Abstract

In this study, we achieved significantly enhanced giant dielectric properties (EG-DPs) in Sc3+–Ta5+ co-doped rutile-TiO2 (STTO) ceramics with a low loss tangent (tanδ ≈ 0.05) and high dielectric permittivity (ε′ ≈ 2.4 × 104 at 1 kHz). We focused on investigating the influence of insulating surface layers on the nonlinear electrical properties and the giant dielectric response. Our experimental observations revealed that these properties are not directly correlated with the grain size of the ceramics. Furthermore, first-principles calculations indicated the preferred formation of complex defects, specifically 2Ta diamond and 2ScVo triangular-shaped complexes, within the rutile structure of STTO; however, these too showed no correlation. Consequently, the non-Ohmic properties and EG-DPs of STTO ceramics cannot be predominantly attributed to the grain boundary barrier layer capacitor model or to electron-pinned defect-dipole effects. We also found that the semiconducting grains in STTO ceramics primarily arise from Ta5+, while Sc3+ plays a crucial role in forming a highly resistive outer surface layer. Notably, a significant impact of grain boundary resistance on the nonlinear electrical properties was observed only at lower co-dopant concentrations in STTO ceramics (1 at%). The combination of low tanδ values and high ε′ in these ceramics is primarily associated with a highly resistive, thin outer-surface layer, which substantially influences their non-Ohmic characteristics.

Similar content being viewed by others

Introduction

Recently, there has been a growing research interest in TiO2-based materials due to their enhanced giant dielectric properties (EG-DPs). These properties include high dielectric permittivity (ε′ > 104), low loss tangent (tanδ < 0.1), and a low temperature coefficient of ε′ at temperatures above 150 °C1,2,3,4,5,6,7,8,9. Materials with enhanced giant dielectric properties (EG-DPs) possess great potential for applications in high-energy density storage devices and ceramic capacitors5.

Although CaCu3Ti4O12 and related ACu3Ti4O12 ceramics are the classic giant dielectric ceramics, exhibiting ε′ values of more than 104 and low tanδ < 0.05, their ε′ values are usually temperature dependent at above 100 °C10,11,12,13,14. EG-DPs cannot be obtained from this material group. Greatly enhanced ε′ ≈ 6 × 104 with low tanδ values of ≈ 0.02 for rutile-TiO2 ceramics was accomplished by partial co-substitution of In3+–Nb5+ ions (InNbTO)1. The ε′ and tanδ values of the InNbTO ceramics are dependent on the co-dopant In3+–Nb5+ concentration, which continuously increases as the doping concentration was enhanced from 0.05 to 10%, while tanδ decreased. Interestingly, it was reported that ε′ of InNbTO ceramics is independent of temperature and frequency over wide ranges. The complete details of the investigations of the EG-DPs of TiO2 ceramics, which were co-doped by other ion pairs such as Ga3+–Nb5+, Sm3+–Ta5+, Sc3+–Nb5+, Al3+–Nb5+, Al3+–Ta5+, and Ga3+–Ta5+, have been reported3,15,16,17,18,19. These ceramics exhibited EG-DPs. It is believed that co-doped TiO2 ceramics are a promising material group with high potential for use in energy-storage devices with high-energy density and capacitors. Furthermore, TiO2-based materials are widely utilized in various applications due to their low cost, abundance, non-toxic nature, and excellent chemical stability20,21,22,23.

The temperature stability of ε′ (i.e., temperature coefficient, Δε′(%)) of InNbTO ceramics and other co-doped TiO2 ceramics may be one of most serious problems inhibiting their practical use24. Improvement of the Δε′(%) value is an important research issue. Another important topic that has been extensively studied is the origination of EG-DPs of TiO2-based materials. Complex defect dipoles inside the grains or polarization at the interfaces of grain boundaries (GBs) and resistive outer-surface layers were proposed as the leading causes of EG-DPs1,2,15,16,17,25,26,27. Each proposed model is reasonable from different points of view. Thus, the actual origin of the EG-DPs of all TiO2 ceramics remains unclear.

The search a new co-doped TiO2 system that exhibits EG-DPs and/or possesses attractive electrical properties is one of the most important activities to increase the available ceramic choices for use in future applications5. Although the giant dielectric properties (ε′ ≈ 1.9 × 104–1.4 × 105) of (A3+1/2Ta1/2)0.1Ti0.9O2 ceramic systems (ATTO, A = In, Ga, Yb, Sm, Al, Fe, Bi, Dy, Sc, or Gd) have been presented by Li et al.18, comprehensive details of experimental results and their discussion focused only on the (Al1/2Ta1/2)xTi1−xO2 system with x = 0–0.15. EG-DPs were obtained in the (Al1/2Ta1/2)xTi1−xO2 system with x = 0.125 (tanδ ~ 0.054 and ε′ ~ 3.76 × 104 at 1 kHz). Recently, we found that the EG-DPs of the ATTO family were formed in Ga3+–Ta5+ co-doped TiO2 (GaTaTO) materials by optimizing the sintering conditions and co-dopant concentrations17. Besides GaTaTO and AlTaTO ceramics, the EG-DPs of various ceramics in the ATTO family may be achieved.

