Abstract

Anchored Single-atom catalysts have emerged as a cutting-edge research field holding tremendous appeal for applications in the fields of chemicals, energy and the environment. However, single-atom-catalysts for crystal growth is a nascent field. Of the few studies available, all of them are based on state-of-the-art in situ microscopy investigations and computational studies, and they all look at the growth of monolayer graphene from a single-atom catalyst. Despite the limited number of studies, they do, collectively, represent a new sub-field of single-atom catalysis, namely single-atom catalytic growth of crystalline solids. In this review, we examine them on substrate-supported and as freestanding graphene fabrication, as well as rolled-up graphene, viz., single-walled carbon nanotubes (SWCNT), grown from a single atom. We also briefly discuss the catalytic etching of graphene and SWCNT’s and conclude by outlining the future directions we envision this nascent field to take.

Similar content being viewed by others

Introduction

Catalysts are a major contributor to the global economy. Over 90% of chemical processes require catalysts and there is a continuous demand for the development of more effective, inexpensive, and green catalysts to secure a sustainable future for our society1. As defined by Berzelius in 1835, a catalyst is a substance capable of accelerating the rate of a chemical reaction without being consumed2. Broadly speaking, there are two groups of catalysts, namely, homogeneous catalysis in which the catalyst is in the same phase as the reactants during the reaction, and heterogeneous catalysis where the catalyst and reactants are in two distinct phases. Because of challenges in separating homogenous catalysts from the reaction product as well as the fact that most are somewhat thermally unstable, most industrial catalysts (ca. 80%) are heterogeneous catalysts1,3. Typically, heterogenous catalytic properties are sensitive to their surface heterogeneity and structure. For instance, metal catalysts are affected by their terminating atom coordination and so steps sites, kinks, vacancies, staking faults and twin boundaries all affect their performance. Moreover, the size of metal particles is also an important factor governing performance4 and has helped drive the use of nanoparticles as catalysts. However, because of surface defects it is near impossible to fabricate two identical nanoparticles. One approach to address this complex issue is to reduce the size of a metal particle down to the atomic level, viz., a single atom serving as a catalyst and in this case there is no longer any surface heterogeneity1. Aside from providing high specific activity, single-atom catalysts (SAC) reduce cost and this is particularly important for expensive noble metals such as Pt, Pd, Ru, Rh and Ir which are important to the petrochemical industry, medicine production, environmental protection and energy applications5. Single-atom catalysts are nearly always prepared on a support material (e.g. metal oxide, metal carbide, carbon nitride, graphene and various other two-dimensional (2D) materials)6,7 and can even be produced at scale now8. SAC’s have compelling properties in that each atom is accessible for the catalytic reaction (100% atomic efficiency), often the metal atom-support interaction enhances charge transfer between the two and they have unsaturated coordination unlike metal clusters which can lower activation energies7,9. SACs resemble heterogenous catalysts since they are immobilized on supports that can be relatively easily separated and re-used. While they also resemble homogeneous catalysts since the strong metal atom-support interactions yield electronic properties similar to those in organo-metallic complexes7. SACs are advantageous in comparison to other heterogeneous catalysts because one can also tune the coordination environment of a single atom. Typically, this is achieved by altering the type of coordinating atoms on the support6. Indeed, the use of isolated single atoms is the most effective method with which to obtain optimal active sites in corresponding catalysts so as to maximize the metal atom efficiency and maintain the necessary catalytic performances5,10,11.

The field of SACs is a highly dynamic and fast-evolving field and can be expected to continue to develop strongly. However, despite the growing body of research on SACs, very little research exists on the use of single atoms for the catalytic growth of crystalline materials. Remarkably, in our extensive literature survey we only found examples based on the growth of a single crystalline material - graphene. Perhaps this is not surprising given the large body of research on graphene and moreover, as a single element 2D material it is technically less challenging to investigate. Of the few studies we found, all are based on state-of-the-art in situ microscopy investigations as well as supporting theoretical studies. Despite the limited number of studies for SAC crystal growth, they do, collectively, represent a new sub-field of SACs, namely single-atom catalytic growth of crystalline solids.

The use of SACs for crystal growth is crucial at the nanoscale, because, as for bulk solids the material’s crystal structure determines its properties, however, at the nanoscale the location and position of each atom becomes critically important. Thus, to fabricate such structures usefully for application, both with known and novel and as yet to be discovered materials, a prerequisite is to synthesize these materials with atom precision. Top down structuring at these levels, while having been so successful (for example in the microelectronics industry) struggles evermore as a manufacturing process at the nanoscale these days as few atom or single atom precision becomes a precondition. Thus, the ability to develop bottom-up approaches, where material is added with atomic precision is crucial. In this context, it becomes self-evident that the ability to construct crystals using a single catalyst atom has advantages, because in affect an atom serves as a tool with which to add atoms and the tool is of the same scale as the bricks (atoms) being used to construct a material. Indeed, the need for precision manufacturing at the atomic scale is ever more pertinent as we discover and develop new nanomaterials such as clusters (quantum dots), nanowires with variable properties and, of course, the rapidly developing 2D materials. All of these hold great promise for a number of applications ranging from bio-medicine, energy and electronics12,13,14. The need for atom precise control for materials fabrication is epitomized by the need for atom precise structuring of 2D materials for device fabrication. For example, in a simple case, the edge termination of graphene influences its properties, such as its chemical properties (e.g. hydrogen evolution reaction)15,16, its magnetic properties17, its mechanical properties18 and its electronic properties19,20,21,22. Similar dependencies are found for other 2D layered materials such as the transition metal dichalcogenides (TMDs)23,24,25, the few atoms-thick layers of transition metal carbides, nitrides, or carbonitrides, commonly referred to as MXENES26,27,28. Such atom precise edge termination control will be imperative if we are to develop electronic circuits based on these 2D materials. Thus, to fabricate such materials from a bottom-up approach using a catalyst it becomes challenging to form the structure using a catalyst particle since the size of the catalyst particle is significantly larger than that of the edge structure and as a result can’t yield atom precise clean edges29. Using a single atom overcomes this obstacle. This is illustrated in Fig. 1 below using graphene as an example. The two canonical types of graphene edges are also provided, namely zig-zag (ZZ) and arm-chair (AC) edge termination are firstly presented schematically (panel a). Then a schematic representation of a single atom growing a single-atom layer on graphene with only a single-atom layer growing is presented (panel b) and in panel c the rough edge termination typically observed from catalyst nanoparticles and clusters at graphene edges is presented.

