Abstract

In recent times, a transformative phenomenon has emerged within the realm of manufacturing known as “manufacturing input servitization.” This concept involves the integration of services into traditional manufacturing processes, and while it has received some attention, its implications for labor income distribution have not been extensively explored. This study embarks on an exploration of the intricate relationship between manufacturing input servitization and labor income share, with a specific focus on its impact on income distribution. Employing rigorous regression analysis techniques, this paper rigorously assesses the relationship between manufacturing input servitization and labor income share. Our analysis also delves into mediation effects, uncovering the pivotal roles played by labor productivity and human capital in driving labor income share improvements. The results consistently reveal a positive correlation between manufacturing input servitization and labor income share, an association that persists even after controlling for various factors. Heterogeneity analysis further showcases that the medium-technology manufacturing sector benefits the most from servitization, closely followed by the high-technology and low-technology sectors. In addition, this research highlights a pronounced impact of manufacturing servitization on labor income in developing economies compared to their developed counterparts. Beyond the empirical discoveries, extended analysis reveals a implication: the enhancement of labor income share in the manufacturing sector contributes significantly to reducing income inequality across the broader economy. These findings hold substantial implications for both policymakers and manufacturing firms. Encouraging the adoption of servitization strategies within manufacturing not only fosters labor income growth but also aligns with the broader societal goal of reducing income inequality. As such, this research provides invaluable insights for stakeholders committed to nurturing inclusive economic growth.

Similar content being viewed by others

Introduction

The phenomenon of manufacturing input servitization has received significant attention in recent years because of its potential impact on the economy. As manufacturers shift from solely producing goods to integrating service-oriented strategies, questions arise regarding the effects on labor income share and income distribution. In order to promote sustainable economic development and address post-pandemic challenges, it is crucial for policymakers, researchers, and businesses to understand the relationship between manufacturing servitization and labor income.

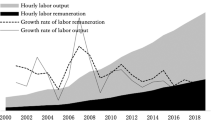

Figure 1 demonstrates positive correlations between the labor income share of all industries and per capita GDP (Gross Domestic Product), and between the labor income share of the manufacturing industry and per capita GDP. Notably, as per capita GDP increases, the labor income share of the manufacturing industry gradually exceeds the average labor income share of all industries. This indicates that optimizing the income distribution structure is necessary for economic development, with the manufacturing industry playing a significant role. It can be seen from Fig. 2 that countries with higher per capita GDP tend to have higher levels of manufacturing servitization. In countries with a medium level of development, the servitization level shows a large degree of dispersion among various sub-industries. This shows that with the improvement of the economic level, the manufacturing industry progresses from partial servitization to overall servitization, and the labor income share also increases.

In recent decades, many countries have faced the challenge of unbalanced and inadequate development. For instance, according to World Wealth and Income data, the income share of the top one percent has increased significantly in major countries, including China and the United States, indicating a widening income gap. This is largely attributed to imbalances in the distribution of production factors such as lower labor share remuneration. To address the issue of unbalanced distribution in the manufacturing industry, it is necessary to enhance the labor income share by improving the level of human capital and wages. This study aims to uncover the mechanisms by which manufacturing servitization influences labor income. As firms transition towards servitization, their input, output, and distribution structures undergo changes. By integrating services into the manufacturing process, firms can enhance their value proposition and competitiveness. The increased utilization of human capital and improvements in labor productivity play crucial roles in mediating the positive impact of servitization on labor income share. Understanding these mechanisms is essential for policymakers and industry leaders seeking strategies to promote manufacturing service-oriented transformation.

The primary research question of this study is: How does manufacturing servitization impact labor income share and income distribution? To answer this question, this paper examines the correlation between manufacturing servitization and labor income share, considering factors such as human capital and labor productivity. Additionally, this paper explores the heterogeneity of this relationship based on technological intensity and economic development status. Furthermore, both theoretical frameworks and empirical evidence are utilized. Theoretical analyses provide insights into the mechanisms through which manufacturing servitization affects labor income, complemented by empirical analysis using multinational multi-industry panel data.

Literature review

Several studies have raised concerns about the decline in labor income share. Karabarbounis and Neiman (2014) observed a significant decrease in labor income share in developed countries since the 1980s. Cai and Wang (2013) emphasized that a low labor income share hinders social distribution fairness and domestic demand improvement. Factors influencing labor income share include the rate of return on capital factors, which affect the relative prices of labor factors (Bentolila and Saint-Paul, 2003). In addition, technological progress impacts the bargaining power of human capital compared to material capital, altering income distribution among factors (Spector, 2004; Acemoglu, 2003).

Manufacturing servitization can be categorized into input servitization, where service factors are increasingly used as intermediate inputs in manufacturing; and output servitization, which involves additional services related to products (Sousa and da Silveira, 2019). The main perspectives on the role of manufacturing servitization include deepening the division of labor mechanisms (Francois, 1990), improving business performance (Song et al., 2022), enhancing total factor productivity and global value chain status (Zhang, 2022), and increasing corporate technology complexity (Zhang et al., 2023).

Scholars have discussed the direct and indirect connections between manufacturing servitization and labor income share. Manufacturing servitization requires extensive integration of knowledge and technology into manufacturing, elevating the role of human capital in production (Hayakawa et al., 2009). This leads to changes in the distribution of capital and labor shares in enterprise income (Li and Yuan, 2018). Furthermore, manufacturing servitization alters the factor input structure and affects the income distribution structure, including labor income share (Gang and Guang, 2010).