Nonlinear current density–electric field (J–E) characteristics have been widely studied in giant-dielectric oxides, especially for CaCu3Ti4O12 and related ACu3Ti4O12 ceramics, due to their attractiveness for varistor applications28,29. However, the giant dielectric and nonlinear J–E characteristics of co-doped TiO2 in the ATaTO family have rarely been reported30. The nonlinear electrical properties in polycrystalline materials typically arise from the interface between the semiconducting and insulating components31,32. The observation of nonlinear J–E characteristics suggests the presence of at least one type of insulating layer, which can influence the EG-DPs of these materials. The objective of this research is to explore the EG-DPs of co-doped TiO2 oxides, with a particular focus on their potential use in ceramic capacitors. Additionally, the study aims to investigate the impact of the introduced insulating surface layer on the EG-DPs.

It was reported that the EG-DPs of co-doped TiO2 ceramics were primarily influenced by multiple factors, depending on the ionic radii of the acceptor dopants used26. In the InNbTO system1,2,26, the electron-pinned defect-dipole (EPDD) was produced, attributed to the relatively larger ionic radius of In3+ (r6 = 80 pm) compared to Ti4+ (r6 = 60.5 pm)33. Therefore, the predominant origin of the EG-DPs in InNbTO was ascribed to the EPDD effect. Contrarily, in GaTaTO ceramics17, theoretical calculations have demonstrated the absence of EPDD formation. The EG-DPs in GaTaTO ceramics were explained by extrinsic effects, such as interfacial polarization at the insulating GBs and resistive outer-surface layers, as opposed to the intrinsic EPDD effect. However, the existence of resistive outer-surface layers has yet to be proved. Furthermore, theoretical studies on the formation of EPDD have only focused on In3+ and G3+ ions. The effect of an acceptor dopant with an ionic radius intermediary to these ions, such as Sc3+ (r6 = 74.5 pm), has not been theoretically investigated.

Therefore, in this study, we successfully synthesized a novel Sc3+–Ta5+ co-doped TiO2 system employing a conventional solid–state reaction (SSR) method. This process resulted in EG-DPs characterized by exceptionally high ε′ of ~ 2.4 × 104 and low tanδ ~ 0.05 values. First-principle calculations were employed to predict the presence of EPDDs. Additionally, we measured the nonlinear J–E properties to confirm the existence of resistive outer-surface layers. Impedance spectroscopy played a key role in revealing the formation of distinct semiconducting and insulating regions. The underlying mechanisms of the EG-DPs were comprehensively elucidated through a synergy of theoretical insights and experimental findings.

Experimental details

An SSR technique was employed to prepare (Sc0.5Ta0.5)xTi1-xO2 (x = 0.01, 0.025, and 0.05) powders. These ceramics are referred to as the 1%STTO, 2.5%STTO, and 5%STTO ceramics, respectively. Single-doped Sc0.025Ti0.975O2 (2.5%STO) and Ta0.025Ti0.975O2 (2.5%TTO) ceramics were also synthesized via the SSR method. The starting raw oxides, purchased from Sigma–Aldrich, consisted of Sc2O3 (99.9% purity), rutile-TiO2 (> 99.9%), and Ta2O5 (99.99%). Details of the SSR method for preparing co-doped TiO2 ceramics are given elsewhere17. First, the starting powders were mixed using a wet-ball milling method in ethanol for 24 h. ZrO2 balls, each with a diameter of 2 mm, served as the grinding media. Second, the ethanol was evaporated by heating in an oven at 90 °C for 6 h. Third, the resulting dried powders were compressed into pellets at a uniaxial pressure of 250 MPa without prior calcination or the addition of a binder. Extending the findings of our previous research17, which demonstrated high ε′ values exceeding 5.0 × 103 in TiO2 co-doped with 2.5% and 5.0% (Ga3+–Ta5+), the pellets were sintered at 1500 °C for a duration of 5 h. In this work, the STTO pellets were similarly sintered at 1500 °C for 5 h.

A UV–vis Raman spectrometer (Horiba Jobin–Yvon T64000), scanning electron microscope (SEM) (SEC, SNE4500M), X-ray diffraction (XRD, PANalytical, EMPYREAN), field-emission scanning electron microscopy (FE-SEM) with energy-dispersive X-ray analysis (EDS) (HITACHI SU8030, Japan), and X-ray photoelectron spectroscopy (XPS) were employed to systematically examine the sintered STTO specimens. Comprehensive details of each technique are provided in our previous published work17. The sintered samples were first polished and then thermally etched at 1200 °C for 30 min. To calculate the mean grain size, the following procedure was employed: First, six different diameters were measured for each grain using the relative scale bars. Next, the average size of each individual grain was determined. Finally, the overall mean grain size for the sample was calculated, based on measurements from approximately 100 grains. The nonlinear J–E properties of as-sintered specimens were tested at ~ 25 °C (Keithley Model 247). The α value was calculated using the following formula:

where E1 and E2 represent the electric fields, at which J1 = 1 and J2 = 10 mA cm−2, respectively. Eb was defined as equal to being E131,32,34,35. Capacitance (Cp) and tanδ values of as-sintered specimens were determined as a function of frequency (40–107 Hz) and temperature (− 60 to 210 °C) by employing a KEYSIGHT E4990A Impedance Analyzer. The ε′ value was calculated by the equation,

where A and d represent the electrode area and sample thickness, respectively. ε0 = 8.854 × 10–12 F/m. The complex dielectric constant (ε*) and complex impedance (Z*) were calculated from the equations,

where ε′ and ε′′ represent the real and imaginary parts of \({\upvarepsilon }^{*}\) (ε′′ = ε′tanδ), while Z′ and Z′′ represent the real part and imaginary parts of Z*, respectively. \({{\text{C}}}_{0}={\upvarepsilon }_{0}{\text{A}}/{\text{d}}\) is the empty cell capacitance. The most preferred configuration for STTO ceramics was determined for the DFT calculations. Details of our computational calculations are given elsewhere17.

