Abstract

Biological treatment of cereal straw for ruminant nutrition purposes might present an environmentally friendly option of valorizing a widely available by-product of grain production for farming systems with low external input. Several strains of white-rot fungi have been selected in the past under mostly controlled laboratory conditions for their capacity of lignin degradation. The study adapted to conditions on farm for upscaling purposes. The development of the in vitro straw digestibility with two different moistening pre-treatments and inoculated with three different fungi species, namely Pleurotus ostreatus, Ceriporiopsis subvermispora and Volvariella volvacea, was determined up to 42 days of fermentation with five sampling times. The effect of physical straw pre-treatments on nutritional parameters was evaluated. The neutral detergent fiber digestibility (NDFD30h), enzymatically soluble organic substance (ELOS) and the gas production (Hohenheim Feed value Test, HFT) as indicators for in vitro ruminal degradability decreased over time independent of the fungus: HFT, ELOS and NDFD30h by up to 50, 35 and 30% of the original straw. Remoistening and autoclaving the straw increased the gas production significantly by 2.6 mL/200 g dry matter (DM), and ELOS and NDFD30h by 45 and 51 g/kg DM compared to the original straw (34.9 mL/200 mg DM, 342 g/kg DM, 313 g/kg NDF).

Similar content being viewed by others

Introduction

Lack of roughage for ruminants due to drought in parts of Europe in 2018–2020 has reactivated the search for alternative fiber sources to forage.

Cereal straw is widely available. In Germany alone, more than 8 Mio t dry matter (DM) are recycled yearly without further use1. However, the main obstacle for its extensive use in animal feeding is its low digestibility due to the high lignin content and its strong bonds in lignin- carbohydrate-complexes2.

After a series of investigations in chemical straw treatment to enhance digestibility in Germany and elsewhere3,4,5,6, since the 1990s more emphasis was placed on biological treatment using white-rot fungi. Various studies have proved that some species and strains are able to degrade lignin under certain conditions7,8,9,10,11. For example, Ceriporiopsis subvermispora (C.s.) delignified wheat straw and oak wood chips during the first 5 weeks of treatment in a laboratory study12. Pleurotus ostreatus (P.o.) expressed ligninolytic peroxidase13, and changed the ratio of the lignin polymers while increasing digestibility14. Banana leaves inoculated with Volvariella volvacea (V.v.) decreased in acid detergent fiber (ADF) and lignin (ADL)15. Despite the numerous publications, to date, to our knowledge no or at least few practical implementations have taken place on a larger scale on farm.

The aim of our study was to test selected fungal strains of P.o., C.s. and V.v. on their efficacy to enhance ruminal digestibility in vitro, to question the effects of the pretreatments and to identify whether they could be applied under practical farm conditions for example in Germany.

There exist different and contradictory statements with respect to the optimal fermentation time. Van Kuijk et al.12 found an optimal lignin degradation after 5 weeks with C.s., while Owen et al.16 recommended a maximum fermentation time of 6–8 days in general to limit organic matter losses. Thus, samples were obtained during a time course for analysis.

Materials and methods

Statement on the use of plants

All local and national guidelines and legislation were adhered to when using agricultural cereal crops in the study.

Winter wheat (Triticum aestivum Linnaeus) straw without visible fungal infestation was harvested in July 2018 in Köllitsch (51.5° latitude, 13.1° longitude), Northern Saxony, Germany, and stored as square bales in a dry ambient. It was obtained from the Agricultural Teaching and Testing Station of the Saxon State Office for Environment, Agriculture and Geology and had been cultivated within the agricultural production. It had a chopping length of 7–10 cm.

In this article, four trials, performed in 2019, are described: three on fungal treatments (two with soaked and drained straw and two with only remoistened straw) (Table 1) and one trial on physical treatment.

Biological treatment

An overview of the biological treatments is given in Table 1.

Preparation of inoculum

Grain spawn was produced using wheat grain inoculated with Ceriporiopsis subvermispora CBS 347.63, Pleurotus ostreatus CBS 411.71 and PO93 resp., Volvariella volvacea DSM 6190, incubated at 24 °C (30 °C in the case of V. volvacea) for 8–14 days as described in Martens et al.17.