In summary, previous research has enriched the relevant literature, but there are still areas that can be further explored. First, there is a lack of empirical research on the relationship between manufacturing servitization and labor income from a transnational macro perspective. This gap in the literature hinders our understanding of the impact of this phenomenon on labor income on a broader scale. Second, the causes of heterogeneity have not been thoroughly analyzed. It is important to delve deeper into the factors that contribute to variations in outcomes in order to gain a comprehensive understanding of the phenomenon. Third, there is a lack of detailed analysis of the mechanism linking manufacturing servitization with labor income share and its connection to practical issues such as income disparity. By examining the specific mechanisms at play, we can shed light on the potential consequences of this economic shift on income distribution.

This study utilizes statistical data from the WIOD and the Organization for Economic Co-operation and Development (OECD) database to investigate the impact of manufacturing servitization on labor income share, in order to identify strategies for improving income distribution through this shift. This paper contributes to the existing literature by comprehensively analyzing the effects of manufacturing input servitization on labor income share and distribution. By integrating theoretical frameworks and empirical evidence, this study aims to bridge the gap in the understanding of the mechanisms and implications of servitization in the manufacturing sector. In addition, it provides valuable insights for policymakers and stakeholders in promoting sustainable economic development, reducing poverty gaps, and fostering post-pandemic stability by highlighting the heterogeneity of the impact across different industries and economies.

Theoretical analyses

Definition of concepts

Total manufacturing output (Y) normally comprises both intermediate inputs (II) and value-added (VA). Intermediate Inputs generally include physical inputs (such as raw materials, components, and machinery) and service inputs (such as transportation, logistics, and maintenance services). Manufacturing servitization refers to the transformation of traditional manufacturing firms into service-oriented organizations (Paiola and Gebauer, 2020), which involves integrating services into core manufacturing processes and offering a combination of products and services to customers (Reiskin et al., 1999). Manufacturing servitization encompasses input servitization and output servitization. Manufacturing input servitization (MIS) measures the proportion of service inputs (SI) in the overall intermediate inputs used in manufacturing. It indicates the extent to which services are utilized alongside physical inputs (PI) in the production of manufactured goods.

Value-added represents the additional value created by a firm in the production process. It is calculated as the difference between the final selling price of a product or service and the cost of its intermediate inputs. Value-added accounts for the contribution made by labor and capital in transforming intermediate inputs into the final output (Jorgenson et al., 2007).

Labor Income Share (LIS) represents the proportion of value-added that is allocated to workers as income. It indicates the distribution of economic benefits between labor (L) and capital (K) in the manufacturing sector.

Theoretical mechanism

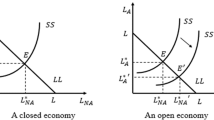

From the previous definitions and equations, it can be seen that an increase in manufacturing input servitization implies a higher proportion of service factor input relative to physical factor input. This shift towards greater service input tends to contribute significantly to enhancing value-added (Konan and Maskus, 2006). It is crucial to consider how this increased value-added is distributed between capital and labor. Compared with physical factors, service factors often necessitate a larger quantity or higher quality of labor input (Tregenna, 2008). As a result, labor becomes more important than capital, promoting an upward trajectory in labor income share.

Conversely, a decrease in the proportion of service inputs in manufacturing indicates reduced reliance on services. In such cases, the manufacturing process may become more capital-intensive. Consequently, the value added in manufacturing may not experience significant growth, and the labor income share may remain relatively stable or even decline. This occurs because the value created by workers through providing physical inputs may not be as substantial as that derived from service-oriented tasks.

Based on the above, the following hypothesis is proposed:

H1: Manufacturing input servitization positively impacts labor income share.

It is important to note that the relationship between manufacturing input servitization and labor income share is not deterministic and can be influenced by various factors, including technological advancements, labor market conditions, and industry-specific dynamics (Feng et al., 2021). Therefore, the actual impact of manufacturing input servitization on labor income share may vary in different contexts. Thus, the following hypothesis is proposed:

H2: The impact of manufacturing input servitization on labor income share varies across different industries and economies.

As manufacturing firms embrace servitization strategies, leading to higher labor productivity and profitability, they are able to allocate a larger proportion of value added to labor in the form of higher wages and benefits. This redistribution of income helps to address the income gap within the economy, promoting a more equitable distribution of wealth. By enhancing the labor income share, servitization in the manufacturing industry plays a crucial role in mitigating income inequality, thereby fostering social cohesion and economic stability. Based on the above, the following hypothesis is proposed:

H3: An increase in the labor income share within the manufacturing industry helps to reduce income inequality.

Intermediate channel

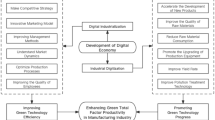

With the rapid development of smart, digital, and information-based economies, services have gradually integrated into the real economy. To enhance competitiveness, the manufacturing sector has shifted from being production-oriented to service-oriented, resulting in the transformation and upgrading of the industry.

Servitization increases labor income share by improving labor productivity

Empirical evidence suggests that as manufacturing firms incorporate service inputs into their production processes, higher levels of labor productivity often result. For example, Opazo-Basáez et al. (2018) found that in the automotive manufacturing industry, the adoption of service-oriented practices led to significant improvements in labor productivity.

