Abstract

Zanthoxylum limonella essential oil possesses potential antimicrobial activity and is of considerable interest as food flavouring and traditional herb. In this study, an enzymolysis-pretreatment-microwave-assisted extraction (EP-MAE) method was used to extract Z. limonella essential oil. The response surface methodology (RSM) with Plackett–Burman design (PBD) and Box-Behnken design (BBD) models were employed to optimize conditions in the EP-MAE method. Seven variables including water to plant ratio, enzyme amount, incubation temperature, incubation time, shaking speed, microwave time, and microwave power were selected to determine the optimal values for extracting Z. limonella essential oil. As the results, four variables including water to plant ratio, enzyme amount, microwave time and power were evaluated as significant variables affecting on yield and volatile compounds of Z. limonella essential oil from both PBD and BBD experiments. The optimum conditions of EP-MAE was obtained as follows: water to plant ratio (11.16 mL/g), enzyme amount (0.68%), microwave time (36.73 min), and power (1665 W). The Z. limonella essential oil composition and its yield from EP-MAE was compared to those extracted from MAE and hydrodistillation. The optimal extraction conditions in the EP-MAE method enhanced significantly higher essential oil yield (7.89 ± 0.08 mg/g) compared to those found by MAE (7.26 ± 0.04 mg/g) and hydrodistillation (7.04 ± 0.03 mg/g), respectively. Fifty-one volatile components were identified among these methods, with similar major compounds of limonene, β-pinene, and α-phellandrene, showing percentage ranging between 34.59–35.78%, 19.91–22.67%, 8.47–8.75%, respectively. However, an extremely higher content of compounds was detected using the EP-MAE method. This study demonstrates the significance of EP-MAE, which may be applied as a more potent extraction method for essential oils in aromatic plants compared to MAE and hydrodistillation.

Similar content being viewed by others

Introduction

Essential oils are viscous liquids containing complex components with aromatic odour. They have been broadly used in various applications in pharmaceuticals and natural therapies, as well as food industries since ancient time until now1,2. They have also been applied as antimicrobial and antioxidant agents for food security, replacing chemical and synthetic drugs1,2. Generally, essential oil is mainly extracted by hydrodistillation due to its ease of operation and low cost. However, this technique consumes both time and energy. In addition, this method often results in low yields and the production of degradation products, including thermosensitive components3. Due to the high demand of essential oils, there is a growing concern for improving yields. Development of novel cost-effective and environmentally friendly techniques are encouraged to extract essential oils. Microwave-assisted extraction (MAE) is a novel and efficient method for extracting essential oil significantly reducing extraction times and enhancing essential oil yield4.

MAE technique is widely known as green, and efficient technique for extracting essential oil without use of organic solvents5,6. The extraction of essential oils through the MAE technique is directly correlated to the microwave radiation's interaction with polar compounds and water, leading to elevated temperatures and pressures within the plant cells6,7. The essential oil disperses easily and rapidly from aromatic plant reducing time and energy consumption7. In this method, essential oil yield and content of volatile compounds are also enhanced. Moreover, enzymolysis pretreatment (EP) is known to improve essential oil yield from aromatic plants by interfacing with extraction techniques such as MAE according to high efficiency, low cost of enzyme concentration, simple method, and friendly environment8,9. Various hydrolytic enzymes are used in this approach to destroy the plant cell cytoderm and easy release endocellular components8,9. Therefore, using an alternative method of enzymolysis pretreatment combined with microwave irradiation has been interested and quickly increased for extraction of essential oils8,10.

Zanthoxylum limonella is a perennial tree belonging to the Rutaceae family. It is normally cultivated in Southeast Asia11. It is generally planted for the purpose of food flavouring and traditional herb for treatment of several diseases such as stomach, and tooth infections and respiratory diseases12. Utilization of Z. limonella is also detected as a source of strong antimicrobial agents which has been used as food additives with major components of limonene, phellandrene, and sabinene11,12,13. Hydrodistillation has been major technique for extracting Z. limonella essential oil. However, using new extraction technology instead of conventional hydrodistillation to enhance yield of Z. limonella essential oil is still limited. Thus, efficient method for with great ecological and economic benefits has been investigated to extract of essential oil from Z. limonella fruits13.