Solid state fermentation of wheat straw

Trial 1—soaked and drained straw

Wheat straw was soaked in abundant tap water for 20–24 h, i.e. submerged, and drained afterwards for 2–3 h. This “drained straw” was then inoculated with grain spawn and incubated at 21 °C for a maximum of 6 weeks as described in Martens et al.17. See also Table 1. All samples were weighed at day 0 and were removed in triplicates in weekly intervals. Then they were weighed again. Besides the weight, the dry matter (DM) content and the pH value were determined. The straw was visually examined. Samples were frozen at − 20 °C for further analysis.

Trial 2 and 3—remoistened straw

A defined volume of water was added to the wheat straw. In this way, a target DM of 250 g/kg was achieved. After 22 h for absorbing the water and turning around in the meantime the remoistened straw was inoculated with grain spawn as described in Martens et al.17. See also Table 1.

Samples of around 1200 g were stored aerobically in perforated bags at 23–24 °C (17 for details) and removed in quadruplicates in weekly intervals in Trial 2 and after 0, 5, 7, 10 and 14 days in Trial 3. All samples were weighed at day 0 and when removed for analysis, the DM content and the pH value were determined. The straw was visually examined. Samples were frozen at − 20 °C for further analysis.

Physical treatment

In a second step, after evaluating the analytical results of the first trials of the biological treatments, the influence of soaking plus draining or remoistening only, and autoclaving, on the nutrient content of straw was tested. Straw was packed in nylon bags. Treatments in triplicates:

-

A.

Control (air dry straw)

-

B.

Tap water (2680 ml/kg air dry straw) was added to the bags in a plastic tub, bags were turned over after some hours. After 20 h the content of the bags was loosely filled in the tub to soak the remaining water for one more hour.

-

C.

As B. After that, loose straw was filled in a cage to autoclave at 121 °C for 20 min.

-

D.

Abundant tap water was filled in buckets with nylon bags filled with straw. After 20 h of soaking, the bags were hanged to drain for 3 h.

-

E.

As D. After that, loose straw was filled in a cage to autoclave at 121 °C for 20 min.

The samples were chemically analyzed.

Chemical analysis

Samples of untreated and treated straw were analyzed for DM, crude ash, neutral detergent fiber assayed with a heat stable amylase and expressed exclusive of residual ash (aNDFom), acid detergent fiber expressed exclusive of residual ash (ADFom), acid detergent lignin (ADL), ether extract (EE), crude protein, enzymatically soluble organic substance (ELOS), gas production according to the Hohenheim Feed value Test (HFT) (all parameters according to VDLUFA18 and NDF digestibility (NDFD30h)19.

The following parameters were calculated for the exclusively physically treated samples: digestible aNDFom (g/kg DM) = NDFD30h (in %)/100 * aNDFom (g/kg DM), indigestible aNDFom = aNDFom (g/kg DM) – digestible aNDFom (g/kg DM), Non-fiber carbohydrates (NFC) = (1000-(aNDFom + CP + EE + ash)), cellulose = (ADFom-ADL), the ratio ADL/ADFom as indicator of degree of lignification, total digestible nutrients TDNgrass = (NFC * 0.98) + (CP * 0.87) + (FA * 0.97 * 2.25) + (NDF * 0.93 * (22.7 + 0.664 * NDFD30h)/100) − 10 (in % of DM, FA fatty acids = ether extract – 1; equation for grass according to Moore and Undersander20; NDFD48h replaced with NDFD30h), estimated dry matter intake (DMIgrass) = − 2.318 + 0.442 * CP − 0.01 * CP2 – 0.0638 * TDN + 0.000922 * TDN2 + 0.18 * ADFom − 0.00196*ADF2 – 0.00529 * CP * ADFom (for grass: Moore and Kunkle21), relative forage quality RFQ = (DMIgrass, % of BW)*TDNgrass, % of DM)/1.23 (Undersander and Moore22).