Increased labor productivity, in turn, can contribute to higher profitability for manufacturing firms. Shen et al. (2021), for example, have shown that firms engaged in servitization strategies tend to achieve higher levels of productivity and profitability than those purely focused on manufacturing.

The rise in profitability resulting from improved labor productivity allows companies to allocate a larger proportion of value added to labor in the form of higher wages and benefits. This increase in compensation can raise the labor income share within the economy. A case study by Baines et al. (2009) examining the servitization efforts of a manufacturing company found that the integration of services resulted in increased labor productivity, leading to higher wages and a more equitable distribution of income.

Therefore, manufacturing input servitization could enhance labor productivity, leading to higher profitability and subsequently increasing the labor income share. These findings highlight the significance of the intermediary channel of labor productivity in explaining the impact of manufacturing input servitization on labor income share.

Based on the above, the following hypothesis is proposed:

H4: Manufacturing input servitization affects labor income share through human capital and labor productivity.

Servitization increases labor income share by improving human capital

Empirical evidence suggests that as manufacturing firms incorporate service inputs into their operations, they often require a more skilled and specialized workforce. This demand for higher levels of human capital can lead to an increase in the per capita wage level. For example, a study by Crozet and Milet (2017) analyzing French manufacturing firms found that those engaged in servitization had significantly higher wages than firms focused solely on manufacturing.

The integration of service inputs in manufacturing processes often requires training employees in new service-oriented tasks. This training enhances their skill sets and increases their human capital. Karatzas et al. (2020) demonstrated that the development of service capabilities through servitization led to improvements in employee skills and knowledge.

The increase in human capital can make workers more productive and valuable, resulting in higher wages and an increase in the per capita wage level. A case study by Fontagné and Harrison (2017) analyzing manufacturing firms in the UK found that servitization efforts led to a greater emphasis on employee development, resulting in higher wages and a more sophisticated workforce.

Therefore, manufacturing input servitization can contribute to an augmented per capita wage level by increasing the demand for human capital and enhancing employee skills. This, in turn, influences the labor income share, as a greater proportion of the overall income generated in the manufacturing sector is allocated to workers.

Based on the above, the following hypothesis is proposed:

H5: Manufacturing input servitization affects the labor income share through human capital.

The above path analyses are shown in Fig. 3.

Model construction

Benchmark model

Building on the previous analysis, the following ordinary least-squares (OLS) regression equation is designed:

In this equation, \(\ln LIS\) and \(\ln MIS\) represent the natural logarithms of labor income share and manufacturing input servitization level, respectively. The subscripts i, j, and t indicate the economy, manufacturing industry sector, and year, respectively. X serves as the control variable, and τi, ϑj, and δt account for fixed effects. In addition, ε represents the random error term, and β is the parameter to be estimated.

Variable description

Dependent variables

The labor income share (LIS) is determined by the proportion of labor income in each manufacturing sector relative to the sector’s value-addition. This follows the principle of the factor income method and the composition principle of GDP, as indicated by Eq. (5) and supported by macro data.

Independent variables

In Eq. (3), service are considered a type of intermediate input in manufacturing. Similar to previous studies, this research measures manufacturing input servitization by examining the proportion of service input in intermediate input. Typically, extant studies use input–output tables to calculate direct and complete consumption coefficients, which enable the measurement of an industry’s input servitization (Lay et al., 2010). The direct consumption coefficient refers to the ratio of the direct consumption from sector i to the total intermediate input for one unit of output from sector j. Mathematically, the direct consumption coefficient (aij) is computed using values extracted from the input–output table, as shown in Eq. (7):

Here, xij represents direct consumption by sector j of products from sector i. Moreover, the complete consumption coefficient (bij) encompasses both direct and indirect consumption of sector i’s product when producing one unit of final product in sector j. The complete consumption coefficient matrix (B) is obtained by computing the sum of all rounds of consumption, as demonstrated in Eqs. (8) and (9):

Here, bij represents the sum of all rounds of consumption of the sector i’s products for one unit of output from sector j. A refers to the direct consumption coefficient matrix. This approach allows the calculation of services entirely consumed by one unit of the manufacturing industry’s final output. It reflects the manufacturing industry’s dependency on services, thereby yielding the level of manufacturing input servitization (MIS).

Table 1 shows the level of input servitization in various manufacturing sub-industries for major countries, which demonstrates that resource-intensive manufacturing sectors, such as wood and softwood products (excluding furniture), coke, refined petroleum products, and nuclear fuel, generally exhibit low levels of servitization. This can be attributed to the relative simplicity of industrial and value chains within these sectors, resulting in a lower reliance on service factors. The limited servitization in these industries is influenced by industry characteristics, technological requirements (Constantinescu et al., 2019), specialized labor needs, and market dynamics, which prioritize physical transformation and resource handling over extensive service integration.

Control variables

For industry-level control variables, the following factors are considered: (1) Capital stock (Cap) is expressed as the share capital, representing the capital investment in an industry and its influence on the distribution of income between labor and capital. (2) The number of employees (Emp), which is expressed in terms of industry employees, reflects labor input in the industry and its impact on labor income share. Changes in employment levels may lead to changes in labor market dynamics and income distribution. (3) Value-added rate (Var) measures the proportion of value added to total output value. A higher value-added rate may indicate increased profitability and potentially higher labor income share. (4) Rate of return on capital (Roc) indicates the share of capital return to nominal share capital. Higher returns on capital may lead to increased income for capital owners and potentially lower labor income share.

