Abstract

The carbon emissions of paving projects are the focus of urban managers and researchers. By introducing the life cycle assessment (LCA) method and drawing up the study time and boundary, this study analyzed the carbon emissions activities of the plaza ground paving project and established a computational model of the cast-in-place architectural concrete (CAC) and natural stone pavement’s life cycle during the construction stage by comprehensively utilizing the carbon emission coefficient method and the direct source consumption statistics method of the production line. Based on the model, this study employed the ground paving of a top-notch Theme Park Plaza in Beijing as a sample to calculate the carbon emissions of two different types of building materials at various phases of their life cycle and made a comparative evaluation. It is concluded that the carbon emissions (expressed in CO2) produced by the CAC ground in the sample area is 75.46 kg CO2/m2, while that of the natural stone pavement is 110.81 kg CO2/m2. Our results demonstrate significantly linear relationship between the overall emissions of carbon and the material carbon factor. This study adds to the body of knowledge by calculating the carbon emissions and determining the trend of carbon footprint for ground paving. Furthermore, the study's findings can be used to enhance construction management options and choose green materials. The findings can also be used to provide supporting theories for the development of regulations and carbon reduction policies based on constructing energy conservation and greenhouse gas reduction.

Similar content being viewed by others

Introduction

The greenhouse effect has become a widespread issue faced by the whole world and has a significant impact on human survival and progress1. “Carbon emissions” is an abbreviation for greenhouse gas emissions. Since CO2 is the most significant greenhouse gas, the word “carbon” is used as a representative, and “carbon emissions” is also understood as “CO2 emissions”2,3. The increase in carbon emissions will have a serious impact on social and economic development, which has attracted the attention of all countries in the world4. According to the research from World Business Council for Sustainable Development (WBCSD), in today's energy consumption structure, building energy consumption accounts for a large proportion, surpassing industrial energy consumption5. Statistics show that by 2020, carbon emissions from the construction sector accounted for 37% of all global emissions6. The three major sources of global carbon emissions are the construction, industrial, and transportation sectors7. Therefore, it is crucial to accurately assess buildings' carbon emissions and reduce their overall carbon footprint. SAP (Standard Assessment Procedure) issued by the Ministry of the Interior of the United Kingdom provided a comprehensive assessment of residential buildings as well as a calculation method for estimating the energy consumption of buildings an took the environmental impact grade of CO2 as a vital assessment index8.

The life cycle assessment (LCA) process quantifies and identifies the use of substances and energy in products, manufacturing processes, and activities, as well as their environmental emissions9. LCA covers the whole life cycle of commodities, production processes, and activities, including raw material exploration and processing, manufacturing, and transporting, as well as the use, reuse, maintenance, recycling, and final treatment10. The life cycle theory has been the foundation of extensive research into the estimation of the carbon emissions of construction engineering11,12. For instance, by measuring the carbon emissions of concrete based on the life cycle theory, Tae concluded that high-strength concrete consumes less energy and emits less CO2 than regular concrete13. Similarly, Zhao8 completed the carbon emission evaluation of the granite pavement in the garden using the life cycle theory, and Wu14 calculated the carbon emissions of recycled concrete pavement bricks across the whole life cycle. The LCA theory is also applied in the carbon emission calculation of residential buildings15, wind farms16, stone dams17, and other structures18,19.

The natural stone granite is chosen as the object in this study, mainly consisting of feldspar, quartz, and mica. Granite is resistant to acid, alkali, and weathering corrosion due to its hard texture. Moreover, granite also has a beautiful color that does not fade, which gives people a sense of nature. The excellent properties mentioned above make granite a popular material for outdoor ground decoration20. Architectural concrete is produced by mixing cement and pigment with different ratios and then adding proper amounts of plasticizer, curing, and release agent to produce a finish that resembles natural stone21. Architectural concrete refers to the architectural concrete designed, mixed, and poured at the construction site. Architectural concrete is economical, durable, and environmentally friendly, and can be adjusted in color and shape as needed, making it a popular material in the construction of large-scale parks22.