Statistical analysis

For the biological treatments, the following effects on in vitro digestibility were tested:

1st trial (soaked and drained straw):

where µ = general mean, i = 1, 2, 3 (C. subvermispora, P. ostreatus (2 strains)), j = 1, 2, 3, …, 7 (0 d, 7 d, 14 d, 21 d, 28 d, 35 d, 42 d fermentation time), εij = residual error

2nd and 3rd trial (remoistened straw):

where µ = general mean, i = 1, 2, 3 (C. subvermispora, P. ostreatus PO93, V. volvacea), j = 1, 2, 3, …, 5 (0 d, (5 d,) 7 d, (10 d,) 14 d, (21 d, 28 d) fermentation time), εij = residual error

The software IBM® SPSS® Statistics (Version 19, SPSS, Inc., IBM Company©) was used. Variance analysis using the procedures univariate and multivariate was performed for the treatments after the respective storage time, while the posthoc Tukey test comprised the original straw values. Linear regression analysis was performed for various digestibility indicators, calculating the Pearson correlation.

For the physical treatments a two factorial model with fixed effects and interactions was applied using SAS® (Version 9.4 TS Level 1M7, SAS Institute Inc., Cary, NC, USA, 2020):

where i = 1, 2 (remoistening, soaking + draining), j = 1, 2 (no, yes), εijk = residual error

Results

DM losses

From the mere physical treatments, it was calculated that soaking in abundant water plus draining resulted in an average loss of 90.6 g/kg DM, while straw remoistened with a defined amount of water lost only 3.5 g/kg DM.

Within 14 days of fermentation the remoistened treatments lost around 108 g/kg DM (Trial 2 and 3), which was similar to the drained straw inoculated with PO93 (Trial 1) (excluding losses by draining) (Fig. 1a,b). Losses of the drained C. subvermispora treatment were comparably low at that point (29 g/kg DM), but increased to 241 g/kg by day 28 (Fig. 1a). A similar level of the drained treatment with PO93 was achieved only at day 42, while with P. ostreatus CBS 411.71 losses were lowest (139 g/kg at day 42). V. volvacea increased DM losses almost linearly from day 7 to 28 in the remoistened straw (y = 0.725x − 0.642, R2 = 0.97, p = 0.002) to 192 g/kg DM at day 28 (Fig. 1b).

Dry matter losses calculated from the start of incubation: (a) drained straw inoculated with two strains of Pleurotus ostreatus (P.o.) and Ceriporiopsis subvermispora (C.s.), (b) remoistened straw inoculated with Pleurotus ostreatus (P.o.), Volvariella volvacea (V.v.) and Ceriporiopsis subvermispora (C.s.).

Changes in the chemical composition

Physical treatment

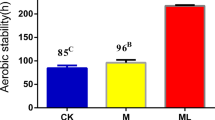

The results of chemical composition of straw following physical treatment are presented first (Tables 2, 3, 4). The interaction of type of wetting and autoclaving or not was significant for ADFom, whose content increased both by soaking plus draining and by autoclaving (Table 2). Parameters resulting from calculations including ADFom were equally affected. Most of the parameters were influenced by the type of wetting (Table 3). Draining led to higher EE, aNDFom and ADL contents while NDFD30h and ELOS were reduced compared to remoistening. Autoclaving enhanced gas production slightly and increased ELOS (Table 4). When compared to the original straw, remoistening plus autoclaving increased the in vitro digestibility in terms of NDFD30h, gas production and ELOS.

Biological treatment

There was a significant interaction of fungal strain and storage time of the drained straw for all three indicators of in vitro digestibility (Table 5). In the remoistened treatments, these indicators showed a uniform decrease starting in the second week and were less influenced by the fungal strain (Fig. 2). Although numerically higher, the NDFD30h did not increase significantly during the first week after inoculation, both in the drained and the remoistened treatments (Fig. 2a,b). Instead, it decreased in the course of time. Comparing drained and remoistened straw inoculated with P. ostreatus PO93 and C. subvermispora after 7 and 14 days, only NDFD30h of C. subvermispora in the drained straw was significantly higher than its counterpart in the remoistened straw. ELOS and HFT values were comparable within the two fungal strains at the same time. At no time either of the in vitro digestibility parameters was improved compared to the starting point or the dry control straw (Fig. 2, grey baseline).

