Abstract

To improve the CO2/N2 separation performance of metal–organic frameworks (MOFs), amine functionalized deep eutectic solvents (DESs) (choline chloride/ethanolamine (DES1), choline chloride/ethanolamine/diethanolamine (DES2), and choline chloride/ethanolamine/methyldiethanolamine (DES3)) confined in the NH2-MIL-53(Al). NH2-MIL-53(Al) impregnated with DES was synthesized and characterized using N2-sorption analysis and Fourier transform infrared (FTIR) spectroscopy. Morphology of the synthesized MOFs was investigated using scanning electron microscopy (SEM). Also, elemental analysis was determined by energy-dispersive X-ray spectroscopy (EDX). CO2 adsorption isotherms of amine-functionalized DESs impregnated NH2-MIL-53(Al) were measured at temperatures range of 288.15–308.15 K and pressures up to 5 bar. The results reveal that the impregnated MOF with functional group of amine DES improves separation performance NH2-MIL-53(Al). CO2 adsorption capacity of DES1/NH2-MILS-53(Al) was twofold respect to of pristine NH2-MIL-53(Al) at 5 bar and 298.15 K; which helps to guide the logical design of new mixtures for gas separation applications. Also, the heat of adsorption for the synthesized NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) were estimated. Most importantly, CO2 chemisorption by NH2 group in the sorbent structure has a significant effect on the adsorption mechanism.

Similar content being viewed by others

Introduction

One of the most significant challenges of world is climate change which its prevention and modification received widespread attention. Rapid economic growth and ongoing industrial development have resulted in an increase in the atmospheric carbon dioxide (CO2) concentration from 270 ppm before the industrial revolution to 400 ppm now1,2. Hence, the emission of CO2 has received widespread concern own to its ecosystem changes and environmental effects3. Rising global temperatures about 2 °C by the end of this century pose an urgent threat to the planet. The temperature increase of the earth is attributed to the greenhouse gases, of which CO2 accounts for more than 70% of the total4. To overcome these troubles, the carbon capture and storage concept (CCS) was offered to control the CO2 amount in the atmosphere5. As a key step in CCS, CO2 is required to be captured from CO2 emissions.

Technologies to separate CO2/N2 include membrane separation, molecular sieves, cryogenic separation, and absorption6,7,8,9. Current technologies employ aqueous amine solutions (monoethanolamine, diethanolamine and methyldiethanolamine), which adsorb CO2 at ambient temperature in a thermally reversible manner10. Though this adsorption system has numerous advantages such as high reactivity, low cost and good adsorption capacity, it presents some serious disadvantages including solvent loss, emission of VOCs, corrosion and high energy required for the stripping of CO211.

To overcome these disadvantages new technologies must be developed. Among the above-mentioned technologies, molecular sieves are of high interest due to the differences in the molecular size, diffusion, and gases affinity. Adsorption and separation of CO2 using porous, solid adsorbents as an alternative for amine-based absorption/stripping processes has received much attention during the past decade. Metal–organic frameworks (MOFs), Zeolites, mesoporous silicas, and active carbons adsorbents have been tested for their CO2 adsorption behavior12,13.

