Abstract

Fluoride glasses in the binary system ZrF4–BaF2 were prepared via mechanochemical treatment. The glass-forming region of the ZrF4–BaF2 system obtained using the mechanochemical method was wider than that obtained using the conventional melt-quenching method. The glass–ceramic 60ZrF4·40BaF2 (mol%) sample was obtained by heat treatment and shows a higher conductivity of 1.2 × 10–6 S cm−1 at 200 °C than the pristine glass. This study revealed that mechanochemical treatment was effective for the synthesis of fluoride glasses.

Similar content being viewed by others

Introduction

Fluoride glasses have been widely investigated as materials for fiber optics1,2. Goldschmidt first reported BeF2 as a fluoride glass. BeF2 is the only fluoride that can form glass by itself. However, its extreme toxicity and high hygroscopicity render it an unsuitable device material3. In addition to fluoroberyllate glass, Poulain discovered fluorozirconate glass4,5. ZBLAN is a fluorozirconate glass that refers to the system of ZrF4–BaF2–LaF3–AlF3–NaF and is widely known as a practical material for optical fiber applications6,7. Fluoride glasses have been reported to exhibit optical and ionic conduction properties8,9,10,11,12. The latter property is expected to be suitable for solid electrolytes for all-solid-state fluoride-ion batteries and oxygen sensors, which have been the focus of much attention13,14,15,16,17. Although fluoride glasses are key materials used in optical and electrochemical devices, the synthesis of fluoride glasses is more difficult than that of oxide glasses because fluoride molten reacts with atmospheric oxygen and crucibles containing Al2O3 and SiO2. Thus, fluoride glasses basically require synthesis in an inert gas atmosphere in a glassy carbon crucible18. Furthermore, fluorine gas is generated during melting, which shifts the composition. NH4F·HF is extensively used as a fluorine source and an additive in fluoride mixtures18.

The mechanochemical (MC) method using a planetary ball mill is useful for solving these problems. The MC method is effective for compounds containing highly volatile elements because it uses a sealed container19. Sulfide lithium or sodium ion-conducting glasses are synthesized using the MC method20,21. Compared to the melt-quenching method, the MC method can be used to prepare glass with a wider composition22. Furthermore, in cation conductors, it is known that glass–ceramics prepared by heat treatment of glass have higher conductivity than glass when high ionic conducting phase forms23,24.

In this study, we applied the MC method to synthesize fluoride glasses, followed by the preparation of fluoride glass–ceramics by heat-treating the glasses. ZrF4–BaF2 glasses with fluoride-ion conductivity, which were previously prepared by the melt-quenching method, were selected as the model material25. Their structures, ionic conductivities, and thermal behaviors were investigated using X-ray diffraction (XRD), Raman spectroscopy, transmission electron microscopy (TEM), AC electrochemical impedance spectroscopy, and differential thermal analysis (DTA).

Experimental

Sample preparation

ZrF4 (99.9%, Strem Chem. Inc., USA) and BaF2 (99.9%, Kojundo Chem. Lab. Co. Ltd., Japan) were used to prepare the (100 − x)ZrF4·xBaF2 samples (x = 10, 15, 40, 45, and 50 mol%). These reagents were mixed in appropriate stoichiometric ratios in an Ar atmosphere. Samples were prepared by a mechanochemical (MC) method using a planetary ball mill apparatus (Pulversette 7, Fritsch Japan Co. Ltd., Japan) with zirconia pots (volume: 45 ml) and zirconia balls (diameter: 5 mm, mass: 75 g). The total mass of the starting material in each pot was 0.5 g, and the rotational speed and milling duration were 510 rpm and 50 h, respectively. To obtain the glass–ceramic sample, the 60ZrF4·40BaF2 (mol%) sample prepared by the MC method was heated at 235 °C for 2 h under Ar flow.

Characterization

The obtained powders were characterized by XRD with Cu-Kα radiation (Smart Lab, Rigaku, Japan) and Raman spectroscopy with a 325 nm He–Cd laser (LabRAM HR800, Horiba Ltd., Japan).

The densities of the compact samples (d1) were calculated from the weights and volumes of the pellets, and those of the powders (d2) were measured using a gas pycnometer (AccuPyc II 1340, Shimadzu, Japan). The relative density was defined as d1 / d2.

The structure of the pellet cross-section was observed using scanning electron microscopy (SEM; JSM-6610A, JEOL, Japan).

A DTA curve was obtained for the powder sample in an Al pan under a N2 atmosphere using a thermal analyzer (Thermo-plus 8110, Rigaku, Japan). The heating rate was 10 °C min−1 from room temperature to 500 °C.

