Abstract

The aim of the present study was to maximize the extraction of gymnemic acid (GA) from Phak Chiang Da (PCD) leaves, an indigenous medicinal plant used for diabetic treatment in Northern Thailand. The goal was to overcome the low concentration of GA in the leaves, which limits its applications among a larger population and develop a process to produce GA-enriched PCD extract powder. The solvent extraction method was employed to extract GA from PCD leaves. The effect of ethanol concentration and extraction temperature were investigated to determine the optimum extraction conditions. A process was developed to produce GA-enriched PCD extract powder, and its properties were characterized. In addition, color analysis (L*, a*, and b*) was performed to evaluate the overall appearance of the PCD extract powder. Antioxidant activity assay was conducted to assess the ability of the PCD extract powder to neutralize DPPH free radicals. The results showed that the concentration of 50% (v/v) ethanol at 70 °C for 2 h resulted in a higher GA concentration of 8307 mg/kg from dried PCD leaves. During the drying process, the use of maltodextrin at a concentration of 0.5% (w/v) was found to produce PCD extract powder with the maximum GA concentration. The color analysis revealed that the PCD extract powder had a dark greenish tint mixed with yellow. The antioxidant activity assay showed that 0.1 g of PCD extract powder was able to neutralize 75.8% of DPPH free radicals. The results concluded that PCD extract powder could potentially be used as a source of nutraceuticals or as a functional food ingredient. These findings suggest the potential value of GA-rich PCD extract powder in various applications in the pharmaceutical, nutraceutical, or food industries.

Similar content being viewed by others

Introduction

Gymnemic acid (GA) is a complex group of molecules found in the leaves of Gymnema sp.1 and known for its hypoglycemic effects, making it a popular natural treatment for diabetes2,3. Due to the structural similarity with glucose, GA can bind to the sweet taste receptors on the taste buds, effectively competing with sugar molecules for receptor binding. As a result, the sensation of sweetness is hindered, as GA occupies the receptors and prevents their activation by sugar molecules. This effect can help reduce sugar cravings and may help control blood sugar levels in people with diabetes4. In addition to its potential anti-diabetic effects, GA has also been studied for its anti-inflammatory, anti-obesity, and anti-cancer properties3,5.

In this regard, Gymnema inodorum, indigenous to Thailand, one of the local Thai vegetables, found everywhere in the northern region and locally named “Phak Chin Da” or “Phak Chiang Da” (PCD) have been used as a traditional medicine for the management of diabetes6,7,8. While the leaves of the G. inodorum plant have been used for centuries in traditional medicine to treat various ailments, using whole leaf extract has some disadvantages that should be considered. For instance, Gymnema extract can contain varying amounts of GA, which can make it difficult to achieve consistent dosing. The extract can contain other compounds that may interact with medications or have other side effects. Moreover, some compounds in whole leaf extracts may hinder the absorption of GA by the body, reducing its bioavailability and effectiveness9.

To overcome this, there have been several research articles that have investigated the extraction and quantification of GA from Gymnema leaves using various extraction methods and solvents. Few studies found that ultrasound assisted extraction of G. sylvestre leaves was efficient and faster technique in extracting GAs and other bioactives10,11,12,13,14 when compared to other conventional methods. On the other hand, Mandal et al.15, found that microwave-assisted extraction was superior than other extraction methods such as heat flux extraction, maceration and stirring extraction for the recovery of GAs. Although several extraction methods have been described in the literature, solvents-based extraction is the most widely used method where the solvent penetrates the solid matrix solubilizing the solute that diffuses out of the matrix. While some researchers have demonstrated that solvent-based Soxhlet extraction yielded highest GAs from G. inodorum leaves16,17, others have stated that solvent maceration-based extraction was suitable for the recovery of GAs18,19,20,21,22,23. In general, solvent-assisted extraction methods have several advantages over other methods in terms of higher extraction efficiency, selectivity and reduced energy consumption.

The extraction of GA from Gymnema leaves can be achieved using different solvents, including water, methanol, ethanol, and acetone. The choice of solvent may depend on various factors, including the solubility of GA in the solvent, the extraction efficiency, and the safety and environmental impact of the solvent. Generally, polar to medium polar solvents are used to extract phenolic acids, alkaloids, flavonoids and tannins which are polar in nature. In this study, ethanol, an organic polar solvent was employed in the extraction of GA due its polarity24. It was also reported that a combination of polar solvents such as ethanol and water at different proportions can be ideal to extract phenolic acids since both the solvents have different polarity values (ethanol: 0.654, water: 1.0) and their acceptability for human consumption25. In addition to the choice of the solvent, several parameters such as solvent concentration, extraction temperature, solvent-to-solid ratio and extraction duration may significantly influence the extraction efficiency and concentration of bioactive compounds26.

Although several reports have been published on the preparation of extracts from PCD leaves27,28,29, there is scarce information on the preparation of powder formulation utilizing the extracts. The idea of preparing a powder formulation from the extracts of PCD leaves will more likely to gain popularity in the food and nutraceutical industry due to added benefits. Generally, to prepare a powder from the extracts, carriers such as maltodextrin30,31, starch31,32, and cellulose derivatives33,34 are used during drying process. The selection of a carrier may depend on several factors such as the physical and chemical properties of the extract, solubility and stability of the active compounds, the compatibility of the carrier with the active compounds in the plant extract and the intended application35,36,37. Maltodextrin is preferred over other carriers for their excellent flowability and dispersibility. It can reduce moisture reabsorption and reduce powder particle agglutination, make the extract powder retain its shape for a longer time and extend the shelf life30. Moreover, the addition of maltodextrin can have the advantages over other drying agents for its cost-efficient, highly soluble and poorly hygroscopic characteristics30,38,39, thus chosen in the present study.

The aim of the present study is to optimize the extraction conditions for higher recovery of GA from G. inodorum leaves and to develop a process for the production of PCD dried extract powder.

Materials and methods

Plant material and chemicals

The medium-matured leaves of G. inodorum (Lour.) Decne. were procured from Wor Kaew Subdistrict, Hang Chat District, Lampang Province, which is a well-known area for commercial farms growing G. inodorum in Northern Thailand. The leaves were collected between January and February 2022 using species No. 6 from certified Agricultural Land Plot No. DOA-52120700-9058-0006 with permission from the owner of this Land Plot under supervision of Department of Agriculture for specimen collection. The use of this economic plant, which was not endangered or protected species, complied with international and national guidelines of Good Agricultural Practices (GAP) for Food Crops/Thai Agricultural Standard (TAS) 9001(G)-2021. All records of specimens and Agricultural Land Plot usage were kept at Plant Standard and Certification Division, Department of Agriculture, Ministry of Agriculture and Cooperatives, Bangkok, Thailand. The ethanol used for extraction in this study was food grade with 99.8% (v/v) purity (Liquor Distillery Organization, CAS No. 64-17-5, Chachoengsao, Thailand). All other chemicals utilized were either Analytical or HPLC grades.

Preparation of dried PCD leaves powder

PCD leaves powder was prepared as described by Ounjaijean et al.40 with slight modifications. Briefly, PCD leaves were washed thoroughly, drained, and dried in a hot air dryer (Owner Foods Machinery Co., Ltd., Model SO 6A, Bangkok, Thailand) until a constant weight was obtained. Dried leaves were ground with a grinder mill (Huang Cheng, Model 4500A, China) and sieved through a sieve shaker (Endecotts, Model Octagon 200, London, United Kingdom) using a 100-mesh sieve size to yield the particle size not more than 150 µm.