Grafting of amines onto surfaces of porous materials to enhance adsorption of the acidic CO2 molecule is another strategy that has been applied for silica-based sorbents and zeolites14,15. Arstad et al.16 reported CO2 adsorption isotherms on three new types of amine-functionalized MOFs. Adsorption capacities of up to 60 wt % were obtained. Dautzenberg et al.17 have studied aromatic amine-functionalized covalent organic frameworks (COFs) for CO2/N2 separation, The COF shows a high CO2/N2 IAST selectivity under flue gas conditions (273 K: 83 ± 11, 295 K: 47 ± 11). The interaction of the aromatic amine groups with CO2 is based on physisorption, which is expected to make the regeneration of the material energy efficient. Ariyanto et al.18 have studied DES-impregnated porous carbon which derived from the palm kernel shell for the separation of CO2/CH4. They indicated that separation performance increased in comparison to pristine porous carbon. Lin et al.19 have investigated CO2 capture in DES (choline chloride + ethylene glycol) confined into the graphene oxide (GO) with different HBA/HBD molar ratios by molecular dynamics simulation method and concluded that GO provides nanoconfined space for the DES. However, the isotherm data for DESs impregnated on MOFs for separation process is scarce. Metal–organic frameworks (MOFs) are a category of porous materials, which their structure is composed of metal ions networks or metal ion clusters and organic linkers connected through coordination bonds. MOFs own a high internal surface area, tunable multifunctional pores, adaptable porosity, and high thermal and chemical stabilities problems20,21. However, the capacity of adsorption of CO2 in MOFs is quite low, and hence an enhancement is required. To improve the CO2 adsorption capacity, the modification of MOFs using amines particularly monoethanolamine (MEA) can be performed because of availability, low cost, low viscosity, and high affinity to CO222,23. However volatile and corrosive nature are disadvantages of amines which led to an unsavory process. Thus, researchers have offered more efficient sorbents such as ionic liquids (ILs) and deep eutectic solvents (DESs) as potential alternatives for conventional amine solutions24,25. DESs due to unique properties including high solvation capacity, relatively low cost, higher biodegradability, and nontoxic make them environmentally and technologically superior alternatives to highly expensive ionic liquid26. In this research, three-component DESs were prepared by choline chloride:ethanolamine (1:7) (DES1), choline chloride: ethanolamine:diethanolamine (1:7:1) (DES2) and choline chloride:ethanolamine:methyldiethanolamine (1:7:1) (DES3). NH2-MIL-53(Al) is composed of octahedral AlO4(OH)2 linked by a free-standing amine group27. In addition, NH2-MIL-53(Al) has high pore volume, surface area, and thermal stability28. Also, the terephthalate ligands in NH2-MIL-53(Al) can increase their compatibility with the DESs. In order to, DESs-impregnated NH2-MIL-53(Al) was synthesized for CO2 adsorption. The CO2 adsorption in these DESs-impregnated NH2-MIL-53(Al) was measured using quartz crystal microbalance (QCM). To study the potential of the material for separation purposes, adsorption isotherms were investigated. A novel hybrid model has been offered for correlating CO2 isotherm. In addition, CO2/N2 selectivity was carried out to examine the practical efficacy of the prepared adsorbents.

Experimental

Materials

Aluminum nitrate nonahydrate (Al(NO3)3·9H2O) (> 99% purity), 2-amino terephthalic acid (NH2-H2BDC ≥ 99%), Choline chloride (> 99% purity), Ethanolamine (EA) (≥ 98% purity), diethanolamine (DEA)(≥ 98% purity), and methyldiethanolamine (MDE) (≥ 99% purity) were purchased from Sigma–Aldrich products. N,N-Dimethylformamide (DMF) (99% purity), Ethanol (> 99% purity) were supplied by Merck. CO2 gas (> 99.9% purity) was used in gas absorption tests.

Synthesis of the DES

In this study, DES based on choline chloride as the HBA and ethanolamine, ethanolamine/diethanolamine, and ethanolamine/methyldiethanolamine as the HBD with special ratio were mixed to determine mole ratios under stirring at 360 K for about 2 h. Then obtained homogeneous solution had melting points below room temperature. The mole ratio of (HBA: HBD) and the melting point of DESs prepared are tabulated in Table 1 which resulted in good agreement with the literature29.

Synthesis of NH2-MIL-53(Al) and DES-confinement in NH2-MIL-53(Al)

Hydrothermal technique was used to synthesis NH2-MIL-53(Al). for this purpose, 6.71 g of aluminum nitrate (Al(NO3)3·9H2O) was mixed with 3.74 g of 2-aminoterephthalic acid (NH2-H2BDC) and 50 mL of deionized water in a Teflon-lined autoclave at 423 K for 5 h. The obtained product was washed with acetone several times. The synthesized NH2-MIL-53(Al) was treated at 423 K for about 48 h in DMF to eliminate the unreacted and trapped NH2-H2BDC in the pores30. DESs solution in ethanol with a ratio of 1:1 wt/vol was impregnated in NH2-MIL-53(Al) using a vacuum impregnation method. To removal of ethanol, the obtained slurry was dried in oven at 378 K for 24 h.

Characterization of MOF

A FT-IR (Bruker, Tensor 27) spectrometer was used to recording the FT-IR spectra of NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al). The morphology of synthesized MOF was investigated using providing FESEM images (EDX & Map & Line). X-ray diffraction (XRD) analysis (SHIMADZU, Labs XRD-6100) was conducted to determine particle size and crystalline structure. EDX spectra was recorded at 10 keV to distinguish the Al of the MOF. Nitrogen adsorption/desorption isotherms were recorded at 77 K (BELSORP MINI II instrument). The samples were degassed at 120 °C under vacuum condition for 10 h prior to the measurements. The BET surface area of the NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) were obtained by measuring the nitrogen adsorption at 77 K.

