Abstract

To further explore the mechanism of coal spontaneous combustion and better grasp the laws of spontaneous combustion, this article studied the adsorption behavior of O2 in coal. Materials studio software was applied to study the adsorption of oxygen under different water content, different pore sizes, and different oxygen-containing functional groups by means of grand canonical Monte Carlo and molecular dynamics simulation methods. The results show that the adsorption capacity of O2 decreases with the increase in water content. With the increase of molecular pore size of coal, the adsorption capacity of O2 increases, and the tight adsorption amounts decrease. The equivalent adsorption heat is less than 42 kJ/mol, indicating that the adsorption of O2 in coal pores is physical adsorption. The smaller the physical adsorption energy and charge transfer value of the hydroxyl group for O2, it indicates that the hydroxyl group is the active group for the physical adsorption of O2.

Similar content being viewed by others

Introduction

Spontaneous combustion of coal not only wastes a large number of resources, but also damages the surrounding ecological environment, aggravates air pollution, and threatens the lives of relevant personnel1,2,3. Therefore, accurate and scientific determination of coal spontaneous combustion is of great significance to society and the public. However, coal is a substance with a complex structure and composition, and the oxidation of coal is accompanied by physical and chemical reactions4,5,6. The research on the low-temperature oxidation mechanism of coal is very important for proposing effective prevention and control measures, improving the efficiency of spontaneous combustion prevention, and has important practical value for protecting the personal safety of miners, protecting coal mine resources, and purifying the ecological environment7,8,9.

The low-temperature oxidation of coal is a complex process, and the factors affecting its oxidation include coal rank, pore size, temperature, and air humidity. Oxygen acts on the surface of coal through physical or chemical adsorption. In recent years, scholars have applied molecular mechanics, molecular dynamics, and Monte Carlo methods to the calculation of coal-adsorbed gases10,11,12. Sang et al.13 conducted in-depth research on the mechanism of interaction between coal and adsorbed gas, and proposed that in a solid gas adsorption system, the adsorption capacity plays a decisive role in the adsorption amount. Dai et al.14 proposed through research that the decisive factor for low-temperature oxidation of coal is its own oxygen absorption capacity; The three stages of physical adsorption, chemical adsorption, and chemical reaction occur simultaneously. Many scholars15,16,17,18 have conducted experimental research and theoretical analysis on the physical adsorption of oxygen by coal using coal spontaneous combustion tendency meters. A series of results indicate that factors affecting oxygen uptake include temperature, particle size, moisture, etc. Coal adsorption of oxygen can reach saturation in a short period of time, but the oxidation process is very slow; The premise of the coal spontaneous combustion process is the physical adsorption of coal oxygen, which mainly serves to transport oxygen for subsequent chemical adsorption and reaction. These studies often use the measurement of the amount of gas released by low-temperature oxidation of coal to calculate oxygen adsorption, which has certain limitations.

The coal-oxygen recombination reaction begins with the physical adsorption of coal and oxygen. After coal is in contact with oxygen, oxygen enters into the pore structure of coal, forming adsorption state on the coal surface, and further coal-oxygen composite reaction occurs. The pore structure of coal provides reaction space for coal-oxygen adsorption and composite reaction. At present, the research focus of coal adsorption gas is the adsorption of coalbed methane and gas, and the main research content is coalbed methane mining, gas extraction, etc. To further explore the mechanism of coal spontaneous combustion and better grasp the law of spontaneous combustion, we should increase the research on coal oxygen adsorption. In this paper, the process of coal physical adsorption of oxygen will be numerically simulated, analyze the relevant factors affecting coal oxygen adsorption, get the law of coal physical adsorption of oxygen, to provide theoretical support for the determination of coal spontaneous combustion, so as to better prevent accidents caused by coal spontaneous combustion.

Methods

Model construction and optimization

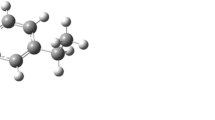

The molecular structure model of bituminous coal proposed by Li was adopted in this study19, whose molecular formula is C174H148O5N2.

