Abstract

Hexagonal boron nitride nanosheets (BNNSs) are promising two-dimensional materials to boost the mechanical, thermal, electrical, and optical properties of polymer nanocomposites. Yet, BNNS-polymer composites face many challenges to meet the desired properties owing to agglomeration of BNNSs, incompatibility, and weak interactions of BNNSs with the host polymers. This work systematically reviews the fundamental parameters that control the molecular interactions of BNNSs with polymer matrices. The surface modification of BNNSs, as well as size, dispersion, and alignment of these nanosheets have a profound effect on polymer chain dynamics, mass barrier properties, and stress-transfer efficiency of the nanocomposites.

Similar content being viewed by others

Introduction

Boron nitride nanosheet (BNNS)-polymer composites are one of the important classes of materials with a wide range of applications spanning from automotive1,2,3, aerospace4,5, healthcare and medicine6,7,8, energy storage9,10,11 to electronic engineering12. While many efforts have been devoted to graphene incorporation into polymer materials13,14,15,16,17,18,19, BNNS-polymer composites are less explored. Boron nitride (BN) nanomaterials have superior fracture strength (165 GPa), high Young’s modulus (0.8 TPa)20, high thermal stability (up to 800 °C in the air)21,22, excellent thermal expansion coefficient (−2.72 × 10−6 K−1)23, and outstanding thermal conductivity (300–2000 Wm−1 K−1)22,24,25. Unlike other two-dimensional (2D) materials such as graphene and MXene26,27,28,29,30, BNNS is electrically insulative due to the wide bandgap (~5.6 eV) with a dielectric constant (4 ~ 8), low leakage current, and high voltage breakdown strength (12 MV cm−1)31. These characters suggest that BNNS-polymer nanocomposites can be engineered with superior performances.

Although both BN and carbon nanotube (CNT) nanomaterials show van der Waals (vdW) force and π–π interactions with polymers, the partial ionic electronic structure of B-N bonding can be advantageous in terms of molecular interactions with polymer materials32,33,34,35,36. Molecular dynamics (MD) simulation predicted that the molecular interaction between polymers and BN materials could be more efficient when compared with carbon nanofillers because of the polarized nature of B-N bonding, the high bonding potentials (deep potential well) of B and N atoms, along with vdW force and Coulomb interactions between BN and polymer matrix37,38. As a result, there would be better opportunities to enhance the molecular interactions between BN materials and polymers if nanocomposites are properly designed and synthesized. Consequently, the number of publications in the field of BN-polymer nanocomposites are increased significantly in recent years (Fig. 1).

Number of BN-based polymer composite publications from 2006 to 2021. (Keywords used for searching “polymer” and “boron nitride”. Source: www.scifinder.cas.org, accessed in February 2021).

The focus of this review article is to investigate the factors that govern the incorporation of BN nanosheets (BNNSs) into polymer materials. In particular, the interfacial and non-interfacial engineering between BNNSs and polymers are critically discussed to address the low stress-transfer, BNNS agglomeration, and failure mechanisms in polymer composites. Here, we outline the important material design factors that govern mechanical reinforcement (tensile modulus and strength), as well as the thermal (thermal conductivity, glass transition temperature (Tg), and thermal stability), electrical (dielectric breakdown strength, electrical resistivity, and Li+ ion conductivity), and optical (optical transparency, IR absorption, ultraviolet (UV) absorption, and filtering) properties of BNNS-polymer nanocomposites. Notably, the key findings of our study can also be extended for other 2D materials such as graphene and MXene composite systems. This review is quite distinct from other published review papers on BN-polymer composite materials24,25,39,40,41,42,43,44. Zhi et al.42, Zheng et al.44, and Weng et al.25 reviewed the functionalization of boron nitride nanotubes (BNNTs) and BNNSs to enhance the processability and solubility for versatile applications of their nanocomposites. Verma and co-workers41 demonstrated different atomistic modeling techniques for engineering polymer-BN composites. Wang et al.39, Yu et al.40, and Meng et al.24 focused primarily on thermal conductivity of BN-polymer nanocomposites. However, these review articles fall short in determining the important underlying factors that govern the mechanical reinforcement, thermal, electrical, and optical property changes in BNNS-polymer nanocomposites. Moreover, Tg, thermal stability, and optical properties of BNNS-incorporated polymer nanocomposites were not reviewed before. We also have outlined emerging applications of the BNNS-polymer composites that require addressing the critical challenges of such composite systems.

Structure and properties of boron nitride

Hexagonal boron nitride (hBN) is the most stable form under standard conditions among all three crystalline structures (hBN, cubic BN, and wurtzite BN). hBN is available in zero-dimensional (0D fulborenes), one-dimensional nanotube (1D BNNT), and 2D nanosheet (2D BNNS) forms. In the atomic structure of hBN, B and N atoms are bonded with a strong covalent bond in a honeycomb configuration similar to graphene. Multiple BN layers are attached with weak vdW forces. They are oriented in such a way that B and N atoms are placed above and below each other in adjacent layers25,45.

Key properties, including crystal structure parameters of bulk BN, few-layer BNNSs, BNNT, and graphene nanomaterials, are demonstrated in Table 1. The Young’s modulus, fracture strength, and crystallographic structure information of BN materials are similar to graphene. However, BN has better thermal stability and a significantly higher electronic bandgap compared with graphene, thus making it suitable for electrical insulation application. Although most of the properties are comparable for all three types of BN nanomaterials (bulk BN, few-layer BNNS, BNNT), few-layer BNNSs have very high surface area (~2600 m2 g−1) compared to bulk BN (~10 m2 g−1) and BNNT (212–254 m2 g−1). The thermal conductivity of mono/few-layer BNNSs show significantly higher values (2000 W m−1 K−1) compared with bulk BN materials (390 W m−1 K−1). In 2D morphology, BNNSs have a high aspect ratio that facilitates high surface area for interfacial molecular interaction within nanocomposite matrix24. Thus, a maximum amount of reinforcement can be realized into a polymer matrix using a very low amount of BNNSs.

Factors affecting BNNS-polymer nanocomposite materials

The nanocomposite properties depend on a wide range of factors, including molecular interactions between BNNSs and polymers, BNNSs surface area, interphase properties, interface spacings or voids formed at the polymer-BNNSs interfaces, dispersion of BNNSs within nanocomposite matrix, and processing parameters. These elements are categorized into two broad thrusts: (i) interfacial and (ii) non-interfacial factors (Fig. 2) in this review for systematic analysis of the corresponding nanocomposites. The following sections (Sections 3.1–3.5) provide an overview of these factors, and later these factors are discussed for polymer-BNNS composites properties such as mechanical (Section 4.1), thermal (Section 4.2), electrical (Section 4.3), and optical (Section 4.4).

Interfacial factors include covalent and non-covalent interactions, interfacial surface area, and interphase at the BNNS-polymer interface. Non-interfacial factors include dispersibility, mechanical interlocking, interface spacing, and processing parameters. These factors modify polymer nanocomposite properties by engineering chain dynamics, load or stress transfer, and mass barrier.

Physical and chemical interactions between BNNSs and polymers

Interfacial interaction is one of the fundamental part of understanding the corresponding polymer nanocomposite materials because they govern the mechanical, thermal, electrical, and optical properties of the materials46. Poor interfacial interactions between BNNSs and polymer matrix may result in BNNSs slippage, ineffective load transfer, and void formation, resulting in poor nanocomposite properties. Interfacial interactions could be divided into two types: physical and chemical. Physical interactions involve morphological and structural activations of BNNSs, which are very weak; consequently, the interphase strength is also weak47,48,49. On the other hand, chemical interactions including covalent and non-covalent interactions are stronger than physical ones47,48,49. Although BN shows a partially ionic character, the inertness of BN still makes it challenging to form favorable interactions with polymers. Such limitations could be overcome by functionalizing BNNSs with appropriate functional groups. As a result, molecular interactions between BNNSs and polymers could be ameliorated, resulting in: (i) increased compatibility by reducing the surface energy difference between polymers and BNNSs and (ii) uniform dispersion of BNNSs into organic/inorganic solvent/matrix50.

A summary of chemical functionalization (covalent and non-covalent) of BNNSs using different types of molecules is demonstrated in Fig. 3. In spite of having enhanced bonding strength, covalent functionalization might not be suitable for some particular applications such as electrical and optical owing to the structural damages caused by functionalization51. Such functionalization could modify the electronic band structure via introduction of impurities/defects in the BN crystal structure. However, these impurities/defects-induced structurally damaged 2D materials are likely to either decrease or increase the thermal conductivity of the composite materials depending on the type of defects52. To overcome such limitations, non-covalent functionalization with molecules as such aniline, amine, and acidic groups are also shown in Fig. 3. Non-covalent functionalization involves creating H-bond, vdW force, Coulomb interactions, and π–π stacking of BNNSs with functional molecules. Functional groups such as hydroxyl, acidic, and amine are suitable to form H-bond with hydrophilic polymer matrices25,53. In contrast, silane groups are compatible with both hydrophilic and hydrophobic types of polymer matrices54,55. BNNSs functionalization with appropriate molecules is, therefore, necessary to design and construct the interfacial layers between BNNSs and polymer resins.

