalysts. Science 336, 893–897 (2012).

Roy, K., Artiglia, L. & van Bokhoven, J. A. Ambient pressure photoelectron spectroscopy: opportunities in catalysis from solids to liquids and introducing time resolution. ChemCatChem 10, 666–682 (2018).

Artiglia, L. et al. Introducing time resolution to detect Ce3+ catalytically active sites at the Pt/CeO2 interface through ambient pressure X-ray photoelectron spectroscopy. J. Phys. Chem. Lett. 8, 102–108 (2017).

Artiglia, L. et al. In situ X-ray photoelectron spectroscopy detects multiple active sites involved in the selective anaerobic oxidation of methane in copper-exchanged zeolites. ACS Catal. 9, 6728–6737 (2019).

Hansen, P. L. et al. Atom-resolved imaging of dynamic shape changes in supported copper nanocrystals. Science 295, 2053–2055 (2002).

Creemer, J. F. et al. Atomic-scale electron microscopy at ambient pressure. Ultramicroscopy 108, 993–998 (2008).

Ek, M., Ramasse, Q. M., Arnarson, L., Georg Moses, P. & Helveg, S. Visualizing atomic-scale redox dynamics in vanadium oxide-based catalysts. Nat. Commun. 8, 305 (2017).

Huang, X. et al. Atomic-scale observation of the metal-promoter interaction in Rh-based syngas upgrading catalysts. Angew. Chem. Int. Ed. 58, 8709–8713 (2019).

Dry, M. E. in Handbook of Heterogeneous Catalysis 2nd edn (ed. Ertl, G. et al.) 2965–2994 (Wiley, 2008).

Schlögl, R. in Handbook of Heterogeneous Catalysis 2nd edn (ed. Ertl, G. et al.) 2501–2575 (Wiley, 2008).

Hinrichsen, K.-O., Kochloefl, K. & Muhler, M. in Handbook of Heterogeneous Catalysis 2nd edn (ed. Ertl, G. et al.) 2905–2920 (Wiley, 2008).

Hansen, J. B. & Højlund Nielsen, P. E. in Handbook of Heterogeneous Catalysis 2nd edn (ed. Ertl, G. et al.) 2920–2949 (Wiley, 2008).

Stoltze, P. & Nørskov, J. K. Bridging the ‘pressure gap’ between ultrahigh-vacuum surface physics and high-pressure catalysis. Phys. Rev. Lett. 55, 2502–2505 (1985).

Reece, C., Redekop, E. A., Karakalos, S., Friend, C. M. & Madix, R. J. Crossing the great divide between single-crystal reactivity and actual catalyst selectivity with pressure transients. Nat. Catal. 1, 852–859 (2018).

Goodman, D. W. Model studies in catalysis using surface science probes. Chem. Rev. 95, 523–536 (1995).

Freund, H. J. Model studies in heterogeneous catalysis. Chemistry 16, 9384–9397 (2010).

Campbell, C. T. Energies of adsorbed catalytic intermediates on transition metal surfaces: calorimetric measurements and benchmarks for theory. Acc. Chem. Res. 52, 984–993 (2019).

Esposito, D. Mind the gap. Nat. Catal. 1, 807–808 (2018).

Barcaro, G. et al. Building principles and structural motifs in TiOx ultrathin films on a (111) substrate. J. Phys. Chem. C 116, 13302–13306 (2012).

Bron, M. et al. Bridging the pressure and materials gap: in-depth characterisation and reaction studies of silver-catalysed acrolein hydrogenation. J. Catal. 234, 37–47 (2005).

van Spronsen, M. A., Frenken, J. W. M. & Groot, I. M. N. Surface science under reaction conditions: CO oxidation on Pt and Pd model catalysts. Chem. Soc. Rev. 46, 4347–4374 (2017).

Oosterbeek, H. Bridging the pressure and material gap in heterogeneous catalysis: cobalt Fischer–Tropsch catalysts from surface science to industrial application. Phys. Chem. Chem. Phys. 9, 3570–3576 (2007).

Corma, A., Serna, P., Concepción, P. & Calvino, J. J. Transforming nonselective into chemoselective metal catalysts for the hydrogenation of substituted nitroaromatics. J. Am. Chem. Soc. 130, 8748–8753 (2008).

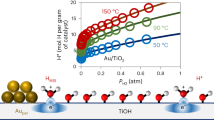

Kattel, S., Ramírez, P. J., Chen, J. G., Rodriguez, J. A. & Liu, P. Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts. Science 355, 1296–1299 (2017).

Kattel, S., Ramírez, P. J., Chen, J. G., Rodriguez, J. A. & Liu, P. Response to Comment on ‘Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts’. Science 357, eaan8210 (2017).

Nakamura, J. et al. Comment on ‘Active sites for CO2 hydrogenation to methanol on Cu/ZnO catalysts’. Science 357, eaan8074 (2017).

