Abstract

Plant proteins have become attractive for biomedical applications such as wound dressing and drug delivery. In this research, nanofibers from pristine zein (plant protein) and zein loaded with tungsten oxide (WO3) were prepared (WO3@zein) using less toxic solvents (ethanol and acetic acid). Morphological and biological properties of the zein nanofiber were determined. Prepared nanofibers were defined by thermogravimetric analysis (TGA), X-ray diffraction (X-RD), Fourier-transform infrared spectroscopy (FT-IR), and scanning electron microscopy. The average fiber diameter was unchanged with an increase in WO3 concentration from 0.001 to 0.008%. FT-IR spectroscopy and X-RD indicated the presence of WO3 in WO3@zein nanofibers. In comparison to WO3-free, WO3@zein nanofibers showed higher safety and preserved the anticancer effect of WO3 against human melanoma cell line (A375) melanoma cells compared to WO3-free. Moreover, both WO3-free and WO3@zein caused a fourfold increase in the cellular proliferation of reactive oxygen species (ROS) in the treated A375 cells compared to untreated cells. ROS elevation led to apoptosis-dependent cell death of A375 cells as evidenced by up-regulating the expression of p53-downstream genes (p21 and Bax) (tumor-suppressor gene) while down-regulating the expression of key oncogenes (BCL2 and cyclin D). In conclusion, the prepared nanofiber represents a promising and safe candidate for anticancer applications.

Similar content being viewed by others

Introduction

Cancer is currently recognized as a global problem that unfortunately lacks a worldwide solution1. Predestined annual cancer cases were 18.1 million including 9.6 million deaths-2 years ago- which is expected to double by 20402. Radiation therapy, chemotherapy, and surgery are used as anticancer therapies, but they all have cons such as significant side effects and limited effectiveness3. Cancer issue awareness pushes the scientific community to embark on extensive mechanistic studies and different drug discovery protocols4. The scientific community is currently interested in nanoparticles (NPs) because of their applicable properties and distinctive structural properties5. NPs were used to target cancer tissue precisely due to their small size5. It inducts reactive oxygen species (ROS) that prompt apoptotic cell death in cancer6. ROS play a critical role in both cell cycle progression and apoptosis6. Metal oxides (inorganic NPs) are promising materials for biomedical applications (such as cancer therapy, drug delivery, and cell imaging)7,8. For example, cobalt, iron, and nickel NPs are used in medical biotechnology due to their magnetic properties9. Metal oxide NPs were used as a potential therapeutic against cancer since they caused many effects such as DNA damage, genotoxic effects, induction of oxidative stress, and anti-inflammatory responses10. Tungsten oxide (WO3) NPs is a fascinating transition metal oxide with inclusive applications such as electrochromic, sensors, anti-cancer, and antimicrobial due to its unique structures and properties11,12,13. There are various methods to prepare WO3 NPs with diverse morphologies such as nanofibers, nanosheets, one-dimensional nanoneedles, or two-dimensional nanoplates14,15,16. NPs can be incorporated into polymer nanofibers via electrospinning polymer solutions containing NPs16,17. For instance, a facile one-step electrospinning technique was used to construct mesoporous PtO − WO3 nanofibers for highly sensitive and selective acetone sensing17.

In recent years, there has been an incredible surge in the demand for polymeric nanofibers. These remarkable materials hold great promise in a wide range of applications, such as tissue engineering, blood vessels, the nervous system, drug delivery, protective clothing, filtration, and sensors18,19,20. Nanofibers were prepared by different methods such as drawing techniques, the spinneret-based tunable engineered parameter (STEP) method, phase separation, self-assembly, template synthesis, freeze-drying synthesis, and interfacial polymerization21. The electrospinning technique has recently attracted attention because of its unusual properties18,22. Notable progress has been made in engineering of electrospun nanofibers and the development of electrospinning techniques to facilitate several applications. Electrospinning produces fibers with tens of nanometer diameters18. Various polymers (natural and synthetic) are used for preparing nanofibers via electrospinning which have tremendous potential for biomedical applications18. Synthetic polymers are limited for medical applications due to their non-degradable nature, the diversity of chemical composition, or complications owing to their degradation products20. While natural polymers display many vital features, including biocompatibility, biological stability, and biodegradability; thus, they are superior to synthetic polymers19,21. Zein protein -an example of natural polymers- is categorized as a safe material by food and drug administration (US-FDA)23. Also, it is one of the plant proteins that is used in tissue engineering, food industry, and medical applications24. It is commonly used as a carrier for controlling the release of hydrophobic drugs due to its hydrophobic properties23. Recently, zein microsphere containing quercetin has been expanded as a promising scaffold for tissue engineering25. Zaersabet et al. research has shown that 3D zein scaffold could be a potential candidate for bone tissue engineering due to their promising surface topography, osteoinductivity, biodegradability, and mechanical behavior26. Several herbs and anticancer drugs such as curcumin, exemestane/resveratrol, and daidzin were encapsulated in zein nanofiber27,28,29. Although the formation of nanofibers from the huge majority of protein polymers is slightly difficult – because of their complicated macromolecular structure- zein can simply form fibers30. Zein scaffolds were found to have a high porous-walled structure, porosity, microbial attack resistance, adequate biocompatibility, and antioxidant activity26,31. But, the morphological stability and mechanical weakness of zein fibers in wet conditions are the key limitations. To tackle this issue, it was found that using chemical cross-linkers such as citric acid or glutaraldehyde or incorporating other synthetic polymers enhanced the mechanical properties of prepared zein fibers32,33,34. For instance, cross-linked zein fibers (using citric acid) could retain their fibrous structure after submersion in phosphate buffer saline (PBS) for two weeks at 37 C34. Also, addition of polyvinyl alcohol (PVA) and gelatin to zein electrospun (PVA/Zein/Gelatin) has been fabricated to enhance the shelf life of food by assuring the food quality35.

