Abstract

With the development of communication infrastructure, the design of supply chains has changed significantly. Blockchain technology, as one of the most cutting-edge technologies, can promote transparency among members of the supply chain network. To the best of our knowledge, this is the first study that tries to develop a novel bi-objective optimization model to integrate the transparency resulting from the use of blockchain for designing a three-level supply chain network. The first objective function is to minimize total cost while the second objective function seeks to maximize transparency based on the application of blockchain technology. Moreover, it is worth noting that it is the first attempt to investigate the role of a blockchain model under stochastic conditions. The bi-objectiveness and stochastic nature of the proposed model are then treated using Fuzzy Goal Programming (FGP) and Chance-Constrained programming (CCP) approaches, respectively. To tackle the problem, an improved Branch and Efficiency (B&E) algorithm is developed by incorporating transparency along with cost and service. The impacts of blockchain exclusively through transparency (Case 1) or through transparency, cost, and benefits (Case 2) in Supply Chain Design (SCD) are compared. The results demonstrated that the first case has less computational complexity and better scalability, while the second case has more transparency, less congestion, and more security. As one of the main implications, supply chain managers who are focused on cost minimization as well as transparency maximization are advised to take into account the trade-off between featuring costs and benefits of blockchain technology.

Similar content being viewed by others

Introduction

Supply Chain Design (SCD) is mainly focused on cost, time, environment, and distance criteria, and efficiency criterion is less considered1,2,3,4. However, there are few articles in the literature that addressed efficiency along with other criteria. Grigoroudis et al.5 configured a biomass supply chain based on cost and efficiency criteria which was then developed by Petridis et al.6 developed by considering more criteria to calculate the efficiency. In this regard, Moheb-Alizadeh et al.7 discussed the efficiency of SCD in addition to cost and environmental issues. Generally, the criteria taken into account in the efficiency are related to service and cost and do not pay attention to transparency.

Transparency has become an important issue in supply chain planning with pressure from stakeholders8. For example, stakeholders may have concerns about practices and processes related to raw materials in the supply chain. By applying transparency in the supply chain, operations and products become clear for the stakeholders and such concerns are resolved. Blockchain can bring such transparency even to the entire supply chain9. In this regard, supply chain data is stored and recorded in blocks that cannot be manipulated10. In this way, the transparency expected by the stakeholders in the supply chain emerges. Therefore, blockchain technology can provide transparency in the supply chain. On the flip side, Transparency is one of the prominent characteristics of using blockchain, which leads to an increase in the level of trust, information integrity and visibility in the supply chain11. For this reason, by implementing blockchain in the supply chain from the transparency perspective, firms can build trust and gain better visibility of the supply chain. In a survey of supply chain leaders, it was reported that 40% of them tend to invest in blockchain technologies and 46% of leaders plan to use the Internet of Things (IoT)12. Forecasts show that by 2025, revenues from the application of blockchain will grow to 39 billion US dollars13. In a survey among 1280 respondents, 45% stated that they employ blockchain technology as a platform for information exchange in their companies14. The market size of next-generation supply chains, in which services are based on the digital revolution, was equal to 32 billion US dollars in 2019, and this number is expected to double by 203015. The global distributed ledger market, which includes immutable records, smart contracts, digital identity, and proof-of-work, is dominated by supply chain audits and will increase to more than $103 billion by 203016. With an annual growth rate of 53.2%, the blockchain supply chain market size is expected to reach $3272 million by 2026 from $253 million in 202017.

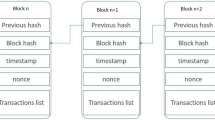

Blockchain technology can share digital events among all blockchain members because it is a distributed database18. The data stored in each block is encrypted based on a value called “hash”19. In a blockchain, each block comprises the hash value of the previous block. Therefore, it becomes very difficult for an attacker to manipulate data on the blockchain20,21. One of the effects of using blockchain is transparency because blockchain leads to data immutability. In this regard, as much as the number of blocks increases, the level of transparency can increase10. The physical flow of the supply chain can be converted into a digital flow through IoT tools (such as QR code, Near-Field Communication (NFC), Radio-Frequency IDentification (RFID), online certification, etc.) and then converted to the blockchain network so that the stored information becomes immutable and the supply chain partners are able to confirm the information22,23. It is worth noting that, despite the many efforts of researchers, how blockchain is applied in the supply chain is still open to interpretation24.

In the following, the research works that have addressed the application of blockchain in the supply chain are reviewed under three topics of blockchain adoption in the supply chain, implementation of smart contracts through blockchain, and measuring transparency. Zheng et al.25 examined the adoption of blockchain in the spacecraft supply chain, which includes the spacecraft builder, supplier, and logistics service integrator under risk decision-making. The results showed that the overall profits of the supply chain grow with the blockchain adoption due to the two reasons of sharing information and reducing the cost of transactions. Xia et al.26 implemented fleet sharing through blockchain technology in the last mile delivery problem. Their results revealed that the higher the sharing power, the lower the costs. Munim et al.27 evaluated blockchain adoption strategies in the oil and gas industry through a decision-making method called Bayesian Best Worst Method (BWM). They found that expertise related to technology, collaboration, and operational costs had the greatest impact on blockchain adoption. Lack of expertise related to technology as well as lack of supply chain partner collaboration are barriers and decreasing operating costs is the driver of blockchain adoption. Zhang et al.28 dealt with the strategic pricing of two retailers (initial retailer and emerging retailer) in a competitive environment where they are able to decide whether to apply blockchain technology or not. They found that although information transparency leads to increased consumer desire, privacy data leakage hinders blockchain adoption. Therefore, the trade-off between the two can determine whether retailers use blockchain technology or not.

