Abstract

Phase change materials (PCMs) are an important class of innovative materials that considerably contribute to the effective use and conservation of solar energy and wasted heat in thermal energy storage systems (TES). The performance of TES can be improved by using environmentally friendly PCMs called ionic liquids (ILs) based on ethanolamines and fatty acids. The 2-hydroxyethylammonium, bis(2-hydroxyethyl)ammonium, and tris(2-hydroxyethyl)ammonium palmitate ILs, which function is in the temperature range of 30–100 °C and provide a safe and affordable capacity, are introduced in this study for the first time as PCMs. PCMs' chemical composition and microstructure were examined using fourier transformation infrared spectroscopy (FT-IR) and scanning electron microscopy (SEM), respectively. DSC was used to evaluate the ILs' latent heat of fusion and specific heat capacity, while TGA was used to establish their thermal stability. Finally, a home-made device with a PCMs (synthesized ILs) container cell and a commercial thermoelectric generator device to record the real-time voltage (V) was used to convert thermal energy into electrical energy.

Similar content being viewed by others

Introduction

Energy consumption has experienced unpredictable growth in recent decades due to technological advancements and improved living standards. To mitigate the adverse effects it generates, it is imperative to explore alternative energy generation methods rooted in renewable sources1. Due to some problems of traditional fuels, there is a global push to transition to cleaner and more sustainable energy sources, such as wind, solar, hydroelectric, and nuclear power, in order to address the environmental, economic, and social challenges associated with traditional energy sources. Applications of renewable energies help reduce greenhouse gas emissions, combat climate change, enhance energy security, and create sustainable and cleaner energy systems for the future. For many years, a well-known option has been thermal energy storage (TES), which comprises methods of energy storage in the form of sensible heat (resulting in a change in material temperature), the heat of chemical reaction, and latent heat associated with a phase shift. A phase change material (PCMs) is a substance that undergoes a phase transition (change in its physical state) from a solid to a liquid or from a liquid to a solid at a specific temperature, often referred to as its melting point or freezing point2,3,4. By using PCMs as energy storage, the energy supply and demand gap is reduced, energy distribution networks are made more efficient and reliable, and overall energy conservation is greatly increased5,6,7,8. The isothermal phase transition of PCMs also offers a broad variety of applications in proper temperature-sensitive systems, chemical reactors, the human body, and smart electrical devices9,10,11,12,13,14. Throughout the development of PCMs, research has been conducted on a wide range of material classes, including chemical compounds (such as fatty acids and paraffin), mineral compounds (salt hydrates and salts), and even polymeric materials (such as PEG)15,16.

A broad electrochemical stability window, strong ionic conductivities, low vapor pressures, thermal stability, and lack of flammability are just a few of the notable advantages of the new family of materials known as ionic liquids (ILs). Due to their exceptional qualities, ILs have found extensive usage as "green" organic solvents, electrolytes in double-layer capacitors, fuel cells, batteries, and dye-sensitive solar cells. In the last ten years, several fundamental investigations on the thermodynamic properties of ILs for application as thermal storage medium and heat transfer fluids have been conducted17,18,19.

However, unlike paraffin, which is made from petroleum, fatty acids may be derived from living resources without the need of fossil fuels20. They have several advantageous qualities, including as affordability, non-toxicity, and corrosion resistance. Additionally, they frequently exhibit favorable phase transition temperatures, great ability to store latent heat, no supercooling or phase separation, and strong thermal and chemical stability21,22,23.

As researchers looked for more environmentally friendly chemical processes, the field of ILs was developing and fast increasing as the globe struggled with the terrible effects of the carbon-based energy sector24,25,26. In light of the fact that many ILs have low flammability, volatility, and corrosivity, which are drawbacks of conventional PCM materials, it has recently been obvious that these features are advantageous for PCMs27. A number of ILs have been used as PCMs for TES applications28,29,30,31,32. The value of ILs based on hydroxyethyl ammonium is considerable since they are also used as thermal energy storage devices33,34,35.