Changes over time of in vitro digestibility of wheat straw inoculated with different fungal strains. Left: drained straw inoculated with two strains of Pleurotus ostreatus (P.o.) and Ceriporiopsis subvermispora (C.s.), right: remoistened straw inoculated with Pleurotus ostreatus (P.o.), Volvariella volvacea (V.v.) and Ceriporiopsis subvermispora (C.s.). NDFD30h neutral detergent fibre digestibility, ELOS enzymatically soluble organic substance, HFT gas production (Hohenheim Feed value Test). Grey solid line: baseline from original untreated straw. Error bars represent the standard deviation SD.

Discussion

Solid state fermentation of straw with basidiomycetes is an approach of valorizing field crop residues either for ruminant nutrition10 or for human mushroom consumption23 or biofuel production. Moisture, temperature, indigenous microflora are some factors, which influence both the growth of the fungi24, but also the nutritional composition and digestibility of the straw post-harvest25. To make uptake on farm likely, all processing steps have to be considered and minimized if possible. The same applies to losses from the field to the feeding trough.

Most of the studies on straw treatment with fungi soak the straw for several hours or days in abundant water and drain it then for several hours11,26,27. The presented study started with this following the recommendations for hobby mushroom cultivation28. However, in the chemical analysis it was realized that most of the fermentable carbohydrates got lost and that the lignin concentration increased by around 23%17 with decreasing digestibility at the same time. That is why the pre-treatment was changed to watering the straw with a limited volume of water to get a dry matter of approximately 25%. According to Streeter et al.29 a higher DM content (50%) was recommendable for incubation, which is in contrast to the observations by Abdullah et al.30 who recommended 80% moisture content for optimal fungal growth.

A second point in the pre-treatment is autoclaving, which is a common practice in laboratory studies (e.g.31,32). To make practical uptake on-farm more likely, this approach was abandoned.

To evaluate the effect of the physical pre-treatment a separate trial was performed. Remoistening plus autoclaving had the clearest effect on digestibility increase. Most advantages were seen in NDFD30h (+ 17%) and ELOS (+ 12%). High-pressure steam treatment resulted in higher digestibility of DM and cell wall constituents with different roughages33, and even hot water at pH 4–7 had an effect by removing lignin and hemicellulose34.

The relation of cellulose/ADL was highest in the remoistened straw without autoclaving. However, this parameter was obviously less related to digestibility in contrast to the findings of Nayan et al.11, who determined a correlation of r = 0.64 between (cellulose + hemicellulose)/ADL and IVGP (in vitro gas production). The ratio of ADL/ADFom showed also no clear relationship to digestibility. The calculated forage quality parameters (TDN, RFQ, DMI) were similar between the remoistened and the original straw while they were lower for the drained treatments. This is linked to the formulae as they include both NFC contents and NDFD30h. As NFC contents were significantly reduced by almost half due to leaching this had a major influence on the parameters. However, ELOS remained on the same level as the original straw.

In contrast to these findings, no digestibility increase was found in the fermented straw although NDFD30h was numerically higher within the first 7 days on average. That was a reason for shortening the fermentation period to 14 days in Trial 3 and having a look at closer sampling intervals.

In the presented trials, the same strain of C. subvermispora (CBS 347.63) was used as in other experiments performed in Wageningen. In those studies, the IVGP increased during a 7-week period of SSF based on drained and autoclaved wheat straw by around 30% although it was not compared to the original dry straw11,27. In any case, no increase in IVGP (HFT) was observed under the non-sterile conditions of the presented study. Decrease in digestibility in these trials went along with increase in lignin concentration by up to 42 g ADL/kg DM17. Nayan et al.35 suspected a problem in the ADL analyses when handling mushrooms as they observed increased IVGP by 28–48% despite high ADL values. However, gas production did not increase in the presented trials.

The P. ostreatus strain CBS 411.71 was earlier employed in an experiment for bioethanol production from wheat straw36. There, after 14 and 28 days, it improved enzymatic digestibility, increasing (hemi)cellulose digestibility from 35 to 55%. However, fermentable sugar yields were comparably low.