TEM was performed using a JEM-2100Plus instrument at an acceleration voltage of 200 kV (JEOL, Japan). High-resolution TEM (HR-TEM) images were obtained using a high-speed camera (OneView, Gatan) to minimize electron damage. The synthesized powders were dispersed on carbon grids in an Ar atmosphere in a glove box. The specimens were transferred without exposure to air using a vacuum transfer holder (Mel-Build Co.).

Electrochemical impedance spectroscopy

The obtained powder samples were pelletized at 360 MPa via uniaxial pressing. Au thin-film electrodes were sputtered on both sides of the dense pellets. Electrical conductivities were measured by two-terminal AC electrochemical impedance spectroscopy in an Ar atmosphere from 30 to 300 °C with an amplitude voltage of 90 mV and a frequency of 1.0 × 107–1.0 × 10−1 Hz using an impedance analyzer (Solartron 1260, Solartron Metrology, UK).

Results and discussion

Figure 1 shows the XRD patterns of the (100 − x)ZrF4·xBaF2 (x = 10–50 mol%) samples prepared using the mechanochemical (MC) method. The XRD patterns of the x = 15, 25, 40, and 45 samples were halo-pattern, suggesting that the samples were amorphous. The x = 10 sample contained a fraction of ZrF4 reagent. Diffraction peaks attributable to Ba2ZrF8 (ICSD:85,717) were observed for the x = 50 sample.

To investigate the morphology of the (100 − x)ZrF4·xBaF2 (x = 15 and 45) samples, TEM observations were carried out. Figure 2 shows HR-TEM images and electron diffraction (ED) patterns of the (100 − x)ZrF4·xBaF2 (x = 15 and 45) samples. The HR-TEM images depict typical amorphous contrast without periodic crystalline lattices. Accordingly, the halo patterns without crystalline spots were observed in the ED patterns obtained from the same region. Thus, an amorphous phase was mainly formed in the range of 15 ≤ x ≤ 45. The glass-forming region of the (100 − x)ZrF4·xBaF2 system by the MC method is wider than that of the reported melt-quenching method (25 ≤ x ≤ 45)25. The ZrF4–BaF2 fluoride-glasses were prepared with a stoichiometric ratio using MC method. This technique could also be effective for the synthesis of fluoride glasses in other systems.

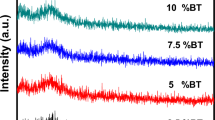

The local structures of the (100 − x)ZrF4·xBaF2 (x = 10–50 mol%) samples were analyzed using Raman spectroscopy. Figure 3 shows the Raman spectra of the (100 − x)ZrF4·xBaF2 (x = 10–50 mol%) samples prepared using the MC method. Bands at approximately 580 cm−1 and 480 cm−1 were observed and attributed to the Zr–F non-bridging symmetrical stretch vibration and the Zr–F bridging asymmetrical stretch vibration, respectively26. The intensity ratio of I580/I480 increased with increasing BaF2 content in the ZrF4–BaF2 system. This trend suggests that the proportion of non-bridging Zr–F increases.

To measure the electrical conductivities of the samples, the prepared powders were pelletized at 360 MPa by uniaxial pressing. The densities of the compact pellets (d1) and powders (d2) and the relative densities of the prepared samples are listed in Table 1. The relative densities of all the samples were approximately 70%. SEM images of the cross sections of the pressed sample of 60ZrF4·40BaF2 are shown in Fig. S1. The pellets seemed dense as just pressed. The Nyquist plot obtained for the x = 40 sample at 181 °C is shown in Fig. S2. The Nyquist plot consists of a semicircle in the high-frequency region and a sharp spike in the low-frequency region, suggesting that the prepared sample is a typical ionic conductor. The total resistance of the sample was used to determine its conductivity. Figure 4 shows the temperature dependence of the ionic conductivities of the (100 − x)ZrF4·xBaF2 (x = 10–50 mol%) samples. The conductivities were enhanced with increasing BaF2 content, but reached a maximum at x = 40 and decreased with further increase in BaF2 content. The increase in conductivity is because of the increased Zr–F non-bridging content based on the Raman spectroscopy measurement results. In contrast, the decrease in the conductivity of the x = 50 sample was caused by precipitation of the Ba2ZrF8 crystal (Fig. 1).