Solar power plants are one of the renewable energy power plants that the international community considers as national sources of high-capacity power generating. Solar panels have the potential to be diminished or even destroyed in the absence of sunlight. PCMs that have performed well have been utilized to solve this issue. In order to provide electrical compensation, PCMs will evaluate the solar panel's thermal performance with a new design. In this study, we investigate the state-of-the-art PCMs for TES applications in solar cells to produce electricity, as well as current efforts to develop innovative PCMs with enhanced performance and security. TES materials were created using PCMs based on 2-hydroxyethylammonium palmitate, bis(2-hydroxyethyl)ammonium palmitate, and tris(2-hydroxyethyl)ammonium palmitate. PCMs' microstructure and chemical makeup were examined using Fourier transformation infrared spectroscopy (FT-IR) and scanning electron microscopy (SEM), respectively. DSC and TGA studies were used to calculate the prepared PCMs' latent heat of fusion and thermal stability. Finally, a home-made instrument with a PCM container cell and a commercial thermoelectric generator device to record the real-time voltage (V) was used to execute the thermal-to-electric energy conversion.

Experimental measurements

Chemicals

The following sources provided the materials for this study: Mono, di, and triethanolamine from Shazand Petrochemical Co. had a purity greater to 99%, and palmitic acid from Merck Co. Ethanolamines were simply neutralized by palmitic acid in an acid–base reaction to produce the ionic liquids (2-hydroxyethylammonium palmitate), bis(2-hydroxyethyl)ammonium palmitate, and tris(2-hydroxyethyl)ammonium palmitate. They were not further purified before usage.

Synthesize of ionic liquid as phase change materials (PCMs)

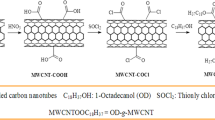

First, the ethanolamines were introduced to a glass flask with three necks and a reflux condenser. The magnetic stirrer was used to agitate the flask while the molten palmitic acid was added dropwise. Stirring was kept up for 24 h at room temperature to finish the reaction. All compounds' specifications are shown in Table 1. Schematic of the synthesized ionic liquids as phase change materials (PCMs) is shown in Fig. 136.

Chemical characterization

FT-IR Transmittance Spectra of the PCMs, [HEA]Pal, [DHEA]Pal, and [THEA]Pal via KBr have been recorded using Bruker (Tensor 270-KBr). Also, to examine the microstructure and morphology of produced PCMs, a device scanning electronic microscope (TESCAN, MIRA3 FEG-SEM) was utilized.

Thermal characterization

To ascertain the thermophysical characteristics of the newly developed PCMs [HEA]Pal, [DHEA]Pal, and [THEA]Pal, produced ILs were measured calorimetrically. With a thermal investigation utilizing a differential scanning calorimeter (Netzsch DSC-200 F3) up to 373 K, the heat capacities and heat of fusion were characterized. To achieve this, heating rates of 10 K/min were used throughout the thermal stages. The samples were heated to 373 K in this regard. The heating stage allowed for the determination of the PCMs' thermal characteristics, including heat capacity and heat of fusion. At a rate of 10 K/min, the PCMs' specific heat capacity were measured between 313.15 and 348.15 K. PCM sample weights were measured using an electronic balance with a precision of ± 10−3 g. The DSC device has a sensitivity of 10–5 µV·mW−1.

In addition, a thermal analysis equipment (METTLER TOLEDO, TGASDTA 851e) was used to record the thermogravimetry study of the synthesized PCMs, [HEA]Pal, [DHEA]Pal, and [THEA]Pal in order to assess their thermal stability across a range of 50–700 °C under N2 (30 mL min−1).

Thermal-to-electric energy conversion and storage

The creation of system configurations, simulation models, prototype trials, and electrical and thermal performance assessment have dominated research into solar cells-PCM systems. The possibility of enhancing the PV module's ability to generate energy through the use of a PCM was examined in this study through an experiment. A home-made instrument containing a PCM container cell and a commercial thermoelectric generator device to record the real-time voltage (V) was used to convert heat energy into electrical energy. We employed a vacuum cup filled with a heat sink as a heat source and a sample that absorbed and collected heat from a simulated thermal source as a cold source.