Zhang and Song29 investigated sustainability risk factors in blockchain adoption in the supply chain. It was proved that the increased costs and additional audits are among the most important risk factors for using this technology in a sustainable supply chain. Prajapati et al.30 integrated the normal and virtual closed-loop supply chain with regard to the IoT and Blockchain technology. For this purpose, a Mixed Integer Non-Linear Programming (MINLP) model was offered, which took into account energy consumption costs, tag purchase costs, security costs, and data non-manipulation costs in addition to the common costs of the supply chain. Zeng et al.31 established information sharing between suppliers, manufacturers and distributors based on blockchain technology. Applying blockchain can lead to the identification of less efficient nodes in the supply chain scheduling problem. De Carvalho et al.32 analyzed the deployment of blockchain in SCD where the information of the transportation time is stored in the blockchain. They found that the partial adoption of the blockchain in the supply chain can improve the total profit value.

Rahmanzadeh et al.33 made the design part of the supply chain dependent on external capabilities. To protect the intellectual property of those who present their innovative design, the authors used blockchain technology. After registering the idea by the designer and producing the products in the product chain, the designers receive their reward. The obtained results demonstrated that considering blockchain in tactical supply chain planning can reduce the costs of non-original designs. Dolgui et al.34 presented a smart contract in the form of flexible flow shop scheduling on the blockchain platform so that in this contract logistics companies are assigned to jobs and their operations are scheduled. The companies participate in the design of the blockchain through the information service resulting from the executing operation. Manupati et al.35 implemented a smart contract through blockchain technology in order to monitor supply chain performance to optimize operating costs and emission levels in the production allocation problem. They found that the blockchain approach was successful in reducing costs and emission levels. Wang et al.36 addressed information sharing between upstream and downstream members of the supply chain through blockchain, where the supplier adjusts its inventory level based on the retailers' demand. For this purpose, they designed a blockchain system that focuses on data usage tracking, proper data valuation, and fair compensation.

Bai and Sarkis37 evaluated blockchain technologies to be employed in the supply chain through a decision-making approach based on fuzzy logic. In addition to technical characteristics, transparency factors for sustainability were among the criteria used in this evaluation. Maity et al.10 applied blockchain to the sausage supply chain. By creating a relationship between supply chain nodes and produced blocks, they introduced a measure called transparency. By increasing the number of blocks, more transparency is provided in the supply chain, and such an increase in transparency makes it hard for the attacker to manipulate the supply chain data.

Table 1 provides a comparative analysis of the most relevant research works in summary.

As can be seen in Table 1, the previous studies ignored the simultaneous consideration of cost objective functions (related to SCD and blockchain) and transparency (resulting from the blockchain network). In addition, in the design of the blockchain network, stochastic conditions are not investigated. It is noteworthy that nowadays, there is a need for the stakeholders of a supply chain to have a common understanding and access to information about the product without delay and without distortion38. To fulfill this necessity, it is essential to make supply chains transparent. Blockchain technology can deploy such transparency in supply chains37. Therefore, it is an important motivation for this work to integrate supply chain planning and blockchain technology. In this regard, this work integrates supply chain network design and blockchain under stochastic conditions to provide a practical decision support system. Therefore, the main contributions of the study are listed below:

-

i.

Integrating supply chain network design with blockchain technology,

-

ii.

Designing the supply chain based on transparency criterion in addition to common criteria such as cost and service,

-

iii.

Partial design of the blockchain network and supply chain with regard to efficiency criterion,

-

iv.

Considering stochastic conditions for blockchain to be modeled using Chance-Constrained Programming (CCP),

-

v.

Presenting a bi-objective mathematical model based on cost and transparency and treating it based on Fuzzy Goal Programming (FGP),

-

vi.

Providing different analyses on cost, transparency, and service based on the simultaneous design of blockchain and supply chain,

-

vii.

Developing an improved B&E algorithm according to the proposed FGP and blockchain adoption criterion.

The rest of the manuscript is structured as follows. “Problem descriptions and models” section describes the problem as well as the developed bi-objective optimization model. The proposed methodology is elaborated in “Methododlogy” section. “Numerical results and analysis” section represents the obtained numerical results along with practical implications. Finally, “Conclusion and outlook” section gives the concluding remarks and draws the outlook of the research.

Problem descriptions and models

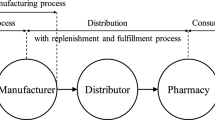

Here, the aim is to integrate blockchain technology with SCD to configure a blockchain-enabled three-level supply chain network. The examined supply chain includes three echelons (factory, warehouse and customer). Warehouses are the members of the supply chain that can be decided about their installation or non-installation, but other members are already available. The products are produced in the plant and shipped from the first layer to the second layer of the supply chain. Then, products are shipped from warehouses to demand areas to meet customer demand. Here, costs are related to the transportation and installation activities. The decision variables include the installation of warehouses, the installation of links between two levels, and the amount of goods in the flow at each stage of the supply chain. There are two objective functions in this work for supply chain planning. One of the two is related to the minimization of the mentioned costs. Another objective function is transparency. Members of the second layer of the supply chain can be equipped with IoT tools to convert the physical flow of the supply chain into a digital flow and thus generate blocks. To form a chain of blocks, it is necessary that at least one member of the first layer and also one member of the second layer are connected to the equipped member of the second layer.

