Abstract

Here, we have demonstrated a metal-free energy-efficient mechanochemical approach for expedient access to a diverse set of 2-amino-3-cyano-aryl/heteroaryl-4H-chromenes, tetrahydrospiro[chromene-3,4′-indoline], 2,2′-aryl/heteroarylmethylene-bis(3-hydroxy-5,5-dimethylcyclohex-2-enone) as well as tetrahydro-1H-xanthen-1-one by employing the reactivity of 5,5-dimethylcyclohexane-1,3-dione/cyclohexane-1,3-dione with TsOH⋅H2O as Brønsted acid catalyst under water-assisted grinding conditions at ambient temperature. The ability to accomplish multiple C–C, C=C, C–O, and C–N bonds from readily available starting materials via a domino multicomponent strategy in the absence of metal-catalyst as well as volatile organic solvents with an immediate reduction in the cost of the transformation without necessitates complex operational procedures, features the significant highlights of this approach. The excellent yield of the products, broad functional group tolerances, easy set-up, column-free, scalable synthesis with ultralow catalyst loading, short reaction time, waste-free, ligand-free, and toxic-free, are other notable advantages of this approach. The greenness and sustainability of the protocol were also established by demonstrating several green metrics parameters.

Similar content being viewed by others

Introduction

The current global challenges associated with environmental safety concerns due to chemical pollution caused by volatile organic solvents, toxic reagents, or hazardous chemicals during a chemical process both at laboratory and industrial scales; demand novel synthetic routes that provide expedient access to complex structural scaffolds by introducing environmentally benign reaction conditions with the main focus to reduces the cost-effectiveness of the transformation to make a pollution-free and sustainable environment1,2,3,4,5,6,7. With this perspective, mechanochemistry appears to be a highly attractive and promising environmentally benign activation method and has recently received a considerable and steadily increasing interest from synthetic potentiality as well as green and more sustainable chemistry point of view8,9,10,11. Despite, the tremendous growth accomplished in the mechanochemical synthesis by ball milling or grinding via a mortar and pestle (also termed as “grindstone chemistry”) in the past decades, which are mainly demonstrating the potentiality of the solvent-free green synthesis12,13,14; the use of a small amount of liquid in the reaction mixture at the time of grinding, termed as liquid assisted grinding (LAG)15,16,17,18,19 offers an outstanding environment to execute organic synthesis with better reactivity and selectivity as compared to traditional solution phase, alternative solvent-less synthesis as well as solid-state mechanosynthesis. In addition, the exploitation of water as solvent or co-solvent in organic synthesis poses significant challenges to the synthetic community due to the poor solubility of most of the organic compounds in water20,21,22,23. However, the attractive benefits associated with water include wide abundance, safe and eco-friendly, non-flammable, toxic-free, hazard-free nature, and sometimes provides better reactivity and selectivity as compared to other solvents; making water as the recent choice of reaction medium for organic synthesis with respect to synthetic efficiency and from the viewpoint of sustainability24,25,26.

On the other hand, multicomponent reactions (MCRs) which allowed the formation of multiple bonds in a single operation, have been demonstrated as a promising tool for the creation of diverse molecular structures with enhanced efficiency, reduced waste, and high atom economy from easily accessible simple and inexpensive starting materials by effortless mixing of the reactant. The ability to accomplish the requisite products in “one-pot” by operationally simple workup procedure without using complex purification techniques and avoiding the isolation of the reaction intermediate, features multi-component reaction a powerful strategy for green or sustainable synthesis27,28,29.

The construction of oxygen and nitrogen-containing heterocycles have always been attracted as a key fascinating area for organic synthesis owing to their widespread prevalence in the domain of drug design and developments, medicinal and pharmaceutical chemistry, as well as material sciences30,31,32. Chromene and their derivatives, particularly 2H-chromene-2-one also known as coumarin6, and 2-amino-4H-chromene33, possessing cyano functionality at the C-3 position, constitute such an imperative class of oxygen-containing heterocycles, which have potential therapeutic application in the treatment of diverse range disease manifestations such as Alzheimer’s disease, psoriatic arthritis, rheumatoid arthritis, amyotrophic lateral sclerosis, Parkinson’s disease, cancer therapy, as well as in Huntington’s disease.34,35,36,37 They frequently exist in the basic skeleton of numerous natural products, and synthetic drug candidates and hold a pivotal position in medicinal chemistry owing to their notable pharmacological activities including anti-allergic, anticoagulant, antitumor, antimicrobial, antiproliferative, antioxidant, and antifungal (Fig. 1, Entry A–D)38,39,40,41,42. Some material science application such as fluorescence markers, optical brighteners, and laser dyes, has been established in the last decades43,44,45. They are also used in cosmetics, biodegradable agrochemicals, pigments, etc.46,47,48.

Recognizing such prominent features and therapeutic potential of 2-amino-3-cyano-4H-chromene, the synthesis of heterocycles possessing chromene moiety is of increasing scientific and academic interest. Accordingly, several synthetic methods to realize this heterocycle by using different catalytic systems such as heterogeneous or homogeneous catalysts49,50,51, magnetic nanoparticles52,53,54, ionic liquids55,56,57, metal complex58,59,60, organocatalysts61,62,63,64, polymers65, carbon quantum dots66, organic–inorganic hybrids67, metal–organic frameworks68, deep eutectic solvents69, as well as catalyst-free conditions70,71 were developed in the last decades.