In this study, we employed the electrospinning technique to create polymeric scaffolds using a natural polymer called zein protein. These scaffolds were loaded with Tungsten oxide, resulting in the development of a unique material scaffold (WO3@zein) that exhibits enhanced characterization suitable for biomedical applications. Nanofibers scaffolds were characterized by Scanning Electron Microscopic Images (SEM), Fourier transform infrared spectroscopy (FT-IR), X-ray diffraction (X-RD), and thermal analysis (TGA). MTT assays on normal human skin melanocyte (HBF4) cell line were performed to assess the cytotoxicity. Finally, the anticancer effect of the WO3@zein nanofiber was evaluated against A375 human melanoma cell line. These nanofibers scaffold could be a promising candidate for treating melanoma

Experimental

Materials

Zein protein was purchased from Sigma-Aldrich (St. Louis, MO, USA). Ethanol (95%) and acetic acid (96%) were purchased from Lonza (New Jersey, USA). Dimethyl sulfoxide (DMSO) was purchased from Merck (Germany). Dulbecco’s Modified Eagle’s Medium (DMEM) was purchased from Lonza (USA), while fetal bovine serum (FBS) was purchased from GIBCO Company (USA). 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) was purchased from Sigma Aldrich (Germany). SYBR-green PCR assay kit, cDNA synthesis kit, and Gene JET RNA purification kit were purchased from Thermo Fisher Scientific (Waltham, Massachusetts, USA). Tungsten oxide was provided by our colleague in our institute as it was prepared as earlier reported36. Human melanoma cell line (A375) was provided kindly from Genetic Engineering and Biotechnology Research Institute, City of Scientific Research and Technological Applications (SRTA-City), New Borg EL-Arab City, 21934, Alexandria, Egypt. All chemicals had high purity and were used without any additional purification.

Methods

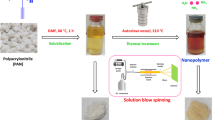

Preparation of WO3@Zein nanofiber

The zein (40% w/v) was dissolved in acetic acid (96%) and ethanol (95%) in a ratio of 1:1 and stirred for 1 h. To incorporate tungsten oxide in zein nanofiber (WO3@zein), WO3 in amounts of (0.001 and 0.008%) was dissolved in zein solution just before electrospinning to get WO3@zein1 and WO3@zein8, respectively (Table 1). The formed zein and WO3@Zein solutions were transferred to a polypropylene plastic syringe with a 20G stainless steel blunt needle. Afterwards, the net zein solution was electrospun at a voltage of 17 kV from a high voltage source (nanoNC, electrospinning system, Model: ESR100D, Seoul, Korea). The nanofibers were collected on a static plate collector at 20 cm from the needle, keeping the feeding rate at 0.25 mL/h. While, WO3@zein solution was electrospun at a voltage of 15 kV, 0.3 mL/h (feeding rate) and 20 cm (collector distance). The nanofibers were collected on sheets of aluminum foil, dried under vacuum overnight to eliminate the residual acetic/ethanol solvent. They kept in a dry/cold condition to prevent any possible contamination. Neat zein and WO3@zein nanofibers scaffold were cross-linked using glutaraldehyde vapor. Table 1 describes nanofibers scaffolds designation and WO3 concentration.

Characterization of WO3@zein nanofiber

Scanning electron microscopic images

The morphology of the nanofibers scaffold was assessed by SEM analysis (JEOL, JSM-6460LV, Tokyo, Japan). Before SEM analysis, the samples were sputtered with gold using a sputter coater (JOEL, Tokyo, Japan). Average fiber diameters were calculated from measurements of 50 fibers from each sample using Image J software (National Institute of Health, Bethesda, MD, USA).

Fourier transform infrared spectroscopy (FT-IR) analysis

ATR FT-IR-8400 S (Shimadzu, Kyoto, Japan) was used to record IR spectra of the WO3@zein nanofibers scaffolds. For all spectra, thirty scans were collected from 4000 to 400 cm−1 wavelength with a 4 cm−1 resolution.

X-ray diffraction (X-RD) analysis

X-ray diffraction analysis of net zein and WO3@zein nanofibers scaffolds was carried out using Shimadzu X-Ray diffraction 7000 (Shimadzu, California, USA). The radiation wavelength was 1.5406. The data were acquired in the form of 2θ versus intensity (a.u) chart.

