Abstract

The storage of CO2 and hydrogen within depleted gas and oil reservoirs holds immense potential for mitigating greenhouse gas emissions and advancing renewable energy initiatives. However, achieving effective storage necessitates a thorough comprehension of the dynamic interplay between interfacial tension and wettability alteration under varying conditions. This comprehensive review investigates the multifaceted influence of several critical parameters on the alterations of IFT and wettability during the injection and storage of CO2 and hydrogen. Through a meticulous analysis of pressure, temperature, treatment duration, pH levels, the presence of nanoparticles, organic acids, anionic surfactants, and rock characteristics, this review elucidates the intricate mechanisms governing the changes in IFT and wettability within reservoir environments. By synthesizing recent experimental and theoretical advancements, this review aims to provide a holistic understanding of the processes underlying IFT and wettability alteration, thereby facilitating the optimization of storage efficiency and the long-term viability of depleted reservoirs as carbon capture and storage or hydrogen storage solutions. The insights gleaned from this analysis offer invaluable guidance for researchers, engineers, and policymakers engaged in harnessing the potential of depleted reservoirs for sustainable energy solutions and environmental conservation. This synthesis of knowledge serves as a foundational resource for future research endeavors aimed at enhancing the efficacy and reliability of CO2 and hydrogen storage in depleted reservoirs.

Similar content being viewed by others

Introduction

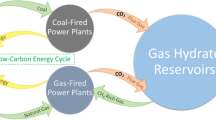

While the emission of greenhouse gases (GHG) caused by human activities remains the primary driver of global warming and climate change, it is rapidly increasing1,2, The implementation of appropriate measures to reduce global temperature and its associated human impacts has become increasingly vital. Carbon dioxide resulting from the burning of fossil fuels in power plants and energy industries constitutes approximately three-fourths of greenhouse gases3,4. However, alongside the pivotal role of hydrocarbons in energy production, efforts to curb the resulting greenhouse gas emissions and the promotion of clean energy have gained significant traction5. Carbon Capture and Storage (CCS) is an essential technique, with contemporary initiatives forecasted to diminish CO2 discharges by a remarkable 30 million tonnes annually. In addition, CCS alone could contribute almost 20% to reducing greenhouse gas emissions by 2050 and the removal of CCS would increase global costs for achieving emission reduction targets by as much as 70%6. Net CO2 emission reductions, significant storage capacity, longterm operational separation of CO2 from the atmosphere, cost-effectiveness, and low environmental impact mitigation are crucial features of carbon dioxide storage options7. Moreover, the employment of hydrogen (H2) as an eco-friendly energy origin has also drawn extensive international focus from the global energy community8. The energy density of hydrogen is 3.2 times less than that of natural gas and 2700 times less than that of gasoline. Therefore, it can be inferred that hydrogen can serve as an energy carrier instead of a source of energy. This implies that hydrogen can store and deliver energy in a usable form. The higher hydrogen efficiency (60% compared to 22% for gasoline or 45% for diesel) contributes to the improvement of energy efficiency for the use of clean energy in the future. A number of methodologies have been proposed for the creation and storage of hydrogen in underground caverns. As a result, underground hydrogen storage (UHS) presents a hopeful technique for enclosing H2 in geological formations beneath the earth's surface, allowing for its retrieval when necessary9,10,11.

Given the importance of interfacial tension (IFT) and wettability in determining the storage capacity, trapping, and recovery of carbon dioxide and hydrogen, this study for the first time will comprehensively investigate the changes in these two parameters during gas storage, considering various factors such as temperature, pressure, salinity, and different nanoparticles based on previous studies. The results of this research can help to understand the interactions during gas storage and lead to improving the efficiency of these operations.

Gas storage in depleted reservoirs

Investigating the broad features, structure and efficiency of hydrocarbon reservoirs as an environment for storing hydrocarbons becomes important after the end of the extraction period and converting them into a gas storage device.

To expand, oil or gas reserves, also referred to as hydrocarbon reservoirs, are geological structures that have gone through different diagenetic processes including formation from a source rock, subsequent movement, and maturation to eventually function as a storage medium for hydrocarbons. Predominantly, these formations are sealed by a non-permeable cap rock, which frequently benefits from the support of the underlying water boundaries. When a gas field approaches the end of its effective extraction period, it often transitions into a storage site for gas. A gas reservoir that has been depleted or is nearing depletion typically exhibits reduced pressure and higher water saturation in the space formerly occupied by the gas, brought about by variations in aquifer levels. Consequently, the level of gas saturation behind the advancing water front varies from a minimum—associated with the residual gas saturation close to the original gas and water contact point—to a maximum near the area where gas and water are actively contacting each other12. In simpler terms, one could conceptualize a depleted gas reservoir as being a component of an aquifer system—or more specifically, geological traps—where water remains only in minimal quantities within the pores, with gas constituting the predominant substance.When a gas field approaches the tail end of its production phase, it’s often repurposed into a storage area for gas. As it gets depleted, the reservoir’s characteristics change; it’s marked by diminished pressure and an increase in water presence in the areas that gas once filled. The water movement alters the levels of gas saturation, creating a spectrum from the lowest at the initial gas–water interface to the highest around the proximity of this contact zone. Thus, a gas field at the brink of exhaustion can be seen as a segment within a water-bearing geological formation, one where gas predominantly fills the pore spaces, despite the presence of limited water volumes. Depleted gas fields can be utilized for gas storage as their impermeability (resistance) has been proven over geological time13. Until now, these types of reservoirs have been well identified due to their geological characteristics, trap integrity, and prior exploration, development, and production activities that have been extensively researched. They are commonly used for natural gas storage14. The inventory of underground gas storage is composed of two types of gas: working gas and cushion gas, as we have seen15,16. In this scenario, the operational gas H2 is conventionally introduced and removed from the storage as needed. Meanwhile, the cushion or base gases, such as CO2, CH4, N2, and even H2, are maintained in the facility to ensure pressure levels are upheld through the compression and expansion processes during injection and extraction cycles17. Furthermore, it prevents water ingress for optimal storage space. The inventory of subterranean gas storage is typically made up of working gas and what’s known as cushion or base gas, as studies15,16 have shown. In instances where H2 serves as the working gas, it is regularly cycled in and out of the storage system in response to demand fluctuations. Meanwhile, the cushion gas, which might be CO2, CH4, N2, or even H2, stays consistently within the storage system. Its main function is to preserve the necessary pressure by means of compression and decompression during the cycles of injection and extraction17. This enduring gas presence also plays a key role in safeguarding against the infiltration of water, thereby optimizing the available storage capacity18 and reducing the impact of injected gas impurities. Throughout the operational phase, hydrogen that is pumped into the reservoir interacts with and gradually moves the pre-existing fluids, which include brine and any leftover gas, found inside the pore spaces. This hydrogen then extends and permeates across a low-permeability barrier which is designed to contain fluids8. Due to density variations between the injected H2 and the native fluid, which occur with pressure increase, the fluid is pushed downwards or laterally to create storage space. As pressure increases steadily during the injection, an interface between the fluid and gas develops. This newly-created boundary, separating H2 from the brine and gas within the pores, can impede the extraction process, posing particular challenges for short-duration storage scenarios19,20. Since this phase is miscible with the injected hydrogen (H2), it is logical to anticipate that in the initial cycles of hydrogen injection and withdrawal, the recovered gas will contain a certain proportion of this mixture, which is expected to decrease as the number of storage cycles increases. But it remains unclear how much native gas mixing is taking place, for example, CH4, CO2, N2, and the injection gas interaction with gaseous phases. While previous experience in the storage of natural gas has demonstrated that pistonlike behavior and limited mixing between injected gases and natural gas occurs, it is not known whether this applies to H2 during injection into a tank. As H2 is introduced under increasing pressure, its density differs from that of the indigenous fluid, causing the resident fluid to be displaced downward or sideways, thus carving out space for storage. As the pressure continues to escalate, an interface of fluid and gas takes shape in the course of the injection phase. This emerging boundary within the pore spaces, where H2 meets brine or gas, can impede the retrieval of gas, an issue that’s particularly pronounced in short-duration storage scenarios19,20. Since the phase encountered will blend with the H2, one could foresee that the initial cycles of injecting and drawing H2 would result in the extraction of a diminishing portion of this mixed gas as the storage cycles progress. The extent to which the originally present gases (e.g., CH4, CO2, N2) will mix with the H2, and how the gas and liquid phases will interact, remains a subject shrouded in uncertainty. Prior knowledge gained from storing natural gas suggests a piston-like movement with minimal intermingling of the injected and native gases, but whether this pattern will be replicated with H2 injections into the reservoir is yet to be determined21.