Results and discussion

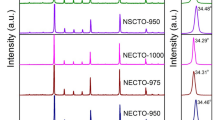

Figure 1a gives XRD patterns of single as well as co-doped specimens, confirming that the main phase of rutile-TiO2 (JCPDS 21-1276) contains no impurity phases. Both the ionic radii Sc3+ (r6 = 0.745 Å) and Ta5+ (r6 = 0.64 Å) dopants are larger than the host Ti4+ ion (r6 = 0.605 Å)33. Thus, cell parameters of the rutile-structure may be changed by doping with Sc3+ and/or Ta5+ ions. Consequently, the lattice parameters (a and c values) were obtained from Rietveld refinement method. TiO2, 2.5%STO, 2.5%TTO, 1%STTO, 2.5%STTO and 5%STTO ceramics showed respective a values of 4.593, 4.595, 4.595, 4.598, 4.598 and 4.601 Å, while c values were 2.959, 2.960, 2.962, 2.965, 2.965 and 2.969 Å, respectively. The unit cell volumes were 62.44, 62.50, 62.54, 62.68, and 62.68 Å, respectively. Single and co-doped ceramic a and c values are slightly greater than for a pure TiO2 ceramic. Therefore, both Sc3+ and Ta5+ dopant ions could be substituted into the rutile-TiO2 structure.

Figure 1b shows Raman spectra of STTO specimens compared to that of a pure TiO2 material. Overall, the Raman spectra are similar to co-doped TiO2 systems reported in literature17,19,30,36,37. Here, we focused on the strongest Eg and A1g peaks. These affect the giant dielectric response of TiO2-based oxides. These two main peaks are usually associated with oxygen vacancies and O–Ti–O bonds, respectively37. Eg mode Raman peaks for TiO2, 1%STTO, 2.5%STTO and 5%STTO ceramics are, respectively, at 447.9, 447.1, 446.3, and 443.3 cm−1, while the A1g peaks are at 611.3, 610.1, 611.2, and 610.2 cm−1, respectively. The Eg peak of the STTO specimens shifted to lower wave numbers as the Sc3+ and Ta5+ co-dopant concentrations increased from 0 to 5 at.%, whereas the A1g peak is not changed significantly. Generally, substitution of an acceptor dopant, such as Sc3+, into the TiO2 structure requires oxygen vacancies for charge compensation, following Eq. (1). According to this equation, the nominal composition of the 5%STTO ceramic with an Eg peak appeared at 443.33 cm−1, the theoretical ratio of [O]/[Ti] in the 5%STTO ceramic should be 1.987. This result is in agreement with Parker et al.38. They reported that the TiO2−x Eg peak decreased from 447 to 443 cm−1 as the [O]/[Ti] ratio in a rutile-TiO2 was reduced, from 2.0 to 1.99. The Eg peak shifting to lower a wave number confirms that the presence of oxygen vacancies in STTO materials, which increased with the Sc3+ concentration. Oxygen vacancies detected using Raman analysis confirms the origin of the enlarged grain size of the co-doped 5.0%STTO ceramic was due to diffusion of oxygen vacancies when compared to that of the 2.5%TTO ceramic, since the average grain size of the 2.5%TTO specimen enlarged with addition of 2.5 at% Sc3+ ions (5.0%STTO).

The XPS technique was used to further analyze the possible effects of the dopants on the presence of defects in co-doped STTO materials. As illustrated in Fig. S1a (supplementary Information), the fitted XPS peaks of O1s confirmed the oxygen lattices, oxygen vacancies, and surface hydroxyl (OH) groups in the 5.0%STTO ceramic1,16,36. Therefore, it can be confirmed that substitution of Sc3+ can contribute to promoting oxygen vacancies, following Eq. (1). Furthermore, the presence of Ti4+ and Ti3+ was confirmed1,39, Fig. S1b. Furthermore, the XPS results also showed Ta5+ (Fig. S1c)39,40 and Sc3+ (Fig. S1d)15. The Ti3+/Ti4+ ratio of the 5.0%STTO material was found 4.84%, which was larger than the expected ratio calculated from the nominal composition of the 5.0%STTO ceramic (2.63%), following:

A higher Ti3+/Ti4+ ratio is generally due to the oxygen loss during sintering, following the relationship.

Figure 2a–f reveal the effects of Sc3+ and Ta5+ dopants upon the microstructural evolution of TiO2 specimens. Highly dense materials with no porosity are achieved in these sintered materials. Average grain sizes of the un-doped TiO2, single-doped 2.5%TTO, and 2.5%STO are about 42.9 ± 16.0, 12.6 ± 4.1, and 85.6 ± 33.6 µm, respectively. Only doping TiO2 with Sc3+ ions causes a great increase in an average grain size, by ~ 2 times. This result is likely attributed to diffusion of oxygen vacancies (\(V_{{\text{O}}}^{ \cdot \cdot }\)), which are produced as part of the Sc3+-doped TiO2 structure owing to charge compensation, following:

A highly enlarged grain size of the 2.5%STO ceramic is similar to that described by Tuichai et al.17 for a Ga3+-doped TiO2 ceramic. Doping TiO2 with a pentavalent cation, such as Ta5+, resulted in a remarkable reduction in a grain size. The primary contribution of the Ta5+ dopant is to suppress the GB mobility17.

