Abstract

Controlled anisotropic growth of two-dimensional materials provides an approach for the synthesis of large single crystals and nanoribbons, which are promising for applications as low-dimensional semiconductors and in next-generation optoelectronic devices. In particular, the anisotropic growth of transition metal dichalcogenides induced by the substrate is of great interest due to its operability. To date, however, their substrate-induced anisotropic growth is typically driven by the optimization of experimental parameters without uncovering the fundamental mechanism. Here, the anisotropic growth of monolayer tungsten disulfide on an ST-X quartz substrate is achieved by chemical vapor deposition, and the mechanism of substrate-induced anisotropic growth is examined by kinetic Monte Carlo simulations. Results show that, besides the variation of substrate adsorption, the chalcogen to metal (C/M) ratio is a major contributor to the large growth anisotropy and the polarization of undergrowth and overgrowth; either perfect isotropy or high anisotropy can be expected when the C/M ratio equals 2.0 by properly controlling the linear relationship between gas flux and temperature.

Similar content being viewed by others

Introduction

Transition metal dichalcogenides (TMDCs) have been a star family of two-dimensional (2D) materials,1 which is attributed to their excellent electronic and optical properties. In particular, monolayer TMDCs typically including MoS2, MoSe2, WS2, and WSe2, with remarkable advantages over the few-layers or blocks of such materials, have more potential applications in low-dimensional semiconductors and next-generation optoelectronic devices.2,3,4,5,6,7 Methods including mechanical exfoliation, liquid exfoliation, physical vapor deposition, and chemical vapor deposition (CVD) have been developed to prepare monolayer or few-layers TMDC materials.8,9 Among those methods, vapor-phase-based growth approaches like CVD are more desirable due to the potential to scale up and obtain wafer-scale 2D TMDCs.

To enable the direct growth of large single crystals and nanoribbons by CVD,10 the flake alignment of 2D materials can be one of key factors and the growth anisotropy should be intensively investigated, since it has been shown that the wafer-scale single-crystalline graphene can be grown if the initial graphene nuclei have the same orientation11 and the alignment of monolayer TMDC nanoribbons is largely determined by the orientation of the crystal substrate.12,13 Currently,14 in many synthesis approaches, 2D TMDC materials nucleate randomly on substrates, and their orientation cannot be well controlled. Controlled anisotropic growth of large-area or high-aspect-ratio single crystals is still in the early stage of development, and the detailed mechanism remains unclear, though there have been efforts and attempts on the location- and orientation-controlled growth of monolayer TMDCs.15,16,17

Recently, substrates such as sapphire, mica, graphite18,19,20,21 have been used in the alignment of as-grown TMDC flakes, which is attributed to the van der Waals (vdW) epitaxial interaction between the crystal substrate and monolayer TMDCs. The substrate-induced growth anisotropy of 2D TMDC flakes has been found in the experiments. For example, Chen et al. reported a step-edge-guided approach for the aligned or oriented growth of 2D WSe2 on the C-plane sapphire substrate by CVD and found that at a high temperature (>950 °C), the growth is strongly guided by the atomic steps on the substrate surface;18 using graphene on Ir(111) as substrates, Hall et al. grew well-oriented monolayer flakes of TMDCs by a two-step molecular beam epitaxy synthesis.22 However, the substrate-induced anisotropic growth of 2D TMDC samples is almost driven by the optimization of experimental parameters without understanding the fundamental mechanism dictating the 2D domain morphology under diverse growth conditions.

Systematic understanding of the anisotropic growth of monolayer TMDCs is a theoritical challenge due to the diversity of involved kinetic mechanisms and the wide range of growth conditions (e.g., gas flux, C/M ratio, temperature, and substrate conditions). The Monte Carlo simulation,23,24 as an excellent tool to investigate the cumulative statistical effects of the kinetic processes at the atomic level, can help quantify these diverse experimental conditions and significantly reduce the number of variables, so that one can develop a unified conceptual framework on the deposition mechanism of 2D compound crystals. Rajan et al. proposed a generalized kMC model with special consideration to CVD reactor parameters for the growth of 2D TMDC monolayers, which is predictive of mophological evolution with variations of growth conditions.25 Nie et al. introduced a full-diffusion kinetic Monte Carlo (kMC) model coupled with first-principles calculations to study the deposition process of WSe2 monolayers on graphene,26 which can reproduce different morphologies such as compact, fractal, and dendrite. Nevertheless, substrate effects27,28 that can largely determine the growth anisotropy are not introduced to those kMC models.

