Abstract

Carbon-based single-atom catalysts (SACs) for electrochemical nitrogen reduction reaction (NRR) have received increasing attention due to their sustainable, efficient, and green advantages. However, at present, the research on carbon nanotubes (CNTs)-based NRR catalysts is very limited. In this paper, using FeN3@(n, 0) CNTs (n = 3 ~ 10) as the representative catalysts, we demonstrate that the CNT curvatures will affect the spin polarization of the catalytic active centers, the activation of the adsorbed N2 molecules and the Gibbs free energy barriers for the formation of the critical intermediates in the NRR processes, thus changing the catalytic performance of CNT-based catalysts. Zigzag (8, 0) CNT was taken as the optimal substrate, and twenty transition metal atoms (Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Nb, Mo, Tc, Ru, Rh, Pd, W, Re, Ir, and Pt) were embedded into (8, 0) CNT via N3 group to construct the NRR catalysts. Their electrocatalytic performance for NRR were examined using DFT calculations, and TcN3@(8, 0) CNT was screened out as the best candidate with a low onset potential of − 0.53 V via the distal mechanism, which is superior to the molecules- or graphene-support Tc catalysts. Further electronic properties analysis shows that the high NRR performance of TcN3@(8, 0) CNT originates from the strong d-2π* interaction between the N2 molecule and Tc atom. TcN3@(8, 0) CNT also exhibits higher selectivity for NRR than the competing hydrogen evolution reaction (HER) process. The present work not only provides a promising catalyst for NRR, but also open up opportunities for further exploring of low-dimensional carbon-based high efficiency electrochemical NRR catalysts.

Similar content being viewed by others

Introduction

Ammonia (NH3) is not only essential for the production of fertilizers, but also a promising carbon-free energy carrier for hydrogen energy storage1,2,3. With the ever-increasing demand for NH3, the artificial synthesis of NH3 by nitrogen (N2) conversion has attracted extensive attention. Currently, industrial NH3 synthesis mainly relies on Haber–Bosch method, which commonly needs extreme reaction conditions (15–35 MPa and 400–600 °C)4,5 with massive energy consumption and simultaneously leads to amount of CO2 emission6,7,8. Hence, it is vital to develop a promising, efficient, and mild approach for sustainable production of NH3. Inspired by biological enzyme nitrogen fixation, electrocatalytic N2 reduction reaction (NRR) has been regarded as one of the promising NH3 production methods9,10,11. As the core component of electrocatalytic NRR system, a large number of electrocatalysts have been predicted through screening catalysts with different compositions and structures12,13,14,15,16, and some electrocatalysts also have been experimentally fabricated for NH3 production at ambient conditions17,18. However, due to the extremely high stability of N2 and high energy barrier for N≡N bond cleavage, exploring novel catalysts with high activity and low cost has always been an important goal and challenge of NRR research5,19.

As a class of novel heterogeneous catalysts, single atom catalysts (SACs) based on carbon materials have been successfully used for N2 fixation due to their lowly coordinated electronic structure and efficient utilization of the active species13,14,20,21,22. Up to now, various SACs based on graphene or nitrogen-doped graphene for NRR have been reported both experimentally and theoretically17,23,24,25,26, and the controllability of the coordination between metal atoms and substrate has also been realized experimently26,27,28. Additionally, one-dimension carbon nanotubes (CNTs) have also been used as SAC substrates due to their high surface area, high stability, high conductivity, and tailorable properties. CNT-based SACs have already emerged as promising electrocatalysts to catalyze oxygen reduction reactions29,30,31 and oxygen evolution reactions32,33, and the inherent properties of CNTs are believed to significantly contribute to enhancing the catalytic performance. The surface of CNT can be regarded as a curved graphene surface, which provides a potential means to use this feature to tune the catalytic performance. However, there are still relatively few researches on CNT-based SACs in the field of NRR17,34. Therefore, it is critical to investigate the structures, catalysis performance and reaction mechanisms of SACs based on CNTs to advance the development of highly efficient electrocatalysts for NRR.

In this work, using the density functional method, the effect of CNT curvatures on the catalytic performance of CNT based catalysts for NRR were investigated firstly. According to the criteria proposed for the screening of eligible electrocatalysts for NRR, zigzag (8, 0) CNT was selected as the optimal substrate to construct CNT based NRR catalysts. Through screening twenty transition metal atoms, Tc atom were found to exhibit the best N2 to NH3 conversion capabilities via the distal pathway with the extremely low limiting potential (− 0.53 V). Further calculations were performed to investigate the electronic properties to explain the high NRR performance of TcN3@(8, 0) CNT, and to evaluate the selectivity between NRR and hydrogen evolution reaction (HER).