In this work, the EP-MAE was employed to extract Z. limonella essential oil and the extraction conditions were optimized using RSM with PBD and BBD models. Yield of Z. limonella essential oil extracted by MAE and hydrodistillation were also compared with those extracted by EP-MAE method. Z. limonella essential oil composition obtained by all methods was also analysed by gas chromatography-mass spectrometry (GC–MS).

Results

Screening of significant variables by PBD

Seven variables (Table 1) including water to plant ratio, enzyme amount, incubation temperature, incubation time, shaking speed, microwave time, and microwave power were employed to optimize the suitable values for extracting Z. limonella essential oil. All selected variables affecting on yield of Z. limonella essential oil was evaluated by PBD model with twelve trial runs (Table 2). From PBD design, the regression equation was achieved which was able to predict the variables influenced essential oil yield. The model equation for the yield of Z. limonella oil can be achieved as Y = 1.40 + 0.05A + 0.92B + 0.01C-0.01D + 0.01E + 0.02F + 0.01G. Figure 1 shows the significance of each variable via a Pareto chart with T and P values. As the results, the sign—could reflect the negative effect whereas the sign + of T values indicated positive effect of variables on the extraction condition. The variables were higher than the T value limit (3.28) and the Bonferroni limit (5.06) were determined as significant variables in EP-MAE method. It was found that four variables including microwave time and power, enzyme amount, and water to plant ratio are considered as the significant variables on yield of Z. limonella essential oil in the EP-MAE method.

Optimization of extraction method by BBD

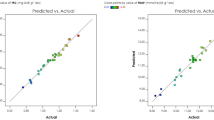

Due to four significant variables including water to plant ratio, enzyme amount, microwave time and power, 29 trial experiments were performed by BBD model. The actual and predicted yields are demonstrated in Table 3. The significance of each variable and the coefficient (R2) are also summarized in Table 4. The model equation for the yield of Z. limonella essential oil can be found as Y = 6.82 + 0.34A + 0.57B + 0.36F + 0.54G−0.17AF + 0.14AG−0.16BF−0.16BG + 0.18FG–0.26A2−0.39B2−0.21F2−0.38G2. Analysis by ANOVA for BBD model demonstrated that the generated model was significant (p < 0.0001), and residual lack of fit was not significant (p = 0.1971 > 0.05). Adjusted coefficient and correlation coefficient was 0.9711 and 0.9855, respectively.

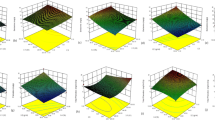

Three-dimensional and contour plots obtained from BBD results are shown in Fig. 2. These plots demonstrate the effects between two variables on the yield of Z. limonella essential oil with the other two independent variables. A weak mutual interaction resulting in a low yield of Z. limonella essential oil was found in Figs. 2a, 2c, and 2d which predict the relationship between the water to plant ratio and microwave time, the relationship between microwave power and enzyme amount, and the relationship between microwave power and microwave time, respectively, whereas a strong mutual interaction resulting in a high yield of Z. limonella essential oil was found in Fig. 2b, and 2e which illustrate the relationship between the water to plant ratio and microwave power and the relationship between microwave power and microwave time.

Three-dimensional and contour plots from BBD model; effect between water to plant ratio versus microwave time (a); effect between water to plant ratio versus microwave power (b); effect between microwave power versus enzyme amount (c); effect between microwave power versus microwave time (d); and effect between microwave time versus enzyme amount (e) on Z. limonella essential oil yield.

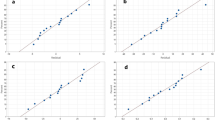

Checking of model adequacy is illustrated in Fig. 3. Normal plot (Fig. 3a) shows a straight line presenting normal distribution independent on each variable. Residuals versus run number plot (Fig. 3b) shows a random distribution ranging values from + 3 and -3 indicating the quadratic model correlation between the causal factors of the EP-MAE method and the Z. limonella oil yield. The plots between predicted versus actual values are shown in Fig. 3c. This plot presents a straight line suggesting that this generated model was accomplished to predict accurately comparing to the actual response values. It was found that proposed model from three residual plots can be applied to optimize extraction method of Z. limonella essential oil.