Preparation of PCD extract powder

PCD extract powder preparation was adapted from Jiménez-Moreno et al.41, Fig. 1 shows the step-by-step process of PCD extract powder production. Briefly, the PCD leaves were dried at optimized drying temperature (“Effect of PCD leaves drying temperature” section) prior to attrition process with industrial high-speed grinder (Huang Cheng, Model 1500A, China) with screen size of 100 mesh (Endecotts, Model Octagon 200, London, United Kingdom) to attain PCD leaves powder. Further, 1 kg leaves powder was suspended in 20 L ethanol at the optimized concentration (“Effect of ethanol concentration during GA extraction from dried PCD leaves powder” section) in a 50 L double jacketed continuous stirring bioreactor (FEBIX International, Model ST-50L, Chiang Mai, Thailand) and stirred at a speed of 50 rpm for 2 h. The extraction was carried out at optimized temperature (“Effect of temperature during GA extraction from dried PCD leaves powder” section). The resultant slurry was filtered with double layer muslin cloth and the ethanol fraction was concentrated using a rotary evaporator (FEBIX International, Model REvap001, Chiang Mai, Thailand) at 50 °C and 10 rpm. When 50% (v/v) of the ethanol volume was evaporated, maltodextrin was added at the optimized concentration (“Effect of maltodextrin concentration during production of PCD extract powder” section) to the concentrated extract. The extract was then evaporated to dryness at 65 °C using a laboratory-scale vacuum dryer equipped with a diaphragm vacuum pump (Vacuubrand, Model MZ 2C NT + AK + EK, Wertheim, Germany) for creating the necessary vacuum (76 ± 5 cm Hg) inside the drying chamber. The dried material was pulverized into powder using an electric food chopper (Kenwood, Model CH550, Hampshire, UK).

Experimental design

In this study, firstly, a single factor experiment was used to optimize the extraction of GA from PCD leaves by studying the effects of three factors, namely drying temperature, ethanol concentration and extraction temperature41. In this experiment, one of the parameters is changed at a time while the other parameters are kept constant. Secondly, the PCD extract obtained using optimized conditions was processed further into PCD extract powder and the maltodextrin concentration was optimized during the preparation. Finally, the PCD extract powder prepared with optimized concentration of maltodextrin was evaluated for its GA, chlorophylls content, water activity (aw), moisture content, color (L*, a*, b*) and antioxidant capacity by 2,2-diphenyl-1-picrylhydrazyl (DPPH) method. The details are described in the analytical section.

Effect of PCD leaves drying temperature

Three different temperature levels, 40, 50 and 60 °C were applied during the drying process of PCD leaves while the concentration of ethanol and extraction temperature were kept constant at 50% (v/v) and 70 °C, respectively during extraction of GA from dried leaves. The levels of drying temperature used in this study were selected based on the literature where the authors have reported that drying at above 70 °C was detrimental to the bioactive properties and temperature up to 60 °C retained most of the bioactive compounds42,43. The best drying temperature was chosen based on the color L* a* b* and GA content of dried leaves. For GA extraction, PCD leaves powder obtained from each drying temperature level was extracted with 50% (v/v) ethanol at a 1:20 (w/v) ratio in a water bath (Memmert, Model WNB 7-45, Germany) at 70 °C for 2 h under static conditions. The concentration of ethanol, extraction temperature and duration were selected from our previous preliminary research where solvent concentration above 50%, extraction temperature above 70 °C and duration beyond 2 h resulted in decreased GA content of G. inodorum cultivated in different region (unpublished data). The slurry after extraction was filtered through a double layered muslin cloth to separate the residue and extract. The extract was filtered using an Agilent PTFE syringe filter (0.45 µm) and aliquot was transferred to an HPLC vial. The content of GA in the extracts was quantified with HPLC as described in the analytical section.

Effect of ethanol concentration during GA extraction from dried PCD leaves powder

Ethanol was chosen for the extraction of GA as it considered to be a food grade solvent44,45 and moreover it was found to be the appropriate solvent by virtue of safety and efficiency46. The effect of ethanol concentration on GA extraction was studied using the PCD leaves dried at best drying temperature chosen from the previous step and pulverized. Six levels of ethanol concentration, namely 0, 20, 30, 40, 50 and 60% (v/v) prepared in distilled water were used for the extraction of GA from PCD leaves powder while the extraction temperature was maintained at 70 °C. The slurry after extraction was processed as stated above and quantified for GA content. The minimum ethanol concentration that resulted in the optimized GA content and extraction yield was utilized for further experiments.

Effect of temperature during GA extraction from dried PCD leaves powder

The PCD leaves dried at best drying temperature determined in the first step and powdered was used to select the suitable extraction temperature. PCD leaves powder was extracted by holding at different extraction temperature namely, 40, 50, 60, 70 and 80 °C for 2 h under stationary condition while the concentration of ethanol was kept constant at the best concentration chosen from the second step. The extracts were then filtered through muslin cloth and GA content in the filtrate was quantitated as mentioned earlier. The best extraction temperature was chosen according to the optimized GA content and extraction yield.

Effect of maltodextrin concentration during production of PCD extract powder

The PCD extract powder was produced by drying the PCD leaves at optimum drying temperature followed by powdering and extracting with optimum ethanol concentration at optimum extraction temperature. Methods described by Lachowicz et al.47 and Widyaningsih et al.48 were adapted for the production of PCD extract powder using maltodextrin with slight modifications. Different concentrations of maltodextrin ranging from 0 to 5.0% (w/v) were used for the study and added to the concentrated slurry which was concentrated by two times after rotary evaporation stage. The upper concentration of maltodextrin was restricted to 5% considering its high glycemic index. For the extraction of GA, PCD extract powder prepared with or without maltodextrin was suspended in 50% (v/v) ethanol, centrifuged twice at 2822×g (Nuve, Model NF 200, Ankara, Turkey) for 5 min followed by 6742×g (Eppendorf, Model Mini spin, Hamburg, Germany) for 1 min and filtered through Agilent PTFE syringe filter (0.45 µm) before HPLC analysis. The suitable maltodextrin concentration was chosen based on the higher GA content and extraction yield.

Analytical methods

Color analysis

Color parameters of samples were measured using a color meter (Minolta, Model CR-300 chroma meter, Osaka, Japan) and reported as L*, a*, b* values. L* indicates lightness (100) or darkness (0), a* means red (+) or green (−) and b* represents chromaticity yellow (+) or blue (−)49,50.

Determination of moisture content

The moisture content on mass basis was determined as per the 17th edition of Association of Official Analytical Chemists (AOAC)51. Briefly, a known amount of sample was weighed and dried in a hot air oven (Daihan Lab Co., Ltd., Gangwon, Korea) at 105 °C for 4–5 h until constant weight to determine the moisture content and calculated according to the Eq. (1) 52.

Determination of water activity (aw)

The aw of the samples was performed using a water activity meter (AQUA Lab, Model CX3TX, Washington, USA). The aw was determined from the triplicate samples (2 g) held at 25 ± 0.1 °C until equilibrium was reached52.

Quantification of chlorophylls content

For the extraction of chlorophylls, 0.5 g of PCD extract powder was mixed with 10 mL of ice-cold acetone and shaked in an orbital shaker (LabTech, Model LSI 3016R, Korea) at 250 rpm for 1 h at 30 °C. Later, 5 mL of ice-cold ethanol was added to it and shaked again at the similar condition. The samples were filtered and the extraction process were repeated until the sample residue become colorless. The extracted samples were pooled together and concentrated under vacuum at 65 °C53. The residue was re-dissolved in HPLC-grade absolute methanol (1 mL) before analyzed by HPLC. Chlorophylls content were determined using a reversed-phase HPLC system equipped with a degasser, autosampler and diode array detector (Agilent Technologies, Model 1260 Infinity series, Santa Clara, California, USA). HPLC analysis of chlorophylls was performed according to the method described by Varzakas and Kiokias54 with some modifications. The column used for chlorophylls detection was an Agilent Poroshell 120 SB-C18 with a specification of 2.1 × 100 mm, 2.7 µm which was maintained at 30 °C. The isocratic mobile phase consisted of ethyl acetate: methanol (20:80, v/v) at the flow rate of 0.60 mL/min with a run time of 15 min and the injection volume was 5 µL. The spectra were recorded and the chromatograms were obtained at 430 nm for chlorophyll a and 474 nm for chlorophyll b. The identification of chlorophylls was based on the respective standards and their retention times. The identified compounds were quantitated from the peak area using respective calibration curve prepared in the range from 0 to 200 ppm (1 ppm = 1 mg/L). The chlorophylls content calculated in ppm was converted into mg/L of extract and expressed as mg/kg on dry weight basis by considering the initial dried weight of powder used for the extraction.