Computational details

All calculations are based on density functional theory as implemented in the Vienna ab initio simulation package (VASP)35. Our exchange-related functional adopts the revised Perdew–Burke–Ernzerhof (rPBE)36 under the generalized gradient approximation (GGA) method37. The projector augmented wave (PAW) method38 is used to describe the ion–electron interaction, and the PAW cutoff is set to 550 eV. The van der Waals interaction is calculated using the DFT-D3(IVDW = 11) method39. 1 × 1 × 3 supercells of carbon nanotubes are used to construct the structure models. In order to eliminate the interactions between two periodic repeating structures, the lattice parameters in the vacuum directions are set as 25.0 Å. The Brillouin zone is sampled using the Monkhorst–Pack k-point mesh40 of 1 × 1 × 2. All the structures are fully optimized until the energy convergence standard of 10–5 eV and the force convergence standard of − 0.01 eV/Å are reached. To further investigate the structural stability of the most likely carbon nanotube-supported monatomic catalysts, Ab initio molecular dynamics (AIMD) simulations in the canonical ensemble (NVT) with the Nose´–Hoover thermostat41 were performed at 500 K for 5 ps with a time-step of 1.0 fs.

The Gibbs free energy change (ΔG) in each elementary step is calculated based on the computational hydrogen electrode (CHE) model proposed by Norskov et al.42. The free energy of a proton–electron pair (H+ + e−) is equivalent to 1/2 H2 (g) under standard reaction conditions (pH = 0, 298.15 K, 101.325 kPa) at an external potential of 0 V. The free energy of the H* (ΔGH) is calculated to be − 0.62 eV in this work. The following equation is used for the calculations43:

Among them, ΔE is the electron energy difference between two intermediates; ΔZPE is the change in zero point energy; T is the temperature (298.15 K); ΔS is the change in entropy calculated by frequency; ΔGU = − eU, it represents the contribution of the electrode potential U to the free energy, where e is the number of transferred electrons, and U is the applied electrode potential; ΔGpH = kBT × ln10 × pH, it represents the free energy correction of pH, where kB is the Boltzmann constant, and pH value is set to be zero.

In addition, the adsorption energy is defined as:

where Eads-sub represents the total energy of the system after adsorption, and Eads is the total energy of the adsorbent, Esub represents the total energy of the substrate.

Results and discussion

Effect of CNT curvature on the catalytic performance of CNT based catalysts

Initially, eight zigzag (n, 0) CNTs (n = 3–10), were considered as substrates to anchor transition metal (TM) atoms to construct single atom catalysts. As shown in Fig. 1a, on the surface of a CNT, one carbon atom is deleted to form a single-vacancy defect, and then three carbon atoms possessing dangling bonds are substitutionally doped with nitrogen atoms to form a N3 group. The TM atoms are adsorbed at the center of the N3 groups. Previous studies have shown that FeN3-embedded graphene exhibits excellent catalytic performance for the N2-to-NH3 conversion13. Therefore, Fe was employed as the representative TM atom to study the effect of CNT curvature on the NRR catalytic performance of TMN3@(n, 0) CNTs.

The spin magnetic moment of the Fe center in FeN3@graphene is proved to be critical for the activation of the inert N2 molecule by the catalysts13. Therefore, the spin-resolved density of FeN3@(n, 0) CNTs were investigated firstly, and the results (Fig. 1b–i) demonstrate that all the FeN3 centers are highly spin-polarized. The Fe atoms protrude outside the CNT surfaces, and the charge clouds is distributed near the Fe atoms, indicating that the Fe atoms contribute most of the spin moments. With the decrease of the CNT curvatures from (3, 0) CNT to (10, 0) CNT, the spin magnetic moment decreases from 3.43 to 3.02 \({\mu }_{B}\), approaching that of FeN3@graphene. These results suggest that the curvatures of the substrates anchoring Fe atoms can affect the spin polarization of Fe atoms, and the larger the curvature, the greater the degree of the spin polarization.

Figure 2a demonstrates the variation of the N\(\equiv\)N bond lengths of N2 molecules adsorbed on FeN3@(n, 0) CNTs. There is a good linear relationship between the change of the N\(\equiv\)N bond lengths and the CNT curvatures, indicating that the CNT curvature plays an important role in weakening the N\(\equiv\)N bond. After adsorption, the N\(\equiv\)N bond is stretched from 1.10 Å in free N2 molecule to 1.129–1.141 Å, indicating that N2 is effectively activated by FeN3@(n, 0) CNTs. With the decrease of the CNT curvatures from (3, 0) CNT to (6, 0) CNT, the N\(\equiv\)N bond length increases from 1.129 to 1.141 Å. While the elongation of the N\(\equiv\)N bond by FeN3@(n, 0) CNTs (n = 7–10) are very similar, ranging from 1.138 to 1.141 Å. Therefore, reducing the curvature of CNTs can improve the activation of N2 molecules by FeN3 to a certain extent.