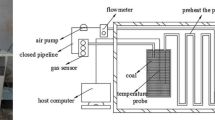

In order to obtain a relatively stable adsorbent structure model, this study carried out geometric optimization of coal molecular monolith under the Forcite module. The selection of the force field is very important in simulation calculation. In setting the force field, the Universal force field (UFF) was used. Compared with the Dreiding force field adopted by Sun et al.20, UFF includes all elements in the periodic table and can specify a method for charge calculation with high calculation accuracy. Smart flexible optimization method was adopted. The convergence mass deviation was set to Ultra-fine, the value 0.001 kcal/mol, the RMS Force 0.1 kcal/mol, and the RMS Displacement was set to 0.03 Å. The charge balance method was adopted for charge calculation, the cutoff radius was 4.5 Å, buffer width was 0.5 Å. Atom-Based van der Waals action was adopted, electrostatic action was the Ewald method, and the number of iterative calculation steps was set to 500021,22. The stable configuration of the coal molecular cell obtained after the repeated iterative calculation is shown in Fig. 1.

After it obtained the constructed coal macromolecular models, it used the Forcite module to optimize the system at the steepest descent, eliminating overlapping conformations, and setting the maximum iterative steps, force field, charge, electrostatic, and van der Waals parameters as well as those specified in the optimization. Finally, the model of coal macromolecular surface adsorbent was optimized. In addition, the energy comparison before and after optimization of the model structure in Table 1 shows that the overall energy of the model decreases, indicating that the overall structure of the model tends to be stable and the stable configuration is finally obtained.

Adsorption simulation parameter settings

The GCMC method is used for adsorption simulation calculation, which is mainly used to solve the problem of molecular random diffusion, and is widely used in materials, chemistry, and physics23.

It is assumed that the molecular model of coal does not deform during the adsorption process and the layer spacing is unchanged. The adsorption of O2 was calculated under the Sorption module. Fixed pressure was selected for the task, and the Metropolis method was adopted. The simulated balance steps and process steps were both set as 1.5 × 106 steps, the fixed pressure was 101 kPa, and the force field was the universal force field (UFF). The charge balance method (Qeq) was used for the charge, the Atom-Based van der Waals interaction was used, and the Ewald method was used for electrostatic interaction. The simulated adsorption calculation was carried out at a temperature of 298 K.

Parameter setting of molecular dynamics simulation

After completing the adsorption calculation of the model, MD should be used to study the motion trajectories of molecules in the system, through which the adsorption concentration data can be obtained. The lowest energy configuration returned was selected, and the Dynamics task was selected under the Forcite module. The canonical ensemble (NVT) was used for simulation calculation, and the temperature corresponding to the adsorption temperature was selected respectively. The time step of the simulation was set as 1 fs, the total number of steps was 1 × 106, and the total simulation time was 1000 ps. Other parameters were set with the adsorption simulation parameters. When researching the effect of water content on coal Adsorption of oxygen molecules, the first time to determine the adsorption position of water molecules in coal macromolecular structure model was using the adsorption module. After adding water molecules to the model, structural optimization and MD simulation need to be carried out again.

Density functional theory

Density functional theory (DFT) calculation of the adsorption of different functional groups in coal molecules is carried out in the CASTEP (Cambridge sequential total energy package) module of MS software24. The exchange–correlation function for geometric optimization of different functional group structures uses the GGA-PWE function and the OBS method of PW91 functional (for dispersion correction), and the plane wave truncation energy is set to 400 eV25.

Results and discussion

Influence of moisture content on adsorption of O2

In this research, the O2 adsorption capacity of the coal structure model is calculated when the temperature is 298 K, the pressure is 101 kPa, and the water content is 0%, 0.5%, 1%, 2%, 3%, and 4% respectively. Corresponding to 0, 3, 5, 8, and 10 water molecules were added to the coal molecules.

Figure 2 is the initial and final states of the water-coal system and the water-coal-oxygen system.

The formula for calculating water content is as follows:

where MH2O is the molecular mass of water, g/mol; Mcoal is the molecular mass of coal, g/mol; W is water content, %.

When analyzing the influence of water content on gas adsorption capacity, the water content in coal is set as 0%, 0.5%, 1%, 2%, 3%, and 4% respectively. The relationship between oxygen adsorption capacity and water content is shown in Fig. 3. It can be seen from the figure that oxygen adsorption capacity decreases with the increase in water content. Through linear fitting, it is found that the adsorption capacity of O2 decreases linearly with the increase of water content in the range of 0–4%.