Study on the substrate-induced anisotropic growth of monolayer WS2 can provide a complete perspective closer to reality on the growth of 2D materials. In this work, by introducing local substrate effects on the adsorption, desorption, and diffusion processes, a substrate-sensitive kMC model is established to study the growth anisotropy using the representative case of the CVD growth of monolayer WS2 on ST-X quartz. And the kMC model introduces the on-the-fly calculation of substrate-induced variation of atomic potential energy. Then the growth morphological anisotropy and its origin are analyzed and discussed with experimental observations and simulation results.

Results and discussion

Observation and measurement of growth anisotropy

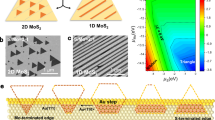

We conducted a preliminary experiment and observed the anisotropic growth of monolayer WS2 before the experimental optimization. It has been found that the morphology of TMDC flakes varies from upward triangle to downward triangle and to hexagon due to the variation of conditions such as temperature (T), gas flux (Ra, defined as the adsorption rate of W atoms in the kMC model), the C/M ratio, and substrate adsorption contrast (xEads, the ratio of the highest adsorption energy to the lowest on the same substrate). The experimental part is detailed in the Methods section. Fig. 1 shows the growth of monolayer WS2 on the ST-X quartz substrate at specific locations, where (a) and (b) are photographed with amplification of 1000 at two upstream neighbor spots of sample #1; (c) and (d) are photographed with amplification of 1000 at two downstream neighbor spots of sample #1; (e) and (f) are photographed with amplification of 1000 at two separated spots downstream from sample #2. Specifically, sample #1 is placed at the downstream of the S source and sample #2 is arranged at the further downstream, which is 1.5 cm away from sample #1. Fig. 1 shows a high degree of consistency in orientation of WS2 flakes and, particularly, Fig. 1f shows a morphological evolution of WS2 flakes from trapezoid to triangle.

Quantitative analysis is applied to observation and measurement of the anisotropic growth of 2D TMDC flakes. To make the growth anisotropy measurable, anisotropic growth ratio (AGR) is defined to describe the extent of growth anisotropy and the formula for calculating AGRs is as follows:

where a, b, and S are the polygon diameter, grown length along a side, and area of the TMDC flake, respectively. Fig. 2a, b illustrate the AGR calculation of a triangular or hexagonal TMDC flake by measuring the three parameters in Eq. (1). Fig. 2c–e show three representative morphologies of monolayer WS2 flakes having AGRs of about 1.0, which are grown with uniform substrate adsorption under different growth conditions.

a, b Illustrate how to calculate the AGRs of monolayer WS2 flakes with different shapes, including c hexagon, d upward triangle, and e downward triangle, where the downward trianglar flake is terminated by three W-zigzag (-zz) edges, the upward by three S-zz edges, and the hexgonal by both three W-zz and three S-zz edges

The morphological classification of TMDC flakes is conducted to extract the growth tendency and make the high-dimensional simulation data readable, where the flake with the area ratio (to the defined substrate lattice) >20% is set as overgrowth while the one with the area ratio <3% as undergrowth according to rules of thumb. Similarly, the flake with AGR > 4.0 is considered as (extremely) anisotropic growth whereas the flake with AGR around 1.0 as isotropic growth. For example, Fig. 1a–c show that the average AGRs of monolayer WS2 flakes are >4.0, indicating the extremely anisotropic growth occured.

Substrate-sensitive kMC model

To study the anisotropic growth of 2D TMDCs, we propose a full-diffusion kMC model coupling with local substrate effects including substrate adsorption and surface diffusion, which are considered as two key factors that influence the topological evolution of TMDC monolayers and would result in the anisotropy of film growth. Compared with the bond-counting model of first order approximation, as shown in Fig. 3, our model additionally does the on-the-fly counting of interactions between source atoms (W or S) and substrate atoms (Si or O). Therefore, substrate-induced variations of adsorption energy and diffusion energy are calculated in real-time and then, specifically, the model can simulate the anisotropic growth of WS2 on the ST-X quartz substrate.

Before the kMC simulations, we conducted first-principles calculations to obtain energy parameters for modeling the above-mentioned kinetic events. Without loss of generality, the growth of WS2 monolayers on a ST-X quartz substrate is investigated. The calculated results are presented in Table 1.