Since the blockchain concept is based on decentralization, the more blocks produced by the equipped warehouses, the greater the transparency. It is assumed the transparency criterion is based on the probability that the attacker will not succeed in manipulating the blockchain. Furthermore, the distribution of such probability is “negative binomial (According to Maity et al.10, \({\mathrm{P}}_{\mathrm{failure}}=(\frac{r+k-1}{k}){{\mathrm{P}}_{\mathrm{H}}}^{r}{{\mathrm{P}}_{\mathrm{a}}}^{k}{(1-\frac{{\mathrm{P}}_{\mathrm{a}}}{{\mathrm{P}}_{\mathrm{H}}})}^{k}\) determines the probability that the attacker will fail (\({\mathrm{P}}_{\mathrm{H}}\), \({\mathrm{P}}_{\mathrm{a}}\) and \(k\) indicate probability related to an honest node, probability related to an attacker, and the number of failures, respectively). There is an assumption wherein \(r\) is equal to 1; i.e., the first time the attacker can manipulate the data, he/she can take control of the entire blockchain. For more details, please see Page 9 in Maity et al.10.)”. The reason for choosing this distribution by Maity et al.10 is that compared to other distributions, negative binomial distribution has the ability to consider the number of failures and successes of attackers, where the attacker intends to manipulate the supply chain data recorded in blocks. Each member of the second layer of the supply chain incurs the costs of being equipped with IoT tools in order to create blockchain infrastructure and provide services to other levels. In this study, this cost is regarded as a proportion of the installation costs of that member. Members who join the blockchain will benefit from advantages such as transparency, tracking, better planning and security. These benefits can lead to cost savings. Part of these savings can be taken into account as revenue in the supply chain. Considering that the members of the blockchain must be negotiated to know the benefits, and these benefits are interactive between the members, these benefits are treated as a factor of the cost of interactions between levels (such as the cost of transportation). SCD and blockchain are integrated into Eqs. (1)–(27). The notation related to the equations is given in Table 2.

Now, the developed model is given as follows:

The first objective function maximizes the total number of blocks extracted from the second layer of the supply chain. Due to this function, the network aims to be decentralized. On the other hand, where an attacker intends to manipulate data by attacking the blockchain, the attacker’s progress (in terms of failure); i.e., parameter \({f}_{b}^{pr}\) (when attacking the chain), is obtained by summing the negative binomial distribution at each step of the attack. The greater the number of blocks (\(b\)), the higher the failure progress because more distributions related to the number of blocks are added together. Therefore, the attacker’s success decreases drastically as \(b\) increases. The second objective function seeks to minimize the costs such as the fixed and variable costs of transportation in each stage of the supply chain, production costs, and warehouse installation costs. The benefits of supply chain members from joining the blockchain and the cost of using the blockchain are also shown in the second objective function. Constraint (3) balances the number of produced goods in the first layer of the supply chain and the number of products received by warehouses in the second layer of the supply chain. Constraints (5) and (6) state the upper and lower thresholds of production in each plant. Constraint (6) balances the number of products that are received by the warehouse from the first layer of the supply chain and the number of products that are shipped from the warehouse to the customers in the third level of the supply chain. Constraints (7) and (8) guarantee that if and only if there is a connection between two levels of the supply chain, the products of each stage are shipped according to the capacity of the connection. Constraints (9) and (10) create a relationship between the installation of warehouses and their connections. Constraints (11) and (12) determine the minimum and maximum capacity of each warehouse. Constraint (11) is based on the coefficient of the number of products received by the warehouse and the initial inventory of the warehouse. Constraint (12) is on the basis of the upper capacity of each warehouse. Constraint (13) specifies the amount of unmet demand for each customer. Constraint (14) indicates the upper threshold of the unmet demand for all customers. Constraints (15)–(25) show the relationships between supply chain network and blockchain. Constraint (15) expresses that the block can be produced if the warehouse is installed. Constraints (16) and (17) guarantee that for the presence of warehouse j in the blockchain, at least one member of the first layer (plants) and at least one member of the third level (customers) of the supply chain are present in that chain. Constraints (18) and (19) explain that the blockchain is formed when there is a physical flow between the levels of the supply chain. Constraints (20) and (21) indicate that the blockchain is formed when warehouse j is equipped with an IoT tool for block production. Constraint (22) determines the transparency thresholds expected of the supply chain manager. With the aim of decentralization, the minimum number of independent warehouses in the blockchain is guaranteed in constraint (23). Constraints (24) and (25) specify the total number of independent blocks produced in the second layer. Constraints (26) and (27) show non-negative continuous and binary decision variables, respectively.

Methodology

Improved branch and efficiency algorithm

As discussed before, most studies focus on the impacts of cost, time, service, and other criteria and ignore the efficiency criterion. In this research, the efficiency of the solutions obtained from the optimization model is computed through Data Envelopment Analysis (DEA). In this way, not only the solutions are optimal but also efficient. For this purpose, an improved B&E algorithm is developed and applied to take into account transparency as well as service and cost. In this regard, Eqs. (1)–(27) are called “Master Problem”. After solving the master problem, installed warehouses (solutions) are determined. Unlike other research works, in addition to cost and service, the solutions are evaluated based on transparency criteria as shown in Fig. 1.

To evaluate the solutions, the Simultaneous Data Envelopment Analysis (SDEA) is utilized. For more information, please see Klimberg and Ratick39. SDEA takes into account transparency (called SDEAT) in addition to common criteria such as cost and service according to Fig. 1. In the SDEAT model, the index \(j\) represents decision-making units (which denotes warehouses in our proposed mathematical model), \(p\) represents outputs (based on transparency and service criteria), and \(q\) represents inputs (types of costs). The objective function, Eq. (28), maximizes the level of efficiency of DMUs. Constraint (29) measures the efficiency of each DMU. The weighted sum of inputs is optionally set equal to 1 in Constraint (30). Constraint (31) calculates the efficiency of each DMU according to the weighted sum of outputs. Constraint (32) sets the upper threshold of the efficiency of each DMU equal to 1. Constraints (33) and (34) indicate positive continuous and non-negative continuous decision variables, respectively.

When the solutions of the master problem are evaluated by Eqs. (28)–(34) based on transparency, cost, and service criteria, the most efficient solutions are determined. Efficient solutions are the solutions whose efficiency is greater than the minimum efficiency expected by supply chain managers. Equation (35) shows the efficient solutions.