Kondrat, S. A. et al. Stable amorphous georgeite as a precursor to a high-activity catalyst. Nature 531, 83–87 (2016).

Nakamura, J., Choi, Y. & Fujitani, T. On the issue of the active site and the role of ZnO in Cu/ZnO methanol synthesis catalysts. Top. Catal. 22, 277–285 (2003).

Grunwaldt, J.-D., Molenbroek, A., Topsøe, N.-Y., Topsøe, H. & Clausen, B. In situ investigations of structural changes in Cu/ZnO catalysts. J. Catal. 194, 452–460 (2000).

Kuld, S. et al. Quantifying the promotion of Cu catalysts by ZnO for methanol synthesis. Science 352, 969–974 (2016).

Frei, E. et al. Cu−Zn alloy formation as unfavored state for efficient methanol catalysts. ChemCatChem 12, 4029–4033 (2020).

Lunkenbein, T. et al. Bridging the time gap: a copper/zinc oxide/aluminum oxide catalyst for methanol synthesis studied under industrially relevant conditions and time scales. Angew. Chem. Int. Ed. 55, 12708–12712 (2016).

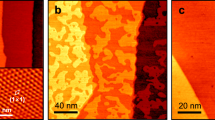

Lunkenbein, T., Schumann, J., Behrens, M., Schlögl, R. & Willinger, M. G. Formation of a ZnO overlayer in industrial Cu/ZnO/Al2O3 catalysts induced by strong mMetal-support interactions. Angew. Chem. Int. Ed. 54, 4544–4548 (2015).

Wagner, J. B. et al. In situ electron energy loss spectroscopy studies of gas-dependent metal–support interactions in Cu/ZnO catalysts. J. Phys. Chem. B 107, 7753–7758 (2003).

Kuld, S., Conradsen, C., Moses, P. G., Chorkendorff, I. & Sehested, J. Quantification of zinc atoms in a surface alloy on copper in an industrial-type methanol synthesis catalyst. Angew. Chem. Int. Ed. 53, 5941–5945 (2014).

Divins, N. J. et al. Operando high-pressure investigation of size-controlled CuZn catalysts for the methanol synthesis reaction. Nat. Commun. 12, 1435 (2021).

Frost, J. C. Junction effect interactions in methanol synthesis catalysts. Nature 334, 577–580 (1988).

Schott, V. et al. Chemical activity of thin oxide layers: strong interactions with the support yield a new thin-film phase of ZnO. Angew. Chem. Int. Ed. 52, 11925–11929 (2013).

Zander, S. et al. The role of the oxide component in the development of copper composite catalysts for methanol synthesis. Angew. Chem. Int. Ed. 52, 6536–6540 (2013).

Spencer, M. S. α-brass formation in copper/zinc oxide catalysts: III. Surface segregation of zinc in α-brass. Surf. Sci. 192, 336–343 (1987).

Clausen, B. S. & Topsøe, H. In situ high pressure, high temperature XAFS studies of Cu-based catalysts during methanol synthesis. Catal. Today 9, 189–196 (1991).

Holse, C. et al. Dynamic behavior of CuZn nanoparticles under oxidizing and reducing conditions. J. Phys. Chem. C 119, 2804–2812 (2015).

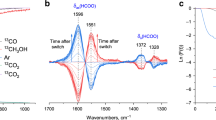

Martin, O. et al. Operando synchrotron X-ray powder diffraction and modulated-excitation infrared spectroscopy elucidate the CO2 promotion on a commercial methanol synthesis catalyst. Angew. Chem. Int. Ed. 55, 11031–11036 (2016).

Fujitani, T. & Nakamura, J. The effect of ZnO in methanol synthesis catalysts on Cu dispersion and the specific activity. Catal. Lett. 56, 119–124 (1998).

Zabilskiy, M. et al. The unique interplay between copper and zinc during catalytic carbon dioxide hydrogenation to methanol. Nat. Commun. 11, 2409 (2020).

Frahm, R. et al. The dedicated QEXAFS facility at the SLS: performance and scientific opportunities. AIP Conf. Proc. 1234, 251–255 (2010).

Moog, I., Prestipino, C., Figueroa, S., Majimel, J. & Demourgues, A. Dual Ce4+/Fe3+ redox phenomena into nanocrystalline Ce1−xFexO2−x/2 solid solution. J. Phys. Chem. C 118, 22746–22753 (2014).

Hsu, H. S. et al. Evidence of oxygen vacancy enhanced room-temperature ferromagnetism in Co-doped ZnO. Appl. Phys. Lett. 88, 242507 (2006).

Neogi, S. K., Ahmed, M. A., Banerjee, A. & Bandyopadhyay, S. Enhanced ferromagnetism by ion irradiation for substitutionally cobalt doped ZnO films. Appl. Surf. Sci. 481, 443–453 (2019).

