Abstract

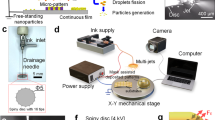

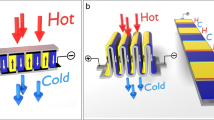

Microthermoelectric modules can be used as energy harvesters, active coolers and thermal sensors in integrated systems. However, manufacturing such modules with traditional microfabrication processes is costly and produces only two-dimensional thermoelectric films, which limit the formation of high-temperature gradients and thus the amount of power generated. Here we show that microscale three-dimensional thermoelectric architectures can be fabricated through the direct writing of particle-based thermoelectric inks. Using size control and surface oxidation, the characteristics of (Bi,Sb)2(Te,Se)3-based particle inks are engineered to create colloidal inks with high viscoelasticity and without organic binders, and the inks are directly written into complex architectures using a 3D printing process. The resulting structures exhibit high thermoelectric figures of merit of 1.0 (p type) and 0.5 (n type), which are comparable to those of bulk ingots. Microthermoelectric generators made from three-dimensionally written vertical filaments exhibit large temperature gradients and a power density of 479.0 μW cm–2.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Haras, M. & Skotnicki, T. Thermoelectricity for IoT—A review. Nano Energy 54, 461–476 (2018).

Ando, J. et al. A review of the development and applications of thermoelectric microgenerators for energy harvesting. Renew. Sustain. Energy Rev. 91, 376–393 (2018).

Pletcher, N. M. et al. A 52 μW wake-up receiver with –72 dBm sensitivity using an uncertain-IF architecture. IEEE J. Solid-State Circuits 44, 269–280 (2009).

Gilbert, J. M. & Balouchi, F. Comparison of energy harvesting systems for wireless sensor networks. Inter. J. Autom. Comput. 5, 334–347 (2008).

Zhang, Y. et al. A batteryless 19 μW MICS/ISM-band energy harvesting body sensor node SoC for ExG applications. IEEE J. Solid-State Circuits 48, 199–213 (2013).

Yan, J. et al. Review of micro thermoelectric generator. J. Microelectromech. Syst. 27, 1–18 (2018).

Rabaey, J. M. et al. PicoRadios for wireless sensor networks: the next challenge in ultra-low power design. In 2002 IEEE ISSCC Digest of Technical Papers, 200–201 (2002).

Park, S. C. et al. A micro-thermoelectric gas sensor for detection of hydrogen and atomic oxygen. Analyst 134, 236–242 (2009).

Blachowicz, T. & Ehrmann, A. 3D printed MEMS technology—recent developments and applications. Micromachines 11, 434 (2020).

Dhawan, R. et al. Si0.97Ge0.03 microelectronic thermoelectric generators with high power and voltage densities. Nat. Commun. 11, 4362 (2020).

Li, G. et al. Integrated microthermoelectric coolers with rapid response time and high device reliability. Nat. Electron. 1, 555–561 (2018).

Hong, C. T. et al. Spray-printed CNT/P3HT organic thermoelectric films and power generators. J. Mater. Chem. A 3, 21428–21433 (2015).

Wang, Y. et al. Flexible thermoelectric materials and generators: challenges and innovations. Adv. Mater. 31, 29 (2019).

Mehran, M. & Zorman, C. A. SiC MEMS: opportunities and challenges for applications in harsh environments. Thin Solid Films 355–356, 518–524 (1999).

Davidson, E. C. et al. 3D printable and reconfigurable liquid crystal elastomers with light-induced shape memory via dynamic bond exchange. Adv. Mater. 32, 1 (2020).

Hensleigh, R. et al. Charge-programmed three-dimensional printing for multi-material electronic devices. Nat. Electron. 3, 216–224 (2020).

Vyatskikh, A. et al. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 9, 593 (2018).

Lewis, J. A. & Ahn, B. Y. Device fabrication: three-dimensional printed electronics. Nature 518, 42–43 (2015).

Sun, K. et al. 3D printing of interdigitated Li-ion microbattery architectures. Adv. Mater. 25, 4539–4543 (2013).