Based on the efficient solutions, the master problem should be updated. For this purpose, efficient solutions are added to the master problem as feasible solutions through “efficiency cuts”. The constraints related to efficiency cuts are shown in Eqs. (36)–(41). Therefore, all the terms involved in the master problem with the warehouse installation are updated by Eqs. (36)–(41):

The master problem, which is updated with efficiency cuts, can be re-solved. The results extracted from the updated master problem are evaluated by criteria based on cost, service, and transparency. Once more, the master problem can be updated by efficiency cuts. As can be seen, such a solution process is iterative to find both optimal and efficient solutions. For this reason, the B&E algorithm is implemented to treat the proposed model in this research, which is shown in Fig. 2.

In the first iteration of the algorithm, the master problem is solved. It is necessary to check the number of DMUs (warehouses) because the DEA model does not have sufficient ability to evaluate very small numbers of DMUs. In addition, the supply chain manager may set a minimum number of supply chain members. Then, based on the solutions extracted from the master problem, the values of the criteria introduced in Fig. 1 are determined.

The solutions are evaluated by the SDEAT model and the most efficient solution is specified according to the threshold requested by the supply chain manager. Efficient solutions are added to the master problem by efficiency cuts. The updated master problem is solved. If the problem space is infeasible, then the supply chain manager should either accept the solution of the previous iteration as the optimal solution or reduce his/her acceptance threshold in terms of efficiency so that more solutions can be considered in the updated master problem. If the updated master problem is not infeasible, then the values of the objective functions are checked. If these values do not change, the algorithm terminates. Otherwise, the algorithm is implemented on the updated master problem. Various conditions can be taken into account for the termination of this algorithm. Achieving a certain number of solutions, running a certain number of iterations, no change in the values of the objective functions in two consecutive iterations, etc. are among these conditions.

Proposition

If \({S}^{f,1}\) represents the solution space of the master problem, Eqs. (1)–(26), and \({S}^{f,t}\) denote the solution spaces of the subsequent iterations which contain efficiency cuts, then we have \({F}^{co,1}\ge {F}^{co,2}\ge \dots \ge {F}^{co,T}\), where \({F}^{co,t}(t=\mathrm{0,1},\dots ,T)\) stands for the cost objective function in each iteration.

Proof

In each iteration, a set of constraints called efficiency cuts is added to the optimization model of the previous iteration. In this way, the number of DMUs is reduced because inefficient DMUs are eliminated. As a result, continuous and binary decision variables related to inefficient DMUs are removed from the optimization model. For this reason, in each iteration, the feasible space is reduced. Therefore, in each iteration, the value of the cost objective function decreases.

Uncertainty treatment: chance-constraint programming

Nowadays, blockchain has attracted a lot of attention from industries and research due to its many advantages (including security, traceability, and transparency), and this has made blockchain be used in a wide range of applications, including supply chain management. However, the large geographical spread of some supply chains, generation, and transfer of blocks are among the things that increase the possibility of insecurity in the blockchain. Therefore, considering stochastic conditions in the blockchain is recommended by researchers40,41. Furthermore, since blockchain is applied in supply chain management, it is clear that real-world conditions affect it where there is no real-world certainty. CCP is one of the methods of optimization programming and one of the types of stochastic programming that can investigate random data variations42.

CCP can be converted into deterministic equivalents43. One of the famous distributions used for the randomness of parameters in this programming is the normal distribution44. In this research, it is supposed that \({B}^{N}\) is under uncertain conditions and this parameter follows a normal distribution. Therefore, uncertainty is regarded where it affects supply chain members and blockchain. Equation (42) indicates the stochastic parameter related to the minimum number of blocks in the blockchain. Equation (43) expresses the chance constraint. Equation (44) reformulates the chance constraint based on the standard normal distribution. Equation (45) displays the cumulative distribution function. According to Eq. (45), the chance constraint is re-written in Eq. (46). Equation (47) specifies the inverse cumulative distribution function. The deterministic equivalent of chance constraint is given in Eq. (48), which is a simple form of the previous equation.

Fuzzy goal programming

The master problem studied in this work has two objective functions. Generally, to solve multi-objective problems, it is necessary to transform the objective functions into a single objective function. One of the methods that transform multi-objective problems into single-objective problems is Goal Programming (GP)45. In this programming, an aspiration level (goal) is determined for each objective function. The new objective function is the minimization of the sum of the deviations of the objective functions from the goals. But determining a deterministic value for the aspiration levels is difficult for decision-makers and managers for various reasons such as uncertain conditions. For this reason, Zimmermann46 developed a model that takes ambiguous goals into account. On the other hand, Tiwari et al.47 offered a fuzzy programming model to incorporate ambiguity into the goals. They calculated the ideal and anti-ideal values of the objective functions and based on these values, they transformed the objective functions into membership functions. Finally, the objective functions were transformed into the maximization of the weighted sum of the membership functions. Here, the method suggested by Tiwari et al.47 is implemented to solve the bi-objective problem. The aspiration levels for Objective Functions (1) and (2) are defined in Eqs. (49) and (50) based on fuzzy goals. In these Equations, this sign “\(\lesssim\)” indicates the term “approximately less than or equal to”.

To transform the objective functions into membership functions, it is necessary to calculate the ideal and anti-ideal values for the objective functions. Ideal values are obtained when each objective function is optimized alone. When one objective function is optimized alone, the anti-ideal value of the other objective function can be computed. Based on this, Objective Functions (1) and (2) become membership functions in Eqs. (51) and (52).

In order to transform the problem of the bi-objective optimization model into a single-objective optimization model, it is necessary to consider the weighted sum of the membership functions obtained in Eqs. (51) and (52) as the new objective function. Other Equations (i.e., Constraints (3)–(27)) do not change. Therefore, Eqs. (53)–(56) represent the single-objective optimization model, which is the single-objective counterpart of Eqs. (1)–(27).