Results and discussion

Due to their superior heat transfer characteristics, non-volatility, non-flammability, and high chemical and thermal stability, ionic liquids (ILs) based on monoethanolamine, diethanolamine, triethanolamine with palmitic acid are good PCM candidates37. Additionally, a wide variety of cations and anions makes it possible to construct ILs with the ideal characteristics, notably melting point, for the desired usage. Using the 2-hydroxyethylammonium [HEA]Pal, bis(2-hydroxyethyl)ammonium [DHEA]Pal, and tris(2-hydroxyethyl)ammonium palmitate [THEA]Pal ILs as a base, we describe a unique PCM here.

Characterization of the synthesized PCMs

FT-IR spectrum of the synthesized PCMs

The FT-IR spectra of the synthesized ILs [HEA]Pal, [DHEA]Pal and [THEA]Pal are depicted in Fig. 2. The FT-IR index peaks for palmitic acid are as follows: 549, 685, 723, 939, 1261, 1299, 1422, 1464, 1695, 2848, 2913 and 295038. The FT-IR index peaks for ILs are as follows. FT-IR (KBr, cm−1) for [HEA]Pal IL: 528.80, 721.22, 1013.48, 1076.48, 1138.10, 1411.44, 1466.81, 1542.72, 2851.96, 2921.53, 3170.78, and 3384. FT-IR (KBr, cm−1) for [DHEA]Pal IL: 566.04, 718.90, 806.16, 966.61, 1061.17, 1102.76, 1409.71, 1464.57, 1536.04, 1620.99, 2850.74, 2920.08, 3199.13, and 3380.40. FT-IR (KBr, cm−1) for [THEA]Pal IL: 529.44, 566.62, 719.30, 915.44, 1031.06, 1075.54, 1294.29, 1408.57, 1470.18, 1561.81, 2850.64, 2918.83, 3151.99, and 3359.21. As seen in Fig. 2, the ILs displayed peaks in the same locations as the characteristic peaks of monoethanolamine, diethanolamine, triethanolamine and palmitic acid, which is ascribed to the [HEA]Pal, [DHEA]Pal and [THEA]Pal having the same molecular structure. The substance's characteristics may be accurately predicted by looking at the COO− absorption peaks, which are located at roughly 528 and 720 cm−1. Additionally, the long-chain alkyl group is reflected by the strong distinctive peaks at 2850 and 2920 cm−1, which are associated with the symmetric and anti-symmetric detention vibration peaks of CH2, respectively. Peaks at roughly 1464–1470 cm−1 are used to represent the in-plane bending, symmetric, and out-of-plane bending vibrations of the fatty acid carboxyl COOH, respectively. Peaks at approximately 1075 cm−1 are used to represent the anti-symmetric stretching vibration peaks of CH3, where they appear as two faint peaks39. In all ILs, there is a peak that corresponds to N–H at about 3359–3384 cm−1. According to the index peaks of palmitic acid and the synthesized ILs, it can be concluded that the ILa were correctly synthesized and the additional peaks in the ILs were used for the raw materials of ethanolamines.

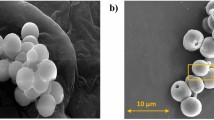

SEM imaging of the synthesized PCMs

The SEM images of the synthesized PCMs are shown in Fig. 3. The ILs have a rough surface and a layered structure, as seen in this image40. As seen in Fig. 3, monoethanolamine, diethanolamine, and triethanolamine all responded well to the palmitic acid. The mechanical strength of ILs is increased, and they stop the leakage of monoethanolamine, diethanolamine, and triethanolamine as a result of interactions between the ionic force in the network structure of the generated ILs and the surface tension forces of fatty acid39,40. Another observation from Fig. 3 is that [HEA]Pal is smaller size than [DHEA]Pal and [THEA]Pal and has more homogeneous microstructures. The ILs are all layered and in the form of laminates, which have a greater surface ratio than the raw materials and need more energy to melt and solidify, as can be seen from the SEM photos.