Hydrogen and carbon dioxide storage

The study of various characteristics and chemical and physical properties of hydrogen and carbon dioxide on storage and its type in geological structures is investigated due to its wide effects.

Carbon dioxide storage

In geological settings, carbon dioxide can be confined through a range of physical and chemical capture methods, undergoing transformations in its physical state due to the unique pressures and temperatures found beneath the Earth's surface. Under conditions prevalent at the surface, CO2 is in gaseous form and possesses a slightly higher density than air, at 1.872 kg/m3.

Physical trapping

The physical capture of CO2 happens when CO2 is confined as a supercritical fluid or a stabilized gas, and it is a process that depends on volume. There are two forms of physical trapping:

-

a.

Static trapping means that CO2 is blocked by a low-permeability layer or a man-made barrier, and can only flow if there is an opening.

-

b.

Residual trapping means that CO2 is stuck in the pores of the rock, and cannot flow even if there is an opening, because of the surface tension between CO2 and water.

Chemical trapping

Chemical trapping occurs when CO2 is absorbed onto organic matter present in coal and shale (adsorption trapping), or dissolved in subsurface fluids (solubility and ion trapping), and may react with the rock matrix (mineral trapping)22,23.

CCS

CCS involves a wide range of processes for capturing, separating, transporting, storing, and monitoring CO2 emissions. However, due to the large amount of carbon that needs to be stored and the fact that the pure CO2 is buoyant, whether gas or supercritical and has a tendency to migrate, the storage of captured carbon during CCS efforts presents challenges. It can reoccur if it's not sufficiently preserved. There are currently two deep subsurface storage options being examined. The first approach is to inject captured carbon into sediment basins where CO2 can be physically trapped under impermeable rock, preventing it from being transferred onto the surface. Ensuring that the system's caprock is sufficiently impermeable to ensure longterm storage without leakage is a key requirement for such storage. On the other hand, the captured carbon can be stored by injection into reactive rocks such as basalts or ultramafic rocks, which lead to the trapping of carbon in stable carbonate minerals. The injected carbon is permanently sequestered and poses minimal risk of returning to the atmosphere by stimulating the mineralization of the injected CO2 in carbonate minerals such as calcite, dolomite, and magnesite by injecting it into reactive host rocks24.

Recently, ionic liquids (ILs) have been proposed as a potential replacement solvent for amines in the carbon capture processes. Strong ion-ion interactions for ILs lead to negligible evaporation at the ambient conditions. Other appealing properties of ILs are their high thermal stability, large electrochemical window, and ability to dissolve compounds with various polarities25.

One other materials that can be used for carbon capture operations are liquid polymers. Using these materials for CCS comes with advantages such as:

-

Can be obtained from natural products and by-products from industries

-

Biodegradable

-

Reasonable permittivity and selectivity

-

Easy to utilize in industries

-

Can be used by itself or as an auxiliary component alongside ionic liquids

And some disadvantages like:

-

Cannot be used for intensive carbon capture

-

Requires higher pressures for optimal performance26.

CO2 separation options

Potential CO2 separation options include groundwater storage, ocean depths, and mineral carbonation as part of CCS23. In the realm of Carbon Capture and Storage (CCS), plausible techniques for the sequestration of CO2 encompass a variety of strategies such as subterranean geological storages, deep oceanic disposals, and mineral carbonation processes23. The geological storage category encompasses a range of alternatives including saline formations, depleted oil and gas fields, coal deposits that are not viable for mining, hydrate formations for CO2 capture, and pioneering geothermal energy systems powered by CO227,28,29.

Underground geological CO2 storage

Geological storage is the best way to deposit CO2 underground for CCS. It is also better than mineral carbonation or ocean acidification because of cost, location, safety, and environmental impact.

Saline aquifers

Storing CO2 in saline aquifers is effective due to its high storage potential and limited conflicting uses. However, the lack of infrastructure makes many such aquifers economically unattractive for water storage29,30,31,32,33,34,35,36,37.

Depleted oil and gas reservoirs

Storing CO2 in depleted oil and gas reservoirs is highly effective due to existing infrastructure and prior assessment for storage capacity. Additionally, gas injection techniques used in the oil and gas industry can be applied for CO2 storage38,39,40,41,42,43.

Unmineable coal seams

Storing CO2 in unmineable coal seams is a viable option due to the presence of fractures and pores in the coal matrix, allowing for gas absorption. The injected CO2 replaces methane, leading to increased production and storage of significant CO2 amounts, while enhancing profitability in coal bed methane operations. Successful implementation of Enhanced Coal Bed Methane (ECBM) requires specific technical criteria outlined by IEAGHG, including reservoir homogeneity, minimal faulting/fracturing, optimal depth range, concentrated coal seam geometry, and sufficient permeability44,45,46,47.

Basalt formations

Basalt rocks constitute approximately 8% of the Earth's continents and comprise a significant portion of the ocean floor, indicating their enormous potential for CO2 storage48. Primary favorable characteristics of these substances regarding their carbon-capture capabilities encompass their significant reactive nature along with the plentiful presence of bivalent metal ions within these minerals, which may have the capacity to trap CO2 over extended geological periods49.

Hydrate storage of CO2 within the subsurface environment

Subsurface storage of CO2 as hydrates is a promising option, utilizing CO2 hydrates to trap CO2 molecules within a network of water molecules. It can be formed quickly in the presence of water and good pressure/temperature conditions and may offer self-sealing properties in some cases. However, its use in certain environments is restricted by stability limitations at moderate pressures and temperatures below 10 °C, such as in shallow deposits under freezing waters and dense permafrost without nearby CO2 sources28,50,51.

CO2-based enhanced geothermal systems

CO2, with its superior physical characteristics including lower viscosity and greater clarity, can efficiently transfer heat and be used for geothermal energy generation. It can penetrate rock masses and serve as a working fluid in enhanced geothermal systems due to its low viscosity. Unlike water, the use of CO2 in enhanced geothermal systems doesn't result in fluid loss, which has economic consequences. Additionally, CO2 -based EGS offers the potential for geological storage of CO2 underground, providing an additional benefit27,52,53,54,55.

Deep ocean storage

An intentional injection of CO2 into deep ocean waters is a potential alternative strategy for human CO2 separation. The average depth of the oceans is 3.8 km, covering 70% of Earth's surface56, During the Industrial Age, they absorbed approximately one-third of the cumulative anthropogenic CO2 emissions57. The mathematical models show that CO2 injected into the ocean could last for centuries56. These cold (approximately 1°C) and deep (around 4 to 5 km) waters move slowly and can remain separate from the atmosphere for millennial time scales. Direct dissolution of CO2 in seawater is the primary proposed approach to ocean storage. Liquid CO2 shall be discharged directly to the bottom of the sea in the first approach, forming a series of rising droplet columns. On the other hand, liquid CO2 is injected into a column in which it reacts with seawater to form hydrates under controlled conditions58.

Mineral carbonation

The concept of mineral carbonation of CO2 (mineralization) as an alternative strategy for CO2 sequestration was first introduced by Sifrits59. This approach segregates the sequestered CO2 through a mineralization procedure, wherein CO2 engages in chemical reactions with oxides or hydroxides of alkaline earth metals, such as those found in calcium and magnesium-rich minerals, to form stable carbonate compounds, as illustrated in Reactions 1 and 2. There are two principal strategies for mineral carbonation: in situ and ex-situ. The in situ strategy involves the creation of carbonates by pumping CO2 into subsurface rock formations, while the ex-situ strategy refers to the generation of carbonates using pre-mined or locally sourced minerals in a controlled, above-ground industrial set-up. The in situ process pumps CO2 directly into underground formations prompting the natural formation of carbonates. On the other hand, the ex-situ process takes place within industrial facilities at the surface, leveraging either mined or accessible minerals to synthetically create carbonates60,61.

According to the report of Vatalis et al., cheap and efficient CCS methods are obtained through new physicochemical methods in which CO2 adsorption is enhanced based on adsorption in zeolite pores or depleted lignite matrices62.