Various studies have been using LCA to assess the carbon output of construction projects but there is not much research on the plaza paving of large amusement parks. Therefore, in order to analyze the environmental impact of the paving process of the plaza ground, it is necessary to developing a comprehensive model to quantify the carbon emission in plaza ground paving project. Because a clear life-cycle framework for carbon emissions allows more detailed analysis of how to weaken carbon emissions at each stage. By quantifying carbon emissions from different materials, designers can receive more professional references when designing low-carbon buildings. In this study, we will calculate the carbon emissions of ground paving by developing a model based on LCA and calculate the carbon emissions of two different materials using a theme park plaza in Beijing as an example. Meanwhile, explore the determining factors and emission reduction potential of carbon emissions from ground pavement projects. In this research work, firstly, a concise literature review performing constructions carbon footprint is calculated using LCA. Second, refine the system boundary of the life cycle and construct a computational model by analyzing the process of ground laying at the case site. Third, estimate and compare the carbon emissions produced by paving with CAC and granite materials. Finally, examine the factors that affect carbon footprint during ground paving and the potential for emission reduction. In general, the findings of this study can offer theoretical foundation and technical support for evaluating the effect of technologies for energy conservation and emission reduction.

Methods

Boundary determination of life cycle assessment

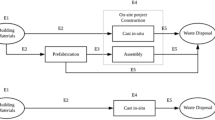

The life cycle framework of this study was built in accordance with “Life Cycle Assessment: Principles and Framework” (ISO 14040, 2006). In this study, the life cycle of the ground paving includes the production stage of materials (W1): the acquisition of raw materials, such as the mining of stones and the process of transporting the stones to the production workshop. Transportation stage (W2): carbon emissions produced from the fuel consumption of transporting raw materials from the origin to the paving site. Construction stage (W3): carbon emissions generated from the energy consumption of relevant construction machinery and equipment. Ground use and maintenance stage (W4): carbon emissions from pavement cleaning and maintenance. Cleaning and recycling stage (W5): carbon emissions generated from energy consumption of various mechanical vehicles. Considering that the carbon footprint is minimal because there is almost no machinery involved in the maintenance phase of the plaza, the production of raw materials is set as the starting point of the study time, with the formation of the ground paving as the endpoint (as shown in Fig. 1). Based on this, this study calculates the carbon emissions of the ground paving within the boundaries of this study time. The calculation formula of carbon emissions over the life cycle (during the project implementation phase) of a ground paving project is CT = Cp + Ct + Cc. (Cp, Ct, Cc is the amount of carbon emission emitted by the production stage, transportation stage, construction stage, respectively). As an amusement park, almost no vehicles enter the square, and no machinery for maintenance and cleaning is required. The same carbon emissions during the maintenance phase have no impact on the comparison of the two materials. So, Carbon emission in the cleaning and maintenance stage is ignored.

Selection of carbon emission factors

According to the research of the United Nations Intergovernmental Panel on Climate Change (IPCC) and other relevant institutions, in the statistical process on the production and use of materials, the relevant data of engineering quantities or energy consumption cannot directly reflect the carbon emissions produced by the corresponding activities23. In the case of analyzing the carbon emissions in actual construction projects, the carbon emission factor is introduced to convert different types of statistical data into carbon emission values. The amount of CO2 emitted is usually measured in terms of operability and economy24.

Carbon emissions accounting model

In this study, a combination of the carbon emission coefficient method and the direct energy consumption statistics method of the production line was employed to calculate the carbon emissions. The direct energy consumption statistics method of the production line is to analyze and calculate the carbon dioxide emissions from the output and energy consumption data of the enterprise, which is used in the calculation of carbon emissions generated in the transportation, construction stage in this study. The calculation formula for carbon emissions generated by energy consumption is as follows:

where Q1 refers to the amount of carbon dioxide emitted by energy; P1 refers to the energy consumption per unit output; I1 refers to the emission coefficient of carbon dioxide emitted per unit of energy; M1 refers to the output.

The calculation formula for carbon dioxide generated during the transportation process is as follows:

where Y represents carbon emissions, F represents the emission coefficient of transport vehicle; L represents the transportation distance; N represents the amounts of materials.

