Abstract

Dry processing is ineffective in preserving fresh jujubes (Zizyphus jujuba Mill.), contributing largely to the delayed jujube harvest in Xinjiang. However, no studies have evaluated the impact of delayed harvest periods on processing quality. Therefore, the present study investigated the effects of different delayed harvest periods on the characteristics of the quality of jujubes in Xinjiang after hot air drying. Six batches (S1–S6) were sampled over a 7-d period. Various indicators of jujubes changed significantly during the extended harvest period (P < 0.05). The water content of the fruit decreased progressively. While the percentages of soluble solids, total sugars, and reducing sugars increased continuously, the total weight of these parameters in a single jujube fruit decreased continuously. The proportion of ascorbic acid, total weight, and drying time decreased steadily. The fruit had the highest ascorbic acid content at the S4 stage after hot air drying (87.14 mg 100 g−1). Fewer color differences were recorded in hot air-dried fruits as compared with fresh jujubes; the cracking rate decreased after hot air drying, but the fruit could be rehydrated more effectively. A comprehensive evaluation revealed that jujubes harvested in the S4 stage were better suited for dry processing.

Similar content being viewed by others

Introduction

China, being the origin of jujube (Zizyphus jujuba Mill.), produces more than 95% of the world's total amount of jujubes grown each year1. Xinjiang is the largest producer of jujubes in China, with an annual production of nearly 4 million tons owing to its unique geographical and climatic conditions2. This accounts for more than 45% of the overall output in China3 and is primarily composed of the Junzao cultivar and gray jujube. The combined output of the two accounts for more than 90% of the annual jujube production in Xinjiang4. The jujube fruit is large, nutritious, sweet and sour, rich in sugars, organic acids, ascorbic acids, phenolics, and other nutrients5. Fresh jujubes are fermentable due to their high water content and often lose up to 15–30% of their value after harvesting6. Therefore, 95% of jujubes are dried and sold worldwide7. Drying technology for jujube is currently established, with typical drying methods, including hot air8, microwave9, vacuum freezing10, and infrared drying11. Hot air drying has become the primary method for jujube drying in Xinjiang, China, because it does not require specialized equipment, is simple to set up, consumes less energy, and is highly efficient12. Xinjiang jujube is not harvested immediately when ripe. They are dried in the sun, wind, or other natural forces to reduce the water content within the jujube; this process, known as delayed harvest, lasts approximately 40 days. The approach of determining the delayed jujube harvest is based primarily on farmer experience and market demand, and it does not consider the influence on jujube quality, which has yet to be validated.

()Many researchers have investigated how fruit quality changes with growth stage13. Gou Xi et al.14 examined variations in the contents of cyclic adenosine phosphate, soluble sugar (SS), and mineral element of Lingwu jujube at different stages of maturity. Zhang Kekun et al.15 found significant differences in the characteristics of grape (Vitis vinifera L.) quality at different stages of hang-on tree storage. Deng et al.16 investigated the physicochemical parameters and drying kinetics of apricot (Prunus armeniaca L.) fruit at different maturity stages and discovered that the drying rate decreased after a particular stage of maturity. Liu Qinyuan et al.17 revealed that the aroma and color of the finished product differed when peaches (Pr. persica [L.] Batsch) at different levels of maturity were used to manufacture wine. Wang et al.18 evaluated the effects of postharvest ripening on the physicochemical properties, microstructure, cell wall polysaccharide content, and nanostructure of kiwifruit (Actinidia deliciosa [A. Chev] CF Liang et AR Ferguson). Tang Ni et al.19 found that the crude fat and contents of 17 amino acids of different avocado varieties (Persea americana Mill.) achieved peak levels. The optimal harvest period for each avocado variety was determined by monitoring changes in the curve of the content of the components. Hu Can et al.20 investigated the variations in quality and drying kinetics between delayed harvesting and drying of apricots in Xinjiang. Diop Alioune et al.21 assessed drying mangoes (Mangifera indica Linn.) and discovered that the fruit browning was more pronounced as the mangoes ripened; these data demonstrated that ripeness significantly influenced the color of dried mangoes. While the above data strongly demonstrate that the physical and chemical properties and processing characteristics of fruit differ significantly at different stages of harvesting, to our knowledge, no investigations have been reported on potential changes in quality over the jujube drying period.

The present study investigated the effect of different picking stages on the physicochemical and drying characteristics of jujubes. The process from ripening to actual harvest was categorized into six sampling stages, and the content and changes in total sugars (TS) and reducing sugars (RS), SS, titratable acids (TA), and ascorbic acid were analyzed. The drying characteristics of jujube at different picking stages and the retention of nutrient, color, and cracking rate after drying were analyzed using hot air drying to provide a theoretical reference for determining the optimal picking period suitable for drying and processing of jujube.