From the BBD experiment, the optimum condition for extracting Z. limonella oil by EP-MAE method consisted of a water to plant ratio of 11.16 mL/g, enzyme amount of 0.68%, microwave time of 36.73 min, and power of 1665 W. The predicted yield of Z. limonella essential oil was 7.85 mg/g. The values obtained from optimum condition was set in the actual experiments in order to compare yield of Z. limonella oil. The results showed that average yield of Z. limonella essential oil was 7.89 ± 0.08 mg/g was obtained from the actual experiments. The obtained results were similar to those obtained from the predicted value demonstrating the precision by the generated model. In addition, yield of Z. limonella essential oil obtained from EP-MAE was compared to those obtained from MAE and hydrodistillation. As the results, yield of Z. limonella essential oil obtained from MAE and hydrodistillation was lower significantly than those found by EP-MAE representing 7.26 ± 0.04 mg/g and 7.04 ± 0.03 mg/g, respectively,

Analysis of volatile compounds in Z. limonella essential oil

The volatile compounds in Z. limonella essential oils and their relative peak area obtained from EP-MAE, MAE, and hydrodistillation are listed in Table 5. Similar volatile profile was found among these extraction methods. In total, 51 volatile components were identified with same major compounds of limonene, β-pinene, and α-phellandrene showing percentage ranging between 34.59 and 35.78%, 19.91 and 22.67%, 8.47 and 8.75%, respectively. In addition, concentration of most volatile components obtained by EP-MAE was greater significantly than those obtained by MAE, and hydrodistillation, respectively. These volatile compounds consisted of myrcene, α-terpinene E-β-ocimene, terpinen-4-ol, and germacrene D. However, some compounds such as camphene, iso-isopulegyl acetate, citronellol perilla alcohol, carvacrol possessed similar contents in all extraction methods.

Discussion

Yield of Z. limonella essential oil achieved from cellulase enzymatic pretreatment was significantly higher than those obtained from other methods without pretreatment. The results showed that cellulase enzymatic pretreatment on extraction of Z. limonella essential oil was affected on its yield and essential oil composition. The results were similar to those found in previous studies describing that cellulase can hydrolyse the β-1,4 glycosidic bonds in plant cell structure mainly cellulose8,14,15. Several results demonstrated the successful of cellulase enzymatic pretreatment in the extraction of essential oil of eaglewood16, citrus17, basil18, cinnamon8, and lavender9. It was noted that the structure of Z. limonella cell walls were broken and depolymerized mainly by cellulase in the pretreatment subsequently releasing intracellular essential oil in the mixture and resulting higher yield in the extraction.

The PBD experiment revealed that four variables including water to plant ratio, enzyme amount, microwave time and power were evaluated as the significant variables affecting on yield and volatile compounds of Z. limonella essential oil obtained from the EP-MAE method. Our result was accordance with the study of Liu et al.8 reporting these four factors were the major factors on essential oil yield. Karami et al. (2015)19 reported that water to plant ratio was one of the important factors in extraction of essential oils. Incomplete extraction may be detected in the extraction using low water to plant ratio whereas complicated separation with undesired products may be found when using high water to plant ratio. Amount of cellulase enzyme was also considered as key factor enhancing the essential oil yield by interaction between substrates and enzyme cell resulting cell wall solubilization8,20. However, the efficiency of enzyme was depended on their cost, and extracted sources21. In addition, microwave time and power had the most significant impact on yield and volatile compounds of Z. limonella essential oil. Prolonged extraction and high power of microwave could lead to the decomposition of volatile compounds, resulting in a lower yield of the Z. limonella essential oil5. Therefore, these four factors were further used to optimize extraction condition in the EP-MAE method. This optimization aims to achieve cost savings, reduce extraction time, and obtain a high yield along with the essential volatile compounds of Z. limonella essential oil.