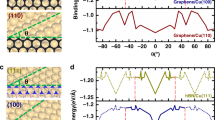

ST-X quartz, also called 42.75° Y-X quartz (see Fig. 4a), has been widely used as the substrate of surface acoustic wave (SAW) resonators.29 Because the normal to ST-X quartz surface is 42.75° rotated with respect to axis Y, there is a periodical sawtooth profile with a slightly tilt on the ST-X quartz surface (see Fig. 5) and the vdW interaction between the WS2 and substrate varies peridically along the sawtooth profile. The orientation of as-grown WS2 flakes in Fig. 1 is consistent with the X axis of ST-X quartz substrate, which is illustrated in Fig. 4b. It should be mentioned that the temperature in the CVD process of monolayer WS2 is much higher than the phase-transition temperature of quartz crystals (around 550 °C), so the ST-X quartz is in β phase during the growth process.

For simplicity, as illustrated in Fig. 5, the ST-X quartz substrate is reduced into a binary model that only has two types of substrate adsorption domain: strong adsorption domain marked by Si and ordinary adsorption domain marked by O. With the reduced configuration of the ST-X quartz substrate, it can simplify the kMC computations without loss of physical content. The seed for the initialization of the kMC simulation is taken to be a hexagonal W3S6 nucleus. The simplified substrate model is applied to the following kMC simulations, which is in default a 30 × 30 lattice with a 2 × 30 ‘belt’ marked by Si of strong substrate adsorption compared to other areas marked by O of ordinary substrate adsorption.

Simulation of substrate-induced anisotropic growth

Three groups of kMC simulations are designed and presented in Table 2. The anisotropic growth and isotropic growth co-occur when the substrate adsorption is neither large nor small (xEads = 1.25 or 1.5), which agrees with the observations in the preliminary experiment, so the substrate adsorption contrast is estimated to be 1.4.

As is shown in Fig. 6, the C/M ratio is possibly a major contribution to the surge of growth anisotropy and the polarization of undergrowth and overgrowth; the specific linear relationship between gas flux and temperature can help growth isotrophy or anisotropy maintain in an expected manner. The AGR surges at the vicinity of the C/M ratio of 2.0, as is shown in Fig. 6a, c, and too high or too low temperature (or too small or too large gas flux) can weaken the dramatic increase, which is observed at the AGR curves of T = 1123, 1173 and Ra = 3, 9, 12. Fig. 6b, d show that anisotropic growth is observed as the C/M ratio increases and reaches over 2.0, while at the same time very low temperature or very large gas flux would result in overgrowth. At the dashed line of the C/M ratio of 2.0, the morphological classification is diverse and the morphology varies with the change of either temperature or gas flux. Moreover, Fig. 6c, e provide more details for the calculated results when the C/M ratio equals to 2.0. It is clearly shown that WS2 monolayers grow isotropically only in the center area where both the temperature and gas flux are not too low or too high, and the anisotropic growth of WS2 monolayers also has a similar “safe zone”. After linear regression calculations, it is found that the domains for perfect isotropic growth and extremely anisotropic growth are near two regression lines (see Fig. 6f), i.e., Ra = 0.045T − 41.535 and Ra = 0.054T − 56.442, respectively. That would be the key to the synthesis of large-area or extremely-anisotropic WS2 monolayers.

On the kMC perspective, there exists a competitive balance among the gas flux, C/M ratio, and temperature with regard to the impact on growth anisotropy. Fig. 6a shows that the curve of T = 1123 is similar to that of T = 1173, which indicates that the temperature growth from 1123 to 1173 K and the shift from 2.0 to 2.5 in the C/M ratio have the equivalent effect on growth anisotropy. Similarly, Fig. 6f shows that the transition from isotropic to anisotropic zone can be achieved by increasing temperature or decreasing gas flux. The evolution of growth morphology in essence is the movement of terminated edges. And the type consistent of terminated edges determines whether the monolayer TMDC flakes can grow isotropically. As shown in Fig. 7m, the simulated flake is isotropically grown and it is terminated by three bottom-layer S-zz edges. In comparison, the simulated flake shown in Fig. 7k has the extremely anisotropic growth morphology, which is outlined by three different types of terminated edges including bottom-layer S-zz, middle-layer W-zz, and top-layer S-zz. At the vicinity of isotropic growth conditions, the AGR increase eventually as the terminated edges lose their type consistent to some extent. That explains why the AGR does not increase monotonically as the C/M ratio grows up (see Fig. 6a, c).