The carbon emission coefficient method directly calculates the carbon dioxide emission by multiplying the carbon dioxide emission coefficient of a specific material by the amount of this material, which applies to the situation where the statistical data cannot be directly obtained from the enterprise25. In this study, this method was employed to calculate the carbon emissions generated during the production of building materials. Calculating carbon emission factors by experimental determination is complicated, and there has been a unified carbon emission factor database for building materials. Therefore, published carbon emission factor databases are frequently employed in most current researches26,27,28,29. Since the calculation results are more objective and accurate when employing the databases with the same source, the carbon emission factors of building materials in this research are all based on the carbon emissions list issued by the Department of Mechanical Engineering of Bath University, as shown in Appendix I (Stone Federation Great Britain, 2011). The list is calculated by SIS Tech (a sustainable development research institute in the UK) in cooperation with the Heriot-Watt University. And, the data source is precise and reliable, covering the concrete, granite, cement, and sand required in this study.

The corresponding calculation formula is:

where Q2 is the amount of CO2 emitted by the production of materials; N is the number of materials; I2 refers to the carbon dioxide emission per unit of cement, natural sand, and stone.

Calculation of carbon emissions in the production stage

This stage includes carbon emissions generated during the extraction and production of the required raw materials. Based on carbon emission factor method, the calculation equation is as follows:

where Cp is the amount of carbon emission emitted by the production stage, n is the total number of material types, mi is the amount of type ‘i’ (kg or m3); The value of mi represents the amount of material that is required (Paving area multiplied by pavement thickness), gi is the carbon emission coefficient of type ‘i’(kg/kg or kg/m3 CO2).

Calculation of carbon emissions in the transportation stage

This phase refers to the transportation process from the origin to the construction site after completing the production of raw materials. During the transportation process, vehicles will consume a certain amount of fuel and release greenhouse gases such as carbon dioxide. The calculation formula is as follows:

where Ct is the amount of carbon emission emitted during the transportation stage. f represents the emission coefficient of the corresponding vehicle in the transportation process; L refers to the transportation distance (km); Ni is the mass of material ‘i’ (t).

Calculation of carbon emissions in the construction stage

The fuel and electricity consumed by the construction machinery used in this stage will generate carbon emissions. The calculation equation is as follows:

where Cc is the amount of carbon emission emitted during the construction stage. Qi refers to the energy consumption of machinery i during the construction; Ri refers to the carbon emission factor of the energy used by machinery ‘i’; Fi refers to the area that machinery ‘i’ can construct per hour. After the ground pavement project in this study is completed, the service life of the plaza could be 100–150 years. Furthermore, different construction methods have no discernible effect on the square's service life. As a result, the impact of lifespan on carbon emissions is not taken into account in this study.

Case study analysis and results

Life cycle carbon emissions of concrete ground paving

-

1.

Production Stage: Fig. 2 displays that the primary raw materials used for CAC ground paving are concrete. Designers created different paving thicknesses based on various materials to ensure pavement functionality. The pavement per m2 is used as the unit in this study to investigate the differences in carbon emissions from various materials used in the same project. According to the structural design drawing, 519.2 kg of concrete is consumed per m2 of ground paving, and the total carbon emissions in the production phase are 67.496 kg/m2, according to Table 1.

-

2.

Transportation Stage: this study investigated the production sites of cement and aggregate in three concrete batching plants and found that the average transportation distance of cement and aggregate from origin to the project site is 124 km and 129 km, respectively. According to the proportion of cement and aggregate in concrete, the comprehensive transportation distance of concrete is 128 km. The total carbon emissions in the transportation phase were calculated based on the transportation energy consumption of diesel vehicles, which is 7.77 kg/m2 (Table 2).

-

3.

Construction Stage: the equipment used at the concrete pavement construction site is a concrete polisher, with an average construction rate of 200 m2/h. Its energy consumption is shown in Table 3. The total carbon emissions in this construction phase are calculated to be 0.1910 kg/m2.

It can be calculated that the total carbon emissions of the CAC ground paving over the life cycle are 75.457 kg/m2.

Life cycle carbon emissions of granite ground paving

-

1.

Production Stage: Fig. 2 displays that the primary materials used for granite ground paving in this study include 60 mm granite, 20 mm cement, and 220 mm concrete from top to bottom. 519.2 kg of concrete, 167.4 kg of granite, 5.2 kg of cement, and 15.6 kg of sandstone were used per m2 of the ground paving. The total carbon emissions in this stage were calculated to be 88.378 kg/m2, according to Table 1.

-

2.