At the economic level, the control variables are: (1) Per capita GDP (Pgdp) measures the economic output per person and reflects the overall economic development of a country or region, which may influence labor income share through factors such as wage levels and income distribution. (2) Capital intensity (Fdi) represents the sum of inward and outward foreign direct investment (FDI), considering the influence of foreign capital and market dynamics and the impact of international investment flows on labor income share. (3) Technological intensity (Rd) is represented by the total expenditure on research and development (R&D)—as a percentage of GDP—conducted by all resident companies, research institutes, universities, government laboratories, and other entities, capturing the level of technological innovation within an economy, which may affect labor income share by influencing productivity and the demand for skilled labor. (4) Trade barriers (Barr) are based on data from the OECD, enabling assessment of international trade policies’ effects on employment and wage dynamics within the manufacturing sector and their potential impact on labor income share.

Mediation variables

The following mediation variables were selected based on previous analysis: (1) Labor productivity (Prod) is measured as the ratio of total output to the number of employees. When manufacturing incorporates services, it may lead to increased efficiency, improved processes, and higher output per employee. This increase in productivity can then have a influence on labor income share. (2) Human capital (Pay) is expressed as the ratio of labor income to the number of employees. Human capital represents the skills, knowledge, and capabilities possessed by workers. Higher levels of human capital are often associated with higher productivity (Peng et al., 2020), and thus higher wages. The integration of services in manufacturing processes requires a workforce with advanced skills, expertise, and specialized training. As a result, servitization tends to result in higher wages for workers, which can impact labor income share.

Data sources

Table 2 provides the descriptive statistics for the mentioned variables. Data for this study were collected from various sources, including the latest World Input–Output Tables and Socio-Economic Accounts from WIOD (2016), the Asian Development Bank (2022), and the OECD (2021) database. The combined data cover 43 economies and 18 manufacturing sub-sectors from 2000 to 2014. Industries were classified according to the International Standard Industrial Classification Rev.4. It is important to note that the data used exclude the effects of exchange rates and prices, and price index and exchange rate data were obtained from WIOD. In addition, all variables were transformed into logarithmic form for analysis.

Empirical results

Analysis of the basic regression results

The Hausman test produces a P value of 0.000, indicating the suitability of fixed-effect models over random-effects models. In Table 3, columns (2) and (3) present the results after controlling for industry, economy, and time-fixed effects. In addition, industry time-fixed effects are taken into account in this section to address unobservable variables specific to each industry and time period, as shown in Columns (4) and (5). The inclusion of clustering standard errors at the economy level enhances the reliability and validity of the findings. Clustering effects account for potential similarities and correlated factors within specific economies. By considering these effects, the analysis ensures that the relationship between manufacturing servitization and labor income share is accurately described, without distortion or bias from individual economy characteristics. These measures provide a higher level of confidence in the robustness of the results and their generalizability to a wider range of economies.

In summary, Table 3 presents regression results for the overall sample: a significant positive correlation between \(\ln LIS\) and \(\ln MIS\) is consistently observed in the OLS benchmark regression, regardless of the inclusion of fixed effects or control variables. This result implies that as manufacturing companies incorporate more services into their operations, the proportion of total income allocated to labor increases, which preliminarily verifies hypothesis H1. This could be attributed to several factors. First, services integration often necessitates a greater demand for skilled labor or specialized services, resulting in higher wages and overall labor income. In addition, the inclusion of services in manufacturing processes may enhance productivity and efficiency, leading to higher profits that are subsequently shared with employees in the form of increased labor income. Overall, these findings underscore the positive potential impact of input servitization on labor income share in the manufacturing sector, suggesting that firms’ integration of services into their production processes may create more favorable conditions for workers in terms of income distribution.

The regression results for the control variables at the manufacturing industry level are shown in Table 3, columns (3)–(5). The regression coefficient of \(\ln Cap\) consistently demonstrates a negative relationship. There is a substitution relationship between capital and labor in manufacturing production (Klump et al., 2008). Specifically, increasing capital input replaces labor input to some extent, thus reducing the labor income share. The negative correlation between \(\ln Roc\) and \(\ln LIS\) is significant at the 1% level. As the profit maximization process enhances the rate of return on capital, it strengthens the influence of capital, resulting in a “crowding out effect” on labor income. The regression coefficients of \(\ln Emp\) and \(\ln Var\), which are control variables, differ in significance or direction depending on the specific conditions. This indicates that factors such as economy-specific characteristics, regional differences, or changing economic conditions contribute to the variations in the coefficients.

Table 3, column (5) presents the results after incorporating control variables at the economy level, including per capita GDP, FDI, R&D expenditure, and trade barriers. First, a higher per capita GDP corresponds to a larger labor income share within the manufacturing sector. This association emerges because of the more developed and prosperous nature of economies with higher per capita GDP, leading to increased demand for highly skilled labor and higher wages in manufacturing. Second, a higher FDI level in an economy is associated with a lower labor income share in the manufacturing industry. One potential reason for this is that increased FDI leads to the adoption of capital-intensive production methods, resulting in a reduced labor income share within manufacturing. Furthermore, a higher level of R&D expenditure in an economy corresponds to a larger labor share in manufacturing. This connection can be attributed to the fact that higher investments in R&D facilitate technological advancements and innovation in the manufacturing industry. These developments create more high-skilled and productive job opportunities, thus contributing to a higher labor income share. Lastly, a higher trade barrier in an economy is associated with a lower labor income share within the manufacturing industry. Elevated trade barriers restrict competition and limit market access, ultimately leading to reduced productivity and a decline in the labor income share in manufacturing.