Thermogravimetric analysis (TGA)

Thermogravimetric Analyzer TGA-50 (Shimadzu, Kyoto, Japan) was used to study thermal stability for prepared nanofibers scaffolds under a nitrogen atmosphere (10 ml/min). Temperature scale was set from 35 to 700 °C with a heating rate of 20 °C/min.

Cytotoxicity evaluation for WO3@Zein nanofiber

Cytotoxicity of WO3-free and WO3@zein nanofibers scaffolds was evaluated against a normal human skin melanocyte (HBF4) cell line. DMEM medium (supplemented with 10% FBS) was used to culture HBF4 in a 96-well cell culture plate (5 × 103 cells per well) and incubated at 37 ºC in a 5% CO2 incubator. After 24 h for cell attachment, the nanofibers scaffolds WO3@zein as well as WO3-free (0.3, 4.3, and 8.6 mM), were incubated (separately) with HBF4 cells for 72 h (as previously reported37). The cell viability was then evaluated by MTT method38. Effective safe concentration (EC100) of WO3-free and WO3@zein nanofibers scaffolds at which cell viability is 100% was estimated by the Graphpad Instat software. Additionally, morphological alterations of treated HBF4 relative to the untreated cells were captured using a digital camera fitted on a phase contrast inverted microscope (Olympus, Japan).

Anticancer activity evaluation of WO3@Zein nanofibers scaffolds

The anticancer effect of the WO3@zein nanofibers scaffolds was evaluated against A375 human melanoma cell line cultured in DMEM (supplemented with 10% FBS) and seeded in sterile 96-well plates (4 × 103 cells/well). After 24 h, the nanofibers scaffolds WO3@Zein as well as WO3-free (0.3, 4.3, and 8.6 mM) were incubated with A375 cells for 72 h at 37ºC in a 5% CO2 incubator. The percentage of growth inhibition of A375 cells was calculated at each corresponding dose, relative to the untreated cells using the MTT method. Moreover, cellular morphological changes before and after treatment with the most effective and safest concentration of WO3@Zein nanofibers scaffolds were captured using a phase contrast inverted microscope with a digital camera (Olympus, Japan).

Measurement of the increment in intracellular ROS generation in A375 cells

The cellular ROS level was quantified after incubation of the untreated and treated A375 with 2′,7′-dichlorodihydrofluorescein diacetate (DCFH-DA) for 48 h. DCFDA is oxidized by cellular ROS to fluorescent DCF, which was assessed using a spectrofluorometer (BMG Labtech, Germany) at 480 nm excitation and 530 nm emission. The relative fold change in ROS content in the treated cells relative to the untreated was calculated.

Quantitative detection for the change in the expression of proapoptotic genes and oncogenes in the treated cancer cells

Total RNAs of untreated and the tested anticancer compounds-treated A375 cells were extracted using Gene JET RNA Purification Kit (Thermo Scientific, USA). The cDNA was synthesized from mRNA using cDNA Synthesis Kit (Thermo Scientific, USA). Real-time PCR was performed using SYBR green master mix and specific primers (Forward/Reverse) were mentioned in Table 2. The change in gene expressions in the treated cancer cells, relative to the untreated cancer cells, was estimated using the 2−ΔΔCT equation (it is a simple formula used to calculate the relative fold gene expression of samples when performing real-time polymerase chain reaction).

Statistical analysis

The data are expressed as mean ± standard error of the mean (SEM) and the significant values were considered at p < 0.05. The unpaired T-tests were used for evaluating the difference between the mean values of the studied treatments. The analysis was done for three measurements using SPSS software version 16.

Results and discussion

Characterization

Scanning Electron Microscopic Images (SEM) for nanofibers scaffolds

Figure 1 shows SEM images of neat zein and WO3@zein nanofibers scaffolds that show a ribbon-like morphology with smooth fibers. The average fiber diameter of neat zein nanofiber scaffold (1190 nm) is insignificantly different from WO3@zein1 (1085 nm) and WO3@zein8 nanofiber (1152 nm). Ribbon-like morphology was also reported by Selling et al. when zein was dissolved in aqueous ethanol39. Also, our SEM results agree well with earlier reported results when zein was used as carriers to stabilize (-)-epigallocatechin gallate40. Ribbon-like morphology could be created by the formation of “garden hose” structures that fall to form ribbon-like as they land on the collector41. “Garden hose” structure formed due to the solution droplets (during the electrospinning step) is observed to have an outside skin which collapsed inner as the solvent evaporated41. Morphology and diameter of electrospun zein are affected by several parameters, such as solvent, polymer concentration, distance between collector and spinneret, solution flow rate, and applied DC voltage42. For example, when we used a low concentration of zein (< 40%), beads and fibers were formed and when we used a high concentration (40%), we got continuous fibers. Increasing concentration causes molecular chain entanglement, which prevents the polymer jet from breaking up into droplets40. Also, increasing polymer concentration (to a specific limit) boosts the interaction between the solvent and the polymer, thus reducing the tendency of the polymer solution to form droplets under the effect of solvent surface tension40.