The generally observed decreasing digestibility in the presented trials might also be related to the lacking autoclaving in terms of sterilization prior to inoculation as the competing epiphytic microflora might have consumed the nutrients released by the white rot fungi similar to the observation made by Lang et al.37. Or fungal degradation was inhibited by an effect of competition with the native microflora38,39. In any case, Streeter et al.29 stated that autoclaving in his small samples sizes was not necessary. Tuyen et al.40 compared the gas production of straw inoculated with different fungi for up to 7 weeks to only autoclaved wheat straw (control). On day 21, out of 6 fungal species, C. subvermispora and L. edodes showed a higher gas production, on day 35, P. eryngii went beyond the control. However, the other species did not surpass the control line. V. volvacea inoculated straw declined linearly in IVGP from day 21 to day 49 of incubation40, which was more comparable to our observation.

For upscaling, Zadrazil et al.7 worked with non-sterile culture conditions. However, the author did not present digestibility differences compared to sterile conditions. Also Rai et al.41 seem to have worked without autoclaving using Coprinus fimetarius in rice straw and obtained results in feeding trials with goats in India, which were comparable to urea treated straw.

The temperature optimum for growth and metabolism differs from species to species and strain to strain. The temperature range for incubation from 21 to 24 °C applied in the presented study is similar to the one reported by Nayan et al.27, van Kuijk et al.12 and Fazaeli et al.42, although it is lower for V. volvacea compared to Belewu and Belewu15 with 35 °C for example. In any case, growth was observed for all inoculated strains, both under acidic and alkaline conditions17.

The treatment of draining and soaking alone led to about 10% DM losses and even higher losses in NFC concentration. Another 10% DM were lost within 14 days of incubation independent from the pre-treatment. Some studies quantify the different losses. With fungi of the genus Ionotus about 24% DM losses were observed after 30 days of incubation in wheat straw43. Zuo et al.44 found up to 50% DM loss with Pleurotos chrysosporium in maize stover after 28 days, which was relatively high compared to other findings14,45. Although a certain increase in in vitro DM digestibility was achieved when incubating wheat straw with P. ostreatus and Erwinia carotovora, DM losses of 52% question the loss of 69% lignin which led to a slightly higher IVDMD in another study46. Besides, DM loss did not necessarily go along with the desired loss of lignin11,43 and/or increase of digestibility as shown in the physical treatments here.

Some authors recommended a short fermentation period of 6–15 days to minimize losses16,41,47,48 and to increase nutrient intake in vivo41. Besides, some white rot fungi have a high initial selectivity for lignin49. Shrivastava et al.50 even found the highest in vitro OM digestibility after 5 days of SSF. That is one reason why in Trial 3 the fermentation time and the sampling intervals were reduced. However, it is in conflict with the different potential delignification phases described by Zadrazil et al.7,25 and van Kuijk et al.9.

Conclusions

The study emphasizes the complexity of solid state fermentation with the purpose of ruminant nutrition. None of the tested fungal strains was able to improve the in vitro ruminal straw degradability under the given conditions. Pre-treatment gains the more importance the more it comes to upscaling. Moistening enables the fibrous complex to swell and thus be more easily attacked by the ruminal microbiome. As autoclaving is rather unrealistic for on-farm application, simple physical treatments such as the use of hot process water should be focused as a potential economical option to enhance ruminal fermentability of lignocellulosic materials.

Data availability

The datasets generated during the presented study are available from the corresponding author on reasonable request.

References

Brosowski, A. et al. Biomassepotenziale von Rest-und Abfallstoffen: Status quo in Deutschland [Potential of biomass from residues and waste materials: status quo in Germany]. (2015).

Lee, H. V., Hamid, S. B. A. & Zain, S. K. Conversion of lignocellulosic biomass to nanocellulose: Structure and chemical process. Sci. World J. 2014, 631013. https://doi.org/10.1155/2014/631013 (2014).

Flachowsky, G. Physikalische, chemische und biologische Methoden der Strohaufbereitung und Möglichkeiten der praktischen Nutzung [Physical, chemical and biological methods of straw treatment and options for their practical application]. Wissenschaftliche Zeitschrift der Karl-Marx-Universität Leipzig 36, 232–247 (1987).

Block, H. J., Weissbach, F. & Prym, R. Untersuchungen zum Feuchtaufschluss von Stroh mit Natronlauge. 1. Mitteilung: Veränderungen der Verdaulichkeit und der Energiekonzentration [Investigations on the treatment of moist straw with caustic soda. 1st Communication: Changes of the digestibility and of the energy concentration]. Arch. Anim. Nutr. 35, 61–80. https://doi.org/10.1080/17450398509426968 (1985).