Kuzmin, A., Larcheri, S. & Rocca, F. Zn K-edge XANES in nanocrystalline ZnO. J. Phys. Conf. Ser. 93, 2–8 (2007).

Słoczyn ́ski, J. & Bobin ́ski, W. Autocatalytic effect in the processes of metal oxide reduction. I. Kinetic model of the reduction. J. Solid State Chem. 92, 420–435 (1991).

Voge, H., & Atkins, L. T. Uniformity of supported CuO from rate of reduction with hydrogen. J. Catal. 1, 171–179 (1962).

Rodriguez, J. A., Kim, J. Y., Hanson, J. C., Pérez, M. & Frenkel, A. I. Reduction of CuO in H2: in situ time-resolved XRD studies. Catal. Lett. 85, 247–254 (2003).

Vesborg, P. C. K. et al. Transient behavior of Cu/ZnO-based methanol synthesis catalysts. J. Catal. 262, 65–72 (2009).

Beck, A. et al. The dynamics of overlayer formation on catalyst nanoparticles and strong metal-support interaction. Nat. Commun. 11, 3220 (2020).

Laudenschleger, D., Ruland, H. & Muhler, M. Identifying the nature of the active sites in methanol synthesis over Cu/ZnO/Al2O3 catalysts. Nat. Commun. 11, 3898 (2020).

Zabilskiy, M., Sushkevich, V. L., Newton, M. A. & van Bokhoven, J. A. Copper–zinc alloy-free synthesis of methanol from carbon dioxide over Cu/ZnO/faujasite. ACS Catal. 10, 14240–14244 (2020).

Newton, M. A. et al. Unwanted effects of X-rays in surface grafted copper(ii) organometallics and copper exchanged zeolites, how they manifest, and what can be done about them. Phys. Chem. Chem. Phys. 22, 6826–6837 (2020).

Chupas, P. J. et al. A versatile sample-environment cell for non-ambient X-ray scattering experiments. J. Appl. Crystallogr. 41, 822–824 (2008).

Clark, A. H., Imbao, J., Frahm, R. & Nachtegaal, M. ProQEXAFS: a highly optimized parallelized rapid processing software for QEXAFS data. J. Synchrotron Radiat. 27, 551–557 (2020).

Figueroa, S. J. A. & Prestipino, C. PrestoPronto: a code devoted to handling large data sets. J. Phys. Conf. Ser. 712, 012012 (2016).

Binsted, N. EXCURV98 (CCLRC Daresbury Laboratory, 1998).

Binsted, N., Strange, R. W. & Hasnain, S. S. Constrained and restrained refinement in EXAFS data analysis with curved wave theory. Jpn. J. Appl. Phys. 32, 141–143 (1993).

Acknowledgements

We thank H. Frey, D. Cartagenova, I. Sadykov and M. Ghosalya for support during the beamtime experiments; Z. Jovanovic for discussion on the kinetics; F. Krumeich for the provided electron microscopy. The authors also thank A. Clark for providing access to the ProXAS program for qXAS spectra calibration, normalization and SIMPLISIMA-LCF analysis. Part of this work was performed at the Swiss Light Source, Paul Scherrer Institute, Switzerland. We acknowledge the Swiss Light Source for providing synchrotron radiation beamtime at the SuperXAS beamline. A.B. and J.A.v.B. acknowledge the SNSF project 200021_178943. M.W. acknowledges funding from the SNSF project 200021_181053. M.A.N. acknowledges Shell Global Solutions for the part funding of his position.

Author information

Authors and Affiliations

Contributions

A.B. wrote the manuscript. A.B., M.Z. and O.S. conducted the experiments and performed the data analysis. M.A.N. contributed the EXAFS analysis. A.B., M.W. and J.A.v.B. designed the study. All authors participated in discussions and writing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Catalysis thanks Janis Timoshenko and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–5, Figs. 1–22 and Tables 1–4.

Rights and permissions

About this article

Cite this article

Beck, A., Zabilskiy, M., Newton, M.A. et al. Following the structure of copper-zinc-alumina across the pressure gap in carbon dioxide hydrogenation. Nat Catal 4, 488–497 (2021). https://doi.org/10.1038/s41929-021-00625-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-021-00625-x

This article is cited by

-

Reverse water gas-shift reaction product driven dynamic activation of molybdenum nitride catalyst surface

Nature Communications (2024)

-

A Ce-CuZn catalyst with abundant Cu/Zn-OV-Ce active sites for CO2 hydrogenation to methanol

Nature Communications (2024)

-

Visualizing the gas-sensitive structure of the CuZn surface in methanol synthesis catalysis

Nature Communications (2024)

-

Low-nuclearity CuZn ensembles on ZnZrOx catalyze methanol synthesis from CO2

Nature Communications (2024)

-

Unraveling the evolution of oxygen vacancies in TiO2−x/Cu and its role in CO2 hydrogenation

Science China Chemistry (2024)