Covalent functionalization of BNNSs with hydroxyl group, amine group, silane group, alkyl group, and halogen group51,122,229,230,231,232,233,234,235,236,237,238. Non-covalent functionalization of BNNSs with acidic group, amine group, and aniline trimmer49,239,240,241,242,243,244. [Green arrows indicate conversion reaction to form other funcitonalized BNNS].

BNNS-polymer interfacial surface area and interphase

Molecular interactions at the BNNS-polymer interface create a transitional zone, termed as interphase, which is the origin of property changes in polymer nanocomposites56. Interphases have a vital role in transferring mechanical stress, thermal heat, and electrical load from one phase into another57,58,59,60,61,62,63. Several interphase modeling works were developed, where increase in modulus and strength was explained by polymer chain adsorption64, as well as deformational interphase formation around BNNSs65. By studying microstructural and micromechanical properties of nanocomposites, the interfacial adhesion strength could be tailored by the surface chemistry of nanofillers and polymer functionalities64. Kovalev et al.65 proposed a deformational interphase model where transition zone was accountable for variable gradient layers. This graded approach offered the transparent consideration of the gradient of the mechanical properties and introduced the transfer of the mechanical deformation between layers represented by a specifically selected transfer function. In addition, high surface area to volume ratio of BNNSs facilitates in enhancing molecular interaction with polymer matrix, thus creating higher interfacial volume in a composites than that of composites formulated from lower surface area nanosheets at the same loading amount66. Such high surface area to volume ratios could be achieved by downsizing the micro-size BN nanomaterials into nanosized particles or sheets. Another method used to synthesize high specific surface area BNNSs (i.e., 140 m2 g−1) was “chemical blowing technique”, as reported in literature67,68. Together with high surface area to volume ratios, strong interphases at the polymer-BNNS interfaces will improve load transfer efficiency in polymer nanocomposites.

Dispersibility and interface spacing

Owing to the nanosheet structure and partially ionic configuration of BNNSs, surface energy of BNNSs (35–37 mJ m−2), vdW and electrostatic force among BNNSs are high69,70,71. These lead to agglomeration of BNNSs into most solvents and polymer matrices72,73,74. Agglomeration has significant detrimental effects on nanocomposite properties, including Tg from loosened chain dynamics75, reduced thermal conductivity from phonon scattering76,77, low mechanical reinforcement from weak interphases78,79,80, and reduced optical transparency from light absorption81. Accumulation of BNNSs not only results in interphase volume reduction but also impede the percolating networks formation75. Defects, originated from the loss of interphase volume, can act as a phonon scattering. Thus, thermal conductivity of the polymer nanocomposites is reduced significantly76,77. In addition, tensile properties of nanocomposites suffer significantly owing to the loss of specific surface area and effective volume fraction of nanoparticles79. Figure 2 shows three different type of BNNSs dispersion, which are usually found in nanocomposite matrices: intercalated, exfoliated, and separated or segregated. Exfoliated and intercalated BNNSs utilize maximum surface area per unit volume and are dispersed uniformly within nanocomposites compared with separated or segregated BNNSs. Techniques such as tuning surface energy, functionalizing BNNSs, and utilizing surfactants are utilized to overcome agglomeration within nanocomposites82,83. Moreover, nanocomposite processing such as twin-screw extrusion, stirring, and sonication are few other techniques that are developed to mitigate the agglomeration of BNNSs into nanocomposites84.

Mechanical interlocking

Polymer chain dynamics are influenced to a great extent owing to the mechanical interlocking effects of 2D nanofillers56,85,86,87. One of the widely used theories for explaining the mechanical interlocking effect into nanocomposites is “reptation doctrine”88. According to the reptation doctrine, polymer chains are confined in a transiently existing virtual tube, which is further surrounded by other polymer chains. If a force is applied on a polymer matrix, these chain entanglements create restrictive forces and are reflected in mechanical reinforcement. BNNSs act as a mechanical interlocking point and restrict polymer chain mobility owing to their spatial confinement. Thus, material properties that require chain movement, i.e., tensile modulus, strength, and Tg could be modified accordingly89. Peña-Bahamonde et al.89 reported an increase in Tg of polymer materials because of such mechanical interlocking effect that is originated from 2D nanofillers within nanocomposite matrix.

Processing parameters

Despite the fact that the wide range of nanocomposite fabrication methods are available today, BNNS-based polymer nanocomposites are mostly developed in three main approaches: in situ polymerization, melt-extrusion, and solution-blending90. In situ polymerization involves synthesis of polymer materials from monomers while solution-blending and melt-extrusion method involve compounding materials with the help of solvent and heat, respectively90. Such fabrication processes involve varieties of parameters as such mixing temperature and pressure for melt-extrusion, solvent selection (polarity/non-polarity) and removal for solution-blending, reaction pressure, temperature, and chemical reactivity of the constituents for in situ polymerization90. These process conditions/parameters affect defect formation, agglomeration, and dispersion within nanocomposites, thus affecting the final material properties. On top of the commonly used fabrication methods, especially designed techniques such as ball milling, sonication, pressing, chemical modifications, chemical grafting, latex emulsion blending, layer-by-layer assembly, and direct assembly methods are also developed to incorporate nanofillers into polymer matrix91,92,93,94,95,96,97,98,99,100. Moreover, pre-, and post-processing techniques such as BNNSs alignment by magnetic field force or stretching are reported to improve anisotropic properties such as thermal conductivity into nanocomposites. For example, BNNSs alignment was demonstrated by Lin et al.101 using magnetic field and Jan et al.102 using material drawing operation. Such techniques are crucial to align BNNSs within nanocomposite matrix.

BNNS-polymer nanocomposite properties

Mechanical properties

Ashby plot (Fig. 4) shows the elastic modulus and tensile strength of conventional elastomers, polymers, polymer-BNNS composites, and BNNSs materials. The modulus and strength of polymer-BNNS composites are scattered between polymers and BNNS materials, indicating the potential to develop super-strong materials with proper interfacial engineering.

Ashby plot of elastic modulus and tensile strength comparing the mechanical properties of conventional elastomers, polymers, polymer-BNNS composites, and BNNSs. Different color regions represent families of each material. The mechanical properties of polymer-BNNS composites are scattered between polymers and BNNSs in this Ashby plot, indicating to develop super-strong polymer composite materials in the near future if properly designed and manufactured. Ashby plot was made use of reported values from many literatures cited in this review article. References: Ashby, M. F. Material and Process Selection Charts, Chart created using CES EduPack 2018, Granta Design Ltd, and literature reports from refs. 49,67,81,92,102,105,108,109,110,112,113,132,140,152,156,183,233,236,245,246,247,248,249.

The main factors affecting the reinforcement of BNNS-polymer nanocomposites include BNNSs aspect ratio (length to thickness ratio), BNNSs dispersion, efficient stress-transfer between BNNSs and polymer, and BNNSs alignment within the nanocomposite matrix. The stress-transfer between BNNSs and polymer materials is one of the most important parameters that allow transferring and distribution of external applied load disproportionately103. Stress induced within the nanofillers is proportional to the stress developed at the interphase104. Hence, the reinforcement effect depends mainly on the properties of interphase. The interphase fails at a critical external load, which is called interfacial fracture shear stress (IFSS). Figure 5 shows an illustration of the load/stress transfer at the interphase regions, where stresses or loads are propagating from one phase (polymer) to another (BNNS). Hence, it is crucial to improve the intrinsic properties of interphase by maximizing the volume of the interfacial regions and strengthening by forming chemical bonds among constituents. Uniform dispersion and increased aspect ratios or surface area to volume ratio of BNNSs are desirable to maximize the volume of the interfacial region. At the same time, physical and chemical bonding between fillers and matrix could facilitate to developing stronger interphases.

A schematic illustration of the load/stress transfer at the interphase regions where stresses or loads are propagating from one phase to another250,251,252. The increased surface area of BNNS and interphase strength facilitate to increase effective load/stress transfer from the polymer matrix to BNNSs.