Block, H. J. & Weissbach, F. Untersuchungen zum Feuchtaufschluss von Stroh mit Natronlauge. 2. Mitteilung: Veränderungen der Alkalität bei der Lagerung von NaOH-Aufschlussstroh [Investigations on the treatment of moist straw with caustic soda. 2nd Communication: Changes of the alcalinity during the storage of NaOH treated straw]. Arch. Anim. Nutr. 35, 147–161. https://doi.org/10.1080/17450398509426968 (1985).

Mbatya, P. B. A. Methods of improving the utilization of cereal straw by ruminants. III. A note on the effect of ensiling straw treated with urea. Anim. Feed Sci. Technol. 9, 181–183. https://doi.org/10.1016/0377-8401(83)90032-9 (1983).

Zadrazil, F., Kamra, D. N., Isikhuemhen, O. S., Schuchardt, F. & Flachowsky, G. Bioconversion of lignocellulose into ruminant feed with white rot fungi—review of work done at the FAL, Braunschweig. J. Appl. Anim. Res. 10, 105–124. https://doi.org/10.1080/09712119.1996.9706139 (1996).

Mahesh, M. & Mohini, M. Biological treatment of crop residues for ruminant feeding: A review. Afr. J. Biotechnol. 12, 4221–4231. https://doi.org/10.5897/AJB2012.2940 (2013).

van Kuijk, S. J. A. Fungal Treatment of Lignocellulosic Biomass (Wageningen University, 2016).

van Kuijk, S. J. A., Sonnenberg, A. S. M., Baars, J. J. P., Hendriks, W. H. & Cone, J. W. Fungal treated lignocellulosic biomass as ruminant feed ingredient: A review. Biotechnol. Adv. 33, 191–202. https://doi.org/10.1016/j.biotechadv.2014.10.014 (2015).

Nayan, N., Sonnenberg, A. S. M., Hendriks, W. H. & Cone, J. W. Screening of white-rot fungi for bioprocessing of wheat straw into ruminant feed. J. Appl. Microbiol. 125, 468–479. https://doi.org/10.1111/jam.13894 (2018).

van Kuijk, S. J. A. et al. Fungal treatment of lignocellulosic biomass. 88–110 (Wageningen University, 2016).

Fernandez-Fueyo, E. et al. Ligninolytic peroxidase gene expression by Pleurotus ostreatus: Differential regulation in lignocellulose medium and effect of temperature and pH. Fungal Genet. Biol. 72, 150–161. https://doi.org/10.1016/j.fgb.2014.02.003 (2014).

Valmaseda, M., Martinez, M. J. & Martinez, A. T. Kinetics of wheat straw solid-state fermentation with Trametes versicolor and Pleurotus ostreatus: Lignin and polysaccharide alteration and production of related enzymatic activities. Appl. Microbiol. Biotechnol. 35, 817–823. https://doi.org/10.1007/BF00169902 (1991).

Belewu, M. A. & Belewu, K. Y. Cultivation of mushroom (Volvariella volvacea) on banana leaves. Afr. J. Biotechnol. 4, 1401–1403 (2005).

Owen, E., Smith, T. & Makkar, H. Successes and failures with animal nutrition practices and technologies in developing countries: A synthesis of an FAO e-conference. Anim. Feed Sci. Technol. 174, 211–226. https://doi.org/10.1016/j.anifeedsci.2012.03.010 (2012).

Martens, S. D., Wildner, V., Greef, J. M., Zeyner, A. & Steinhöfel, O. Growth and influence of white-rot fungi on the chemical composition of wheat straw inoculated under varying pre-conditions. Fermentation 8(12), 695. https://doi.org/10.3390/fermentation8120695 (2022).

VDLUFA VDLUFA Book of Methods Volume III The chemical analysis of feedstuff. VDLUFA-Verlag, Darmstadt (1976).

LKS Landwirtschaftliche Kommunikations- und Servicegesellschaft mbH Determination of in-vitro Neutral Detergent Fiber Digestibility. Internal method LKS FMUAA 223, Rev. 02/02/2018. Lichtenwalde, Germany (2018).