Gas adsorption apparatus

Gas adsorption measurements were done by QCM sensor. Detail of adsorption apparatus performance has been explained in the prior papers by authors31,32,33,34,35. The adsorption capacity, \(Q_{e}\) \(\left( {{\text{mg}}_{{{\text{CO}}_{{2}} }} \cdot {\text{g}}_{{\text{DESs/MOF}}}^{{ - {1}}} } \right)\) was calculated as follows:

where \(\Delta F_{C}\) frequencies difference between the coated crystal with adsorbent and the uncoated crystal. \(\Delta F_{S}\) is the difference between the frequencies adsorbent coated crystal under vacuum and after CO2 adsorption.

Thermodynamic model

The CO2 experimental isotherms achieved on NH2-MIL-53(Al) in this study are correlated to the three-parameter Redlich–Peterson (R–P) model as follows36:

where Q related to the amount of adsorption per mass of adsorbent \(\left( {{\text{mg}}_{{{\text{CO}}_{{2}} }} \cdot {\text{g}}_{{\text{DESs/MOF}}}^{{ - {1}}} } \right)\), p is gas pressure at equilibrium condition, n is the dimensionless adsorbent parameter and its value was considered as n = 1 in this study, also Qm and c are parameters of model. Moreover, to correlate the experimental data of CO2 solubility in DESs-impregnated on MOF a hybrid law of Henry and Redlich–Peterson (R–P) model are used as below:

where H is the CO2 Henry’s law constant.

The adsorption selectivity for CO2/N2 was calculated as follows:

where \(Q_{{CO_{2} }}\) and \(Q_{{N_{2} }}\) are adsorbed values of CO2 and N2, respectively.

Results and discussion

Characterization

FT-IR spectra

The FT-IR spectra of the NH2-MIL-53(Al) and DES-impregnated on NH2-MIL-53(Al) are illustrated in Fig. 1. As seen from Fig. 1 the symmetric and anti-symmetric N–H and O–H stretching vibrations of DESs are observed at 3300–3500 cm−1 and the single C-H stretching vibration is located at 2880–2950 cm−1. C–N vibration is observed at 1086 cm−1. Also, analysis of FT-IR peaks in Fig. 1d indicates the peak at 3400 cm−1 is related to the presence of NH2 group MOF. The characteristic peaks at 1612 cm−1 and 1402 cm−1 are corresponding to the carboxylic acid which coordinated to Al37. Also, the peak at 1240 cm−1 is attributed to the C–N bending and the band observed at in the range of 965 cm−1 is attributed to aromatic C–H in-plane bending. Moreover, another band 629 cm−1 correspond with previous observations for MIL-5338. The characteristic peaks of both DESs and MOF are observed in DESs/NH2-MIL-53(Al) (Fig. 1e–g) which is imply to success impregnation of DESs in MOF.

X-ray diffraction (XRD)

The crystalline structure of NH2-MIL-53(Al) and DES/NH2-MIL-53(Al) were investigated using XRD spectra. XRD pattern of NH2-MIL-53(Al) and DES1/NH2-MIL-53(Al) powder are illustrated in Fig. 2. From Fig. 2, it can be observed that the powder sample shows XRD peaks at 2θ values of 8.1°, 12.4°, 17.5°, 24.5° and 25.9° which confirmed the structure of NH2-MIL-53(Al)39. The characteristic peaks of NH2-MIL-53(Al) and DES1/NH2-MIL-53(Al) are observed at the same angles which imply that crystalline structure of MOF remain unchanged during DES impregnation. However after impregnation the related peaks are broadened which attributed to the decreasing crystallinity degree.

EDX pattern

The distribution of different elements in NH2-MIL-53(Al) was identified by EDX analysis. The pattern corresponding to the characteristic elements of NH2-MIL-53(Al) is illustrated in Fig. 3. The results of the characteristic elements indicate that the mass fraction of C and N is 56.52% and 8.59%. The corresponding molar ratio of C to N is equal to 6.58, which is close to the molar ratio of C to N in the NH2-H2BDC structure. These results indicate the purity of the prepared NH2-MIL-53 (Al) phase.