In order to maximize the load transfer at the interphase regions, the aspect ratios or surface area to volume ratio of nanosheets need to be increased since a high surface area of BNNSs could interact more with polymer chains compared with lower surface area BNNSs at same amount of loading. Such result was illustrated by assessing mechanical reinforcement for poly [2,2-(p-oxydiphenylene)-5,5′-bibenzimidazole]-BN composite systems where exfoliated and non-exfoliated BN nanomaterials were utilized105. The tensile modulus was increased by 3% (3.3–3.4 GPa) for non-exfoliated BN nanomaterials as opposed to 18% for exfoliated BNNSs at the same 4 wt.% loading level. Exfoliation increases aspect ratios of BNNSs, thus creating a larger volume of interphase around BNNSs. As a result, increased load transfer could be achieved at the interface regions.

Such reinforcement of polymer composites is investigated by both simulation and experimental techniques, as such for polyethylene (PE)-BNNS composite systems106,107. While the experimental results reported an increase in the tensile strength and Young’s modulus by 27 and 64.1%, respectively, the MD simulation predicted the increment of the fracture stress by 21% at 5 wt.% BNNS loading, indicating a good agreement with experimental results107. This paper also predicted that the aspect ratio, weight fraction, and geometry distribution of BNNSs (dispersed or stacked) significantly affected the mechanical properties of the composite materials107. The MD simulation carried out by Rouhi et al.38 found that the high surface area to volume ratio of BNNSs exposed more atoms, resulting in increased molecular interactions between polymer and BNNSs.

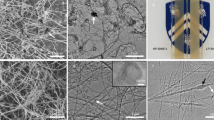

Although it is understandable to increase the interfacial surface area by loading more BNNSs, such high amount of BNNSs may lead to agglomeration because of the electronic structure of BNNS. The partial ionic electronic and 2D structure of BNNSs create electrostatic and vdW force interactions between BN nanosheets. With increasing the amount of BNNS loading, the net interaction energy becomes negative, resulting in agglomeration of nanosheets as suggested by the Derjaguin-Landau-Verwey-Overbreak theory74. Agglomeration is a major issue because the effective surface area of BNNSs can be significantly reduced, and agglomerated BNNSs may act as stress concentrating points making polymers to be vulnerable to early failure under tensile loading. As for example, polydimethylsiloxane (PDMS) polymers reported formation of BNNSs agglomeration within PDMS nanocomposites (Fig. 6)108. Boron nitride foams (BNFs) were added into the pure PDMS matrix to enhance the tensile strength, where BNFs could bear and resist the applied deformational force, thus increasing the tensile strength of the materials. The reinforcement of tensile strength was further increased from 1.65 to 1.95 MPa by adding up to 8 wt.% BNNSs. Interestingly, tensile strength was decreased from 1.95 to 1.7 MPa when the amount of added BNNSs was further increased from 8 to 10 wt.%. As evidenced by the SEM images in Fig. 6h, higher amount of BNNSs results in agglomerations, acting as a stress concentrating point and expedites crack propagation. Another study showed that 40 wt.% BNNSs incorporated epoxy composites resulted in ~80% tensile strength and ~20% elastic modulus reductions109. High amount of BNNSs was likely accumulated within nanocomposites that failed earlier under tensile load than pure epoxy matrix. Besides acting as stress concentrating points, the accumulated BNNSs are suspected of creating heterogeneous microstructures within the nanocomposites and form defects110. Such heterogenous nanocomposite structures with defects are also vulnerable to early material failures under tension forces.

Mechanical reinforcement of BNF-PDMS and BNNS-BNF-PDMS nanocomposites: a, b optical photographs of flexible BNF-PDMS and BNNS-BNF-PDMS, SEM images of tensile fractured surfaces of c PDMS, d BNF-PDMS, and e–h BNNS-BNF-PDMS nanocomposites at 2, 5, 8, 10 wt.% BNNSs loading, respectively. The digital photographs of composite hydrogels: i original, j stretched, k bent, and l stretched after being knotted; SEM images of m PAA hydrogel, n BNNS-NH2 based PAA hydrogel composites; o schematic illustration of the formation of a PAA-BNNS-NH2 composite hydrogel with self-healing ability. a–h reprinted from ref. 108, Copyright (2017), with permission from Elsevier. i–o reprinted by permission from Springer Nature: ref. 112, Copyright 2018.

To avoid the accumulation of the BNNSs, several techniques have been developed, including functionalization, where appropriate organic/inorganic molecules are attached to the BNNSs. Polar functional molecules, i.e., amine (NH2), hydroxyl (OH), and silane, can be attached with BNNSs to increase the compatibility with polar polymers (e.g., nylon 6, epoxy, and poly(methyl methacrylate) (PMMA))111. Similarly, second-degree alkyl amide and aniline trimmers are excellent functional molecules to attach with BNNSs, thus increasing the compatibility with nonpolar polymers (e.g., polyethylene, polypropylene, and natural rubbers). Compatible polymers and BNNSs are likely to be easily mixed, resulting in well-dispersed BNNSs within matrix. As a result, the maximum amount of load transfer could be achieved at the interphases with the lowest amount of BNNSs loading. For example, Young’s modulus and tensile strength of polyacrylic acid (PAA) hydrogel (water content 70 wt.%) composites were increased by 244% and 57%, respectively, when 0.5 g L−1 BNNSs was added to the PAA hydrogel112. This excellent reinforcement was achieved because of the increased compatibility of the amino group (NH2) functionalized BNNSs with the PAA matrix. Polar–polar interaction between NH2 functional group and the PAA matrix leads to form stronger interphase by creating hydrogen bonding between them (Fig. 6o). An MD simulation study reported that the polarized nature of the B-N bonds, high bonding potentials of B and N atoms, strong vdW and Coulomb interactions between BN nanosheets and polymers could be the reasons for 35% higher IFSS for BN compared with CNT composites, resulting in enhanced stress transfer at the BN and polymer matrix interface37. As a result of such an increase in IFSS, the fracture strength of the polymer-BNNS nanocomposites was improved compared with the base polymer matrix.

In addition to the factors mentioned above, several post-processing strategies have been developed to improve the mechanical properties of the materials. For example, uniaxial and biaxial drawing of composites can result in the alignment of BNNSs within matrix. As a result, Young’s modulus of ultra-high molecular weight polyethylene-BNNS composites113 was increased by 11 times, and the tensile strength of polyvinyl chloride-BNNS composite102 was increased by 100% by such drawing operation. The chain unfolding from the surface-grown lamellae produced enough force to exfoliate the accumulated BNNSs, thus yielding a more favorable interface area for stress transfer.

Although 2D materials are effective in reinforcing the polymer materials owing to their ultra-high surface area, strong mechanical strength, and mature technology, inclusion of 2D materials into polymers yield distinct properties making them suitable for specific applications114. For example, the addition of electrically conductive graphene increases the mechanical strength and electrical conductivity of the corresponding polymer composites. On the other hand, BNNSs play a decisive role in reinforcing polymers for applications where electrical insulation is important such as thermal interface material (TIM)115,116 and load-bearing electrical insulators.

In summary, the mechanical properties (e.g., tensile modulus and strength) of polymer composites can be increased up to the theoretical limit by incorporating BNNSs. Such nanocomposites can be developed by controlling various interfacial and non-interfacial factors at different length scales, including microscopic features (voids/defects, interphases, functional groups), and macroscopic structure (aspect ratios, and mechanical interlocking). However, increasing the amount of BNNSs may lead to the agglomeration of nanosheets that act as load concentrating points and eventually reducing the load transfer efficiency. Uniformly distributed BNNSs with strong interphase and negligible defects in the polymer nanocomposites are most effective in load transfer between constituents, resulting in improved mechanical properties of the composite materials.

Thermal properties

Thermal properties of polymer-BNNS composite materials are further reviewed to assess the effect of BNNSs on the thermal conductivity, thermal stability, and Tg of polymer materials. Thermal conductivity (k) is a material property that allows measurement of the ability or efficiency of heat transfer through a material. Thermal conductivity measures the vibrational energy conduction through a material by phonons or electrons. As BN does not have free electrons, phonons are the primary heat carriers in polymer-BN composite systems. In crystalline materials, thermal energy transfers from the heat source to the surface atoms, then propagates in a wave at the same speed throughout the materials. However, semi-crystalline and amorphous materials such as polymers cannot diffuse heat in the same manner because of the interface resistance117. This thermal interfacial resistance is originated from irregular polymer chain structures (amorphousness), phonon-scattering spots, and lower mean free paths. A number of theoretical studies have been conducted to demonstrate the effect of thermal interface resistance on the thermal conductivity of the polymeric composites118,119,120,121. These simulation studies demonstrate that effective thermal conductivity is improved when thermal interfacial resistances are reduced. By adding thermally conductive BNNSs into the polymer matrix, the thermal conductivity of nanocomposites can be increased exponentially (Fig. 7)68,109,110,122,123,124,125,126,127,128,129,130,131,132. Nevertheless, some limitations prevent polymer composites from utilizing the full potentials of BNNSs. The crucial elements that are needed to be considered for designing thermally conductive polymer composite materials can be categorized into two broad thrusts: structural factors and phonon scattering (Fig. 8).