The use of single-atom catalysts for crystal growth with atomic precision is in its infancy and there remain many challenges. To highlight some of these challenges let us consider the case of a SAC for the growth of a device from a 2D material, e.g., graphene. To achieve growth one needs to first determine an appropriate catalyst atom and then nucleate a seed maintaining a SAC at an edge or place the catalyst atom at an edge of an initial seed. For atom precise growth, control of the edge atom will then be required, as well as systems to provide the appropriate feedstock etc. From these few aspects it is clear there are many hurdles ahead, but overcoming them presents enormous potential for atom scale crystal growth with many potential applications we have as yet to imagine or discover.

At this early stage, we are only just beginning to show how single and even paired atoms can be used to grow 2D materials (namely graphene) and what factors can be used to control the SACs and even cause them to switch between catalytically growing or catalytically etching a material. The road ahead appears exciting.

In this review, we examine the studies that employ a SAC for the edge growth of graphene on a substrate and as a freestanding structure as well as the case of rolled-up graphene, viz., single-walled carbon nanotubes (SWCNT). We also briefly discuss the catalytic etching of graphene and carbon nanotubes and finally discuss the future directions we envision this nascent field to take.

Single-atom Sp2 carbon crystal growth

The potential for a catalytic role from single metal atoms to grow sp2 crystalline carbon was predicted theoretically for graphene30 and for single-walled carbon nanotubes31. As mentioned in the introduction the potential and relevance of SACs for 2D crystal growth were laid out. In particular, if one considers the importance of edge terminations on the properties of 2D materials and even device systems relying on single and few atoms, such as single-atom transistors32,33, molecular electronics34 and thereby quantum electronics and logic at the atomic scale35. If we consider the case of graphene, the fabrication of edge terminations with atomic control we could construct entire integrated electrical circuits. Equally if we are able to control single atoms to grow and control the chirality of single-walled carbon nanotubes we could also build entire integrated electronic circuits from carbon nanotubes (see Fig. 2). Such technological developments will be groundbreaking and highlight the importance of developing the use of SAC’s for crystal growth and in particular sp2 carbon nanomaterials.

a schematic and circuit from defined graphene ribbons (inspired by ref. 53). b Schematic showing controlled growth of a single-walled carbon nanotube from a SAC (left) leading integrated single-walled carbon nanotube circuit components (right).

However, it is only in the last few years that experimental evidence for the growth of graphene from a single metal atom has started to emerge. This is because both high spatial and temporal resolution are required to provide an understanding of the reaction pathways. Thus far, two microscopy techniques have demonstrated their potential to provide direct observational information at the atomic scale. They are the transmission electron microscope and scanning tunneling microscopes for freestanding graphene growth and supported graphene growth studies, respectively. Here, we begin with the case of supported growth.

Graphene growth on a substrate

Shu et al.36 conducted a comprehensive study on the stability of several graphene edge configurations on Cu (111) and other metal surfaces during chemical vapor deposition (CVD) growth conditions using density functional theory (DFT) calculations. The work found that the termination of armchair (AC) edges by individual Cu atoms was energetically preferred as compared to zigzag (ZZ) edges that tend to keep their pristine structure. Moreover, the study showed that the Cu atom passivation of AC edge sites on the graphene significantly lowers the barrier of incorporating carbon atoms into the growing graphene edge from 2.5 to 0.8 eV. This results in very fast growth at the AC edge of the graphene. As a consequence, the authors state, that, on the basis of the classical theory of crystal growth, the ZZ edge should be the dominant edge of growing graphene edges in agreement with broad experimental observations36. In another work, the same group looked at the role of Ni adatoms at graphene edges (in comparison to Cu) using DFT calculations. The study showed that C species can be inserted (added) through individual Ni atoms at kink sites at the edges37. Indeed, mobile adatoms which are commonly present on metal surfaces at elevated temperatures are involved in several chemical processes taking place on surfaces and at the solid-liquid interface38,39.

