Abstract

Plastic accumulation is a severe threat to the environment due to its resistivity to thermal, mechanical and biological processes. In recent years, microbial degradation of plastic waste disposal is of interest because of its eco-friendly nature. In this study, a total of 33 fungi were isolated from the plastisphere and out of which 28 fungal species showed halo zone of clearance in agarized LDPE media. The fungus showing highest zone of clearance was further used to evaluate its degradation potential. Based on morphological and molecular technique, the fungus was identified as Cladosporium sphaerospermum. The biodegradation of LDPE by C. sphaerospermum was evaluated by various methods. The exposure of LDPE with C. sphaerospermum resulted in weight loss (15.23%) in seven days, higher reduction rate (0.0224/day) and lower half-life (30.93 days). FTIR analysis showed changes in functional group and increased carbonyl index in LDPE treated with C. sphaerospermum. SEMimages evidenced the formation of pits, surface aberrations and grooves on the LDPE film treated with the fungus whereas the untreated control LDPE film showed no change. AFM analysis confirmed the surface changes and roughness in fungus treated LDPE film. This might be due to the extracellular lignolytic enzymes secreted by C. sphaerospermum grown on LDPE. The degradation of polyethylene by Short chain alkanes such as dodecane, hexasiloxane and silane were identified in the extract of fungus incubated with LDPE film through GC–MS analysis which might be due to the degradation of LDPE film by C. sphaerospermum. This was the first report on the LDPE degradation by C. sphaerospermum in very short duration which enables green scavenging of plastic wastes.

Similar content being viewed by others

Introduction

Plastics have become an inevitable material in our lives, and it plays a significant role in the global economy1. Plastic production increased over time, and approximately three hundred and twenty million tons of plastics are produced every year2,3. Polyethylene is the prominent plastic widely used in various industries. High-density polyethylene (HDPE) and Low-density polyethylene (LDPE) are different grades of polyethylene which are long chain polymer of ethylene4. LDPE is used in manufacturing disposable bags, grocery bags, food packaging etc. and contributes to 60% of total plastic production5. The accumulation of its waste led to environmental issues6,7,8. The conventional method of plastic disposal involves land filling, incineration, thermal degradation, etc.7,9,10 produces secondary pollutant/persistent organic pollutants causing further hazards to the environment4,11. Hence, safe remediation of plastic debris is very important for preserving the ecosystem. Therefore, the development of eco-friendly and sustainable plastic waste disposal methods are of interest in recent years. Bioremediation/Biodegradation is the only eco-friendly approach in plastic waste management for safe disposal of plastics12,13,14. Various researchers report the degradation of LDPE by bacteria, fungi, microalgae etc.15,16,17,18. These microorganisms grow and secrete extracellular enzymes and degrade the plastics and release oligomers/monomers19,20. Among the microbes, fungi comprise nearly 3% in the plastisphere and play a vital role in degradation of plastics21. Plastic degrading fungi (including Aspergillus spp., Fusarium spp., Penicillium spp.) have been detected from plastisphere by various researchers3,22,23. However, these fungi are reported to take longer duration for degradation. Therefore, this study focused on isolation of fungi which degrade LDPE in shorter duration.

Materials and methods

Preparation of LDPE powder and films

Polyethylene was purchased from Sigma-Aldrich (low density, melt index 25 g/10 min; 190 °C/2.16 kg, Cat. No. 428043). LDPE granules boiled with xylene and crushed to powder when it is warm24 and sterilized with 70% (v/v) ethanol. For films, commercially available LDPE bags were purchased from local markets (above 50 microns), cut into small pieces and sterilized with 70% ethanol and dried in a vacuum oven.

Isolation and preliminary screening of LDPE degrading fungi

Plastic waste (single use plastic bags) from various garbage dumpsites and contaminated water bodies were collected in Chennai, Tamil Nadu, India (Supplementary Fig. S1) and stored in a sterile zip lock bag and brought to the laboratory. Fungi were isolated by spreading it on potato dextrose agar (PDA) medium. After 48 h of incubation, fungal colonies were selected and stained using lactophenol cotton blue and examined under a light microscope at 40X magnification. Isolated (pure) fungal cultures were maintained in PDA slants.

The individual culture was then inoculated on quarter strength potato dextrose broth (PDB) media supplemented with 0.5% (w/v) LDPE powder and incubated in an orbital shaker (100 rpm) at room temperature for 24 h. For control, medium without any fungus inoculation was used. The filtrate from both control and fungus inoculated was collected after centrifugation at 10000G for 10 min. The filtrate (50 µL) was introduced into a well of 0.5% (w/v) LDPE agarized petri plates (19 cm diameter) and incubated for 24 h at 37 °C. The plate was flooded with congo red stain, fixed with NaCl and the excess stain was removed. The halo zone of clearance was measured using a HiMedia zone measuring scale (in mm).