Thermal analyses of the synthesized PCMs

Differential scanning calorimetry (DSC) of the synthesized PCMs

The calorimetry data for the synthesized PCMs are displayed in Fig. 4 and given in Table 2. According to the DSC graphs, Fig. 4 depicts the heating curves (exothermic up) for the ILs [HEA]Pal, [DHEA]Pal, and [THEA]Pal. The melting points for the ILs [HEA]Pal, [DHEA]Pal, and [THEA]Pal are 349.43 K, 342.58 K, and 338.92 K, respectively, as indicated in Table 2. According to the findings, the IL [HEA]Pal requires a stronger structure and more energy to melt than the ILs [DHEA]Pal and [THEA]Pal.

The characteristics of the produced ILs during phase transitions are very comparable to the composition of palmitic acid. The melting latent heat for the [HEA]Pal, [DHEA]Pal, and [THEA]Pal are determined to be 158.9 kJ kg−1, 139.8 kJ kg−1, and 123.2 kJ kg−1, respectively, according to Table 2. The ionic forces in the cation and anion create the latent heat of this kind of ILs when acidic H is transferred from palmitic acid to the NH2 group of ethanolamines.

The Cp values of the synthesized ILs at T = 313.15 to 373.15 K were calculated using the DSC data and are shown in Fig. 5 and Table 3 respectively. Despite the fact that all ILs contain the same anion—palmitate—there are variations in the examined ILs' specific heat capacities because of the various cations at play. Due to a larger ionic force between the cation and anion in IL [HEA]Pal than in the other two ILs, the Cp values are higher.

Thermogravimetry analyses (TGA) of the synthesized PCMs

Figure 6 displays the TGA and DTG curves for the ILs [HEA]Pal, [DHEA]Pal, and [THEA]Pal. The amount of charred residue at 700 °C and the temperature at which the most weight is lost are shown in Table 2. The three-step heat deterioration mechanisms are shown in Fig. 6. The weight loss of the [HEA]Pal is considerably smaller throughout three-step thermal degradation processes than that of the [DHEA]Pal and [THEA]Pal. As seen in Fig. 6, the first step, which corresponds to the release of water molecules adsorbed in the network of ILs, occurs between 20 and 100 °C. The second stage occurs between 100 and 220 °C, where the ILs' molecular chains experience a 45% thermal degradation. Users of solar thermal energy storage are advised to utilize the synthesized ILs in this study. Given that solar cell systems and solar thermal storage are capable of operating at temperatures of up to 150 °C, the synthesized ILs exhibit above 97% thermal stability at this temperature, indicating the need for appropriate PCMs. The results shown in Fig. 6 show that [HEA]Pal, [DHEA]Pal, and [THEA]Pal have respective thermal stabilities of 97, 99, and 100%. According to the analysis of thermal stability, it can be understood that the synthesized ILs showed remarkable thermal stability compared to the used palmitic acid and ethanolamines and are stable at higher temperatures38,41,42.

Real-time voltage (V) results

A homemade instrument was performed for the thermal-to-electric energy conversion with a commercial thermoelectric generator device to record the real-time voltage (V). Schematic of the instrument is shown in Fig. 7. In this regard, the electrical voltage output of cell containing ILs as a new generation of PCMs is represented in Fig. 8, which indicated that electrical voltage of PCM based on [HEA]Pal is higher than [DHEA]Pal and [THEA]Pal.

It is found that a PCM as a practical storage medium may achieve a 20% greater total day electrical output per unit storage volume than liquid water in a full-storage approach where electrical energy generation from the PCM is offset to meet the weekday evening peak in demand. The isothermal operation of the PCM during phase-change enables a lower diurnal storage temperature variance and a greater energy conversion efficiency from the solar collector array.