Field examples of carbon dioxide storage by storage type

-

EOR

-

Petra Nova Carbon Capture (TX, USA)

-

Abu Dhabi CCS Project (Abu Dhabi, UAE)

-

Uthmaniyah CO2EOR Demonstration (Eastern Province, SAU)

-

Lula (BR)

-

-

Saline aquifers

-

Illinois Industrial Carbon Capture and Storage (IL, USA)

-

Quest (AB, CAN)

-

Tomakomai (JP)

-

Hydrogen storage

Hydrogen must be packed, moved, stored, and delivered from production to end use as any other form of product. Investigations are underway to perfect materials for hydrogen storage that are not only secure and dependable but also space-efficient and economically viable for use in fuel cell systems. Similar to other commodities, hydrogen requires encapsulation, movement, containment, and conveyance from the point of manufacture to the end-user. If specific materials are available, Hydrogen can be stored using chemical storage processes or physical absorption. The schematic representation of hydrogen storage is shown in Fig. 163.

Chemical storage

Hydrogen storage using chemical methods is a method that draws on techniques where hydrogen production takes place through the process of synthesis. Some substances such as ammonia and LOHCs are used in this method.

Ammonia can be modified for hydrogen production without harmful waste or it can be effectively burned by blending it with existing fuels64. The advantage of this material is that not releasing CO2 emissions. Advancement in the secure containment of ammonia is progressing through the creation of metal-amine compounds65.

Metal hydrides

Metal hydrides possess a distinct capability to store hydrogen and can discharge it at ambient temperature or upon heating the storage vessel. They can store hydrogen up to 5–7% of their weight, but only when heated to temperatures of 2500 °C or higher. These hydrides exhibit a high attraction to hydrogen and necessitate temperatures between 120 to 200 °C to release their contained hydrogen. The metal hydrides selected for storage applications have low reactivity (high safety) and high hydrogen storage density. Metal hydrides possess a distinct characteristic whereby they can uptake hydrogen and subsequently discharge it on-demand, achievable at ambient temperatures or upon the application of heat to the storage vessel. These compounds can typically store hydrogen at a concentration of 5–7% by mass, yet this storage potential is accessible predominantly at elevated temperatures, starting from 2500 °C. Moreover, they exhibit a notable propensity to bond with hydrogen and necessitate temperatures ranging from 120 to 200 °C to liberate the stored hydrogen (Fig. 2). The chosen metal hydrides for storage solutions are characterized by their low level of reactivity (ensuring greater safety) and a high density of hydrogen storage The schematic of metal hydrides is shown in Fig. 29,66,67.

Formic acid

Given that the hydrogen produced from the reaction does not contain carbon monoxide, there is research interest in utilizing formic acid as a hydrogen storage material. The reaction employs ruthenium catalysts that are dissolved in water, which selectively decompose formic acid into hydrogen and carbon dioxide in an aqueous solution. The stability and lifetime of the catalyst, together with the removal of CO, are improved by applying pressure between 1 and 600 bar, resulting in a durable hydrogen storage material. Carbon dioxide, a typical byproduct of industrial processes, can be repurposed as a hydrogen carrier by hydrogenating it to form formic acid. Scientists are exploring the potential of formic acid for hydrogen storage due to the purity of hydrogen released—devoid of carbon monoxide contamination—during decomposition. This process utilizes ruthenium catalysts that are water-soluble, which selectively break down HCOOH into H2 and CO2 within an aqueous medium. By exerting pressure within the range of 1 to 600 bar, enhancements in catalyst robustness and operational lifespan are achieved, alongside the elimination of CO, thereby converting it into a more enduring hydrogen storage substance. Additionally, carbon dioxide, a prevalent secondary output in this breakdown procedure, can be repurposed as a hydrogen transporter by its hydrogenation back into formic acid68,69,70. This process is shown in Fig. 3.

Carbohydrates

Carbohydrates are the most plentiful renewable biomass resource and offer a high-density storage option for hydrogen in liquid form, achievable under reduced pressure and temperature conditions. Additionally, they can be preserved in solid form. As a result of its complete conversion and moderate reaction conditions, carbohydrates can act as high energy density hydrogen carriers with their polymeric structure evidenced by the formula C6H10O5, making them one of the most abundant sources of renewable biomass. They possess a notable hydrogen storage density when kept in a liquid form, which notably does not necessitate high pressure or temperature conditions. Alternatively, carbohydrates can also be maintained in a solid, powdery state. Owing to their capacity for full conversion under moderate reaction circumstances, carbohydrates serve as an efficient, high-energy density medium for H2 transport. (14.8% by weight)63,71,72.

Liquid Organic Hydrogen Carriers (LOHCs)

LOHCs, which have a gravimetric storage density of approximately 6% by weight, are unsaturated organic compounds able to store large amounts of hydrogen. Hydrogen energy may be released or absorbed by LOHs, e.g. Nethyl carbazol. LOHCs, which are unsaturated organic compounds, have the remarkable capability to store considerable quantities of hydrogen. They exhibit a gravimetric storage density that is about 6% by weight. Specific LOHCs, such as N-ethylcarbazole, have the dynamic ability to either emit or absorb hydrogen energy in response to demand. This makes them quite appealing for various applications where hydrogen needs to be stored and transported efficiently73.

Physical adsorption

This is a process in which H2 molecules are poorly absorbed by the material's surface. Physical adsorption is one way of improving kinetic storage and maintaining the molecular identity of H2 during this process. Physical adsorption occurs when H2 molecules are weakly bound to the surface of the substrate material. This method retains the molecular integrity of H2 and can enhance the kinetics of hydrogen storage. Porous materials are particularly effective for this purpose and have been the subject of extensive research. The large surface areas of materials used for this method provide ample space for hydrogen adsorption, making them good candidates for efficient hydrogen storage technologies.

Advantages of physical adsorption

The method of compressing gas necessitates high starting pressures that can pose safety risks. On the other hand, cryogenic storage for hydrogen compression requires a significant amount of input energy for initial compression. Complex hydrides (such as Mg2NiH4) are more expensive, sensitive to impurities, have a lower reversible weight capacity, and can be decomposed at higher temperatures.

Carbon-based materials

Hydrogen is adsorbed via van der Waals interaction on the surface of carbon, 6 Kjmol. There is a very low volume density of many special carbon materials with large surface areas, e.g. carbon foam, carbon nanotube, carbon aerogel, and Activated Carbons. Fullerenes, on the other hand, need a very high surface area to be able to achieve an adequate density of packaging. Hydrogen adsorption onto carbon structures occurs through van der Waals interactions, typically around 6 kJ/mol. This relatively weak force is sufficient to bind hydrogen to the extensive surface areas presented by various forms of carbon. Numerous unique carbon configurations, such as carbon foam, carbon nanotubes, carbon aerogels, and activated carbon, exhibit these vast surfaces. Despite their impressive surface area, these materials often have very low volumetric densities. Contrastingly, fullerenes, which are spherical, closed-cage carbon molecules, necessitate a significantly high surface area to attain an adequately dense packing of hydrogen molecules. The high surface-to-volume ratio of fullerenes and other carbon allotropes is beneficial for adsorbing hydrogen, but achieving sufficient volumetric storage densities for practical applications is a challenge, often requiring operation under high pressures or at low temperatures to increase hydrogen uptake.

Fullerenes

Fullerenes are made up of five or six interconnected rings, and they each play a role in the formation of C60 molecules by means of their twisted structure. Fullerenes, characterized by their pentagonal or hexagonal rings, form a spheroidal geometry that culminates in the C60 molecule. For a metal atom secured to a carbon-based fullerene, the significant difference in electronegativity with C60 propels electron migration from the metal to the C60, rendering the metal atom positively charged. Consequently, these cationic metal ions capture molecular hydrogen via polarization-driven interaction. Nonetheless, theoretical models suggest the metal atom retains significant isolation when positioned on C60. Titanium, in particular, tends to aggregate on C60, and this clustering phenomenon is unrelated to the type of hydrogen bonds present. Such aggregation of titanium, however, detracts from the weight efficiency of hydrogen storage.74,75.

Carbon nanotubes

Carbon nanotubes (CNTs) are microscopic carbon tubes76 with a thickness of about two nanometers. They are capable of containing hydrogen within their minuscule pores or inside the actual structure of the tubes. The structure of carbon nanotubes is depicted in Fig. 4. Nanotubes may exhibit a structure of either a single layer or multiple layers, possess numerous sites for adsorption, exhibit a substantial density of packing, and hold a theoretical weight capability of 6%74. Both carbon nanotubes and fullerene-like structures have undergone chemical alterations with transitional or alkaline metals to augment the adherence of H2 molecules upon these metal-enhanced carbon nanotube composites77.