Transportation Stage: the transportation distance data for this study is provided by the case site construction team. When granite is used as a paving material, concrete and sandstone are still required, according to the construction drawings (Fig. 2). So, it’s important to not only think about the carbon emissions that happen when transporting granite, but also to figure out how much carbon dioxide is released when transporting general concrete and sandstone. The natural stone granite selected in this case was from the Stone Industrial Park in Jietou Town, Wulian County, Shandong Province, with a transportation distance of 688 km. The carbon emissions in the process were calculated based on the energy consumption of diesel vehicles. The transportation distance of concrete adopts the above comprehensive transportation distance of cement and aggregate from the origin to the project site. The total carbon emissions in this stage were calculated to be 21.562 kg/m2, according to Table 2.

-

3.

Construction Stage: forklift and concrete mixer was used at the granite pavement construction site for the required 20 mm cement mortar, with an average output of concrete that can be paved with an area of 500m2 per hour. The total carbon emissions in this stage are 0.8686 kg/m2, according to Table 3.

It can be calculated that the total carbon emissions of the granite ground paving over the life cycle is 110.809 kg/m2.

Comparative analysis of the carbon emissions of CAC and granite ground paving over the life cycle

This research explores the carbon emissions intensity of different materials from the case study. Results show that different paving structures will cause differences in carbon emissions intensity. As illustrated in Fig. 3, the carbon emissions of the granite ground paving in this study are 110.81 kg CO2/m2, while that of CAC is 75.46 kg CO2/m2. Figure 4 demonstrate that in the life cycle of the two materials, the production phase accounts for the maximal part of total carbon emissions, followed by the transportation phases. Carbon emissions from production and transportation exceed 99% of total emissions. The carbon emissions in the construction stage account for a tiny proportion because large machinery like the crane tower was not used on construction location. The carbon emissions of granite pavement are higher than that of CAC, because concrete can be used as a structural layer with surface decoration. By contrast, granite can only serve as the surface decoration layer in the ground structure of granite pavement, and the cushion is a concrete layer with the same thickness as in the CAC ground. Therefore, the total carbon emissions of granite pavement also include the carbon emissions of granite and cement mortar compared with the CAC pavement. According to Manuel’s study, paving sidewalks with granite slabs results in 35 kg more CO2 emissions per m2 than with concrete slabs20. This is due to granite's excellent hardness and abrasion resistance, which necessitates the use of powerful machinery to cut it. As a result, a large amount of energy consumption will be generated when mining and processing granite. Additionally, CAC is widely accessible in many cities, whereas stone materials must be transported from far-off origins to the construction site. Therefore, the stone pavement will consume a large amount of fuel in the transportation stage, thus increasing carbon emissions.

Analysis of carbon source and emission reduction potential in the ground paving of the plaza

Influencing factors of carbon emissions in construction projects

The carbon emissions generated by granite pavement in Spain during the material production stage are very similar to our research20. However, a concrete motorway in Florida is higher than our study19. The density of materials used in different regions varies, and carbon emission factors from different sources are used, which explains the differences in carbon emissions during the manufacturing phase. In the future, it is critical to specify a standard carbon emission factor pool based on regional differences. In this study, the transportation carbon emission factor is 0.117 kg CO2 (t/km). This finding is consistent with the findings of numerous studies. Transportation data for recycled concrete and concrete pavement from China, for example, show 0.111 kg CO2 (t/km) and 0.1759 kg CO2 (t/km) emissions, respectively30,31. There is also a small gap between the multi-purpose university building in Sri Lanka and this study, which was 0.1526 kg CO2 (t/km)5. Because most modes of transportation use trucks, and some regions use concrete mixer trucks, but almost all use diesel fuel. At this stage, however, different transportation distances can lead to distinct total emissions20. Only about 1% of carbon emissions occur during the construction phase. A concrete mixer, a forklift and a troweling machine capable of constructing 200–500 m2 per hour were used in this study. When large machinery, such as bulldozers, road rollers, asphalt mixing equipment, and cranes, are used in construction, the carbon footprint increases19.