At the same time, 2,2′-methylene-bis(3-hydroxy-5,5-dimethylcyclohex-2-enone) also known as tetraketones, belonging to one of the most promising classes of oxygen-containing heterocycles, have received substantial attention of chemists and pharmacologist both at academic and industrial level for their remarkable therapeutic activities such as tyrosinase inhibitors, antibacterial, antioxidant, antiviral, and lipoxygenase inhibitors, etc. (Fig. 1, Entry E–F)72,73,74,75,76. Besides these, they were considered as versatile building blocks for the construction of value-added compounds such as xanthendione, acridindione, and thiaxanthenes that offer significant applications in the pharmaceutical industry and laser technology77,78,79. A vast array of synthetic procedures has been developed by employing different catalytic systems such as In(OTf)380, urea81, SmCl382, Nano Fe/NaY zeolite83, Pd NPs84, Fe3O4@SiO2–SO3H85, Na2CaP2O786, and PPA–SiO287.

Notwithstanding, the reported works offer several advantages, most of them suffer serious drawbacks such as the utilization of toxic materials, expensive catalysts, as well as metal catalysts, volatile organic solvents, prolonged reaction time, requirements of high energy conditions, excess amounts of solvents, tedious work-up procedures, and high loading of catalysts, etc.

Considering all these aspects and the synergic combination of the features of liquid assisted grinding as an eco-friendly activation method with the synthetic efficiency associated to the metal-free multicomponent reactions to create a pollution-free environment, the present research demonstrated an Brønsted acid-catalyzed mechanochemically scalable one-pot approach for the rapid access to a diverse set of highly functionalized 2-amino-3-cyano-aryl/heteroaryl-4H-chromenes 4a–t, 2-amino-3-cyano-tetrahydrospiro-[chromene-3,4′-indoline] 6a–l, 2,2′-aryl/heteroarylmethylene-bis(3- hydroxy-5,5-dimethylcyclohex-2-enone) derivatives 7a–p as well as tetrahydro-1H-xanthen-1-one 9a–j by employing the reactivity of 5,5-dimethylcyclohexane-1,3-dione/cyclohexane-1,3-dione 3a–b based on a domino multicomponent strategy under energy-efficient grindstone chemistry with water as grinding additives at ambient conditions (Fig. 2).

Result and discussion

Recently, the use of liquid-assisted grinding techniques for controlling or accelerating organic transformation has become one of the current interests of synthetic organic chemistry in the move towards green or sustainable synthesis. In line with this, along with establishing the standard reaction condition for the synthesis of 2-amino-3-cyano-4H-chromene derivatives 4a–t, we choose the initial multicomponent reaction of benzaldehyde 1a, malononitrile 2, and 5,5-dimethylcyclohexane-1,3-dione 3a as the representative example (Fig. 3) that was being executed in different catalytic as well as non-catalytic systems under different reaction conditions (Table 1). An immediate analysis of the data presented in Table 1 for the preparation of our desired product 4a revealed that the reaction performed without using any catalyst failed to yield any product even after 24 h under grinding conditions (Table 1, Entry 1). Similarly, with K2CO3, and Na2CO3; no product formation was noticed after a long reaction time (Table 1, Entry 2–3). Alternatively, switching the catalytic system from inorganic bases to organic bases including Et3N, DABCO, DBU, and DMAP in grinding conditions leads to the corresponding products in poor to moderate yields with slightly reduced reaction times (Table 1, Entry 3–6). The excellent yield of the product was achieved when the reaction was executed by grinding the reactants, benzaldehyde 1a, malononitrile 2, and 5,5-dimethylcyclohexane-1,3-dione 3a in a mortar and pestle in presence of 10 mol% of Brønsted acid TsOH⋅H2O by using water (η = 0.35 μL/mg) as the liquid assisted grinding additives (LAGs) at ambient temperature within 5 min. The effects of different energy inputs on the model reaction in presence of TsOH⋅H2O were also investigated among which grinding proven to be efficient compared to others (stirring or reflux) as they required prolonged times and the yield of the product was not satisfactory (Table 1, Entry 7). With the aid of TFA, the corresponding product 4a was achieved in 78% yield within 36 min under grinding conditions (Table 1, Entry 8). In the meantime, the model reaction under ultrasound irradiation was found to slightly proceed in presence of NH2SO3H as the organocatalyst to deliver the desired product 4a in 70% yield where using grinding only 65% of the product was isolated after 2 h (Table 1, Entry 9). The applicability of taurine as a green bio-based catalyst under grinding as well as reflux conditions were also demonstrated. But no improvements in the rate of the reaction and complete conversion were observed (Table 1, Entry 10). The synergic combination of the features of TsOH⋅H2O as operationally simple, inexpensive, and readily available metal-free catalyst along with the efficiency associated to the use of water as a safe, eco-friendly green liquid assisted grinding solvent prompted us to consider water-assisted grinding of benzaldehyde, malononitrile, and 5,5-dimethylcyclohexane-1,3-dione with the aid of a simple mortar and pestle by employing 10 mol% of TsOH⋅H2O as the optimum reaction condition for the synthesis of 2-amino-3-cyano-4H-chromene at ambient temperature.

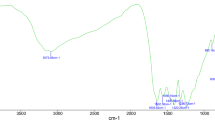

The effect of different LAGs and the amount of catalyst on the model reaction was further examined (Fig. 4). The preliminary used EtOH, IPA, DMF, DCM as LAGs (η = 0.35 μL/mg) and neat grinding under the influences of TsOH⋅H2O reduces the yield of the products even after increasing the amount of the catalyst from 2 to 15 mol%. To our delight, the best results were accomplished while performing the reaction with water by employing 10 mol% of catalyst at ambient conditions. Further, increases or decreases in the catalyst loading had no suspicious significance in the rate of the reaction. The temperature of the reaction mixture (monitored by using IR thermometer of accuracy range ± 0.03 °C) was found to be slightly raised from 35.4 to 36.5 °C after 1 min of grinding and after 1.5 min a slight change was observed and then remained constant during the course of the reaction.