NRR process is complicated and can occur through distal, alternating, enzymatic and other mechanisms. During the NRR process, the effective adsorption of N2 on active sites of the catalyst and its activation are prerequisites. The chemisorption of N2 will make sufficient activation of the inert N≡N triple bond. According to previous studies, the formation of *N2H and *NH3 usually have relatively high free energies, thus making them the potential determining steps. Therefore, the following criteria have been proposed for the screening of eligible electrocatalysts for NRR12: (1) The adsorption energies of N2 should be lower than − 0.50 eV, corresponding to the chemisorption of N2 molecule, so as to ensure the effective activation of the inert N–N triple bonds; (2) The Gibbs free energy changes in the conversion processes of *N2 to *N2H (\({\mathrm{\Delta G}}_{{\mathrm{N}}_{2}-{\mathrm{N}}_{2}\mathrm{H}}\)) and *NH2 to *NH3 (\({\mathrm{\Delta G}}_{{\mathrm{NH}}_{2}-{\mathrm{NH}}_{3}}\)) should be lower than 0.55 eV to achieve an onset potential comparable to or lower than the predicted onset potential of the most efficient catalysts made of pure transition metals44. Therefore, in the following study, these three key steps in the N2 reduction reactions catalyzed by FeN3@(n, 0) CNTs, rather than all the reaction steps, were calculated to investigate the effect of the CNT curvatures on the NRR catalytic performance of FeN3@(n, 0) CNTs.

In Fig. 2b, the obtained adsorption energies of N2 on FeN3@(n, 0) CNTs, the Gibbs free energy changes \({\mathrm{\Delta G}}_{{\mathrm{N}}_{2}-{\mathrm{N}}_{2}\mathrm{H}}\) and \({\mathrm{\Delta G}}_{{\mathrm{NH}}_{2}-{\mathrm{NH}}_{3}}\) are shown. The N2 molecule can be adsorbed stably on all the FeN3@(n, 0) CNTs structures, but only the adsorption energy on the smallest (3, 0) CNT is higher than − 0.50 eV. With the decrease of the curvatures from (3, 0) to (10, 0) CNT, the adsorption of N2 becomes more stable. From (8, 0) to (10, 0) CNT, the adsorption energies vary in a very small range. This is because as the CNT diameter increases, the curvature of CNTs decreases, and their surfaces gradually become a plane. Therefore, the adsorption energy will gradually approach a limit, that is, the adsorption energy of N2 on FeN3@graphene. These results demonstrate that, except for CNTs with very small diameters, most other CNTs-based catalysts can adsorb N2 stably to ensure the effective activation of the inert N–N triple bonds.

For the formation of *N2H, the effect of CNT curvatures is very small. \({\mathrm{\Delta G}}_{{\mathrm{N}}_{2}-{\mathrm{N}}_{2}\mathrm{H}}\) varies in a very small range of 0.78–0.92 eV, indicating that all the FeN3@(n, 0) CNTs are inefficient for the catalysis of NRR. On the other hand, the CNT curvatures have a significant effect on the final protonation step of forming the *NH3 intermediate. From (3, 0) to (5, 0) CNT, \({\mathrm{\Delta G}}_{{\mathrm{NH}}_{2}-{\mathrm{NH}}_{3}}\) increases sharply from − 0.90 to − 0.40 eV. While, from (5, 0) to (10, 0) CNT, \({\mathrm{\Delta G}}_{{\mathrm{NH}}_{2}-{\mathrm{NH}}_{3}}\) increases much slowly from − 0.40 to − 0.16 eV. This shows that the decrease of the CNT curvatures will increase the Gibbs free energy barrier of the formation of the *NH3 intermediate, thus reducing the performance of the CNTs-based NRR catalyst.

After carefully examining the influence of CNT curvatures on the spin polarization of the Fe centers, the activation of the adsorbed N2 molecules, and three critical steps, we have selected (8, 0) CNT as the optimal substrate to anchor TM atoms to construct the computational models. Figure 1a shows the optimized structure of FeN3@(8, 0) CNT. The bond length between the Fe atom and the upper N atom is 1.84 Å, and the bond lengths of the other two Fe–N bonds are 1.95 Å. Owing to the relatively compact N3 pores, the adsorption site of Fe atom is slightly elevated above the plane composed of N atoms.

Screening of TM atoms

Next, 20 TM atoms (TM = Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Nb, Mo, Tc, Ru, Rh, Pd, W, Re, Ir and Pt) anchored at the N3 center of (8, 0) CNT were screened to obtain an electrochemical NRR catalyst with excellent performance. The relative stability of TMN3@(8, 0) CNTs were evaluated by calculating the binding energies (Eb) using the following equation:

where ETM@CNT, ECNT and ETM represent the energies of TMN3@(8, 0) CNTs, the (8, 0) CNT, and the isolated single TM atoms, respectively. As shown in Fig. 3a and Supplementary Table S1, all the calculated binding energies are negative, indicating that all the 20 TM atoms can be stably adsorbed by (8, 0) CNT. The binding energy of Zn atom is the weakest, while that of Sc atom is the strongest.