As a result of this research work, PCM performance for thermal energy storage applications will be enhanced by the employment of a synthesized ILs with noteworthy features. According to FT-IR data, chemical processes take place during the creation of ILs. The ILs were also discovered by SEM to be in the form of layered, homogenous microcrystals, and by heating them, a lot of energy is released in the solid–liquid process because of the higher number of layers.

Utilizing novel materials with high latent heats of fusion, heat capacities, and thermal stability will enable the introduction of thermal energy storage applications. In this regard, the synthesized ILa as PCMs described in this study have greater latent fusion energies up to about 158.9 kJ kg−1, large heat capacities, and high thermal stabilities up to 97%. The main takeaway from this study is the effectiveness of PCMs with excellent performance for solar cell thermal energy storage. In this manner, solar cells lose heat up to 150 °C. This unused heat may be turned into energy by using PCMs. It is conceivable to eliminate the need for power at night by continually releasing the latent heat of fusion of these PCMs, which may be accomplished by storing the wasted heat in PCMs when there is no sunlight.

Conclusions

There is a lot of potential for significant, environmentally friendly, and long-lasting effect with the newly developed use of ionic liquids for renewable thermal energy storage. The development of phase transition materials based on palmitic acid and ethanolamine ([HEA]Pal, [DHEA]Pal, and [THEA]Pal) is presented. DSC studies revealed that the PCMs' melting point was in the range of 30–100 °C. For the [HEA]Pal, [DHEA]Pal, and [THEA]Pal, the latent heat of fusion was calculated to be 158.9, 139.8, and 123.2 kJ kg−1, respectively. It is clear that among them, the [THEA]Pal has the maximum thermal stability, indicating that it is a good PCM up to 150 °C. The increased size of the cation, which results in the production of strong ionic interactions in the structure of this IL, may be the cause of the [THEA]Pal's improved thermal characteristics. Additionally, as seen by the shape of ILs, [HEA]Pal becomes compressed and coiled around itself as the cation size decreases. More energy was required to disassemble its structure. The [HEA]Pal has higher Cp values than the other two ILs, indicating a larger storage capacity.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Shuba, E. S. & Kifle, D. Microalgae to biofuels:‘Promising’alternative and renewable energy, review. Renew. Sustain. Energy Rev. 81, 743–755 (2018).

Sarbu, I. & Dorca, A. Review on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials. Int. J. Energy Res. 43, 29–64 (2019).

Pielichowska, K. & Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 65, 67–123 (2014).

Cárdenas, B. & León, N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renew. Sustain. Energy Rev. 27, 724–737 (2013).

Rathod, M. K. & Banerjee, J. Thermal stability of phase change materials used in latent heat energy storage systems: A review. Renew. Sustain. energy Rev. 18, 246–258 (2013).

Warmińska, D., Nowosielski, B., Szewczyk, A., Ruszkowski, J. & Prokopowicz, M. Effect of choline chloride based natural deep eutectic solvents on aqueous solubility and thermodynamic properties of acetaminophen. J. Mol. Liq. 323, 114834 (2021).

Zhang, Y., Zhou, G., Lin, K., Zhang, Q. & Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 42, 2197–2209 (2007).

Sharma, A., Tyagi, V. V., Chen, C. R. & Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. energy Rev. 13, 318–345 (2009).

Wang, X., Li, G., Hong, G., Guo, Q. & Zhang, X. Graphene aerogel templated fabrication of phase change microspheres as thermal buffers in microelectronic devices. ACS Appl. Mater. Interfaces 9, 41323–41331 (2017).

Ye, Q. et al. Form-stable solar thermal heat packs prepared by impregnating phase-changing materials within carbon-coated copper foams. ACS Appl. Mater. Interfaces 11, 3417–3427 (2018).

Lyu, J. et al. Nanofibrous kevlar aerogel films and their phase-change composites for highly efficient infrared stealth. ACS Nano 13, 2236–2245 (2019).