Scanning electron microscopy

Crystal morphology and size of the products were determined using SEM. SEM image of the NH2-MIL-53(Al) is depicted in Fig. 4. As seen in the SEM image, the NH2-MIL-53(Al) indicates a three-dimensional hexahedral structure with good regularity.

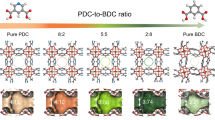

Textural properties of NH2-MIL-53(Al)

Nitrogen adsorption isotherms at 77 K were used to analyze the samples' textural characteristics, such as their specific surface area (ABET), micropore volume (VMP), and total pore volume (VP). As depicted in Fig. 5, typical of microporous crystalline materials were obtained Type Ib isotherms40. In other words, the N2 isotherm of NH2-MIL-53(Al) showed hysteresis behavior. The NH2-MIL-53(Al) and DESs-impregnated NH2-MIL-53(Al) samples displayed high volume adsorption at extremely low pressures, virtually achieving the maximum adsorption capacity. According to the isotherm of DES3-impregnated NH2-MIL-53(Al), the sample had a low capacity for adsorption and a rise in adsorbed volume at relative pressures above 0.9, which are signs of macropore filling that may be caused by interstitial gaps. The textural properties of NH2-MIL-53(Al) and DES/NH2-MIL-53(Al) are reported in Table 2. The micropore volume and BET surface area of MOF is comparable with values reported in the literature28,41. The textural properties indicated that the impregnation procedure decreased the values of micropore volume, specific surface area and total pore volume relative to the original NH2-MIL-53(Al) sample. Moreover, DES3/NH2-MIL-53(Al), the higher the reduction in textural parameters and N2 adsorbed volume at 77 K. This behavior reveals that DES molecules were incorporated in the pores of NH2-MIL-53(Al) because of the impregnation process.

Adsorption isotherms

CO2 and N2 gas adsorption in NH2-MIL-53(Al) and DESs-impregnated NH2-MIL-53(Al) were measured at range temperature of 288.15–308.15 K and pressure of up to 5 bar. The CO2 and N2 gas adsorption data are tabulated in Tables 3 and 4. The experimental data of CO2 and N2 gas adsorption in NH2-MIL-53(Al) and DESs-impregnated NH2-MIL-53(Al) is correlated by the hybrid model. The parameters of the Redlich–Peterson (R–P) model \(q_{m}\) and c, and Henry’s constant (H), for CO2 and N2 on the synthesized NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) are reported in Tables 5 and 6, respectively. The absolute average relative deviation is lower than 0.02, which implies to suitable capability of the proposed model. The calculated data indicate that the amount of CO2 adsorbed was more than the amount of N2 adsorbed. According to the data, the DESs-impregnated NH2-MIL-53(Al) exhibit stronger adsorption and increases the CO2 adsorption capacity. NH2-MIL-53(Al) has a CO2 adsorption capacity of 28.87 \({\text{mg}}_{{{\text{CO}}_{{2}} }} \cdot {\text{g}}_{{{\text{NH}}_{{2}} {\text{ - MIL - 53}}}}^{{ - {1}}}\), while DESs-impregnated NH2-MIL-53(Al), DES1/NH2-MIL-53(Al), DES2/NH2-MIL-53(Al), and DES3/NH2-MIL-53(Al) have adsorption capacities of 62.68, 39.66, and 31.84 \({\text{mg}}_{{{\text{CO}}_{{2}} }} \cdot {\text{g}}_{{{\text{DES/NH}}_{{2}} {\text{ - MIL - 53}}}}^{{ - {1}}}\) , respectively at temperature of 298.15 K and pressure 5 bar. The isotherm curves of CO2 and N2 gas adsorption of the studied systems at different temperatures and pressures are illustrated in Fig. 6. In NH2-MIL-53(Al) main interaction between CO2 and MOF arises from carboxylate oxygen atoms and –NH2 group in MOF, can increase preferential interactions between the frameworks and CO2. In the MOF impregnated with DESs, gas adsorption arises from two factor; first factor is DESs which confinement in pores and second factor is DESs which immobilized in the surface of pores. The schematic interaction of DES with NH2-MIL-53(Al) and CO2 are illustrated in Fig. 7. With impregnation of DES in MOF a monolayer of DES is immobilized on the surface of MOF pores via hydrogen bond interactions. However residual DES so far away from surface which could not forming hydrogen bond. Therefore except of monolayer, the residual of DES is confined in the pores of MOF. When most of the pore surface of support is occupied by the immobilized DESs, the CO2 sorption capacity of nano-confined DESs is dominated by the immobilized DESs rather than solid adsorbent. In the NH2-MIL-53(Al) impregnated with DESs, at low pressure gas adsorption take placed on the immobilized DESs on surface of NH2-MIL-53(Al); whereas at high pressure gas adsorption take placed on the confinement DESs on pores of NH2-MIL-53(Al). Moreover, the chemical reaction between CO2 molecules and the amine group affects the CO2 adsorption NH2-MIL-53(Al). Improving the pore characteristics of NH2-MIL-53(Al) with different active sites, among which the creation of carboxylate oxygen atoms and NH2 functional group, can increase preferential interactions between the frameworks and CO2. The comparison of adsorption isotherm in DESs-impregnated NH2-MIL-53(Al) was illustrated in Fig. 8 at temperature of 298.15 K and pressure of up to 5 bar. The values of adsorption capacity follow the trend of: DES1/NH2-MIL-53(Al) > DES3/NH2-MIL-53(Al) > DES2/NH2-MIL-53(Al). The highest CO2 adsorption is corresponding to DES1/NH2-MIL-53(Al) and the lowest adsorption is attributed to DES2/NH2-MIL-53(Al), indeed, the addition of the secondary amine to DES1/NH2-MIL-53(Al) reduced CO2 adsorption. Reactivity of amines with CO2 is in the order as Primary > Secondary > Tertiary. Hence, the addition of secondary amine decreased the absorption capacity of primary amine. Also, in DES3/NH2-MIL-53(Al), when the tertiary amine is added to the DES1/NH2-MIL-53(Al) adsorption capacity decreases however in compared to the DES2/NH2-MIL-53(Al) the adsorption capacity increased due to the stronger intermolecular hydrogen bonds in DEA, consequently reaction between MDE and CO2 is easier than reaction between DEA and CO2 which leads to increase values of adsorption capacity. Overall, impregnation of MOF with DES1, DES2 and DES3 enhance the adsorption capacity about 130%, 14% and 52%, respectively. The similar results were reported in literatures. For example, Ariyanto et al.18 have studied adsorption capacity of porous carbon which impregnated with three DESs (choline chloride:butanol, choline chloride:ethylene glycol and choline chloride:glycerol). They results reveals that the enhance adsorption capacity were 68%, 71% and 95%, respectively. The selectivity of CO2/N2 for NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) are shown in Fig. 9. The value of CO2/N2 selectivity decreases with increase in the pressure which is in good agreement with the literature42,43. DES1/NH2–MIL–53(Al) displays batter selectivity with respect to the NH2-MIL-53(Al).