Identification of fungi degrading LDPE

The fungus capable of degrading LDPE (showing distinct zone of clearance) was identified through morphological and molecular methods. Morphological identification of the fungus was carried out by Dr. Sanjay K. Singh at Agharkar Research Institute, Pune, India. Molecular identification was done by ITS amplification using ITS primers (Forward primer ITS1-[5ʹ-TCCGTAGGTGAACCTGCGG-3ʹ] and Reverse primer ITS4-[5ʹ-TCCTCCGCTTATTGATATGC3ʹ]). The genomic DNA was extracted by the method of25 with slight modifications. PCR reaction was carried out using the Eppendorf thermal cycler. The reaction condition was initial denaturation for 4 min at 94 °C followed by 30 cycles of denaturation at 94 °C for 1 min, annealing at 55 °C for 30 s and polymerization at 72 °C for 2 min. The amplified PCR product was electrophoresed on 1.2% (w/v) agarose gel, and the amplicon was purified and sequenced through outsourcing (Applied Biosystems, Bangalore). This was blasted with available sequence by BLASTN program. The sequence was submitted to NCBI GenBank and accession number was obtained (Accession Number OQ135202). Multiple sequence alignment was made using ClustalX2 and phylogenetic tree was constructed using neighbour joining tree method with Mega 11 software26.

Biodegradation studies

Experimental design

The fungus C. sphaerospermum showing distinct zone of clearance on LDPE plate was selected for biodegradation of polyethylene films. A small piece of LDPE film (2 × 2 cm weighing ≈ 7 mg) was aseptically introduced into a quarter strength PDB medium and the pure fungal culture C. sphaerospermum (3 mm disc from 7 day old culture) was inoculated. Media containing a pre-weighed LDPE film (no fungal inoculation) served as a control. The experimental setup was maintained under controlled environmental conditions under static condition with optimum temperature of 35 °C for 7 days. After 7 days, the LDPE films were removed, washed and analysed for biodegradation. The experiment was done in triplicate.

The culture filtrate collected after centrifugation at 10,000 G for 10 min was used to analyse the degradation products through GC–MS analysis. The filtrate was also used to quantify laccase (Lac), Manganese peroxidase (MnP) and Lignin peroxidase (LiP). Protein content was evaluated according to27.

Laccase was assayed following the procedure of Kalra et al.28. The reaction mixture consists of one mL of culture filtrate, 1 mL of 2 mM guaiacol and 3 mL of 10 mM sodium acetate buffer (pH 4.6), incubated at 30 °C for 15 min and read at 450 nm. Lac was expressed in Units, where one unit is the amount of enzyme required to oxidize 1 µmol of guaiacol in one minute.

MnP was assayed following the procedure of Paszcynski et al.29. The reaction mixture consists of 100 µL of culture filtrate, 200 µL of 0.5 M sodium tartarate buffer (pH 5.0) to which 1 mL of 1 mM guaiacol, 100 µL of 1 mM MnSO4 and 400 µL of distilled water. The reaction was initiated by adding 100 µL of 1 mM H2O2 and the absorbance was read at 465 nm. One unit of MnP is the amount of enzyme required to oxidize 1 µmol of guaiacol in one minute.

For LiP assay, the assay mixture consisted of 1 mL of 125 mM sodium tartarate buffer (pH 3), 500 µL of 10 mM veratryl alcohol and 500 µL of culture filtrate. The reaction was initiated by the addition of 500 µL of 200 mM H2O2 and absorbance was read at 310 nm30. One unit of LiP is the enzyme required for oxidation of 1 µmol of vertaryl alcohol to veratrylaldehyde in one minute.

Weight loss measurement

The LDPE strip was carefully removed from the flask and rinsed well with 30% (w/v) SDS for removal of adherent mycelia, followed by 70% (v/v) ethanol wash, sterile distilled water and dried in vacuum oven at 35 °C. The LDPE strip was weighed using an electronic weighing balance. The percentage weight loss was calculated using the following formula13

With the acquired data, the reduction rate constant (K) of LDPE was calculated using the following equation:

where t denotes the degradation time in days. The result (K) was used to determine the half-life (t1/2) of the treated LDPE using the following formula31:

Microscopic analysis

Optical microscope

The LDPE strip was observed under Leica ATC 2000 at 10X magnification to assess the adsorption and colonization of fungus on LDPE strip.

SEM analysis

The changes in surface morphology of the fungus treated LDPE strip was analysed by comparing the results of untreated control LDPE strip through SEM (TESCAN VEGA3) at 30 kV. The LDPE strip was washed with 30% SDS (w/v) to remove any microbial debris, vacuum dried and coated with gold sputter.

AFM analysis

The surface erosion/modification was also evaluated by comparing both control and C. sphaerospermum treated LDPE strip using Atomic Force Microscopic analysis (Park Systems XE-70). The images were obtained with a scan speed of 1.0 Hz.