Quantification of GA content

GA content was determined using a reversed-phase HPLC system equipped with a degasser, autosampler and diode array detector (Agilent Technologies, Model 1260 Infinity series, Santa Clara, California, USA). HPLC analysis of GA was performed according to the method described by Salunkhe and Magdum55 with some modifications. The column used for GA detection was an Agilent Zorbax Eclipse Plus C18 with a specification of 4.6 × 100 mm, 3.5 µm which was maintained at 40 °C. The gradient mobile phase consisted of solvent A as 1% (v/v) phosphoric acid and solvent B as absolute methanol (HPLC grade). The flow rate was fixed at 0.65 mL/min and the injection volume was 5 µL. The gradient elution program was started with 90% (v/v) A and 10% (v/v) B (0 min). At 4 min, the gradient reached was 30% A (v/v) and 70% B (v/v) and maintained for 12 min. The gradient then finally reached 90:10% (v/v) (A: B) at 16 min and maintained for 4 min with a total run time of 20 min. The detection was carried out at 210 nm55. The identification of GA was based on the standard and its retention time. The identified compounds were quantitated from the peak area using respective calibration curve prepared in the range from 0 to 100 ppm. The GA content calculated in ppm was converted into mg/L of extract and expressed as mg/kg on dry weight basis by considering the initial dried weight of powder used for the extraction. Mass yield percentage of extracted GA (%YGA) was calculated as shown in Eq. (2).

Improved purity percentage of GA content in PCD extract powder relative to dried PCD leaves powder (% PExt/Leaves) was calculated as shown in Eq. (3).

DPPH scavenging activity

DPPH free radical scavenging capacity of PCD leaves extract powder was analyzed as previously described by Meza et al.56. Briefly, a 0.1 mM ethanolic stock solution of DPPH was prepared and diluted ten times to obtain the working solution. A 300 µL of sample solution containing PCD extract powder suspended in absolute ethanol at 10 mg/mL concentration was mixed with DPPH working solution (1600 µL). The mixture was incubated in the absence of light for 1 h and absorbance was measured at 515 nm using a UV–Vis spectrophotometer (Agilent Technologies, Model Cary 60 UV–Vis, Santa Clara, California, USA). Ascorbic acid and gallic acid dissolved in absolute ethanol at 10 mg/mL were used as positive controls for comparing the antioxidant activity. The percentage of radical scavenging activity (%RSA) was calculated according to the Eq. (4) 57.

where A0 is the absorbance of DPPH radical solution at 515 nm without extract or standard at 0 min; A60 is the absorbance of DPPH radical solution at 515 nm in the presence of extract or standard at 60 min.

Statistical analysis

Three replications were carried out in each experiment and the results were expressed as mean ± standard error. Statistical analyses were carried out as described in our earlier studies58,59,60 with Statistical Packages for the Social Sciences (SPSS, version 17.0) applying one-way analysis of variance (ANOVA). Statistical differences between means were measured using Duncan's multiple range test (DMRT) and considered significant at p ≤ 0.05.

Results

Effect of PCD leaves drying temperature

The GA content presented in PCD leaves when dried at 40, 50 and 60 °C was analyzed through HPLC (Fig. 2) and shown in Table 1. The dried leaves at 40 and 50 °C had a moisture content of no more than 5.0 ± 0.5% (w/w). The GA content of PCD leaves was significantly (p ≤ 0.05) influenced by drying temperature beyond 40–50 °C range and tended to decrease with increased temperature. For instance, when the drying temperature increased to 60 °C, the GA content significantly (p ≤ 0.05) decreased by 5% (w/w) when compared to drying at 50 °C. However, the GA content (8307 ± 39 mg/kg) presented in PCD leaves when dried at 50 °C was not significant (p > 0.05) when compared to drying at 40 °C.

Color is an important parameter in which L* indicates a light–dark spectrum with a range from 0 (black) to 100 (white), a* denotes the green (-60) to red (+ 60) spectrum, and b* means the blue (− 60) to yellow (+ 60) spectrum dimensions49. The different temperatures in the drying method had a significant effect (p ≤ 0.05) on the lightness (L*), redness (a*), and yellowness (b*) of PCD leaves. As illustrated in Fig. 3, L* values decreased significantly (p ≤ 0.05) from 63.8 to 54.8 when the drying temperature increased from 40 to 60 °C. The lesser the L* value, the darker the leaves became. It was also observed that the color of the leaves gradually shifted in green and yellow directions. This was evident from a decrease in greenness (a*) and an increase in yellowness (b*). However, the leaves dried at 40 °C possessed less green color when compared to 50 or 60 °C. In terms of redness (a*), samples dried at 60 °C showed an increase in positive a* values. Similarly, b* value increased upon increasing temperature. As the drying temperature of 60 °C resulted in the darker color of the leaves when compared to using a lower temperature, using the temperature between 40 and 50 °C is thus suggested for drying. However, considering the energy consumption rate, drying at 40 °C consumes more energy in terms of duration as it requires 24 h for complete drying. On the other hand, drying at 50 °C is considered energy efficient as the drying process is completed within 12 h. The leaves were dried at 50 °C for 12 h with a mass yield of 11.7 ± 1.1% (w/w) on a fresh weight basis further ground to powder, and sieved through a siever to yield powder particles of not more than 150 µm in size.

Effect of drying temperature on color parameters of PCD leaves. The symbol “ ” represents a spectrum of lightness and darkness, ranging from 0 (representing black) to 100 (representing white). The symbol “

” represents a spectrum of lightness and darkness, ranging from 0 (representing black) to 100 (representing white). The symbol “ ” signifies the spectrum of green (− 60) to red (+ 60), while “

” signifies the spectrum of green (− 60) to red (+ 60), while “ ” represents the spectrum of blue (− 60) to yellow (+ 60). Error bars indicate the standard errors which deviated from the mean (n = 3). The average values with different alphabets indicated a significant difference (p ≤ 0.05) among the same type of color value between drying temperatures.

” represents the spectrum of blue (− 60) to yellow (+ 60). Error bars indicate the standard errors which deviated from the mean (n = 3). The average values with different alphabets indicated a significant difference (p ≤ 0.05) among the same type of color value between drying temperatures.

Effect of ethanol concentration during GA extraction from dried PCD leaves powder

The dried PCD powder obtained from the previous step was extracted with different concentrations of ethanol and the results are presented in Fig. 4. From the results, an increase in GA content was observed with the elevated concentration of ethanol used for the extraction. Distilled water as a solvent (0% ethanol) could extract the least amount of GA with only 3894 ± 87 mg/kg of dried PCD leaves powder. Extraction of PCD leaves powder with 20 to 50% (v/v) ethanol resulted in 4912 ± 71 to 8414 ± 82 mg/kg. The YGA at 50% (v/v) ethanol was 2.2-fold higher when compared to GA extracted with distilled water. The %YGA was found to be 0.84% on dried weight basis of PCD leaves powder. From the results, it was observed that when the concentration of ethanol was increased to 60% (v/v), a significant (p ≤ 0.05) drop in GA content was noticed when compared to 50% (v/v). From the results, it is suggested that a concentration of 50% (v/v) ethanol was the optimum level for extracting 8414 ± 82 mg/kg GA from dried PCD leaves.

Effect of ethanol concentration on GA content ( ) and mass yield percentage (

) and mass yield percentage ( ) of extracted GA of dried PCD leaves powder. A constant extraction temperature of 70 °C for 2 h was maintained while varying different concentrations of ethanol. Error bars indicate the standard error from the mean (n = 3). Means with different lowercase alphabets indicated a significant difference (p ≤ 0.05) between ethanol concentrations. PCD Phak Chiang Da, GA gymnemic acid.

) of extracted GA of dried PCD leaves powder. A constant extraction temperature of 70 °C for 2 h was maintained while varying different concentrations of ethanol. Error bars indicate the standard error from the mean (n = 3). Means with different lowercase alphabets indicated a significant difference (p ≤ 0.05) between ethanol concentrations. PCD Phak Chiang Da, GA gymnemic acid.