Compare with similar studies, Wu calculated the carbon emissions of recycled concrete pavement bricks across the whole life cycle, and the result was 317.53 kg/m314. According to the thickness mentioned in the article, each m3 of concrete brick can pave 20 m2 of pavement, results of carbon emissions was 15.8 kg/m2. This result is much lower than our research due to the low material consumption, thin thickness, and short transportation distance of recycled concrete pavement bricks. Moreover, the life cycle of Wu's study included the production of natural and recycled aggregates, and the demolition of waste concrete. Additionally, the carbon emissions of granite pavement in this study is far higher than that of Suzhou tennis court (5.39 kg/m2)8. The reason is that the recycling stage in the life cycle of granite was included in that study, which partially offset carbon emissions, and since the construction site was unique, it was not necessary to estimate the carbon emissions of transporting the building materials from the production workshop to the construction site. However, the results of this study are close to the carbon emissions (110 kg/m2) of granite pavements in Spain20. As displayed in Table 4, the consequences of this research are far below those of projects such as grassland wind farms40, prefabricated floor slabs, composite beams33, and others because there were fewer building materials used in this study, no need for large-scale equipment during construction, and manual cleaning rather than mechanical maintenance was used to maintain the square while it was in use. However, compared with residential10, wood construction34, fill dams17, and other projects, the carbon emissions in this study are higher because it is more environmentally friendly by selecting appropriate materials according to the function and service life of the construction.

In conclusion, the carbon emissions of construction projects were mainly affected by material selection, transportation distance, and construction machinery. In addition, the difference in the definition of life cycle time boundary has a considerable effect on carbon emissions as the basis and premise for the calculation. Liu's research found that when the life cycle boundary is different, the change rate of carbon emissions will be as high as 70%40. This conclusion has also been confirmed in the life cycle assessment of the urban35 and farmland ecosystems36. If our study employs a cradle-to-grave life cycle, with the carbon emissions of the recycling stage included, the calculation results will change unpredictably. However, the carbon emissions from the recycling stage were not factored into the calculation, because the research site in this study is Theme Park Plaza, whose ground is only for people, not heavy trucks, and the business period of this research site is quite lengthy.

Model construction and analysis of more cases

After analysis and calculation, the results show that the carbon emissions generated in the production and transportation phases of the ground paving process account for more than 99% of the total. As a result, the carbon emissions model in this research will disregard the construction stage. There are almost no vehicles on the square, which is primarily used as a sidewalk. As a result, the plaza’s daily management consists primarily of manual cleaning, which does not necessitate extensive mechanical maintenance. Furthermore, the paving material, whether concrete or natural stone, can last for more than 100 years. Accordingly, the maintenance and recovery phases are not considered in the model construction. In summary, the carbon emissions calculation model developed in this study for ground paving is as follows:

where C is the amount of carbon emission, n is the total number of material types, mi is the amount of type ‘i’, gi is the carbon emission coefficient of type ‘i’. f represents the emission coefficient of the vehicle in the transportation process; L refers to the transportation distance; Ni is the mass of material ‘i’.

In order to more accurately analyze the determinants of carbon emissions from plaza ground paving projects, in addition to concrete (A) and granite (B), this study assumes five cases with reference to the carbon emission factors and densities of marble (C), clay tiles (D), slate (E), sandstone (F) and finish tiles (G). The transportation distance is set randomly and the carbon emissions are calculated by substituting into the above model. And the thickness of the material laying was 60 mm concerning the design drawings of this study. The results are listed in Table S1.

Sensitivity analysis of influencing factors

The above equation shows that the factors influencing total carbon emissions include carbon emission factor, transportation distance, and material density. Therefore, in this study, surface models were constructed to reflect the relationship between carbon emissions and the three variables when the transportation distance and material density were constant, respectively (Fig. 5).

Grey relation analysis is a technique to assess the level of correlation between variables ground on their trend similarity or dissimilarity. The basic idea is to evaluate the stiffness of the correlation ground on the geometric shape of the sequence curve37. The grey relational correlations of carbon emissions with material carbon emission factor, material density, and transportation distance were calculated to be 0.790, 0.724, and 0.662, respectively (Table 5). A grey correlation coefficient above 0.5 suggests the presence of a linkage between both the two, and the larger the coefficient, the stronger the correlation38. As a result, there is a relationship between the life cycle carbon emissions of ground paving and the material carbon emission factor, material density, and transportation distance, with the material carbon emission factor having the highest sensitivity, followed by the material density, and finally the transportation distance.

Furthermore, to gain a greater appreciation for the connection between carbon emissions and material density, transportation distance, and material carbon emission factors, this study used Pearson correlation analysis to fit the above relationships separately. The carbon emission factor of materials is significantly correlated positively with carbon emissions, according to Fig. 6. However, Pearson’s analysis did not find a linear relationship between transportation distance and material density.