With the optimum conditions in hand, the general feasibility of the present protocol was demonstrated by treating a diverse set of aryl aldehydes 1b–o with malononitrile 2, and 5,5-dimethylcyclohexane-1,3-dione 3a in presence of 10 mol% of TsOH⋅H2O in water (η = 0.35 μL/mg) using liquid assisted mechanical grinding conditions (Fig. 5, Table 2). Surprisingly, the corresponding 2-amino-3-cyano-4H-chromene products 4a–t were obtained in good to excellent yield in all the cases within 5–10 min. Aldehydes possessing electron-donating groups including methyl and –OMe afforded the desired products 4b and 4c in 88% and 86% yield respectively at 8 min (Table 2). While substitution by different halogen groups like F, Cl, Br on C-4 and C-3 positions of the phenyl ring of the aldehyde was found to be efficiently delivered the products 4d, 4e, 4f, 4j, 4l in excellent yields. Strong electron-withdrawing groups like NO2 and CN attached to the benzaldehyde ring proceeded smoothly under the standard condition. The reaction was also found to be well worked for heteroaryl aldehydes, getting the respective products 4m, 4n, and 4o in 90%, 92%, and 93% yields correspondingly. Similarly, using cyclohexane-1,3-dione 3b instead of 5,5-dimethylcyclohexane-1,3-dione 3a, the three-component reaction with various aryl as well as heteroaryl aldehydes and malononitrile under the standard reaction conditions afforded the desired products 4p–t in good to excellent yield (86–97% yield) within 6 to 10 min (Table 2).

Enlightened by these results, we extended this domino three-component reaction of malononitrile 2, 5,5-dimethylcyclohexane-1,3-dione 3a with isatins 5a by replacing aryl/heteroaryl aldehydes 1a–o in presence of 10 mol% of TsOH⋅H2O with water as LAGs under mechanochemical grinding at ambient temperature for 5 min (Fig. 6, Table 3). To our delight, the corresponding 2-amino-7,7-dimethyl-2′,5-dioxo-5,6,7,8- tetrahydrospiro[chromene-4,3′-indoline]-3-carbonitrile 6a was obtained in 96% yield only at 5 min. Then we carried out a total of eleven reactions with different types of isatin derivatives such as 5-chloro isatin 5b/5-bromo isatin 5c/5-nitro isatin 5d/N-methyl isatin 5e/N-propyl isatin 5f/N-benzyl isatin 5g with malononitrile 2 and 5,5-dimethylcyclohexane-1,3-dione 3a/cyclohexane-1,3-dione 3b under the standard conditions to furnished the respective products 2-amino-3-cyano-tetrahydro-spiro[chromene-4,3′-indoline] 6b–l in 90–97% yields at 4 to 8 min (Table 3). Isatins having substitutions like chloro, bromo, nitro are well suited for this reaction, delivering the products 6b, 6c, 6d, and 6i in good to excellent yield. Similarly, N-unsubstituted isatins (R3 = H) (5a–d) as well as N-substituted isatins (R3 = Me, propyl, benzyl) (5e–g), were efficiently tolerated by this reaction.

To further explore the applicability of the present approach, we investigated a series of trial reactions between 1 equivalent of benzaldehyde 1a with 2 equivalent of 5,5-dimethylcyclohexane-1,3-dione 3a under different reaction conditions (Fig. 7). Initial execution of the reaction in the absence of any catalyst as well as any solvents or in presence of EtOH either in stirring, grinding, or reflux conditions, formation of the desired product 2,2′-(phenylmethylene)bis(3-hydroxy-5,5-dimethylcyclohex-2-enone) 7a was not detected (Table 4, Entry 1–3). Grinding the reactants under catalyst-free conditions in water furnished the desired product in a 40% yield (Table 4, Entry 2). Then we employed 2 mol% of TsOH⋅H2O as the easily accessible catalyst in the model reaction in solvent-free stirring or grinding conditions, but no improvements in the rate of the reaction were observed (Table 4, Entry 5–6). Surprisingly, switching the neat grinding to liquid assisted grinding by employing ethanol, and water as the liquid assisted grinding additive (LAGs), an increase in the yield of the product was observed (Table 4, Entry 7–8). With water as the LAGs, the desired product 7a was achieved in 87% yield in only 8 min under the influences of 2 mol% of the catalyst (Table 4, Entry 8). By increasing the loading of the catalyst from 2 to 5 mol%, the yield of the product was found to be increased up to 95% in only 3 min (Table 4, Entry 9). However, there was no change in the product yield with increased loading of the catalyst from 5 to 10 mol% (Table 4, Entry 10). In the meantime, the reaction rate was found to be slow when we changed the reaction condition with 5 mol% of TsOH⋅H2O in EtOH, ACN as LAGs under mechanical grinding (Table 4, Entry 11–12). On the other hand, the unusual requirements of long reaction time and low yield of the product for the reaction conducted in reflux or ultrasonication with 5 mol% of TsOH⋅H2O using water as the solvent system suggest the mechanochemical grinding as the best method of choice for this three-component reaction (Table 4, Entry 13–14). Furthermore, the yield of the product was also decreased when employing 5 mol% of secondary amine catalyst L-proline in water under grinding or reflux conditions (Table 4, Entry 15–16).