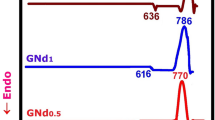

To increase the ionic conductivity of the x = 40 sample, we prepared a glass–ceramic sample via heat treatment. The DTA curve of the 60ZrF4·40BaF2 sample prepared using the MC method is shown in Fig. 5. A baseline change attributable to the glass transition was observed at 193 °C. Exothermic peaks were also observed at 210, 330, and 440 °C. The exothermic peak at 210 °C is not observed in the reported sample prepared using the melt-quenching method27. According to previous reports, the exothermic peaks at 330 and 440 °C correspond to the crystallization temperature from glass to β-BaZrF6 and transformation temperature from β-BaZrF6 to α-BaZrF6, respectively27. The sample was heated at 235, 400, and 550 °C based on the exothermic peak temperatures in the DTA curve (Fig. 5). The XRD patterns of the heated samples are shown in Fig. 6. After heating at 235 °C, the sample exhibited a halo-pattern and contained small diffraction patterns of α-BaZrF6 crystal. This is because a high-temperature phase tends to precipitate as the primary phase in crystallization from a glass phase28. The XRD pattern of the sample heated at 400 and 550 °C could be indexed with β-BaZrF6 and α-BaZrF6, respectively.

Figure 7 shows the HR-TEM images and ED patterns of the 60ZrF4·40BaF2 samples before and after the heat treatment at 235 °C. No lattice fringes or Bragg spots were detected in the sample without heat treatment (Fig. 7a and b). These observations suggest that the sample without heat treatment was amorphous. Conversely, in the sample after heat treatment, the HR-TEM images show lattice fringes indicated by the circles in Fig. 7c, demonstrating that crystalline nanoparticles were formed after heat treatment. Crystalline spots and halo patterns are observed, as shown in Fig. 7d. Consistent with the XRD results, the ED spots are indexed to α-BaZrF6 (Fig. 7e), which is the high-temperature phase. These results indicate that the heat-treated sample was composed of amorphous and crystal phase of α-BaZrF6.

Figure 8 shows temperature dependance of the ionic conductivity of 60ZrF4·40BaF2 heated at 235 °C. The 60ZrF4·40BaF2 sample with heat treatment at 235 °C achieved 3 times higher conductivity than that without heat treatment at 200 °C (1.2 × 10−6 S cm−1). The activation energy of the heated sample (0.74 eV) was lower than that of the non-heated sample. The reported ionic conductivities at 200 °C and activation energies of α-BaZrF6 and β-BaZrF6 are 1.9 × 10−9 and 3.7 × 10−8 S cm−1 and 1.02 and 0.89 eV, respectively25. If α- and/or β-BaZrF6 crystalline phases appeared in the glass phase, the conductivity decreased. However, the conductivity increased owing to crystal precipitation. This is believed to be a unique phenomenon in glass–ceramic solid electrolytes; for example, vacancies are introduced during the crystallization process, as in Na3PS4 glass-ceramics29.

Conclusion

We successfully prepared ZrF4–BaF2 glass using the MC method. The glass-forming region in the ZrF4–BaF2 binary system was expanded using the MC method compared with the melt-quenching method. 60ZrF4·40BaF2 glass–ceramics prepared by heat treatment were found to exhibit higher ionic conductivity than those without heat treatment. This study revealed that the MC method is effective for the synthesis of fluoride-ion glass. In addition, this study demonstrates that fluoride glass and glass–ceramics are a promising material group for noble fluoride-ion-conducting materials.

Data availability

Data underlying the results presented in this paper are available from Dr. Kota Motohashi (kota.motohashi@omu.ac.jp) upon reasonable request.

References

Gan, F. Optical properties of fluoride glasses: A review. J. Non-Cryst. Solids. 184, 9–20 (1995).

Lucas, J., Smektala, F. & Adam, J. L. Fluorine in optics. J. Fluor. Chem. 114, 113–118 (2002).

Baldwin, C., Almeida, R. & Mackenzie, J. D. Halide glasses. J. Non-Cryst. Solids. 43, 309–344 (1981).

Poulain, M., Poulain, M. & Lucas, J. Verres fluores au tetrafluorure de zirconium proprietes optiques d’un verre dope au Nd3+. Mater. Res. Bull. 10, 243–246 (1975).

Poulain, M., Chanthanasinh, M. & Lucas, J. Nouveaux verres fluorés. Mater. Res. Bull. 12, 151–156 (1977).

Zhu, X. & Peyghambarian, N. High-power ZBLAN glass fiber lasers: Review and prospect. Adv. OptoElectron. https://doi.org/10.1155/2010/501956 (2010).

Kanamori, T. & Sakaguchi, S. Preparation of elevated NA fluoride optical fibers. Jpn. J. Appl. Phys. 25, L468 (1986).

Chandrashekhar, G. & Shafer, M. Anion conduction in fluorozirconate glasses. Mater. Res. Bull. 15, 221–225 (1980).

Ravaine, D., Perera, G. & Poulain, M. Anionic conductivity in fluoride glasses. Solid State Ion. 9, 631–637 (1983).

Sorokin, N. I. Anion-conducting fluoride and oxyfluoride glasses. Russ. Chem. Rev. 70, 801–807 (2001).