From BBD results, A high R2 value of 0.9855 was found for the response. R2 value in this study is acceptable due to higher R2 than 0.75. The adjusted and predicted R2 value was 0.9711 and 0.9251, respectively. It can be noted that the created model was extremely significant with a P value < 0.0001 and an F value was higher than 60. The F and P value of the lack of fit revealed nonsignificant difference in variance with a value of 2.49 and 0.1971, respectively. The suggested model also presented adequacy precision of 30.38 which this model could be employed to design variables in the EP-MAE method. As noticed, both the linear and the quadratic terms of the two variables, enzyme amount and microwave power, exhibited significant significance. Additionally, the linear terms from the two variables, water-to-plant ratio and microwave time, demonstrated high significance. The interactive effects between water to plant ratio and microwave time, as well as the effects between enzyme amount and microwave time, and effect between enzyme amount versus microwave time were highly significant while interactive terms of water to plant ratio versus enzyme amount was nonsignificant.

As noticed, both high and low water-to-plant ratios could have an impact on the dissolution, with high ratios potentially leading to incomplete extraction8,20. However, use of high microwave power probably destroys the essential oil cells while low microwave power could reduce the dielectric heating22,23. Initial radiation in the MAE system could enhance essential oil solubilization while employment of high microwave power may degrade enzymes and plant materials decreasing essential oil yield5,6,7. It was found that the optimal microwave power was 1665 W in this study. As noticed, high power of microwave was not affected on yield of Z. limonella essential oil. The optimal conditions obtained by BBD model revealed higher content significantly of all volatile compounds in the EP-MAE than those found in the MAE and hydrodistillation, respectively. The extremely low content of these volatile compounds in the hydrodistillation method may be contributed to the long extraction time resulting completely oxidization, hydrolysis, and even other reactions in the system22. The obtained result was similar to the study by Liu et al.24 describing that endo-borneol content of Cinnamomum camphor essential oil was significantly higher by extracting with EP-MAE method comparing to those found by MAE method. This phenomenon may be due to the hydrolysis reaction by enzymolysis pretreatment. In addition, some volatile compounds containing higher dipole force usually demonstrated more drastic response during microwave irradiation resulting more easily separation from the plant material6,7.

The EP-MAE method proved successful for the extraction of Z. limonella essential oil. The extraction variables were optimized using RSM with PBD and BBD models. It was found that four variables including water to plant ratio, enzyme amount, microwave time and power were evaluated as significant variables on yield and volatile compounds of Z. limonella essential oil. The optimal conditions in EP-MAE were found as follows: water to plant ratio (11.16 mL/g), enzyme amount (0.68%), microwave time (36.73 min), and power (1665 W). The Z. limonella essential oil composition and its yield from EP-MAE was compared to those obtained by MAE and hydrodistillation. The optimum conditions of the EP-MAE method led to a significant increase in essential oil yield (7.89 ± 0.08 mg/g) compared to those found by MAE (7.26 ± 0.04 mg/g) and hydrodistillation (7.04 ± 0.03 mg/g). GC–MS analysis revealed an unchanged volatile profile when compared to the profiles obtained using the MAE and hydrodistillation method. The major compounds identified among all methods were limonene, β-pinene, and α-phellandrene. Overall, the EP-MAE improved the yield compared to those obtained by MAE and hydrodistillation, respectively. The EP-MAE holds promise as an extraction technique for Z. limonella essential oil without compromising its quality. This suggests that its favorable potential could extend to extracting essential oils from a variety of aromatic plants as well.

Materials and methods

Plant material and chemicals

The aerial parts of Z. limonella were collected from Pua district, Nan Province, Thailand in September 2021. The collection site access was approved by Mrs. Panid Taewa, the farm owner. The plant material was collected with the consent of the Mae Fah Luang University. No further regulation was required for collection of this plant. In addition, the collection of plant material was complied with the relevant institutional (Mae Fah Luang University), national, and international guidelines and legislation. It was identified by a taxonomist Dr. Jantrararuk Tovaranonte, head of Mae Fah Luang Botanical Garden with a voucher specimen MFU 10064. It was deposited at the Mae Fah Luang Botanical Garden, Mae Fah Luang University, Chiang Rai, Thailand. The Z. limonella fruits were dried in oven at 60 °C for 12 h prior kept in plastic bag at room temperature until use. Neutral cellulase (> 10,000 U/g) enzyme was purchased from Sigma-Aldrich Inc. (St. Louis, MO). All analytical grade chemicals from Sigma-Aldrich Inc. (St. Louis, MO) were used in this study.