Materials and methods

Test materials

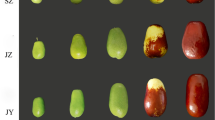

The jujube used in the experiment were harvested from farm No. 8, 10th regiment, Alar City, Xinjiang Uygur Autonomous Region, China (81°12′15.53″E, 40°38′16.21″N), 1,023 m a.s.l. Branches with the same orientation and fruit maturity were selected from 30 jujube trees that were 10 years old and had grown uniformly. Jujubes on the branches were marked (as designated by the Xinjiang Special Forestry and Fruit Industry Export Marketing Board22. The first picking was performed on September 16, 2022, with a 7-d interval for each sample. Six batches of samples, designated S1–S6, were collected. The samples were cleaned with alcohol, sealed, and stored at 4 °C to prevent the loss of moisture and nutrients. Batches of experiments were conducted the next day to minimize errors that occur when sampling the fruit over a longer period. Table 1 depicts the surface conditions of jujubes at different picking stages. Figure 1 depicts the photographs of jujubes at different picking stages in this experiment.

The experimental site was selected from the key Laboratory of Modern Agricultural Engineering, Tarim University, Alar, Xinjiang Uygur Autonomous Region, and the experiment ran from September 16, 2022 to October 30, 2022. All experiments followed the relevant national, international, or institutional guidelines and regulations.

Measurement methods for each indicator

Determination of moisture content and average weight

The weight and moisture content were determined as described by Pu23.

Determination of total sugars and reducing sugars

The TS content was determined as described in GB/T 10782-2021, "General rules for the quality of preserves"24. The RS content was determined using the direct titration method in GB5009.7-2016 "Determination of reducing sugars in foodstuffs"25.

Determination of the titratable acids

Ten jujubes were selected, and 15 g of flesh was randomly weighed from different parts of the fruit and crushed. The TA was determined from the collected filtrate by neutralization titration with sodium hydroxide26. Malic acid was the primary acid in the jujube27.

Determination of the soluble solids (SSC)

Ten jujubes were selected, and 5 g of samples were randomly weighed from various parts of different jujubes and pulverized. The filtrate was collected and deposited in the test area of a hand-held refractometer (LH-Y28, Lu Heng China) for measurement and reading at 22 °C. The results were expressed as a percentage of the total mass fraction.

Determination of ascorbic acid (VC) content

Ascorbic acid content was determined using the 2,6-dichloroindophenol titration method described in GB 5009.86-201628.

Determination of color

The color variation between picked and dried jujubes from S1 to S6 was determined using a spectrophotometer (YS6003, Sanenshi China) and the CIELAB color chart system. The brightness L*, green–red value a*, and blue-yellow value b* were determined. The color difference in values between the colors at the different picking stages and the jujubes dried in hot air were analyzed and calculated as follows29:

where ∆E denotes the value between different colors; ∆L*, ∆a*, and ∆b* denote the difference in color parameters between the fruit picked at stages S2–S6 and S1, respectively.

Drying of jujubes

Drying equipment

Twenty jujubes of roughly the same size, shape, and hardness were selected from each batch, removed from 4 °C storage, brought to room temperature, and wiped dry. The starting weight was the whole weight of the fruit. The drying conditions were set at 65 °C, 1.5 m s−1 wind speed, and 40% relative humidity using a hot air thin layer drying test apparatus (homemade by the Key Laboratory of Modern Agricultural Engineering, Tarim University)30.

The dryer was switched on, and the heating and air supply device was initiated during the trial. After 15 min of operation, the material bin was preheated to set parameters and attain a constant value. The jujubes were then evenly distributed in the drying chamber trays. The weight sensor within the material bin was automatically weighed and recorded every hour. Tray quality was evaluated to determine their real-time moisture content until the dry base of the jujubes reached < 33.3%. The drying test was completed at this point. The fruit was left to cool, and the surface cracks were examined using a stereo microscope. The jujubes were bagged, sealed under a vacuum, and stored at room temperature before testing.

Drying parameters

(1) Moisture content of the dry base

The moisture content of jujubes varies as they dry. \({M}_{t}\) denotes the dry basis moisture content of jujubes at time t, and it is expressed as follows:

where \({G}_{t}\) denotes the total weight of all jujubes in the material tray at time t (g). \({G}_{0}\) denotes the starting weight of all jujubes in the material tray (g), and \({M}_{0}\) denotes the initial wet base moisture content of the jujubes (%).

(2) Drying rate

The drying rate of any stage (Drying rate) is expressed as a function of the moisture content of the dry base at the start and end stages versus time as follows31:

where \({\mathrm{M}}_{{\mathrm{t}}_{1}}\) denotes the dry basis moisture content at the start of the stage. \({\mathrm{M}}_{{\mathrm{t}}_{2}}\) denotes the dry basis moisture content at the end of the stage. \({\mathrm{t}}_{1}\) denotes the start of the phase, and \({\mathrm{t}}_{2}\) represents the end of the stage.

(3) Effective diffusion coefficient of moisture

The effective diffusion moisture coefficient during hot air drying of jujubes was calculated according to Fick's second law equation32:

Where MR represents moisture content ratio; \({\mathrm{D}}_{\mathrm{eff}}\) denotes effective moisture diffusion coefficient (m2 s−1); re denotes volume equivalent radius (m), and t denotes drying time (s).