Effect of temperature during GA extraction from dried PCD leaves powder

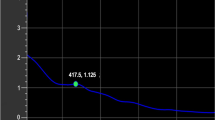

In this experiment, PCD leaves powder was extracted with 50% ethanol as optimized from the previous experiment and extraction temperature was studied ranging from 40 to 80 °C maintained for 2 h. The results of the GA content in the extracts are depicted in Fig. 5. The study found that the concentration of GA tended to increase significantly (p ≤ 0.05) from 7006 ± 78 to 8416 ± 80 mg/kg dried weight with increasing extraction temperature from 40 to 70 °C respectively. The %YGA increased from 0.7% at 40 °C to 0.84% at 70 °C on dried weight basis of PCD leaves powder. However, when the extraction temperature was set at 80 °C, the GA significantly (p ≤ 0.05) mitigated by 6.14% when compared to that of 70 °C. From the results, it is suggested that the extraction of leaves powder with 50% (v/v) ethanol at 70 °C for 2 h is appropriate to yield a higher GA content of 8414 ± 82 mg/kg from dried PCD leaves.

Effect of extraction temperature on GA content ( ) and mass yield percentage (

) and mass yield percentage ( ) of extracted GA of dried PCD leaves powder. A constant ethanol concentration of 50% (v/v) was maintained while varying different extraction temperatures. Error bars indicate the standard error from the mean (n = 3). Means with different lowercase alphabets indicate a significant difference (p ≤ 0.05) between extraction temperatures. PCD Phak Chiang Da, GA gymnemic acid.

) of extracted GA of dried PCD leaves powder. A constant ethanol concentration of 50% (v/v) was maintained while varying different extraction temperatures. Error bars indicate the standard error from the mean (n = 3). Means with different lowercase alphabets indicate a significant difference (p ≤ 0.05) between extraction temperatures. PCD Phak Chiang Da, GA gymnemic acid.

Effect of maltodextrin content during production of PCD extract powder

GA content of PCD extract powder prepared with maltodextrin

Overall, there was an increase in purity percentage of GA in PCD extract powder relative to that of PCD leaves powder. A 252% (w/w) of %PExt/Leaves was seen in purity percentage on mass basis when PCD extract powder prepared without maltodextrin. However, the value gradually decreased from 223% (w/w) at the addition of 0.5% (w/v) maltodextrin to 116% (w/w) with 5% (w/v) maltodextrin. The results showed that the amount of GA found in PCD extract powder was inversely related to the amount of maltodextrin used for the preparation. The increased amount of maltodextrin resulted in decreased GA content as shown in Fig. 6. The extract powder prepared without maltodextrin contained a GA content of 20,900 ± 70 mg/kg. From Fig. 6, it was observed that the concentration of maltodextrin added between 0.5 and 5% (w/v) had a significant (p ≤ 0.05) effect on the mitigation of the GA content by 53.8% (w/w) (9660 mg/kg at 5.0%/20,900 mg/kg at 0% × 100 − 100%). when compared to the powder prepared without maltodextrin. Although the extract powder prepared with 0.5% (w/v) maltodextrin affected the GA content, the physical stability of the powder prepared with 0.5% (w/v) maltodextrin was retained after 30 days of storage while the powder prepared without maltodextrin caused solid coagulation. Thus, low concentration, 0.5% (w/v) maltodextrin could be chosen as an anti-caking agent in the drying process to retain the powder quality during storage.

The actual GA content ( ) and improved purity percentage (

) and improved purity percentage ( ) of GA in PCD extract powder prepared with different maltodextrin concentrations relative to dried PCD leaves powder. Error bars indicate the standard errors from the means (n = 3). The averages with different lowercase alphabets indicate a significant difference (p ≤ 0.05) between maltodextrin concentrations. PCD Phak Chiang Da, GA gymnemic acid.

) of GA in PCD extract powder prepared with different maltodextrin concentrations relative to dried PCD leaves powder. Error bars indicate the standard errors from the means (n = 3). The averages with different lowercase alphabets indicate a significant difference (p ≤ 0.05) between maltodextrin concentrations. PCD Phak Chiang Da, GA gymnemic acid.

Characterization of PCD extract powder prepared with maltodextrin

The comparison of color parameters, moisture content, aw, GA and chlorophylls content between current study and another research61 has been depicted in Table 2. From the color analysis, PCD extract powder obtained in the current study had a brightness (L*) value of 47.5 ± 0.21, which is lower when compared to leaves dried at 50 °C indicating that the final product had a darker appearance than starting material. This might be due to the addition of maltodextrin that contributed to the darker appearance when combined with PCD leaves extract at a high temperature (65 °C). Similarly, the mitigation in negative value of a* (− 1.49 ± 0.01) and a positive sign of the b* (14.6 ± 0.3) are indicative of the destruction in green and yellow color of the sample respectively when compared to starting material. Thus, the overall appearance of the PCD extract powder was a dark greenish tint mixed with yellow. Among the chlorophylls, chlorophyll a is more sensitive to pheophytization than chlorophyll b. In the present study, the PCD extract powder contained 356 ± 20 and 270 ± 14 mg/kg of chlorophyll a and b respectively. The GA concentration present in the PCD extract powder prepared with maltodextrin was found to be 18,500 ± 60 mg/kg. The moisture content and aw of the powder sample were found to be 4.76% ± 0.10 (w/w) and 0.246 ± 0.001, respectively (Table 2). In general, powders with a moisture content of less than 10% (w/w) can be considered microbiologically safe. For instance, in the present study, the PCD powder with 4.76% ± 0.10 moisture had an aw of only 0.246 ± 0.001. This level of aw and moisture content are sufficient enough to prevent the growth of various microorganisms and are ideal for dry or powdered products.

Table 3 compares the antioxidant potential of PCD extract powder prepared with 0.5% (w/v) maltodextrin with that of Gymnema extracts by others research23,62,63,64. From the results of present study, it was found that PCD extract powder was able to neutralize 75.8% ± 2.6 of DPPH free radicals at 1.58 mg/mL concentration. Results also showed that the standards (gallic acid and ascorbic acid) had stronger scavenging activities against the radical than the PCD extract powder at the same concentration tested.

Discussion

The study highlights the importance of optimizing the drying temperature for PCD leaves to preserve the GA content and associated antioxidant activity. The results, as shown in Table 1, indicated that the drying temperature had a significant impact on the GA content in the leaves. The dried leaves at 40 and 50 °C with less than 5.0% moisture content suggests that these temperatures were suitable for drying the leaves without retaining excessive moisture, which is crucial for preventing microbial growth and ensuring the stability of the plant material. Drying temperatures within the range of 40–50 °C were found to be favorable for maintaining a higher GA concentration, while temperatures above 60 °C were detrimental to both GA content and overall antioxidant levels. The decrease in GA content observed at 60 °C could be attributed to the oxidation of compounds at relatively high temperatures in the presence of air65. When exposed to elevated temperatures, certain heat-labile phytochemicals, including GA, can undergo degradation or chemical changes, resulting in reduced concentrations. This finding aligns with previous reports by Peries et al.66 and Sagrin and Chong67, which indicated that high drying temperatures can lead to the destruction of heat-labile phytochemicals in plant materials. Furthermore, the study suggested that drying temperatures above 60 °C could significantly mitigate the antioxidant content of the leaves67,68. Antioxidants play a crucial role in neutralizing harmful free radicals and preventing oxidative damage. However, excessive heat during the drying process may cause the degradation or denaturation of these antioxidants, leading to a decline in their concentration and thus reducing the overall antioxidant activity of the plant material.