FTIR analysis

The changes in polymer bonds of C. sphaerospermum treated LDPE strip was analyzed using a FTIR spectrophotometer (BRUKER-ALPHA Platinum ATR-IR) by KBr pellet method. The pellets were scanned in the region of 500 to 4000 cm−1. The carbonyl index (CI) was assessed for various bonds like ester bond (ECI), vinyl bond (VI), keto carbonyl bond (KCI) and internal double bond (IDI) to measure the degree of biodegradation with the following formula14:

The crystallinity percentage of the LDPE strip was determined using the following formula32:

From these results the reduction percentage was calculated:

where C is the crystallinity % in control untreated LDPE film and T is the crystallinity % in C. sphaerospermum treated LDPE film.

GPC analysis

Molecular weight differences between fungus treated polyethylene and untreated control polyethylene was measured by high temperature gel-permeation chromatography (HT-GPC) at a temperature of 150 °C with a liquid phase containing tetrachlorobenzene (TCB) using viscometric detector.

GC–MS analysis

The culture filtrate (both control and C. sphaerospermum treated) was extracted with ethanol and used to identify the degradation products of LDPE, using GC–MS analysis (Shimadzu QP2020, Japan). One microliter of sample was injected through AOC-20i auto injector. The oven temperature was held at 50 °C, increased to 280 °C at a rate of 6 °C/min. The Ion source was maintained at a temperature of 200 °C at a threshold of 1000. A whole scan range from 50 to 500 m/z with a scan time of 0.30 s was setup.

Statistical analysis

All the experiments were carried out in triplicates (n = 3) and the results are presented in mean value with standard deviation. All statistical analysis was performed with GraphPad Prism 7.0 software.

Results and discussion

Preliminary screening and identification of LDPE degrading fungal isolates

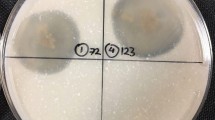

A total of 33 fungi were isolated (Table 1) from the plastisphere and out of which 28 fungal species were found to be capable of utilizing LDPE as a carbon source. The culture filtrate of these fungi showed halo zone of clearance in agarized LDPE media (Fig. 1). Maximum clearance zone of 16 mm was observed in fungus 21S4S followed by 21S1B and 21S3Q with 14 mm clearance zone at 24 h. Therefore, the fungus 21S4S was used in this study.

Based on the morphological characters, the fungus (21S4S) was identified as Cladosporium sphaerospermum (culture code 2054-S). The molecular identification also revealed the same with 90.43% similarity (Accession number OQ135202). Multiple sequence alignment was shown in Supplementary Fig. S2. The phylogenetic tree constructed showed a major clade with C. sphaerospermum and showed the phylogenetic relationship between other species of Cladosporium (Supplementary Fig. S3). The outgroup in the phylogentic tree was Amanita muscaria, Chaetomium globosum and C. thermophilum.

Biodegradation

Weight loss measurements

Polymer deterioration is measured by weight difference, SEM etc.22,33. The analytical method of weight loss measurement was used initially to evaluate the biodegradation process after 7 days. Significant weight loss (%) of 15.12% was observed in C. sphaerospermum treated LDPE film whereas there was no change in weight was observed in control. El-Sayed et al.2 reported 3.8%, 2.26% weight loss by Aspergillus carbonarius and A. fumigatus respectively on 30 days whereas mixed culture showed a 5.85% weight loss under the same condition. Nearly 35% and 38% weight loss in 90 days by A. clavatus and Penicillium citrinuum respectively was reported34,35. Though weight loss was high in these cases, it takes nearly 90 days whereas C. sphaerospermum used in this study showed weight loss in a week time. The weight loss in LDPE films treated with C. sphaerospermum might be due to consumption of LDPE as a carbon source which is in accordance with previous reports1,36. The reduction rate (k) of LDPE by C. sphaerospermum was found to be 0.0224/day and the half-life (t1/2) was 30.93 days. Roughly 31 days might be required to reduce the PE strip to half the weight. This was the first report on the degradation of LDPE by C. sphaerospermum in a very short duration. These results indicate that during the nutrient depleted conditions, C. sphaerospermum might utilize LDPE and degrade it. Increased rate of biodegradation by consortium of Aspergillus sp. results in weight loss was reported by Dsouza et al.19. Poitin et al.37 reported that C. sphaerospermum isolated from aged gas plant efficiently degraded polyaromatic hydrocarbons. There are reports that bacteria as well as few microalgae degrade LDPE but the half-life time to degrade LDPE by these organisms were very high14,18,38. This showed that the fungus is more potent than other microorganisms in degradation of LDPE. LDPE degradation by Trichoderma viride, Paecilomyces varioti, Aureobasidium pullulans were also reported3,4. Gong et al.39 reported that heat treatment followed by Cephalosporium sp. treatment result in weight loss of LDPE in 30 days. The fungus Neopestalotiopsis phangngaensis degrade LDPE after 90 days incubation was reported by40.

Optical microscopy

The growth of C. sphaerospermum on the LDPE strip was observed under the microscope (Supplementary Fig. S4).