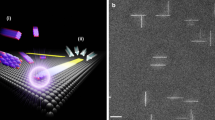

In a detailed high-speed STM characterization study on epitaxial graphene growth on Ni (111) the researchers observed single Ni atoms at kink sites on the graphene edges at elevated temperatures40. The time resolution was on the order of milliseconds. The edge termination of the epitaxial graphene were identified as zigzag (zz) and Klien (k) edges. For both edges kink sites (where there are interruptions on the last two C rows) were observed with individual Ni atoms. These kink sites were shown to act as nucleation centers for graphene growth. Growth was shown to proceed from the kink site by the orderly completion of the two interrupted carbon rows while moving the kink ahead. The observational data pointed to mobile Ni adatoms diffusing along the edges and that these single Ni atoms at kink sites are directly involved with the growth process. This is in agreement with the above discussed theoretical study which is in agreement with the above mentioned DFT studies37. Moreover, the experimental team also conducted molecular dynamic (MD) studies. The MD studies at a temperature of 710 K showed Ni adatoms to move randomly over the bare metal surface until they reached a graphene edge. Once at a graphene edge the Ni atoms diffuse parallel to the edge and showed considerably longer residence times when encountering a kink site. Experimentally the STM image series showed that, in most cases, the adatoms presence was accompanies by C dimer attachment nearby strongly suggesting a catalytic role of the single Ni atom. Figure 3 shows a sequence corresponding to the k edge. Two short-lived Ni adatom configurations can be identified at the kink sites (panels B, C, F, and G). Constant-height simulated images (panels D and H) matched the corresponding STM data. In short, the stable configurations observed by STM, as well as theory point to individual Ni atoms playing a catalytic role in the insertion of C at kink sites, viz. graphene growth while on a metal surface40.

A Ni adatom diffusing on a surface in a region delimited by graphene z (right) and k (left) edges with kinks. Two representative trajectories obtained by MD simulations with ReaxFF performed at 710 K for 100 ps are shown. Color palette for Ni trajectories: from green (initial position) to white (final position). The final steps are highlighted by increasing the ball size. B–I Short-lived configurations of Ni adatom at k-edge kinks: B and F High-speed STM images from movie S2 (20) (V = 20 mV; I = 7 nA). C and G Laplace-filtered version of images from (B) and (F) with superimposed ball models. D and H constant-height STM simulated images based on the calculated geometries (E and I). Reproduced with permission from the American Association for the Advancement of Science40.

While synthetically grown graphene is mostly achieved on substrates, the above works show that the actual growth process is complicated and that there remains much to study, in particular regards growth on substrates involving a SAC. The only clear evidence thus far is for a Ni atom, but how other elemental SACs can be used, can SACs be used on differing substrates, what are the roles for differing environmental aspects (e.g., feedstock, presence of hydrogen, pressure etc), can multiple SACs be employed etc, are but a few of the critical questions that need to be explored when employing SACs for crystal grow on a substrate. One of the greatest challenges to explore SAC driven crystal growth, at least through direct observation studies, are the limited choices in characterization tools. STM has proven itself, but is still a challenging approach. We envision that in the future, electron transparent ultrathin substrates could be employed in dynamic in situ environmental TEM systems. TEM based studies may also pave the way for a broader set of synthesis conditions to be explored than that through STM based studies.

Freestanding growth at graphene edges

We now turn our attention to the case of single metal atoms at the edges of freestanding graphene. In all these experimental studies a TEM was used to study the individual metal atoms at the edge of the freestanding graphene. In some cases additional heating was provided to help drive the catalytic reaction, however, in most cases, electron irradiation is sufficient to drive the reaction. Details of the electron beam-specimen interactions that help drive the reaction can be found in reference41. The carbon feedstock for growth is obtained from hydrocarbon contamination within the TEM column42.

We begin with the case of single iron atoms at graphene edges43. The iron atoms were provided from FeCl3 which was used as an etchant during the transfer of the CVD grown graphene44. The Fe atoms attach to the edges more easily because of the larger binding energy of edges as compared to the basal plane of the graphene. The researchers43 found two ubiquitous configurations of a single Fe atom residing at an AC edge. In the first configuration, an Fe atom incorporated into a five-atom ring forming a pentagon while in the second an Fe atom incorporated into a five-atom ring to form a distorted pentagon (i.e., substituting a C atom). However, when irradiated by the electron beam the Fe atoms diffuse along the graphene edge and at times incorporate additional carbon.

Figure 4 shows a cycle of the single Fe atom catalytically adding in two carbon atoms. In panels A–D a typical translocation of a single unit cell for an Fe at is shown. The Fe atoms changes from a pentagon structure and absorbs some carbon atoms. As it absorbs the carbon atoms it moves to the right (this is observed as a shadow line in panel C as the motion occurred during the image exposure). It then stops at a nearby location, again, forming a pentagon. Stick and ball models show the different atomic rearrangements of the process in panel E. While panel G shows the corresponding translocations added a micrograph of the process. During the process the single Fe atoms unit cell shifts to the right on a ZZ edge, the whole cycle represents a single catalytic growth cycle for graphene from a Fe atom incorporating two C atoms43. The external carbon atoms arise from hydrocarbon contamination with the TEM42. It is also worth noting that the in situ TEM studies on Fe atoms at graphene edges, the researchers also observed the catalytic etching of graphene, which, is discussed later. A similar study was conducted to investigate the behavior of Cr atoms at graphene edges45. Upon electron beam irradiation the Cr atoms diffuse along the edge and after their migrations, new carbon atoms were found to have been incorporated between the Cr atoms initial and final position. This led to the formation of new hexagonal structures leaving a ZZ edge.

A–D A series of high-resolution TEM images or 4 s; the Fe atom is highlighted as a red dot, whereas the nearby carbon atoms are highlighted as black dots. The dark shadow line, which is highlighted by the red circle in (C), is because of the motion of the Fe atom during exposure time. (Scale bar: 0.5 nm.) E The corresponding atomic structures for (A–D). F The combination of (A–D), which shows the trace of the Fe atom during the one-unit cell translocation. (Scale bar: 0.5 nm.) G The atomic structure for the whole growth process (two carbon atoms are added). Reproduced with permission from National Academy of Sciences43.