The CO2 adsorption in (A) NH2-MIL-53(Al); (B) DES1/NH2-MIL-53(Al); (C) DES2/NH2-MIL-53(Al); (D) DES3/NH2-MIL-53(Al) at different temperatures (♦) 288.15 K; (▲) 293.15 K; (●) 298.15 K; (■) 303.15 K; (*) 308.15 K; the N2 adsorption at different temperatures (◊) 288.15 K; (∆) 293.15 K; (○) 298.15 K; (□) 303.15 K; (✖) 308.15 K; (–) fitting results by Eq. (3).

(A) The CO2 adsorption in (♦) NH2-MIL-53(Al); (▲) DES1/NH2-MIL-53(Al); (●) DES2/NH2-MIL-53(Al); (■) DES3/NH2-MIL-53(Al); and N2 adsorption in (◊) NH2-MIL-53(Al); (∆) DES1/NH2-MIL-53(Al); (○) DES2/NH2-MIL-53(Al); (□) DES3/NH2-MIL-53(Al); at temperatures 298.15 K; (–) fitting results by Eq. (3).

Enthalpy of adsorption

In order to evaluate the heat of adsorption, the adsorption experiments were carried out in the 288.15–308.15 K range temperature. The isotherms of the studied systems indicate that the adsorption isotherm are dependent to temperature while Mahdipoor et al.44 indicate that the adsorption isotherm of MIL-101(Fe)–NH2 is independent on temperature. Hence, the value of adsorption heat is assumed to equal the activation energy for primary alkanolamines. The molar enthalpy of absorption is a measure of interaction strength between the adsorbate molecule and the adsorbent surface identified isosteric heat of adsorption. The molar enthalpy of absorption is evaluated by calculated the gas adsorption at different temperatures45,46. Isosteric heat has calculated by differentiate an adsorption isotherm at a constant adsorbate loading which like as the Clausius–Clapeyron equation47,48:

where T and R, are temperature and universal gas constant, respectively. The effect of temperature on the CO2 adsorption in DES1/NH2-MIL-53(Al) sorbents is illustrated in Fig. 9. According to Fig. 10, the isosteric heat for NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) is obtained from plots ln(p) vs. 1/T. The value of isosteric heat for NH2-MIL-53(Al) and DESs/NH2-MIL-53(Al) are listed in Table 7. The calculated data for systems in this study indicate that the adsorption isotherm is dependent to temperature.