After ascertaining the optimal reaction conditions and to broadening the scopes of the reaction, a series of different types of aldehydes possessing electron-rich as well as electron-deficient substituents were treated with 5,5-dimethyl cyclohexane-1,3-dione 3a/cyclohexane-1,3-dione 3b (Fig. 8). The reaction condition was proven to be very efficient for all the substrates and as represented in Table 5, the respective 2,2′-aryl/heteroaryl-methylene-bis(3-hydroxy-cyclohex-2-enone) products 7a–p were formed in good to excellent yields within 3–8 min without resulting in any side products. This operationally simple and highly beneficial approach efficiently tolerates different halogenated groups such as fluoro, chloro, bromo as well as other functional groups like nitro, hydroxyl present in the different positions of the aryl ring of aldehydes with both 5,5-dimethyl cyclohexane-1,3-dione 3a or cyclohexane-1,3-dione 3b and furnished the product 7b, 7c, 7d, 7f, 7g, 7j, 7k, 7l, 7m, and 7n in 98%, 96%, 93%, 95%, 94%, 95%, 93%, 87%, 96% and 95% yield respectively. Similarly, methoxy substituted aldehydes are well documented for this reaction. The reaction condition was found to be limited to aliphatic aldehydes.

Xanthenes and their derivatives on the other hand recently gained tremendous interest in medicinal chemistry and material sciences due to their remarkable therapeutic potential and optoelectronic properties allowed by their attractive structural features88,89. They are commonly encountered in agricultural90, laser technology91 and found in diverse pharmacological applications92,93,94 such as antiestrogenic, antibacterial, antimicrobial as well as hypoglycaemic activities, neuropeptide YY5 receptor antagonist, etc.

Consequently, a vast array of catalytic systems such as sulfamic acid95, diethylamine96, 2,4,6-trichloro-1,3,5-triazine97, p-TSA98, and catalyst-free99 conditions have been discovered. Although the reported methodology offers several advantages, some of them suffer disadvantages like harsh reaction conditions, prolonged reaction time, high energy inputs, utilization of volatile organic solvents, non-recyclable catalytic system, low yield, and narrow substrate scopes.

Recognizing all these limitations and encouraged by our aforementioned results, as well as our ongoing interest in the multicomponent synthesis of medicinally privileged heterocycles100,101,102,103, we performed a domino three-component reaction between 1 equivalent of salicylaldehyde 8a and 2 equivalent of 5,5-dimethyl cyclohexane-1,3-dione 3a by employing water (η = 0.25 μL/mg) as the liquid assisted additives in presence of 5 mol% of TsOH⋅H2O as the Brønsted acid catalyst under mechanochemical grinding conditions. To our delight, the reaction afforded the corresponding 9-(2-hydroxy-4,4-dimethyl-6-oxocyclohex-1-en-1-yl)-3,3-dimethyl-2,3,4,9-tetrahydro-1H-xanthen-1-one, 9a in 96% yield within 8 min. Enlightened by this successful result, we attempted a series of reactions between different derivatives of salicylaldehydes 8 and 5,5-dimethyl cyclohexane-1,3-dione 3a/cyclohexane-1,3-dione 3b under the standard conditions (Fig. 9, Table 6). Salicylaldehydes with halogenated substrates (R = Br) and electron releasing substrates (R = 4-OMe, 6-OMe) all were found to be very suitable for this reaction and furnished the desired products in excellent yield. On the other hand, heteroaryl substituted salicylaldehyde like 2-hydroxy naphthaldehyde also worked well in these reaction conditions (Table 6).

All of the synthesized compounds were isolated pure just by filtering off the precipitate along with continuous washing by water followed by recrystallization from ethanol. Notably, the approach does not necessitate the use of time-consuming column chromatographic techniques. The structure of the synthesized compounds has been determined based on spectroscopic analysis such as 1H NMR, 13C NMR, and HRMS (see supporting information).

To further validate the potentiality of the present one-pot three-component domino work, three preparative scales up reaction for the synthesis of 4d, 6b, 7b, and 9b on a 10 mmol scale (Fig. 10). With the help of 10 mol% of TsOH⋅H2O, the mechanochemical water-assisted grinding of 4-flurobenzaldehyde 1d, malononitrile 2, and 5,5-dimethyl cyclohexane-1,3-dione 3a smoothly afforded 2.94 g (94% yield) of the desired product 4d after 10 min at ambient conditions (Fig. 10a). Similarly, the three-component reaction between 1.47 g of 5-chloro isatin, 0.66 g of malononitrile, and 1.42 g of 5,5-dimethylcyclohexane-1,3-dione 3a efficiently proceeded at 8 min of grinding using 10 mol% of the TsOH⋅H2O in presence of water as LAGs to deliver 3.51 g of the product 6b (95% yield) (Fig. 10b). Alternatively, we were also successful in the construction of 3.59 g of the product 7b (93% yield) from1.24 g of 3-flurobenzaldehyde 1b, and 2.8 g of 3a (Fig. 10c). Similarly, by employing 5 mol% of TsOH⋅H2O with the aid of water-assisted mechanochemical grinding via a mortar and pestle, we synthesized the products 9b in 4.22 g (95% yield) (Fig. 10d). Although all the four reactions took place in a slightly longer reaction time when using 10 mmol scales as compared to 1 mmol scales, the yield of the products was accomplished in the almost same quantity.