Figure 5 shows an example of this process. The authors conducted a statistical analysis of the number of new hexagons forming at an open graphene edge and found one to six formed within a one-frame-per-second micrograph capture rate. Unlike the case for Fe atoms at graphene edges, with Cr atoms no etching of the graphene was observed. The Cr atom at graphene edge study also included a MD study comparing Fe and Cr atoms at a graphene edge. The MD study showed confirmed both Fe and Cr single atoms can catalytically grow graphene; however, there were some differences. The Fe atom was shown to be far more dynamic both from a temporal and spatial perspective. These differences were attributed to their energetic and kinetic stability and these aspects affect the catalytic efficiency of the atoms in that an efficient SAC should have a good balance between stability and migration. Stability is important to provide a nucleation site, which is needed to attract C atoms for the catalytic process. However, the atoms potential to migrate is also important to keep the catalyst atom active along the graphene edge and avoid poisoning. The comparative MD study on Cr and Fe atoms at graphene edges indicated that Cr is a more efficient SAC as compared to Fe for graphene edge growth45.

A–C, with partial stick-and-ball models to aid viewing (D)–(F), image simulations of the growth process G–I, and complete stick-and-ball models J–L. The blue ball indicates Cr, whereas red balls and green arrows signify new C atoms. All scale bars are 1 nm. Reproduced with permission from Springer20.

In another study, the role of single Cu atoms at graphene edges was investigated46. They observed Cu atoms frequently in pentagon structures at the graphene edge (similar to the case for Fe described above). With electron irradiation and heating (150 oC or 300 oC) they observed graphene growth mediated by a single Cu atom. Figure 6 shows examples of the growth. Panels A and B show before and after examples of the growth. The shaded region in panel B shows extensive growth after 3 min of irradiation. Panels C to G show more details of the actual growth process. In a previous study by the team, they showed substitutional Cu atoms can promote the rotation of C–C bonds in graphene47. Such C–C rotations can convert pentagon-heptagon pairs into hexagons which is what they observed in the Cu atoms at graphene edge study (panels C and D) which triggered further rotations as shown in panel E. Panels F and G provide another example of a Cu atom translocation over a different edge system and the incorporation of new C atoms as it does so, further confirming the catalytic growth of graphene by a single Cu atom.

A TEM image of two Cu atoms at the graphene edge. B TEM image taken ∼3 min after (A). C–G TEM images and schematic atomic models showing the Cu-mediated mending of the graphene edge. All of these TEM images were extracted from Movie S1 in the online supplementary data at http://stacks.iop.org/APEX/10/025104/mmedia, where (A) corresponds to t = 0 s. Scale bars represent 0.5 nm. Reproduced with permission from the Japan Society of Applied Physics46.

A more recent study examined the role of Sn atoms at graphene edges48. The study examined single Sn atoms (monomers) as well as Sn atom pairs (dimers) as SACs. Both graphene growth and etching was observed from both monomer and dimer SACs, and the switching mechanism between growth or etching is discussed a little later. The experimental data and supporting DFT studies showed a good correlation between the observed frequency of Sn-graphene bonding configurations and their relative energies (i.e., energy difference relative to the most commonly observed configuration of an Sn atom residing at an armchair position at the graphene edge). In terms of the dynamic diffusion of Sn atom SAC pairs a remarkable tendency was observed, namely, a synchronized diffusion between the two atoms (for growth and etching) was observed (see Fig. 7). More in-depth experimental and theoretical investigations revealed the synchronized diffusion occurred in a step-wise shuffle of the two atoms, viz. after the first Sn SAC atom shifts, the second one follows, rather than a hopping process which was also postulated as a possible mechanism.

a–c HRTEM images showing binary atoms activity. d–f HRTEM images with partial ball models to aid viewing. g–i HRTEM images showing possible atom hopping activity. j–l HRTEM images showing possible atom shuffle activity. The rose-red balls indicate the Sn atom, and the translucent rose-red balls represent the previous positions of the Sn atom. Dose ca. 1.8 × 106 A/m2, and all scale bars are 0.5 nm. Reproduced with permission from Wiley-VCH GmbH48.

While most observations showed Sn dimer SAC diffusion to occur synchronously, occasionally the Sn pair would diffuse in opposite directions and the dimer would collapse to two Sn monomers. A detailed statistical analysis of the dimers diffusion showed the vast majority diffused as a dimer (indicating an attractive interaction which was also supported by DFT studies). Moreover, the study showed an edge dependency, such that ZZ edges tended to lead to dimer collapse, while AC edges and chiral edges tented to favor dimer synchronized diffusion. Calculations of the relative binding energies showed two interesting aspects (see Fig. 8). In the first, the relative binding energy for zigzag edges is positive and indicates that ZZ edges favor individual Sn SACs rather than dimer SACSs. Thus, paired SACs (dimers) are likely to separate (collapse) on diffusing, exactly as was observed experimentally. Secondly, in the case of Sn single and binary atoms at AC edges, the binding energy for Sn pairs (dimers) was found to be significantly lower than for a single Sn atom. Thus, the study explains why when the binary SAcs are at AC sites they prefer to synchronize their diffusion such that as soon as one atom moves, the second will follow in the same direction (shuffle) so as to minimize their energy and it explains why, experimentally, the synchronized diffusion of binary atoms was observed so often and moreover, why this was found predominantly at armchair sites48.

a The relative occurrence diffusion behavior (as a pair or splitting) for different Sn dimer/edge configurations under electron irradiation. b The optimized configurations of Sn monomers and dimers at a zigzag edge. c The optimized configurations of Sn monomers and dimers at an armchair edge. Reproduced with permission from Wiley-VCH GmbH48.