Regeneration efficiency of DES/NH2-MIL-53(Al)

Regeneration efficiency was used to evaluating adsorption/desorption performance of DES1/NH2-MIL-53(Al) adsorbent. Five cycles of adsorption/desorption test in DES1/NH2-MIL-53(Al) were tested to evaluation reuse capacity. The CO2 adsorption capacity in five cycles of CO2 adsorption/desorption test are illustrated in Fig. 11. In the adsorption/desorption test, CO2 adsorption has tested at 298.15 K and 1 bar and desorption test was done in vacuum condition at 298.15 K for 90 min. The values of CO2 adsorption are obtained as 20.408, 20.408, 20.407, 19.665 and 19.665 in five consecutive cycles of adsorption/desorption. The CO2 adsorption capacity reduction in the DES1/NH2-MIL-53(Al) compared to the fresh sample was estimated at about 4% after 5 cycles. This results confirms that the DESs/NH2-MIL-53(Al) is stable and reusable under the practical condition of regeneration.

Conclusions

Deep eutectic solvents contain choline chloride in conjunction with different amines were impregnated in amino functionalized NH2-MIL-53(Al) to improve the separation of CO2/N2. FTIR, SEM, EDX, and N2-sorption analysis confirmed the impregnation of DES on porous MOF. The adsorption isotherms and separation tests of CO2/N2 revealed that DES1/NH2-MIL-53(Al) exhibited a better performance. The obtained results indicate that in addition to physical adsorption of CO2 by DES/NH2-MIL-53(Al), CO2 chemisorption by NH2 functional group in the sorbent structure has also a notable effect on the adsorption mechanism. The DES1/NH2-MIL-53(Al), can be employed repeatedly without losing separation performance and could increase the CO2 uptake capacity twofold which introduce a novel category of highly porous adsorbents for the efficient adsorption of different compounds.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Kang, S., Chung, Y. G., Kang, J. H. & Song, H. CO2 absorption characteristics of amino group functionalized imidazolium-based amino acid ionic liquids. J. Mol. Liq. 297, 111825 (2020).

Ma, L., Svec, F., Tan, T. & Lv, Y. Mixed matrix membrane based on cross-linked poly[(ethylene glycol) methacrylate] and metal–organic framework for efficient separation of carbon dioxide and methane. ACS Appl. Nano Mater. 1, 2808–2818 (2018).

Krishnan, A. et al. Ionic liquids, deep eutectic solvents and liquid polymers as green solvents in carbon capture technologies: A review. Environ. Chem. Lett. 18, 2031–2054 (2020).

Anderson, T. R., Hawkins, E. & Jones, P. D. CO2, the greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth System Models. Endeavour 40, 178–187 (2016).

Pianta, S., Rinscheid, A. & Weber, E. U. Carbon capture and storage in the United States: Perceptions, preferences, and lessons for policy. Energy Policy 151, 112149 (2021).

Barzagli, F., Mani, F. & Peruzzini, M. A 13C NMR study of the carbon dioxide absorption and desorption equilibria by aqueous 2-aminoethanol and Nmethylsubstituted 2-aminoethanol. Energy Environ. Sci. 2, 322–330 (2009).

Mandal, B. P., Kundu, M. & Bandyopadhyay, S. S. Physical solubility and diffusivity of N2O and CO2 into aqueous solutions of (2-amino-2-methyl-1-propanol + 20 monoethanolamine) and (N-methyldiethanolamine + monoethanolamine). J. Chem. Eng. Data 50, 352–358 (2005).

Ebner, A. D. & Ritter, J. A. State-of-the-art adsorption and membrane separation processes for carbon dioxide production from carbon dioxide emitting industries. Sep. Sci. Technol. 44, 1273–1421 (2009).