(a) The binding energies of 20 TM atoms on the surface of (8, 0) CNT; (b) The adsorption energies of N2 molecule on TMN3@(8, 0) CNTs via end-on and side-on configurations; (c) The Gibbs free energy changes in the formation of *N2H and *NH3 species catalyzed by TMN3@(8, 0) CNT. The numbers indicate \({\mathrm{\Delta G}}_{{\mathrm{N}}_{2}-{\mathrm{N}}_{2}\mathrm{H}}\) and \({\mathrm{\Delta G}}_{{\mathrm{NH}}_{2}-{\mathrm{NH}}_{3}}\) catalyzed by TcN3@(8, 0) CNT.

Following the above-mentioned criteria, the catalytic performance of TMN3@(8, 0) CNTs was then investigated. The adsorption energies of N2 on the TM atoms in both end-on and side-on fashions are shown in Fig. 3b and Supplementary Table S1. The results show that the end-on configuration is energetically more favorable than the side-on configuration for all TM atoms except for W atom. The capture of N2 via side-on configuration can not meet criterion 1 except for Mo, W, Re, Ir, and Pt. While, in the end-on configurations, only Sc, Mn and Zn are eliminated because of the higher adsorption energies. Therefore, the end-on configuration for N2 adsorption is employed to investigate the Gibbs free energy changes of the formation of *N2H and *NH3, and the results are shown in Fig. 3c and Supplementary Table S1. For the formation of *N2H, most of the TM atoms are ruled out as NRR catalysts because of the large Gibbs free energy change except for Nb, Mo, Tc, W, and Re. Further considering the formation of *NH3, Nb, Mo, W, and Re are ruled out. Eventually, TcN3@(8, 0) CNT is the only high-performance NRR candidate catalyst that meets all the above criteria.

Moreover, ab initio molecular dynamics (AIMD) simulations using canonical (NVT) ensemble is used to investigate the thermal stability of TcN3@(8, 0) CNT structure. After heating at the temperature of 500 K for 5 ps with a time step of 1 fs, we found that the structural reconstruction did not take place, implying that the TcN3@(8, 0) CNT structure can withstand temperature as high as 500 K. The variations of energy with respected to the time for AIMD simulations, and the snapshots of initial and final atomic configurations during the AIMD simulations are shown in Supplementary Fig. S1.

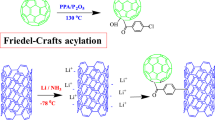

NRR catalyzed by TcN3@(8, 0) CNT

The full NRR processes catalyzed by TcN3@(8, 0) CNT is further investigated via three possible pathways, including distal, alternating and enzymatic mechanisms. The schematic diagrams and the optimized structures of the intermediates in the three mechanisms are depicted in Fig. 4. The full reaction processes can be divided into seven steps, including the first step of N2 adsorption and six consecutive protonation steps. The distal and alternating mechanisms starts with the N2 end-on adsorption. In the distal mechanism, the distal N atom in the adsorbed *N2 will be fully hydrogenated via accepting three proton-electron pairs until the first NH3 molecule is released, then the proximal N atom continues to accept three proton-electron pairs to form the second NH3 molecule to complete the whole catalytic process. In the alternating mechanism, the remote and the proximal N atoms of the adsorbed *N2 alternately accept the proton–electron pairs to form NH3 molecules. The enzymatic mechanism starts with the N2 side-on configuration, and the six proton–electron pairs will be attached alternately to the two N atoms as in the alternating mechanism.

Figure 5a–c are the calculated Gibbs free energy diagrams for the three possible NRR mechanisms. And the corresponding Gibbs free energy barriers are list in Supplementary Table S2. Our results show that the ΔG values of N2 adsorption via end-on and side-on fashions are − 0.01 eV and 0.59 eV, respectively. Compared with the side-on adsorption configuration, the end-on adsorption is more advantageous in terms of energy. Due to the extremely stable N–N triple bond in N2 molecule, breaking it to achieve protonation is often accompanied by a certain energy barrier. From the end-on configuration, the first protonation step requires an energy input of 0.53 eV. Then, the following protonation can take place through two paths, namely, the distal and alternating pathways. In the distal pathway, the energy consumption of the second protonation step (formation of the *N2H2 intermediate) is 0.03 eV. In the subsequent steps, the release of the first NH3 molecule and the first two protonation steps of the *N intermediate are all exothermal reactions. The formation of the *NH3 intermediate requires a 0.29 eV barrier in the last protonation step. Therefore, the maximum energy barrier of the whole distal reaction pathway is 0.53 eV and the first protonation step (formation of the *N2H intermediate) is the potential decisive step (PDS).