Simultaneously taking the logarithm of both sides of the equation yields the following:

The slope method was used in calculating the effective diffusion coefficient of moisture. The slope expression from Eq. (5) is as follows:

Observation of the superficial surface cracks

The high heat and mass transfer rate during jujube hot air drying accelerates heat expansion, water loss, and shrinking, which readily cause cracks. The presence of cracks results in nutrient loss, an enrichment of the microbial population and their entry into the fruit, and other conditions that influence drying quality. Each batch included 20 jujubes without initial cracks selected for drying. The surface of the jujubes was examined using a stereomicroscope (TD-2KH, Sanmang Teda China), and the rates of jujube cracking at different picking stages after hot air drying were calculated using the statistical method that is employed to calculate the cracks that occur in hazelnut (Corylus spp.) after drying33.

where P denotes the rate of cracked fruits; \({\mathrm{N}}_{\mathrm{d}}\) denotes the number of stepped jujubes with cracks after hot air drying, and \({\mathrm{N}}_{\mathrm{w}}\) denotes the total number of dried jujubes.

Determination of the rehydration ratio

Rehydration is a crucial indicator of dried jujube quality. Five dried jujube were randomly selected, weighed, and placed at 50 °C for 40 min, dried on absorbent paper, and left to dry for 20 min and re-weighed. The rate of rehydration of jujubes was calculated as follows34:

where R denotes the rehydration ratio; \({\mathrm{M}}_{\mathrm{d}}\) denotes the initial weight, and \({\mathrm{M}}_{\mathrm{w}}\) denotes the weight after rehydration.

Integrated methods of evaluation

The Analytical Hierarchy Process (AHP) was used on a scale of 1–9. A pairwise comparison matrix of the factors was constructed, followed by a consistency test. The indicators used to evaluate the jujubes after hot air drying required normalization. The positive indicators included ascorbic acid content and rehydration ratio after hot air drying, whereas the negative indicators included drying time, cracking rate, and color difference. The normalization formula \({y}_{i}\) is illustrated in Eqs. (9) and (10):

where \({y}_{i}\) denotes the normalized values of the indicators; \({x}_{i}\) denotes the actual values of the indicators, and the \({x}_{max}\) and \({x}_{min}\) denotes the maximum and minimum values of the indicators, respectively.

The combined score for the drying quality of jujubes at different picking stages \(\mathrm{y}\) was determined as follows:

where \({\mathrm{y}}_{1}\) ,\({\mathrm{y}}_{2}\) ,\({\mathrm{y}}_{3}\) ,\({\mathrm{y}}_{4}\) and \({\mathrm{y}}_{5}\) are the normalized values for ascorbic acid content, rehydration ratio, drying time, cracking rate, and color difference, respectively, and \({\mathrm{l}}_{1}\) ,\({\mathrm{l}}_{2}\) ,\({\mathrm{l}}_{3}\) ,\({\mathrm{l}}_{4}\) and \({\mathrm{l}}_{5}\) represent the corresponding weights.

Statistical analysis

The data are expressed as mean ± SD. The data were subjected to a one-way analysis of variance (ANOVA) using SPSS 25.0 (IBM, Inc., Armonk, NY, USA) to examine significant differences in the median fruit index at different harvest periods (P < 0.05). The correlation of fruit quality indices was analyzed using Pearson's method. Furthermore, the correlation Plot plugin in Origin 2018 (OriginLab, Northampton, MA, USA) was employed to generate a correlation heat map of quality indicators. The consistency of the matrix was assessed using MATLAB.

Results and discussion

Moisture content and weight change analysis

The moisture content and weight are the key parameters used to evaluate the growth state of jujubes35. As shown in Fig. 2, the dry basis moisture content and mean weight of jujubes picked at different stages of the delayed harvest period ranged from 208 to 56% and 13.32–29.38 g, respectively. The jujubes were dehydrated during the delayed picking period with significant differences (P < 0.05) between the moisture content and mean weight of those picked at S1–S4. The most significant reduction in water content was observed in stages S2–S3 and S3–S4. The fruit in this ripening period incurred the primary amount of dehydration during the delayed harvest period, compared with those harvested at stages S1–S2. There was less variation in moisture content, and the jujubes weighed less during the S1–S2 stages. These changes potentially occurred because the branches continually supply water and other materials to the fruit36. The range of change in moisture content in the S4-S6 stage decreased significantly (P < 0.05). The surface of the jujube lost water rapidly during this period, and natural environmental factors were insufficient for the internal water of the jujube to rapidly migrate to the surface and diffuse into the air37.

Changes in the contents of nutrients

The total weight of material within a single jujube fruit was used to reveal the changes in the indicators during the delayed harvest periods as the moisture content and average weight of the batches of jujubes continued to decrease.

SS represents solid substances that are water soluble in fruits, including sugars, acids, and trace elements. Sugar is the most essential nutrient and flavoring element in jujube38. As depicted in Table 2 and Fig. 3, the TS and RS ranges of variation were 28.13–56.22% and 16.73–38.02%, respectively, while the SS range was 32.41–63.89%. The percentage content of both the TS and RS increased as the harvest time was extended, possibly due to the evaporation of water in the fruit, resulting in a further concentration of dry matter. Furthermore, the total content within a single fruit increased and decreased, peaking at the S2 stage. The percentage TS content and total content of a jujube within a single fruit showed the highest increase from S1 to S2. Jujube is considered to be in the "reddening stage" and starch is metabolized to SS39. Simultaneously, the total content of compounds in a single jujube decreased at the S2–S6 stages, indicating that the jujubes absorbed internal nutrients during respiration. Fruit metabolism is reduced following a drop in its moisture content, and the loss rate of total nutritional content at each stage similarly decreases with the steady decrease in respiration40.