The roles of Sc3+ and Ta5+ ions on the microstructural evolution of TiO2 ceramics are totally different. The combination effect of co-doped Sc3+–Ta5+ ions was therefore studied to determine the dominant effect of Sc3+ or Ta5+. Mean grain sizes of co-doped 1%STTO, 2.5%STTO, and 5%STTO specimens are about 27.3 ± 10.5, 20.2 ± 5.1, and 17.8 ± 6.9 µm, respectively. Although these grain sizes are between those of the 2.5%STO and 2.5%TTO specimens, they are closer to a single-doped 2.5%TTO material than that of the 2.5%STO ceramic. These indicate that the restorative force inhibiting GB migration caused by the Ta5+ dopant is more dominant than that of the driving force for promoting grain growth that primarily resulted from the Sc3+ dopant17.

Dopant dispersion in STTO ceramics is revealed in the elemental images shown in Fig. 2g, h. The Ta and Sc dopants are observed to homogeneously disperse throughout the microstructure with no segregation towards any specific region.

It was suggested that the EPDDs in co-doped TiO2 ceramics is determined by the ionic size of the acceptor dopant26,37. Ga3+–Nb5+ and Ga3+–Ta5+ co-dopants in TiO2 ceramics cannot create EPDDs owing to the lower ionic radius of Ga3+ (r6 = 62.0 pm) compared to that of an In3+ dopant (r6 = 80.0 pm)33. Considering that the ionic radius of Sc3+ (r6 = 74.5 pm) is between that of Ga3+ and In3+ ions33, EPDDs could be formed in the current study. Thus, the possible formation of EPDDs in Sc3+–Ta5+ co-doped TiO2 ceramics is theoretically predicted using first-principles calculations. An oxygen vacancy was shown to exist the XPS and Raman results. Thus, for the first step of the calculation, one oxygen atom was removed from the rutile structure, and two Sc atoms were substitute into the positions of two Ti atoms. Such a defect cluster is referred to (Ti–2Sc–Vo)O2. Various characteristics of the defect cluster were tested. For each characteristic, all atoms were allowed to relax completely with no symmetrical constraints. As presented in Fig. 3, by considering the total energy, the (Ti–2Sc–Vo)O2 characteristic with a triangular shape was the most stable. According to our previous work 17, with substitution of two Ta atoms in the rutile TiO2 structure, the most preferable structure of a (Ti–2Ta)O2 defect cluster was diamond shaped. Finally, the lowest energy configuration, which indicates the most stable among the diamond-shaped (Ti–2Ta)O2 and triangular–shaped (Ti–2Sc–Vo)O2 defect clusters, was then was calculated. The result showed that these two types of defect clusters are preferentially separated from each other, as illustrated in Fig. 3. Thus, EPDDs are not created in Sc3+–Ta5+ co-doped TiO2 ceramics.

Influences of Sc3+ and Ta5+ dopants on the dielectric response in TiO2 materials was explored at ~ 25 °C from 102 to 106 Hz. As displayed in Fig. 4, the ε′ of the 2.5%TTO was very high (104–105), while its tanδ was also very large. Thus, EG-DPs cannot be obtained in the 2.5%TTO ceramic. This result is usually seen in Nb5+ and Ta5+ doped TiO2 ceramics1,17,26. Alternatively, both the ε′ and tanδ values of the 2.5%STO ceramic were very low, ~ 150 and 0.03, respectively. The dielectric characteristics of the single-doped 2.5%STO ceramic are similar to those reported for acceptor doped TiO2 ceramics, such as Al3+–, In3+–, and Ga3+-doped TiO2 ceramics1,16,17,30. Therefore, the EG-DPs of TiO2 cannot be accomplished in single-doped Ta5+ or Sc3+. Nevertheless, EG-DPs can be accomplished by co-doping with Sc3+–Ta5+. A high ε′ of 2.4 × 104 with a low tanδ ~ 0.06 was obtained, as shown in the inset of Fig. 4a. According to the first principles calculations, the EG-DPs of Sc3+–Ta5+ co-doped TiO2 materials are not likely attributable to the EPDDs. The defect clusters associated with the Ta5+ and Sc3+ dopants are not correlated. Therefore, these EG-DPs should be attributed to extrinsic factors such the internal and/or surface barrier layer capacitor (IBLC/SBLC) effects.