The study also examined the effect of drying temperature on the color characteristics of PCD leaves. Color analysis was conducted using the L*, a*, and b* parameters, which represent the lightness, redness, and yellowness dimensions, respectively. The results presented in Fig. 3 indicated that the drying temperature had a significant effect on the lightness (L*), redness (a*), and yellowness (b*) of PCD leaves. As the drying temperature increased from 40 to 60 °C, the L* values decreased significantly, indicating darker leaves. This darkening of the leaves could be attributed to the degradation of chlorophylls during the drying process69. Chlorophylls, responsible for the green color in leaves, undergo degradation when exposed to heat, leading to a decrease in greenness. Furthermore, the color of the leaves gradually shifted in the green and yellow directions. Leaves dried at 40 °C exhibited less green color compared to those dried at 50 or 60 °C, indicating that the degradation of chlorophylls depends not only on the drying temperature but also on the drying duration. The longer drying duration of 24 h at 40 °C, compared to 12 and 8 h at 50 and 60 °C, respectively, likely contributed to the reduction in greenness. This is consistent with the results of Rudra et al.70 who reported that drying at higher temperatures and long drying durations are the two important factors resulting in reduced lightness of samples during dehydration process. The increase in positive a* value in samples dried at 60 °C could be attributed to the high temperature exposure, which transforms chlorophylls into pheophytin and pyropheophytin71. Similar observations have been reported in studies on other plant materials, such as pandan leaves, where drying at high temperatures led to increased redness. The increase in yellowness (b*) values with increasing temperature could be explained by the degradation of chlorophylls into derivatives caused by the high temperature. This degradation contributes to the brownish color of PCD leaves dried at 60 °C72. Overall, the drying temperature and duration play crucial roles in the appearance and color of the leaves during the drying process. The study suggests that a drying temperature between 40 and 50 °C is recommended to preserve the desired color characteristics of the leaves. However, it is worth considering the energy consumption aspect. Drying at 40 °C requires a longer duration of 24 h, while drying at 50 °C completes the process within 12 h, making it more energy-efficient.

When different concentrations of ethanol used for the extraction of GA from PCD powder, the results (Fig. 4) indicate that the GA content increased with higher concentrations of ethanol used for extraction. Comparing the results of the present study with previous research, it is noted that Ahamad et al.13 reported a higher %YGA of 12.2% from G. sylvestre leaves. The difference in yield could be attributed to the extraction methods used in the respective studies. Ahamad et al.13 employed ultrasonic sound in coupled with Soxhlet extraction, while the present study utilized ethanol extraction without ultrasonic sound. Additionally, different species of Gymnema were used, which could contribute to variations in GA content. Another study by Suwan et al.16 mentioned that PCD leaves extract using ethanol as an extractant produced approximately 40,000 mg/kg dried weight of GA, which was about 5 times higher compared to the present study’s results with a %YGA of 4%. The higher yield in Suwan et al.’s16 study may be attributed to the prolonged extraction period of 3 days compared to the 2 h used in the current study. Furthermore, the authors point out that cultivated PCD from different regions may have varying GA content16, which could explain the relatively lower GA content observed in the current study. This indicates that environmental factors and cultivation practices might influence the GA content in PCD leaves. It was also observed that increasing the ethanol concentration from 50 to 60% (v/v) led to a significant drop in GA content. This finding aligns with the research conducted by Srinuanchai et al.27, who studied G. inodorum leaves and found that 75% (v/v) ethanol resulted in higher GA content compared to 95% (v/v) ethanol. The addition of water to ethanol was suggested as a factor that enhances the solubilizing capacity and improves the surface area for GA-ethanol interaction, facilitating the extraction process73. It is worth noting that glycoside molecules like GA are generally more readily extracted in aqueous solvents than alcoholic solvents14. Because, glycosides like gymnemic acid are polar compounds due to the presence of hydroxyl groups and other polar functional groups. Ethanol, on the other hand, is a polar solvent due to its ability to form hydrogen bonds with other polar molecules. In a 50% (v/v) ethanol solution, the presence of water also contributes to its polarity. When PCD leaves extracted with a 50% (v/v) ethanol solvent, hydrogen bonding and other intermolecular interactions can occur between the hydroxyl groups of GA and the hydroxyl groups of ethanol and water in the solvent. This interaction could have facilitated the dissolution of GA in the solvent. Based on the results, the study suggests that a concentration of 50% (v/v) ethanol provided the highest GA yield compared to distilled water and higher ethanol concentrations.

The study found that increasing the extraction temperature from 40 to 70 °C led to a significant increase in GA concentration. This observation is consistent with other research that has shown an increase in the recovery of phenolic compounds with the increase in extraction temperature, up to a certain point74. Higher extraction temperatures enhance solubility, diffusion rate, mass transfer rate, and surface tension, which improve the extractability of phenolic compounds75. These factors contribute to the increased extraction of GA from the PCD leaves at temperatures up to 70 °C. However, when the extraction temperature was set at 80 °C, there was a significant decrease in GA content compared to 70 °C. The decrease in GA content at 80 °C can be attributed to the degradation of heat-sensitive GA as the temperature increases. This phenomenon is supported by the findings of a study by Manika et al.73, where drying Gymnema leaves using sun drying drastically reduced GA content by 53% compared to shade drying. This suggests that high temperatures can lead to the degradation of GA. The authors also suggest that exposure to light, in addition to temperature, may have a deleterious effect on GA concentration73. This implies that protecting the extract from light during the extraction process is important to preserve the GA content. Similar observations have been made in studies on the extraction of phenolic compounds, where increasing extraction temperatures resulted in decreased total phenolic content76,77. This suggests that the degradation or loss of phenolic compounds can occur at higher temperatures.

The results indicate an inverse relationship between the amount of maltodextrin used and the GA content in the extract powder. These findings are consistent with other studies that have shown that an increase in maltodextrin concentration leads to a reduction in polyphenols, flavonoids, and antioxidant capacity in end products78,79,80. The decreasing trend in GA content with increasing maltodextrin concentration could be attributed to the dilution effect caused by maltodextrin, which reduces the concentration of GA in the extract79. The results indicate that increasing the concentration of maltodextrin leads to a decrease in GA content, likely due to dilution effects. The results also suggest that the inclusion of maltodextrin, even at a low concentration, can improve the physicochemical stability of the powder during storage. It's important to note that maintaining the physicochemical state of the dried product is crucial to preserve powder quality during storage81. In this context, using a relatively low concentration of maltodextrin, such as 0.5% (w/v), as an anti-caking agent during the drying process is recommended. This concentration not only retains the powder quality during storage but also improves solubility.

The characteristics of PCD extract powder prepared with maltodextrin was compared with previous research in terms of color parameters, moisture content, aw, GA content, and chlorophyll. Color analysis reveals that the PCD extract powder obtained in the current study had a lower brightness (L*) value compared to leaves dried at 50 °C, indicating a darker appearance of the final product. This darker appearance can be attributed to the addition of maltodextrin and the higher temperature (65 °C) used during the drying process. Previous research Binnisha et al.61, also reported similar findings, where Gymnema leaves powder dried at low temperatures resulted in increased brightness, greenness, and yellowness. The degree of greenness in dried leaves is influenced by the content of chlorophylls, which are susceptible to heat and light82. Chlorophyll a is more sensitive to degradation (pheophytization) than chlorophyll b. In the current study, the PCD extract powder contained relatively low amounts of chlorophyll a and chlorophyll b compared to the results reported by Binnisha et al.61. The usage of a solar dryer in their study minimized the destruction of chlorophylls during drying. On the other hand, the concentration of GA in the PCD extract powder was found to be higher in the current study compared to Binnisha et al.’s study61. This difference in GA content could be attributed to variations in the plant species used in the studies. Similarly, Jeytawan et al.62 reported the lowest concentrations of gymnemic acid in roasted G. inodorum leaves and suggested that variations in gymnemic acid content might be due to differences in the regions where the samples were obtained. The decrease in greenness observed in the PCD extract powder can be attributed to the conversion of chlorophylls into pheophytin and pyropheophytin during the drying process at high temperatures in the presence of maltodextrin71. However, it is worth noting that chlorophyll degradation products could still possess health effects similar to chlorophylls in terms of nutritional benefits82. Regarding moisture content and aw, the obtained data aligns with the results of other studies, which reported moisture content values lower than 10% (w/w) for extract powders30,83. A low aw value (0.20–0.40) indicates stability against browning, lipid oxidation, microbial growth, hydrolysis, and enzymatic reactions84. It is a measure of available free water responsible for chemical, biochemical changes, and microbiological growth84. In the current study, the PCD powder with its low moisture content and a low aw provides conditions that are sufficient to prevent the growth of various microorganisms and are considered ideal for dry or powdered products85.