Carbon emissions reduction potential in ground paving

To summarize, the consumption of electricity or oil for large machinery in the material production phase is the main carbon source in the ground paving project, followed by the consumption of oil trucks during material transportation from the origin to the construction site. The key factor affecting carbon emissions is the carbon emission factor of materials, followed by the density and transportation distance of materials. As a result, the carbon reduction of the ground paving project should concentrate on material selection and energy-efficient transportation.

The stone mining industry has problems of environmental damage and resource waste that cannot be ignored39. In the background of promoting the construction of the low-carbon city, sponge cities and ecological cities, the transformation of the stone industry is a vital measure to saving energy and lowering emissions when facing climate change. To meet the goal of low carbon emission and not affect performance, it is critical to select materials with low carbon emission factors. The material production stage can also cut emissions by optimizing the production process and increasing the material resource utilization.

Numerous studies demonstrate that the plurality of carbon emissions in the building engineering sector are induced during the phases of material production and transportation14. To limit greenhouse gas emissions, it is critical to select materials with close origins without compromising building functions. Similarly, since different fuels (diesel, engine oil, electricity) or vehicles with varying specifications affect carbon emissions, it is crucial to choose an energy-efficient method of transportation33. Promotion of construction management and green building practices is also required in the construction stage29. For instance, choosing more ecofriendly fuels for the heavy equipment used in construction will help to lower greenhouse gas emissions. Reduction of emissions during the installation and construction phase can also be achieved by improving the construction plan.

Conclusion

-

1.

In this research, the life cycle system boundary of the piazza ground paving project was determined and a carbon emissions calculation model was created. The carbon emission of cast-in-place architectural concrete is lower than that of natural stone granite ground paving under the premise of the same use function, according to the results of carbon emissions calculation of two kinds of materials for ground paving of a world-class Theme Park Plaza in Beijing, which was 75.46 kg CO2/m2 and 110.81 kg CO2/m2 respectively.

-

2.

In the life cycle of ground paving, the carbon emissions are primarily caused by the manufacturing stages of the construction materials, with the construction stage taking into consideration less than 1% of the total. The main carbon source in the piazza ground paving project is electricity or oil for large machinery in material production, followed by oil trucks during material transportation from the origin to the construction site.

-

3.

The key factor affecting carbon emissions is the carbon emission factor of materials, followed by the density and transportation distance of materials. The carbon emissions factor of materials and the carbon emissions of engineering have a significant linear relationship.

-

4.

In summary, it can be concluded that utilizing environmentally friendly and locally sourced building materials and cleaner fuels can shorten the transportation distance and effectively reduce the greenhouse gas in the process of ground paving of the park plaza.

Limitations and future studies

Some limitations in carrying out this study could be recognized. For starters, basic data on carbon emission factors in China has remained deficient. Some variables could only be acquired through data collected in other countries. Second, the study area for this research was a large park in Beijing. The findings may not be directly applicable to other locations. Furthermore, due to a scarcity of real projects data sources, there are limitations in the construction of the surface model and the analysis of the Pearson correlation. In the future, we still need to collect multiple real projects data to verify the model of this study. Even so, the research results may contribute to the applicable body of knowledge. The findings might offer a scientific foundation for better construction management and the promotion of low-carbon building technology. They might serve as a guide for by administration and developers in developing and refining rules and regulations for conservation of energy and reducing emissions. Future work could assess ground paving carbon footprint in other origins in order to develop an accurate carbon emissions calculation agreement for numerous states.

Data availability

The datasets during the current study are available from the corresponding author on reasonable request.

References

Kwak, Y., Kang, J. A., Huh, J. H., Kim, T. H. & Jeong, Y. S. An analysis of the effectiveness of greenhouse gas reduction policy for office building design in South Korea. Sustainability 11, 7172 (2019).

Paustian, K., Ravindranath, N. H. & Amstel, A. V. 2006 Ipcc guidelines for national greenhouse gas inventories. Int. Panel Clim. Change 2006, 145 (2006).

Zhang, M. & Wang, W. W. Analysis of spatial distribution of global energy-related CO2 emissions. Nat. Hazards 73, 165–171 (2014).

Li, L. & Chen, K. Quantitative assessment of carbon dioxide emissions in construction projects: A case study in Shenzhen. J. Clean. Prod. 141, 394–408 (2017).