Another important SAC is Ni which is a well-known and commonly used transition metal catalyst material in its bulk form due to its availability and cost. To this end, we have been investigating Ni atoms as SAC candidates for graphene growth. Initial studies show that Ni SACs can effectively grow graphene in situ in TEM under electron beam irradiation. At times we observe Ni SACs to catalytically etch graphene (data not shown). An example of a Ni SAC catalytically growing graphene is presented in Fig. 9.

a–b HRTEM images showing the Ni atom before and after catalytic activity. c–d HRTEM images with added balls to aid viewing. Ni is rose colored and the added C atom is in red. e–f Image simulations of the HRTEM images. g–h Complete stick-and-ball models of the structures used for the image simulations. Note: The red line is the reference line. All scale bars are 5 Å.

Figure 9 (a) shows a Ni atom initially residing in a hexagonal location at a graphene edge (i.e., the Ni atom substitutes a C atom). After 20.25 sec. the Ni atom shifts to the left and locates in an armchair configuration (pentagon). Its former location now has a C atom, indication growth. Where this C atom came from is unclear. It could have come from the position the Ni atom translocated to, or from the Klein edge that existed at the far left of the initial system (panel a), or from the vacuum. Regardless, the translocation confirms the catalytic action of the Ni atom at a graphene edge.

To summarize this section a number of metal atoms (Fe, Cr, Cu, Sn, and Ni) all show the potential as SACs for crystal growth, at least for graphene. Moreover, in all instances a single or few carbon atoms get incorporated during the catalytic growth cycle of the metal SACs, confirming that in reality SACs offer the potential to grow graphene edges with atom precision. Equally attractive is the potential for single atoms to grow single-walled carbon nanotubes with atomic precision (and hence chiral control). Reportedly, the Nobel Laurette Richard E. Smalley, proposed a single catalyst atom could grow a single carbon nanotube by adding C at an open edge (see the bottom left panel in Fig. 4). In the next section, we examine SAC growth of single-walled carbon nanotubes (SWCNT).

SWCNT Growth at Edges

Single-walled carbon nanotubes are, in essence, rolled-up tubules of graphene strips. Depending on the manner in which the graphene strip is rolled (their so called chirality), the tubes electronic properties can be either semiconducting or conducting. Moreover, SWCNT combining different chirality’s leads to interesting properties such that carbon nanotubes can serve as (ballistic) interconnects and devices (e.g., rectifiers, transistors etc.)49. Their controlled combinations can yield integrated electronic circuits. However, at this stage, such integrated circuits remain challenging to produce since it requires fabrication control at the atomic scale. SACs could potentially provide a means to overcome this hurdle.

While we did not find any examples of a SACs growing a single-walled carbon nanotube experimentally, we did find a theoretical study looking at a single Ni atom growing a freestanding SWCNT. The study was based on density functional total energy calculations. A temperature of 1200 oC was used.

Figure 10 shows the intermediate steps involved in the catalytic growth of a SWCNT, as well as the binding energies. The study looked at the energetics and in the first scenario a Ni atom forms a pentagon structure (panel A1), then a carbon atom gains energy (4.5 eV) by forming a pentagon defect (panel A2). The high mobility Ni atom nearby reacts with the carbon to form a hexagon (panel A3) The authors argue that an incoming C atom would then push out the substitutional Ni atom (panel A4). Then, because of the weak attachment energy (inferred from the geometries in panels A4 and A5), the Ni atom can continue its diffusion along the edge and further grow the SWCNT. Further intermediate steps for carbon insertion are provided in panels A1’ to A5’ for a different catalytic cycle. Both catalytic cycles are exothermic and occur with no activation barriers which would suggest a high reaction rate. In short, using concerted exchange mechanisms, the single Ni atom at the open SWCNT edge can catalyze growth by the continued formation of hexagons.

A Schematic diagram of intermediate steps involved in the catalytic annealing of pentagon defects at the growing nanotube edge by a concerted exchange mechanism, leading to defect-free growth. B Corresponding binding energies of the two carbon atoms and one Ni atom to the nanotube. Reproduced with permission from the American Physical Society31.

As an early step to investigate the propensity if Ni SAC’s to catalytically grow sp2 carbon we explored their SAC behavior in situ in a TEM at graphene edges under electron irradiation. As discussed at the end of the previous section, indeed, Ni SACs can grow graphene. The presented example (Fig. 9 does not, however, show growth from AC sites as theoretically predicted31, although we do observe Ni atoms at AC edges (see Fig. 11) and so we may yet observe the predicted growth. Moreover, the synthesis conditions in our studies are rather different in that the reaction is driven by an electron beam and is conducted at room temperature. We also plan on conducting experimental studies with SACs at the end of open SWCNT. There is much to be explored regards SACs and SWCNT growth.

Single-atom Sp2 carbon crystal etching

While the focus of this article is on the growth of graphene from SACs, it is worth briefly looking at SACs potential to etch graphene catalytically. We begin with the case of Fe SACs which although they can grow graphene under electron beam irradiation, as discussed above, they can also etch graphene17. In that study, the conditions to determine which catalytic process occurred was not clear since the conditions were more or less the same. Another example is that of Cr, which on one study was only found to grow graphene and no etching was observed20. While in another study looking at Cr, Ti, Pd, Ni, Al and Au, the authors claim to have only observed etching from these SACs50. This might be due to differences in the electron beam conditions, given that in the study with Cr SACs where only growth was observed, the imaging mode was in TEM (parallel imaging) while in the latter study the scanning TEM (STEM) mode was used. Moreover the latter article did not present analytical data confirming the presence of Cr atoms at the graphene edge. In another TEM study, the use of Pt SACs at graphene edges at the elevated temperatures of 150 oC or 300 oC were investigated and only etching was observed. In the same study, Au atoms at graphene edges observed in TEM at room temperature showed neither catalytic etching or growth51. Thus, the contradictory results between the different studies highlight a need for careful studies on the actual conditions implemented. In terms of SAC for graphene etching, Si, a non-metal atom, has also been shown to catalytically etch graphene24. In this study, the researchers were able to form clean graphene edges or pores from Si SACs under electron beam irradiation (see Fig. 12).