Graphene

To control the interaction between hydrogen and graphene, it is possible to adjust the distance between adjacent layers, adjust the curvature of the sheet, or use chemical functionalization to control the adsorption and desorption of hydrogen (Fig. 5)78. This approach entails trapping hydrogen between graphite layers, which is typically only releasable when heated to approximately 450 °C. It is more efficient compared to carbon nanotubes as it is not only cost-effective but also safe and easy to prepare. The engagement of hydrogen with graphene can be modulated by fine-tuning the spacing amidst neighboring layers, altering the sheet’s curvature, or via chemical modification, which facilitates regulated hydrogen adsorption and release76. Employing this technique, hydrogen is retained between graphite layers and is designed to discharge only upon being heated to roughly 450 °C. This approach is recognized as more efficient than the use of carbon nanotubes, given its cost efficiency as well as its safety and simplicity in preparation79. The schematic of graphene is shown in Fig. 5.

Zeolites

Under high temperatures and pressure, H2 is forced to move into molecular sieves with different structures and compositions of the pores in zeolites80. When the zeolites cool to room temperature, H2 is trapped inside their pores and can be released with an increase in system temperature. Within zeolites, H2 is compelled to navigate through the pores of the molecular sieve, which is subjected to elevated temperatures and pressures and possesses a variety of pore structures and compositions78. On cooling the zeolites to ambient temperatures, H2 is ensnared within these pores and can subsequently be liberated by heating the system. Studies indicate that zeolites featuring sodalite cages have demonstrated an ability to store hydrogen at a capacity of 9.2 cm3/g at a temperature of 573 K and a pressure of 10.0 MPa79. The high thermal resistance, affordability, and tunable composition of zeolites have led to their acknowledgment in various domains81.

Metal–organic frameworks

Metalorganic frameworks: MOFs are a family of nanoporous materials consisting of well-defined building blocks, polarized metal oxide centers, and nopolar organic connections. MOFs with oxide components maintain stability even when their pores are vacant or subjected to heating. MOFs exhibit desirable characteristics such as robust stability, high void volumes, well-defined and homogeneously sized cavities, extensive surface areas, adjustable pore sizes, and controllable thermal properties which allow them to stay at an acceptable temperature. MOFs stand as a distinct group of nanoscopic structures characterized by meticulously arranged foundational units, comprising polar metallic oxide junctures (binding points) and apolar organic spans. Even in scenarios where their cavities are vacant or subjected to heat, MOFs with oxide constituents maintain their integrity. These frameworks boast robust constancy, substantial empty spaces, cavities that are consistent in shape and size, extensive surfaces, pores whose dimensions are adjustable, properties that can be modified as needed, and a reliable level of heat resistance82,83.

Covalent organic frameworks (COFs)

The premier benefit of 3D-COFs, setting them apart from other porous organic materials, stems from their crystalline architecture, facilitating a high surface area. COF-1 and COF-5 epitomize 2D structures, in contrast to COF-102, COF-105, and COF-108, which exemplify 3D configurations—these offer thrice the storage capacity compared to their 2D siblings. Of noteworthy mention is COF-102–3, the only one to present a weight uptake of 26.7% at 77 K and 6.5% at 300 K under a pressure of 100 bar. The primary benefit of 3D-COFs over other porous organic materials of light weight is their crystalline composition, which results in a considerably extensive surface area. COF-1 and COF-5 possess bidimensional formations, in contrast to COF-102, COF-105, and COF-108, all of which feature a tridimensional framework that enables a tripling in storage capabilities when compared to their 2D counterparts. Specifically, COF-102–3 stands out as the singular structure exhibiting significant mass absorption, with 26.7% at the cryogenic temperature of 77 K and 6.5% at the higher temperature of 300 K under the pressure of 100 bar84.

Micro porous metal coordination materials (MMOMS)

These materials have pore dimensions equivalent to the molecular size of H2, making them an efficient storage material for H2. Based on aromatic carbon rings, they're composed of open channels. In order to change the curvature of channels, their internal surfaces can be easily changed so as to increase interaction with H2 adsorbents. These materials excel at storing H2 due to their pore sizes being closely matched to the molecular size of H2. Constructed with open pathways formed by aromatic carbon loops, the internal surfaces of these materials are readily adjustable, allowing for alterations in the pathways’ curvature, which enhances the interactions critical for H2 adherence85.

Clathrate

Clathrate hydrates are compounds that can trap molecules within their polyhedral cages; these cages are constructed by water molecules linked through hydrogen bonding. Type I, type II, and H16 are commonly formed into two cubic forms. The crystallographic properties of each structure are different, and the shapes and sizes of the holes are different. Clathrate hydrates consist of compounds that trap guest molecules within their polyhedral enclosures, created by a network of water molecules connected through hydrogen bonds. Typically, they crystallize into two cubic structures, known as type I and type II, as well as a hexagonal variety, type H16. Each of these structural types showcases unique crystallographic characteristics, along with cavities varying in both shape and dimension86,87,88.

Glass capillary arrays

The glass capillary arrays are located in the steel tanks which have been designed to withstand pressure. The membranes are secured by melting one end and sealing the other end with an alloy composed of sealing materials. The process of hydrogen addition persists until the desired storage pressure is achieved within the steel container. Currently, glass capillary arrays are employed in mobile applications to ensure the safe injection, storage, and regulated release of hydrogen. Arrays of glass capillaries are fitted within tanks crafted from pressure-tolerant steel. These membrane arrays are subsequently sealed—one end is melted shut, while the opposite end is capped using a sealing metal alloy. Hydrogen is introduced into this assembly until it attains the target storage pressure within the steel vessel. Currently, these glass capillary systems are employed for the secure injection, containment, and regulated discharge of hydrogen, specifically in mobile contexts89,90.

Glass microspheres

At a temperature of 1 °C, the glass microspheres are initially filled with hydrogen at about 350 to 700 bar pressure. They'll be rapidly cooled to room temperature afterward. For controlled hydrogen release, the spheres shall be transferred to a low-pressure storage vessel and heated again at temperatures of 200–300 °C. These materials not only have low volumetric capacity but also require high-pressure filling. Glass microspheres are subjected to an initial fill of hydrogen at heightened pressures ranging from 350 to 700 bar, and this is conducted at a chilled temperature of about 1 °C. Following the pressurization, they are briskly brought back to ambient room temperature. These spheres are then relocated to a storage vessel with diminished pressure. For the controlled dissemination of the hydrogen, they are reheated to temperatures within the scope of 200–300 °C. While employing these materials, it is worth noting that they are characterized not only by a limited volumetric capacity but also necessitate the application of high pressure during the filling process91.

Organotransition metal complexes

Transition metal complexes are compounds with a carbon foundation that encompass intermediate metals in their design, serving to amplify the hydrogen storage capability of the composite structure. Transition metal complexes are composed of carbon frameworks that integrate transition metals, thereby elevating the composite’s capacity to store hydrogen hydrogen. The schematic of the optimized structure of the C2H4Nb(14H2) complex is shown in Fig. 692,93,94.

Theoretical aspects of hydrogen storage

To determine the position at which hydrogen molecules are absorbed into the chemical adsorption system, energy scans have been performed using single-point energy changes as a function of the radial distance of the H2 molecule from the center of the H2 adsorbent system to the outer surface95,96. The dynamic stability significantly influences the efficiency of hydrogen storage, and this theoretically corresponds to the energy difference between the HOMO–LUMO levels of the linked adsorbent group. For optimized H2 storage, the dynamic stability of the complex is projected to increase as H2 molecules are incrementally added to the metal complex. Variations in single-point energy have been employed to execute energy assessments, reporting them with the gradual outward movement of an H2 molecule from the heart of the H2 containment structure to its external limit. This procedure determines the exact point at which hydrogen molecules are genuinely integrated into the chemical containment apparatus94,95. Dynamic robustness, which is theoretically related to the energy differential between HOMO–LUMO levels in a Absorbent Group, has an important impact on efficient hydrogen storage. It is expected that the addition of H2 molecules in sequence to a metal complex increases the system's dynamic stability and thereby promotes efficient retention of H295,97.