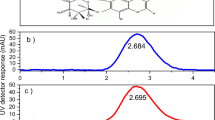

Fourier transform infrared spectroscopy (FT-IR) for nanofibers scaffolds

Proteins have secondary structures due to the presence of amide I and II groups which have distinguished vibrational peaks and so FT-IR provides information about this structure (Fig. 2)43. Neat-zein displays a considerable peak at 3,289 cm-1 referring to –NH stretching (from amide structure) and an association absorption peak of –OH that is formed by amino acid residues (i.e. adsorbed water on the surface) (Fig. 2a)44. It is possible to distinguish between 2 types of water: surface-entrapped water (our case) and hydrate (a crystal-structured water molecule). Zein is a hydrophobic material and insoluble in water, so surface water acts as a plasticizer for nanofibers. Those results are in harmony with previous results that showed that zein was significantly plasticized by water45. C–H stretching (asymmetric and symmetric) has strong peaks at 2876 cm−1, 2,949 cm−1, and 1446.2 cm−1 43. Amide III (C–N), amide II (N–H), and amide I (C=O) stretching illustrate peaks at 1245.1 cm−1, 1,532 cm−1, and 1,644 cm−1, respectively46. Those results agree with the previous FT-IR analysis of neat zein43,44. FT-IR for WO3@Zein nanofiber scaffold shows unchanged peak positions and intensities (Fig. 2b,c). In other words, zein and WO3 are mixed physically without any chemical reaction. Those results are a line with the work of El Fawal et al. when adding WO3 to hydroxy ethyl cellulose (HEC) and there is no change in HEC peaks37.

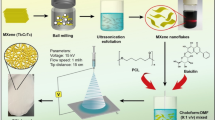

X-ray diffraction (X-RD) analysis

X-RD data of neat zein and WO3@zein nanofibers scaffolds can be seen in Fig. 3. Neat zein nanofiber scaffold has an amorphous peak around 2θ = 9° and a wide peak around 2θ = 20°, as reported previously47. The first peak describes the α-helix structure of neat zein (intra-helix average backbone distance), while the second peak represents intra-helix packing between neighboring chains48,49. While, WO3 has two crystalline peaks at 2θ = 23.6°, and 31.8°, may be attributed to (0 0 2) and (2 0 0) planes (Reference pattern ICDD Card No. 00-043-0679) as earlier stated in the literature36. X-RD pattern of WO3@zein nanofiber scaffold shows coexistence of both peaks of WO3 and zein which are broad and less intense, which can be attributed to encapsulation of WO3 and its ability to form amorphous metal50. Also, crystalline peaks of WO3 disappeared in WO3@zein nanofiber scaffold may be due to the covering of crystalline form of WO3 by zein molecules. Those results are a line with Dhanalakshmi et al. when used ZnO Ns with starch molecule to prepare antibacterial film51.

Thermogravimetric analysis (TGA)

Thermogravimetric curves of neat zein and WO3@zein nanofiber scaffolds are shown in Fig. 4. Thermal stability of prepared nanofibers scaffolds (neat zein and WO3@zein) is examined via thermal gravimetric analysis (TGA) by measuring mass loss as a function of temperature52. In all samples, the TGA curve has two weight loss stages. First stage (44.5–66.9 °C) refers to the loss of water and any residual solvent (acetic acid: ethanol) from the nanofiber53. Second stage (213–456 °C) relates to the progressive depolymerization and decarboxylation of thermally unstable protein units54. These results are in agreement with those obtained in previous TGA54,55. Furthermore, WO3 addition does not affect zein thermal stability due to the low concentration of WO3 compared to zein concentration. These results are consistent with those found when WO3 (low concentration) was added to hydroxyethyl cellulose (HEC) and HEC thermal stability remained unchanged37.

Cytotoxicity evaluation for nanofibers scaffolds

Cytotoxicity of WO3-free and WO3@zein nanofibers scaffolds is tested against HBF4 normal melanocytes and A375 cells to determine its potential toxicity on normal cells (Fig. 5). Results indicate that growth of the WO3- free-treated HBF4 cells (at 0.3, 4.3, and 8.6 mM) reduce to 63.09%, 53.41%, and 33.86%, respectively, compared to 91.64%, 85.68, and 76.14%, respectively, in the case of WO3@zein nanofiber scaffold. Therefore, the growth of WO3@zein-treated HBF4 cells is maintained at > 76% even at the highest dose (8.6 mM). These results confirm the ability of the newly developed formula to reduce the toxic effect of WO3 on normal cells. Tungsten was reported to accumulate in several organs and/or tissues such as kidneys, liver, ovaries, and uterus causing detrimental toxic effects which have limited its biomedical applications56. Limitations of metal/metal oxide toxicity, instability, and aggregation can be overcome through incorporation or encapsulation into polymers57,58. Polymers deliver metal/metal oxide with lower toxicity but with augmented efficiency when given at reduced doses 46,59. For instance, the cytotoxicity of WO3 (towards normal cells) was decreased when incorporated into hydroxyethylcellulose 37.