Ascorbic acid (Vitamin C) is an essential vitamin that the human body cannot synthesize41. The percentage of ascorbic acid varied from 377.25 mg 100 g−1 to 111.61 mg 100 g−1 during delayed harvest, following the same trend as the total content, and demonstrated a distinct declining trend during the S1-S6 stages, as previously described42. A hypothesis exists that the continuous loss of ascorbic acid during ripening and drying is related to its high susceptibility to oxidation.

TA can significantly change the taste of fruit in general43. The level of total TA in a single jujube fruit increased slightly from S1 to S2 throughout the delayed harvest period. The total content of jujube gradually decreased during the S2–S6 stage. Minyan44 et al. also discovered that the titrable acid content of jujube decreased with maturity during the jujube growing phase. As a result, jujube was sweeter and less sour after delayed harvesting, which explains why we selected it as the main raw material for Xinjiang dried fruit processing.

Color changes

The appearance and color of the fruit is the primary determinant of consumer purchase45. Table 3 outlines the change in color at the delayed harvest stage.

The brightness L* of jujubes decreased significantly (P < 0.05) throughout the delayed harvest process in the S1–S4 stage. The S1–S2 stage decreased dramatically from 51.26 to 39.82 due to the green coloration on the epidermis of the S1 stage fruit. The contrast between green and red increased. The brightness in the S2–S4 stage dropped from 39.82 to 31.48 because of the rapid water loss between these stages. The light reflection decreased parallel with water loss from the epidermal cells, and the fruit turned from a luminous maroon to a dull dark red. However, there was no statistically significant change in brightness between the S4 and S6 stages (P < 0.05).

The surface condition of jujubes progressively stabilized after the S4 stage. The red-green value a* was significantly lower in the S1 stage than in the S2–S6 stages. The red-green value a* did not change significantly after the S2 stage, which was consistent with the S1 stage. The "red-change" stage is considered the most critical for changes in the compounds responsible for fruit coloring46. The blue-yellow value b* decreased significantly between S1 and S4 and did not change significantly between S4 and S6, which is consistent with the trend of brightness L*. The chromatic aberration value of the S2–S4 stages increased and stabilized during the S4-S6 stage such that the chromatic aberration value of each stage of S1-S4 was significant. However, there was no significant difference in the S4–S6 stage and these results may be because water content influences the material coloration; water on the surface of the jujube is completely lost after the S4 stage, and the color change remains insignificant. Thus, while differences in fruit coloration might indicate jujube maturity in the growth phase47, they cannot be used as a criterion for the delayed harvest procedure.

Quality correlation analysis

The correlation coefficient between the jujube quality indices at the different stages of delayed harvest is depicted in Fig. 4, and the SS content significantly positively correlated with the TS, RS, TA, red and green values (P < 0.05), and ascorbic acid and blue-yellow values (P < 0.05). Ascorbic acid positively correlated with the TS, RS, red-green values, and TA (P < 0.05), and negatively with the blue-yellow values (P < 0.05). The TS and RS, TA, and red-green values all had a significant positive correlation, whereas the blue-yellow values had a significant negative correlation (P < 0.05). The red-green and blue-yellow values had a significant negative correlation (P < 0.05). In a nutshell, changes in various indicators are co-related rather than independent, exhibiting positive or negative correlations during the delayed harvesting process. The SS comprised soluble sugars, acids, minerals, and other water-soluble compounds, and the SS accounted for the largest proportion. As the harvesting process was delayed, the moisture content of jujubes decreased, while the percentage content of SS, TS, RS, and TA increased. However, the unstable nature of VC increased the rate of loss on the trees throughout the drying process. As a result, VC was a negative correlation with the other nutritional indicators. Brightness and indicators were weakly correlated. There was a high correlation between the blue-yellow and red-green values for the other indicators. Thus, the blue-yellow and red-green values indicate the delayed harvest stages.

Correlation coefficient diagram showing the quality of jujubes at different stages of delayed harvest. Based on Pearson's correlation analysis, red represents positive correlation, blue represents negative correlation, darker colors represent higher correlations, * indicates 0.05 level, and the numbers in the graph indicate correlation coefficients between indicators.

Drying characteristics

Influence of the picking stage on the kinetics of hot air drying of jujubes

Figure 5 depicts the hot air drying rate curves for the different picking stages. The drying time required for each batch of jujubes from S1 to S6 was 22 h, 19 h, 14 h, 10 h, 7 h, and 6 h, respectively. Thus, the overall time for hot air drying decreased as the jujubes from the delayed harvest matured naturally, and the rate of drying of the samples from S1-S4 exhibited an increasing trend and then decreased. The jujubes were in the preheating and initial heating stage at the start of the drying period, and the drying rate increased first. The internal regulation of moisture diffusion decreased at a later stage48. The drying curves of the samples in S5–S6 were more comparable to those of uniform drying, indicating that lowering the initial moisture content hastened the preheating and heating process of the jujubes. It was easier to disperse moisture from the surface of the jujube during hot air drying than it was to move moisture from the interior of the jujube to the surface. However, at the end of drying, the drying rate in the S5–S6 stage was higher than at the S1–S4 stage.