Łoczechin, A. et al. Functional carbon quantum dots as medical countermeasures to human coronavirus. ACS Appl. Mater. Interfaces 11, 42964–42974 (2019).

Lyu, J., Li, G., Liu, M. & Zhang, X. Aerogel-directed energy-storage films with thermally stimulant multiresponsiveness. Langmuir 35, 943–949 (2019).

Li, K. et al. A yolk/shell strategy for designing hybrid phase change materials for heat management in catalytic reactions. J. Mater. Chem. A 5, 24232–24246 (2017).

Shukla, A., Buddhi, D. & Sawhney, R. L. Thermal cycling test of few selected inorganic and organic phase change materials. Renew. Energy 33, 2606–2614 (2008).

Kenisarin, M. & Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 11, 1913–1965 (2007).

Faraji, S., Shekaari, H., Zafarani-Moattar, M. T. & Mokhtarpour, M. Experimental studies on thermophysical properties of protic ionic liquids for thermal energy storage systems. J. Energy Storage 54, 105251 (2022).

Le Bideau, J., Viau, L. & Vioux, A. Ionogels, ionic liquid based hybrid materials. Chem. Soc. Rev. 40, 907–925 (2011).

Vioux, A., Viau, L., Volland, S. & Le Bideau, J. Use of ionic liquids in sol-gel; Ionogels and applications. C. R. Chim. 13, 242–255 (2010).

Zhang, R. et al. Preparation and thermal properties analysis of fatty acids/1-hexadecanol binary eutectic phase change materials reinforced with TiO2 particles. J. Energy Storage 51, 104546 (2022).

Rezaie, A. B. & Montazer, M. Shape-stable thermo-responsive nano Fe3O4/fatty acids/PET composite phase-change material for thermal energy management and saving applications. Appl. Energy 262, 114501 (2020).

Yuan, Y., Zhang, N., Tao, W., Cao, X. & He, Y. Fatty acids as phase change materials: A review. Renew. Sustain. Energy Rev. 29, 482–498 (2014).

Kenisarin, M. M. Thermophysical properties of some organic phase change materials for latent heat storage. A review. Sol. Energy 107, 553–575 (2014).

Nagar, S. & Sharma, K. Modern solar systems driven by nanoparticles-based fatty acids and paraffin wax phase change materials. J. Mater. Sci. 56, 4941–4966 (2021).

Nagar, S., Sharma, K., Pandey, A. K. & Tyagi, V. V. Effect of graphene and its derivatives on thermo-mechanical properties of phase change materials and its applications: a comprehensive review. Front. Energy 16, 150–186 (2022).

Nagar, S., Sharma, K., Singh, M., Kumar, P. & Pandey, A. K. Charging analysis and characterizations of COOH group functionalized graphene combined with paraffin wax as phase change material for thermal energy storage applications. J. Therm. Anal. Calorim. 147, 11021–11038 (2022).

Piper, S. L., Kar, M., MacFarlane, D. R., Matuszek, K. & Pringle, J. M. Ionic liquids for renewable thermal energy storage—A perspective. Green Chem. 24, 102–117 (2022).

Faraji, S., Shekaari, H., Zafarani-Moattar, M. T., Mokhtarpour, M. & Asghari, E. Thermal properties of phase change materials ionic liquid/fatty acids for thermal energy storage applications. J. Energy Storage 67, 107464 (2023).

Rabideau, B. D. et al. Tuning the melting point of selected ionic liquids through adjustment of the cation’s dipole moment. Phys. Chem. Chem. Phys. 22, 12301–12311 (2020).

Zhang, Z., Salih, A. A. M., Li, M. & Yang, B. Synthesis and characterization of functionalized ionic liquids for thermal storage. Energy Fuels 28, 2802–2810 (2014).

Matuszek, K. et al. Pyrazolium phase-change materials for solar-thermal energy storage. ChemSusChem 13, 159–164 (2020).