In the range of 0–4% water content, the adsorption capacity of O2 decreased from 21.54 mmol/g at 0% water content to 14.82 mmol/g at 4% water content. Water molecules are polar molecules. When dry coal is in contact with moist air, water molecules will react with oxygen-containing free radicals on the surface of coal to form chemically bound water. The free radical-oxygen-carbohydrate generated by the reaction promotes the formation of water and provides more active sites for the adsorption of coal and oxygen. The greater the amount of oxygen adsorbed by coal, the more water molecules in the air can promote the oxygen adsorption of coal at this stage. However, with the increasing water content, when all oxygen-containing functional groups are occupied, the excess water molecules begin to adsorb on the pore surface of coal in the form of free water and keep condensing, and finally form water-containing liquid film on the pore surface, hindering the diffusion and adsorption of oxygen26.

Influence of pore size on oxygen adsorption

Coal is a porous medium consisting mainly of micropores and mesoporous. The micropore size is less than 2 nm and the mesopore size is between 2 and 50 nm. The adsorption behavior mainly occurred in micropores and mesoporous pores, while the diffusion behavior mainly occurred in mesoporous pores27. Figure 4 shows a model of the five types of pores.

As shown in Fig. 5, with the increase of the molecular pore size of coal, the adsorption capacity of gas also increases. This suggests that the larger the pore size, the more molecules of coal and gas can be accommodated in the pores. The adsorption heat of O2 ranges from 7 to 10 kJ/mol and is less than 42 kJ/mol, indicating that the adsorption of O2 in coal pores is physical adsorption28.

By analyzing the concentration of gas molecules in different pore models, the distribution of gas molecules in the coal molecular layer and pores can be obtained, as shown in Fig. 6. When the pore size is 0.5 nm, the adsorption rate of O2 in the pore is 9.2%. It can be found that the concentration distribution of gas in the pore is proportional to the pore size.

The tight gas adsorption capacity of different pore models is shown in Fig. 7. The adsorption capacity of tight gas in different pore models decreases with the increase of pore size. In the 0.5 nm pore model, the adsorption capacity of O2 was 19.18 mmol/g. In the 5 nm pore model, the adsorption capacity of O2 is 17.55 mmol/g, which is 8.5% lower than that in the 0.5 nm pore model. In micropores, the distance between adjacent coal molecular layers is very small, so the coal molecular layer in micropores exerts greater force on gas molecules than the coal molecular layer in mesoporous pores. Therefore, the adsorption of gas molecules in coal molecules decreases with the increase of pore size. With the decrease in pore size, the number of pores exposed to air increased, and the oxygen adsorption capacity increased.

The diffusion characteristics of gases with different pore sizes were studied. Through MD simulation, the relationship between the root mean square displacement (MSD) of the gas in the pore model and simulation time was obtained, as shown in Fig. 8.

The diffusion coefficient in Fig. 9 was obtained from the slope in Fig. 8. As shown in Fig. 9, the diffusion coefficient of the gas increases with the increase of the aperture. The diffusion coefficient of O2 increases from 3.98 × 10−8 to 9.85 × 10−8 m2/s. With the change of pore size, the gas diffusion in microporous structure is obviously weaker than that in mesoporous structure. In the effective cutoff radius (1.25 nm), gas molecules are more affected by van der Waals forces in the pore. In contrast, when the atomic spacing exceeds 1.25 nm, the effects of van der Waals forces and electrostatic forces are weakened and the diffusion of gas molecules through pores is enhanced29.

Adsorption of O2 by different functional groups

The carbon-containing functional groups on the surface of coal are mainly aromatic carbon (C–C) and lipid carbon (C–H), and the oxygen forms on the surface of coal are mainly carbonyl, hydroxyl, ether bond and carboxyl group. According to this result, four different coal structural units are constructed: –OH (phenolic hydroxyl unit), –COOH (carboxyl unit), –C=O (carbonyl unit,) and –O– (ether bond unit). The four different coal structural units and water substructure models are shown in Fig. 10. Four different coal structure units are optimized. Using the same exchange–correlation function, truncation energy, and convergence criteria as the bulk, the surface, O2 molecule, and four coal structural units are optimized geometrically. Based on quantum chemistry, the physical adsorption parameters of O2 adsorption by functional structural units on coal surface were calculated.