Along with the characteristics of shrinkage of the porous media that holds moisture during drying, the high initial moisture content of jujube is regarded to be more destructive to the tissue structure during hot air drying due to the long drying period and quick rate of mass transfer. Furthermore, the drying rate inside the early drying stage is substantially lower than that on the surface of the jujube. Uneven water migration produces biological stress, causing the jujube to shrink, deform, and eventually destroy the water migration channel. Shrinkage of jujubes with a low initial moisture content is not readily visible due to slower heat and mass transfer, better preservation of the pore structure of the flesh, and increased efficiency of water passage during delayed harvest periods.

Effect of the picking stage on the effective diffusion coefficient of water in jujubes

The effective moisture diffusion coefficient reflects how rapidly moisture inside the material migrates to the surface during the drying process, which is influenced by the changes in material structure, moisture content, and drying temperature. The results are shown in Table 4. The effective moisture diffusion coefficient ranged from 9.3621 × 10−10 m2 s−1 to 10.7400 × 10−10 m2 s−1 from S1 to S6, exhibiting an increasing trend followed by a decreasing trend43. These data suggest that jujubes picked in the early stages have a high initial moisture content and rapid water diffusion during the initial drying stage; on the other hand, they produce severely wrinkled and crusted fruit, which distorts and damages the internal water transfer channels, reducing water diffusion. In contrast, jujubes picked too late exhibited a comparably slow water diffusion mechanism owing to their low initial moisture content and water primarily bonded internally. Jujubes e picked at S4 during the delayed harvest process had the highest effective water diffusion coefficients due to variations in moisture content and cracking.

Drying quality of jujube at different picking stages

Cracking rate of jujube after hot air drying at different stages

The formation of drying cracks is related to the drying method, moisture content, mechanical properties, and tissue structure of the material49. The cracking rate of jujubes during hot air drying continuously decreased with the prolonged picking stage. The early stage of hot air drying is the primary stage in which cracks form, and a higher initial moisture content increases the likelihood of crack formation in the early stage. The cracking rate of jujubes at the end of drying was 16.7%, 13.3%, 11.6%, 5.0%, 0%, and 0% at initial dry base moisture contents of 208%, 158%, 111%, 78%, 63% and 56%, respectively (Table 5). It is believed that hot air drying of jujubes with a high moisture content (S1–S3) heats the internal water in the fruit, which rapidly vaporizes. Figure 6a depicts the condition of fresh jujube before drying. The fruit could not completely discharge the water in time, causing internal expansion and cracking of the peel under stress (Fig. 6b). This phenomenon generally occurs during the accelerated drying phase. Owing to the strong water ability of the crack site to secure the water molecules, the mass transfer rate of the cracked area will be significantly higher than that of the rest of the area (Fig. 6c), resulting in crack diffusion, juice outflow, linear deep shrinkage, and other conditions that impact drying quality (Fig. 6d). Therefore, the drying process parameters, including low temperatures and increased humidity, should be regulated when jujubes have high moisture to limit the heat mass transfer rate of the surface during the early drying phase.

Comprehensive evaluation of the delayed harvest stages

As illustrated in Table 6, the average quality of hot air-dried jujube at each picking stage ranged between 11.29 and 13.25 g. Considering the changes in the nutrient content of fresh fruits at different stages and the actual drying conditions, it is believed that jujubes at the picking stage have a high initial moisture content, an extended hot air drying time, and a rapid heat and mass transfer rate, resulting in the thermal decomposition and sugar precipitation11. In contrast, low moisture content impacts the quality of jujube after drying due to nutrient depletion by respiration during the delayed harvest process. Unlike heat-tolerant substances such as sugars, ascorbic acid is highly vulnerable to oxidation and thermal degradation during high-temperature drying; determining ascorbic acid concentrations is better suited to evaluating the quality of dried fruit50. In the present investigation, because the weight after drying differed significantly (P < 0.05), we determined the mass of ascorbate in a single dried fruit by multiplying the percentage of ascorbate measured by the mass after drying. The initial content of ascorbate decreased with the extension of the picking stage; however, the rate of ascorbate retention increased owing to the reduction in hot air drying time required. Surface water evaporation and chemical reactions such as enzymatic browning, non-enzymatic browning, and caramelization reactions can cause differences in the color of jujubes during high-temperature drying51. The color of jujube was compared before and after drying. The results revealed that the brightness L* of jujube in the S1-S3 stage decreased by 34%, 32%, and 21.3% during the different stages, respectively, whereas the brightness L* of jujube in the S4-S6 stage did not change significantly. These data demonstrated that hot air drying potentially influenced the brightness L*, and a higher moisture content resulted in a longer drying time and a higher degree of influence. However, the L* of the S1 stage remained the highest. The red and green value a* improved significantly during the S1 stage, i.e., the green faded and the red colors brightened compared with before drying, and there was no significant change in the other stages. These observations indicated that hot air drying primarily influenced the contents of green compounds on the jujube surface34. The blue-yellow value b* of the samples at each picking stage after drying was significantly the highest in S1 and the lowest in S6 (P < 0.05), comparable to before drying. Furthermore, there was no significant variation in color at each stage after drying (P < 0.05). Rehydration reflects the structural damage of the jujubes after drying. The jujube harvested at the S4–S6 stage rehydrated the fastest after drying, while that picked at the S1–S2 stage rehydrated the slowest. It is considered that the rapid thermal expansion and water-loss shrinkage during the hot air drying of jujube with a high initial moisture content caused more irreversible damage to the tissue structure of fruit and a poor intercellular water storage capacity52. The five indicators described above were combined with the drying time and the crack rate to assess jujube quality after hot air drying.