To further describe the primary cause of EG-DPs, the effect of co-dopant content on the dielectric characteristics of Sc3+–Ta5+ co-doped TiO2 materials was further studied. As demonstrated in Fig. 5 and its inset, the ε′ of the Ta5+–Sc3+ co-doped TiO2 materials increases with the Ta5+–Sc3+ content from 1.0 to 5.0% over a measured frequency range. From frequencies of 102–105 Hz, the tanδ of the 1.0%STTO material was the largest. Values of tanδ at 1 kHz for the 1.0%SSTO, 2.5%SSTO, and 5.0%SSTO ceramics were 0.22, 0.05, and 0.07, respectively. EG-DPs of the Sc3+–Ta5+ co-doped TiO2 materials are similar to that found in the (Zn2+–Nb5+)4, (Ga3+–Ta5+)17, (In3+–Nb5+)1,24,25, (Sc3+–Nb5+)15, (Al3+–Nb5+)37, and (Ga3+–Nb5+)26 co-doped TiO2 systems. The IBLC and SBLC models41 indicated that the giant dielectric response is dependent on the charge carrier density inside the semiconducting portion (semi-P), the C value at the internal interface between the (semi-Ps) and insulating regions (in-Ps). Conductivity and tanδ are dependent on the resistivity of the in-Ps. According to Eq. (2), the free charge concentration in Sc3+–Ta5+ co-doped TiO2 materials is increased with the Ta5+ content. Thus, more charge carriers inside the in-Ps trapped at the internal interface of the in-Ps gives rise to significantly increased ε′ value.

Impedance spectroscopy was carried out to further confirm the presence of semi-Ps and in-Ps in Sc3+–Ta5+ co–doped TiO2 materials. Figure 6a and its inset show impedance complex plane (Z*) plots at ~ 25° and nonzero intercept on the Z′-axis at high-frequencies for Sc3+–Ta5+ co-doped TiO2 materials compared to that of Ta5+ single-doped TiO2. A full semicircular arc was not observed at ~ 25 °C for any of the samples. Only portions of a large semicircular arc are appeared in the Z* plot. The observed large arcs and nonzero intercepts in the Sc3+–Ta5+ co-doped TiO2 materials indicates the electrical responses of the in-Ps and semi-Ps, respectively42. Resistance of the semi-Ps significantly decreased with increasing co-dopant content, from 1.0 to 2.5%, following Eqs. (2) and (3). However, a nonzero intercept was observed in the single-doped 2.5%TTO ceramic. Clearly, a small semicircular arc is observed in this ceramic (inset of Fig. 6b) with relatively large semicircular arcs of the GB and electrode responses. Formation of semi-Ps (grains) in TiO2 is usually caused by substitution of pentavalent ions, following Eqs. (2) and (3). Alternatively, substitution of Sc3+ cannot create semi-Ps, as displayed in Fig. 6c and its inset. Only parts of a large arc are observed with no nonzero intercept. This can be explained by Eq. (1), where \(V_{{\text{O}}}^{ \cdot \cdot }\) was created in the single-doped 2.5%STO ceramic, rather than free electrons. A complete large arc can be observed at high temperatures for all co-doped ceramics, as demonstrated in Fig. 6d for the 5.0%STTO material. This result indicates that the resistance of the in-Ps decreases with increasing temperature. According to the impedance spectroscopy, the EG-DPs of the STTO materials should primarily be attributed to extrinsic factors such as the IBLC/SBLC effect.

(a) Z* plots at RT for Ta single–doped and (Sc3+–Ta5+) co–doped TiO2 ceramics; inset shows an expanded view near the origin. (b) Z* plot of 2.5%TTO ceramics; the blue solid curve is the estimated Rgb value. Inset of (b) illustrates Z* plot close to the origin, showing the electrical response of the semiconducting grains of the 2.5%TTO ceramic. (c) Z* plot of 2.5%STO ceramic at RT; inset demonstrates an expanded view close to the origin, showing zero intercept on Z′ axis. (d) Z* plots at various temperatures for the 2.5%STTO ceramic.

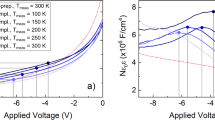

The nonlinear J–E characteristics of the single and co-doped TiO2 ceramics were investigated at ~ 25 °C. As shown in Fig. 7a, all as-sintered ceramics exhibit nonlinear J–E properties. Their Eb and α values significantly increased with decreasing co-dopant concentration. Surprisingly, the α value of the 1.0%STTO ceramic was very, ~ 1459 V/cm, calculated in the J range of 1–10 mA/cm2. The α value of the 2.5%STTO ceramic was also very large, ~ 37.0 V/cm, compared to that of CaCu3Ti4O12-based ceramics13. Nevertheless, as shown in the inset of Fig. 7a, the Eb and α values of the single-doped 2.5%TTO ceramic were very low (~ 2 V/cm) since there was no acceptor Sc3+ dopant in the sample. This result clearly shows the essential role of acceptor-Sc3+ dopant ions to form the in-Ps. It is noteworthy that both the Eb and α values of the 2.5%STTO and 5.0%STTO materials were lower than that of the 1.0%STTO ceramic. According to the impedance spectroscopy results, the resistance of the semi-Ps for the 2.5%STTO and 5.0%STTO ceramics was smaller than that of the 1.0%STTO ceramic, indicating that the free charge concentration (Ns) in these two samples is higher than that of the 1.0%STTO ceramic. According to the double Schottky barrier models in polycrystalline ceramics42, the potential barrier height at the internal insulating interface (Φb) is reduced with increasing Ns in the semi-Ps. The significantly decreased Φb values of the 2.5%STTO and 5.0%STTO ceramics may be the primary cause of the decreased Eb values, even though their GB densities were larger than that of the 1.0%STTO ceramic (due to larger average grain sizes).