A The edge of one TEM grid hole covered by a single-layer graphene sample (highlighted with light orange color). The sample is decorated with SiO2 nanoparticles (highlighted with deep blue color), mostly clustered on either suspended graphene or the carbon grid. B High-resolution image of the suspended graphene sample showing coexistence of clean pristine graphene and aggregation of impurities (upper left corner). C Images of molecular-scale graphene pores of various sizes, with mobile catalyst Si atoms on the edges. The lower panel images illustrate the corresponding atomic configurations. Reproduced with permission from the American Chemical Society54.

A recent study exploring single-atom and binary Sn SACs, an interesting concept, based on Au nanoparticle catalyst action, was postulated to explain the observation that in some cases SAC’s catalytic behavior followed either growth or etching despite similar or identical in situ TEM conditions48. To explain this fact they argue, the atoms follow exactly the same catalytic action when growing or etching a graphene edge. The difference lies in where the SAC obtains a carbon atom from and where it then deposits that captured carbon atom during the dynamic catalytic action. This is illustrated in Fig. 13, panel a. During the first catalytic step on the left, a C atom from the vacuum is captured by the Sn catalyst atom and then deposited at the graphene edge and this step represents growth. While on the right example a C atom from the graphene edge is captured by the Sn SAC and then the C is ejected to the vacuum and this cycle represents etching. However, to the Sn SAC there is no difference in its catalytic action since it simply captures a C atoms and then releases/deposits it somewhere else. However, the more costly cycle energetically will be the capture of a C atom from a graphene edge, as compared to C from the vacuum, since additional energy tip extract the C from the graphene edge is required. Thus in this argument, by controlling the supply of C atoms one can control if a SAC grows or etches Graphene. The catalytic process of an Sn SAC in the presence of a C supply in the vacuum (for graphene growth) is shown schematically in panel b, while in panel c the scenario where there is a lack of C atoms in the vacuum is shown and, thus, C atoms from the graphene edges are consumed (etched). Finally, in panel d the schematic shows the scenario where only a limited supply of C atoms are present in the vacuum and thus, both growth and etching can be observed.

a Left: C capture from vacuum by an Sn atom and subsquebt release to a graphene edge (growth). Right: C capture from a graphene edge and release to the vacuum (etch). b Schematic showing the catalytic growth of graphene from a single Sn atom with a plentiful C supply in vacuum. c Schematic showing the catalytic etching of graphene from a Sn atom due to a lack of C atoms in vacuum. d Schematic showing catalytic growth and etching of graphene at the same time with a limited C supply in vacuum. The rose-red balls indicate a Sn atom. The orange balls with red arrows indicate newly inserted C atoms. The orange balls with green arrows indicate captured/removed C atoms. The translucent orange balls represent the previous positions of the C atoms. The V symbol and G symbol marked on the C atom represent if the carbon atoms were captured from vacuum or graphene, respectively. Reproduced with permission from Wiley-VCH GmbH48.

Finally, we turn to the case of a SAC etching a SWCNT, for which we did not find any experimental evidence, but has been explored theoretically. The study explored the potential of a single Fe atom in an H2 environment52. The computational study suggests H helps passivate edge C atoms and thus release the Fe atom for the continuous unzipping of the SWCNT. The curvature energy is released during the unzipping process and serves as the main energy source to support the continuous unzipping. Moreover, it can enable chirality and diameter dependent unzipping behavior. In this way tailored graphene nanoribbons can form.

In terms of SAC atoms at the open end of a SWCNT, we can expect, like graphene, that a SACs catalytic action to etch (or grow) can be controlled by the feedstock supply in the vicinity. In short, controlling the feedstock supply could be a simple and effective means to switch a SACs behavior between the growth and etching. Other parameters can also be expected to affect a SACs catalytic activity too.

Outlook and summary

The studies examined in this review provide both unequivocal theoretical and experimental evidence that SAC’s can drive crystal growth and we anticipate significant developments on SAC based crystal growth over the next decade. Clearly, future studies need to focus on more in-depth investigations to understand the underlying mechanisms at play and how, armed with that knowledge, controlled crystal growth with atomic accuracy can be achieved. Various aspects need to be developed in this sense. Figure 14 summarizes the different key aspects. One important aspect is understanding the different elemental atoms, such as their divergent catalytic efficiency which depends on the crystal (single or hetero-crystals) being grown, their variation in terms of the bonding and coordination environment etc. Then there are the synthesis conditions which will involve aspects such as temperature, background gas/vacuum conditions, electron beam conditions (where relevant), sample purity, substrate choice (where relevant), feedstock type and availability etc. All these will depend to on the choice and phase of the crystals being grown. For example, forming a OD structure, such as a quantum dot will have differing needs as compared to a 1D nanoribbon or a 2D lateral heterolayer structure (e.g. integrated electronic circuit) or stacked heterolayers and small 3D structures with functional single atoms (e.g., single-atom transistors). Even then variations for devices at the atom scale will be of significance too.

To achieve success there will be a need for numerous systematic and detailed studies, in particular, microscopy-based studies with supporting characterizations and intense supporting and predictive theoretical investigations will be of great importance. It is not hard to envision how important their use could be in the fabrication of atom accurate device production in the future. In short, SAC crystal growth could be a game changer to the semiconductor industry, as well as other technologies.