Reau, J. & Poulain, M. Ionic conductivity in fluorine-containing glasses. Mater. Chem. Phys. 23, 189–209 (1989).

Kawamoto, Y., Nohara, I., Fujiwara, J. & Umetani, Y. Exploration of fluoride glasses with faster fluoride-ion conduction. Solid State Ion. 24, 327–331 (1987).

Miura, N., Hisamoto, J., Yamazoe, N., Kuwata, S. & Salardenne, J. Solid-state oxygen sensor using sputtered LaF3 film. Sens. Actuators 16, 301–310 (1989).

Kuwata, S., Miura, N., Yamazoe, N. & Seiyama, T. A potentiometric oxygen sensor using LaF3 single crystal operative at room temperature. Chem. Lett. 13, 981–982 (1984).

Miura, N., Hisamoto, J., Kuwata, S. & Yamazoe, N. Solid electrolyte oxygen sensor using LaF3 sputtered film workable at room temperature. Chem. Lett. 16, 1477–1480 (1987).

Miura, N., Matayoshi, N. & Yamazoe, N. Solid-state glucose sensor using LaF3-based transducer. Jpn. J. Appl. Phys. 28, L1480 (1989).

Reddy, M. A. Batteries based on fluoride shuttle. J. Mater. Chem. 21, 17059–17062 (2011).

Parker, J. Fluoride glasses. Annu. Rev. Mater. Sci. 19, 21–41 (1989).

Hayashi, A., Hama, S., Morimoto, H., Tatsumisago, M. & Minami, T. Preparation of Li2S–P2S5 amorphous solid electrolytes by mechanical milling. J. Am. Ceram. Soc. 84, 477–479 (2001).

Tatsumisago, M. & Hayashi, A. Sulfide glass-ceramic electrolytes for all-solid-state lithium and sodium batteries. Int. J. Appl. Glass Sci. 5, 226–235 (2014).

Hayashi, A., Sakuda, A. & Tatsumisago, M. Development of sulfide solid electrolytes and interface formation processes for bulk-type all-solid-state Li and Na batteries. Front. Energy Res. 4, 25 (2016).

Hayashi, A., Furusawa, D., Takahashi, Y., Minami, K. & Tatsumisago, M. Structure and properties of lithium borate glass electrolytes synthesised by a mechanochemical technique. Phys. Chem. Glasses-Eur. J. Glass Sci. Technol. Part B 54, 109–114 (2013).

Mizuno, F., Hayashi, A., Tadanaga, K. & Tatsumisago, M. New, highly ion-conductive crystals precipitated from Li2S–P2S5 glasses. Adv. Mater. 17, 918–921 (2005).

Hayashi, A., Noi, K., Sakuda, A. & Tatsumisago, M. Superionic glass-ceramic electrolytes for room-temperature rechargeable sodium batteries. Nat. Commun. 3, 856 (2012).

Kawamoto, Y. & Nohara, I. Ionic conductivities of ZrF4–BaF2–CsF glasses. Solid State Ion. 22, 207–212 (1987).

Wasylak, J. & Samek, L. Structural aspects of fluorozirconate glasses and some of their properties. J. Non-Cryst. Solids 129, 137–144 (1991).

Kawamoto, Y. & Sakaguchi, F. Thermal properties and Raman spectra of crystalline and vitreous BaZrF6, PbZrF6, and SrZrF6. Bull. Chem. Soc. Jpn. 56, 2138–2141 (1983).

Hayashi, A., Noi, K., Sakuda, A. & Tatsumisago, M. Superionic glass-ceramics electrolytes for room-temperature rechargeable sodium batteris. Nat. Commun. 3, 856 (2012).

Ikeda, K. et al. Vacancies introduced during the crystallization process of the glass-ceramics superionic conductor, Na3PS4, investigated by neutron total scattering and reverse monte carlo method. J. Phys. Chem. C 127, 6199–6206 (2023).

Acknowledgements

This work was supported by JSPS KAKENHI (Grant Number JP23K13547).

Author information

Authors and Affiliations

Contributions

K. M. contributed the following: funding acquisition, investigation, data curation, and writing original draft. H. H. performed the experiments. H. N. and S. M. performed TEM observation and wrote–review and editing manuscript. A. S. and A. H. discussed the results and wrote–review and editing manuscript. The ideas and experiments were conceived, planned, and analyzed by all co-authors under the supervision of A. H. All the authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Motohashi, K., Higuchi, H., Nakajima, H. et al. Mechanochemical synthesis of fluoride-ion conducting glass and glass–ceramic in ZrF4–BaF2 binary system. Sci Rep 14, 8808 (2024). https://doi.org/10.1038/s41598-024-59040-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-59040-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.