Theorem

Equations (53)–(56) generate a solution that is a Pareto efficient solution for the model presented in Eqs. (1)–(27).

Proof

Let Eqs. (53)–(56) generate the optimal solution “\({\varphi }^{*}\)”, where the optimal decision variables are indicated by \({\varphi }^{*}\). If \({\varphi }^{*}\) is not an efficient solution for Eqs. (1)–(27), then there is another feasible solution, such as \({\gamma }^{*}\), which can generate better objective function values compared to \({\varphi }^{*}\). In other words, \({\gamma }^{*}\) is a solution that is not worse than \({\varphi }^{*}\) and is better than \({\varphi }^{*}\) in at least one of the values of the objective functions. Therefore, the membership functions derived by \({\gamma }^{*}\) are not worse than the membership functions derived by \({\varphi }^{*}\), and at least one of the membership functions derived by \({\gamma }^{*}\) is better than \({\varphi }^{*}\). This means that \({\gamma }^{*}\) is the optimal solution of Eqs. (53)–(56), which is in contradiction with the optimality of \({\varphi }^{*}\).

Numerical results and analysis

Here, the application and validation of the developed models within the given framework of the methodology are demonstrated based on the illustrative example in Petridis et al.6. The examined supply chain has two stages including plant-warehouse and warehouse-customer. In this supply chain, there are 5 plants, 20 candidate warehouses, and 5 customers. The data related to the costs of production, transportation, installation, and the amount of initial inventory are extracted from Tables 5 to 8 given in Petridis et al.6. The adoption parameter of blockchain technology is considered randomly in the interval1,2,3,4,5 based on the Likert scale. The probability of success of the attacker to manipulate the blocks is assumed to be 0.33.

Here, in addition to the number of blocks, the focus is on the amount of transparency obtained from the generation of blocks. It is noteworthy that increasing the number of blocks and level of transparency is not equivalent. By increasing the standard deviation of the random parameter, both the number of blocks and the amount of transparency increase. With the increase of blocks, the transparency also increases, so with the increase of each block, the amount of increase in transparency decreases. Figure 3a,b illustrate the increase in the number of blocks and transparency, respectively. It should be noted that these figures show that with the intensification of uncertainty, the number of blocks increases and more transparency is achieved for the supply chain. This result is remarkable for the supply chain manager in the sense that the supply chain aims to increase transparency to deal with increasing uncertainty.

In order to generate blocks, warehouses need to be equipped with IoT tools so that they can convert physical flow into blocks through digital flow. To equip with this tool, in our article, a fee is taken into consideration that is proportional to the installation cost. Other members who interact with the second layer (warehouses) benefit from being connected to the blockchain network. These benefits include tracking, transparency, security, better planning, and others. For this reason, these members are willing to provide a part of these benefits to equipped warehouses. Therefore, the benefits of using blockchain in the supply chain are assumed as a proportion of the fixed transportation cost between the warehouse and other members of the supply chain. Figure 4a represents that where the benefit factor is set equal to 100, with the increase in the cost factor of equipping warehouses with the IoT, the value of the cost objective function increases, while Fig. 4b shows that where the cost factor of the equipment is set equal to 0.1, as the benefit factor increases, the value of the cost objective function diminishes. Figure 5 displays the effects of the importance of objective functions against each other. By raising the weight of the objective function related to transparency, that is, the first objective function compared to the second objective function, the amount of transparency increases (the number of blocks increases from 5 to 8), while the supply chain costs may increase up to 5.59%. At the same time, it should be noted that the first-step increase in transparency (from 5 to 6 blocks) has caused the biggest change in the amount of transparency.

The important managerial conclusion extracted from these results is that supply chain managers can benefit from the adoption of blockchain technology when other co-members are willing to participate in the blockchain. In two cases, the suggested B&E algorithm is executed on the master problem based on the fuzzy programming presented in Eqs. (49)–(56). In Case 1, the costs and benefits of using blockchain in the supply chain are ignored, while in Case 2, these costs and benefits are considered. According to Petridis et al.6, the number of iterations of the algorithm is set to 2. The results are reported in Table 3. It must be noted that since FGP was executed to solve our proposed model, the values of the objective and membership functions corresponding to the iterations of B&E algorithm are reported in Table 3. As stated in the proposition, costs are reduced in the second iteration compared to the first iteration. On the other hand, due to the fact that the generation of blocks is dependent on the installation of supply chain members, the second iteration leads to a decrease in transparency. Compared to the first case, the second case cannot only reduce costs, but also create more transparency. Since the majority of research studies treat cost as an important criterion in the supply chain, thus, supply chain managers are recommended to use the developed B&E algorithm in the design of the supply chain because this algorithm is able to reduce costs by moving forward in iterations. In addition, supply chain managers using the first case can not only reduce costs but also ensure at least transparency in the supply chain. If supply chain managers can convince their partners of the benefits of using blockchain, by using the second case, they will both reduce costs and build more transparency for the supply chain compared to the first case. In this regard, it is worth mentioning that the amount of production in both the first and second cases is 25,000, but in the first case, the warehouses serve an average of 2.5 customers. However, the warehouses serve an average of 3.7 customers in the second case. It illustrates that in our investigation, the second case is more decentralized and customers receive service from more warehouses.

The efficiency values obtained from the SDEAT model are reported in Table 4. Accordingly, the efficiency values of warehouses in the first and second cases obtained by our SDEAT model are shown in Table 4. When the benefits and costs of using blockchain are not taken into account, 12 warehouses are efficient, while when such costs and benefits are considered, the efficiency of warehouses is improved and the number of efficient warehouses reaches 15. Therefore, supply chain managers are recommended to focus on the adoption of blockchain technology by supply chain members in order to enhance the efficiency of supply chain members.