In summary, we have collated a number of experimental and computational works examining the growth of crystalline monolayer graphene from a single-atom serving as the catalyst. Experimental examples on graphene growth from a SAC are shown for both substrates based growth and freestanding growth. A number of important theoretical studies yield deeper insight into the underlying mechanisms involved. Collectively, these works represent a new sub-field of SACs, namely SAC growth of crystalline solids. Clearly, a great deal of research into this exciting new field can be anticipated in the near future and such studies could have significant impact in the controlled growth of atom-level structures and devices fabricated with atomic precision.

Data availability

Data sharing was not applicable to this paper, as no original datasets were generated or analyzed for this review.

References

Li, J., Stephanopoulos, M. F. & Xia, Y. Introduction: Heterogeneous Single-Atom Catalysis. Chem. Rev. 120, 11699–11702 (2020).

Berzelius, J. J. Årsberättelse om Framstegen i Fysik och Kemi, Annual Report on Progress in Physics and Chemistry, Royal Swedish Academy of Sciences (P.A. Norstedt & Söner, Stockholm, Sweden, 1835).

Sun, R. et al. Heterogeneous catalysts for CO2 hydrogenation to formic acid/formate: from nanoscale to single atom. Energy Environ. Sci. 14, 1247–1285 (2021).

Chen, M. S. & Goodman, D. W. The structure of catalytically active gold on titania. Science 306, 252–255 (2004).

Cheng, N., Zhang, L., Doyle-Davis, K. & Sun, X. Single-Atom Catalysts: From Design to Application. Electro Ener. rev. 2, 539–573 (2019).

Zhang, B., Fan, T., Xie, N., Nie, G. & Zhang, H. Versatile Applications of Metal Single-Atom @ 2D Material Nanoplatforms. Adv. Sci. 6, 1901787 (2019).

Weon, S. et al. Environmental Materials beyond and below the Nanoscale: Single-Atom Catalysts. ACS EST Eng. 1, 157–172 (2020).

He, X. et al. Mechanochemical Kilogram-Scale Synthesis of Noble Metal Single-Atom Catalysts. Cell Rep. Phys. Sci. 1, 100004 (2020).

Zhang, L., Ren, Y., Liu, W., Wang, A. & Zhang, T. Single-atom catalyst: a rising star for green synthesis of fine chemicals. Natl Sci. Rev. 5, 653–672 (2018).

Dyck, O. et al. Building Structures Atom by Atom via Electron Beam Manipulation. Small 14, e1801771 (2018).

Yang, X. F. et al. Single-atom catalysts: a new frontier in heterogeneous catalysis. Acc. Chem. Res 46, 1740–1748 (2013).

Zhu, Y., Yuan, D., Zhang, H., Xu, T. & Sun, L. Atomic-scale insights into the formation of 2D crystals from in situ transmission electron microscopy. Nano Res. 14, 1650–1658 (2020).

Tapia, M. A. et al. Phosphorene and other layered pnictogens as a new source of 2D materials for electrochemical sensors. Trends Anal. Chem. 139, 116249 (2021).

Yanling, Y., Zhongmin, T., Han, L. & Jianlin, S. Emerging two-dimensional material nanozymes for theranostic nanomedicine. Biophysics Rep. 7, 159–172 (2021).

Kumatani, A. et al. Chemical Dopants on Edge of Holey Graphene Accelerate Electrochemical Hydrogen Evolution Reaction. Adv. Sci. 6, 1900119 (2019).

Jiang, D. E., Sumpter, B. G. & Dai, S. Unique chemical reactivity of a graphene nanoribbon’s zigzag edge. J. Chem. Phys. 126, 134701 (2007).

Krompiewski, S. One edge magnetic configurations in graphene, stanene and phosphorene zigzag nanoribbons. J. Magn. Magn. Mater. 534, 168036 (2021).

Lopez-Polin, G., Gomez-Navarro, C. & Gomez-Herrero, J. The effect of rippling on the mechanical properties of graphene. Nano Mater. Sci. 10, 1–9 (2021).

Castro Neto, A. H., Guinea, F., Peres, N. M. R., Novoselov, K. S. & Geim, A. K. The electronic properties of graphene. Rev. Mod. Phys. 81, 109–162 (2009).

Abdelsalam, H. et al. Electronic and adsorption properties of extended chevron and cove-edged graphene nanoribbons. Phys. E Low. Dimens. Syst. Nanostruct. 126, 114438 (2021).

Wakabayashi, K., Takane, Y., Yamamoto, M. & Sigrist, M. Edge effect on electronic transport properties of graphene nanoribbons and presence of perfectly conducting channel. Carbon 47, 124–137 (2009).

Saraswat, V., Jacobberger, R. M. & Arnold, M. S. Materials Science Challenges to Graphene Nanoribbon Electronics. ACS Nano 15, 3674–3708 (2021).

Guo, N. et al. Electronic and magnetic properties of group-V TMDs monolayers with defects: a first-principles study. Comput. Mater. Sci. 176, 109540 (2020).

Zhang, W., Zhang, Y., Qiu, J., Zhao, Z. & Liu, N. Topological structures of transition metal dichalcogenides: A review on fabrication, effects, applications, and potential. InfoMat 3, 133–154 (2020).

Wang, Q. H., Kalantar-Zadeh, K., Kis, A., Coleman, J. N. & Strano, M. S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 7, 699–712 (2012).

Pang, J. et al. Applications of 2D MXenes in energy conversion and storage systems. Chem. Soc. Rev. 48, 72–133 (2019).

Liu, Z. & Alshareef, H. N. MXenes for Optoelectronic Devices. Adv. Electron. Mater. 2100295 (2021).