Kumanayake, B. & Luo, H. Life cycle carbon emission assessment of a multi-purpose university building: A case study of Sri Lanka. Front. Eng. Manag. 5, 381–393 (2018).

Ji, Z. & Tang, B. Climate change 2014—mitigation of climate change. Clim. Change 2015, 144 (2015).

Sun, L., Wang, Q., Zhou, P. & Cheng, F. Effects of carbon emission transfer on economic spillover and carbon emission reduction in China. J. Clean. Prod. 112, 1432–1442 (2016).

Zhao, B., Zhang, J., Liu, H. & Wei, W. Study on carbon emissions of the granite of garden pavement. J. Nanjing For. Univ. Nat. Sci. Ed. 40, 101–106 (2016).

Huang, Y., Bird, R. & Bell, M. A Comparative study of the emissions by road maintenance works and the disrupted traffic using life cycle assessment and micro-simulation. Transp. Res. Part D: Transp. Env. 14, 197–204 (2009).

Zhang, Y., Zhang, X., Zhang, H., Chen, G. & Wang, X. Carbon emission analysis of a residential building in China through life cycle assessment. Front. Env. Sci. Eng. 10, 150–158 (2016).

Kang, S., Yang, R., Ozer, H. & Al-Qadi, I. Life-cycle greenhouse gases and energy consumption for material and construction phases of pavement with traffic delay. Transp. Res. Rec. J. Transp. Res. Board 2428, 27–34 (2014).

Liu, Y., Ye, K., Wu, L. & Chen, D. Estimating quantity and equity of carbon emission from roads based on an improved lca approach: The case of China. Int. J. Life Cycle Assess. 27, 759–779 (2022).

Tae, S., Baek, C. & Shin, S. Life cycle Co 2 evaluation on reinforced concrete structures with high-strength concrete. Environ. Impact Assess. Rev. 31, 253–260 (2011).

Wu, S., Jiang, Y., Wang, X. & Wang, B. The calculation of carbon emissions on the life cycle of recycled concrete pavement brick. Constr. Technol. 43, 33–38 (2014).

Wu, P., Song, Y., Zhu, J. & Chang, R. Analyzing the influence factors of the carbon emissions from China’s building and construction industry from 2000 to 2015. J. Clean. Prod. 221, 552–566 (2019).

Li, J., Li, S. & Wu, F. Research on carbon emission reduction benefit of wind power project based on life cycle assessment theory. Renew. Energy 155, 456–468 (2020).

Noh, S., Son, Y. & Park, J. Life cycle carbon dioxide emissions for fill dams. J. Clean. Prod. 201, 820–829 (2018).

Luo, Z., Liu, Y. & Liu, J. Embodied carbon emissions of office building: A case study of China’s 78 office buildings. Build. Environ. 95, 365–371 (2016).

Yu, B. & Lu, Q. Life cycle assessment of pavement: Methodology and case study. Transport. Res. Part D 17, 380–388 (2012).

Mendoza, J., Oliver-Sola, J., Gabarrell, X., Josa, A. & Rieradevall, J. Life cycle assessment of granite application in sidewalks. Int. J. Life Cycle Assess. 17, 580–592 (2012).

Naganna, S. R. et al. A insights into the multifaceted applications of architectural concrete: A state-of-the-art review. Arab. J. Sci. Eng. 46, 4213–4223 (2021).

Chang, H. et al. Durability and aesthetics of architectural concrete under chloride attack or carbonation. Materials 13, 839 (2020).

Noshadravan, A., Wildnauer, M., Gregory, J. & Kirchain, R. Comparative pavement life cycle assessment with parameter uncertainty. Transp. Res. Part D Transp. Env. 25, 131–138 (2013).

Li, X. J., Lai, J. Y. & Zheng, Y. D. Using lca to research carbon footprint for precast concrete piles during the building construction stage: A China study. J. Clean. Prod. 245, 118754 (2019).

Peng, C. Calculation of a building’s life cycle carbon emissions based on ecotect and building information modeling. J. Clean. Prod. 112, 453–465 (2016).

Gomes, K. C., Carvalho, M., Diniz, D., Abrantes, R. & Junior, P. Carbon emissions associated with two types of foundations: Cp-II portland cement-based composite vs geopolymer concrete. Matér. Rio De Janeiro 24, 4 (2019).