An illustration of changes in thermal conductivity with varying BNNSs loading for the reported BNNS-polymer composites68,109,110,122,123,124,125,126,127,128,129,130,131,132. The percentage of thermal conductivity enhancement is calculated based on the neat polymer material. [PMMA polymethyl methacrylate, NFC nanofibrillated cellulose, CNF cellulose nanofiber, TPU thermoplastic polyurethane, PDMS polydimethylsiloxane, PE polyethylene, PA-6 polyamide 6, PS polystyrene, PVA polyvinyl acetate].

Structural factors of polymer nanocomposites include BNNSs dispersion, crystallization & chain orientation, and 3D network and BNNSs alignment50. Phonon scattering in polymer nanocomposites includes phonon-phonon scattering (such as random polymer chain scattering), phonon-interface scattering (such as polymer-BN interface), and phonon-defect scattering (such as voids)43. Red arrows indicate desired change (i.e., increase or decrease) of the corresponding factors to improve thermal conductivity of the polymer nanocomposites.

The major obstacle in utilizing the full potentials of highly thermally conductive BNNSs into nanocomposites is phonon scattering. Figure 8 demonstrates several phonon scattering that is usually occurred in polymer composites, including (i) phonon-phonon scattering, (ii) phonon-interface scattering, and (iii) phonon-defect scattering43. The phonon scattering can be reduced in several ways, such as creating a strong/immobile interphase, increasing filler geometry, creating a 3D network, and aligning BNNSs within the nanocomposite matrix43,76.

Functionalization is one of the several techniques that have been utilized to minimize these scattering by strengthening interphases. For instance, Huo et al.133 increased the thermal conductivity of epoxy-BNNS composites by 513.5% when modifying BNNSs with coupling agent silane. This increase was attributed to the reduction in thermal resistance by strengthening the interphase between BNNSs and epoxy. Thermal resistance could be further reduced by increasing the bonding strength or molecular interaction type. Such results were demonstrated for the epoxy-BNNP composites utilizing stronger chemical bonding, i.e., covalent (BNNP-HBP) and weaker chemical bonding, i.e., non-covalent functionalized BNNP (BNNP-ODA)134. BNNP-HBP composites exhibited a thermal conductivity increase of 40-fold, whereas BNNP-ODA showed an increase of 35-fold. The BNNP-HBP creates a stronger molecular interaction with the epoxy matrix compared with BNNP-ODA, resulting in better thermal conductivity.

Increasing interfacial surface area and filler geometry also play a crucial role in shortening thermal conductivity paths. As such, the thermal conductivity of PMMA-BNNS was increased by ~1700% for 140 m2 g−1 surface area of BNNSs68 as opposed to ~60% for 6.77 m2 g−1 surface area of BNNSs127 at the same amount of loading127. As heat fluxes are transferred from polymer matrices to BNNSs through the interfaces, increasing interfacial surface area facilitates the transfer of a higher amount of heat from matrix to nanosheets. As a result, exfoliation and well-dispersion of BNNSs are very effective in increasing the thermal conductivity131,135.

Phonon scattering is highly dependent on the irregularity, interface structures, and defects of the nanocomposites. Therefore, structural factors such as polymer chain organization, shape, size, and orientation of BNNSs regulate the heat conduction paths of the materials50. For instance, polymers of higher crystallinity, such as high-density polyethylene, are highly thermally conductive (0.5 W m−1 K−1), whereas amorphous-rich polymers, like low-density polyethylene, show low thermal conductivity (0.26 W m−1 K−1)136. Interestingly, BNNSs can act as a nucleating point and increase crystallinity. Li et al.110 reported that incorporating BNNSs increased crystallinity of the polymers from 36 to 38%, therefore increasing the thermal conductivity by 154%. High aspect ratio and lateral dimension of thermally conductive 2D nanosheets are also likely to reduce the interface numbers, therefore reducing phonon scattering and increasing mean free paths for heat conduction137.

A well-structured and interconnected 3D network of BNNSs can further reduce phonon scattering, originated from structural defects of amorphous polymers (Fig. 8)43. Several techniques have been explored to create a 3D network of BNNSs, including tape casting138, spin-casting139, applying shear force140, mechanical stretching140, employing magnetic force141, or electric fields142. For example, Lin et al.101 modified the BNNSs surface by imparting iron oxide and aligned the BNNSs by applying a magnetic field. Thermal conductivity was increased 5.7-fold by adding vertically aligned BNNSs while randomly oriented BNNSs improved that by 2.8-fold at the same 20 wt.% loading amount. Because of the anisotropic nature of thermal conductivity, heat can transfer faster along the in-plane direction than the through-plane direction of BNNSs. As a result, aligning the BNNSs within nanocomposites and creating an interconnected BNNSs network could increase the heat conductivity by higher values than randomly oriented BNNS composites.

It is interesting to note that the experimental measurement of thermal conductivity of polymer-BNNS composites could be different than the predicted thermal conductivity evaluated by simulation studies. For example, Lin and co-workers showed that the predicted enhancement of thermal conductivity of epoxy-BNNS composites is ~32% while experimental values showed an enhancement of 104%127. This discrepancy was explained considering several factors: (i) the complexity of real composite systems when compared with theoretical calculation such as BNNSs size, shape, and thickness. Such complexity of the system could lead the calculation to underestimate or overestimate thermal conductivities of the polymer composite materials, (ii) thermal boundary resistance (TBR) values could not be measured experimentally, therefore, TBR values are assumed in theoretical calculation, resulting in an error in predicted values, (iii) because of the anisotropic nature of BNNSs, the assumed thermal conductivity of BNNSs are either lower or higher in theoretical calculation than the actual thermal conductivity of BNNSs, and (iv) experimental error, originated from either method or procedures, could also contribute to the discrepancies between theoretical and experimental results127,143,144.

He et al.145 developed a ternary composite via a high-temperature pressing method to reduce void formation. The high-temperature pressing method reduces the structural defects/voids originating from low dense packing and microstructural defects (such as grain boundaries, stacking faults). These defects are occupied by air, resulting in reduced thermal conductivity. As a result of reducing defects, lower phonon scattering and higher thermal conductivity are achieved compared with the constituent binary composites.

Thermal stability of a material is the ability to resist or delay the degradation of molecular structures owing to heating. For polymer materials, the chemical structure consists of long-chains and short-chains of polymer molecules that are bonded with weak vdW forces. As a result, these polymer materials are susceptible to easy degradation under heating. Polymer usually decomposes into different volatile gases and produces chars either in the presence of oxygen (oxidative degradation) or in the absence of oxygen (pyrolytic degradation)146. Nanofillers may reduce these thermal degradation processes by acting as a mass barrier and catalyst147,148. 2D materials such as BNNSs can reduce the diffusion and transmission rate of oxygen and decomposed volatile gases within the nanocomposite matrix, thus slowing down the decomposition reaction rate (Fig. 9)149,150,151.

Schematic illustration of factors affecting the thermal degradation of polymer-BNNS composites. Straight diffusion/migration paths used by volatile gases and oxygen molecules for polymer matrix result in fast thermal degradation. In contrast, BNNSs create tortuous paths within the matrix; therefore, volatiles and oxygen gases are required to pass around BNNSs, resulting in delayed thermal degradation149,150,151.

Because of the morphology, 2D nanosheets are more effective as a gas barrier than any other shapes such as 0D, 1D, and bulk materials152,153,154. Owing to the impermeable nature of 2D nanosheets, both volatile and oxygen gases have to diffuse around BNNSs instead of taking straight paths within polymer nanocomposites (Fig. 9). Thus, the mean free paths of gas diffusion through the polymer nanocomposites are increased, leading to a delay in the material degradation process. The barrier property of BNNSs was illustrated for polyacrylonitrile (PAN) composite systems (PAN-10 wt.% BNNS), where a 15% improvement in thermal stability (5 wt.% mass loss temperature) was reported155. Increasing the surface area of BNNSs would impede the gas flow even higher, resulting in more enhancement in thermal stability. Mesoporous BNNSs have a higher specific surface area (140 m2 g−1) compared with conventional BNNSs (27~50 m2 g−1), resulting in ~35% improvement in thermal stability (10 wt.% mass loss temperature) compared with pure PMMA68. These mesoporous structures can trap the mobile gases and reactive molecules; therefore, the transmission rate of volatile gases, free radicals, and oxygen molecules can significantly be reduced. Although volatile gas reduction could delay the weight loss of the materials, free radicals and oxygen reduction would obstruct the material degradation processes.