Figure 6 displays the volume of customer demand met by warehouses in the first and second cases. The dispersion of service between warehouses that are active in the first case is less than the dispersion of service between warehouses that are active in the second case. This shows that in the first case, the workload for the service is fairly distributed between warehouses. The second layer of the supply chain is connected to customers. Since the number of warehouses in the first case is small, the volume of demand satisfaction by each warehouse is high. In other words, this leads to traffic congestion of the goods and may delay the delivery time of the goods to the customer or disrupt the receipt of the goods by the customer. In this regard, supply chain managers are advised to benefit from the second case if decongestion is important to them, and from the first case if fairness among supply chain members is important to them.

Figure 7 outlines the members participating in the blockchain network in the first and second cases as well as the first and second iterations. Both for the first case and the second case, the participating members in the second iteration are fewer compared to the first iteration. The complexity, in terms of the number of participating members and the number of connections between them, is greater in the second case than in the first case. The first case provides the minimum necessary transparency while the second case aims to maximize the transparency. Therefore, it is recommended to supply chain managers; (a) If they work in an environment that is legislated for minimum transparency and they only want to follow the law, the first case is recommended, (b) if they are looking to maximize transparency, application the second case, (c) if they are looking for a higher level of security in the blockchain network, they need to use the second case due to its greater complexity, and (d) if they do not have advanced tools for blockchain-related computations, they should employ the first case.

In the second case, the negotiation power of supply chain managers is important to persuade members to join the blockchain. As mentioned in De Carvalho et al.32, blockchain is sometimes defined as the flow of information between levels of the supply chain. In this case, the establishment of the members of the supply chain requires a lower equipment cost because the activities of that member are not completely recorded in the blockchain. Accordingly, if the strategy of supply chain managers is cost minimization, the result of the second iteration of the second case can be improved. For this purpose, the term written in Eq. (57) is added to the cost Objective Function (2). In addition, the Constraints (16) and (17) are changed into Constraints (59) and (60), and Constraints (20) and (21) are changed into Constraints (61) and (62), where \(\delta\) represents the cost factor of equipping the supply chain member to record the flow of information in the blockchain and \({\theta }_{j}^{DN}\) represents the member who records the flow of information in the blockchain. Constraint (58) shows the relationship between the blockchain members and supply chain. Constraint (63) guarantees that the member can only record information about flows or can only record a wide range of information about its internal activities in the blockchain.

Figure 8 compares the full participation of members and the partial participation of members (only information flow) in the blockchain with each other in terms of transparency and cost. Partial participation can significantly reduce costs while reducing transparency, although the reduction in transparency is much less than the cost reduction value. Therefore, considering partial participation can be suitable for managers who are very sensitive about the cost.

The participating members in the blockchain must verify the creation of the block through a consensus mechanism. Despite the fact that increasing the size of the network and the number of nodes can lead to transparency in this mechanism, the consumption of resources and time increases which can pose a challenge for blockchain under the name of scalability. Such an increase can lead to the density of operations related to blockchain technology and even damage the blockchain. To calculate the density of the blockchain network, the ratio of the number of edges of the blockchain network is utilized to the total possible edges of the blockchain network. Based on this, the blockchain network resulting from the first case and the blockchain network resulting from the second case are compared in Fig. 9. The numbers in this figure are reported as normalized numbers. Case two, compared to Case one, not only has a greater number of existing and possible edges, but also has a higher density.

A summary of managerial implications obtained from the results is outlined in Table 5.

It is worth noting that the current research differs substantially from the existing research on the blockchain adoption. Very important topics such as carbon trading between users in road transportation48, blockchain adoption in large-scale networks49, and the limitation of some blockchain characteristics (such as storage capacity)50, have been investigated in the field of blockchain technology in the research literature. Furthermore, blockchain members were addressed based on supply chain network, scalability, complexity and limitations of blockchain in this research. However, our method of investigation has differences from what have been done in the literature so far. The distinguishing point is that in the research literature, the blockchain adoption (e.g., in networks and supply chain) has been considered, while our study is thoroughly based on optimization models which are formulated according to operations research. Through these models, the supply chain is simultaneously designed and the blockchain is adopted on it. In this way, both the supply chain network affects the configuration of blockchain technology and the blockchain technology also affects the configuration of the supply chain network. Hence, decision-makers and supply chain managers may learn the application and advantages of our proposed models. In case of institutionalizing transparency in the supply chain at the same time as designing and planning the supply chain, the proposed models in this study are recommended.

Another difference between this work and the research literature is in decision-making levels. Our paper plans supply chain design and adoption of blockchain at the same time, while the research literature generally seeks to adopt and implement the blockchain technology in supply chain. Therefore, the supply chain managers in our view are involved in strategic and tactical decisions, while they are more involved in operational decisions according to the view of the research literature. All in all, according to the conditions of the supply chain, managers must pay attention to what level of decision-making they are amenable to adopt the blockchain technology in supply chain.

Conclusion and outlook

Immutable sharing of information between supply chain members is an essential issue in the supply chain. For this purpose, the members of the supply chain should connect with each other in a transparent manner, and blockchain technology can bring such transparency to supply chains. This work aimed to integrate the three-level SCD with the adoption of blockchain technology. In this regard, for the first time in the literature, a bi-objective optimization model was proposed, which considers not only the costs of the supply chain (such as transportation, production, and installation) and IoT equipment related to blockchain, but also the transparency resulting from the adoption of blockchain technology in the supply chain. In addition, to the best of the authors’ knowledge, this study is the first attempt to address stochastic conditions for the minimum blockchain length. The proposed mathematical model is solved through the proposed B&E algorithm and FGP to generate both optimal and efficient solutions. In our article, the adoption of blockchain in SCD was investigated by comparing two cases. In the first case, only the transparency resulting from the use of blockchain was integrated into SCD, while in the second case, in addition to transparency, the cost and benefits resulting from the application of blockchain were addressed. The results revealed that the first case is superior in reducing computational complexity, creating fairness between service members to customers, and reducing scalability compared to the second case, while the second case is superior in creating more transparency, security, and efficiency of the supply chain members, and reducing congestion compared to the first case.