The simulated growth morphologies of monolayer WS2 under diverse experiment conditions. a–e The simulated results at 1e8 kMC steps, f–j at 2e8 kMC steps, k–n at 3e8 kMC steps, and o–s at 2e8 kMC steps; a–n are grown on an anisotropic substrate while o–s on an isotropic substrate. The gas flux is 9.0 W atoms/s

As for the controlled growth of nanoribbons of TMDC materials, we think it is feasible but still a challenge to obtain a reliable CVD product of TMDC nanoribbons though the preliminary experiment result presents a good and potential tendency to the controlled growth of elongated flakes. At first, the two regression lines shown in Fig. 6f are so close to each other that the morphological transition between anisotropy and isotropy is possible to occur frequently under the practical experimental conditions. And second, the optimization of experimental parameters in the kMC simulation is relatively not limited while the CVD experiment is considerably limited by the feasibility and reliability of control of parameters.

Compared with the above-mentioned experiment results in Fig. 1, the similar evolution is reproduced in the kMC simulation results. Fig. 1 shows that flakes located at the upstream of gas flow have a higher AGR than those located at the downstream and the transition from trapezoid to triangle is observed on the sample at the downstream of gas flow. Comparisons of the first, third, and fifth rows in Fig. 7 show that the growth morphology evolves from anisotropy to isotropy as the C/M ratio slightly decreases and explain why the transition from trapezoid to triangle is more likely to be observed at the downstream of gas flow. Moreover, comparisons between the second, third, and fourth rows in Fig. 7 indicate that the increase of temperature also drives the morphological evolution from high anisotropy to almost perfect isotropy. In our experimental installation, the concentration of W atoms is designed to be evenly distributed and that of S atoms would gradually decrease due to the consumption along the direction of gas flow. The C/M ratio is thus likely to go down gradually along the direction of gas flow while the temperature variation at a small sample substrate can be ignored.30 Consequently, the experiment results in Fig. 1 are much possibly attributed to the C/M ratio and, on the whole, the average AGR of monolayer WS2 flakes is positively proportional to the C/M ratio.

The different effects of anisotropic and isotropic substrates on the growth of monolayer WS2 also can be investigated by comparing the kMC simulation results. Fig. 1o–s show the simulated morphologies of monolayer WS2 grown on the isotropic quartz substrate and the corresponding AGRs are about 1.0. While, as shown in Fig. 1a–n, the monolayer WS2 flakes grown on the anisotropic ST-X quartz substrate tend to be expanded horizontally or along the X axis. The comparisons suggest that the anisotropic growth of monolayer WS2 is most possibly induced by the anisotropic property of the specific substrate.

In practice, AGR measurement curves and morphological classification maps provide a whole picture and detailed guide for operation. The steep slope of AGR curves displayed in Fig. 6a, c should be avoided to improve the controllability and reliability of experiments. Because the gas flow is usually unidirectional during CVD process, the C/M ratio on the same substrate may fluctuate with the position. The temperature and gas flux can be optimized according to the morphological classification maps shown in Fig. 6b, d. When the C/M ratio is significantly >2.0, the varied range of C/M ratio is still away from the steep slope, therefore, 2D TMDC flakes of uniform morphology can be obtained. In addition, although it is challenging to finely control the C/M ratio, the well control of the C/M ratio benefits much more than others. Those two regression lines indicate that, when the C/M ratio is well controlled, the transition between anisotropy and isotropy can be easily made by adjusting either temperature or gas flux or both. The above gives a whole picture of the dynamical morphologies in the anisotropic growth of monolayer WS2 on ST-X quartz substrate. Generally, those results and discussions can also apply to other TMDCs and even other 2D materials.

The anisotropic growth of monolayer TMDCs such as WS2 is a critical step to reach the controlled growth, which would be a practical and effective approach to produce large single crystals and nanoribbons. We studied the extremely anisotropic growth induced by the specific substrate using kMC simulations, proposed a quantitative model to measure the growth anisotropy and determine whether it is overgrown or undergrown, and provided a phenomenological picture of the morphological evolution of TMDC monolayers. The simulation results not just predict the tendency of substrate-induced growth anisotropy but also provide the general technical requirments for the CVD equipment in order to produce TMDC nanoribbons. For example, multi-zone temperature control and dual-direction gas flow control may be required to precisely control temperature and gas flow in the CVD furnace.