Uniform distribution of BNNSs into polymers is vital to disseminate the heat; otherwise, local hotspots can be created from agglomerated BNNSs. For instance, the thermal stability of thermoplastic polyurethane (TPU)-BNNS composites was reduced from 347 to 343 °C for 10% weight loss temperature because of BNNS agglomeration. Agglomerated BNNSs act as a heat concentrating point, thus expediting the thermal degradation process compared to neat polymers. Such results were also demonstrated for other polymers, including thiol-epoxy156, epoxy133, polyimide (PI)157, polystyrene (PS)158, polybenzimidazole105, and photosensitive polyimide159 composite systems.

Flame retardancy, usually evaluated by measuring the limiting oxygen index (LOI), is another crucial parameter that gives insights into the thermal stability of a material. LOI indicates the minimum amount of oxygen concentration needed for polymer combustion. Adding BNNSs into polymer materials increases LOI, resulting in a higher amount of oxygen required for polymer combustion. A PAN-based polymer nanocomposite (PAN-BNNS) reported an increment of LOI from 18 to 27% because of 10 wt.% BNNSs addition155.

On top of the barrier properties, nanofillers, modifiers, or any other decomposed products (chars) may exhibit catalytic effects. As a result, thermal decomposition reaction kinetics could be changed/modified by altering the activation energy and reaction mechanisms160,161,162,163,164,165,166,167. It is possible to impart catalytic functionalities by attaching BNNSs with appropriate functional molecules. Thus, thermal degradation mechanisms such as rate-limiting steps, reaction kinetics could be changed accordingly. To the best of our knowledge, the catalytic behavior of BNNSs for thermal decomposition of polymer nanocomposites has not been reported yet.

Tg of amorphous or semi-crystalline polymer materials indicates a gradual transformation from a brittle or glassy state into a viscous or rubbery state. The Tg can give fundamental insights into the polymer chain dynamics and helps to explore more areas of application. For example, materials with below room temperature Tg indicate pliable application, whereas materials with higher than room temperature Tg indicate a rigid application. In the molecular scale, various nanoscale chain dynamics such as atom translational mobility, bond or segmental reorientation dynamics, torsional dynamics, and dynamic heterogeneity play a crucial role in influencing Tg168. As a result, polymer chain interaction regulates the chain dynamics of materials by either attractive or repulsive force169,170,171,172,173,174,175,176,177,178. Although attractive force leads to an increase in Tg, repulsive force gives rise in chain mobility and accelerates structural relaxation179,180,181,182.

2D materials such as BNNSs have effects on polymer chain mobility because of the mechanical interlocking characteristics and molecular interactions at the interphase regions161. The mechanical interlocking characteristic increases activation energy for polymer chain movement and reduces chain mobility within nanocomposite matrix183. Increasing the amount of BNNSs would effectively raise the activation energy of the chain mobility, thus hiking Tg. Such result was demonstrated for the PMMA composite matrix where Tg was increased from 3 to 13°C when the amount of BNNSs was increased from 0.3 to 15 wt.%68,183.

Aside from physical interaction originated from BNNSs interlocking with polymer chains, molecular interactions can also be forged between constituent nanocomposites to engineer the Tg. By controlling the molecular interactions, immobile interphase at the BNNS-polymer interface can be developed133. For example, BNNP was functionalized in both covalent (BNNP-HBP) and non-covalent (BNNP-ODA) methods and utilized to fabricate epoxy-BNNP49. As covalent bonding is more robust than non-covalent bonding, a reduction in chain mobility by BNNP-HBP was observed to be higher compared with BNNP-ODA. As a result, the Tg of BNNP-BHP composites was increased to higher values. Such effect of functionalization was also investigated by MD simulations, where the predicted change in Tg of PMMA composites agreed well with the experimental results184. These simulation studies indicate that the polymer-nanofillers interactions have an important role on the polymer chain mobility, resulting in increased or decreased Tg182.

As Tg depends on local chain mobility, the higher heat transport should prevent local hotspots formation; otherwise, local polymer chains at the hotspots would move quickly185. Local hotspots (or heat concentrating points) are common consequence of BNNSs agglomeration. Detailed discussion to avoid heat concentrating points is explained in the thermal conductivity section of this article. Research reported degradation in Tg for TPU-BNNS composites by 23% (compared with TPU)186 and PS-BNNS composites by ~4% (compared with PS)158 because of BNNSs agglomeration.

2D materials with high thermal conductivity are poised to potentially solve the increasingly high heat dissipation problems that are common in electronic devices. For example, graphene and WS2 incorporated polymer nanocomposites with very high thermal conductivity can be utilized to distribute the heat of energy storage devices187,188,189. Unfortunately, such nanocomposites also showed increased electronic conductivity that is detrimental for applications like TIM and battery electrolytes or battery packaging. In such cases, BNNSs incorporated polymer nanocomposites are ideal190.

In summary, the thermal properties of polymer materials can be improved through appropriate assemblies of BNNSs into polymer materials as such by controlling BNNSs loading, dispersion, orientation, and void/defect formation within nanocomposites. The structure, regularity, and interface of the polymer matrix and thermally conductive BNNSs play a key role in the thermal conductivity value of the final polymer composites. However, phonon scattering is a limiting factor toward developing thermally conductive composite materials. Fortunately, well dispersion of BNNSs and strengthened interphase between BNNSs and polymer matrix potentially minimize the phonon scattering. Interconnected networks of BNNSs with strong interphase and minimized agglomerations are most effective in developing thermally conductive nanocomposites. On the other hand, the barrier and catalytic properties of BNNSs could further reduce the volatile gas flow of the polymer nanocomposites during thermal degradation process and increase the thermal stability of the composite materials.

Electrical and electrochemical properties

Applications such as power electronics use high dielectric polymer materials that show promising reliability and higher voltage breakdown strength191,192. However, these materials fail to perform well at extreme conditions such as at high temperatures193. Polymer nanocomposites could be configured to address such problems by incorporating the merits of BNNSs and polymers. For example, Wang et al.194 developed BNNSs incorporated divinyltetramethyldisiloxane-bis(benzocyclobutene) (cBCB) nanocomposites for dielectric application at high temperatures. At high-temperature (70°C) operation, dielectric losses of conventional polymers were increased from 15 to 76%. On the contrary, BNNSs incorporated cBCB composites showed surprisingly very low increment (dielectric loss was increased from 15 to 18% at 70°C).

High electrical resistivity and dielectric breakdown strength are critical for many applications, including TIM and microwave electronic packaging. Because of the high bandgap in BN materials, the addition of BN nanomaterials into the polymer matrix does not increase the electrical resistivity of polymers. There have been reports on no change in electrical conductivity for BNNSs incorporated PMMA, polyvinyl butyral, PS, poly (ethylene-vinyl acetate)109,126. In addition, the voltage breakdown strength of epoxy matrix increased from ~251 kV mm−1 (for pristine epoxy) to ~260, 281, 242, and 176 kV mm−1 in the nanocomposites containing 0.2, 0.6, 1, and 5 vol.% of BN nanomaterials, respectively195. The improvement of breakdown strength at low loading could be attributed to the lower dielectric loss and higher thermal conductivity. In contrast, the decreased breakdown strength at higher loading levels could be attributed to the possibility of the presence of structural imperfections. Such structural imperfections are resulted from the agglomeration of BNNSs, thus increasing the possibility of void formation around nanosheets195. It is important to create strong interphase and uniform dispersion of BNNSs into polymer matrix in order to improve the breakdown strength196. For example, Xing et al.197 fabricated polymer nanocomposites by incorporating functionalized BNNSs. The authors reported a monotonic increase in both dielectric breakdown strength and electrical resistivity with increasing BNNSs loading up to 8 vol.%. Such results indicate the importance of creating strong interphase and uniform dispersion of BNNSs in order to develop electrically insulative and high dielectric strength materials.

Lithium battery technology is yet another emerging domain that is growing fast to address pollutant emission, independence to fossil fuel resources, and global warming concerns. However, this requires tackling critical challenges such as poor thermal conductivity of battery materials, low ionic conductivity of electrolytes, and lack of sufficient mechanical robustness in separators to suppress lithium (Li) dendrites, leading to battery failure and exothermic thermal runaways. Chen et al.198 demonstrated that the thermal conductivity of electrolytes with BNNSs could be increased up to ~50 times compared with pristine electrolytes. Also, such composites exhibited reduced dielectric loss, increased electrical resistivity, and enhanced voltage breakdown strength that enable them to be promising for cooling applications. Shim et al.199 substantially improved ionic conductivity, Li+ ion transference number, and mechanical properties (i.e., modulus) of gel-electrolytes using a very low amount of functionalized boron nitride nanoflake (BNNF) (0.5 wt.%). Because of the Lewis acid–base interaction, BNNFs increased Li+ ion conduction by trapping the anions of the electrolytes. Besides, Li+ ion can also be transported through the segmental motion of the electrolytic polymer matrices, and such segmental motion depends on the amorphous portion of the polymer materials200. In such cases, nanofillers such as BNNSs could be utilized to increase the amorphous portion of the polymers (i.e., plasticizing effect), therefore increasing the ionic conductivity of polymer electrolyte materials201. Waqas et al.202 fabricated a bi-layer PE-BN/poly(vinylidene flouride-co-hexagluoropropene) (PVDF-HFP) separator that significantly suppressed lithium dendrite growth owing to the great adsorption energy with polymers, large interactive surface area, and superior mechanical properties (i.e., modulus).