Extraction of Z. limonella essential oil

The EP-MAE extraction was performed of two parts including enzymatic pretreatment and further extraction in microwave system. This method was applied following method of Liu et al.8 Firstly, dried Z. limonella fruits were pulverized into a homogeneous size by a disintegrator (50–60 mesh). After that, 100 g of homogeneous Z. limonella fruit powder, cellulase enzyme solution at pH 5, and 10 µL of 100 mg/L of 2,6-dimethylpyridine, internal standard, were mixed and further incubated using a digital shaking water bath oscillator (Bioevopeak, Shandong, China) prior subjected to microwave extraction apparatus (ETHOS™, Metrohm, Australia). The excess waters in essential oils were removed using anhydrous Na2SO4. The obtained Z. limonella oils were transferred in sealed amber vials and kept at 4 °C. The MAE method was performed using same optimized extraction conditions described in EP-MAE method without any pretreatment. In addition, Z. limonella essential oil was also extracted by hydrodistillation. Briefly, 100 g of Z. limonella fruit powder and 1 L of distilled water was placed in flask container. The essential oil was extracted by hydrodistillation with a Clevenger-type apparatus (Apex Chemicals, Thailand) until no essential oil was found. The extraction method in MAE and hydrodistillation was the same as described in EP-MAE. The essential oils obtained by MAE and hydrodistillation were used as control comparing to those obtained by EP-MAE method. The yield was calculated based on dried raw materials.

Experimental design

PBD model with seven variables was employed to optimize variables influencing the yield of Z. limonella essential oil. The method in this study was modified from the study of Liu et al.8 In pre-experiments, influences of seven variables were studied to optimize the suitable ranges for extracting of Z. limonella essential oil. The mathematical optimization from all variables and the obtained results are shown in Table 1. A first-order polynomial mathematical equation: Y = β0 + ∑βi + Xi where Y is the % yield, β0 and βi instant for the constants of the intercept term and the regression coefficient, respectively. Seven different and independent variables including water to plant ratio, enzyme amount, incubation temperature, incubation time, shaking speed, microwave time, and power were investigated to appraise the comparatively significant variables for extraction of Z. limonella essential oil (response). All independent variables are shown in Table 2 designing as − 1 and + 1 for low and high value with twelve experiments. Average Z. limonella essential oil yield from each experiment was calculated using Design Expert 13 software.

BBD model was also used to optimize extraction conditions in EP-MAE method with the independent factors in the extraction of Z. limonella essential oil. Three levels of each variable were evaluated and represented as low, central, and high, respectively. Twenty-nine experiments were designed using Design Expert 13 software and the results are provided in Table 3. The extraction of Z. limonella essential oil was evaluated by the following second-order polynomial equation, and the real yield of essential oil was obtained by the multiregression analysis. Y = β0 + ∑3 i = 1 βiXi + ∑3 i = 1 βiiX2 i + ∑2 i = 1 ∑3 j = i + 1 βijXiXj where Y is the average yield of Z. limonella essential oil. β0, βi, βii, and βij are the corresponding regression coefficients of the intercept, linear, quadratic, and interactive terms, respectively; and Xi and Xj are the coded independent variables.

Identification of volatile compounds by GC–MS

An Agilent 6890 N gas chromatograph connected with electron impact ionization mass-selective detector (Agilent Technologies, Santa Clara, CA, USA). A fused-silica capillary DB5-MS (J&W Scientific, USA) with diameter size of 30 m × 0.25 mm i.d., 0.25 µm was employed to separate volatile compounds. Essential oils obtained by all extraction methods were diluted with hexane with a ratio of 1:100 v/v. Each sample solution (1.0 µL) was injected into the injection port of GC–MS apparatus in split mode (split ratio of 1:50). Helium gas with a rate of 1.0 mL/min was used as a carrier gas. The electron impact ionization mode with the injector, ion source, and interface temperature of 250 °C were used in this work. The programmed temperature was used with initial temperature at 60 °C and then increased to 220 °C at a rate of 3 °C/min. The volatile compounds were identified using MassHunter Acquisition software (Agilent Technologies, Santa Clara, CA, USA) by comparing their mass spectra with those obtained from the Wiley7N and W8N08 and Adams libraries25. The retention indices of all volatile compounds were also calculated correlating to those obtained by C9-C16 n-alkanes. The relative contents of identified compounds were calculated as ratios of their peak areas to the peak areas of the internal standard (2,6- dimethylpyridine).