Gibbs free energy profiles for NRR via (a) distal; (b) alternating; (c) enzymatic pathways at different applied potentials. PDS is labeled in each Gibbs free energy profile. In the symbols depicting the intermediates, the N atom with “*” on its left means that it is adsorbed on the metal atom of the catalyst, and “NxHy” represents the formula of the intermediate. The illustrations show the structures of N2 molecules adsorbed on the catalyst surface. (d) The variation of N–N and Tc–N bond lengths via distal pathway.

When the NRR occurs via the alternating pathway (Fig. 5b), the formation of the *N2H2 and *NH2NH2 intermediates are endothermal reactions and they require energy inputs of 0.80 and 0.26 eV, respectively. The second protonation step (*N2H → *N2H2) becomes the PDS for the alternating mechanism. In the enzymatic path, the maximum energy barrier of the six protonation steps is only 0.29 eV, and the N2 adsorption (0.59 eV) is the PDS. Here, we use the onset potential (U, its value is defined as: U = − ΔGmax/e, where ΔGmax is the free energy variation of the PDS in each pathway) as a measure of the NRR performance. The onset potentials of the three possible mechanisms are − 0.53 V, − 0.80 V and − 0.59 V, respectively. Therefore, the distal mechanism is the most energetically favorable pathway for N2 reduction to ammonia catalyzed by TcN3@(8, 0) CNT. Previously, Tc atom has been reported to be the active center of catalyst for NRR. For example, tetracyanoquinodimethane molecules-supported Tc atom (Tc-rTCNQ) can catalyze NRR with a limiting potential of − 0.65 V45, while the limiting potential of Tc@N6-Graphene is − 0.56 V46. It can be observed that the utilization of suitable CNT as a substrate to adsorb Tc atom can effectively improve its catalytic performance.

Figure 5d shows the variation of N–N and Tc–N bond lengths in each step of the distal pathway. The N–N bond is firstly stretched from 1.10 Å in free N2 molecule to 1.15 Å in the *N2 intermediate, indicating that N2 is effectively activated by the adsorption on TcN3@(8, 0) CNT. Then the N–N bond is gradually elongated by protonation and finally breaks at the third protonation step. The Tc–N bond length is strongly correlated with the release of the first NH3 molecule. Before the formation of the *N intermediate, the Tc–N bond length decrease stepwise. And after that, the Tc–N bond length increases gradually until the release the second NH3 molecule.

We further explore the charge density difference (Fig. 6a) and the variation of the projected density of states (PDOS) of N2 before and after adsorption in the distal mechanism (Fig. 6b–d). As shown in Fig. 6a, the results of charge density difference indicate that N2 molecule can interact with the catalyst and the charge transfer is obvious when adsorption occurs. The charges mainly accumulate on the N atoms, while the charges between the N–N is dissipated, indicating that the N2 molecule is activated and the strength of N–N bond is weakened. The charge accumulation and depletion between TcN3@(8, 0) CNT and N2 can be explained via the donation-back donation mechanism, in which the unoccupied d orbitals of Tc can accept electrons from the occupied orbitals of N2, simultaneously the d orbitals electrons of Tc can be transferred to the antibonding orbitals of N2. This can be confirmed by the PDOS of N2 molecule before and after adsorption on TcN3@(8, 0) CNT as shown in Fig. 6b–d. The degenerate 2π orbital and 2π* orbital in free N2 molecule split into individual occupied orbitals after the adsorption of N2 on the TcN3@(8, 0) CNT surface. Some electrons are transferred from the 3σ and spilt 2π orbitals to the unoccupied d orbitals of Tc atom, which can effectively enhance the adsorption of N2 molecule. Meanwhile, the 2π* antibonding orbitals split into two parts, i.e., occupied and unoccupied orbitals, in which the electrons of the occupied orbitals originate from the back donation of the occupied d orbitals of Tc. The strong d-2π* interaction between N2 molecule and Tc atom is the key to promote the activation of the N2 molecule. Therefore, the adsorbed N2 on TcN3@(8, 0) CNT surface can be activated efficiently, which also explains why TcN3@(8, 0) CNT can efficiently catalyze the N2 reduction reaction via distal mechanism.

(a) The charge density difference of N2 adsorbed on TcN3@(8, 0) CNT in end-on configuration. The charge accumulation and depletion are depicted by yellow and cyan, respectively. The isosurface value is set as 0.005e/Å3. (b) The density of states of d orbitals of Tc before N2 is adsorbed on TcN3@(8, 0) CNT. (c) The projected density of states of free N2 molecule; (d) The density of states of N2 and the d orbitals of Tc atom after N2 is adsorbed on TcN3@(8, 0) CNT in the distal mechanism.