SEM analysis

The SEM micrographs of LDPE film treated with C. sphaerospermum and untreated control was shown in Fig. 2. Mycelial adherence and thick biofilm formation was observed on the LDPE strip even after several washes with SDS (Fig. 2a,b). Similar type of results of fungal adhesion and penetration was reported by2. The LDPE strip after a thorough wash with SDS processed for SEM showed surface changes in C. sphaerospermum treated LDPE. SEM image of treated LDPE showed worn and deteriorated surface in the form of pits, cracks and cavities (Fig. 2c–e) whereas the surface of the untreated control LDPE strip had a smooth surface with no defects (Fig. 2f). Hence, this might be due to the penetration of the fungus by utilizing the carbon chain of LDPE and contributes to biodegradation. This result is in accordance with previous reports of LDPE degradation by Aspergillus sp.1,19. It has been reported that fungal penetration resulted in physical weakening and disintegration of LDPE strip1. Sanyasi et al.18 reported the appearance of pits, grooves, and corrosion on LDPE strip treated with microalgae due to adhesion molecules or by lignin degrading enzymes.

AFM analysis

To further confirm the results obtained from SEM analysis, AFM analysis was carried out both in control (fungus untreated LDPE) and treated (C. sphaerospermum treated LDPE) sample. The 3D images of C. sphaerospermum treated LDPE film showed an increase in roughness and surface erosion whereas in control strip no change was observed (Figs. 3 and 4).

AFM topography image of Control (a) and C. sphaerospermum treated (e) LDPE films. Grain images of LDPE films, control (b) showing even distribution of grain and C. sphaerospermum (d) treated with uneven distribution of grains. The height distribution histogram of control (c) with maximum height in the range of 125 nm to 150 nm whereas C. sphaerospermum treated (f) LDPE films showing heights at 120 to 220 nm evidencing the increased surface roughness due to biological activity.

Amplitude and spatial parameters such as roughness average (Ra), root mean square roughness (Rq), maximum height of roughness (Rt), maximum roughness valley depth (Rv), maximum roughness peak height (Rp), average maximum height of the profile (Rz), mean spacing profile irregularities (Sm) and the average wavelength of the profile (λa) were determined. Roughness average (Ra), roughness peak height (Rp) and roughness valley depth (Rv) are the important factors in determining the biodeterioration of LDPE sheet surface18. The increase in roughness peak height and valley depth in C. sphaerospermum treated LDPE strip when compared to fungus untreated control LDPE film (Fig. 5a) clearly indicates the surface erosion in C. sphaerospermum treated LDPE strip. As a result, the average roughness increased in C. sphaerospermum treated LDPE strip (Fig. 5a). The increase in peak height (1056 nm) and valley depth (8.971 nm) in C. sphaerospermum treated samples in comparison to control (6.116 nm and 6.028 nm respectively) clearly indicates the surface erosion. As a result, the average roughness increased in C. sphaerospermum treated LDPE strip in comparison to control. There was a decrease in Sm and λa in C. sphaerospermum treated LDPE strip was recorded (Fig. 5b) which supports the biodegradation of LDPE film by the fungus. All the parameters evidenced the surface changes in the LDPE strip due to C. sphaerospermum activity. Ojha et al.4 reported the increase in roughness due to formation of grooves and cracks in the LDPE film treated with P. oxalicum and P. chrysogenum for 90 days. Fungal enzymes act on the surface of the LDPE strip which corrodes the surface molecules subsequently increasing the surface roughness.

The surface parameters of control and C. sphaerospermum treated LDPE film. Amplitude (a) pertaining to roughness average (Ra), root mean square roughness (Rq), maximum height of roughness (Rt), maximum roughness valley depth (Rv), maximum roughness peak height (Rp), average maximum height of the profile (Rz); spatial parameters (b)—mean spacing profile irregularities (Sm) and average wavelength of the profile (λa).

Lignolytic enzymes

The assimilation of larger complexes into a cell can be facilitated by production of complex enzymes, particularly extracellular enzymes that could bind to the hydrophobic surfaces and acts in cleavage of long chains2. Lignolytic enzymes play a key role as natural surface activators, by oxidation it creates surface morphological changes that could result in increased surface compatibility41. Polyethylene degradation by microbes facilitated through Lac, MnP and LiP has been reported38,41,42,43. Hence, the major lignolytic enzymes viz., Lac, MnP and LiP were quantified in the culture filtrate of C. sphaerospermum grown in LDPE medium on the 7th day. The extracellular protein content was quantified to be 20.67 ± 0.29 µg/ml. Both the peroxidases (MnP and Lip) production was high in LDPE film incubated with C. sphaerospermum whereas Lac was produced in minimal amount (Fig. 6). These results are in accordance with previous reports that adherence of fungal mycelia to LDPE film is followed by enzyme production and results in surface aberrations and erosion44,45. Lac, MnP and LiP produced by microbes involved in biodegradation of PE46 by enhancing the hydrophilicity of PE, allows the microorganisms to attach to PE45,47 and degrade the polymers into small oligomers, dimmers and monomers40. Weight loss in LDPE by microalgae due to lignolytic enzymes was reported by48. Dsouza et al.19 reported that the weight loss in LDPE film treated with Aspergillus sp. is due to the action of enzymes that break the lignolytic polymers into monomers and oligomers which could be directly utilized by the organism. In this study, we have observed weight loss, fungal adherence, pits and cracks in SEM analysis in LDPE strip treated with C. sphaerospermum and production of extracellular lignolytic enzymes by C. sphaerospermum grown in LDPE containing medium. It might be possible that the lignolytic enzymes produced by C. sphaerospermum might break the LDPE polymer into simple oligomer/monomer and degrade it.