Plausible mechanism

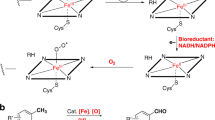

The suggested mechanism for the formation of 2-amino-tetrahydro-spiro[chromene-3,4-indoline]-3-carbonitrile derivatives 6a–l and 2,2′-aryl/heteroaryl-methylene-bis(3-hydroxy-cyclohex-2-enone) products 7a–p were represented in Fig. 11A and B respectively. For products 6a–l, an initial acid-catalyzed Knoevenagel condensation between substituted isatin 5a-g with active methylene compound 2 took place smoothly to deliver the intermediate Int-2 after the successful removal of water from Int-1. Besides, the keto-enol tautomerization of either 5,5-dimethyl cyclohexane-1,3-dione 3a or cyclohexane-1,3-dione 3b under the influences of the catalyst efficiently furnished the intermediate Int-3 which eventually underwent Michael addition with intermediate Int-2 to form the Int-4. The subsequent 6-exo-dig cyclization of the –OH group onto the cyano moiety of Int-5 delivers the imine intermediate Int-6 that yields the final products 6a-l after an imine-enamine tautomerization (Fig. 11A).

On the other hand, the mechanism for products 7a–r proceeded through the formation of intermediate Int-8 via an acid-catalyzed Knoevenagel condensation of substituted aldehydes 1a–o with enol form Int-3 of one molecule of 5,5-dimethyl cyclohexane-1,3-dione 3a or cyclohexane-1,3-dione 3b. This intermediate Int-8 further experiences nucleophilic attack from the enol form Int-3 of the second molecule of 5,5-dimethyl cyclohexane-1,3-dione 3a or cyclohexane-1,3-dione 3b, thereby delivering the intermediate Int-9. Consequently, the intermediate Int-9 produced the respective product 7a–r through the tautomerization reaction (Fig. 11B).

Green chemistry metrics calculation

The assessment of the greenness of different chemical processes is crucial in order to formulate the practical advancement of chemical synthesis and chemical processes in both industry and academics in the move toward more environmental sustainability104. The quantification of sustainable practices has to lead to the development of a series of metrics to support and reinforce the behavior change of chemical technology with the aim to address green or sustainable chemistry105,106,107,108,109. Most importantly used green metrics including Atom Economy (AE), atom efficiency (AEf), the environmental impact factor (E-factor), Reaction Mass Efficiency (RME), Carbon Efficiency (CE) are calculated for our newly developed methodology among which we examined the value of the metrics for compound 4g, 6d 7b and 9b (see supporting information). The overall results are depicted in Table 7. From Table 7, it was observed that the calculated value of the atom economy and atom efficiency for compounds 4g, 6d 7b, and 9b were much closer to the ideal value of AE and AEf, which indicates the presence of all starting material in the final product. The ideal value of the E-factor is considered zero for a chemical process and the calculated E-factor for compounds 4g, 6d 7b, and 9b was found to be almost similar to the ideal value that points out the avoidance of waste products from the reaction. Similarly, the value of RME ranges from 0–100%, and the greater amount of RME provides the “cleanness” of a chemical reaction. The calculated value of RME for compounds 4g, 6d 7b, and 9b resemble the ideal value which confirms the cleanness of the presented protocol. Also, the value of CE is matched with the calculated value for compounds 4g, 6d, 7b, and 9b. The graphical representation of the calculated data for various parameters is depicted in Fig. 12 in the form of a radial pentagon diagram which clearly showcases/supports the greenness or sustainability of the present approach (for further information see supporting information).

Conclusions

In this study, we have disclosed an energy-efficient and environmentally sustainable route for the construction of a diverse set of 2-amino-3-cyano-4H-chromenes, tetrahydro- spiro[chromene-3,4′-indoline]-3-carbonitriles as well as 2,2′-aryl/heteroaryl-methylene-bis(3-hydroxy-cyclohex-2-enones) via water-assisted grinding induced Brønsted acid-catalyzed one-pot domino multicomponent reactions by employing the reactivity of 5,5-dimethyl-cyclohexane-1,3-dione/cyclohexane-1,3-dione at ambient conditions. With the help of low loading (only 5–10 mol%) of TsOH⋅H2O as the catalyst, all the synthesized products were achieved in good to excellent yields. The ability to accomplish the multiple C–C, C=C, C–O, C–N bond in a mechanochemical single pot operation from readily accessible materials without using any hazardous chemicals with water as green LAGs under metal-free conditions with great success in reducing the complex purification steps and cost of the overall process features the significant advantages of this approach. The practical effectiveness of the present method was established by demonstrating scale-up synthesis in almost quantitative yield with ultralow catalyst loading. The calculated green metrics for the present protocol were found to ideally resemble in all the cases, which supports the sustainability credentials of the current transformation. Other notable features of this environmentally benign, and highly atom economic procedure include short reaction time, broad functional group tolerances, operationally simple, mild setup procedure, cost-effective, energy-efficient, column chromatography free, metal-free, ligand-free, waste-free, toxic-free, high atom economy, atom efficiency, low E-factor, high reaction mass efficiency, open-air work, and easy isolation of products, which ensures the present approach an alternative sustainable route to the existing method.

Experimental section

General experimental detail

All commercially available chemicals were used without further purification. Thin Layer Chromatography (TLC) was executed utilizing silica gel 60 F254 (Merck) plates. Proton nuclear magnetic resonance spectra (1H NMR spectra) were obtained on Bruker 500 MHz, JEOL 400, and 600 MHz NMR spectrometers in CDCl3 and DMSO-d6 solvents. 13C NMR spectra were recorded on Bruker at 125 MHz, 100, and 150 MHz. Chemical shifts are reported in parts per million (ppm) relative to the TMS signal. Multiplicity is indicated as follows: s (singlet); bs (broad singlet); d (doublet); t (triplet); q (quartet); m (multiplet); dd (doublet of doublets), etc. TOF and quadrupole mass analyzer types are used for the HRMS measurements.