Charge variation in the distal pathway and HER competition

In order to further understand the superior NRR catalytic performance of TcN3@(8, 0) CNT, we calculated the Bader charge variation of the reaction intermediates in the favorable distal mechanism and the results are shown in Fig. 7 and Supplementary Table S3. According to previous studies47,48,49, we divided each intermediate in this process into three parts: moiety 1 (carbon nanotube), moiety 2 (TcN3), and moiety 3 (the adsorbed NxHy species). The charge variation refers to the charge difference of each moiety between the current step and the previous step. The charge variation at the first step demonstrates that the N2 molecule obtains 0.40e from CNT and TcN3 moieties during the end-on fashion adsorption. Both CNT and TcN3 play an important role in the activation process of the adsorbed N2 molecule. TcN3 donates electrons to both CNT and moiety 3 at the second step. At the third and fourth steps, the charge variation of TcN3 is about zero, and the charge variation of moiety 1 and moiety 3 is complementary to each other. While TcN3 and moiety 3 get almost the same amount of electrons from CNT at the fifth and the sixth step. At the final step, the second NH3 molecule is formed and moiety 3 returns the excess electrons to the catalyst itself. Based on the above analysis, we found that CNT acts as an electron reservoir in the whole catalytic process, while the active center TcN3 acts sometimes as a bridge to transport electrons. Both these two parts make an important contribution to the high NRR catalytic performance of TcN3@(8, 0) CNT.

Bader charge variation of the three moieties along the distal mechanism. Moieties 1, 2 and 3 represent (8, 0) CNT, TcN3, and the adsorbed NxHy species, respectively. The abscissa represents reaction steps in the distal mechanism, as depicted in Fig. 4.

In addition to the structural stability and high catalytic activity, an idea NRR catalyst should be also able to suppress the HER, a key side reaction in NRR, to achieve the high Faraday efficiency (FE). Therefore, we evaluated the catalytic selectivity of TcN3@(8, 0) CNT via two measures. On the one hand, the adsorption energies of N2 and proton on the catalyst are calculated to be − 0.94 eV and − 0.81 eV, respectively. The adsorption energy results indicate that the adsorption of N2 molecule is more stable than that of proton, which prevents the adsorption of a large number of protons on the catalyst surface, thus hindering the HER process. On the other hand, the measure of the difference of the limiting potentials between NRR and HER is calculated as: ΔU = UPDS(NRR)—UPDS(HER), where UPDS(NRR) and UPDS(HER) respectively represent the limiting potentials of NRR and HER16,48. A positive value represents that HER is suppressed to enhance the selectivity of NRR50. Our calculation results show that the limit potential of HER is − 0.62 V. Hence, ΔU is 0.09 V (As shown in Supplementary Fig. S2), which demonstrates its high selectivity to NRR.

Conclusion

In summary, first-principles calculations were performed to explore high efficiency NRR single-atom catalysts based on CNTs. At first, the effect of CNT diameters on the NRR catalytic performance of CNTs based catalysts were investigated. The results showed that CNT curvatures have a significant effect on the spin polarization of the catalytic active centers, the activation of the adsorbed N2 molecules and the Gibbs free energy barriers for the formation of the *NH3 intermediate, but have little effect on the formation of *N2H intermediate. With the decrease of the CNT curvatures, the adsorption of N2 will become more effective, but the onset potential of the formation of the *NH3 intermediate will also increase, thus reducing the performance of the CNTs-based NRR catalyst. Therefore, zigzag (8, 0) CNT was selected as the substrate to anchor twenty TM atoms (Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Nb, Mo, Tc, Ru, Rh, Pd, W, Re, Ir, and Pt) and their catalytic ability were investigated systematically according to the criteria for the screening of eligible electrocatalysts for NRR. TcN3@(8, 0) CNT is the only possible candidate catalyst for high performance NRR after screening, and our calculations illustrate that NRR prefers the distal pathway with a low limiting potential of − 0.53 V. The strong d-2π* interaction between the active center and N2 molecule is the key to facilitate the N2 molecule activation. Furthermore, TcN3@(8, 0) CNT exhibits higher selectivity for NRR than the competing HER process. Considering that Tc is a radioactive material, in the future, a pseudo-Tc material51 (such as Mo–Ru alloy) may be designed based on the concept of density of states engineering to effectively prevent any potential risks associated with radioactivity while retaining the desirable catalytic properties. We expect that our results would inspire more research on low-dimensional carbonaceous materials in the field of NRR electrocatalysis.

Data availability

Data are available from the corresponding author on reasonable request.