By moving towards the use of renewable energies in order to decarbonize and reduce fossil fuels, the use of hydrogen as a source of clean energy becomes important. The properties of hydrogen, including the potential to improve national energy security and fuel economy, boost a country's economy. It also diversifies transportation alternatives for a more flexible system when used to power electric vehicles with highly efficient fuel cells98,99.

Field examples of hydrogen storage by storage location

-

Depleted oil and gas

-

o

Dladema project (Argentina)

-

o

Underground Sun (Austria)

-

o

-

Saline aquifers

-

o

Ketzin project (Germany)

-

o

Beynes project (France)

-

o

Lobodice project (Czech Republic)

-

o

-

Salt caverns

-

o

Teesside project (UK)

-

o

Clemens dome project (USA)

-

o

Moss bluff project (USA)

-

o

Spindletop project (USA)

-

o

Kiel project (Germany)

-

o

Wettability alteration during gas storage

Thermophysical and petrophysical factors including wettability of rock-brine-gas systems and interfacial tension (IFT) between rock and liquids are effective parameters to evaluate the ability to store CO2 and H2 in the reservoir.

One of the influencing parameters on gas storage is rock wettability, which determines fluid mechanics, storage capacity, and rock containment security.

Wettability measurement

Usually, measuring wettability is done by measuring the contact angle between solids and fluids. There are various methods for determining the contact angle, including sessile drop, captive bubble, Wilhelmy plate, tilted plate, and capillary rise. The schematic of each of these methods is shown in Fig. 7. The sessile drop method is most commonly used in measuring contact angle values. This method involves placing a liquid droplet on a solid surface and measuring the angle formed between the tangent to the droplet at the common surface with the solid surface. The contact angle provides information about surface wettability100.

Schematic of contact angle measurement methods100.

There are challenges while measuring the contact angle parameter, some of which are:

-

Surface contamination: Contaminants on the surface can alter contact angle measurements, leading to inaccuracies.

Resolution: Implement thorough surface cleaning protocols using appropriate solvents and techniques. Utilize clean substrates and ensure proper handling to minimize contamination101,102.

-

Substrate heterogeneity: Variations in substrate properties can introduce inconsistencies in contact angle measurements.

Resolution: Select substrates with uniform surface properties and minimal heterogeneity. Conduct surface characterization to identify and mitigate any inherent substrate variations103,104.

-

Dynamic nature of gas dissolution: Gas dissolution can lead to time-dependent changes in surface properties, affecting contact angle measurements.

Resolution: Employ dynamic contact angle analysis techniques to capture changes over time. Conduct experiments under controlled environmental conditions to minimize variability105.

-

Instrumental limitations: Inaccuracies in measurement instruments or techniques can impact the reliability of contact angle data.

Resolution: Use high-precision instruments with appropriate calibration and validation procedures. Follow standardized measurement protocols to ensure consistency and reliability106.

-

Gas adsorption: Gas molecules can adsorb onto the substrate surface, altering its properties and influencing contact angle measurements.

Resolution: Minimize gas adsorption effects by conducting experiments in controlled atmospheres or vacuum conditions. Utilize appropriate surface treatments or coatings to mitigate gas adsorption107.

-

Interfacial instabilities: Rapid changes in gas composition or pressure can induce interfacial instabilities, affecting contact angle measurements.

Resolution: Control gas composition and pressure gradients during experiments to minimize interfacial instabilities. Employ stabilization techniques or additives to maintain interface integrity108.

Wettability alteration during carbon dioxide storage

In 2007, Chiquet et al. investigated the contact angle of brine and CO2 as fluid on mica and quartz as solid surfaces at a pressure range of 1 to 11Mpa and salinities of 0.01, 0.1, 0.2, 0.5, and 1 M of NaCl and a temperature of 35°C. The results demonstrated a transition from a water-wet state at low pressures to an intermediate water-wet state at pressures higher than 10 MPa. This change was more pronounced for mica compared to quartz109.

At high pressures, the contact angle of water increases with the absorption of CO2 onto the rock surface. This process is illustrated in Fig. 8.

In 2017, a study conducted by Al-Anssari et al. investigated the impact of pressure (0.1 to 20 Mpa), temperature (23, 50, and 70 °C), silica concentration(0.01, 0.05, and 1%wt,) and treatment duration (0.5 to 4 h) and salinity (0 to 20%wt of NaCl and CaCl2) on wettability. Through nanoparticle treatment, they were able to transform the wettability of calcite from an intermediate wet state to strongly water-wet. Furthermore, they noted that the reduction in water contact angle due to nanoparticle treatment became less pronounced at higher treatment temperatures. Conversely, the decrease in water contact angle caused by CO2 pressure showed an upward trend across all temperature levels. The contact angle experienced a decline with both time and nanoparticle concentration. The study also established that under normal pressure conditions, the optimal pH range for desirable wettability was between 4 and 6. However, when subjected to elevated CO2 pressure, a pH range of 6 to 8 exhibited the most significant effect on surface wettability. Generally, the presence of NaCl did not substantially alter the contact angle of natural calcite. On the contrary, the introduction of CaCl2 led to a noticeable reduction in water contact angle. On the contrary, an increase in pH corresponds to a decrease in the contact angle of calcite treated with nanospheres. In particular, the effects of divalent ions were more pronounced than those of NaCl110.

In 2021, the study by Fatah et al. delved into the influences of time (3, 5, 7, 9, 11, 13, 15 at 18Mpa and 70°C), temperature (40, 50, 60, 70, 80, and 90°C at 10Mpa for 48 h), and pressure (9, 12, 15, 18, 24Mpa at 10°C for 48 h) on wettability. The findings revealed that shale formations rich in clay could undergo alterations in their CO2-wet characteristics as treatment time and pressure increased. Conversely, shales with significant quartz content retained their robust hydrophilicity. Raising the temperature heightened the interaction between shale and CO2, with a minor effect on shale wettability. Moreover, an augmentation in cohesive energy density led to a decrease in surface hydrophilicity111.

In 2023, Lu et al. conducted a study focused on modifying wettability within water/shale/CO2 systems through the application of nanoparticles with dosages of 0.025, 0.05, 0.1, 0.2, and 0.4%wt. In the study, the substrates were divided into nanofluid-treated and nanofluid-untreated groups. The treated group underwent ScCO2 treatment (4 days/16 MPa/40°C) to reduce hydrophilicity, followed by immersion in nanofluids at different times and concentrations. They were then dried at 60°C for 24 h and exposed to ScCO2 again. The untreated group was continuously exposed to ScCO2 (8 days/16 MPa/40°C). The introduction of supercritical carbon dioxide led to an increase in the water contact angle within treated samples. Nevertheless, the utilization of nanofluids had the potential to reverse this effect. The research indicated that in this reversion process, silica nanofluids displayed more effective outcomes compared to alumina nanofluids112.

In 2021, Iglauer and Al-Yaseri presented a solution to address challenges related to CO2 storage by suggesting the application of anionic surfactants on basalt surfaces at pressures of 5 to 15Mpa at 308.15, 323, and 333.15K and a NaCl concentration of 0.3M. Their approach involved the use of sodium dodecylbenzene sulfonate. The experimental findings strongly underscored the success of this technique. Notably, even when subjected to elevated pressures and low concentrations of sodium dodecylbenzene sulfonate, basalt exhibited completely water-wet behavior. This outcome highlighted the efficacy of their proposed strategy113.

In 2022, Al-Yaseri et al. explored the influence of organic acids on the wettability of calcite, mica, and quartz minerals. The findings unveiled a consistent pattern wherein the ascending order of mineral hydrophobicity was calcite > mica > quartz across all conditions. At a temperature of 323K and a pressure of 25 MPa, when stearic acid was present at a concentration of 10–2 mol/l, quartz underwent a transition to an intermediate wet state. In contrast, mica and calcite demonstrated CO2-wet behavior under the same conditions114.

In 2024, Sakthivel et al. conducted an exploration into the impact of carbon nanodots on the wettability of carbonate rock/brine/CO2 systems. This investigation encompassed diverse concentrations of carbon nanodots (0–1000 ppm), varied temperatures (20–80°C), and pressures (14.7–3000 psi). The study unveiled that even following treatment with carbon nanodots, the carbonate rock maintained a robust water-wet nature. Upon elevating the pressure to 1000 psi, across all temperatures, the initially oil-wet carbonate samples underwent a shift toward CO2-wet behavior. Interestingly, when subjected to 3000 psi pressure and treated with carbon nanodots, the carbonate samples transformed into a mildly water-wet state. Generally, the trend observed indicated that an increased concentration of carbon nanodots correlated with a decline in the contact angle. However, with the augmentation of both temperature and pressure, the contact angle exhibited an upward trend115.