FTIR analysis

Assimilation of plastics by the fungi can be measured by FTIR33. Changes in the structural and functional group can be determined through FTIR which could possibly explain the weight loss in the LDPE film. The peaks at 2914 cm−1, 2847 cm−1 corresponds to CH2 asymmetric and symmetric stretches respectively. The bending deformation at 1462 cm−1 and peaks at 729 cm−1 and 718 cm−1 corresponds to rocking deformation which is characteristics of polyethylene (Fig. 7a). The LDPE strip treated with C. sphaerospermum showed an intensity drop in wavelength 2914 cm−1 region (Fig. 7b). There was a shift in peak to 2846.92 cm−1 and 1464.97 cm−1 in comparison to control that correlates to CH2 symmetric deformation. Alike deformation caused by Cephalosporium sp. was reported by49. A strong, broad peak at 3362.62 cm−1 that corresponds to hydroxyl group and a small stretch at 1042.55 cm−1 indicating C–O group (anhydride) was observed in the treated LDPE film. Another peak at 1077.70 cm−1 which corresponds to primary alcohol was also detected in LDPE treated with C. sphaerospermum (Fig. 7b). FTIR spectra showed appearance of new functional groups assigned to hydrocarbon degradation confirming the role enzymes. The peaks at 729 cm−1 and 718 cm−1 corresponds to CH2 rocking deformation which is in accord with previous report50. These shifts in the peaks, reduction in peak intensity and formation of new peaks can be put forth as a result of biodegradation.

Biodegradation of polyethylene involves oxidation of polymer chains as a first step and results in production of carbonyl groups14. Therefore, carbonyl index was used to measure the degree of biodegradation51. For this, FTIR indices of ester, keto, vinyl and internal double bonds were used to evaluate LDPE biodegradation. An increase in the carboxyl index (KCI, ECI, VI and IDI) was observed in the C. sphaerospermum treated LDPE (Fig. 8) which further confirms that C. sphaerospermum play role in biodegradation of LDPE. These results are in accord with4. As biodegradation progresses, these oxidized polymers are consumed by the microbes52. During biodegradation, various enzymes catalyse the chemical reactions viz., oxidation, reduction, esterification etc. Among them, keto and ester carbonyl bonds were reported to be the major products during oxidoreductase reaction53.

The crystallinity percentage of fungus untreated control LDPE was 31.6% whereas C. sphaerospermum treated LDPE was 27.3% which denotes the deterioration of LDPE by C. sphaerospermum. Gowthami et al.14, reported that when deterioration progresses, the crystallinity percentage reduces. In our study, the crystallinity reduction of 13.5% was observed. A maximum crystallinity reduction of 8.5% was reported in LDPE treated with Bacillus spericus54. LDPE biodegradation is associated with change in physical and chemical properties19. In this study also we found the loss of weight, change in surface functional groups etc.

GPC analysis

GPC analysis showed that C. sphaerospermum treated polyethylene reduced the Mn and Mw when compared to untreated control (Table 2). The molecular weight of fungus treated LDPE decrease and the dispersion index was increased which indicates the depolymerisation of LDPE by C. sphaerospermum. This might be due to the lignolytic enzymes produced by C. sphaerospermum. The results of the present study are in accord with the previous reports on polyethylene degradation by microbes55,56.

Gas chromatography and mass spectrometric analysis

GC–MS analysis of extract of C. sphaerospermum grown in LDPE showed significant difference in components when compared to the untreated control (Fig. 9). In control, the presence of benzene dicarboxylic acid (RT 34.825 and RT 37.482) was observed. Due to the degradation of LDPE by C. sphaerospermum several short chains of alkanes, carboxylic acids and other molecules were identified in the extract. Several short chained carbon compounds such as dodecane (RT 6.653), hexasiloxane (RT 38.869) and silane (RT 39.183) were identified in the extract of C. sphaerospermum grown on LDPE. Alcohols and carboxylic acids such as 1-Eicosanol (RT 40.063) and dihydroxy benzoic acid (39.945) and succinic acid (RT 39.413) were also observed in the extract of C. sphaerospermum grown in LDPE (Table 3). A large number of short-chained hydrocarbons were present in the extract of C. sphaerospermum grown in LDPE which might be due to biodegradation. Awasthi et al.57 reported the presence of alkanes and carboxylic acids as a result of LDPE degradation by Rhizopus oryzae. GC–MS analysis of PE showed release of fatty acids due to esterase activity was reported by Khandare et al.58. They also reported that extracellular enzymes like esterase, lignin peroxidase, laccase etc. produced by microorganisms are responsible for degrading plastic. Similar type of results was also reported by microbial degradation2,18. Pretreatment of plastics prior to biodegradation was reported to be efficient by Rad et al.59.