The adsorption energy of gas molecules on the surface of coal is defined as30:

In the formula, Ecoal/gas is the total energy of coal adsorbed gas molecules; Ecoal and Egas are the energies of coal and gas molecules, respectively. According to this definition, Eads is a negative value and represents exothermic adsorption. The larger the absolute value, the stronger the adsorption.

The physical adsorption parameters of O2 molecule are listed in Table 2. It can be seen that hydroxyl and ether bonds have lower physical adsorption energy values, and they have higher physical adsorption capacity for O2 molecules. The physical adsorption equilibrium distance between hydroxyl group and O2 is relatively small, while the physical adsorption distance between other adsorption sites and O2 is greater than 3 Å. Milliken charge transfer represents the degree of polarization of O2 in physical adsorption, with the hydroxyl group having a higher charge, followed by the carbonyl group and ether bond, indicating that O2 is adsorped more stably near these adsorption sites. During the adsorption process, the smaller the physical adsorption energy and charge transfer value of O2, indicating that O2 is more likely to be physically adsorbed around the adsorption site. Therefore, the hydroxyl group is the active group for the physical adsorption of O2.

Conclusion

MS software was applied to study the adsorption of oxygen under different water content, different pore sizes, and different oxygen-containing functional groups by means of GCMC and MD simulation methods. The conclusions are as follows:

-

(1)

With the increase in water content, oxygen adsorption capacity decreases. Water molecules gather on the pore surface of coal to form a water film, which hinders the transport and adsorption of oxygen and reduces the amount of oxygen adsorption.

-

(2)

The pore size of coal also affects the adsorption capacity of oxygen, and as the pore size of coal molecules increases, the adsorption capacity of O2 increases. However, the dense adsorption capacity decreases with the increase in pore size. The adsorption heat of equal amounts is less than 42 kJ/mol, indicating that the adsorption of O2 in coal pores is physical adsorption.

-

(3)

Due to the minimum physical adsorption energy and charge transfer value of hydroxyl on O2, it indicates that hydroxyl is the active group for the physical adsorption of O2.

-

(4)

One of the physical adsorption functions of coal spontaneous combustion is to transport oxygen for oxidation reaction. The study of the influencing factors in the process of low-temperature oxidation can provide theoretical basis for the analysis of the process of low-temperature oxidation of coal and the prevention and control of spontaneous combustion of coal. In the future, on the basis of this research, we will study inert gases, inhibitors and other fireproof materials to reduce the physical adsorption of coal oxygen, more effectively reduce the low-temperature oxidation of coal and the occurrence of coal fire.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Onifade, M. & Genc, B. A review of research on spontaneous combustion of coal. Int. J. Min. Sci. Technol. 30(3), 303–311 (2020).

Zhou, B. Z. et al. Variation characteristics of active groups and macroscopic gas products during low-temperature oxidation of coal under the action of inert gases N2 and CO2. Fuel 307, 121893 (2022).

Tan, B. et al. Molecular simulation for physisorption characteristics of O2 in low-rank coal. Energy 242, 122538 (2022).

Long, H. et al. Molecular simulation of the competitive adsorption characteristics of CH4, CO2, N2, and multicomponent gases in coal. Powder Technol. 385, 348–356 (2021).

Qiao, L. et al. Study on calcium catalyzes coal spontaneous combustion. Fuel 307, 121884 (2022).

Cheng, G. et al. Simulation of the adsorption behavior of CO2/N2/O2 and H2O molecules in lignite. J. China Coal Soc. 46(S2), 960–969 (2021).

Liang, G. D. & Guo, J. Statistical analysis of the causes of coal mine gas accidents in China. Energy Environ. Prot. 40(11), 75–78 (2018).

Li, J. H., Li, Z. H. & Yang, Y. L. Study on the generation of active sites during low-temperature pyrolysis of coal and its influence on coal spontaneous combustion. Fuel 241, 283–296 (2019).

Zheng, Y. N. et al. Effect of multi-component gases competitive adsorption on coal spontaneous combustion characteristics under goaf conditions. Fuel Process. Technol. 208, 106510 (2020).