Consideration of blockchain in SCD through transparency has been neglected in research. In addition, there is not enough data on the implementation of blockchain in the supply chain and measuring the resulting transparency in the research literature. For this reason, the lack of access to similar articles and sufficient data is among the limitations of this study. Given that the examined subject is related to the use of cutting-edge technologies in SCD, this work can provide researchers with many research opportunities. Defining the application of blockchain through the combination of members and links simultaneously, considering the conditions of uncertainty in the measurement of transparency and other measurement related to blockchain technology, the adoption of blockchain in other supply chain structures are among the important innovations for future research.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Bidhandi, H. M., Yusuff, R. M., Ahmad, M. M. H. M. & Bakar, M. R. A. Development of a new approach for deterministic supply chain network design. Eur. J. Oper. Res. 198(1), 121–128 (2009).

Contreras, I., Fernández, E. & Reinelt, G. Minimizing the maximum travel time in a combined model of facility location and network design. Omega 40(6), 847–860 (2012).

Wang, F., Lai, X. & Shi, N. A multi-objective optimization for green supply chain network design. Decis. Support Syst. 51(2), 262–269 (2011).

Durmaz, Y. G. & Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 272, 115259 (2020).

Grigoroudis, E., Petridis, K. & Arabatzis, G. RDEA: A recursive DEA based algorithm for the optimal design of biomass supply chain networks. Renew. Energy 71, 113–122 (2014).

Petridis, K., Dey, P. K. & Emrouznejad, A. A branch and efficiency algorithm for the optimal design of supply chain networks. Ann. Oper. Res. 253(1), 545–571 (2017).

Moheb-Alizadeh, H., Handfield, R. & Warsing, D. Efficient and sustainable closed-loop supply chain network design: A two-stage stochastic formulation with a hybrid solution methodology. J. Clean. Prod. 308, 127323 (2021).

Gligor, D. M. et al. Utilizing blockchain technology for supply chain transparency: A resource orchestration perspective. J. Bus. Logist. 43(1), 140–159 (2022).

Hellani, H., Sliman, L., Samhat, A. E. & Exposito, E. On blockchain integration with supply chain: Overview on data transparency. Logistics 5(3), 46 (2021).

Maity, M., Tolooie, A., Sinha, A. K. & Tiwari, M. K. Stochastic batch dispersion model to optimize traceability and enhance transparency using Blockchain. Comput. Ind. Eng. 154, 107134 (2021).

Iranmanesh, M. et al. Effects of supply chain transparency, alignment, adaptability, and agility on blockchain adoption in supply chain among SMEs. Comput. Ind. Eng. 176, 108931 (2023).

Placek, M. Supply chain investments in blockchain worldwide 2018–2019. Statista. https://www.statista.com/statistics/1095144/global-supply-chain-blockchain-investment/ (2022).

Statista Research Department. Blockchain technology market size worldwide 2018–2025. Statista. https://www.statista.com/statistics/647231/worldwide-blockchain-technology-market-size/ (2022).

Statista Research Department. Use cases for blockchain technology in organizations worldwide 2021. Statista. https://www.statista.com/statistics/878732/worldwide-use-cases-blockchain-technology/ (2022).

Placek, M. Global next-gen supply chain market size 2019–2030. Statista. https://www.statista.com/statistics/1095393/global-next-gen-supply-chain-market-size/ (2022).

Statista Research Department. Size of distributed ledger market worldwide 2020–2030, by use case. Statista. https://www.statista.com/statistics/1259858/distributed-ledger-market-size-use-case-worldwide/ (2022).

Marketsandmarkets. https://www.marketsandmarkets.com/Market-Reports/blockchain-supply-chain-market-90851499.html/ (2021).

Crosby, M., Pattanayak, P., Verma, S. & Kalyanaraman, V. Blockchain technology: Beyond bitcoin. Appl. Innov. 2(6–10), 71 (2016).

Wang, J. et al. Research on multi-person collaborative design of BIM drawing based on blockchain. Sci. Rep. 12, 16312 (2022).

Kume, J., Abe, M. & Okamoto, T. New cryptocurrency protocol without proof of work. In Symposium on Cryptography and Information Security (SCIS) (2016).

Pradhan, N. R. et al. A blockchain based lightweight peer-to-peer energy trading framework for secured high throughput micro-transactions. Sci. Rep. 12(1), 1–15 (2022).

Kamilaris, A., Fonts, A. & Prenafeta-Boldύ, F. X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 91, 640–652 (2019).

Sharif, A. et al. Making assembly line in supply chain robust and secure using UHF RFID. Sci. Rep. 11(1), 1–17 (2021).

Saberi, S., Kouhizadeh, M., Sarkis, J. & Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 57(7), 2117–2135 (2019).

Zheng, K., Zhang, Z., Chen, Y. & Wu, J. Blockchain adoption for information sharing: Risk decision-making in spacecraft supply chain. Enterprise Inf. Syst. 15(8), 1070–1091 (2021).

Xia, Y. et al. Joint optimisation of drone routing and battery wear for sustainable supply chain development: A mixed-integer programming model based on blockchain-enabled fleet sharing. Ann. Oper. Res. 1, 1–39 (2021).

Munim, Z. H., Balasubramaniyan, S., Kouhizadeh, M. & Hossain, N. U. I. Assessing blockchain technology adoption in the Norwegian oil and gas industry using Bayesian Best Worst Method. J. Ind. Inf. Integr. 28, 100346 (2022).