Methods

kMC simulations and DFT calculations

The open-source codes, i.e., atomic simulation environment (ASE)31 and Quantum ESPRESSO (QE),32,33 are utilized to prepare atomistic configurations and conduct density-functional theory (DFT) calculations. The ASE suite was used to prepare the configuration of WS2 and ST-X quartz. The QE suite was used to conduct DFT calculations, where the bond energy is obtained by the regression of vacancy activation energies, the diffusion energy is calculated by the nudged elastic band method, and the adsorption energy is estimated by relaxation.

The kMC package, kmos,24 was used and the on-the-fly counting of nearest neighbors, including source atoms and substrate atoms, is enabled. The kMC model has defined all physical processes involved in the CVD of monolayer TMDCs such as adsorption, desorption, and diffusion, and has also introduced local effects such as substrate adsorption and surface diffusion into those processes.

Growth and characterization of WS2 monolayers

The substrate-induced anisotropic growth of WS2 on ST-X quartz substrate (8 mm × 10 mm) was carried out in a quartz tube furnace (2 inch diameter). The ST-X quartz substrate and SiO2/Si wafers were cleaned in the sequence of acetone, isopropanol, and DI water for 10 min, respectively. Five-nanometer WO3 films pre-deposited onto SiO2/Si substrates via thermal evaporation of WO3 powders (Alfa Aesar, 99.9%) and S powders (Aladdin, 99.99%) were used as precursors. Subsequently, WO3-coated SiO2/Si substrates were loaded into the tube together with the ST-X quartz substrates placed face-down above the former. A boat with 200 mg of S powder was placed outside the furnace and this zone was wrapped with a heating belt. After purging the quartz tube to 3.0 × 10−2 Torr with a mechanical pump, the atmospheric pressure was recovered by introducing Ar gas. Then the substrate zone was heated to 875 °C at a rate of 20 °C/min while the S was heated to a temperature of 200 °C when the substrate zone reached 650 °C. The growth process was conducted at 875 °C for 30 min and then the furnace was cooled down to the room temperature naturally.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Manzeli, S. et al. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2, 17033 (2017).

Kumar, P. et al. Scalable faceted voids with luminescent enhanced edges in WS2 monolayers. Nanoscale 10, 16321–16331 (2018).

Lu, A.-Y. et al. Janus monolayers of transition metal dichalcogenides. Nat. Nanotechnol. 12, 744 (2017).

Hsu, Y.-T. et al. Topological superconductivity in monolayer transition metal dichalcogenides. Nat. Commun. 8, 14985 (2017).

Christiansen, D. et al. Phonon sidebands in monolayer transition metal dichalcogenides. Phys. Rev. Lett. 119, 187402 (2017).

Steinhoff, A. et al. Exciton fission in monolayer transition metal dichalcogenide semiconductors. Nat. Commun. 8, 1166 (2017).

Duan, X. et al. Two-dimensional transition metal dichalcogenides as atomically thin semiconductors: opportunities and challenges. Chem. Soc. Rev. 44, 8859–8876 (2015).

Choi, W. et al. Recent development of two-dimensional transition metal dichalcogenides and their applications. Mater. Today 20, 116–130 (2017).

Wong, S. L., Liu, H. & Chi, D. Recent progress in chemical vapor deposition growth of two-dimensional transition metal dichalcogenides. Progress. Cryst. Growth Charact. Mater. 62, 9–28 (2016).

Zhang, Q. et al. Reliable synthesis of large-area monolayer WS2 single crystals, films, and heterostructures with extraordinary photoluminescence induced by water intercalation. Adv. Opt. Mater. 6, 1701347 (2018).

Tsivion, D. et al. Guided growth of millimeter-long horizontal nanowires with controlled orientations. Science 333, 1003–1007 (2011).

Chen, Y. et al. Fabrication of MoSe2 nanoribbons via an unusual morphological phase transition. Nat. Commun. 8, 15135 (2017).

Li, S. et al. Vapour–liquid–solid growth of monolayer MoS2 nanoribbons. Nat. Mater. 17, 535–542 (2018).

Artyukhov, V. I. et al. Topochemistry of bowtie-and star-shaped metal dichalcogenide nanoisland formation. Nano. Lett. 16, 3696–3702 (2016).