Moore, J. E. & Undersander, D. J. In 13th Annual Florida Ruminant Nutrition Symposium. 16-292002.

Moore, J. E. & Kunkle, W. E. Evaluation of equations for estimating voluntary intake of forages and forage-based diets. J. Anim. Sci. Suppl. 1, 204 (1999).

Undersander, D. & Moore, J. E. In Proceedings, National Alfalfa Symposium, 13–15 December, 2004, San Diego, CA, UC Cooperative Extension. (University of California, Davis,2004).

Chang, S. T. The origin and early development of straw mushroom cultivation. Econ. Bot. 31, 374–376 (1977).

Wan, C. & Li, Y. Fungal pretreatment of lignocellulosic biomass. Biotechnol. Adv. 30, 1447–1457. https://doi.org/10.1016/j.biotechadv.2012.03.003 (2012).

Zadrazil, F. The conversion of straw into feed by basidiomycetes. Eur. J. Appl. Microb. Biotechnol. 4, 273–281. https://doi.org/10.1007/BF00931264 (1977).

Baker, P. W., Charlton, A. & Hale, M. D. C. Fibre degradation of wheat straw by Pleurotus erygnii under low moisture conditions during solid-state fermentation. Lett. Appl. Microbiol. 68, 182–187. https://doi.org/10.1111/lam.13104 (2019).

Nayan, N. et al. Improving ruminal digestibility of various wheat straw types by white-rot fungi. J. Sci. Food Agric. 99, 957–965. https://doi.org/10.1002/jsfa.9320 (2019).

Breck, A. & Breck, H. Pilzzuchtanleitung auf Stroh [Manual for mushroom cultivation on straw]. Pilzhof & Edelpilzzucht Breck GbR, Malschwitz. http://www.pilzmaennchen.de (2021) (Accessed 1 Feb 2019).

Streeter, C. L., Conway, K. E. & Horn, G. W. Effect of Pleurotus ostreatus and Erwinia carotovora on wheat straw digestibility. Mycologia 73, 1040–1048. https://doi.org/10.1080/00275514.1981.12021439 (1981).

Abdullah, A. L., Tengerdy, R. P. & Murphy, V. G. Optimization of solid substrate fermentation of wheat straw. Biotechnol. Bioeng. 27, 20–27. https://doi.org/10.1002/bit.260270104 (1985).

Belal, E. B. & Khalafalla, M. M. E. Biodegradation of Panicum repens residues by Pleurotus ostreatus for its use as a non conventional feedstuff in diets of Oreochromis niloticus. Afr. J. Microbiol. Res. 5, 3038–3050. https://doi.org/10.5897/AJMR11.141 (2011).

Nayan, N., Sonnenberg, A. S. M., Hendriks, W. H. & Cone, J. W. Differences between two strains of Ceriporiopsis subvermispora on improving the nutritive value of wheat straw for ruminants. J. Appl. Microbiol. 123, 352–361. https://doi.org/10.1111/jam.13494 (2017).

Rangnekar, D. V., Badve, V. C., Kharat, S. T., Sobale, B. N. & Joshi, A. L. Effect of high-pressure steam treatment on chemical composition and digestibility in vitro of roughages. Anim. Feed Sci. Technol. 7, 61–70. https://doi.org/10.1016/0377-8401(82)90037-2 (1982).

Hendriks, A. T. W. M. & Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 100, 10–18. https://doi.org/10.1016/j.biortech.2008.05.027 (2009).

Nayan, N., Sonnenberg, A. S. M., Hendriks, W. H. & Cone, J. W. Prospects and feasibility of fungal pretreatment of agricultural biomass for ruminant feeding. Anim. Feed Sci. Technol. 268, 114577. https://doi.org/10.1016/j.anifeedsci.2020.114577 (2020).

Salvachua, D. et al. Fungal pretreatment: An alternative in second-generation ethanol from wheat straw. Bioresour. Technol. 102, 7500–7506. https://doi.org/10.1016/j.biortech.2011.05.027 (2011).

Lang, E., Kleeberg, I. & Zadrazil, F. Extractable organic carbon and counts of bacteria near the lignocellulose-soil interface during the interaction of soil microbiota and white rot fungi. Bioresour. Technol. 75, 57–65. https://doi.org/10.1016/S0960-8524(00)00031-6 (2000).