These five indices, combined with the drying time and crack rate, defined the quality of jujube after drying. A consistency test was performed after constructing a pairwise comparison matrix of factors using the 1–9 ratio scale approach. The weights of ascorbic acid content, rehydration ratio, drying time, crack rate, and color difference were set at 0.3, 0.15, 0.3, 0.15, and 0.1, respectively53. The comprehensive scores of hot-air drying quality at the picking stages of S1–S6 were 0.15, 0.27, 0.58, 0.79, 0.73, and 0.59, respectively (Table 7). While the jujubes picked in the earlier stages had a standard coloration and the drying time and crack rate of the jujubes picked in the later stages were lower, the overall quality of the samples picked in the S4-S5 stage remained the highest. Therefore, the Jun jujubes picked at this stage were more suited for drying and processing.

Conclusions

The delayed harvest stage substantially influenced the nutrient and hot air drying characteristics of jujubes, with varied patterns of change for each indicator. The percentages of SS, TS, and RS increased as the picking stage was delayed, while the total weight in individual fruits increased and subsequently decreased until peaking at the S2 stage. There was a distinct drop in the proportion of ascorbic acid and weight within a single fruit at this stage. At the same time, the percentage of TA did not vary considerably. Additionally, the weight of a single fruit decreased, the sugar-acid ratio continually increased, and the fruit tasted sweeter. The brightness of fruit dropped progressively with picking time, and there was no discernible difference beyond the S4 stage. The time required for hot air drying at each stage gradually decreased, but the amount of ascorbic acid in the fruit gradually increased. The level of ascorbic acid in the jujube fruit was the highest after stage S4. Stereomicroscopy examination of the surface cracks of jujube fruits after drying revealed that jujubes picked in the S4-S5 stage cracked less frequently. The trend of change in water rehydration was comparable to the trend of crack generation. The changes in hot air drying and quality characteristics were integrated, and the jujubes picked at the S4 stage were deemed better suited for subsequent hot air drying processing.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Xinjiang Uygur Autonomous Region Bureau of Statistics. Xinjiang Statistical Yearbook (China Statistics Press, 2020).

Production, X. & Bureau, C. C. S. Statistical Yearbook of Xinjiang Production and Construction Corps (China Statistics Press, 2020).

Hu, D., Ren, Z. J., Li, H. & Jing, M. Xinjiang jujube industry: Development trend and pillar status. Xinjiang Agric. Reclam. Sci. Technol. 45, 1–3 (2022).

Bao, Y., Cheng, H. & Zhang, L. Research on the development of red jujube industry in Xinjiang. Rural Econ. Technol. 33, 146–152 (2022).

Wang, J., Zhang, B. S. & Chen, J. P. Studys on the nutritional composition and functions of red jujube. Food Res. Dev. 02, 68–72 (2003).

Liu, L. G. et al. Experimental study on hot air drying process of jujube. Agric. Mech. Res. 39, 258–263 (2017).

Ren, S. W., Li, C. F., Li, B., Ren, Y. Q. & Ma, B. Application of infrared heating technology in the processing of jujube. Food Ind. 41, 250–253 (2020).

Niu, Y. B. et al. Effect of RF-assisted hot air drying on the textural properties and microstructure of crispy red jujube slices. J. Agric. Eng. 38, 296–306. https://doi.org/10.11975/j.issn.1002-6819.2022.02.033 (2022).

Li, F., Shao, P. L., Han, Y. T., Xie, H. & Zhang, L. F. Effect of drying methods on the content of pigment active ingredients and antioxidant activity of red jujube. Food Sci. Technol. 44, 120–124. https://doi.org/10.13684/j.cnki.spkj.2019.01.022 (2019).

Guo, W. B., Zheng, X., Guo, J. Y., Li, J. & Chen, G. G. Research on processing technology of vacuum freeze-dried jujube powder. Food Ind. 37, 95–99. https://doi.org/10.1016/J.ULTSONCH.2022.106219 (2016).

Wang, K. H. et al. Effect of RF treatment on kinetics and quality characteristics of red jujube dried in short and medium wave infrared. Food Sci. 41, 117–123. https://doi.org/10.7506/spkx1002-6630-20190403-045 (2020).

Liu, D. C. et al. Research progress of red jujube drying technology and equipment. Agric. Mech. Res. 44, 8–18. https://doi.org/10.13427/j.cnki.njyi.2022.01.002 (2022).

Xu, X. G. et al. Application of two-stage variable temperature drying in hot air-drying of paddy rice. Foods. 11, 888. https://doi.org/10.3390/foods11060888 (2022).

Gou, X. et al. Studys on the edibility and nutritional quality of Lingwu long jujube at different maturity levels. Mod. Food Sci. Technol. 30, 98–104. https://doi.org/10.13982/j.mfst.1673-9078.2014.11.019 (2014).