Lewis, J. A. Direct ink writing of 3D functional materials. Adv. Funct. Mater. 16, 2193–2204 (2006).

Jo, S. et al. Ink processing for thermoelectric materials and power-generating devices. Adv. Mater. 31, 1804930 (2019).

Zhang, B. et al. Promising thermoelectric properties of commercial PEDOT:PSS materials and their Bi2Te3 powder composites. ACS Appl. Mater. Interfaces 2, 3170–3178 (2010).

Kato, K. et al. Fabrication of bismuth telluride thermoelectric films containing conductive polymers using a printing method. J. Electron. Mater. 42, 1313–1318 (2013).

Ou, C. et al. Fully printed organic–inorganic nanocomposites for flexible thermoelectric applications. ACS Appl. Mater. Interfaces 10, 19580–19587 (2018).

He, M. et al. Thermopower enhancement in conducting polymer nanocomposites via carrier energy scattering at the organic–inorganic semiconductor interface. Energy Environ. Sci. 5, 8351–8358 (2012).

Burton, M. R. et al. 3D printed SnSe thermoelectric generators with high figure of merit. Adv. Energy Mater. 9, 1900201 (2019).

Su, N. et al. 3D-printing of shape-controllable thermoelectric devices with enhanced output performance. Energy 195, 116892 (2020).

Kim, F. et al. 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nat. Energy 3, 301–309 (2018).

Yang, S. E. et al. Composition-segmented BiSbTe thermoelectric generator fabricated by multimaterial 3D printing. Nano Energy 81, 105638 (2021).

Kim, S. I. et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348, 109–114 (2015).

Li, J.-F. et al. High-performance nanostructured thermoelectric materials. NPG Asia Mater. 2, 152–158 (2010).

Saeidi-Javash, M. et al. 3D conformal printing and photonic sintering of high-performance flexible thermoelectric films using 2D nanoplates. Adv. Funct. Mater. 29, (2019).

Snyder, G. J. & Toberer, E. S. Complex thermoelectric materials. Nat. Mater. 7, 105–114 (2008).

Bark, H. et al. Effect of multiwalled carbon nanotubes on the thermoelectric properties of a bismuth telluride matrix. Curr. Appl. Phys. 13, S111–S114 (2013).

Willenbacher, N. & Georgieva, K. in Product Design and Engineering: Formulation of Gels and Pastes (eds Bröckel, U et al.) Ch. 1, 7–49 (Wiley, 2013).

Barthelmes, G. et al. Particle size distributions and viscosity of suspensions undergoing shear-induced coagulation and fragmentation. Chem. Eng. Sci. 58, 2893–2902 (2003).

Luckham, P. F. & Ukeje, M. A. Effect of particle size distribution on the rheology of dispersed systems. J. Colloid Interface Sci. 220, 347–356 (1999).

Chen, Z. et al. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceram. Int. 45, 11549–11557 (2019).

Maranzano, B. J. & Wagner, N. J. The effects of interparticle interactions and particle size on reversible shear thickening: hard-sphere colloidal dispersions. J. Rheol. 45, 1205–1222 (2001).

Eom, Y. et al. Rheological design of 3D printable all-inorganic inks using BiSbTe-based thermoelectric materials. J. Rheol. 63, 291–304 (2019).

Hong, B. J. et al. Successful stabilization of graphene oxide in electrolyte solutions: enhancement of biofunctionalization and cellular uptake. ACS Nano 6, 63–73 (2012).

Zheng, G. et al. High thermoelectric performance of p-BiSbTe compounds prepared by ultra-fast thermally induced reaction. Energy Environ. Sci. 10, 2638–2652 (2017).

Lidorenko, N. S. et al. Influence of porosity and intergrain-boundary quality on the electrical and thermal conductivities of semiconductive thermoelectric materials. Inorg. Mater. 6, 1853 (1970).

Wu, C.-A. et al. Low thermal conductivity and enhanced zT values of porous and nanostructured Cu1–xNix alloys. Chem. Eng. J. 368, 409–416 (2019).