Zhang, Z., Ren, D., Lan, Y. & Yang, S. Price competition and blockchain adoption in retailing markets. Eur. J. Oper. Res. 300(2), 647–660 (2022).

Zhang, F. & Song, W. Sustainability risk assessment of blockchain adoption in sustainable supply chain: An integrated method. Comput. Ind. Eng. 171, 108378 (2022).

Prajapati, D., Pratap, S., Jauhar, S. K., Kamble, S. S. & Gunasekaran, A. Blockchain and IoT embedded sustainable virtual closed-loop supply chain in E-commerce towards the circular economy. Comput. Ind. Eng. 172, 108530 (2022).

Zeng, M., Sadeghzadeh, K. & Xiong, T. A three-echelon based sustainable supply chain scheduling decision-making framework under the blockchain environment. Int. J. Prod. Res. 1, 1–21 (2022).

De Carvalho, P. R., Naoum-Sawaya, J. & Elhedhli, S. Blockchain-enabled supply chains: An application in fresh-cut flowers. Appl. Math. Model. 110, 841–858 (2022).

Rahmanzadeh, S., Pishvaee, M. S. & Rasouli, M. R. Integrated innovative product design and supply chain tactical planning within a blockchain platform. Int. J. Prod. Res. 58(7), 2242–2262 (2020).

Dolgui, A. et al. Blockchain-oriented dynamic modelling of smart contract design and execution in the supply chain. Int. J. Prod. Res. 58(7), 2184–2199 (2020).

Manupati, V. K. et al. A blockchain-based approach for a multi-echelon sustainable supply chain. Int. J. Prod. Res. 58(7), 2222–2241 (2020).

Wang, Z., Zheng, Z., Jiang, W. & Tang, S. Blockchain-enabled data sharing in supply chains: Model, operationalization, and tutorial. Prod. Oper. Manag. 30(7), 1965–1985 (2021).

Bai, C. & Sarkis, J. A supply chain transparency and sustainability technology appraisal model for blockchain technology. Int. J. Prod. Res. 58(7), 2142–2162 (2020).

Sunny, J., Undralla, N. & Pillai, V. M. Supply chain transparency through blockchain-based traceability: An overview with demonstration. Comput. Ind. Eng. 150, 106895 (2020).

Klimberg, R. K. & Ratick, S. J. Modeling data envelopment analysis (DEA) efficient location/allocation decisions. Comput. Oper. Res. 35(2), 457–474 (2008).

Papadis, N., Borst, S., Walid, A., Grissa, M. & Tassiulas, L. Stochastic models and wide-area network measurements for blockchain design and analysis. In IEEE INFOCOM 2018-IEEE Conference on Computer Communications 2546–2554 (IEEE, 2018).

Kang, H., Chang, X., Mišić, J., Mišić, V. B., Yao, Y. & Chen, Z. Stochastic modeling approaches for analyzing blockchain: A survey. Preprint at http://arXiv.org/2009.05945 (2020).

Liu, B. Stochastic chance-constrained programming. In Theory and Practice of Uncertain Programming (ed. Liu, B.) 77–113 (Physica, 2002).

Charnes, A. & Cooper, W. W. Deterministic equivalents for optimizing and satisficing under chance constraints. Oper. Res. 11(1), 18–39 (1963).

Bai, X. Two-stage multiobjective optimization for emergency supplies allocation problem under integrated uncertainty. Math. Probl. Eng. 2016, 1–13 (2016).

Trzaskalik, T. & Michnik, J. (eds) Multiple Objective and Goal Programming: Recent Developments (Physica Verlag, 2002).

Zimmermann, H. J. Fuzzy programming and linear programming with several objective functions. Fuzzy Sets Syst. 1(1), 45–55 (1978).

Tiwari, R. N., Dharmar, S. & Rao, J. R. Fuzzy goal programming—An additive model. Fuzzy Sets Syst. 24(1987), 27–34 (1987).

Lu, Y. et al. STRICTs: A blockchain-enabled smart emission cap restrictive and carbon permit trading system. Appl. Energy 313, 118787 (2022).

Cai, T. et al. Scalable on-chain and off-chain blockchain for sharing economy in large-scale wireless networks. IEEE Wirel. Commun. 29(3), 32–38 (2022).

Guo, Z. et al. RNS-based adaptive compression scheme for the block data in the blockchain for IIoT. IEEE Trans. Ind. Inf. 18(12), 9239–9249 (2022).

Author information

Authors and Affiliations

Contributions

A.B.: Writing—Original Draft, Conceptualization, Methodology, Data curation, Software. M.R.A.J.: Reviewing and Editing, Supervision, Validation, and Visualization. M.K.: Reviewing and Editing, and Investigation. E.B.T.: Reviewing and Editing, and Validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Babaei, A., Khedmati, M., Akbari Jokar, M.R. et al. Designing an integrated blockchain-enabled supply chain network under uncertainty. Sci Rep 13, 3928 (2023). https://doi.org/10.1038/s41598-023-30439-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-30439-9

This article is cited by

-

Net-zero, resilience, and agile closed-loop supply chain network design considering robustness and renewable energy

Environmental Science and Pollution Research (2024)

-

Innovative supply chain network design with two-step authentication and environmentally-friendly blockchain technology

Annals of Operations Research (2024)

-

A Distributed Software Agent-centric Framework for Supply Chain Networks Empowered by Blockchain: Insights into Smart Contracts

Operations Research Forum (2024)

-

A novel type-2 hexagonal fuzzy logic approach for predictive safety stock management for a distribution business

Scientific Reports (2023)

-

A robust optimization model to design an IoT-based sustainable supply chain network with flexibility

Central European Journal of Operations Research (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.