2D materials such as graphene, MXene, and MoS2, are shown to be good candidates for Li batteries as cathode, anode, and catalyst materials203. However, these 2D materials are not suitable for the battery electrolyte or packaging applications since increased electronic conductivity would fail the battery by short circuiting. In such cases, BNNSs have advantages over other 2D materials (graphene, MXene, and MoS2) where electronic insulation properties are crucial190. In summary, the plasticizing effect and Lewis acid–base characteristic of BNNS may facilitate to Li+ ion conduction through the polymer electrolytes, resulting in increased ionic conductivity of Li batteries. In addition, thermally conductive BNNSs are shown to distribute the heat generated within the electrolytes during battery operation, resulting in the reduced hot-spot formation and avoiding thermal run-away events190.

Optical properties

The interest for the optical properties of polymer materials is increasing in order to design transparent polymer nanocomposites that could exhibit properties such as light absorption (UV, infrared, and visible light), UV photodetion, photoluminescence, dichroism, or non-linear optical properties204. BNNSs possess important optical properties such as UV–vis absorption, deep UV and thermal neutron detection, and photoluminescence205,206,207. The optical properties of BNNSs make them a suitable choice as nanofillers for the fabrication of polymer composites that are likely to develop visible light transparent, UV-blocking with photoluminescence properties into polymer materials208.

The main factors affecting the optical properties of nanocomposites include the electronic nature, size, and spatial distribution of the BN nanosheets within polymer matrices. Although the intrinsic optical properties of BNNSs such as color absorption and emission depend on the nanosheets size, the spatial distribution of the nanosheets has a major role in configuring the optical properties of the materials204. Uniform distribution of nanosheets promotes optical transparency, photoluminescence, UV, and IR absorption while an ordered distribution may favor iridescence, and a uniaxially oriented distribution of nanosheets may favor dichroism204. For example, Min et al.81 incorporated BN nanoparticles and nanosheets into PI and investigated the optical properties of corresponding nanocomposites. The PI-BN nanosheets composites possessed high transparency at the wavelength of 550 nm (75.4% transmittance), as opposed to PI-BN nanoparticles composites (0.1% transmittance) at the same 10 wt.% BN loading. This indicates that the opaque nature of the BN particles decreased the transparency of the composites (UV–vis properties of the polymer nanocomposites). Interestingly, the transparency properties of BNNS composites were not changed much (transmittance of base PI and PI with 3 wt.% BNNS are 88% and 84%, respectively) up to the addition of 3 wt.% BNNS, indicating the uniform distribution of nanosheets within nanocomposite matrix. The addition of more BNNSs (i.e., 10 wt.%) decreased the transparency properties of PI-BNNS composites to 75.4%. As the concentrations of BNNSs increase, the tendency to agglomerate also increases. Such agglomerates act as larger particles, therefore blocking and scattering the visible light that are passing through. In addition, BNNSs also showed intense cathodoluminescence emission properties, indicating the potential use of BNNS nanocomposites as UV laser emitters209. The other optical properties of BNNS such as deep UV photodetectors are interesting because of their military applications such as missile launching detection, gunshot warning, UV flame sensing, and secure space communications210.

The need for UV-protective materials is in great demand owing to the thinning of the atmospheric ozone layer. The BNNS is considered as one of the promising UV-filters that can be incorporated into polymer materials to modify the UV-filtering properties of the composites204. For example, Bisht et al.211 investigated the PMMA composites using amine-functionalized BN nanoflakes where 0.5 wt.% BN nanoflakes incorporated PMMA composites shielded UV-wavelength (UV-B and UV-C) by 325% while retaining high transparency of 65% to visible light. However, increasing the BN nanoflakes loading improves the UV-blocking properties as well as reduces the transparency of the nanocomposites.

Although 2D materials such as graphene are effective in improving the optical properties as such absorbing visible lights, UV-near infrared light, and shielding UV-radiation, such nanocomposites are likely to have high electronic conductivity that is not desirable in certain opto-electric applications212,213. In such cases, the incorporation of BNNSs is likely to be advantageous as the bandgap of BN is much higher (5.7 eV) compared with graphene.

BNNS-polymer nanocomposite applications

Polymeric composite materials are in demand for many emerging applications in consumer electronics, energy storage, and mobility systems. Although there are many nanofillers that can be added to polymer materials, the authors believe that BN nanosheets polymer composites are suited for applications where a combination of very low electrical conductivity, high thermal conductivity, high mechanical properties, and high electrical breakdown is needed. Conventional 2D nanofillers such as graphene and MXene are electrically conductive26,27,28,29, therefore the addition of such nanofillers could increase the electrical conductivity of the nanocomposites. BNNS-polymer nanocomposite materials are suitable for applications where high electrical resistivity is critical as seen in TIM, electrical cable insulation, and battery electrolytes. In addition to high electrical resistivity, such applications require high heat dissipation to avoid local hotspots generation from daily operation. The high thermal conductivity of BNNS is known to increase the heat dissipation capability and reduce the hotspots generation in polymer materials that inherently have very low thermal conductivity. Figure 10 indicates some of the promising applications of BNNS-based materials. Electronic devices often need materials (such as TIM) that can distribute heat efficiently since local hotspots can be created under service operations that may lead to performance and reliability degradation of the devices. Thermally conductive materials and, in particular, BNNSs are promising for such applications because of high electrical resistivity and thermal conductivity214,215. For example, electronic packaging is one important area of application where higher thermal conductivity is required while maintaining electrical insulation101,214. In such cases, BNNSs have the combination of both thermally conductive and electrically insulative properties to improve the polymer materials performance. Sophisticated electronics such as hazardous chemical detectors (these detectors use abundant Π electron clouds of BNNS to detect different chemical species)216, temperature sensors217, and coatings in electronics214 are some other areas of such applications.

Illustration of unique properties of BNNSs and their application in the emerging fields. High thermal conductivity and electrical resistivity are required for thermal management and electronic sensors214,215. Mechanical strength and stiffness are good for structural material application218. Biocompatibility is important for manufacturing biomaterials224. Electronic resistivity but ionic conductivity are unique properties of BNNS and important for energy storage application199,222,226,227. Besides, transparent properties of few layer BNNSs are crucial for optical application208.

The mobility industry, such as automotive and aircraft, require lightweight structural materials with high strength, stiffness, and thermal conductivity. As for example, parts such as fuel tank and engine cover require very high heat management, cable insulation and sheathing require electrical insulation, wheels and tires require good tribological properties218.

Technological improvement in renewable energy demands high-performance energy storage devices that can perform under extreme weather conditions219,220. Recent work demonstrated a BNNS composite membrane separator for batteries that can withstand up to 150 °C221. Besides, the Lewis acidic characteristic of BNNS is shown to increase the Li+ ion mobility, and higher thermal conductivity of BNNS is shown to lead to homogenous thermal distribution and the suppression of dendritic Li growth199,222. Thus, thermally safe, and long cycle batteries can be manufactured in the future for energy storage devices used in electric vehicles and grid-scale energy storage systems223. Because of such properties of BNNS, many applications, including biomaterials224, sorbents217,225, and membranes for water and gas separation226, fire-resistant coatings217, and catalytic support materials have been utilizing BNNSs for their material development227.

To summarize the status of commercial development for BNNSs-polymer composites, an estimated timeline is illustrated in Fig. 11. The key properties of BNNSs including mechanical strength, flexibility, electrical resistivity, optical, and thermal conductivity play a decisive role in the application and commercialization of such products. The most promising applications include electronic and energy materials where insulation and fast heat distribution are required such as TIM, electronic packaging, electronic sensors, cable insulations, battery electrolytes, and battery packaging.

Conclusion and future outlook

In the past decades, nanocomposite engineering has been explored to address the low mechanical properties, thermo-mechanical stability, and thermal conductivity of polymer materials. Particularly, BNNS nanofillers show good potential in electronic and insulation application owing to their exceptional mechanical properties, thermal conductivity, structural stability, and electrical resistivity. However, there are many remaining challenges to develop high-performance BNNS-polymer nanocomposites as such low chemical reactivity of BNNSs, weak molecular interactions between BNNSs and their host polymers, and nonuniform dispersion of BNNSs. Therefore, innovations in BNNS-polymer nanocomposites are still needed to translate the excellent material properties of BNNSs into polymer materials.