Robustness tests

To ensure the reliability of the empirical analysis and validate the impact of manufacturing servitization on labor income share, several robustness tests were conducted. These tests examined the measurement methods for core variables, extreme values, and major events. The results are presented in Table 4.

In the first step, the share of labor income in total output was used to measure labor income share; then OLS regression was performed again. The estimated results for \(\ln MIS\) and the control variables remained robust. The second step involved a 1% bilateral shrinkage and censoring process to mitigate the influence of extreme and abnormal data. Notably, no significant changes were observed in the results after the application of these techniques. Although the regression coefficient of \(\ln MIS\) decreased slightly following censoring, the symbol, and significance remained unaltered. This implies that the effects of extreme values and outliers are limited, and highlights the continued validity of our conclusion. To examine whether the 2008 financial crisis affected the results, the study period was divided into two: 2000–2008 and 2008–2014. Regression analyses were performed on the relevant data again. The results for both time periods did not change significantly, expect for a slight increase in the regression coefficient of \(\ln MIS\) after 2008. Manufacturing servitization and the subsequent rise in the labor income share showed an increasing trend after the financial crisis. This suggests the need to seize new opportunities to enhance manufacturing servitization level, support strategic transformations in manufacturing enterprises, and steadily inprove national income and risk resilience levels.

Furthermore, regression was conducted using a 30% random sampling with replacement. The results aligned with the conclusions drawn from the regression results of the benchmark model. In summary, even after replacing the explained variables, applying bilateral shrinkage and censoring, splitting the period, and conducting random sampling, this paper consistently observed a positive and statistically significant correlation between manufacturing servitization and labor income share. This result reinforces the robustness of the previously established conclusion.

Endogeneity tests

Although the P value of the Hausman Test result does not lead to rejection of the hypothesis that “all explanatory variables are exogenous,” it is important to acknowledge that \(\ln LIS\) may still have a adverse effect on \(\ln MIS\) and the control variables, thereby introducing a two-way causality problem. To address this issue and mitigate endogeneity estimation bias, a two-stage least-squares estimation method (2SLS) was adopted with three instrumental variables chosen specifically for \(\ln MIS\). The first instrumental variable used is the one-period lag of \(\ln MIS\) (\(L.\ln MIS\)), which helps alleviate the impact of labor income on manufacturing servitization. The second instrumental variable is the economy-level manufacturing servitization in the current year (\(\ln MIS\_2D\)). Exploratory variables at the economy level can affect industry-level explained variables, whereas a single industry variable has minimal influence on economy-level variables. Moreover, the correlation between the economy-level variables and omitted explanatory variables of individual industries is relatively weak. This helps alleviate endogeneity issues caused by bidirectional causality and omitted explanatory variables. The third instrumental variable is the growth rate of service value added at the economy level for the current year (Serate). This variable captures the relationship between the manufacturing industry and the development of the service industry. However, because of differences in industry attributes, the growth rate of the added value of the service industry has little association with the current employment income of the manufacturing industry.

When instrumental variables are employed in the 2SLS estimation, the significance and symbols of the results do not change significantly. The P values of the Kleibergen–Paap rk Lagrange multiplier (LM) statistics strongly reject the unrecognizable hypothesis. In addition, all Cragg-Donald Wald F and Kleibergen–Paap rk Wald F statistics indicate no weak instrumental variable problem. Thus, the test results presented in Table 5 confirm the reliability of the conclusions in this paper after endogeneity is considered.

Discussion

Test of influence mechanism

Manufacturing companies that hire skilled labor to integrate service factors are able to optimize human capital and labor productivity on a continuous basis. The increasing trend in labor productivity and human capital enhancement is closely linked to improvement in the labor income share (Acemoglu, 2010). A mediating utility test was conducted in this section, with the results shown in Table 6.

The results in Table 6, column (1) indicate that manufacturing input servitization positively influences labor productivity. This could be attributed to knowledge-intensive support, customization and flexibility, collaborative innovation, and the utilization of technology advancements (Shen et al., 2021). These factors contribute to better resource allocation, enhanced production processes, increased customer satisfaction, and improved overall efficiency, resulting in higher labor productivity for manufacturing firms. The results in Table 6, column (2) show that the increase in labor productivity promotes an increase in the labor income share. This may be because as labor productivity improves, workers become more efficient and produce more output in the same amount of time, leading to higher wages or salaries. In addition, increased productivity can foster economic growth, creating more job opportunities and competition among employers for workers, thereby exerting upward pressure on wages.

The results in Table 6, column (3) demonstrate that manufacturing input servitization has a positive influence on human capital. The could be because incorporating services requires a highly skilled workforce capable of managing technical and service-oriented tasks (Bental and Demougin, 2010), leading to improved employee capabilities and competence. Furthermore, servitization encourages the development of specialized knowledge and expertise among employees, fostering continuous learning and professional growth. The results in Table 6, column (4) reveal that human capital has a positive influence on labor income share. A possible reason for this effect is that human capital plays a crucial role in enhancing innovation (Peng et al., 2020), technological advancement, and overall economic growth. Highly skilled individuals contribute to the development of new ideas and processes, driving productivity gains across industries and resulting in improved profitability and a higher labor income share. In addition, human capital fosters specialization and adaptability in the workforce, enabling individuals to specialize in specific fields and quickly adapt to changing labor market demands. This flexibility may lead to better matching of skills with job requirements, increasing the bargaining power of workers and reducing income inequality.