Conclusion

The present study isolated and identified C. sphaerospermum, a potential fungus from the plastisphere which degrades the LDPE efficiently. Biodegradation of LDPE film was characterized by weight loss, FTIR, SEM, AFM, GPC and GC–MS analyses. A weight loss of 15.12% was observed in C. sphaerospermum treated LDPE film in 7 days. Microscopic analysis showed the adherence of fungal mycelium on LDPE film. SEM analysis revealed the changes on the surface of treated LDPE film in the form of cracks, pits and cavities. This was confirmed by AFM analysis which showed increased roughness and surface erosion in treated LDPE film. The C. sphaerospermum secretes extracellular lignolytic enzymes viz., MnP and LiP when grown in LDPE containing medium. The changes observed in SEM might be due to the activity of these extracellular enzymes produced by C. sphaerospermum. FTIR analysis indicated a change in surface functional groups in LDPE treated with the fungus. In GC–MS analysis several short chains of alkanes, carboxylic acids and other small molecules were identified in the extract of C. sphaerospermum grown in LDPE. This further confirms the significant degradation of LDPE by C. sphaerospermum. The results of this study demonstrated that C. sphaerospermum can be used as a potential microbe to degrade the LDPE in shorter duration.

Data availability

Correspondence and requests for materials should be addressed to M.S.

References

Verma, N. & Gupta, S. Assessment of LDPE degrading potential Aspergillus species isolated from municipal landfill sites of Agra. SN Appl. Sci. 1, 701 (2019).

El-Sayed, M. T., Rabie, G. H. & Hamed, E. A. Biodegradation of low-density polyethylene (LDPE) using the mixed culture of Aspergillus carbonarius and A. fumigates. Environ. Dev. Sustain. 23, 14556–14584 (2021).

Zeghal, E., Vaksmann, A., Vielfaure, H., Boekhout, T. & Niemann, H. The potential role of marine fungi in plastic degradation: A review. Front. Mar. Sci. 8, 738877 (2021).

Ojha, N. et al. Evaluation of HDPE and LDPE degradation by fungus, implemented by statistical optimization. Sci. Rep. 7, 39515 (2017).

Raaman, N., Rajitha, N., Jayshree, A. & Jegadeesh, R. Biodegradation of plastic by Aspergillus spp. isolated from polythene polluted sites around Chennai. J. Acad. Indus. Res 1, 313–316 (2012).

Chaudhary, A. K., Chitriv, S. P., Chaitanya, K. & Vijayakumar, R. P. Synergistic effect of UV, thermal, and chemical treatment on biological degradation of low-density polyethylene (LDPE) by Thermomyces lanuginosus. Environ. Monit. Assess. 193, 513 (2021).

Brunner, I., Fischer, M., Ruthi, J., Stierli, B. & Frey, B. Ability of fungi isolated from plastic debris floating in the shoreline of a lake to degrade plastics. PLoS ONE 13, e0202047 (2018).

Taxeidis, G. et al. Triggering and identifying the polyurethane and polyethylene-degrading machinery of filamentous fungi secretomes. Environ. Pollut. 325, 121460 (2023).

Restrepo-Flórez, J. M., Bassi, A. & Thompson, M. R. Microbial degradation and deterioration of polyethylene: A review. Int. Biodeterior. Biodegrad. 88, 83–90 (2014).

Zhang, Y., Pedersen, J. N., Eser, B. E. & Guo, Z. Biodegradation of polyethylene and polystyrene: From microbial deterioration to enzyme discovery. Biotechnol. Adv. 60, 107991 (2022).

Yao, Z., Jeong, H. & Jang, Y. S. Degradation of low density polyethylene by Bacillus species. Appl. Biol. Chem. 65, 84 (2022).

Cowan, A. R., Costanzo, C. M., Benham, R., Loveridge, E. J. & Moody, S. C. Fungal bioremediation of polyethylene: Challenges and perspectives. J. Appl. Microbiol. 132, 78–89 (2022).

Seenivasagan, R., Karthika, A. & Poonkuzhali, K. In vitro and in silico study of the efficacy of fungi in low-density polyethylene degradation in a disposal paper cup. Water Air Soil Pollut. 233, 77 (2022).

Gowthami, A. et al. Biodegradation efficacy of selected marine microalgae against low-density polyethylene (LDPE): An environment friendly green approach. Mar. Pollut. Bull. 190, 114889 (2023).

Sowmya, H. V., Ramalingappa, M. K. & Thippeswamy, B. Biodegradation of polyethylene by Bacillus cerius. Adv. Polym. Sci. Technol. 4, 28–32 (2014).