References

McEnaney, J. M. et al. Ammonia synthesis from N2 and H2O using a lithium cycling electrification strategy at atmospheric pressure. Energy Environ. Sci. 10, 1621–1630 (2017).

Service, R. F. Liquid sunshine. Science 361, 120–123 (2018).

Galloway, J. N. et al. Transformation of the nitrogen cycle: Recent trends, questions, and potential solutions. Science 320, 889–892 (2008).

Cui, X., Tang, C. & Zhang, Q. A review of electrocatalytic reduction of dinitrogen to ammonia under ambient conditions. Adv. Energy Mater. 8, 1800369 (2018).

van der Ham, C. J. M., Koper, M. T. M. & Hetterscheid, D. G. H. Challenges in reduction of dinitrogen by proton and electron transfer. Chem. Soc. Rev. 43, 5183–5191 (2014).

Smil, V. Detonator of the population explosion. Nature 400, 415–415 (1999).

Kitano, M. et al. Electride support boosts nitrogen dissociation over ruthenium catalyst and shifts the bottleneck in ammonia synthesis. Nat. Commun. 6, 6731 (2015).

Hoffman, B. M., Lukoyanov, D., Yang, Z.-Y., Dean, D. R. & Seefeldt, L. C. Mechanism of Nitrogen fixation by nitrogenase: The next stage. Chem. Rev. 114, 4041–4062 (2014).

Zhou, S. et al. Boron nitride nanotubes for ammonia synthesis: Activation by filling transition metals. J. Am. Chem. Soc. 142, 308–317 (2020).

Li, M. et al. Recent progress on electrocatalyst and photocatalyst design for nitrogen reduction. Small Methods 3, 1800388 (2019).

Minteer, S. D., Christopher, P. & Linic, S. Recent developments in nitrogen reduction catalysts: A virtual issue. ACS Energy Lett. 4, 163–166 (2019).

Ling, C. et al. A general two-step strategy-based high-throughput screening of single atom catalysts for nitrogen fixation. Small Methods 3, 1800376 (2019).

Li, X.-F. et al. Conversion of dinitrogen to ammonia by FeN3-embedded graphene. J. Am. Chem. Soc. 138, 8706–8709 (2016).

Li, H. et al. N-heterocyclic carbene as a promising metal-free electrocatalyst with high efficiency for nitrogen reduction to ammonia. J. Energy. Chem. 46, 78–86 (2020).

Guo, X. et al. Tackling the activity and selectivity challenges of electrocatalysts toward the nitrogen reduction reaction via atomically dispersed biatom catalysts. J. Am. Chem. Soc. 142, 5709–5721 (2020).

Wang, S. et al. Highly efficient photo-/electrocatalytic reduction of nitrogen into ammonia by dual-metal sites. ACS Cent. Sci. 6, 1762–1771 (2020).

Wang, Y. et al. Rational design of Fe–N/C hybrid for enhanced nitrogen reduction electrocatalysis under ambient conditions in aqueous solution. ACS Catal. 9, 336–344 (2019).

Yuan, L.-P. et al. Phosphorus-doping activates carbon nanotubes for efficient electroreduction of nitrogen to ammonia. Nano Res. 13, 1376–1382 (2020).

Seh, Z. W. et al. Combining theory and experiment in electrocatalysis: Insights into materials design. Science 355, 4998 (2017).

Xiao, B. B., Yang, L., Yu, L. B., Song, E. H. & Jiang, Q. The VN3 embedded graphane the improved selectivity for nitrogen fixation. Appl. Surf. Sci. 513, 145855 (2020).

Wang, Y., Zheng, X. & Wang, D. Design concept for electrocatalysts. Nano Res. 15, 1730–1752 (2022).

Jing, H. et al. Theory-oriented screening and discovery of advanced energy transformation materials in electrocatalysis. Adv. Powder Mater. 1, 100013 (2022).

Zhao, J. & Chen, Z. Single Mo Atom supported on defective boron nitride monolayer as an efficient electrocatalyst for nitrogen fixation: A computational study. J. Am. Chem. Soc. 139, 12480–12487 (2017).

Li, Y., Chen, J., Cai, P. & Wen, Z. An electrochemically neutralized energy-assisted low-cost acid-alkaline electrolyzer for energy-saving electrolysis hydrogen generation. J. Mater. Chem. A 6, 4948–4954 (2018).

Guo, X. & Huang, S. Tuning nitrogen reduction reaction activity via controllable Fe magnetic moment: A computational study of single Fe atom supported on defective graphene. Electrochim. Acta 284, 392–399 (2018).

Gu, Y. et al. Boosting selective nitrogen reduction via geometric coordination engineering on single-tungsten-atom catalysts. Adv. Mater. 33, 2100429 (2021).

Li, Y. et al. Boosting electroreduction kinetics of nitrogen to ammonia via tuning electron distribution of single-atomic iron sites. Angew. Chem. 133, 9160–9167 (2021).