Zhang, H., Xu, W., Liu, J., Li, M. & Yang, B. Thermophysical properties of dicationic imidazolium-based ionic compounds for thermal storage. J. Mol. Liq. 282, 474–483 (2019).

Zhu, J., Bai, L., Chen, B. & Fei, W. Thermodynamical properties of phase change materials based on ionic liquids. Chem. Eng. J. 147, 58–62 (2009).

Santos, D. et al. Synthesis and physico-chemical properties of two protic ionic liquids based on stearate anion. Fluid Phase Equilib. 376, 132–140 (2014).

Toledo Hijo, A. A. C. et al. Phase behavior and physical properties of new biobased ionic liquid crystals. J. Phys. Chem. B 121, 3177–3189 (2017).

Shekaari, H., Zafarani-Moattar, M. T. & Faraji, S. Thermophysical properties of protic ionic liquids monoethanolamine, diethanolamine, and triethanolamine lactate in water. J. Chem. Eng. Data 66, 1890–1899 (2021).

Matuszek, K., Vijayaraghavan, R., Kar, M. & MacFarlane, D. R. Role of hydrogen bonding in phase change materials. Cryst. Growth Des. 20, 1285–1291 (2019).

Krishna, Y., Saidur, R., Aslfattahi, N., Faizal, M. & Ng, K. C. Enhancing the thermal properties of organic phase change material (palmitic acid) by doping MXene nanoflakes. In AIP Conference Proceedings. Vol. 2233 (AIP Publishing, 2020).

Liu, J. et al. Preparation and energy storage properties of a lauric acid/octadecanol eutectic mixture. ACS Omega 6, 23542–23550 (2021).

Fang, G., Li, H., Chen, Z. & Liu, X. Preparation and properties of palmitic acid/SiO2 composites with flame retardant as thermal energy storage materials. Sol. Energy Mater. Sol. Cells 95, 1875–1881 (2011).

De Ávila, S. G., Logli, M. A. & Matos, J. R. Kinetic study of the thermal decomposition of monoethanolamine (MEA), diethanolamine (DEA), triethanolamine (TEA) and methyldiethanolamine (MDEA). Int. J. Greenh. Gas Control 42, 666–671 (2015).

Alves, C. T., Peters, M. A. & Onwudili, J. A. Application of thermogravimetric analysis method for the characterisation of products from triglycerides during biodiesel production. J. Anal. Appl. Pyrolysis 168, 105766 (2022).

Zhou, D., Zhou, Y., Yuan, J. & Liu, Y. Palmitic acid-stearic acid/expanded graphite as form-stable composite phase-change material for latent heat thermal energy storage. J. Nanomater. 2020, 1–9 (2020).

Tuncbilek, K., Sari, A., Tarhan, S., Ergüneş, G. & Kaygusuz, K. Lauric and palmitic acids eutectic mixture as latent heat storage material for low temperature heating applications. Energy 30, 677–692 (2005).

Li, X., Li, H., Zhang, L. & Liu, Z. Phase change energy storage material suitable for solar heating system. In IOP Conference Series: Materials Science and Engineering. Vol. 301. 12044 (IOP Publishing, 2018).

Acknowledgements

This research is supported by a postdoctoral grant of the University of Tabriz (S/1437).

Author information

Authors and Affiliations

Contributions

All authors reviewed the manuscript. M.M.: Study conception and design, Wrote the main manuscript text, Contributed data or analysis tools; Collected the data. A.R.: Study conception and design, Reviewed the manuscript. H.S.: Study conception and design, Reviewed the manuscript. A.Z.: Contributed data or analysis tools; Performed the analysis. S.F.: Contributed data or analysis tools; Performed the analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mokhtarpour, M., Rostami, A., Shekaari, H. et al. Novel protic ionic liquids-based phase change materials for high performance thermal energy storage systems. Sci Rep 13, 18936 (2023). https://doi.org/10.1038/s41598-023-45549-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-45549-7

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.