Zhang, K. K. et al. Changes in fruit quality of “Italian” grapes during storage in delayed cultivation hanging trees. J. Hortic. 43, 853–866. https://doi.org/10.16420/j.issn.0513-353x.2015-0702 (2016).

Deng, L. et al. Effects of ripening stage on physicochemical properties, drying kinetics, pectin polysaccharide contents, and nanostructure of apricots. Carbohydrate Polymers. 222, 114980. https://doi.org/10.1016/j.carbpol.2019.114980 (2019).

Liu, Q. Y., Weng, P. F. & Wu, Z. F. Quality and aroma characteristics of honey peach wines as influenced by different maturity. Int. J. Food Propert. https://doi.org/10.1080/10942912.2020.1736094 (2020).

Wang, H. et al. Effects of postharvest ripening on physicochemical properties, microstructure, cell wall polysaccharide contents (pectin, hemicellulose, cellulose) and nanostructure of kiwifruit (Actinidia deliciosa). Food Hydrocolloids. 118, 106808. https://doi.org/10.1016/j.foodhyd.2021.106808 (2021).

Tang, N. et al. Studys on the change of nutrient content during the development of avocado fruit. Guangxi Plant. 24, 1–14. https://doi.org/10.11931/guihaia.gxzw202201025 (2022).

Hu, C. et al. Experimental characterization and mathematical modelling of natural drying of apricots at low temperatures. Agriculture 2022, 12. https://doi.org/10.3390/agriculture12111960 (1960).

Diop, A. et al. Impact of special drying schemes on color stability of mangoes with different maturity degrees. Foods. 11, 656. https://doi.org/10.3390/foods11050656 (2022).

Wu, M. Q., Li, C. F., Luo, H. P., Yi, X. K. & Chen, K. J. Physical characteristics of different grades of Xinjiang steamed jujube and their influence on grading results. J. Agric. Mach. 49, 324–330. https://doi.org/10.6041/j.issn.1000-1298.2018.08.038 (2018).

Pu, Y. et al. Effect of harvest, drying and storage on the bitterness, moisture, sugars, free amino acids and phenolic compounds of jujube fruit (Zizyphus jujuba cv Junzao). J. Sci. Food Agric. 98, 628–634. https://doi.org/10.1002/jsfa.8507 (2018).

GB/T 10782-2021, General rules for the quality of candied fruit. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Available online: https://openstd.samr.gov.cn/bzgk/gb/newGbInfo (accessed on 1 April 2022)

GB 5009.7–2016, National standard for food safety Determination of reducing sugars in foods. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Available online: http://down.foodmate.net/standard/sort/3/49327.html

GB 12456–2021, National Standard for Food Safety Determination of total acids in foods. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Available online: http://down.foodmate.net/standard/sort/3/97830.html

Sun ,M.M. Research on the quality evaluation system of dried jujubes. Northwest University of Agriculture and Forestry Science and Technology, 2016.

GB 5009.86–2016, National standard for food safety Determination of ascorbic acid in foods. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Available online: https://www.antpedia.com/standard/1489571510-1.html

Xiao, H. W. et al. Color change kinetics of American ginseng (Panax quinquefolium) slices during air impingement drying. Dry. Technol. 32, 418–427. https://doi.org/10.1080/07373937.2013.834928 (2014).

Wang, L., Hu, C., Li, C. F., He, X. W. & Yi, X. K. Experimental study of hot air drying process and shrinkage characteristics of red jujube. Chin. J. Agric. Chem. 41, 79–82. https://doi.org/10.13733/j.jcam.issn.2095-5553.2020.01.14 (2020).

Lu, J., Sun, J. F., Wang, J., Yuan, Z. L. & Liu, Z. Q. Effect of hot air drying on the quality of Fuping jujube and its mathematical model construction. Food Ind. Sci. Technol. 34, 97–102. https://doi.org/10.13386/j.issn1002-0306.2013.01.051 (2013).

Qian, J. Y. et al. Effects of three drying techniques on the drying characteristics and quality of red jujube crisps. J. Agric. Eng. 32, 259–265. https://doi.org/10.11975/j.issn.1002-6819.2016.17.034 (2016).

Wang, W. J., Tang, J. M. & Zhao, Y. Y. Investigation of hot-air assisted continuous radio frequency drying for improving drying efficiency and reducing shell cracks of inshell hazelnuts: The relationship between cracking level and nut quality. Food Bioprod. Process. https://doi.org/10.1016/j.fbp.2020.10.013 (2021).

Reche, J., Almansa, M. S., Hernández, F., Amorós, A. & Legua, P. Physicochemical and antioxidant capacity of jujube (Ziziphus jujuba Mill) at different maturation stages. Agronomy 11, 132. https://doi.org/10.3390/agronomy11010132 (2021).

Wang, N. et al. Drying kinetics and quality characteristics of daylily dried by mid-infrared. Int. J. Food Eng. https://doi.org/10.1515/ijfe-2021-0137 (2021).

Chen, K., Fan, D., Fu, B., Zhou, J. & Li, H. Comparison of physical and chemical composition of three chinese jujube (Ziziphus jujuba Mill.) cultivars cultivated in four districts of Xinjiang region in China. Food Sci. Technol. 39, 912–921. https://doi.org/10.1590/fst.11118 (2019).