(a) Nonlinear J–E properties of the 2.5%TTO ceramic and all Sc3+/Ta5+ co–doped TiO2 ceramics at RT; inset shows J–E characteristics of the 2.5%TTO ceramic before (as-fired sample) and after polishing outer surfaces (polished sample). (b, c) J–E characteristics of the co-doped 1.0%STTO and 2.5%STTO ceramics before and after polishing the outer surface.

According to our previous work27, the Eb value of as-fired InNbTO materials was much larger than that of polished samples. This result indicates that the outer surface layer (or SBLC) of the InNbTO materials had a remarkable impact on its J–E characteristics. Therefore, the effect of the surface layer was studied. We first examined the 2.5%TTO ceramic. These results are shown in the inset of Fig. 7a. The outer surface layer (or SBLC) has an effect on the J–E character of the single-doped 2.5%TTO ceramic. Both the Eb and α values of the as-fired and polished specimens are nearly the same. In other words, an SBLC was not formed on the surface of the as-fired 2.5%TTO ceramic due to the absence of an acceptor dopant. The weak nonlinear J–E properties of the 2.5%TTO ceramic result from the weak effect of the IBLC at the GBs. As illustrated in Fig. 7b and c, after removing the outer surface layer, strong nonlinear J–E properties of the polished 1.0%STTO ceramic were found, with an extremely high α value, ~ 615. However, strong nonlinear J–E properties of the polished 2.5%STTO ceramic were not obtained with a low α value, ~ 2.6. This result clearly shows that the SBLC effect was dominant in the 2.5%STTO and 5.0%STTO ceramics. Unfortunately, it should be emphasized that the nonlinear J–E characteristic of the 1.0% STTO ceramic did not exhibit reversibility following the measurement. While the nonlinear J–E characteristic of the 1.0% STTO ceramic precludes its application in varistor devices, this experiment highlighted the significant role of the outer surface layer in the EG-DPs. Therefore, the EG-DPs (high ε′ and low tanδ) of STTO ceramics are attributed to the SBLC effect. However, if we consider only a high ε′ neglecting a low tanδ, such a high ε′ is caused by the IBLC and sample-electrode interface effects. When the outer surface was removed, a high ε′ could be obtained, while tanδ was also very large. This research provides comprehensive guidance for achieving high-performance giant-dielectric response in co-doped TiO2 ceramics by inhibiting the formation of non-Ohmic sample-electrode contact via creation of a highly resistive outer surface layer.

Conclusions

Excellent giant dielectric properties with very high ε′ ≈ 2.4 × 104 and low tanδ ≈ 0.05 coupled with strong non-Ohmic properties with high Eb and α were observed in as-fired STTO ceramics. Based on microstructural analysis and first-principles calculations, these two interesting electrical properties were not primarily caused by the IBLC or EPDD effects. Systematically investigated results clearly show that free charges inside a semiconducting inner core or grain interiors of STTO ceramics were induced by Ta5+ dopant ions. A highly resistive outer surface layer of STTO ceramics, associated with Sc3+ dopant ions, was the key factor contributing to the strong non-Ohmic properties and low tanδ values. The GB contribution to the non-Ohmic properties was only observed in the STTO ceramic that was co-doped with 1%(Sc + Ta).

Data availability

The data of this study are available from the corresponding author upon reasonable request.

References

Hu, W. et al. Electron-pinned defect-dipoles for high-performance colossal permittivity materials. Nat. Mater. 12, 821–826. https://doi.org/10.1038/nmat3691 (2013).

Dong, W. et al. Colossal permittivity with ultralow dielectric loss in In + Ta co-doped rutile TiO2. J. Mater. Chem. A 5, 5436–5441. https://doi.org/10.1039/C6TA08337D (2017).

Li, Z., Wu, J. & Wu, W. Composition dependence of colossal permittivity in (Sm0.5Ta0.5)xTi1−xO2 ceramics. J. Mater. Chem. C 3, 9206–9216. https://doi.org/10.1039/C5TC01659B (2015).

Wei, X. et al. Colossal permittivity properties of Zn, Nb co-doped TiO2 with different phase structures. J. Mater. Chem. C 3, 11005–11010. https://doi.org/10.1039/C5TC02578H (2015).

Wang, Y., Jie, W., Yang, C., Wei, X. & Hao, J. Colossal permittivity materials as superior dielectrics for diverse applications. Adv. Funct. Mater. 29, 1808118. https://doi.org/10.1002/adfm.201808118 (2019).

Zhu, J. et al. Ag+/W6+ co-doped TiO2 ceramic with colossal permittivity and low loss. J. Alloys Compd. 856, 157350. https://doi.org/10.1016/j.jallcom.2020.157350 (2021).

Zhou, X. et al. Enhanced dielectric performance of (Ag1/4Nb3/4)0.01Ti0.99O2 ceramic prepared by a wet-chemistry method. Ceram. Int. 46, 11921–11925. https://doi.org/10.1016/j.ceramint.2020.01.229 (2020).

Liang, P. et al. Good dielectric performance and broadband dielectric polarization in Ag, Nb co-doped TiO2. J. Am. Ceram. Soc. 104, 2702–2710. https://doi.org/10.1111/jace.17660 (2021).

Li, J. et al. Synthesis of (La + Nb) co-doped TiO2 rutile nanoparticles and dielectric properties of their derived ceramics composed of submicron-sized grains. Ceram. Int. 47, 8859–8867. https://doi.org/10.1016/j.ceramint.2020.12.007 (2021).