In recent years, the DPPH scavenging activity assay has emerged as a widely employed method for evaluating antioxidant activity, despite the availability of other techniques such as ABTS, reducing power, and FRAP methods. Its popularity stems from several factors, including its simplicity, affordability, and rapidity. Moreover, the DPPH assay offers versatility by enabling the assessment of diverse sample types, encompassing natural extracts, synthetic compounds, and food products86,87. According to the present study, PCD extract powder exhibited a DPPH scavenging activity of 75.8%. This indicates its ability to neutralize DPPH free radicals. On the other hand, Subramanian et al.23, Fazal et al.63, Ghous et al.64 and Jeytawan et al.62 obtained radical scavenging activity of 73.4, 54.4, 83.0 and 62.6% respectively (Table 3). Jeytawan et al.62 stated that antioxidant capacity of processed leaves was higher when compared to fresh leaves. The authors suggested that lower antioxidant activity in fresh leaves might be due to the absence of dry and wet weight adjustment62. It is also interesting to note that the difference in scavenging activity between different studies might be due to variation in plant species, source of plant collection, type of solvent used for extraction and the extraction parameters.

Conclusion

Although the use of herbal extracts to manage diabetes and other ailments has been long practiced, its utilization in its native form hinders its popularity due to low concentration of active substances, poor absorption, lack of standardization and other characteristics. Thus, preparing a formulation in a form that is acceptable with enriched gymnemic acid will open up interesting applications in the nutraceutical, functional food and therapeutical sectors. In this connection, the present study evaluated the conditions for the preparation of GA-enriched extracts from PCD leaves and their formulation into a powder form with maltodextrin as an anti-caking agent. The results also showed that the PCD extract powder had high radical scavenging activity which is very crucial to destroy the deleterious free radicals in diabetes. Yet, further investigation to assess other specific antidiabetic assays, combine with other herbs for synergistic effects, determine efficient extraction, and apply alternative drying/extraction techniques could be considered in the future. It can be anticipated that when the outcome of the study realized in the future in numerous applications, farmers could prefer the Gymnema cultivation as an alternative cropping choice against sugarcane, rice and corn as disposal of their residues through open burning causes fine PM 2.5 air pollution.

Data availability

The data sets generated during and/or analysed during the current study are available from the corresponding authors on reasonable request.

Abbreviations

- PCD:

-

Phak Chiang Da

- GA:

-

Gymnemic acid

- DPPH:

-

2,2-Diphenyl-1-picrylhydrazyl

- aw :

-

Water activity

- v/v :

-

Volume/volume

- w/v :

-

Weight/volume

- AOAC:

-

Association of Official Analytical Chemists

- HPLC:

-

High performance liquid chromatography

- %YGA :

-

Mass yield percentage of extracted gymnemic acid

- % PExt/Leaves :

-

Improved purity percentage of GA content in PCD extract powder relative to dried PCD leaves powder

- %RSA:

-

Percentage of radical scavenging activity

- ANOVA:

-

Analysis of variance

- DMRT:

-

Duncan’s multiple range test

References

Tiwari, P., Mishra, B. & Sangwan, N. S. Phytochemical and pharmacological properties of Gymnema sylvestre: An important medicinal plant. BioMed Res. Int. 2014, 1–18 (2014).

Alam, O. et al. Recent developments made in the assessment of the antidiabetic potential of gymnema species—From 2016 to 2020. J. Ethnopharmacol. 286, 114908 (2022).

Khan, F. et al. Comprehensive review on phytochemicals, pharmacological and clinical potentials of Gymnema sylvestre. Front. Pharmacol. 10, 1223 (2019).

Turner, S. et al. The effect of a 14-day Gymnema sylvestre intervention to reduce sugar cravings in adults. Nutrients 14, 5287 (2022).

Pamuru, R. R., Yarrapalle, A. & Lakshmi, D. V. Antidiabetic Plants for Drug Discovery 23–53 (Apple Academic Press, 2023).

Bespinyowong, R., Pongthananikorn, S. & Chiabchalard, A. Efficacy and safety of Gymnema inodorum tea consumption in type 2 diabetic patients. Chulalongkorn Med. J. 57, 587–599 (2013).

Abbas, Q., Al-Thawadi, S. & Perna, S. Phytochemicals in the management of diabetes. Nanotechnol. Diabetes Manag. 59, 128 (2022).

Soumyanath, A. Traditional Medicines for Modern Times: Antidiabetic Plants (CRC Press, 2005).

Oboh, M., Govender, L., Siwela, M. & Mkhwanazi, B. N. Anti-diabetic potential of plant-based pentacyclic triterpene derivatives: Progress made to improve efficacy and bioavailability. Molecules 26, 7243 (2021).

Waman, A. A., Dhanani, T. & Manivel, P. Ultrasound assisted extraction: A quick and efficient method for extraction of Gymnemagenin from Gymnema sylvestre (Retz.) R. Br. ex Sm. J. Andaman Sci. Assoc. 27, 54–57 (2022).

Saeed, R., Ahmed, D. & Mushtaq, M. Ultrasound-aided enzyme-assisted efficient extraction of bioactive compounds from Gymnema sylvestre and optimization as per response surface methodology. Sustain. Chem. Pharm. 29, 100818 (2022).

Ramalingam, R. et al. Antimicrobial properties and biocompatibility of electrospun poly-ε-caprolactone fibrous mats containing Gymnema sylvestre leaf extract. Mater. Sci. Eng. C 98, 503–514 (2019).

Ahamad, J., Amin, S. & Mir, S. R. Optimization of ultrasonic-assisted extraction of gymnemic acid from Gymnema sylvestre leaves using response surface methodology. Anal. Chem. Lett. 4, 104–112 (2014).

Sheoran, S., Panda, B. P., Admane, P. S., Panda, A. K. & Wajid, S. Ultrasound-assisted extraction of gymnemic acids from Gymnema sylvestre leaves and its effect on insulin-producing RINm-5 F β cell lines. Phytochem. Anal. 26, 97–104 (2015).

Mandal, V., Dewanjee, S. & Mandal, S. C. Microwave-assisted extraction of total bioactive saponin fraction from Gymnema sylvestre with reference to gymnemagenin: A potential biomarker. Phytochem. Anal. Int. J. Plant Chem. Biochem. Tech. 20, 491–497 (2009).

Suwan, N., Baison, W. & Chuajedton, A. Purification of Gymnema inodorum leaf extract and its antifungal potential against Colletotrichum gloeosporioides. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. 92, 667–677 (2022).

Kameswaran, S. & Perumal, K. Extraction and purification of gymnemic acid from Gymnema sylvestre R. Br. In Medicinal Plants Biodiversity, Sustainable Utilization and Conservation 521–529 (2020).

Saiki, P. et al. Purified gymnemic acids from Gymnema inodorum tea inhibit 3T3-L1 cell differentiation into adipocytes. Nutrients 12, 2851 (2020).

Srinuanchai, W., Nooin, R., Jarussophon, S., Kasemwong, K. & Nuchuchua, O. Determination of gymnemic acid level in Gymnema inodorum leaves using multiple reaction monitoring mass spectrometry. J. Chem. Metrol 13, 75–79 (2019).

Shimizu, K. et al. Suppression of glucose absorption by some fractions extracted from Gymnema sylvestre leaves. J. Vet. Med. Sci. 59, 245–251 (1997).

Youl, E. N. et al. Hypoglycemic and antihyperglycemic activities of the aqueous ethanolic extracts of Gymnema sylvestre (RETZ) R. Br. Ex SCHULT and Sclerocarya birrea (A RICH) HOCHST. Afr. J. Pharm. Pharmacol. 14, 339–346 (2020).

Vaghela, M., Iyer, K. & Pandita, N. In vitro inhibitory effect of Gymnema sylvestre extracts and total gymnemic acids fraction on select cytochrome P450 activities in rat liver microsomes. Eur. J. Drug Metab. Pharmacokinet. 43, 227–237 (2018).