General Procedure for the synthesis of 2-amino-3-cyano-4H-chromene 4 and 2-amino-tetrahydrospiro[chromenes-3,4′-indoline]-3-carbonitriles 6

In a typical grinding method, carbonyl compounds such as aryl/heteroaryl aldehydes 1a–o (1 mmol), or substituted isatin 5a–g (1 mmol), malononitrile (1 mmol), and 5,5-dimethyl cyclohexane-1,3-dione/cyclohexane-1,3-dione 3a–b (1 mmol) were mixed in a mortar and ground properly by a pestle in presence of water (η = 0.35 μL/mg) as LAGs with 10 mol% of TsOH⋅H2O as the catalyst at ambient temperature for the indicated time. The progress of the reaction was determined by TLC (thin layer chromatography). After complete consumption of starting material, as indicated by the TLC, the reaction mixture was transferred to a beaker and filtered off as well as washed with water, and then the crude product was washed with cold ethanol to give analytically pure products 4, and 6. All the compounds were fully characterized based on analytical data and detailed spectral studies including 1H NMR, 13C NMR, and HRMS (Supplementary information).

Spectral Data for the selected compounds 4a, 4b, 6a, and 6b

2-amino-7,7-dimethyl-5-oxo-4-phenyl-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile, 4a

96% yield, white solid. Rf = 0.5 (60% EtOAc/Hexane). 1H NMR (500 MHz, CDCl3) δ 7.29 (t, J = 7.5 Hz, 2H), 7.24–7.19 (m, 3H), 4.52 (s, 2H), 4.41 (s, 1H), 2.46 (s, 2H), 2.23 (d, J = 8.0 Hz, 2H), 1.11 (s, 3H), 1.04 (s, 3H). 13C NMR (126 MHz, CDCl3 + DMSO-d6) δ 195.72, 162.31, 158.54, 144.54, 128.23, 127.28, 127.18, 126.59, 119.80, 113.06, 58.76, 50.25, 35.64, 35.61, 31.87, 28.66, 27.15, 27.10. HRMS (ESI+): m/z calculated for [C18H18N2O2 + H+]: 295.1447; found 295.1439.

2-amino-7,7-dimethyl-5-oxo-4-(p-tolyl)-5,6,7,8-tetrahydro-4H-chromene-3-carbonitrile, 4b

88% yield, white solid. Rf = 0.6 (60% EtOAc/Hexane). 1H NMR (500 MHz, CDCl3) δ 7.10 (q, J = 7.9 Hz, 4H), 4.51 (s, 2H), 4.37 (s, 1H), 2.45 (s, 2H), 2.29 (s, 3H), 2.22 (d, J = 7.9 Hz, 2H), 1.11 (s, 3H), 1.04 (s, 3H). 13C NMR (126 MHz, CDCl3 + DMSO-d6) δ 195.59, 161.35, 157.77, 140.48, 135.78, 128.57, 126.81, 119.15, 113.38, 60.71, 50.16, 34.83, 34.66, 31.64, 28.39, 27.07, 20.54. HRMS (ESI+): m/z calculated for [C19H20N2O2 + H+]: 309.1603; found 309.1625.

2-amino-7,7-dimethyl-2′,5-dioxo-5,6,7,8-tetrahydrospiro[chromene-4,3′-indoline]-3-carbonitrile, 6a

96% yield, white solid. Rf = 0.5 (80% EtOAc/Hexane). 1H NMR (600 MHz, CDCl3 + DMSO-d6) δ 10.20 (s, 1H), 7.15 (qd, J = 7.7, 1.4 Hz, 1H), 6.97–6.94 (m, 1H), 6.92 (dd, J = 13.4, 6.9 Hz, 1H), 6.86 (dd, J = 6.7, 6.2 Hz, 1H), 6.43 (t, J = 11.6 Hz, 2H), 2.53 (dd, J = 9.9, 5.1 Hz, 2H), 2.17 (ddd, J = 42.7, 16.2, 5.5 Hz, 2H), 1.12 (s, 3H), 1.07 (s, 3H). 13C NMR (126 MHz, DMSO-d6) δ 194.93, 178.08, 164.19, 158.81, 142.09, 134.45, 128.21, 123.05, 121.73, 117.39, 110.83, 109.28, 57.53, 50.04, 46.85, 40.43, 31.98, 27.65, 27.05. HRMS (ESI+): m/z calculated for [C19H17N3O3 + H+]: 336.1348; found 336.1318.

2-amino-5′-chloro-7,7-dimethyl-2′,5-dioxo-5,6,7,8-tetrahydrospiro[chromene-4,3′-indoline]-3-carbonitrile, 6b

97% yield, white solid. Rf = 0.45 (80% EtOAc/Hexane). 1H NMR (600 MHz, CDCl3 + DMSO-d6) δ 7.78 (s, 1H), 7.12 (ddd, J = 8.2, 2.0, 0.9 Hz, 1H), 6.93 (d, J = 1.4 Hz, 1H), 6.83–6.80 (m, 1H), 6.69 (s, 2H), 2.54 (d, J = 9.1 Hz, 2H), 2.19 (s, 2H), 1.12 (s, 3H), 1.09 (s, 3H). 13C NMR (151 MHz, CDCl3 + DMSO-d6) δ 208.39, 194.27, 177.62, 163.74, 158.57, 140.42, 135.48, 127.68, 126.12, 122.81, 116.61, 110.29, 49.96, 46.88, 40.26, 31.63, 27.53, 27.32. HRMS (ESI+): m/z calculated for [C19H16ClN3O3 + H+]: 370.0958; found 370.0958.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Sheldon, R. A. Fundamentals of green chemistry: Efficiency in reaction design. Chem. Soc. Rev. 41, 1437–1451. https://doi.org/10.1039/C1CS15219J (2012).