Khan, A. U. et al. Nano-micro-porous skutterudites with 100% enhancement in ZT for high performance thermoelectricity. Nano Energy 31, 152–159 (2017).

Chang, P. H. et al. Giant thermoelectric effect in graphene-based topological insulators with heavy adatoms and nanopores. Nano Lett. 14, 3779–3784 (2014).

Ning, H. et al. Enhanced thermoelectric performance of porous magnesium tin silicide prepared using pressure-less spark plasma sintering. J. Mater. Chem. A 3, 17426–17432 (2015).

Yan, X. et al. Experimental studies on anisotropic thermoelectric properties and structures of n-type Bi2Te2.7Se0.3. Nano Lett. 10, 3373–3378 (2010).

Rojas, J. P. et al. Review—Micro and nano-engineering enabled new generation of thermoelectric generator devices and applications. ECS J. Solid State Sci. Technol. 6, N3036–N3044 (2017).

Francioso, L. et al. Flexible thermoelectric generator for ambient assisted living wearable biometric sensors. J. Power Sources 196, 3239–3243 (2011).

Paradiso, J. A. & Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 4, 18–27 (2005).

Pashinkin, A. S. et al. The heat capacity of solid antimony telluride Sb2Te3. Russ. J. Phys. Chem. 82, 878–879 (2008).

Liu, W. et al. Studies on the Bi2Te3–Bi2Se3–Bi2S3 system for mid-temperature thermoelectric energy conversion. Energy Environ. Sci. 6, 552–560 (2013).

Kim, M. & Cha, C. Modulation of functional pendant chains within poly(ethylene glycol) hydrogels for refined control of protein release. Sci. Rep. 8, 4315 (2018).

Acknowledgements

This work was supported by the Samsung Research Funding Center of Samsung Electronics under project no. SRFC-MA1801–05. J.S.S. acknowledges the Nano-Material Technology Development Program (NRF-2018M3A7B8060697) and the Creative Materials Discovery Program (NRF-2020M3D1A1110502) through the National Research Foundation (NRF) funded by the Ministry of Science and ICT, Republic of Korea.

Author information

Authors and Affiliations

Contributions

F.K., S.E.Y., H.J., H.G.C. and J.S.S. designed the experiments, analysed the data and wrote the paper. F.K., S.E.Y., S.C., J.L., J.S.S. and K.T.K. carried out the synthesis and basic characterization of the materials. S.E.Y., H.J. and H.G.C. performed the characterization of rheological properties. F.K., S.E.Y., G.K. and S.A. performed the characterization of thermoelectric properties. F.K. and S.E.Y. carried out the fabrication and measurement of TEGs. S.K. and C.C. performed the synthesis of hydrogels. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Electronics thanks Yanzhong Pei, Kyu Huong Lee and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–21, Tables 1 and 2, discussion and references.

Supplementary Video 1

Printing of a TE filament.

Supplementary Video 2

Printing of a 3D lattice.

Supplementary Video 3

Printing of p- and n-type TE filaments on a Si/SiO2 substrate.

Rights and permissions

About this article

Cite this article

Kim, F., Yang, S.E., Ju, H. et al. Direct ink writing of three-dimensional thermoelectric microarchitectures. Nat Electron 4, 579–587 (2021). https://doi.org/10.1038/s41928-021-00622-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-021-00622-9

This article is cited by

-

Gradient matters via filament diameter-adjustable 3D printing

Nature Communications (2024)

-

High-performance wood-based thermoelectric sponges for thermal energy harvesting and smart buildings

Nano Research (2024)

-

Additive manufacturing of thermoelectric materials: materials, synthesis and manufacturing: a review

Journal of Materials Science (2024)

-

On-Chip Micro Temperature Controllers Based on Freestanding Thermoelectric Nano Films for Low-Power Electronics

Nano-Micro Letters (2024)

-

Three dimensional architected thermoelectric devices with high toughness and power conversion efficiency

Nature Communications (2023)