Sen, S. K. & Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 3, 462–473 (2015).

Ahmed, T. et al. Biodegradation of plastics: Current scenario and future prospective for environmental safety. Environ. Sci. Pollut. Res. 25, 7287–7298 (2018).

Sanniyasi, E., Gopal, R. K., Gunasekar, D. K. & Raj, P. P. Biodegradation of low0density polyethylene (LDPE) sheet by microalga Uronema africanum Borge. Sci. Rep. 11, 17233 (2021).

DSouza, G. C. et al. Fungal biodegradation of low-density polyethylene using consortium of Aspergillus species under controlled conditions. Heliyon 7, e07008 (2021).

Taghavi, N., Singhal, N., Zhuang, W. Q. & Baroutian, S. Degradation of plastic waste using stimulated and naturally occurring microbial strains. Chemosphere 263, 127975 (2021).

Rogers, K. L., Carreres-calabuing, J. A., Gorokhova, E. & Posth, N. R. Micro-by micro interactions: How microorganisms influence the fate of marine microplastics. Limnol. Oceanogr. Lett. 5, 18–36 (2020).

Zahra, S., Abbas, S. S., Mahsa, M. T. & Mohsen, N. Biodegradation of low-density polyethylene (LDPE) by isolated fungi in the solid waste medium. Waste manag. 30, 396–401 (2010).

Muhonja, C. N., Makonde, H., Magoma, G. & Imbuga, M. Biodegradability pf polyethylene by bacteria and fungi from Dandora dumpsite Nairobi-Kenya. PLOS One 13, e0198446 (2018).

Pramila, R. & Ramesh, K. V. Biodegradation of low density polyethylene (LDPE) by fungi isolated from municipal landfill area. J. Microbiol. Biotechnol. Res 1, 131–136 (2011).

Culling, K. W. Design and testing of a plant specific PCR primer for ecological evolutionary studies. Mol. Ecol. 1, 233–240 (1992).

Tamura, K., Nei, M. & Kumar, S. Prospects for inferring very large phylogenies by using neighbour-joining method. PNAS, USA 101, 11030–11035 (2004).

Bradford, M. M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72, 248–254 (1976).

Kalra, K., Chauhan, R., Shavez, M. & Sachdeva, S. Isolation of laccase producing Trichoderma spp. And effect of pH and temperature on its activity. Int. J. Chem. Environ. Technol. 5, 2229–2235 (2013).

Paszcynski, A., Huynh, V. B. & Crawford, R. Enzymatic activities of an extracellular, manganese-dependent peroxidase from Phanerochaete chrysosporium. FEMS Microbiol. Lett. 29, 37–41 (1985).

Tien, M. & Kirk, T. K. Lignin peroxidase of Phaenerocheate chrysosporium. Methods Enzymol. 161, 238–249 (1988).

Auta, H. S., Emenike, C. U., Jayanthi, B. & Fauziah, S. H. Growth kinetics and biodeterioration of polypropylene microplastics by Bacillus sp. and Rhodococcus sp. isolated from mangrove sediment. Mar. Pollut. Bull. 127, 15–21 (2018).

Tarani, E. et al. Calculation of the degree of crystallinity of HDPE/GNPs nanocomposites by using various experimental techniques. J. Mater. Sci. 58, 1621–1639 (2023).

Sangale, M. K., Shahnawaz, M. & Ade, A. B. Potential of fungi isolated from the dumping sites mangrove rhizosphere soil to degrade polyethylene. Sci. Rep. 9, 1–11 (2019).

Gajendiran, A., Krishnamoorthy, S. & Abraham, J. Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1 isolated from landfill soil. 3 Biotech 6, 1–6 (2016).

Khan, S., Ali, S. A. & Ali, A. S. Biodegradation of low density polyethylene (LDPE) by mesophilic fungus ‘Penicillium citrinum’isolated from soils of plastic waste dump yard, Bhopal, India. Environ. Technol. 44, 2300–2314 (2023).

Bhardwaj, H., Gupta, R. & Tiwari, A. Microbial population associated with plastic degradation. Sci. Rep. 5, 272–274 (2012).

Poitin, O., Veignie, E. & Rafin, C. Biodegradation of polycyclic aromatic hydrocarbons (PAHs) by Cladosporium sphaerospermum isolated from an aged PAH contaminated soil. FEMS Microbiol. Ecol. 51, 71–78 (2004).

Santo, M., Weitsman, R. & Sivan, A. The role of the copper-binding enzyme–laccase–in the biodegradation of polyethylene by the actinomycete Rhodococcus ruber. Int. Biodeterior. Biodegrad. 84, 204–210 (2013).

Gong, Z. et al. Biodegradation of low density polyethylene by fungus Cladosporium sp. recovered from a landfill site. J. Fungi 9, 605 (2023).