Due to the dissolution of carbon dioxide in the formation water, carbonic acid is generated, impacting the wettability values. This phenomenon was explored by Drexler et al. in 2020 at conditions of 60°C and 6.895 MPa. Their findings revealed that carbonated brine lowers the pH of the aqueous phase, facilitating the protonation of acidic and basic compounds in the oil. This elevation in positive charge at the oil/brine interface leads to enhanced repulsion with the positively charged carbonate rock surface. Consequently, there is a shift towards water-wet in terms of wettability116.

Contact angle values were measured by Al-Yaseri et al. for systems containing nitrogen and CO2 and a mixture of these two gases (50% mol). The values of temperature, pressure, and salinity of the system were equal to 333 K, 13 MPa, and 5000 ppm NaCl, respectively. All systems were weakly water-wet and had advancing contact angles equal to 47, 40.6, and 33.9 for pure CO2, pure N2, and the combination of these two gases117.

The effect of SO2 impurity on the wettability of a CO2/brine/quartz system in 2014 investigated by Saraji et al. in the temperature range of 50 to 100 °C, pressure between 2000 and 4000 psig and salinity between 0.2 and 5 M, and weight percent of SO2 between 0 to 6 M. Based on this, increasing the pressure caused a slight increase in the contact angle of advancing and receding. Both the advancing and receding contact angles of water increased with increasing salinity, but no type of contact angle changed with increasing SO2 concentration. All systems were strongly water-wet118.

In 2021, Yong et al. investigated the contact angle of water in a CH4/CO2/graphite system at a temperature of 300 K and a pressure of 5.36 MPa. Accordingly, with the increase in CO2 concentration, while all systems had weak gas-wet properties, the water contact angle increased119.

The wettability of microcline, quartz, and illite at pressures of 2 to 25 MPa and temperature of 40 °C and salinity of 5.19 M was investigated by Botto et al. in 2017. By increasing the pressure from 2 to 7.38 MPa (transition to supercritical), the contact angle values increased strongly. But after that, according to the error values, it can be said that the contact angle remains constant. All samples had strongly water-wet behavior at all pressures120.

The wettability changes of a scCO2-silica-brine system at a pressure of 8.5 MPa and a temperature of 45°C were investigated in different salinities from 0.01 to 5M of NaCl by Kim et al. in 2012. The contact angle of brine increased from values close to 0° to 80° with a larger increase in higher ion strength conditions121.

In 2014, Shojai Kaveh et al. measured the contact angle of the CO2/water/benthemier sandstone system at 45°C and pressures of 0.2 to 15 MPa. Accordingly, by increasing the pressure from 1 to 9.2 MPa, the contact angle reached from 15° to 20.5°. After increasing the pressure to 12.8 MPa, the contact angle decreased. In all pressures, the rock kept its strongly water-wet property105.

Table 1 shows the effect of different parameters on the wettability altrations during the injection of CO2.

Wettability alteration during hydrogen storage

Iglauer et al. conducted research in 2021 to explore the influence of temperature (296–343 K), pressure (0.1–25 MPa), and the concentration of organic acid (10–2, 10–3, 10–5, 10–7, and 10–9 mol/L) on the wettability of quartz rock by hydrogen. The findings indicated that, in an actual storage setting, an escalation in temperature, pressure, and organic acid concentration resulted in an increased hydrogen wettability122.

In 2021, Al-Yaseri and Jha conducted a study examining the wettability of brine/gas/basalt systems at 323K and four distinct pressure levels (5, 10, 15, and 20 MPa). The findings indicated that basalt maintains its strong hydrophilic characteristics when exposed to hydrogen under storage conditions123.

In 2021, Ali et al. conducted a study examining the influence of organic acids on the wettability of quartz at 323K and under three different pressure levels: 0.1 MPa, 15 MPa, and 25 MPa. Their findings indicated that when the sample was exposed to organic acids with longer chains, the quartz surface exhibited a strongly water-wet behavior. However, in the presence of hydrogen at 25 MPa and 323K, it transitioned to intermediate water wet. In contrast, under the same conditions, other acids had either a moderate or limited impact124.

In 2022, Hosseini et al. conducted a study examining the influence of various factors on the contact angle of the water/hydrogen/calcite system. These factors included pressure (0.1-20MPa), temperature (298–353 K), salinity (0–4.95mol/Kg), stearic acid concentration (10–9-10–2 mol/L), tilting plate angle (0 to 45°), and surface roughness (341 nm, 466 nm, and 588 nm). Their findings revealed that raising the system's pressure shifted it from being strongly water-wet to an intermediate water-wet state. Furthermore, an increase in stearic acid concentration resulted in a notable rise in the water contact angle, causing the rock surface to become H2-wet. Conversely, the contact angle decreased as surface roughness increased. Elevating both salinity and the tilting plate angle contributed to an augmentation in the contact angle. Conversely, an increase in temperature led to a decrease in the contact angle. In conclusion, the study identified optimal conditions for hydrogen storage, characterized by high temperature and pressure, low salinity, and low organic surface concentration125.

In a 2022 study conducted by Hosseini et al., they examined the contact angles within the basalt/hydrogen/brine system across varying temperature (308–343 K) and pressure (5–20 MPa) conditions, both without and with the inclusion of organic substances (10–9 to 10–2 mol/L). The study's findings illustrated that this system displayed a high degree of water-wettability under low-pressure conditions but shifted towards a weaker water-wet behavior as pressure levels increased. Furthermore, the system underwent a transition to an intermediate water-wet state with an increase in the concentration of organic acids and temperature126.

In the year 2022, Mukainah et al. conducted an investigation into the impact of total organic content and pressure (14.7–1000 psi) at 50°C on the wettability of the brine/hydrogen/shale system. Their findings revealed that, under atmospheric pressure, the Eagle Ford shale, boasting a substantial total organic content of 3.83%, exhibited complete hydrophobic behavior, whereas the Wolfcamp shale, characterized by a low total organic content of 0.3%, achieved a state of weak water-wettability. Furthermore, it was noted that contact angle values experienced a slight reduction with increasing pressure, suggesting that the shale's hydrogen wettability might not necessarily intensify with pressures up to 1000 psi127.

In the year 2023, Liu et al. conducted a study investigating microbial-induced wettability alteration. They focused on a halophilic sulfate-reducing bacterium growing within a microfluidic pore network saturated with hydrogen gas under specific conditions: a pressure of 35 bar and a temperature of 37 °C. The research team assessed changes in wettability by measuring the contact angle within the three-phase system. Their findings revealed that the presence of bacterial cells brought about a shift in wettability, transitioning it from its initial water-wet state to a state characterized as neutral-wet. Conversely, in the sterilized control experiment, no discernible change in the contact angle was observed. This process is shown in Fig. 9128.

In 2023, Hosseini et al. conducted a study investigating the influence of silica nanofluids with dosages of 0.1, 0.25, and 0.5 wt% and organic acids on the wettability of Indiana limestone, aiming to optimize it for hydrogen storage. The study explored the effects of various organic acids with differing carbon chain lengths under two different sets of temperature and pressure conditions (298 K and 0.1 MPa, 323 K and 8.27MPa). Additionally, the research examined the impact of silica nanofluids at various concentrations. When the limestone samples were treated with organic acids, a notable trend emerged wherein the contact angle increased as the number of carbon atoms in the acids increased, ultimately transitioning the surface to a hydrophobic state. In contrast, when silica nanofluids were introduced into the experiments, it was observed that the hydrophobicity decreased after the use of these nanoparticles129.

In 2023, Zeng et al. carried out a study to investigate how temperature ( 296, 323, and 343 K), pressure (0.1–25 MPa), and varying concentrations of organic acids (10–9-10–2 mol/L) influenced the wettability of hydrogen on quartz surfaces. Their findings revealed that elevating the temperature and pressure had minimal effects on hydrogen wettability. However, as the concentration of organic acids increased, it correspondingly increased the contact angle of brine, indicating an enhancement in hydrogen wettability130.