Dunn, P. J. The importance of green chemistry in process research and development. Chem. Soc. Rev. 41, 1452–1461. https://doi.org/10.1039/C1CS15041C (2012).

Gupta, P. & Mahajan, A. Green chemistry approaches as sustainable alternatives to conventional strategies in the pharmaceutical industry. RSC Adv. 5, 26686–26705. https://doi.org/10.1039/C5RA00358J (2015).

Borah, B., Dwivedi, K. D. & Chowhan, L. R. Recent approaches in the organocatalytic synthesis of pyrroles. RSC Adv. 11, 13585–13601. https://doi.org/10.1039/D1RA01690C (2021).

Borah, B. & Chowhan, L. R. Recent advances in the transition-metal-free synthesis of quinoxalines. RSC Adv. 11, 37325–37353. https://doi.org/10.1039/D1RA06942J (2021).

Borah, B., Dwivedi, K. D., Kumar, B. & Chowhan, L. R. Recent advances in the microwave-and ultrasound-assisted green synthesis of coumarin-heterocycles. Arab. J. Chem. 15, 103654. https://doi.org/10.1016/j.arabjc.2021.103654 (2021).

Dwivedi, K. D., Borah, B. & Chowhan, L. R. Ligand free one-pot synthesis of pyrano [2, 3-c] pyrazoles in water extract of banana peel (WEB): A green chemistry approach. Front. Chem. 7, 944. https://doi.org/10.3389/fchem.2019.00944 (2020).

Howard, J. L., Cao, Q. & Browne, D. L. Mechanochemistry as an emerging tool for molecular synthesis: What can it offer?. Chem. Sci. 9, 3080–3094. https://doi.org/10.1039/C7SC05371A (2018).

Do, J. L. & Friščić, T. Mechanochemistry: A force of synthesis. ACS Cent. Sci. 3, 13–19. https://doi.org/10.1021/acscentsci.6b00277 (2017).

Hernández, J. G. & Bolm, C. Altering product selectivity by mechanochemistry. J. Org. Chem. 82, 4007–4019. https://doi.org/10.1021/acs.joc.6b02887 (2017).

Leonardi, M., Villacampa, M. & Menéndez, J. C. Multicomponent mechanochemical synthesis. Chem. Sci. 9, 2042–2064. https://doi.org/10.1039/C7SC05370C (2018).

Claramunt, R. M., Lopez, C., Sanz, D. & Elguero, J. Mechano heterocyclic chemistry: Grinding and ball mills. Adv. Heterocycl. Chem. 112, 117–143. https://doi.org/10.1016/B978-0-12-800171-4.00003-2 (2014).

Wang, G. W. Mechanochemical organic synthesis. Chem. Soc. Rev. 42, 7668–7700. https://doi.org/10.1039/C3CS35526H (2013).

Friščić, T., Mottillo, C. & Titi, H. M. Mechanochemistry for synthesis. Angew. Chem. 132, 1030–1041. https://doi.org/10.1002/ange.201906755 (2020).

Ying, P., Yu, J. & Su, W. Liquid-assisted grinding mechanochemistry in the synthesis of pharmaceuticals. Adv. Synth. Catal. 363, 1246–1271. https://doi.org/10.1002/adsc.202001245 (2021).

Yadav, R. & Parvin, T. Multicomponent synthesis of styryl linked benzo [h] pyrazolo [3, 4-b] quinoline-5, 6 (10 H)-diones by liquid assisted grinding. New J. Chem. 45, 10388–10395. https://doi.org/10.1039/D1NJ00770J (2021).

Awalt, J. K., Scammells, P. J. & Singer, R. D. Liquid assisted grinding for the N-demethylation of alkaloids. ACS Sustain. Chem. Eng. 6, 10052–10057. https://doi.org/10.1021/acssuschemeng.8b01393 (2018).

Chen, L., Regan, M. & Mack, J. The choice is yours: Using liquid-assisted grinding to choose between products in the palladium-catalyzed dimerization of terminal alkynes. ACS Catal. 6, 868–872. https://doi.org/10.1021/acscatal.5b02001 (2016).

Jiang, Z. J., Li, Z. H., Yu, J. B. & Su, W. K. Liquid-assisted grinding accelerating: Suzuki–Miyaura reaction of aryl chlorides under high-speed ball-milling conditions. J. Org. Chem. 81(20), 10049–10055. https://doi.org/10.1021/acs.joc.6b01938 (2016).

Auria-Luna, F., Fernández-Moreira, V., Marqués-López, E., Gimeno, M. C. & Herrera, R. P. Ultrasound-assisted multicomponent synthesis of 4H-pyrans in water and DNA binding studies. Sci. Rep. 10, 1–17. https://doi.org/10.1038/s41598-020-68076-1 (2020).

Borah, B., Dwivedi, K. D. & Chowhan, L. R. Applications of pyrazolone in multicomponent reactions for the synthesis of dihydropyrano [2, 3-c] pyrazoles and spiro-pyrano [2, 3-c] pyrazoles in aqueous medium. Arkivoc Part I, 273–328. https://doi.org/10.24820/ark.5550190.p011.481 (2021).

Simon, M. O. & Li, C. J. Green chemistry oriented organic synthesis in water. Chem. Soc. Rev. 41, 1415–1427. https://doi.org/10.1039/C1CS15222J (2012).