Acevedo, F., Pizzul, L., Castillo, M. D. P., Cuevas, R. & Diez, M. C. Degradation of polycyclic aromatic hydrocarbons by the Chilean white-rot fungus Anthracophyllum discolor. J. Hazard. Mater. 185, 212–219. https://doi.org/10.1016/j.jhazmat.2010.09.020 (2011).

Lang, E., Kleeberg, I. & Zadrazil, F. Competition of Pleurotus sp. and Dichomitus squalens with soil microorganisms during lignocellulose decomposition. Bioresour. Technol. 60, 95–99. https://doi.org/10.1016/S0960-8524(97)00016-3 (1997).

Tuyen, V. D., Cone, J. W., Baars, J. J. P., Sonnenberg, A. S. M. & Hendriks, W. H. Fungal strain and incubation period affect chemical composition and nutrient availability of wheat straw for rumen fermentation. Bioresour. Technol. 111, 336–342. https://doi.org/10.1016/j.biortech.2012.02.001 (2012).

Rai, S. N., Walli, T. K. & Gupta, B. N. The chemical composition and nutritive value of rice straw after treatment with urea or Coprinus fimetarius in a solid state fermentation system. Anim. Feed Sci. Technol. 26, 81–92. https://doi.org/10.1016/0377-8401(89)90008-4 (1989).

Fazaeli, H., Azizi, A. & Amile, M. Nutritive value index of treated wheat straw with Pleurotus fungi fed to sheep. Pak. J. Biol. Sci. 9, 2444–2449 (2006).

Jalc, D., Nerud, F. & Siroka, P. The effectiveness of biological treatment of wheat straw by white-rot fungi. Folia Microbiol. 43, 687–689. https://doi.org/10.1007/BF02816391 (1998).

Zuo, S. et al. Effect of white-rot fungal treatments on the in vitro rumen degradability of two kinds of corn stover. BioResources 14, 895–907. https://doi.org/10.15376/biores.14.1.895-907 (2019).

Mukherjee, R. & Nandi, B. Improvement of in vitro digestibility through biological treatment of water hyacinth biomass by two Pleurotus species. Int. Biodeterior. Biodegrad. 53, 7–12. https://doi.org/10.1016/S0964-8305(03)00112-4 (2004).

Streeter, C. L., Conway, K. E., Horn, G. W. & Mader, T. L. Nutritional evaluation of wheat straw incubated with the edible mushroom, Pleurotus ostreatus. J. Anim Sci. 54, 183–188. https://doi.org/10.2527/jas1982.541183x (1982).

Shrivastava, B. et al. White-rot fungal conversion of wheat straw to energy rich cattle feed. Biodegradation 22, 823–831. https://doi.org/10.1007/s10532-010-9408-2 (2011).

Zhang, W. et al. Improved treatment and utilization of rice straw by Coprinopsis cinerea. Appl. Biochem. Biotechnol. 184, 616–629. https://doi.org/10.1007/s12010-017-2579-0 (2018).

Otjen, L., Blanchette, R., Effland, M. & Leatham, G. Assessment of 30 white rot basidiomycetes for selective lignin degradation. hfsg 41, 343. https://doi.org/10.1515/hfsg.1987.41.6.343 (1987).

Shrivastava, B., Jain, K. K., Kalra, A. & Kuhad, R. C. Bioprocessing of wheat straw into nutritionally rich and digested cattle feed. Sci. Rep. 4, 6360. https://doi.org/10.1038/srep06360 (2014).

Acknowledgements

We kindly thank Dr. Ulf Müller for his support in the statistical evaluation. The funding by the Saxony Ministry of Environment, Climate and Agriculture as part of the project “Environmentally sound dairy cattle nutrition” is acknowledged.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

S.D.M. and O.S. conceived the experiments, S.D.M. and V.W. conducted the experiments, S.D.M. analyzed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Martens, S.D., Wildner, V., Zeyner, A. et al. In vitro ruminal degradability of wheat straw cultivated with white-rot fungi adapted to mushroom farming conditions. Sci Rep 13, 7794 (2023). https://doi.org/10.1038/s41598-023-34747-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-34747-y

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.