Sang, S. X. et al. Solid-gas interaction mechanism of coal adsorption gas (II)-physical process and theoretical model of coal adsorption gas. Nat. Gas. Ind. 25(1), 16–18 (2005).

Lou, H. Z. & Jia, T. G. Competitive adsorption differences during coal spontaneous combustion process in noble gas atmosphere. China Saf. Sci. J. 30(4), 60–67 (2020).

Wu, S. Y., Jin, Z. X. & Deng, C. B. Molecular simulation of coal-fired plant flue gas competitive adsorption and diffusion on coal. Fuel 239, 87–96 (2019).

Qi, X. Y. et al. Study on oxygen absorption characteristics of coal at low temperature. Coal Sci. Technol. 36(3), 62–65 (2008).

Dai, G. L., Wang, D. M. & Zhang, G. S. Discussion on static oxygen absorption test of coal at room temperature. J. Liaoning Univ. Eng. Sci. 22(4), 475–477 (2003).

Liang, Y. T., Luo, H. Z. & Gao, C. L. Study on oxygen adsorption process characteristics of coal. Chin. J. Saf. Sci. 15(1), 71–73 (2005).

Lu, W. et al. Study on physical adsorption of oxygen by coal. J. Hunan Univ. Sci. Technol. Nat. Sci. Ed. 20(4), 6–10 (2005).

Ma, H. P. et al. Study on physisorption of oxygen during spontaneous combustion of coal. Coal Sci. Technol. 34(7), 26–29 (2006).

Deng, J. et al. Experimental study on oxygen absorption characteristics of coal. Coal Mine Saf. 42(6), 7–10 (2011).

Li, Y. G. Study on Macromolecular Structure Model and Thermal Reactivity of Dongqu No. 2 Coal (Taiyuan University of Technology, 2019).

Cao, Z. et al. Nanoscale liquid hydrocarbon adsorption on clay minerals: A molecular dynamics simulation of shale oils. Chem. Eng. J. 420, 127578 (2021).

Meng, J. Q. et al. Insight on adsorption mechanism of coal molecules at different ranks. Fuel 267(1), 117234 (2020).

Zhang, K. F., Liu, H. T. & Lei, G. P. Molecular simulation of the adsorption characteristics of methane in Zhaozhuang 3# coal. Chin. Sci. Technol. Paper 15(1), 94–99 (2020).

Gao, D. M. et al. Molecular simulation of gas adsorption characteristics and diffusion in micropore of lignite. Fuel 269, 117443 (2020).

Shu, P. et al. Characteristics and mechanism of modified hydrotalcite for coal spontaneous combustion preventing. Energy 265, 126353 (2023).

Yin, Y. et al. Study on the Synergistic Antioxidant Effect of Coal Inhibitors and the DFT Calculation 1–20 (Combustion Science and Technology, 2023).

Xiao, Y., Li, Q. W. & Lu, J. H. The effect of air relative humidity on spontaneous combustion characteristics of coal Impact research. China Saf. Sci. J. 25(3), 34–40 (2015).

Swanson, S. M. et al. Pore characteristics of Wilcox Group Coal, US Gulf Coast Region: Implications for the occurrence of coalbed gas. Int. J. Coal Geol. 139, 80–94 (2015).

Ma, T. et al. Study on the influence of key active groups on gas products in spontaneous combustion of coal. Fuel 344, 128020 (2023).

Zhang, Y. et al. Analysis of oxidation pathways for characteristic groups in coal spontaneous combustion. Energy 254, 124211 (2022).

Wang, C. Y. et al. Study on wettability mechanism of water to pyrite and coal surface based on density functional theory. Compr. Util. Miner. Resour. 1, 157–163 (2022).

Author information

Authors and Affiliations

Contributions

Z.R. wrote the main manuscript text. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ren, Z., Wang, D., Qin, Z. et al. Effects of pore size, water content, and oxygen-containing functional groups on oxygen adsorption in bituminous coal. Sci Rep 13, 10373 (2023). https://doi.org/10.1038/s41598-023-37632-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-37632-w

This article is cited by

-

Oxidation Characterization of Water Immersion Coal on Pore Evolution and Oxygen Adsorption Behavior

Natural Resources Research (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.