This work highlights the design principles of BNNS-polymer composites by reviewing both interfacial (i.e., covalent, and non-covalent interaction, interphase, and interfacial surface area) and non-interfacial (i.e., mechanical interlocking, dispersibility, defects/interface space, and processing parameters) factors. These factors are shown to be major players for controlling the mechanical, thermal, electrical, and optical properties of polymers. The BNNS-polymer composites properties can be increased to the theoretical limits by controlling these factors at different length scales, including microscopic and macroscopic levels. Mechanical properties are affected by the effective load transfer between nanosheets and polymer matrix requiring uniform distribution, strong interphase, and negligible defects. However, agglomeration of BNNSs is an obstacle in achieving uniform dispersion, and such agglomerates may act as stress concentrating points, resulting in low mechanical properties and optical transparency. On the other hand, phonon scattering is the limiting factor toward developing thermally conductive composite materials. The phonon scattering could be minimized by reducing defects, strengthening interphase, and creating a network of BNNSs that can act as a thermally conductive path for conducting heat. In addition, the structure and regularity of polymer chains and BNNSs, and their interfaces play a major role in controlling the thermal conductivity of polymer composites. The interphase between BNNSs and polymer matrix has a crucial role in transferring the mechanical stress, thermal heat, and electrical properties from one phase to another. The interphase strength can be increased by forming physical and chemical bonds such as H-bond, vdW force, and π–π interactions between BNNSs and polymers, thus facilitating an effective load transfer at the interphases. This could be achieved by activating the chemically-inert BNNSs via functionalization.

The functionalization of BNNSs using covalent and non-covalent bonds and their effects on the structure–property relationship of composites are discussed. Chemical compatibility between polymers and BNNSs is vital for achieving mechanically strong and thermo-mechanically stable composites. For example, BNNSs attached with oxide and hydroxide functional groups are compatible with polymers such as polyvinyl acetate (PVA), PAN, PMMA, PAA owing to the polar–polar interactions. In contrast, silane coupling agents develop both polar and nonpolar functionalities and are compatible with either polar or nonpolar types of polymer materials. Such strategies can enhance the polymer adhesion with BNNSs and reduce polymer chain dynamics. A reduction in chain dynamics increases storage modulus, Tg, and dimensional stability of the composites. Furthermore, a homogenous dispersion of monolayer BNNSs is critical for increasing the molecular interactions of polymer chains with individual BNNSs. The agglomeration of BNNSs within nanocomposites usually occurs after a threshold loading amount of BNNSs. Such agglomerations can be reduced by increasing the compatibility of BNNSs with polymer matrix through functionalization. For instance, the attachment of hydrophilic functional groups to the surface of BNNSs is likely to yield uniform dispersion of BNNSs into the hydrophilic type of polymer matrices (e.g., polyacrylamide, poly(ethylene glycol) derivatives) owing to hydrophilic–hydrophilic interaction and vice versa.

Given the mass barrier properties of 2D nanosheets, the high surface area of BNNSs has the potential to reduce the oxygen and decomposed volatile gas flow within the nanocomposite matrix. Hence, reduced oxygen and decomposed gas flow promote the thermal stability of nanocomposites. On the other hand, the incorporation of BNNSs into polymer materials affects the optical properties of the corresponding composite materials. The main reason for the optical property changes is the light scattered by the BNNSs. The nanosheet size and agglomerates of BNNSs, and the defects formed within the nanocomposites are the source of such light scattering. Different strategies are developed to minimize the light scattering such as distributing the BNNSs uniformly within matrix, developing stronger interphase, and downsizing the BN nanosheet sizes. Such approaches require good control of downsizing BNNSs as well as modification of BNNSs. The surface modification includes functionalizing BNNSs with appropriate functional molecules in order to increase the miscibility of nanosheets into polymer matrix and form chemical bonding between nanocomposite constituents. The other optical properties such as UV and IR-wavelength blocking also require good control of the above-mentioned factors to develop the desired properties into polymer nanocomposites.

In the future, attention should be given to the following: (i) to study the polymer-BNNS interphases in more details in terms of their molecular structure and chemistry, and develop structure–property relationships between interphase and properties such as stress transfer, polymer chain dynamics, UV-light transparency, and thermal resistance, (ii) to investigate the mechanisms leading to the aggregation of BN nanosheets depending on the polymer chemistry, functionalized interfaces, and the mitigation strategies, (iii) to explore strategies that can increase the chemical reactivity of BNNSs with the polymer matrix, and (iv) to develop low-cost scalable synthesis of high-quality BN nanosheets and polymer nanocomposites in order to make them appealing for industrial applications. It should be mentioned that the industrial-scale exfoliation of BN nanosheets is still very costly. This is because of the low yield (5–30%) of BNNSs exfoliation resulting from the firm “lip–lip” interaction between B-N bonds228. It is important to explore environment friendly and facile routes for low-cost, large-scale synthesis of BN nanosheets.

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

References

Naskar, A. K., Keum, J. K. & Boeman, R. G. Polymer matrix nanocomposites for automotive structural components. Nat. Nanotechnol. 11, 1026–1030 (2016).

Garcés, J. M., Moll, D. J., Bicerano, J., Fibiger, R. & McLeod, D. G. Polymeric nanocomposites for automotive applications. Adv. Mater. 12, 1835–1839 (2000).

Barua, L., Zou, B. & Zhou, Y. Machine learning for international freight transportation management: a comprehensive review. Res. Transp. Bus. Manag. 34, 100453 (2020).

Hussain, Farzana & Hojjati, M. Polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J. Compos. Mater. 40, 467–471 (2006).

Barua, L., Zou, B., Noruzoliaee, M. & Derrible, S. A gradient boosting approach to understanding airport runway and taxiway pavement deterioration. Int. J. Pavement Eng. 1–15 (2020).

Ciofani, G., Raffa, V., Menciassi, A. & Cuschieri, A. Cytocompatibility, interactions, and uptake of polyethyleneimine-coated boron nitride nanotubes by living cells: Confirmation of their potential for biomedical applications. Biotechnol. Bioeng. 101, 850–858 (2008).

Chen, X. et al. Boron nitride nanotubes are noncytotoxic and can be functionalized for interaction with proteins and cells. J. Am. Chem. Soc. 131, 890–891 (2009).

Horváth, L. et al. In vitro investigation of the cellular toxicity of boron nitride nanotubes. ACS Nano 5, 3800–3810 (2011).

Lei, W. et al. Oxygen-doped boron nitride nanosheets with excellent performance in hydrogen storage. Nano Energy 6, 219–224 (2014).

Li, Q. et al. Sandwich-structured polymer nanocomposites with high energy density and great charge-discharge efficiency at elevated temperatures. Proc. Natl Acad. Sci. USA 113, 9995–10000 (2016).

Yu, Y.-X. A dispersion-corrected DFT study on adsorption of battery active materials anthraquinone and its derivatives on monolayer graphene and h-BN. J. Mater. Chem. A 2, 8910–8917 (2014).

Jang, S. K., Youn, J., Song, Y. J. & Lee, S. Synthesis and characterization of hexagonal boron nitride as a gate dielectric. Sci. Rep. 6, 30449 (2016).

Bai, S. & Shen, X. Graphene-inorganic nanocomposites. RSC Adv. 2, 64–98 (2012).

Wang, D. et al. Surface modification of graphene with layered molybdenum disulfide and their synergistic reinforcement on reducing fire hazards of epoxy resins. Ind. Eng. Chem. Res. 52, 17882–17890 (2013).

Qi, B. et al. Enhanced thermal and mechanical properties of epoxy composites by mixing thermotropic liquid crystalline epoxy grafted graphene oxide. Express Polym. Lett. 8, 467–479 (2014).

Domun, N. et al. Improving the fracture toughness properties of epoxy using graphene nanoplatelets at low filler content. Nanocomposites 3, 85–96 (2017).

Chandrasekaran, S. et al. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 97, 90–99 (2014).

Qi, B. et al. Mechanical and thermal properties of epoxy composites containing graphene oxide and liquid crystalline epoxy. Fibers Polym. 15, 326–333 (2014).

Ramos-Galicia, L. et al. Improved performance of an epoxy matrix as a result of combining graphene oxide and reduced graphene. Int. J. Polym. Sci. 2013, 1–7 (2013).

Boldrin, L., Scarpa, F., Chowdhury, R. & Adhikari, S. Effective mechanical properties of hexagonal boron nitride nanosheets. Nanotechnology 22, 505702 (2011).