Wang, S., Sun, M., Zheng, L. & Zhou, S. On the promising performance of single Ta atom in efficient nitrogen fixation. Chem. Catal. 1, 1322–1330 (2021).

Yu, D., Zhang, Q. & Dai, L. Highly efficient metal-free growth of nitrogen-doped single-walled carbon nanotubes on plasma-etched substrates for oxygen reduction. J. Am. Chem. Soc. 132, 15127–15129 (2010).

Gong, K., Du, F., Xia, Z., Durstock, M. & Dai, L. Nitrogen-doped carbon nanotube arrays with high electrocatalytic activity for oxygen reduction. Science 323, 760–764 (2009).

Lee, D. H., Lee, W. J., Lee, W. J., Kim, S. O. & Kim, Y.-H. Theory, synthesis, and oxygen reduction catalysis of Fe-porphyrin-like carbon nanotube. Phys. Rev. Lett. 106, 175502 (2011).

Yang, L. et al. Emerging linear activity trend in the oxygen evolution reaction with dual-active-sites mechanism. J. Mater. Chem. A 8, 20946–20952 (2020).

Niu, J. et al. Mechanisms of oxygen reduction reaction on B doped FeN4-G and FeN4-CNT catalysts for proton-exchange membrane fuel cells. Int. J. Energy Res. 45, 8524–8535 (2021).

Ma, Y. et al. Synergizing Mo single atoms and Mo2C nanoparticles on CNTs synchronizes selectivity and activity of electrocatalytic N2 reduction to ammonia. Adv. Mater. 32, 2002177 (2020).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Hammer, B., Hansen, L. B. & Nørskov, J. K. Improved adsorption energetics within density-functional theory using revised Perdew–Burke–Ernzerhof functionals. Phys. Rev. B 59, 7413–7421 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Grimme, S., Antony, J., Ehrlich, S. & Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 132, 154104 (2010).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1976).

Hoover, W. G. Canonical dynamics: Equilibrium phase-space distributions. Phys. Rev. A 31, 1695–1697 (1985).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Wang, V., Xu, N., Liu, J.-C., Tang, G. & Geng, W.-T. VASPKIT: A user-friendly interface facilitating high-throughput computing and analysis using VASP code. Comput. Phys. Commun. 267, 108033 (2021).

Skúlason, E. et al. A theoretical evaluation of possible transition metal electro-catalysts for N2 reduction. Phys. Chem. Chem. Phys. 14, 1235–1245 (2012).

Lv, S.-Y., Huang, C.-X., Li, G. & Yang, L.-M. Electrocatalytic mechanism of N2 reduction reaction by single-atom catalyst rectangular TM-TCNQ monolayers. ACS Appl. Mater. Interfaces 13, 29641–29653 (2021).

Liu, S. & Liu, J. Rational design of highly efficient electrocatalytic single-atom catalysts for nitrogen reduction on nitrogen-doped graphene and g-C2N supports. J. Power Sources 535, 231449 (2022).

Shen, Y. et al. A DFT screening of single transition atoms supported on MoS2 as highly efficient electrocatalysts for nitrogen reduction reaction. Nanoscale 10, 1622–1630 (2018).

Li, L., Martirez, J. M. P. & Carter, E. A. Prediction of highly selective electrocatalytic nitrogen reduction at low overpotential on a Mo-doped g-GaN monolayer. ACS Catal. 10, 12841–12857 (2020).

Liu, C. et al. Conversion of dinitrogen to ammonia on Ru atoms supported on boron sheets: A DFT study. J. Mater. Chem. A 7, 4771–4776 (2019).

Montoya, J. H., Tsai, C., Vojvodic, A. & Nørskov, J. K. The challenge of electrochemical ammonia synthesis: A new perspective on the role of nitrogen scaling relations. Chemsuschem 8, 2180–2186 (2015).

Xie, W. & Koyama, M. Theoretical design of a technetium-like alloy and its catalytic properties. Chem. Sci. 10, 5461–5469 (2019).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 11975206, 12075211, U1832150), the Zhejiang Provincial Natural Science Foundation of China (No. LQ20B030002), the Scientific Research Foundation of Zhejiang A&F University (No. 2019FR005, 2019FR006).

Author information

Authors and Affiliations

Contributions

W.L. and K.G. conceived the research; K.G. and S.L. performed the calculations and analyzed the data; W.L., J.X., K.G. and Y.X., wrote the manuscript; L.C. helped to revise the manuscript. All authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Liu, W., Guo, K., Xie, Y. et al. High efficiency carbon nanotubes-based single-atom catalysts for nitrogen reduction. Sci Rep 13, 9926 (2023). https://doi.org/10.1038/s41598-023-36945-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-36945-0

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.