Anticancer activity evaluation of nanofibers scaffolds

Figure 6 illustrates the anticancer potential test of WO3-free and WO3@zein nanofibers scaffolds at the same concentrations that were used in the cytotoxicity test. Results show that the nanofibers scaffolds sustain the growth inhibitory effect of WO3@zein nanofiber scaffolds on A375 melanoma cells (64.14%, 49.23%, and 81.73%) compared to the WO3-free form (63.18%, 50.86%, and 82.59%) at doses of 0.3, 4.3, and 8.6 mM, respectively. Also, the figure shows comparable damage in both normal and melanoma cell lines after 72 h treatment with WO3-free (0.3 mM). Both melanoma and normal cells are inhibited by 50.86% and 36.91%, respectively. In contrast, WO3@zein nanofiber scaffold (at the same concentration) exhibits only morphological damage in treated melanoma cells (which causes 50% growth inhibition) without having a significant effect on normal cell proliferation. The concentration of 0.3 mM of WO3 has been selected for further evaluation of the anticancer potential of the WO3@zein nanofiber scaffold. The pro-oxidant activity of tungsten oxide has been suggested that tungsten-containing compounds can act as catalysts for oxidation reactions60. Several studies have confirmed that tungsten oxide can elevate intracellular reactive oxygen species (ROS) and reduce the antioxidant capacity of mammalian cells56,61.

Measurement of the increment in intracellular ROS generation in A375 cells

Reactive oxygen species (ROS) content of A375 cancer cells is evaluated after treatment with WO3-free and WO3@zein nanofiber scaffold (0.3 mM concentrations) in comparison to untreated control cells (Fig. 7). Results show that both WO3-free and WO3@zein nanofiber scaffold cause a fourfold increase in the cellular generation of ROS (3.94 ± 0.2 and 4.01 ± 0.4, respectively) relative to untreated cells. ROS are biomolecules with multiple functions in mammalian cells related to cellular signaling. Under normal cell conditions, elevated ROS levels induce oxidative stress, leading to cellular senescence, carcinogenesis, or cell death. Therefore, sustaining redox homeostasis in normal cells is crucial for cell survival62. On the contrary, metabolically demanding cancer cells have an elevated level of ROS due to uncontrolled proliferation63. However, a massive accumulation of ROS in cancer cells inhibits tumor growth by suppressing the proliferation signaling pathway, cell cycle, and the biosynthesis of nucleotides and ATP64. Therefore, finding pro-oxidant agents able to deprive cancer cells of the ability to control ROS levels is critical.

Quantitative detection for the change in the expression of proapoptotic genes and oncogenes in the treated cancer cells

Figure 8 presents a molecular study to elucidate the anticancer activity of WO3 (WO3-free and WO3@zein nanofiber scaffold) using qPCR. Oncogenes (B-cell lymphoma 2 “BcL-2” and cyclin D-mediated uncontrolled cell cycle) and for up-regulation of proapoptotic genes (cyclin-dependent kinase inhibitor p21 and Bcl-2-associated X protein “BAX”) are used as examples65. Treatment with WO3 (WO3-free and WO3@zein nanofiber scaffold) induced upregulation of p53-downstream genes (p21 and Bax) while downregulating oncogenes (BCL2 and cyclin D). Pro-oxidant activity of WO3-free and WO3@zein nanofiber scaffold can be linked to its suppressive effect on BCL2 and cyclin D through many explanations. For instance, Hildeman et al. reported that ROS could sensitize T cells to apoptosis by decreasing the expression of Bcl-266. Similarly, BCL-2 inhibition in MIN6 mouse insuloma cells increased the production of peroxides67. Besides, exposure of HeLa human cervical cancer cells and HEK293 human embryo kidney cells to excessive ROS induced inhibition of cyclin D1. This was found to contribute to the induction of cell cycle arrest in G2 phase under oxidative stress68. The pro-oxidant activity of WO3-free and WO3@zein nanofibers scaffold is also linked to its promoting effect on the apoptosis-related genes p21 and Bax. For example, induction of apoptosis by p21 in sarcoma cell lines can be ameliorated with antioxidants and sarcoma cells undergoing p21-dependent cell death had higher sensitivity to oxidants69. Thioridazine induces Bax-dependent apoptosis by enhancing ROS production followed by ER stress70.

Conclusion

In this paper, we have described an effective process to prepare biocompatible nanofiber scaffold from plant protein (zein) as anti-melanoma. Tungsten oxide (WO3) as a metal oxide was incorporated into zein nanofibers scaffold using electrospinning technique. Morphology and the thermal stability of zein nanofibers scaffold unchanged by WO3 addition. While, FT-IR and X-ray diffraction (X-RD) data confirmed the presence of WO3 in WO3@zein nanofiber scaffold. Cytotoxicity of WO3@zein nanofibers scaffolds confirmed its ability to reduce the toxic effect of WO3 on normal cells as the growth of HBF4 cells was maintained at > 76% even at the highest dose (8.6 mM). Moreover, anticancer results for WO3@zein nanofibers scaffolds exhibits only morphological damage in treated melanoma cells (which causes 50% growth inhibition) without having a significant effect on normal cell proliferation. The results demonstrate that WO3@zein nanofiber scaffold prepared by electrospinning could be used as a promising material candidate as anti-melanoma.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Sung, H. et al. Global cancer statistics 2020: GLOBOCAN estimates of incidence and mortality worldwide for 36 cancers in 185 countries. CA Cancer J. Clin. 71(3), 209–249 (2021).