The bootstrap mediating effect test yielded significant results, indicating that labor productivity and human capital have a positive mediating effect on the relationship between manufacturing servitization and labor income share, validating hypotheses H4 and H5. These findings emphasize the importance of enhancing both labor productivity and human capital development strategies as part of the manufacturing servitization process. By doing so, manufacturing firms can drive improvements in labor income distribution, potentially benefiting workers’ wages and overall economic performance.

Group discussion

This section investigates the impact of heterogeneity among technologies, economic development levels, and service inputs of various industries. The manufacturing industry is categorized into low, medium, and high technology for group discussion, while economies are divided into developed and developing based on their degree of economic development. The results are presented in Table 7.

Table 7 reveals that the impact of \(\ln MIS\) on \(\ln LIS\) is consistently positive at a significance level of 1%, further confirming hypothesis H1. Columns (1) to (3) demonstrate that the input servitization of medium-technology manufacturing has the greatest influence on the labor income share, followed by high-technology and low-technology manufacturing. The higher impact of servitization on the labor income share in medium-technology manufacturing can be attributed to several factors. First, the integration of services into the manufacturing process increases the demand for skilled labor, resulting in higher wages and a larger share of income going to labor. Moreover, servitization often involves customization, personalization, and after-sales services, which are more labor-intensive than traditional manufacturing processes. This leads to an increase in labor productivity in medium-technology manufacturing, further contributing to a higher share of labor income. In contrast, high-technology manufacturing relies on advanced automation and capital-intensive processes, resulting in a smaller need for labor. Similarly, low-technology manufacturing utilizes simpler production methods that may not require extensive skills or a significant workforce, leading to a lower impact on the labor income share.

Columns (4) and (5) of Table 7 demonstrate that the impact of manufacturing input servitization on the labor income share is greater in developing economies than in developed economies. One possible explanation for this disparity is the difference in labor market conditions. Developing economies often possess a larger pool of low-skilled labor, which benefits from the increased demand for labor-intensive services associated with servitization. This leads to higher wages and an increased labor income share. In contrast, developed economies may already have a higher proportion of skilled labor, resulting in less significant wage boosts from the shift towards servitization. Additionally, developed economies may have more advanced automation and technology, which can reduce the labor income share even in the presence of servitization. Based on the above, it can be concluded that the impact of manufacturing input servitization on labor income share exhibits heterogeneity across different economies and sub-industries within the manufacturing sector, thereby confirming hypothesis H2.

Extended analysis

Labor income share is a critical indicator for understanding how economic growth benefits different income groups (Dabla-Norris et al., 2015). If servitization in the manufacturing sector leads to an increase in the labor income share, it may contribute to a more equal distribution of economic gains and potentially reduce income inequality. Conversely, if servitization leads to a decline in the labor income share, it could worsen income inequality and pose broader social and economic challenges. Therefore, it is important to conduct an extended analysis of the relationship between the labor income share in manufacturing and the income gap, in order to obtain a comprehensive understanding of the potential social and economic implications of servitization.

This section presents an empirical analysis of the impact of manufacturing servitization (\(\ln MIS\)) on the poverty gap (\(\ln Gap\)), as shown in Table 8. The poverty gap represents the extent to which the average income of the poor falls below the poverty line. The poverty line is defined as half the median household income of the entire population. The control variables in this analysis are gross domestic spending on R&D (\(\ln Rd\)) and gross fixed capital formation (\(\ln Gfcf\)). \(\ln Rd\) is the logarithm of domestic R&D expenditure as a share of GDP. \(\ln Gfcf\) is the logarithm of the amount of acquisition of produced assets. Data on the poverty gap, gross domestic spending on R&D, and investment were obtained from the OECD database, with additional data sourced from the WIOD. All OECD countries compile their data based on the 2008 System of National Accounts.

As indicated in Column (3) of Table 8, an increase in \(\ln MIS\) is associated with a decrease in \(\ln Gap\), significant at the 5% level, which verifies hypothesis H3. This implies that as the labor income share rises, workers in the manufacturing sector receive a larger proportion of the sector’s overall income. This can result in higher wages and improved living standards for workers, ultimately reducing income inequality within countries. In addition, the expansion and increased competitiveness of manufacturing industries may contribute to higher exports, leading to increased foreign exchange earnings and economic growth. This growth, in turn, could help narrow the income gap between economies by providing more resources for investment in social welfare programs and infrastructure development, ultimately benefiting the entire population.

Further, both \(\ln Rd\) and \(\ln Gfcf\) exhibit a negative correlation with \(\ln Gap\). In other words, increasing domestic R&D spending and fixed asset investment can help reduce the poverty gap. First, increased R&D spending could drive product and process innovations, creating new industries and jobs with higher wages (Eeckhout and Pinheiro, 2014). This may foster economic growth and provide individuals with more opportunities to improve their standard of living, thereby lifting them out of poverty. Second, fixed asset investment could enhance infrastructure, such as roads, telecommunications, and healthcare facilities, which may boost productivity and lower business costs. This creates new investment and job prospects, improving economic growth and expanding the tax base, enabling governments to invest more in poverty reduction programs. Overall, increasing R&D spending and fixed asset investment can contribute to a more prosperous economy with greater opportunities for all, leading to poverty reduction and a narrower income gap.