Statistical analysis

Design Expert 13 software (Stat-Ease, Minneapolis, USA) was employed in PBD and BBD experiments. Each experiment was performed for five replications. Data were represented as average values. Analysis of variance (ANOVA) was applied to determine the significance of the essential oil yield and volatile profiles among all samples which all data are shown as the mean values ± standard deviation.

Data availability

All data generated or analysed during this study are included in this published article.

References

Aziz, Z. A. et al. Essential oils: Extraction techniques, pharmaceutical and therapeutic potential-a review. Curr. Drug Metab. 19, 1100–1110. https://doi.org/10.2174/1389200219666180723144850 (2018).

Wińska, K. et al. Essential oils as antimicrobial agents-myth or real alternative?. Molecules 24, 2130. https://doi.org/10.3390/molecules24112130 (2019).

Reyes-Jurado, F., Franco-Vega, A., Ramírez-Corona, N., Palou, E. & López-Malo, A. Essential oils: Antimicrobial activities, extraction methods, and their modeling. Food Eng. Rev. 7, 275–297. https://doi.org/10.1007/s12393-014-9099-2 (2015).

Filly, A. et al. Solvent-free microwave extraction of essential oil from aromatic herbs: From laboratory to pilot and industrial scale. Food Chem. 150, 193–198. https://doi.org/10.1016/j.foodchem.2013.10.139 (2014).

Chemat, F. & Cravotto, G. Microwave-Assisted Extraction for Bioactive Compounds: Theory and Practice Vol. 4 (Springer, 2012).

Stratakos, A. C. & Koidis, A. Methods for extracting essential oils. In Essential Oils in Food Preservation, Flavor and Safety, 31–38, Academic Press. https://doi.org/10.1016/B978-0-12-416641-7.00004-3 (2016).

Lamberti, L. et al. Microwave-assisted hydrodistillation of hop (Humulus lupulus L.) terpenes: A pilot-scale study. Foods 10, 2726. https://doi.org/10.3390/foods10112726 (2021).

Liu, Z. et al. Efficient extraction of essential oil from Cinnamomum burmannii leaves using enzymolysis pretreatment and followed by microwave-assisted method. LWT 147, 111497. https://doi.org/10.1016/j.lwt.2021.111497 (2021).

Rashed, M. M. et al. Isolation of essential oil from Lavandula angustifolia by using ultrasonic-microwave assisted method preceded by enzymolysis treatment, and assessment of its biological activities. Ind. Crops Prod. 100, 236–245. https://doi.org/10.1016/j.indcrop.2017.02.033 (2017).

Zhang, J. et al. Advances in efficient extraction of essential oils from spices and its application in food industry: A critical review. Crit. Rev. Food Sci. Nutr. https://doi.org/10.1080/10408398.2022.2092834 (2022).

Sriwichai, T., Suksathan, R., Charoenlertthanakit, N. & Sommano, S. R. Zanthoxylum spp.: A new potential sources of essential oil for the perfumery and pharmaceutical industries in Thailand. Med. Plants-Int. J. Phytomed. Relat. Ind. 11, 26–45 (2019).

Sriwichai, T., Sookwong, P., Siddiqui, M. W. & Sommano, S. R. Aromatic profiling of Zanthoxylum myriacanthum (makwhaen) essential oils from dried fruits using different initial drying techniques. Ind. Crops Prod. 133, 284–291. https://doi.org/10.1016/j.indcrop.2019.03.031 (2019).

Sharmeen, J. B., Mahomoodally, F. M., Zengin, G. & Maggi, F. Essential oils as natural sources of fragrance compounds for cosmetics and cosmeceuticals. Molecules 26, 666. https://doi.org/10.3390/molecules26030666 (2021).