WHO Report on Cancer (2020). Setting priorities, investing wisely and providing care for all. World Health Organization 2020. https://www.who.int/publications-detail/who-report-on-cancer-setting-priorities-investing-wisely-and-providing-care-for-all.

Rehman, S. An Overview of Cancer Treatment Modalities, in Neoplasm. London, United Kingdom: IntechOpen, 2018. Available: https://www.intechopen.com/chapters/60895 doi: https://doi.org/10.5772/intechopen.76558 (2018).

Pistritto, G., Trisciuoglio, D., Ceci, C., Garufi, A. & D’Orazi, G. Apoptosis as anticancer mechanism: Function and dysfunction of its modulators and targeted therapeutic strategies. Aging 8, 603–619 (2016).

Vinardell, M. & Mitjans, M. Metal/metal oxide nanoparticles for cancer therapy. In Nanooncology: Engineering Nanomaterials for Cancer Therapy and Diagnosis (eds Gonçalves, G. & Tobias, G.) 341–364 (Springer, Cham, 2018).

Kim, M. C., Cui, F. J. & Kim, Y. Hydrogen peroxide promotes epithelial to mesenchymal transition and stemness in human malignant mesothelioma cells. Asian Pac. J. Cancer Prev. 14, 3625–3630 (2013).

Tatyana, I. S., Olga, I. V., Nikolay, L. S. & Mikhail, Y. M. Metal and Metal Oxides Nanoparticles and Nanosystems in Anticancer and Antiviral Theragnostic Agents. Pharmaceutics 15(4), 1181 (2023).

Papis, E. et al. Engineered cobalt oxide nanoparticles readily enter cells. Toxicol. Lett. 189(3), 253–259 (2009).

Khan, I., Saeed, K. & Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 12, 908–931 (2019).

Subhan, M. A. Advances with metal oxide-based nanoparticles as MDR metastatic breast cancer therapeutics and diagnostics. RSC Adv. 12, 32956 (2022).

Tavakoli, F. F., Tavanai, H., Ranjbar, M. & Bahrami, H. Fabrication of tungsten oxide nanofibers via electrospinning for gasochromic hydrogen detection. Sens. Actuators B Chem. 268, 319–327 (2018).

Yao, Y., Sang, D., Zou, L., Wang, Q. & Liu, C. A review on the properties and applications of WO3 nanostructure-based optical and electronic devices. Nanomaterials 11, 2136 (2021).

Samaneh, G., Mahdi, M. & Majid, D. Green synthesis of tungsten oxide (WO3) nanosheets andinvestigation of their photocatalytic and cytotoxicity effects. Micro Nano Lett. 17, 286–298 (2022).

Lu, X., Liu, X., Zhang, W., Ce, W. & Yen, W. Large-scale synthesis of tungsten oxide nanofibers by electrospinning. J. Colloid Interface Sci. 298(2), 996–999 (2006).

Xiao, W., Liu, W., Mao, X., Hua, Z. & Dihua, W. Na2SO4-assisted synthesis of hexagonal-phase WO3 nanosheet assemblies with applicable electrochromic and adsorption properties. J. Mater. Chem. 1, 1261–1269 (2012).

El Fawal, G. F., Hassan, H. S., El-Aassar, M. R. & Marwa, E. Electrospun polyvinyl alcohol nanofibers containing titanium dioxide for gas sensor applications. Arab J. Sci. Eng. 44(1), 251–257 (2019).

Zhang, J. et al. Construction of mesoporous WO3 nanofibers functionalized with nanoscale PtO catalysts for enhanced acetone sensing properties. J. Alloys Compd. 933(5), 167703 (2023).

El Fawal, G. F. Polymer nanofibers electrospinning: A review. Egypt J. Chem. 63(4), 1279–1303 (2020).

Reddy, M. S., Ponnamma, D., Choudhary, R. & Kishor, K. A comparative review of natural and synthetic biopolymer composite scaffolds. Polymers 13(7), 1105 (2021).

Thang, N. H., Truong, B. C. & Dang, X. C. Polymer-based hydrogels applied in drug delivery: An overview. Gels 9(7), 523 (2023).

Alghoraibi, I. & Alomari, S. Different methods for nanofiber design and fabrication. In Handbook of Nanofibers (eds Barhoum, A. et al.) 1–46 (Springer, 2018).

Alyamani, et al. Electrospun polycaprolactone/chitosan nanofibers containing cordia myxa fruit extract as potential biocompatible antibacterial wound dressings. Molecules. 28, 2501 (2023).

Li, F. et al. Size-controlled fabrication of zein nano/microparticles by modified anti-solvent precipitation with/without sodium caseinate. Int. J. Nanomed. 12, 8197–8209 (2017).