Li, L. H., Cervenka, J., Watanabe, K., Taniguchi, T. & Chen, Y. Strong oxidation resistance of atomically thin boron nitride nanosheets. ACS Nano 8, 1457–1462 (2014).

Verma, A., Parashar, A. & Packirisamy, M. Tailoring the failure morphology of 2D bicrystalline graphene oxide. J. Appl. Phys. 124, 015102 (2018).

Paszkowicz, W., Pelka, J. B., Knapp, M., Szyszko, T. & Podsiadlo, S. Lattice parameters and anisotropic thermal expansion of hexagonal boron nitride in the 10–297.5 K temperature range. Appl. Phys. A Mater. Sci. Process. 75, 431–435 (2002).

Meng, W., Huang, Y., Fu, Y., Wang, Z. & Zhi, C. Polymer composites of boron nitride nanotubes and nanosheets. J. Mater. Chem. C. 2, 10049–10061 (2014).

Weng, Q., Wang, X., Wang, X., Bando, Y. & Golberg, D. Functionalized hexagonal boron nitride nanomaterials: emerging properties and applications. Chem. Soc. Rev. 45, 3989–4012 (2016).

Ling, Z. et al. Flexible and conductive MXene films and nanocomposites with high capacitance. Proc. Natl. Acad. Sci. 111, 16676–16681 (2014).

Li, Y. Q., Yu, T., Yang, T. Y., Zheng, L. X. & Liao, K. Bio-Inspired nacre-like composite films based on graphene with superior mechanical, electrical, and biocompatible properties. Adv. Mater. 24, 3426–3431 (2012).

Zhang, M., Huang, L., Chen, J., Li, C. & Shi, G. Ultratough, ultrastrong, and highly conductive graphene films with arbitrary sizes. Adv. Mater. 26, 7588–7592 (2014).

Narayanan, S. et al. On the structure and chemistry of iron oxide cores in human heart and human spleen ferritins using graphene liquid cell electron microscopy. Nanoscale 11, 16868–16878 (2019).

Wen, Y. et al. Direct growth of tungsten disulfide (WS2) on gallium nitride (GaN) and the photovoltaic characteristics of the heterojunctions. Semicond. Sci. Technol. 36, 025016 (2020).

Dean, C. R. et al. Boron nitride substrates for high-quality graphene electronics. Nat. Nanotechnol. 5, 722–726 (2010).

Ren, X. et al. One-pot polymer conjugation on carbon nanotubes through simultaneous p e p stacking and the Biginelli reaction. Polymer 64, 210–215 (2015).

Li, K., Liu, J., Huang, Y., Bu, F. & Xu, Y. Integration of ultrathin graphene/polyaniline composite nanosheets with a robust 3D graphene framework for highly flexible all-solid-state supercapacitors with superior energy density and exceptional cycling stability. J. Mater. Chem. A 5, 5466–5474 (2017).

Roenbeck, M. R. et al. Molecular-level engineering of adhesion in carbon nanomaterial interfaces. Nano Lett. 15, 4504–4516 (2015).

Chen, X. et al. Quantitative nanomechanical characterization of the van der Waals interfaces between carbon nanotubes and epoxy. Carbon N. Y. 82, 214–228 (2015).

Chen, X., Zheng, M., Park, C. & Ke, C. Direct measurements of the mechanical strength of carbon nanotube-poly(methyl methacrylate) interfaces. Small 9, 3345–51 (2013).

Chen, X. et al. Mechanical strength of boron nitride nanotube-polymer interfaces. Appl. Phys. Lett. 107, 253105 (2015).

Rouhi, S. Molecular dynamics simulation of the adsorption of polymer chains on CNTs, BNNTs and GaNNTs. Fibers Polym. 17, 333–342 (2016).

Wang, X., Zhi, C., Weng, Q., Bando, Y. & Golberg, D. Boron nitride nanosheets: novel syntheses and applications in polymeric composites. J. Phys. Conf. Ser. 471, 012003 (2013).

Yu, C., Zhang, J., Tian, W., Fan, X. & Yao, Y. Polymer composites based on hexagonal boron nitride and their application in thermally conductive composites. RSC Adv. 8, 21948–21967 (2018).

Verma, A., Parashar, A. & Packirisamy, M. Atomistic modeling of graphene/hexagonal boron nitride polymer nanocomposites: a review. Wiley Interdiscip. Rev. Comput. Mol. Sci. 8, https://doi.org/10.1002/wcms.1346 (2018).

Zhi, C. Y., Bando, Y., Tang, C. C., Huang, Q. & Golberg, D. Boron nitride nanotubes: functionalization and composites. J. Mater. Chem. 18, 3900–3908 (2008).

Guerra, V., Wan, C. & McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 100, 170–186 (2019).

Zheng, Z., Cox, M. C. & Li, B. Surface modification of hexagonal boron nitride nanomaterials: a review. J. Mater. Sci. 53, 66–99 (2018).

Pakdel, A., Wang, X., Bando, Y. & Golberg, D. Nonwetting ‘white graphene’ films. Acta Mater. 61, 1266–1273 (2013).

Li, J., Chen, J., Zhu, M., Song, H. & Zhang, H. Interfacial characteristics of boron nitride nanosheet/epoxy resin nanocomposites: a molecular dynamics simulation. Appl. Sci. 9, 2832 (2019).

Roy, S., Petrova, R. S. & Mitra, S. Effect of carbon nanotube (CNT) functionalization in epoxy-CNT composites. Nanotechnol. Rev. 7, 475–485 (2018).

Eitan, A., Jiang, K., Dukes, D., Andrews, R. & Schadler, L. S. Surface modification of multiwalled carbon nanotubes: toward the tailoring of the interface in polymer composites. Chem. Mater. 15, 3198–3201 (2003).

Yu, J. et al. Interfacial modification of boron nitride nanoplatelets for epoxy composites with improved thermal properties. Polymer 53, 471–480 (2012).

Guo, Y., Ruan, K., Shi, X., Yang, X. & Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: a review. Compos. Sci. Technol. 193, 108134 (2020).

Radhakrishnan, S. et al. Fluorinated h-BN as a magnetic semiconductor. Sci. Adv. 3, e1700842 (2017).

Yang, H. et al. Influence of doped nitrogen and vacancy defects on the thermal conductivity of graphene nanoribbons. J. Mol. Model. 19, 4781–4788 (2013).

Abdelmouleh, M., Boufi, S., Belgacem, M. N. & Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 67, 1627–1639 (2007).

Rong, M. Z., Zhang, M. Q. & Ruan, W. H. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: a review. Mater. Sci. Technol. 22, 787–796 (2006).

Rasul, M. G. et al. Polyethylene-BN nanosheets nanocomposites with enhanced thermal and mechanical properties. Compos. Sci. Technol. 204, 108631 (2021).

Lipatov, Y. S. Interfaces in polymer-polymer composites. In: Controlled Interphases in Composite Materials (eds. Ishida H.) 599–611 (Springer, 1990).

Nikkhah, S. J., Moghbeli, M. R. & Hashemianzadeh, S. M. Interfacial adhesion between functionalized polyethylene surface and graphene via molecular dynamic simulation. J. Mol. Model. 21, 121 (2015).

Aluko, O., Gowtham, S. & Odegard, G. M. Multiscale modeling and analysis of graphene nanoplatelet/carbon fi ber / epoxy hybrid composite. Compos. Part B 131, 82–90 (2017).

Hadden, C. M. et al. Molecular modeling of EPON-862 / graphite composites: Interfacial characteristics for multiple crosslink densities. Compos. Sci. Technol. 76, 92–99 (2013).

Mansfield, K. F. & Theodorou, D. N. Atomistic simulation of a glassy polymer/graphite interface. Macromolecules 24, 4295–4309 (1991).

Hadden, C. M. et al. Mechanical properties of graphene nanoplatelet/carbon fi ber / epoxy hybrid composites: Multiscale modeling and experiments. Carbon N. Y. 95, 100–112 (2015).

Li, C., Browning, A. R., Christensen, S. & Strachan, A. Composites: part A atomistic simulations on multilayer graphene reinforced epoxy composites. Compos. Part A 43, 1293–1300 (2012).

Zhang, Y., Zhuang, X., Muthu, J., Mabrouki, T. & Fontaine, M. Composites: Part B Load transfer of graphene/carbon nanotube/polyethylene hybrid nanocomposite by molecular dynamics simulation. Compos. Part B 63, 27–33 (2014).

Wan, C. & Chen, B. Reinforcement and interphase of polymer/graphene oxide nanocomposites. J. Mater. Chem. 22, 3637–3646 (2012).

Kovalev, A., Shulha, H., Lemieux, M., Myshkin, N. & Tsukruk, V. V. Nanomechanical probing of layered nanoscale polymer films with atomic force microscopy. J. Mater. Res. 19, 716–728 (2004).