Subramanian, S., Dowlath, M. J. H., Karuppannan, S. K., Saravanan, M. & Arunachalam, K. D. Effect of solvent on the phytochemical extraction and GC-MS analysis of Gymnema sylvestre. Pharmacogn. J. 12, 749 (2020).

Sarker, S. D., Latif, Z. & Gray, A. I. Natural Product Isolation 1–25 (Humana Press, 2006).

Waszkowiak, K. & Gliszczyńska-Świgło, A. Binary ethanol–water solvents affect phenolic profile and antioxidant capacity of flaxseed extracts. Eur. Food Res. Technol. 242, 777–786 (2016).

Gan, C. Y. & Latiff, A. A. Optimisation of the solvent extraction of bioactive compounds from Parkia speciosa pod using response surface methodology. Food Chem. 124, 1277–1283 (2011).

Srinuanchai, W. et al. Inhibitory effects of Gymnema inodorum (Lour.) Decne leaf extracts and its triterpene saponin on carbohydrate digestion and intestinal glucose absorption. J. Ethnopharmacol. 266, 113398 (2021).

Suwan, N., Baison, W. & Chuajedton, A. Purification of Gymnema inodorum leaf extract and its antifungal potential against Colletotrichum gloeosporioides. Proc. Natl. Acad. Sci. India Sect. B 92, 1–11 (2022).

An, J.-P. et al. Oleanane triterpenoids from the leaves of Gymnema inodorum and their insulin mimetic activities. J. Nat. Prod. 83, 1265–1274 (2020).

Caliskan, G. & Dirim, S. N. The effect of different drying processes and the amounts of maltodextrin addition on the powder properties of sumac extract powders. Powder Technol. 287, 308–314 (2016).

Feng, Y., Zhang, M., Fan, K. & Mujumdar, A. S. Effects of drying methods on quality of fermented plant extract powder. Drying Technol. 36, 1913–1919 (2018).

Lee, S. Y., Ferdinand, V. & Siow, L. F. Effect of drying methods on yield, physicochemical properties, and total polyphenol content of chamomile extract powder. Front. Pharmacol. 13, 3209 (2022).

Shang, F., Kryzhska, T. & Duan, Z. Study on the optimization of spray drying process for Areca taro powder with microcystalline cellulose. Technol. Audit Prod. Reserv. 6, 62 (2021).

Cheng, H. et al. Optimization of spray-drying process parameters to study anti-sticking effect of hydroxypropyl methyl cellulose-VLV on Corni fructus extracts. AAPS PharmSciTech 23, 58 (2022).

Stavra, K., Plati, F., Pavlidou, E. & Paraskevopoulou, A. Characterization of lemon juice powders produced by different drying techniques and carrier materials. Drying Technol. 40, 1923–1934 (2022).

Michalska-Ciechanowska, A., Hendrysiak, A., Brzezowska, J., Wojdyło, A. & Gajewicz-Skretna, A. How do the different types of carrier and drying techniques affect the changes in physico-chemical properties of powders from chokeberry pomace extracts? Foods 10, 1864 (2021).

Mutlu, C. & Erbas, M. Evaluating the effects of different drying methods, carrier materials and their ratios to produce bioactive honey-like powder. J. Apic. Res. 62, 364–373 (2023).

Nadeem, H. Ş, Torun, M. & Özdemir, F. Spray drying of the mountain tea (Sideritis stricta) water extract by using different hydrocolloid carriers. LWT Food Sci. Technol. 44, 1626–1635 (2011).

Martinelli, L., Gabas, A. L. & Telis-Romero, J. Thermodynamic and quality properties of lemon juice powder as affected by maltodextrin and arabic gum. Drying Technol. 25, 2035–2045 (2007).

Ounjaijean, S., Sukati, S., Somsak, V. & Sarakul, O. The potential role of Gymnema inodorum leaf extract treatment in hematological parameters in mice infected with Plasmodium berghei. J. Trop. Med. 2021, 1–7 (2021).

Jiménez-Moreno, N., Volpe, F., Moler, J. A., Esparza, I. & Ancín-Azpilicueta, C. Impact of extraction conditions on the phenolic composition and antioxidant capacity of grape stem extracts. Antioxidants 8, 597 (2019).

Oliveira, S. M., Brandao, T. R. & Silva, C. L. Influence of drying processes and pretreatments on nutritional and bioactive characteristics of dried vegetables: A review. Food Eng. Rev. 8, 134–163 (2016).

Vimercati, W. C. et al. Influence of drying temperature on drying kinetics, energy consumption, bioactive compounds and cooking quality of pasta enriched with spinach. J. Food Process. Eng. 43, e13571 (2020).

Roopchand, D. E. et al. Food-compatible method for the efficient extraction and stabilization of cranberry pomace polyphenols. Food Chem. 141, 3664–3669 (2013).

Tavakoli, S. et al. Ultrasonic-assisted food-grade solvent extraction of high-value added compounds from microalgae Spirulina platensis and evaluation of their antioxidant and antibacterial properties. Algal Res. 60, 102493 (2021).

Wang, H. J., Pan, M. C., Chang, C. K., Chang, S. W. & Hsieh, C. W. Optimization of ultrasonic-assisted extraction of cordycepin from Cordyceps militaris using orthogonal experimental design. Molecules 19, 20808–20820 (2014).

Lachowicz, S., Michalska-Ciechanowska, A. & Oszmiański, J. The impact of maltodextrin and inulin on the protection of natural antioxidants in powders made of Saskatoon berry fruit, juice, and pomace as functional food ingredients. Molecules 25, 1805 (2020).

Widyaningsih, T., Akbar, S. & Wijayanti, N. IOP Conference Series: Earth and Environmental Science 012035 (IOP Publishing, 2018).

Youssef, K. M. & Mokhtar, S. M. Effect of drying methods on the antioxidant capacity, color and phytochemicals of Portulaca oleracea L. leaves. J. Nutr. Food Sci. 4, 1 (2014).

Phimolsiripol, Y. et al. Shelf life extension of chilled pork by optimal ultrasonicated Ceylon Spinach (Basella alba) extracts: Physicochemical and microbial properties. Foods 10, 1241 (2021).

AOAC. Official Methods of Analysis 17th edn. (Association of Official Analytical Chemists, 2000).

Khemacheewakul, J. et al. Production and storage stability of antioxidant fiber from pigeon pea (Cajanus cajan) pod. J. Microbiol. Biotechnol. Food Sci. 2021, 293–297 (2021).

Zeb, A. & Ullah, F. Reversed phase HPLC-DAD profiling of carotenoids, chlorophylls and phenolic compounds in Adiantum capillus-veneris leaves. Front. Chem. 5, 29 (2017).

Varzakas, T. & Kiokias, S. HPLC analysis and determination of carotenoid pigments in commercially available plant extracts. Curr. Res. Nutr. Food Sci. J. 4, 01–14 (2016).

Salunkhe, V. R. & Magdum, C. S. UV and HPLC method development of azadirachtin and gymnemic acid in polyherbal churna and its validation. Eur. J. Pharm. Med. Res. 3, 324–335 (2016).

Meza, A., Rojas, P., Cely-Veloza, W., Guerrero-Perilla, C. & Coy-Barrera, E. Variation of isoflavone content and DPPH• scavenging capacity of phytohormone-treated seedlings after in vitro germination of cape broom (Genista monspessulana). S. Afr. J. Bot. 130, 64–74 (2020).

Rachtanapun, P. et al. Characterization of chitosan film incorporated with curcumin extract. Polymers 13, 963 (2021).

Nunta, R. et al. Batch and continuous cultivation processes of Candida tropicalis TISTR 5306 for ethanol and pyruvate decarboxylase production in fresh longan juice with optimal carbon to nitrogen molar ratio. J. Food Process. Eng. 42, e13227 (2019).

Khemacheewakul, J. et al. Validation of mathematical model with phosphate activation effect by batch (R)-phenylacetylcarbinol biotransformation process utilizing Candida tropicalis pyruvate decarboxylase in phosphate buffer. Sci. Rep. 11, 1–11 (2021).