Khruengsai, S., Sripahco, T. & Pripdeevech, P. Low density polyethylene film biodegradation potential by fungal species from Thailand. J. Fungi 7, 594 (2021).

Hasanin, M. S., Abd El-Aziz, M. E., El-Nagar, I., Hassan, Y. R. & Youssef, A. M. Green enhancement of wood plastic composite based on agriculture wastes compatibility via fungal enzymes. Sci. Rep. 12, 19197 (2022).

Iiyoshi, Y., Tsutsumi, Y. & Nishida, T. Polyethylene degradation by lignin-degrading fungi and manganese peroxidase. J. Wood Sci. 44, 222–229 (1998).

Ehara, K., Iiyoshi, Y., Tsutsumi, Y. & Nishida, T. Polyethylene degradation by manganese peroxidase in the absence of hydrogen peroxide. J. Wood Sci. 46, 180–183 (2000).

Gnanavel, G., Valli, V. P. M. J., Thirumarimurugan, M. & Kannadasan, T. Degradation of plastics waste using microbes. Elixir Int. J. Chem. Eng. 54, 12212–12214 (2013).

Tribedi, P. & Sil, A. K. Low-density polyethylene degradation by Pseudomonas sp. AKS2 biofilm. Environ. Sci. Pollut. Res. 20, 4146–4153 (2013).

Wei, R. & Zimmermann, W. Microbial enzymes for the recycling of recalcitrant petroleum-based plastics: How far are we?. Microb. Biotechnol. 10, 1308–1322 (2017).

Jin, J., Arciszewski, J., Auclair, K. & Jia, Z. Enzymatic polyethylene biorecycling confronting challenges and shaping the future. J. Hazard. Mater. 460, 132449 (2023).

Sarmah, P. & Rout, J. Efficient degradation of low-density polyethylene by cyanobacteria isolated from submerged polyethylene surface in domestic sewage water. Environ. Sci. Pollut. Res. 25, 33508–33520 (2018).

Chaudhary, A. K., Chitriv, S. P. & Vijayakumar, R. P. Influence of nitric acid on biodegradation of polystyrene and low-density polyethylene by Cephalosporium species. Arch. Microbiol. 204, 489 (2022).

Gulmine, J. V., Janissek, P. R., Heise, H. M. & Akcelrud, L. Polyethylene characterization by FTIR. Polym. Test. 21, 557–563 (2002).

Albertsson, A. C., Anderson, S. O. & Karlson, S. The mechanism of biodegradation of polyethylene. Polym. Degrad. Stab. 18, 73–87 (1987).

Ratanakamnuan, U. & Aht-ong, D. Preparation and characterization of low-density polyethylene/banana starch films containing compatibilizer and photosensitizer. J. Appl. Polym. Sci. 100, 2717–2724 (2006).

Karlsson, S. & Albertsson, A. C. Biodegradation polymers and environmental interaction. Polym. Eng. Sci 38, 1251–1253 (1998).

Balasubramanian, V. et al. High-density polyethylene (HDPE) degrading potential bacteria from marine ecosystem of Gulf of Mannar, India. Lett. Appl. Microbiol. 51, 205–211 (2010).

Mueller, R. J. Biological degradation of synthetic polyesters-enzymes as potential catalysts for polyester recycling. Process Biochem. 41, 2124–2128 (2006).

Zhang, Y. et al. Screening of polyethylene-degrading bacteria from Rhyzopertha dominica and evaluation of its key enzymes degrading polyethylene. Polymers 14, 5127 (2022).

Awasthi, S., Srivastava, N., Singh, T., Tiwary, D. & Mishra, P. K. Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS 5. 3 Biotech 7, 1–8 (2017).

Khandare, S. D., Agrawal, D., Mehru, N. & Choudhary, D. R. Marine bacterial based enzymatic degradation of low-density polyethylene (LDPE) plastic. J. Environ. Chem. Eng. 10, 107437 (2022).

Rad, M. M., Mohimmi, H. & Azin, E. Microbial Biodegradation of thermo-pretreated low-density polyethylene (LDPE) and polyvinyl chloride (PVC) microplastics by Achromobacter denitrificans Ebl13. Mar. Pollut. Bull. 181, 113830 (2022).

Acknowledgements

RVB thanks DST-INSPIRE (IF 200216) Fellowship for providing financial support to carry out this work. MS thanks RUSA 2.0, MoE, Government of India for financial support.

Author information

Authors and Affiliations

Contributions

R.V.B. performed the experiments, data analysis, and prepared the figures. M.S. wrote the original draft and edited the manuscript. T.S. performed literature collection and formal analysis. N.M. supervised the work and edited the manuscript. R.B. performed formal analysis. All the authors read the present form of the manuscript and approved for submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sathiyabama, M., Boomija, R.V., Sathiyamoorthy, T. et al. Mycodegradation of low-density polyethylene by Cladosporium sphaerospermum, isolated from platisphere. Sci Rep 14, 8351 (2024). https://doi.org/10.1038/s41598-024-59032-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-59032-4

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.