In 2022, the contact angle of systems containing pure methane, pure hydrogen, and a mixture of these two gases by Hashemi et al. on Bentheimer sandstone at temperatures of 30 and 50°C, pressures of 20, 50, 70, and 100 bar in the presence of distilled water and salinities of 5000 and 50,000 ppm of NaCl was measured. No dependence between salinity, temperature, and pressure with contact angle values was observed in these systems. Also, all gas mixtures had a contact angle between 25 and 45° (strongly water-wet) and it was shown that pure hydrogen, pure methane, and their mixtures have similar wetting properties in real fields131.

Table 2 shows the effect of different parameters on the wettability alterations during H2 storage.

Interfacial tension alteration during gas storage

Another key parameter when storing gas is the fluid–fluid surface tension, which affects the fluid distribution at the pore scale and the gas storage capacity in the reservoir.

Interfacial tension measurement

IFT measurement methods can be divided into 5 categories. A schematic of these 5 groups is shown in Table 3. Group IV methods will be explained in the following.

Pendant drop

Using a straightforward approach, two parameters essential for experimental determination in the pendant drop method are the equatorial diameter, denoted as D, and the diameter, labeled as d, measured at a distance D from the top of the drop.

To achieve high-quality and consistent results in interfacial tension measurement, the pendant drop technique, like other methods, demands meticulous cleanliness. Ensuring the needle utilized for suspending the drop is thoroughly cleaned is paramount, while preventing any interface climbing along the needle's outer surface. Needles crafted from stainless steel or glass, known for their ease of cleaning with various agents such as acids, bases, and organic solvents, are commonly preferred in surface chemistry laboratories. It's advisable to employ needles with a diameter less than 0.5 times the equatorial diameter (D) of the drop. However, excessively small needle diameters should be avoided as they diminish the value of d and consequently compromise the precision of interfacial tension determination132.

Sessile drop

The sessile drop technique aligns with the pendant drop method in its approach to analyzing drop shape. However, unlike the pendant drop method where the drop is suspended from a tube, in the sessile drop method, the drop rests on a solid substrate. The wettability of the solid substrate by the fluid significantly affects the outcome in this scenario. By analyzing shape and distance measurements, the interfacial tension can be determined using Eq. (4) as follows:

where ze is the distance from the equator of the drop to its top133.

It should be noted that the challenges mentioned in relation to the contact angle for IFT also exist and should be solved appropriately134,135,136,137.

Interfacial tension alteration during carbon dioxide storage

Rock/CO2 interfacial tension is an essential factor to understand the interaction between CO2 and rocks. Low values of rock/CO2 interfacial tension suggest stronger CO2-rock interaction, thus lower CO2 capacity is inferred, and vice versa138.

In 2007, Chiquet et al. conducted a study to explore the influence of pressure (5–45 MPa) and temperature (308–383 K) on CO2-water IFT. The findings revealed that as the pressure levels increased, there was a significant decrease in the IFT values. Beyond a certain threshold, approximately exceeding 20 MPa, the IFT values reached a pseudo-plateau which slightly increases with temperature. (transitioning from approximately 30 mN/m at 308 K to 23 mN/m at 383 K). Furthermore, the presence of 20 g/L of NaCl had a negligible impact on the IFT values139.

In 2021, Abdulelah et al. conducted a study examining alterations in basalt-CO2 IFT within the pressure range of 4 MPa to 20 MPa and temperatures spanning from 308 to 333 K. The study revealed that basalt-CO2 IFT declined as pressure increased, yet it did not fall below basalt/brine IFT until the contact angle dipped below 90°. Furthermore, the basalt-CO2 IFT exhibited an upswing with rising temperatures, and the solid/brine interfacial energy also increased with higher temperatures. As the contact angle neared roughly 80 degrees or when the pressure reached 17 MPa, the sealing capacity of CO2 decreased by up to 50%. Moreover, a noteworthy correlation emerged between the basalt-CO2 IFT and the density of CO2 at temperatures of 308 K and 333 K138.

In 2023, Sakthivel et al. conducted a study with a nanodotes concentration range of 0–1000 ppm and pressures of 14.7–3000 psi at temperatures from 20 to 80 °C, and their findings indicated a modest reduction in the seawater-CO2 IFT as the concentration of carbon nanodots increased. Nevertheless, on the whole, it can be concluded that the utilization of carbon nanodots did not exert a substantial influence on the seawater-CO2 IFT115.

In 2022, Al-Yaseri et al. explored the influence of organic acids on the rock-CO2 and rock/brine IFT At a temperature of 323K and a pressure of 25 MPa. Their observations revealed that elevating the concentration of stearic acid led to an augmentation in the rock-brine IFT. Interestingly, alterations in pressure did not impact this particular parameter. In contrast, when organic acids were introduced, the rock-CO2 IFT exhibited a decrease114.

Yang et al. investigated the changes in IFT in different ranges of temperature (300–331 K) and pressure (0–30 MPa) in the year 2005. Based on the findings of this research, CO2-brine IFT values have a direct relationship with temperature and an inverse relationship with pressure140.

Bachu and Bennion in 2009 measured IFT values between CO2 and brine at pressures of 2–27 MPa, temperatures of 36–125°C, and salinities of 0–334,000 mg/L. The results showed that IFT decreases with increasing pressure. Also, this parameter has a direct relationship with salinity. As the temperature increases, the IFT values also increase141.

In 2019, Mutailipu et al. discussed the IFT values between brine containing NaCl and KCl and CO2 at temperature (298–373 K), pressure (3–15 MPa), and different salinities (1–4.9 mol/kg). Findings of this research indicated that the IFT parameter has a direct relationship with temperature and salinity and an inverse relationship with pressure142.

In order to investigate the effect of CH4 on IFT, in 2016 Liu et al. measured this parameter for CO2/CH4 mixtures in the temperature range of 77 to 257 °F and pressure between 15 and 5027 psi and salinity 0 to 200,000 ppm. they paid. The results of this research showed that the presence of methane increases the amount of IFT and the intensity of this decrease is also dependent on the molar fraction of this gas. Similarly, in a CO2/CH4-brine system, the amount of IFT also increases with increasing salinity143.

The effect of SO2 impurity on IFT in a CO2/brine/quartz system in 2014 investigated by Saraji et al. in the temperature range of 50 to 100 °C, pressure between 2000 and 4000 psig, and salinity between 0.2 and 5 M and weight percent of SO2 between 0 to 6 M. Based on this study, pressure did not have a significant effect on the amount of IFT, but the increase in temperature caused a slight decrease in IFT. The increase in salinity has also increased IFT. Also, increasing the amount of SO2 has caused a decrease in IFT118.

The values of IFT of CO2 in the presence of H2S in 2008 were investigated by Shah et al. at three temperatures of 40, 70, and 120 °C and pressure between 0 and 15 MPa and 30% molar H2S. Based on the findings of this research, the increase in H2S reduces IFT values drastically144.

The IFT values of CO2-brine, N2-brine, and CO2/N2-brine (50 mol% N2) systems were investigated by Al-Yaseri et al. in 2015 at a temperature of 333 K and 13 MPa. Accordingly, the N2-brine system had higher IFT values than the other two systems, while the CO2-brine and CO2/N2-brine systems had close IFT values117.

Table 4 shows the effect of different parameters on the IFT during the storage of CO2.

Interfacial tension alteration during hydrogen storage

In 2022, Al-Mukainah et al. investigated the effect of pressure (14.7–1000 psi) at 50°C on the interfacial tension of hydrogen-brine. The results showed that the IFT values decreased with increasing pressure (decreasing from 63.68 mN/m at 14.7 psi to 51.29 mN/m at 1000 psi pressure)127.

In 2022, Hosseini et al. conducted measurements of the interfacial tension of hydrogen-brine at different pressures (2.76–34.47 MPa), temperatures (298.15, 323.15, 373.15, and 423.15 K), and salinities (0, 1.05, 3.15, 4.95 mol/kg). When salinity and temperature were kept constant, the IFT decreased linearly with increasing pressure. Additionally, with increasing temperature, the IFT showed a linear decrease. Furthermore, it was observed that with increasing brine molarity, the IFT linearly increased146.

In 2018, Florence chow et al. measured the IFT of systems containing pure hydrogen and a mixture of hydrogen and CO2 at temperatures between 298.15 and 448.15 K and pressures between 0.5 and 45 MPa. Accordingly, with the increase in temperature and pressure, the IFT values decrease and the presence of CO2 will also decrease the values of this parameter147.