Conclusions and recommendations

Conclusions

This study explores the impact of manufacturing input servitization on labor income share and income distribution. Regression analysis consistently reveals a positive correlation between manufacturing input servitization and labor income share, independent of fixed effects or control variables. Moreover, it is found that labor productivity and human capital mediate this relationship, suggesting that input servitization strategies enhance labor productivity and investment in human capital, ultimately increasing labor income share.

Heterogeneity analysis shows that medium-technology manufacturing industries benefit most from servitization, followed by high-technology and low-technology industries, indicating the role of technology in determining the impact of servitization on labor income. Furthermore, in developing economies, a larger impact on labor income is observed relative to developed economies, suggesting varying effects across economic contexts.

Extended analysis reveals that the increased labor income share in manufacturing contributes to reducing overall income inequality. This implies that promoting manufacturing servitization could positively affect income distribution.

These findings underscore the importance of manufacturing input servitization for labor income share and income distribution. By adopting servitization strategies, manufacturing firms can improve labor income and reduce income inequality, providing valuable insights for stakeholders interested in inclusive economic growth.

Recommendations

Based on this study’s findings, the following recommendations are made to advance the understanding and implementation of manufacturing input servitization:

(1) Encourage technological advancement and innovation: As medium- and high-technology industries have a stronger impact on labor income share, investing in R&D, technology transfer, and innovation is crucial for policymakers and firms. Improved technological capabilities could drive productivity growth and higher labor income share.

(2) Strengthen human capital development: Given the mediating role of human capital, prioritizing investment in education, training, and skill development is vital. Governments should collaborate with industry stakeholders to develop programs that enhance workforce skills and knowledge.

(3) Support the adoption of servitization strategies: Policymakers should create an enabling environment for manufacturing firms to embrace input servitization, through the provision of financial incentives, regulatory support, and targeted policy interventions. Establishing knowledge-sharing platforms can facilitate servitization strategy adoption among firms.

(4) Promote academia-industry collaboration: Fostering collaboration between academic researchers and industry practitioners is essential to further understand the dynamics of servitization. Joint research projects, partnerships, and knowledge transfer initiatives can contribute to evidence-based policymaking.

By implementing these recommendations, stakeholders can leverage manufacturing input servitization to promote inclusive economic growth, enhance labor income share, and reduce income inequality.

In conclusion, this study provides evidence of the positive impact of manufacturing input servitization on labor income share and income distribution. However, it is important to acknowledge the limitations of this study and identify potential directions for future research. First, this research mainly focuses on the manufacturing sector, and extending the analysis to other industries would provide a more comprehensive understanding of the effects of input servitization. In addition, future research could explore firm-level analysis, investigate additional mediators or moderators, and examine the effects on other economic indicators and across different economies. Addressing these limitations would further advance the understanding of the dynamics and implications of income distribution.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article (and/or) its supplementary materials.

References

Acemoglu D (2003) Labor- and capital-augmenting technical change. J Eur Econ Assoc 1:1–37. https://doi.org/10.1162/154247603322256756

Acemoglu D (2010) When does labor scarcity encourage innovation? J Pol Econ 118:1037–1078. https://doi.org/10.1086/658160

Baines TS, Lightfoot HW, Benedettini O, Kay JM (2009) The servitization of manufacturing: a review of literature and reflection on future challenges. J Manuf Technol Manag 20(5):547–567. https://doi.org/10.1108/17410380910960984

Bental B, Demougin D (2010) Declining labor shares and bargaining power: an institutional explanation. J Macroecon 32:443–456. https://doi.org/10.1016/j.jmacro.2009.09.005

Bentolila S, Saint-Paul G (2003) Explaining movements in the labor share. Contrib Macroecon 3:9. https://doi.org/10.2202/1534-6005.1103

Cai Y, Wang T (2013) The Chinese savings rate: causes and implications for imbalances. In: Whalley J (ed) China’s trade, exchange rate and industrial policy structure, World Scientific Publishing, Singapore, p 63–85

Constantinescu C, Mattoo A, Ruta M (2019) Does vertical specialisation increase productivity. World Econ 42:2385–2402. https://doi.org/10.1111/twec.12801

Crozet M, Milet E (2017) The servitization of French manufacturing firms. In: Fontagne L, Harrison A (eds) The factory-free economy: outsourcing servitization, and the future of industry, Studies of Policy Reform, Oxford University Press, Oxford, p 111–135. https://doi.org/10.1093/acprof:oso/9780198779162.003.0005

Dabla-Norris E, Kochhar K, Suphaphiphat N, Ricka F, Tsounta E (eds) (2015) Causes and consequences of income inequality: a global perspective. International Monetary Fund, Washington, D.C. https://doi.org/10.5089/9781513555188.006

Eeckhout J, Pinheiro R (2014) Diverse organizations and the competition for talent. Int Econ Rev 55:625–664. https://doi.org/10.1111/iere.12065

Feng C, Jiang L, Ma R, Bai C (2021) Servitization strategy, manufacturing organizations and firm performance: a theoretical framework. J Bus Ind Mark 36(10):1909–1928. https://doi.org/10.1108/JBIM-04-2020-0184