Zdraveva, E. et al. Agro-industrial plant proteins in electrospun materials for biomedical application. Polymers 15(12), 2684 (2023).

Al-Musawi, M. et al. Development of a novel scaffold based on basil seed gum/chitosan hydrogel containing quercetin-loaded zein microshphere for bone tissue engineering. J. Polym. Environ. 31, 4738–4751 (2023).

Mona, Z., Zivar, S., Mahvash, H., Soheila, T. S. & Fataneh, R. N. Development and evaluation of bioactive 3D zein and zein/ nanohydroxyapatite scaffolds for bone tissue engineering application. J. Med. Eng. 236(6), 785–793 (2022).

Podaralla, S. K., Averineni, R. K. & Alqahtani, M. S. Synthesis of novel biodegradable methoxy poly(ethylene glycol)-zein micelles for effective delivery of curcumin. Mol. Pharm. 9, 2778–2786 (2012).

Zou, T. & Gu, L. TPGS emulsified zein nanoparticles enhanced oral bioavailability of Daidzin: In vitro characteristics and in vivo performance. Mol. Pharm. 10, 2062 (2013).

Elzoghby, A., Elzoghby, S., Helmy, M., Marwa, M. A. & Nazik, A. Shell-crosslinked zein nanocapsules for oral codelivery of exemestane and resveratrol in breast cancer therapy. Nanomedicine 12, 2785–2805 (2017).

Dhandayuthapani, B. et al. Biomimetic smart nanocomposite: in vitro biological evaluation of zein electrospun fluorescent nanofiber encapsulated CdS quantum dots. Biofabrication 4, 025008 (2012).

Lai, L. F. & Guo, H. X. Preparation of new 5-fluorouracil-loaded zein nanoparticles for liver targeting. Int. J. Pharm. 404(1), 317–323 (2011).

Wu, F., Wei, J., Liu, C., Brian, O. & Yung, N. Fabrication and properties of porous scaffold of zein/PCL biocomposite for bone tissue engineering. Compos. B Eng. 43(5), 2192–2197 (2012).

Selling, G., Woods, K., Sessa, D. & Atanu, B. Electrospun zein fibers using glutaraldehyde as the crosslinking reagent: Effect of time and temperature. Macromol. Chem. Phys. 209, 1003–1011 (2008).

Jiang, Q. & Yiqi, Y. Water-stable electrospun zein fibers for potential drug delivery. J. Biomater. Sci. Polym. Ed. 22, 1393 (2010).

Ullah, S., Hashmi, M., Shi, J. & Kim, I. S. Fabrication of electrospun PVA/Zein/Gelatin based active packaging for quality maintenance of different food items. Polymers 15, 2538 (2023).

Elnouby, M. et al. Facile synthesis of WO3·H2O square nanoplates via a mild aging of ion-exchanged precursor. J. Ceram. Soc. Jap. 121, 907–911 (2013).

El Fawal, G. F., Abu-Serie, M. M., Hassan, M. A. & Mohamed, E. Hydroxyethyl cellulose hydrogel for wound dressing: Fabrication, characterization and in vitro evaluation. Int. J. Biol. Macromol. 111, 649–659 (2018).

Mosmann, T. Rapid colorimetric assay for cellular growth and survival: Application to proliferation and cytotoxicity assays. J. Immunol. Methods 65(1), 55–63 (1983).

Selling, G. W. et al. Impact of Solvent on electrospinning of zein and analysis of resulting fibers. Macromol. Chem. Phys. 208(9), 1002–1010 (2007).

Li, Y., Lim, L. & Kakùda, Y. Electrospun zein fibers as carriers to stabilize (-)-epigallocatechin gallate. J. Food. Sci. 74(3), 233–340 (2009).

Woerdeman, D. et al. Electrospun fibers from wheat protein: Investigation of the interplay between molecular structure and the fluid dynamics of the electrospinning process. Biomacromolecules 6, 707–712 (2005).

Yao, C., Li, X. & Song, T. Electrospinning and crosslinking of zein nanofiber mats. J Appl. Polym. Sci. 103(1), 380–385 (2007).

Bonnier, F. et al. FT-IR protein secondary structure analysis of human ascending aortic tissues. J. Biophoton. 1, 204–214 (2008).

Gao, Y. et al. Physicochemical properties of zein films cross-linked with glutaraldehyde. Polym. Bull. 79(7), 4647–4665 (2022).

Madeka, H. & Kokinii, J. Effect of glass transition and cross-linking on rheological properties of zein: Development of a preliminary state diagram. Cereal. Chem. 73(4), 433–438 (1996).

Wei, D., Huo, W., Li, G., Qiuling, X. & Yanbin, J. The combined effects of lysozyme and ascorbic acid on microstructure and properties of zein-based films. Chin. J. Chem. Eng. 26, 648 (2017).

Oliveira, J. E., Mattoso, L. H., Orts, W. J. & Eliton, S. Structural and morphological characterization of micro and nanofibers produced by electrospinning and solution blow spinning: A comparative study. Adv. Mater Sci. Eng. 2013, 409572 (2013).