Du, G., Wei, F., Li, W. & Chen, N. Co-doping effects of A-site Y3+ and B-site Al3+ on the microstructures and dielectric properties of CaCu3Ti4O12 ceramics. J. Eur. Ceram. Soc. 37, 4653–4659. https://doi.org/10.1016/j.jeurceramsoc.2017.06.046 (2017).

Peng, Z. et al. Grain engineering inducing high energy storage in CdCu3Ti4O12 ceramics. Ceram. Int. 46, 14425–14430. https://doi.org/10.1016/j.ceramint.2020.02.239 (2020).

Peng, Z. et al. Origin of colossal permittivity and low dielectric loss in Na1/3Cd1/3Y1/3Cu3Ti4O12 ceramics. Ceram. Int. 46, 11154–11159. https://doi.org/10.1016/j.ceramint.2020.01.136 (2020).

Rhouma, S. et al. Effect of Sr/Mg co-doping on the structural, dielectric, and electrical properties of CaCu3Ti4O12 ceramics. J. Mater. Sci. Mater. Electron. 33, 4535–4549. https://doi.org/10.1007/s10854-021-07645-0 (2022).

Hao, W., Xu, P., Han, P. & Wang, M. Optimize the dielectric properties of CaCu3Ti4O12 ceramics by adjusting the conductivities of grains and grain boundaries. J. Eur. Ceram. Soc. 43, 986–992. https://doi.org/10.1016/j.jeurceramsoc.2022.11.022 (2023).

Tuichai, W., Danwittayakul, S., Chanlek, N., Thongbai, P. & Maensiri, S. High-performance giant-dielectric properties of rutile TiO2 co-doped with acceptor-Sc3+ and donor-Nb5+ ions. J. Alloys Compd. 703, 139–147. https://doi.org/10.1016/j.jallcom.2017.01.333 (2017).

Song, Y. et al. The contribution of doped-Al to the colossal permittivity properties of AlxNb0.03Ti0.97−xO2 rutile ceramics. J. Mater. Chem. C 4, 6798–6805. https://doi.org/10.1039/C6TC00742B (2016).

Tuichai, W. et al. Very low dielectric loss and giant dielectric response with excellent temperature stability of Ga3+ and Ta5+ co-doped rutile-TiO2 ceramics. Mater. Des. 123, 15–23. https://doi.org/10.1016/j.matdes.2017.03.037 (2017).

Li, Z., Wu, J., Xiao, D., Zhu, J. & Wu, W. Colossal permittivity in titanium dioxide ceramics modified by tantalum and trivalent elements. Acta Mater. 103, 243–251. https://doi.org/10.1016/j.actamat.2015.09.046 (2016).

Cheng, X., Li, Z. & Wu, J. Colossal permittivity in ceramics of TiO2 Co-doped with niobium and trivalent cation. J. Mater. Chem. A 3, 5805–5810. https://doi.org/10.1039/C5TA00141B (2015).

Dong, G. Z., Fan, H. Q., Zhu, Y. N., Pan, X. B. & Jiang, X. B. Effects of hyperthermia induced crystalline aggregation on properties of TiO2 thin films. Surf. Eng. 30, 600–605. https://doi.org/10.1179/1743294414Y.0000000286 (2014).

Wang, C. et al. Simultaneous tuning of particle size and phase composition of TiO2−δ nanoparticles by a simple liquid immiscibility strategy. J. Mater. Sci. Technol. 145, 1–6. https://doi.org/10.1016/j.jmst.2022.10.026 (2023).

Wang, W. et al. Aging of low-temperature derived highly flexible nanostructured TiO2/P3HT hybrid films during bending. J. Mater. Chem. A 7, 10805–10814. https://doi.org/10.1039/C9TA01544B (2019).

Yang, C., Fan, H., Qiu, S., Xi, Y. & Chen, J. Effects of thermal expansion coefficient mismatch on structure and electrical properties of TiO2 film deposited on Si Substrate. Surf. Rev. Lett. 15, 487–491. https://doi.org/10.1142/s0218625x08011639 (2008).

Tuichai, W., Danwittayakul, S., Maensiri, S. & Thongbai, P. Investigation on temperature stability performance of giant permittivity (In + Nb) in co-doped TiO2 ceramic: A crucial aspect for practical electronic applications. RSC Adv. 6, 5582–5589. https://doi.org/10.1039/C5RA25629A (2016).

Wu, Y. Q., Zhao, X., Zhang, J. L., Su, W. B. & Liu, J. Huge low-frequency dielectric response of (Nb, In)-doped TiO2 ceramics. Appl. Phys. Lett. 107, 242904. https://doi.org/10.1063/1.4938124 (2015).

Dong, W. et al. Colossal dielectric behavior of Ga+Nb Co-doped rutile TiO2. ACS Appl. Mater. Interfaces 7, 25321–25325. https://doi.org/10.1021/acsami.5b07467 (2015).

Siriya, P., Tuichai, W., Danwittayakul, S., Chanlek, N. & Thongbai, P. Surface layer characterizations and sintering time effect on electrical and giant dielectric properties of (In0.05Nb0.05)Ti0.9O2 ceramics. Ceram. Int. 44, 7234–7239. https://doi.org/10.1016/j.ceramint.2018.01.174 (2018).