Nunta, R. et al. Valorization of rice straw, sugarcane bagasse and sweet sorghum bagasse for the production of bioethanol and phenylacetylcarbinol. Sci. Rep. 13, 727 (2023).

Binnisha, N. V., Nalina, L., Mahendiran, R., Rajamani, K. & Uma, D. Effect of Different Drying Methods on Quality Parameters of Gymnema (Gymnema sylvestre R. Br) (2021).

Jeytawan, N. et al. Antioxidant and phytochemical potential and phytochemicals in Gymnema inodorum (Lour.) Decne in Northern Thailand. Plants 11, 3498 (2022).

Fazal, H., Ahmad, N. & Khan, M. A. Physicochemical, phytochemical evaluation and DPPH-scavenging antioxidant potential in medicinal plants used for herbal formulation in Pakistan. Pak. J. Bot. 43, 63–67 (2011).

Ghous, T. et al. Evaluation of α-glucosidase inhibition, antioxidant and antibacterial effects of Gymnema sylvestre R. Br. Banglad. J. Bot. 50, 61–68 (2021).

Bahloul, N., Boudhrioua, N., Kouhila, M. & Kechaou, N. Effect of convective solar drying on colour, total phenols and radical scavenging activity of olive leaves (Olea europaea L.). Int. J. Food Sci. Technol. 44, 2561–2567 (2009).

Peries, C. M., Navarthne, S., Wijesinghe, J., Henagamage, A. P. & Coorey, R. Effect of different drying methods on antioxidant activity and availability of phytochemicals in leaves of Costus speciosus, Coccinia grandis and Gymnema sylvestre. Asian J. Eng. Appl. Technol. 11, 29–35 (2022).

Sagrin, M. S. & Chong, G. H. Effects of drying temperature on the chemical and physical properties of Musa acuminata Colla (AAA Group) leaves. Ind. Crops Prod. 45, 430–434 (2013).

Duvivier, P., Hsieh, P., Lai, P. & Charle, A. Retention of phenolics, carotenoids, and antioxidant activity in the Taiwanese sweet potato (Ipomoea batatas Lam.) CV tainong 66 subjected to different drying conditions. Afr. J. Food Agric. Nutr. Dev. 10, 285 (2010).

Adhamatika, A., Murtini, E. & Sunarharum, W. IOP Conference Series: Earth and Environmental Science 012073 (IOP Publishing, 2019).

Rudra, S. G., Singh, H., Basu, S. & Shivhare, U. Enthalpy entropy compensation during thermal degradation of chlorophyll in mint and coriander puree. J. Food Eng. 86, 379–387 (2008).

Schwartz, S. J., Cooperstone, J. L., Cichon, M. J., Joachim, H. & Giusti, M. M. Fennema’s Food Chemistry 681–752 (CRC Press, 2017).

Ferruzzi, M. G. & Blakeslee, J. Digestion, absorption, and cancer preventative activity of dietary chlorophyll derivatives. Nutr. Res. 27, 1–12 (2007).

Manika, N., Singh, S., Verma, R. & Bagchi, G. Extraction efficacy, stability assessment and seasonal variation of bioactive ‘gymnemagenin’in Gymnema sylvestre. Ind. Crops Prod. 44, 572–576 (2013).

Gunathilake, K., Ranaweera, K. & Rupasinghe, H. Optimizing the extraction of bioactive compounds from leaves of Gymnema lactiferum, an edible green leafy vegetable. South Asian Res. J. Nat. Prod. 1, 1–9 (2018).

Richter, B. E. et al. Accelerated solvent extraction: A technique for sample preparation. Anal. Chem. 68, 1033–1039 (1996).

Bamba, B. S. B. et al. Influence of extraction conditions on ultrasound-assisted recovery of bioactive phenolics from blueberry pomace and their antioxidant activity. Molecules 23, 1685 (2018).

Leksawasdi, N. et al. Ultrasonic extraction of bioactive compounds from green soybean pods and application in green soybean milk antioxidants fortification. Foods 11, 588 (2022).

Vidović, S. S., Vladić, J. Z., Vaštag, ŽG., Zeković, Z. P. & Popović, L. M. Maltodextrin as a carrier of health benefit compounds in Satureja montana dry powder extract obtained by spray drying technique. Powder Technol. 258, 209–215 (2014).

Hamid, T. N. & Thakur, A. Microencapsulation of wild pomegranate flavedo phenolics by lyophilization: Effect of maltodextrin concentration, structural morphology, functional properties, elemental composition and ingredient for development of functional beverage. LWT 133, 110077 (2020).

Mishra, P., Mishra, S. & Mahanta, C. L. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 92, 252–258 (2014).

Mahendran, T. Physico-chemical properties and sensory characteristics of dehydrated guava concentrate: Effect of drying method and maltodextrin concentration. Trop. Agric. Res. Ext. 13, 48 (2011).

Turkmen, N., Poyrazoglu, E. S., Sari, F. & Sedat Velioglu, Y. Effects of cooking methods on chlorophylls, pheophytins and colour of selected green vegetables. Int. J. Food Sci. Technol. 41, 281–288 (2006).

Chong, S. Y. & Wong, C. W. Production of spray-dried Sapodilla (Manilkara zapota) powder from enzyme-aided liquefied puree. J. Food Process. Preserv. 39, 2604–2611 (2015).

Quek, S. Y., Chok, N. K. & Swedlund, P. The physicochemical properties of spray-dried watermelon powders. Chem. Eng. Process. 46, 386–392 (2007).

Chaul, L. T., Conceição, E. C., Bara, M. T. F., Paula, J. R. & Couto, R. O. Engineering spray-dried rosemary extracts with improved physicomechanical properties: A design of experiments issue. Rev. Bras. 27, 236–244 (2017).

Hasanaha, M. & Hilmaa, P. S. Antioxidant activity of extract and fractions from Coffee arabica L. leaves by DPPH radical scavenging method. Sci. Eng. 3, 4 (2016).

Gurning, K., Lumbangaol, S., Situmorang, R. F. & Silaban, S. Determination of phenolic contents and antioxidant activity test of ethanol extract of Sirih merah (Piper crocatum Ruiz & Pav.) leaves using the DPPH method. J. Pendidik. Kim 13, 137–142 (2021).

Acknowledgements

The authors would like to thank funding supports from Thailand Science Research and Innovation (TSRI), Fundamental Fund 2022, Lampang Rajabhat University (Grant Number: SRI-002(3)/2565), Chiang Mai University (CMU), Cluster of Agro Bio-Circular-Green Industry (Agro-BCG) (CE/RU66-P001), Office of Research Administration (ORA), Faculty of Agro—Industry, Bioprocess Research Cluster (BRC), CMU. N. Leksawasdi would like to express his sincere gratitude to Faculty of Agro—Industry as well as ORA CMU for funding/in kinds support. K. Anbarasu is grateful for supports of Postdoctoral Fellowship (Reinventing University), Chiang Mai University.

Funding

1. Fundamental Fund 2022 Lampang Rajabhat University (Grant Number: SRI-002(3)/2565), 2. Cluster of Agro Bio-Circular-Green Industry (Agro-BCG) (CE/RU66-P001), and 3. Chiang Mai University—Postdoctoral Fellowship (Reinventing University).

Author information

Authors and Affiliations

Contributions

Conceptualization, R.N. and N.L.; methodology, R.N.; validation, N.L. and J.K.; data curation, R.N., S.S., C.M., and A.K.; writing—original draft preparation, R.N.; writing—review and editing, R.N., A.K., N.L., J.K., S.S., C.M., Y.P., K.J., and M.C.; project administration, N.L., R.N.; funding acquisition, R.N., N.L. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Nunta, R., Khemacheewakul, J., Sommanee, S. et al. Extraction of gymnemic acid from Gymnema inodorum (Lour.) Decne. leaves and production of dry powder extract using maltodextrin. Sci Rep 13, 11193 (2023). https://doi.org/10.1038/s41598-023-38305-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-38305-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.