Serna-Guerrero, R., Dana, E. & Sayari, A. New insights into the interactions of CO2 with amine-functionalized silica. Ind. Eng. Chem. Res. 47, 9406–9412 (2008).

Wang, Z. & Cohen-Seth, M. Postsynthetic covalent modification of a neutral metal−organic framework. J. Am. Chem. Soc. 129(41), 12368–12369 (2007).

Mondal, M. K., Balsora, H. K. & Varshney, P. Progress and trends in CO2 capture/separation technologies: A review. Energy 46, 431–441 (2012).

Keskin, S. & Sholl, D. S. Selecting metal organic frameworks as enabling materials in mixed matrix membranes for high efficiency natural gas purification. Energy Environ. Sci. 3, 343–351 (2010).

Mason, J. A. et al. Application of a high-throughput analyzer in evaluating solid adsorbents for post-combustion carbon capture via multicomponent adsorption of CO2, N2, and H2O. J. Am. Chem. Soc. 137, 4787–4803 (2015).

Zhang, J., Singh, R. & Webley, P. A. Alkali and alkaline-earth cation exchanged chabazite zeolites for adsorption based CO2 capture. Microporous Mesoporous Mater. 111, 478–487 (2008).

Bernal, M. P., Coronas, J., Menendez, M. & Santamaria, J. Separation of CO2/N2 mixtures using MFI-type zeolite membranes. AIChE J. 50, 127–135 (2004).

Arstad, B., Fjellvag, H., Kongshaug, K. O., Swang, O. & Blom, R. Amine functionalised metal organic frameworks (MOFs) as adsorbents for carbon dioxide. Adsorption 14, 755–762 (2008).

Ellen-Dautzenberg, E., Li, G. & Smet-Louis, C. P. M. Aromatic amine-functionalized covalent organic frameworks (COFs) for CO2/N2 separation. ACS Appl. Mater. Interfaces 15(4), 5118–5127 (2023).

Ariyanto, T. et al. Improving the separation of CO2/CH4 using impregnation of deep eutectic solvents on porous Carbon. ACS Omega 6, 19194–19201 (2021).

Lin, H. et al. Nanoconfined deep eutectic solvent in laminated MXene for efficient CO2 separation. Chem. Eng. J. 405, 126961 (2021).

Sumida, K. et al. Carbon dioxide capture in metal-organic frameworks. J. R. Long Chem. Rev. 112, 724–781 (2012).

Nugent, P. et al. Porous materials with optimal adsorption thermodynamics and kinetics for CO2 separation. Nature 495, 80–84 (2013).

Olajire, A. A. CO2 capture and separation technologies for end-of-pipe applications a review. Energy 35, 2610–2628 (2010).

Yu, C. H., Huang, C. H. & Tan, C. S. A review of CO2 capture by absorption and adsorption. Aerosol Air Qual. Res. 12, 745–769 (2012).

Torralba-Calleja, E., Skinner, J. & Gutiérrez-Tauste, D. CO2 capture in ionic liquids: A review of solubilities and experimental methods. J. Chemother. 2013, 473584 (2013).

Zhang, X. et al. Carbon capture with ionic liquids: Overview and progress. Energy Environ. Sci. 5, 6668–6681 (2012).

Smith, E. L., Abbott, A. P. & Ryder, K. S. Deep eutectic solvents (DESs) and their applications. Chem. Rev. 114, 11060–11082 (2014).

Sánchez-Sánchez, M. et al. Synthesis of metal–organic frameworks in water at room temperature: Salts as linker sources. Green Chem. 17, 1500–1509 (2015).

Chen, X. Y., Hoang, V. T., Rodrigue, D. & Kaliaguine, S. Optimization of continuous phase in amino-functionalized metal-organic framework (MIL-53) based co-polyimide mixed matrix membranes for CO2/CH4 separation. RSC Adv. 3, 24266–24279 (2013).

Sarmad, Sh., Nikjoo, D. & Mikkola, J. P. Amine functionalized deep eutectic solvent for CO2 capture: Measurements and modeling. J. Mol. Liq. 309, 113159 (2020).

Sorribas, S., Gorgojo, P., Tellez, C., Coronas, J. & Livingston, A. G. High flux thin film nanocomposite membranes based on metal-organic frameworks for organic solvent nanofiltration. J. Am. Chem. Soc. 135, 15201–15208 (2013).