Chung, S.-Y., Kim, I.-D. & Kang, S.-J.L. Strong nonlinear current–voltage behaviour in perovskite-derivative calcium copper titanate. Nat. Mater. 3, 774–778. https://doi.org/10.1038/nmat1238 (2004).

Bueno, P. R., Ribeiro, W. C., Ramírez, M. A., Varela, J. A. & Longo, E. Separation of dielectric and space charge polarizations in CaCu3Ti4O12∕CaTiO3 composite polycrystalline systems. Appl. Phys. Lett. 90, 142912. https://doi.org/10.1063/1.2720301 (2007).

Tuichai, W., Danwittayakul, S., Chanlek, N. & Thongbai, P. Nonlinear current-voltage and giant dielectric properties of Al3+ and Ta5+ co-doped TiO2 ceramics. Mater. Res. Bull. 116, 137–142. https://doi.org/10.1016/j.materresbull.2019.04.026 (2019).

Cortés, J. A., Moreno, H., Orrego, S., Bezzon, V. D. N. & Ramírez, M. A. Dielectric and non-ohmic analysis of Sr2+ influences on CaCu3Ti4O12-based ceramic composites. Mater. Res. Bull. 134, 111071. https://doi.org/10.1016/j.materresbull.2020.111071 (2021).

Cotrim, G. et al. Tunable capacitor-varistor response of CaCu3Ti4O12/CaTiO3 ceramic composites with SnO2 addition. Mater. Charact. 170, 110699. https://doi.org/10.1016/j.matchar.2020.110699 (2020).

Shannon, R. D. Revised effective ionic radii and systematic studies of interatomie distances in halides and chaleogenides. Acta Cryst. A32, 751–767. https://doi.org/10.1016/j.ceramint.2013.08.123 (1976).

Ramírez, M. A., Bueno, P. R., Longo, E. & Varela, J. A. Conventional and microwave sintering of CaCu3Ti4O12/CaTiO3 ceramic composites: Non-ohmic and dielectric properties. J. Phys. D: Appl. Phys. 41, 152004. https://doi.org/10.1088/0022-3727/41/15/152004 (2008).

Ramírez, M. A. et al. Evaluation of the effect of the stoichiometric ratio of Ca/Cu on the electrical and microstructural properties of the CaCu3Ti4O12 polycrystalline system. J. Phys. D Appl. Phys. 42, 185503. https://doi.org/10.1088/0022-3727/42/18/185503 (2009).

Liu, G., Fan, H., Xu, J., Liu, Z. & Zhao, Y. Colossal permittivity and impedance analysis of niobium and aluminum co-doped TiO2 ceramics. RSC Adv. 6, 48708–48714. https://doi.org/10.1039/C6RA07746C (2016).

Hu, W. et al. Colossal dielectric permittivity in (Nb+Al) codoped rutile TiO2 ceramics: Compositional gradient and local structure. Chem. Mater. 27, 4934–4942. https://doi.org/10.1021/acs.chemmater.5b01351 (2015).

Parker, J. C. & Siegel, R. W. Calibration of the Raman spectrum to the oxygen stoichiometry of nanophase TiO2. Appl. Phys. Lett. 57, 943–945. https://doi.org/10.1063/1.104274 (1990).

Sheppard, L. R., Holik, J., Liu, R., Macartney, S. & Wuhrer, R. Tantalum enrichment in tantalum-doped titanium dioxide. J. Am. Ceram. Soc. 97, 3793–3799. https://doi.org/10.1111/jace.13201 (2014).

Obata, K., Irie, H. & Hashimoto, K. Enhanced photocatalytic activities of Ta, N co-doped TiO2 thin films under visible light. Chem. Phys. 339, 124–132. https://doi.org/10.1016/j.chemphys.2007.07.044 (2007).

Wu, J., Nan, C.-W., Lin, Y. & Deng, Y. Giant dielectric permittivity observed in Li and Ti doped NiO. Phys. Rev. Lett. 89, 217601. https://doi.org/10.1103/PhysRevLett.89.217601 (2002).

Adams, T., Sinclair, D. & West, A. Characterization of grain boundary impedances in fine- and coarse-grained CaCu3Ti4O12 ceramics. Phys. Rev. B 73, 094124. https://doi.org/10.1103/PhysRevB.73.094124 (2006).

Acknowledgements

This project is funded by the National Research Council of Thailand (NRCT): (N41A640084). This research was also supported by the Fundamental Fund of Khon Kaen University and the Research and Graduate Studies Office of Khon Kaen University. W. Tuichai would like to thank the Thailand Graduate Institute of Science and Technology (TGIST) for his Ph.D. scholarship [Grant Number SCA-CO-2558-1033-TH].

Author information

Authors and Affiliations

Contributions

W.T.: Conceptualization, Methodology, Investigation, Validation, Visualization, Writing—Original Draft, Writing—review & editing. P.S.: Conceptualization, Software, Formal analysis, Validation. S.D.: Conceptualization, Investigation. P.T.: Conceptualization, Data curation, Methodology, Resources, Validation, Writing—Original Draft, Project administration, Writing—review & editing, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tuichai, W., Srepusharawoot, P., Danwittayakul, S. et al. Tuning enhanced dielectric properties of (Sc3+–Ta5+) substituted TiO2 via insulating surface layers. Sci Rep 14, 2593 (2024). https://doi.org/10.1038/s41598-024-53046-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-53046-8

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.