Neo, Y. P. et al. Encapsulation of food grade antioxidant in natural biopolymer by electrospinning technique: A physicochemical study based on zein–gallic acid system. Food Chem. 136(2), 1013–1021 (2013).

Ullah, S. et al. Silver sulfadiazine loaded zein nanofiber mats as a novel wound dressing. RSC Adv. 9, 268–277 (2019).

Ojovan, M. I. & Lee, W. B. Connectivity and glass transition in disorded oxide systems. J. Non. Cryst. Solids. 356(44–49), 2534 (2010).

Dhanalakshmi, A., Palanimurugan, A. & Natarajan, B. Enhanced Antibacterial effect using carbohydrates biotemplate of ZnO nano thin films. Carbohyd. Polym. 168, 191–200 (2017).

Coats, A. W. & Redfern, J. P. Thermogravimetric analysis A review. Analyst. 88(1053), 906–924 (1963).

Silva, S., Silva, R., Botrel, D. & Juliano, E. Development of zein nanofibers for the controlled delivery of essential amino acids for fish nutrition. SN Appl. Sci. 2, 1783 (2020).

Wei, B., Zhao, Y., Wei, Y., Jinrong, Y. & Zhengzhong, S. Morphology and properties of a new biodegradable material prepared from zein and poly(butylene adipate-terephthalate) by reactive blending. ACS Omega. 4(3), 5609–5616 (2019).

Oliviero, M., Di Maio, E. & Iannace, S. Effect of molecular structure on film blowing ability of thermoplastic zein. J. Appl. Polym. Sci. 115(1), 277–287 (2010).

Turkez, H. et al. The risk evaluation of tungsten oxide nanoparticles in cultured rat liver cells for its safe applications in nanotechnology. Braz. Arch. Biol. Technol. 57, 532–541 (2014).

Kaur, P. et al. Synthesis, characterization and in vitro evaluation of cytotoxicity and antimicrobial activity of chitosan-metal nanocomposites. J. Chem. Technol. Biotechnol. 90, 867–887 (2015).

Manuja, A., Raguvaran, R., Kumar, B., Anu, K. & Tripathi, B. N. Accelerated healing of full thickness excised skin wound in rabbits using single application of alginate/acacia based nanocomposites of ZnO nanoparticles. Int. J. Biol. Macromol. 155, 823–833 (2020).

Zhao, Y. et al. Toxicity testing of four silver nanoparticle-coated dental castings in 3-D LO2 cell cultures. J. Zhejiang Uni. B. 19, 159–167 (2018).

Lu, Y. et al. Structural effect of tungsten oxides on selective oxidation of cyclopentene to glutaraldehyde. Catal. Commun. 7, 832–838 (2006).

Chinde, S. et al. Comparative study of cyto- and genotoxic potential with mechanistic insights of tungsten oxide nano- and microparticles in lung carcinoma cells. J. Appl. Toxicol. 38, 896–913 (2018).

Schieber, M. & Chandel, N. S. ROS function in redox signaling and oxidative stress. Curr. Biol. 24(10), 453–462 (2014).

Liou, G. & Storz, P. Reactive oxygen species in cancer. Free Radic. Res. 44(5), 479–496 (2010).

Huang, R., Chen, H. & Liang, J. Dual role of reactive oxygen species and their application in cancer therapy. J. Cancer 12(18), 5543–5561 (2021).

Bukholm, I. K. & Nesland, M. Protein expression of p53, p21 (WAF1/CIP1), bcl-2, Bax, cyclin D1 and pRb in human colon carcinomas. Virchows. Archiv. 436(3), 224–228 (2000).

Hildeman, D. A., Mitchell, T. & Aronow, B. Control of Bcl-2 expression by reactive oxygen species. Proc. Natl. Acad. Sci. USA 100(25), 15035–15040 (2003).

Aharoni-Simon, M., Shumiatcher, R. & Yeung, A. Bcl-2 Regulates reactive oxygen species signaling and a redox-sensitive mitochondrial proton leak in mouse pancreatic β-cells. Endocrinology 157(6), 2270–2281 (2016).

Pyo, C., Choi, J. H., Oh, S. & Choi, S. Oxidative stress-induced cyclin D1 depletion and its role in cell cycle processing. Biochim. Biophys. Acta 1830(11), 5316–5325 (2013).

Masgras, I. et al. Reactive oxygen species and mitochondrial sensitivity to oxidative stress determine induction of cancer cell death by p21. J. Biol. Chem. 287(13), 9845–9854 (2012).

Seervi, M., Rani, A., Sharma, A. K. & Santhosh, K. ROS mediated ER stress induces Bax-Bak dependent and independent apoptosis in response to Thioridazine. Biomed. Pharmacother. 106, 200–209 (2018).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors contributed equally.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El Fawal, G., Omar, A.M. & Abu-Serie, M.M. Nanofibers based on zein protein loaded with tungsten oxide for cancer therapy: fabrication, characterization and in vitro evaluation. Sci Rep 13, 22216 (2023). https://doi.org/10.1038/s41598-023-49190-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-49190-2

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.