Guo, H. L. et al. Assessment of drying kinetics, textural and aroma attributes of Mentha haplocalyx leaves during the hot air thin-layer drying process. Foods https://doi.org/10.3390/foods11060784 (2022).

Niu, H. et al. Effects of harvest maturity and storage time on storage quality of korla fragrant pear based on grnn and anfis models: Part I firmness study. Food Sci. Technol. Res. 26(3), 363–372. https://doi.org/10.3136/fstr.26.363 (2020).

Han, Q., Zhang, Y. & Feng, J. Study on postharvest physiology and key techniques of air conditioning storage of winter jujube. Food Ferment. Ind. 47(04), 33–39. https://doi.org/10.13995/j.cnki.11-1802/ts.024919 (2021).

Yu, D., Zhi, H. & Rachel, L. Physiological disorders, textural property, and cell wall metabolism of “Gem” pears (Pyrus communis L.) affected by oxygen regimes and harvest maturity under controlled atmosphere storage. Scientia Horticulturae https://doi.org/10.1016/j.scienta.2023.112067 (2023).

Wang, L. et al. Characterization of genes involved in pear ascorbic acid metabolism and their response to bagging treatment during “Yali” fruit development. Sci. Hortic. 285, 110178. https://doi.org/10.1016/j.scienta.2021.110178 (2021).

Zhang, Q. Variations of the nutritional composition of jujube fruit (Ziziphus jujuba Mill.) during maturation stages. Int. J. Food Prop. 23, 1066–1081. https://doi.org/10.1080/10942912.2020.1770281 (2020).

Wang, J. Q. et al. Effect of maturity on the kinetics of vacuum pulsation, drying, and product quality of jujube. J. Agric. Eng. 37, 273–279. https://doi.org/10.11975/j.issn.1002-6819.2021.23.032 (2021).

Yan, M. et al. Physicochemical and antioxidant activity of fruit harvested from eight jujube (Ziziphus jujuba Mill.) cultivars at different development stages. Sci. Rep. 12, 2272. https://doi.org/10.1038/s41598-022-06313-5 (2022).

Souhila, G., Brigitte, R., Martin, M. & Nico, G. A rapid tool for the stability assessment of natural food colours. Food Chem. 139, 1–4. https://doi.org/10.1016/j.foodchem.2012.12.064 (2013).

Reche, J., Almansa, M. S., Hernández, F., Amorós, A. & Legua, P. Physicochemical and antioxidant capacity of Jujube (Ziziphus jujuba Mill.) at different maturation stages. Agronomy 11, 132. https://doi.org/10.3390/agronomy11010132 (2021).

Zhao, J. L. et al. Postharvest physiological studies on pear and jujubes. Northwest J. Agric. 11, 61–63 (2002).

Chen, Q. et al. Drying kinetics and quality attributes of jujube (Zizyphus jujuba Miller) slices dried by hot-air and short- and medium-wave infrared radiation. LWT Food Sci. Technol. https://doi.org/10.1016/j.lwt.2015.06.071 (2015).

Zheng, Z. H. et al. Effect of glass transition on drying crack formation of maize kernels. Biosyst. Eng. https://doi.org/10.1016/j.biosystemseng.2022.08.002 (2022).

Bai, J. W., Gao, Z. J., Xiao, H. W., Wang, X. T. & Zhang, Q. Polyphenol oxidase inactivation and vitamin C degradation kinetics of F uji apple quarters by high humidity air impingement blanching. Int. J. Food Sci. Technol. https://doi.org/10.1111/j.1365-2621.2012.03193.x (2013).

Li, Q. Y., Fu, T., Sun, Y., Lian, H. X. & Gao, T. Y. Effect of Merad reaction on silage quality of alfalfa. J. Livestock Ecol. 33, 73–76. https://doi.org/10.1016/J.JAFR.2022.100409 (2012).

Kim, S. Y. et al. A Pulsed electric field accelerates the mass transfer during the convective drying of carrots: Drying and rehydration kinetics, texture, and carotenoid content. Foods. 12, 589. https://doi.org/10.3390/FOODS12030589 (2023).

Zhang, W. P., Gao, Z. J. & Xiao, H. W. Drying characteristics of Poria Cocos under different drying methods based on Weibull function. Trans. Chin. Soc. Agric. Eng. 31(05), 317–324. https://doi.org/10.3969/j.issn.1002-6819.2015.05.044 (2015).

Acknowledgements

A preprint version of this article has been posted 09 Mar, 2023. https://doi.org/10.21203/rs.3.rs-2651017/v1.

Funding

This work was supported by National Natural Science Foundation of China. Grant Number 32160427; Graduate Research and Innovation Project of Tarim University, Grant Number TDGRI202248.

Author information

Authors and Affiliations

Contributions

Resources, Q.Y.; data curation, J.L.; Writing-original draft preparation, C.X.; Writing-review and editing, X.Y.; visualization, Y.Y. and J.Z. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, C., Yi, X., Hu, C. et al. Analysis of the changes in quality and characteristics of hot air drying of Xinjiang jujube (Zizyphus jujuba Mill. cv. Junzao) following a delayed harvest. Sci Rep 13, 16732 (2023). https://doi.org/10.1038/s41598-023-43594-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-43594-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.