In 1957, Slowinski et al. investigated H2-water IFT values in the pressure range of 0–11 MPa and temperature of 298 K. Based on the findings of this research, increasing the pressure decreases IFT values148.

Table 5 shows the effect of different parameters on the IFT during the storage of H2.

Research gaps and future works

Despite the wealth of knowledge garnered from existing research on wettability and IFT alterations during the storage of hydrogen and carbon dioxide, several notable gaps remain, necessitating further exploration for comprehensive understanding and practical applications. While current studies have provided valuable insights into the behavior of these fluids, particularly in relation to changes in wettability and IFT, there is a clear need for more extensive investigations, especially focusing on emerging materials such as specific nanoparticles. Additionally, the literature reveals a conspicuous dearth of research concerning alterations in IFT in the presence of hydrogen, highlighting a crucial avenue for future inquiry.

To fill the current research gaps, the following topics are suggested for future research:

-

IFT measurement for hydrogen and H2S mixtures

-

Examine IFT for combination of hydrogen and SO2

-

Investigate IFT for hydrogen in the presence of organic acids

-

Analyze the effects of nanoparticles such as nanosilica on IFT levels of hydrogen

-

Explore the wettability of hydrogen combined with H2S

-

wettability measurement for hydrogen when mixed with SO2

-

Study the contact angle of hydrogen in the presence of nanofluids

Summary and conclusion

Carbon dioxide is recognized as one of the primary factors causing climate change and global warming. Underground storage of carbon dioxide prevents its release helps preserve the environment and mitigates the effects of climate change. Additionally, hydrogen has emerged as a clean and green energy source with the ability to be stored in various conditions. The storage of hydrogen contributes to increased clean energy production and reduced dependency on fossil fuels. Overall, carbon dioxide and hydrogen storage are key solutions for environmental preservation and clean energy production, aiding in the mitigation of negative impacts of climate change and promoting sustainable development. Surface wettability and interfacial tension (IFT) are two crucial parameters in underground storage and extraction of these gases, and they are of special importance.

In this research, the changes in these two parameters during the storage process of hydrogen and carbon dioxide gases were investigated based on previous studies. According to these studies, the use of nanoparticles and anionic surfactants, as well as carbon nanodots, can increase the wettability of the rock during carbon dioxide injection, while the use of organic acids has the opposite effect. Furthermore, an increase in temperature and pressure leads to a reduction in rock surface wettability. An increase in cohesive energy density results in a decrease in surface wettability. Increasing pressure leads to a decrease in the IFT of brine/carbon dioxide. Changes in salinity and the use of carbon nanodots have little effect on this parameter. Increasing pressure and the presence of organic acids can decrease the rock/carbon dioxide IFT, while temperature increases it. The rock/brine IFT increases with salinity and decreases slightly with temperature. During hydrogen gas injection, the wettability decreases with increasing temperature, pressure, salinity, organic acid concentrations, carbon content, and the presence of sulfate-reducing bacteria, but it increases with surface roughness and the use of nanoparticles. The hydrogen/brine IFT decreases with pressure and temperature and increases with salinity. Additionally, the hydrogen/rock IFT decreases with pressure, temperature, and TOC. With an increase in TOC and salinity, the water/rock IFT increases, while it decreases with temperature. The results of this research can be used in the development of storage and utilization of clean energy as well as in controlling the emission of greenhouse gases.

Figure 10 illustrates the trend of published articles in the field of underground storage of hydrogen and carbon dioxide gases and the articles that have focused on wettability during these processes from 2000 to 2023. Based on this figure, studying changes in wettability in the presence of these gases and different influential parameters is of special importance.

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- CBM:

-

Coalbed methane

- CCS:

-

Carbon capture and storage

- CND:

-

Carbon nanodots

- CNT:

-

Carbon nanotubes

- COF:

-

Covalent organic frameworks

- ECBM:

-

Enhanced coalbed methane

- EGS:

-

Enhanced geothermal system

- EOR:

-

Enhanced oil recovery

- IFT:

-

Interfacial tension

- LOHC:

-

Liquid organic hydrogen carriers

- MMOM:

-

Microporous metal coordination materials

- MOF:

-

Metal organic frameworks

- TOC:

-

Total organic carbon

References

MacDowell, N. et al. An overview of CO2 capture technologies. Energy Environ. Sci. 3(11), 1645–1669 (2010).

Kumar, S. et al. A comprehensive review of value-added CO2 sequestration in subsurface saline aquifers. J. Nat. Gas Sci. Eng. 81, 103437 (2020).

Noinate, M. P. & Pavabutr, P. Does Climate Change Affect Your Equity Portfolio? (Thammasat University, 2017).

Ziegler, F. et al. Adding perspectives to:" Global trends in carbon dioxide (CO2) emissions from fuel combustion in marine fisheries from 1950–2016". Mar. Policy 107, 103488 (2019).

Fakioğlu, E., Yürüm, Y. & Veziroğlu, T. N. A review of hydrogen storage systems based on boron and its compounds. Int. J. Hydrogen Energy 29(13), 1371–1376 (2004).

DECC, C., Roadmap: Supporting deployment of carbon capture and storage in the UK. Department of Energy & Climate Change (2012).

Yamasaki, A. An overview of CO2 mitigation options for global warming—emphasizing CO2 sequestration options. J. Chem. Eng. Jpn. 36(4), 361–375 (2003).

Heinemann, N. et al. Enabling large-scale hydrogen storage in porous media–the scientific challenges. Energy Environ. Sci. 14(2), 853–864 (2021).

Zhou, L. Progress and problems in hydrogen storage methods. Renew. Sustain. Energy Rev. 9(4), 395–408 (2005).

Sherif, S., Barbir, F. & Veziroglu, T. Wind energy and the hydrogen economy—Review of the technology. Solar energy 78(5), 647–660 (2005).

Jain, I., Jain, P. & Jain, A. Novel hydrogen storage materials: A review of lightweight complex hydrides. J. Alloys Compd. 503(2), 303–339 (2010).

Haddenhorst, H.-G. Underground storage of natural gas, in Underground Storage of Natural Gas: Theory and Practice, 15–21. (Springer, 1989).

Rabiu, K. CO2 Trapping and Geo-Electrical Characterisation in the Context of Geological Carbon Sequestration (Loughborough University, 2017).

Lysyy, M., Fernø, M. & Ersland, G. Seasonal hydrogen storage in a depleted oil and gas field. Int. J. Hydrogen Energy 46(49), 25160–25174 (2021).

Tek, M. R. Underground Storage of Natural Gas: Theory and Practice (Springer, 1989).

Heinemann, N. et al. Hydrogen storage in porous geological formations–onshore play opportunities in the midland valley (Scotland, UK). Int. J. Hydrogen Energy 43(45), 20861–20874 (2018).

Muhammed, N. S. et al. A review on underground hydrogen storage: Insight into geological sites, influencing factors and future outlook. Energy Rep. 8, 461–499 (2022).

Tarkowski, R. Perspectives of using the geological subsurface for hydrogen storage in Poland. Int. J. Hydrogen Energy 42(1), 347–355 (2017).

Zivar, D., Kumar, S. & Foroozesh, J. Underground hydrogen storage: A comprehensive review. Int. J. Hydrogen Energy 46(45), 23436–23462 (2021).

Pfeiffer, W. T. & Bauer, S. Subsurface porous media hydrogen storage–scenario development and simulation. Energy Procedia 76, 565–572 (2015).

Hollis, A. P. Some petroleum engineering considerations in the changeover of the rough gas field to the storage mode. J. Petrol. Technol. 36(05), 797–804 (1984).

Perry, K. Natural gas storage industry experience and technology: potential application to CO2 geological storage. Carbon dioxide capture for storage in deep geologic formations 2, 815–825 (2005)

Metz, B. et al. IPCC Special Report on Carbon Dioxide Capture and Storage (Cambridge University Press, 2005).

Krevor, S. et al. Subsurface carbon dioxide and hydrogen storage for a sustainable energy future. Nat. Rev. Earth Environ. 4(2), 102–118 (2023).

Aghaie, M., Rezaei, N. & Zendehboudi, S. A systematic review on CO2 capture with ionic liquids: Current status and future prospects. Renewable Sustain. Energy Rev. 96, 502–525 (2018).

Krishnan, A. et al. Ionic liquids, deep eutectic solvents and liquid polymers as green solvents in carbon capture technologies: a review. Environ. Chem. Lett. 18, 2031–2054 (2020).