Fu, B. et al. MXenes: Synthesis, Optical Properties, and Applications in Ultrafast Photonics. Small 17, e2006054 (2021).

Schaffel, F. et al. Atomic Resolution Imaging of the Edges of Catalytically Etched Suspended Few-Layer Graphene. ACS Nano 5, 1975–1983 (2011).

Zhang, X., Xin, J. & Ding, F. The edges of graphene. Nanoscale 5, 2556–2569 (2013).

Lee, Y. H., Kim, S. G. & Tománek, D. Catalytic Growth of Single-Wall Carbon Nanotubes: An Ab Initio Study. Phys. Rev. Lett. 78, 2393–2396 (1997).

Wyrick, J. et al. Atom‐by‐Atom Fabrication of Single and Few Dopant Quantum Devices. Adv. Funct. Mater. 29, 1903475 (2019).

Obermair, C., Xie, F. Q. & Schimmel, T. The Single-Atom Transistor: perspectives for quantum electronics on the atomic-scale. Europhys. N. 41, 25–28 (2010).

Li, Z. et al. Towards graphyne molecular electronics. Nat. Commun. 6, 6321 (2015).

Radsar, T., Khalesi, H. & Ghods, V. Graphene properties and applications in nanoelectronic. Opt. Quant. Electron 53, 178 (2021).

Shu, H., Chen, X., Tao, X. & Ding, F. Edge Structural Stability and Kinetics of Graphene Chemical Vapor Deposition Growth. ACS Nano 6, 3243–3250 (2012).

Wang, L., Zhang, X., Chan, H. L., Yan, F. & Ding, F. Formation and healing of vacancies in graphene chemical vapor deposition (CVD) growth. J. Am. Chem. Soc. 135, 4476–4482 (2013).

Zhao, L. et al. In Situ Electron Driven Carbon Nanopillar-Fullerene Transformation through Cr Atom Mediation. Nano Lett. 17, 4725–4732 (2017).

Feng, Z. et al. Trapping of Charged Gold Adatoms by Dimethyl Sulfoxide on a Gold Surface. ACS Nano 9, 8697–8709 (2015).

Patera, L. L. et al. Real-time imaging ofadatom-promoted graphene growth on nickel. Science 359, 1243–1246 (2018).

Rummeli, M. H. et al. New Frontiers in Electron Beam-Driven Chemistry in and around Graphene. Adv. Mater. 31, e1800715 (2019).

Rummeli, M. H. et al. In Situ Room Temperature Electron-Beam Driven Graphene Growth from Hydrocarbon Contamination in a Transmission Electron Microscope. Mater. (Basel) 11, 896 (2018).

Zhao, J. et al. Direct in situ observations of single Fe atom catalytic processes and anomalous diffusion at graphene edges. Proc. Natl Acad. Sci. USA 111, 15641–15646 (2014).

Zhao, J. et al. Free-standing single-atom-thick iron membranes suspended in graphene pores. Science 343, 1228–1232 (2014).

Ta, H. Q. et al. Single Cr atom catalytic growth of graphene. Nano Res. 11, 2405–2411 (2018).

Kano, E., Hashimoto, A. & Takeguchi, M. Opposite effects of Cu and Pt atoms on graphene edges. Appl. Phys. Express 10, 025104 (2017).

Kano, E. et al. Interactions between C and Cu atoms in single-layer graphene: direct observation and modelling. Nanoscale 8, 529–535 (2016).

Yang, X. et al. On the Catalytic Activity of Sn Monomers and Dimers at Graphene Edges and the Synchronized Edge Dependence of Diffusing Atoms in Sn Dimers. Adv. Funct. Mater. 31, 2104340 (2021).

Anantram, M. P. & Léonard, F. Physics of carbon nanotube electronic devices. Rep. Prog. Phys. 69, 507–561 (2006).

Ramasse, Q. M. et al. Direct Experimental Evidence of Metal-Mediated Etching of Suspended Graphene. ACS Nano 6, 4063–4071 (2012).

Wang, H. et al. Interaction between single gold atom and the graphene edge: a study via aberration-corrected transmission electron microscopy. Nanoscale 4, 2920–2925 (2012).

Ma, L. & Zeng, X. C. Unravelling the Role of Topological Defects on Catalytic Unzipping of Single-Walled Carbon Nanotubes by Single Transition Metal Atom. J. Phys. Chem. Lett. 9, 6801–6807 (2018).

Areshkin, D. A. & White, C. T. Building Blocks for Integrated Graphene Circuits. Nano Lett. 7, 3253–3259 (2007).

Wang, W. L. et al. Direct observation of a long-lived single-atom catalyst chiseling atomic structures in graphene. Nano Lett. 14, 450–455 (2014).

Acknowledgements

This work was financially supported by the National Science Foundation of China (Grant Nos. 52071225 & 51676154) and the Czech Republic under the ERDF program “Institute of Environmental Technology—Excellent Research” (No. CZ.02.1.01/0.0/0.0/16_019/0000853). M.H.R. and L.F. thank the Sino–German Research Institute for support (Project No. GZ 1400).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

M. H. R., X. Y., and Y. L. conceived the manuscript concept. All authors contributed to the manuscript preparation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, X., Liu, Y., Ta, H.Q. et al. Single-atom catalytic growth of crystals using graphene as a case study. npj 2D Mater Appl 5, 91 (2021). https://doi.org/10.1038/s41699-021-00267-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-021-00267-4

This article is cited by

-

Linear indium atom chains at graphene edges

npj 2D Materials and Applications (2023)

-

Novel nanostructures suspended in graphene vacancies, edges and holes

Science China Materials (2023)