Jayasekara, S. & Ratnayake, R. Microbial cellulases: An overview and applications. Cellulose 22, 92 (2019).

Dashtban, M., Maki, M., Leung, K. T., Mao, C. & Qin, W. Cellulase activities in biomass conversion: Measurement methods and comparison. Crit. Rev. Biotechnol. 30, 302–309. https://doi.org/10.3109/07388551.2010.490938 (2010).

Chandran, J., Amma, K. P. P., Menon, N., Purushothaman, J. & Nisha, P. Effect of enzyme assisted extraction on quality and yield of volatile oil from black pepper and cardamom. Food Sci. Biotechnol. 21, 1611–1617. https://doi.org/10.1007/s10068-012-0214-y (2012).

Chávez-González, M. L., López-López, L. I., Rodríguez-Herrera, R., Contreras-Esquivel, J. C. & Aguilar, C. N. Enzyme-assisted extraction of citrus essential oil. Chem. Pap. 70, 412–417. https://doi.org/10.1515/chempap-2015-0234 (2016).

Morsy, N. F. & Hammad, K. S. Extraction of essential oil from methyl cinnamate basil (Ocimum canum Sims) with high yield in a short time using enzyme pretreatment. J. Food Sci. Technol. 58, 2599–2605. https://doi.org/10.1007/s13197-020-04766-y (2021).

Karami, Z. et al. Optimization of microwave assisted extraction (MAE) and soxhlet extraction of phenolic compound from licorice root. J. Food Sci. Technol. 52, 3242–3253. https://doi.org/10.1007/s13197-014-1384-9 (2015).

Zhang, S., Wang, Z. & Xu, S. Optimization of the aqueous enzymatic extraction of rapeseed oil and protein hydrolysates. J. Am. Oil Chem. Soc. 84, 97–105. https://doi.org/10.1007/s11746-006-1004-6 (2007).

Jiang, L., Hua, D., Wang, Z. & Xu, S. Aqueous enzymatic extraction of peanut oil and protein hydrolysates. Food Bioprod. Process. 88, 233–238. https://doi.org/10.1016/j.fbp.2009.08.002 (2010).

Golmakani, M. T. & Rezaei, K. Comparison of microwave-assisted hydrodistillation with the traditional hydrodistillation method in the extraction of essential oils from Thymus vulgaris L.. Food Chem. 109, 925–930. https://doi.org/10.1016/j.foodchem.2007.12.084 (2008).

Ferhat, M. A., Meklati, B. Y. & Chemat, F. Comparison of different isolation methods of essential oil from Citrus fruits: Cold pressing, hydrodistillation and microwave ‘dry’distillation. Flav. Fragr. J. 22, 494–504. https://doi.org/10.1002/ffj.1829 (2007).

Liu, Z., Deng, B., Li, S. & Zou, Z. Optimization of solvent-free microwave assisted extraction of essential oil from Cinnamomum camphora leaves. Ind. Crops Prod. 124, 353–362. https://doi.org/10.1016/j.indcrop.2018.08.016 (2018).

Adams, R. P. Identification of Essential Oil Components by Gas Chromatography/Mass Spectroscopy 41st edn. (Allured Publishing Corporation, 2017).

Acknowledgements

The authors are grateful to the Medical Plant Innovation Centre of Mae Fah Luang University for supplying MAE in this study. This work was financially supported by Mae Fah Luang University.

Author information

Authors and Affiliations

Contributions

S.K., N.P. and T.S. performed experiments. S.K. and N.P. performed GC-MS analysis, and analysed data. P.S. also analysed data. S.K. and P.P. wrote, reviewed the manuscript. P.P. supervised the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Khruengsai, S., Promhom, N., Sripahco, T. et al. Optimization of enzyme-assisted microwave extraction of Zanthoxylum limonella essential oil using response surface methodology. Sci Rep 13, 12872 (2023). https://doi.org/10.1038/s41598-023-40142-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-40142-4

This article is cited by

-

Preparation, characterization and in vivo pharmacokinetic study of ginsenoside Rb1-PLGA nanoparticles

Scientific Reports (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.