Fontagné L, Harrison A (2017) The factory-free economy: outsourcing, servitization and the future of industry (No. w23016). National Bureau of Economic Research. https://doi.org/10.3386/w23016

Francois JF (1990) Trade in producer services and returns due to specialization under monopolistic competition. Can J Econ 23:109–124. https://doi.org/10.2307/135522

Gang G, Guang Y (2010) Analysis of China’s unequal income distribution from the perspective of functional income distribution. Soc Sci China 31:53–72. https://doi.org/10.1080/02529203.2010.524366

Hayakawa K, Kimura F, Matsuura T (2009) Gains from fragmentation at the firm level: Evidence from Japanese multinationals in East Asia. No. d010. Economic Research Institute for ASEAN and East Asia (ERIA). https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.888.9984&rep=rep1&type=pdf

Jorgenson DW, Ho MS, Samuels JD, Stiroh KJ (2007) Industry origins of the American productivity resurgence. Econ Syst Res 19(3):229–252. https://doi.org/10.1080/09535310701571885

Karabarbounis L, Neiman B (2014) The global decline of the labor share. Q J Econ 129:61–103. https://doi.org/10.1093/qje/qjt032

Karatzas A, Papadopoulos G, Godsell J (2020) Servitization and the effect of training on service delivery system performance. Prod Oper Manag 29:1101–1121. https://doi.org/10.1111/poms.13165

Klump R, McAdam P, Willman A (2008) Unwrapping some euro area growth puzzles: factor substitution, productivity and unemployment. J Macroecon 30:645–666. https://doi.org/10.1016/j.jmacro.2007.06.005

Konan DE, Maskus KE (2006) Quantifying the impact of services liberalization in a developing country. J Dev Econ 81(1):142–162. https://doi.org/10.1016/j.jdeveco.2005.05.009

Lay G, Copani G, Jäger A, Biege S (2010) The relevance of service in European manufacturing industries. J Serv Manag 21:715–726. https://doi.org/10.1108/09564231011092908

Li Q, Yuan Y (2018) What affect the choice of manufacturing enterprises to servitize? (eds.) Paper presented at the 10th International Conference on Financial Risk and Corporate Finance Management, Dalian University of Technology Electronic & Audio-visual Press, Faculty of Management and Economics of Dalian University of Technology, China, p 426–431. https://kns.cnki.net/KCMS/detail/detail.aspx?dbcode=IPFD&filename=DLLD201807001060

Opazo-Basáez M, Vendrell-Herrero F, Bustinza OF (2018) Uncovering Productivity Gains of Digital and Green Servitization: Implications from the Automotive Industry. Sustainability 5:1524. https://doi.org/10.3390/su10051524

Paiola M, Gebauer H (2020) Internet of things technologies, digital servitization and business model innovation in BtoB manufacturing firms. Ind Mark Manag 89:245–264. https://doi.org/10.1016/j.indmarman.2020.03.009

Peng H, Tan H, Zhang Y (2020) Human capital, financial constraints, and innovation investment persistence. Asian J Technol Innov 28:453–475. https://doi.org/10.1080/19761597.2020.1770616

Reiskin ED, White AL, Johnson JK, Votta TJ (1999) Servicizing the chemical supply chain. J Ind Ecol 3:19–31. https://doi.org/10.1162/108819899569520

Shen L, Sun C, Ali M (2021) Role of servitization, digitalization, and innovation performance in manufacturing enterprises. Sustainability 13:9878. https://doi.org/10.3390/su13179878

Song L, Wang H, Song W, Yang Y (2022) Empirical analysis of influence of furniture manufacturing servitization on industry performance based on big data. Sci Program 2022:7115035. https://doi.org/10.1155/2022/7115035

Sousa R, da Silveira GJC (2019) The relationship between servitization and product customization strategies. Int J Oper Prod Manag 39:454–474. https://doi.org/10.1108/IJOPM-03-2018-0177

Spector D (2004) Competition and the capital–labor conflict. Eur Econ Rev 48:25–38. https://doi.org/10.1016/S0014-2921(02)00322-7

Tregenna F (2008) The contributions of manufacturing and services to employment creation and growth in South Africa. S Afr J Econ 76:S175–S204. https://doi.org/10.1111/j.1813-6982.2008.00187.x

Zhang J (2022) Impact of manufacturing servitization on factor productivity of industrial sector using global value chain. Sustainability 14(9):5354. https://doi.org/10.3390/su14095354

Zhang J, Sun X, Dong Y, Fu L, Zhang Y (2023) The impact of servitization on manufacturing firms’ market power: empirical evidence from China. J Bus Ind Mark 38(3):609–621. https://doi.org/10.1108/JBIM-06-2021-0279

Acknowledgements

Supported by the Key project of the National Social Science Foundation of China (19@ZH027).

Author information

Authors and Affiliations

Contributions

HW conceived and designed the study, collected and analyzed the data, and wrote the manuscript. QG contributed to data collection and analysis, provided critical revisions, and assisted in writing the manuscript. Prof. Dr. XK supervised the study, provided guidance throughout the research process, and offered valuable insights in manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

This article does not contain any studies with human participants performed by any of the authors.

Informed consent

This article does not contain any studies with human participants performed by any of the authors.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, H., Guo, Q. & Kuang, X. Effects of manufacturing input servitization on labor income share and income distribution. Humanit Soc Sci Commun 10, 584 (2023). https://doi.org/10.1057/s41599-023-02101-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1057/s41599-023-02101-2