Paik, I. & Na, S. Comparison of carbon dioxide emissions of the ordinary reinforced concrete slab and the voided slab system during the construction phase: A case study of a residential building in South Korea. Sustainability 11, 3571 (2019).

Turner, L. K. & Collins, F. G. Carbon dioxide equivalent (Co2-E) emissions: A comparison between geopolymer and opc cement concrete. Constr. Build. Mater. 43, 125–130 (2013).

Xjl, A., Wjx, A., Cyj, B. & Fan, F. C. Holistic Lca evaluation of the carbon footprint of prefabricated concrete stairs. J. Clean. Prod. 329, 1296 (2021).

Lei, B. et al. Carbon emission evaluation of recycled fine aggregate concrete based on life cycle assessment. Sustainability 14, 1444 (2022).

Huang, Y., Ning, Y., Zhang, T. & Wu, J. Measuring carbon emissions of pavement construction in China. Sustainability 8, 723 (2016).

Kong, A., Kang, H., He, S., Li, N. & Wang, W. Study on the carbon emissions in the whole construction process of prefabricated floor slab. Appl. Sci. 10, 2026 (2020).

Xu, K., Kang, H., Wang, W., Jiang, P. & Li, N. Carbon emission estimation of assembled composite concrete beams during construction. Energies 14, 1810 (2021).

Lin, C. L., Chiang, W. H., Weng, Y. S. & Wu, H. P. Assessing the anthropogenic carbon emission of wooden construction: An lca study. Build. Res. Informat. 51, 138–157 (2023).

Chen, S., Long, H., Chen, B., Feng, K. & Hubacek, K. Urban carbon footprints across scale: Important considerations for choosing system boundaries. Appl. Energy. 259, 114201 (2020).

Chen, R., Zhang, R., Han, H. & Jiang, Z. Is farmers’ agricultural production a carbon sink or source?—Variable system boundary and household survey data. J. Clean. Prod. 266, 122108 (2020).

Kunli, F. & Wen, R. The proof of a new modified Grey Relational Grade. Grey Syst. Theory Appl. 8, 141 (2016).

You, M., Shu, C., Chen, W. & Shyu, M. Analysis of cardinal grey relational grade and grey entropy on achievement of air pollution reduction by evaluating air quality trend in Japan. J. Clean. Prod. 142, 3883–3889 (2017).

Sharma, A., Mishra, A. K. & Choudhary, B. S. Sustainable exploitation of building stone in India—emerging issues. Curr. Sci. 115, 838–844 (2018).

Liu, P., Liu, L., Xu, X., Zhao, Y. & Zhang, Q. Carbon Footprint and Carbon Emission Intensity of Grassland Wind Farms in Inner Mongolia. J. Clean. Prod. 313, 127878–127879. https://doi.org/10.1016/j.jclepro.2021.127878 (2021).

Funding

This study was supported by the National Key R & D plan (grant numbers: 2021YFB3901104).

Author information

Authors and Affiliations

Contributions

H.N. and L.W. wrote the main manuscript text. Tian provided ideas, funding for the research. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix I

Carbon emission factors of common building materials.

Building materials | Carbon emission factors (Kg CO2/t) |

|---|---|

Sandstone | 64 |

Granite | 93 |

Marble | 112 |

General Concrete | 130 |

General Clay Bricks | 220 |

Slate | 232 |

Timber | 450 |

Facing Bricks | 520 |

General Building Cement | 830 |

Steel: Bar and Rod | 1710 |

Steel: Galvanized sheet | 2820 |

Appendix II

Abbreviations.

Full name of the term | Abbreviations |

|---|---|

Life cycle assessment | LCA |

Cast-in-place architectural concrete | CAC |

Intergovernmental Panel on climate change | IPCC |

The carbon emission in the stage of the life cycle stage | CT |

The carbon emission in the stage of the raw material production | Cp |

The carbon emission in the stage of the raw material transportation | Ct |

The carbon emission in the stage of construction of pavement | Cc |

Carbon emissions at a certain stage | Y |

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nie, H., Wang, L. & Tian, M. Analysis on determinants of carbon emissions from plaza ground paving during the construction stage based on life cycle assessment. Sci Rep 14, 136 (2024). https://doi.org/10.1038/s41598-023-47933-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-47933-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.