Noorani, N., Mehrdad, A. & Ahadzadeh, I. CO2 absorption in amino acid-based ionic liquids: Experimental and theoretical studies. Fluid Phase Equilib. 547, 113185 (2021).

Noorani, N., Mehrdad, A. & Chakhmaghi, F. Thermodynamic study on carbon dioxide and methane permeability in polyvinylchloride/ionic liquid blends. Chem. Thermodyn. 145, 106094 (2020).

Noorani, N. & Mehrdad, A. Experimental and theoretical study of CO2 sorption in biocompatible and biodegradable choliniumbased ionic liquids. Sep. Purif. Technol. 254, 117609 (2021).

Noorani, N. & Mehrdad, A. Cholinium-amino acid ionic liquids as biocompatible agents for carbon dioxide absorption. J. Mol. Liq. 357, 119078 (2022).

Noorani, N., Mehrdad, A. & Zareidiznab, R. Thermodynamic study on carbon dioxide absorption in vinyl imidazolium–amino acid ionic liquids. Fluid Phase Equilib. 557, 113433 (2022).

Redlich, O. & Peterson, D. L. A useful adsorption isotherm. J. Phys. Chem. 63(1024), 1024–1024 (1959).

Seoane, B., Téllez, C., Coronas, J. & Staudt, C. NH2-MIL-53(Al) andNH2-MIL-101(Al) insulfur-containing copolyimide mixed matrix membranes for gas separation. Sep. Purif. Technol. 111, 72–81 (2013).

Vimont, A. et al. Evidence of CO2 molecule acting as an electron acceptor on a nanoporous metal–organic-framework MIL-53 or Cr3+(OH)(O2C–C6H4–CO2). Chem. Commun. 21, 3291–3293 (2007).

Cheng, X. et al. Size- and morphologycontrolled H2-MIL-53(Al) prepared in DMF-water mixed solvents. Dalton Trans. 42, 13698–13705 (2013).

Rouquerol, J., Rouquerol, F., Llewellyn, P., Maurin, G. & Sing, K. S. W. Adsorption by Powders and Porous Solids 2nd edn. (Academic Press, 2013).

Kim, J., Kim, W. Y. & Ahn, W. S. Amine-functionalized MIL-53(Al) for CO2/N2 separation: Effect of textural properties. Fuel 102, 574–579 (2012).

Ariyanto, T., Prasetyo, I., Mukti, N. F., Cahyono, R. B. & Prasetya, A. Nanoporous carbon based palm kernel shell and Its characteristics of methane and carbon dioxide adsorption. IOPConf. Ser. Mater. Sci. Eng. 736, 022057 (2020).

Kenarsari, S. D. et al. Review of recent advances in carbon dioxide separation and capture. RSC Adv. 3, 22739–22773 (2013).

Mahdipoor, H. R., Halladj, R., Babakhani, E. G., Amjad-Iranagha, S. & Sadeghzadeh Ahari, J. Synthesis, characterization, and CO2 adsorption properties of metal organic framework Fe-BDC. RSC Adv. 11, 5192–5203 (2021).

Builes, S., Sandler, S. I. & Xiong, R. Isosteric heats of gas and liquid adsorption. Langmuir 29, 10416–10422 (2013).

Sircar, S., Mohr, R., Ristic, C. & Rao, M. B. Isosteric heat of adsorption: Theory and experiment. J. Phys. Chem. B 103, 6539–6546 (1999).

Marathe, R. P., Farooq, S. & Srinivasan, M. P. Modeling gas adsorption and transport in small-pore titanium silicates. Langmuir 21, 4532–4546 (2005).

Pourebrahimi, S., Kazemeini, M., Ganji Babakhani, E. & Taheri, A. Removal of the CO2 from flue gas utilizing hybrid composite adsorbent MIL-53(Al)/GNP metal-organic framework. Microporous Mesoporous Mater. 218, 144–152 (2015).

Acknowledgements

The authors would thank for postdoctoral grant (No: SAD/3938-1400 1225) from university of Tabriz.

Author information

Authors and Affiliations

Contributions

N.N.: data duration, writing-original draft preparation, visualization, investigation. A.M.: conceptualization, methodology, validation, writing-reviewing and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Noorani, N., Mehrdad, A. Impregnation of amine functionalized deep eutectic solvents in NH2-MIL-53(Al) MOF for CO2/N2 separation. Sci Rep 13, 13012 (2023). https://doi.org/10.1038/s41598-023-40191-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-40191-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.