Zhang, Y. et al. Controlled growth of high-quality monolayer WS2 layers on sapphire and imaging its grain boundary. ACS Nano 7, 8963–8971 (2013).

Shi, Y., Li, H. & Li, L.-J. Recent advances in controlled synthesis of two-dimensional transition metal dichalcogenides via vapour deposition techniques. Chem. Soc. Rev. 44, 2744–2756 (2015).

Bersch, B. M. et al. Selective-area growth and controlled substrate coupling of transition metal dichalcogenides. 2D Mater. 4, 025083 (2017).

Chen, L. et al. Step-edge-guided nucleation and growth of aligned WSe2 on sapphire via a layer-over-layer growth mode. ACS Nano 9, 8368–8375 (2015).

Qin, J.-K. et al. Van der waals epitaxy of large-area continuous ReS2 films on mica substrate. RSC Adv. 7, 24188–24194 (2017).

Hwang, J.-Y. et al. Te monolayer-driven spontaneous van der waals epitaxy of two-dimensional pnictogen chalcogenide film on sapphire. Nano. Lett. 17, 6140–6145 (2017).

Bonilla, M. et al. Strong room-temperature ferromagnetism in Vse2 monolayers on van der waals substrates. Nat. Nanotechnol. 13, 289 (2018).

Hall, J. et al. Molecular beam epitaxy of quasi-freestanding transition metal disulphide monolayers on van der waals substrates: a growth study. 2D Mater. 5, 025005 (2018).

Battaile, C. C. & Srolovitz, D. J. Kinetic Monte Carlo simulation of chemical vapor deposition. Annu. Rev. Mater. Res. 32, 297–319 (2002).

Hoffmann, M. J., Matera, S. & Reuter, K. kmos: a lattice kinetic Monte Carlo framework. Comput. Phys. Commun. 185, 2138–2150 (2014).

Govind Rajan, A. et al. Generalized mechanistic model for the chemical vapor deposition of 2D transition metal dichalcogenide monolayers. ACS Nano 10, 4330–4344 (2016).

Nie, Y. et al. First principles kinetic Monte Carlo study on the growth patterns of Wse2 monolayer. 2D Mater. 3, 025029 (2016).

Sun, Y., Wang, R. & Liu, K. Substrate induced changes in atomically thin 2-dimensional semiconductors: fundamentals, engineering, and applications. Appl. Phys. Rev. 4, 011301 (2017).

Ahn, G. H. et al. Strain-engineered growth of two-dimensional materials. Nat. Commun. 8, 608 (2017).

Parker, T. E. & Montress, G. K. Precision surface-acoustic-wave (SAW) oscillators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 35, 342–364 (1988).

Wang, S. et al. Shape evolution of monolayer MoS2 crystals grown by chemical vapor deposition. Chem. Mater. 26, 6371–6379 (2014).

Larsen, A. H. et al. The atomic simulation environment—a Python library for working with atoms. J. Phys.: Condens. Matter 29, 273002 (2017).

Giannozzi, P. et al. Quantum ESPRESSO: a modular and open-source software project for quantum simulations of materials. J. Phys.: Condens. Matter 21, 395502 (2009).

Giannozzi, P. et al. Advanced capabilities for materials modelling with Quantum ESPRESSO. J. Phys.: Condens. Matter 29, 465901 (2017).

Acknowledgements

L. W. thanks J. M. Lorenzi for kind help on the kmos kMC simulation package, and Y. Nie for fruitful discussion on the kMC simulation of the growth of monolayer TMDCs. W. Y. and G. W. acknowledge support from the National Natural Science Foundation of China (Grants No. 61704040 and No. 61411136003). L. W. acknowledges support from the program of China Scholarship Council (No. 201708330397). This research was also partially supported by Zhejiang Provincial Natural Science Foundation of China under Grant No. LGG19F040003.

Author information

Authors and Affiliations

Contributions

L. W. conceived the project and conducted the kMC simulations. W. Y. performed the experiments (CVD growth and characterization of WS2). The manuscript was written through contributions of all authors. All authors have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wu, L., Yang, W. & Wang, G. Mechanism of substrate-induced anisotropic growth of monolayer WS2 by kinetic Monte Carlo simulations. npj 2D Mater Appl 3, 6 (2019). https://doi.org/10.1038/s41699-019-0088-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41699-019-0088-4