Butler, R. N. & Coyne, A. G. Water: Nature’s reaction enforcer-comparative effects for organic synthesis “in-water” and “on-water”. Chem. Rev. 110, 6302–6337. https://doi.org/10.1021/cr100162c (2010).

Chanda, A. & Fokin, V. V. Organic synthesis “on water”. Chem. Rev. 109, 725–748. https://doi.org/10.1021/cr800448q (2009).

Gawande, M. B., Bonifácio, V. D., Luque, R., Branco, P. S. & Varma, R. S. Benign by design: Catalyst-free in-water, on-water green chemical methodologies in organic synthesis. Chem. Soc. Rev. 42, 5522–5551. https://doi.org/10.1039/C3CS60025D (2013).

Butler, R. N. & Coyne, A. G. Organic synthesis reactions on-water at the organic–liquid water interface. Org. Biomol. Chem. 14, 9945–9960. https://doi.org/10.1039/C6OB01724J (2016).

Toure, B. B. & Hall, D. G. Natural product synthesis using multicomponent reaction strategies. Chem. Rev. 109, 4439–4486. https://doi.org/10.1021/cr800296p (2009).

Insuasty, D., Castillo, J., Becerra, D., Rojas, H. & Abonia, R. Synthesis of biologically active molecules through multicomponent reactions. Molecules 25, 505. https://doi.org/10.3390/molecules25030505 (2020).

de Graaff, C., Ruijter, E. & Orru, R. V. Recent developments in asymmetric multicomponent reactions. Chem. Soc. Rev. 41, 3969–4009. https://doi.org/10.1039/C2CS15361K (2012).

Borah, B., Dwivedi, K. D. & Chowhan, L. R. Recent advances in metal-and organocatalyzed asymmetric functionalization of pyrroles. Asian J. Org. Chem. 10, 2709–2762. https://doi.org/10.1002/ajoc.202100427 (2021).

Borah, B., Dhar Dwivedi, K. & Chowhan, L. R. 4-Hydroxycoumarin: A versatile substrate for transition-metal-free multicomponent synthesis of bioactive heterocycles. Asian J. Org. Chem. 10, 3101–3126. https://doi.org/10.1002/ajoc.202100550 (2021).

Mermer, A., Keles, T. & Sirin, Y. Recent studies of nitrogen containing heterocyclic compounds as novel antiviral agents: A review. Bioorg. Chem. 114, 105076. https://doi.org/10.1016/j.bioorg.2021.105076 (2021).

Azath, I. A., Puthiaraj, P. & Pitchumani, K. One-pot multicomponent solvent-free synthesis of 2-amino-4 H-benzo [b] pyrans catalyzed by per-6-amino-β-cyclodextrin. ACS Sustain. Chem. Eng. 1, 174–179. https://doi.org/10.1021/sc3000866 (2013).

Datta, B. & Pasha, M. A. Glycine catalyzed convenient synthesis of 2-amino-4H-chromenes in aqueous medium under sonic condition. Ultrason. Sonochem. 19, 725–728. https://doi.org/10.1016/j.ultsonch.2012.01.006 (2012).

Gourdeau, H. et al. Antivascular and antitumor evaluation of 2-amino-4-(3-bromo-4, 5-dimethoxy-phenyl)-3-cyano-4H-chromenes, a novel series of anticancer agents. Mol. Cancer Ther. 3, 1375–1384. https://doi.org/10.1158/1535-7163.1375.3.11 (2004).

Kemnitzer, W. et al. Discovery of 4-Aryl-4 H-chromenes as a new series of apoptosis inducers using a cell-and caspase-based high-throughput screening assay. 1. Structure—activity relationships of the 4-Aryl group. J. Med. Chem. 47, 6299–6310. https://doi.org/10.1021/jm049640t (2004).

Mohr, S. J., Chirigos, M. A., Fuhrman, F. S. & Pryor, J. W. Pyran copolymer as an effective adjuvant to chemotherapy against a murine leukemia and solid tumor. Cancer Res. 35, 3750–3754 (1975).

Hatakeyama, S., Ochi, N., Numata, H. & Takano, S. A new route to substituted 3-methoxycarbonyldihydropyrans; enantioselective synthesis of (–)-methyl elenolate. J. Chem. Soc. Chem. Commun. 17, 1202–1204. https://doi.org/10.1039/C39880001202 (1988).

Bonsignore, L., Loy, G., Secci, D. & Calignano, A. Synthesis and pharmacological activity of 2-oxo-(2H) 1-benzopyran-3-carboxamide derivatives. Eur. J. Med. Chem. 28, 517–520. https://doi.org/10.1016/0223-5234(93)90020-F (1993).

Görlitzer, K., Dehne, A. & Engler, E. 2-(1H-Tetrazol-5-yl)-4, 5-dihydro-4-oxo-indeno [1, 2-b] pyran. Arch. Pharm. 316, 264–270. https://doi.org/10.1002/ardp.19833160315 (1983).

Alvey, L. et al. A new synthetic access to furo [3,2-f] chromene analogues of an antimycobacterial. Bioorg. Med. Chem. 167, 8264–8272. https://doi.org/10.1016/j.bmc.2008.06.057 (2008).

Kumar, R. R., Perumal, S., Senthilkumar, P., Yogeeswari, P. & Sriram, D. An atom efficient, solvent-free, green synthesis and antimycobacterial evaluation of 2-amino-6-methyl-4-aryl-8-[(E)-arylmethylidene]-5, 6, 7, 8-tetrahydro-4H-pyrano [3, 2-c] pyridine-3-carbonitriles. Bioorg. Med. Chem. Lett. 17, 6459–6462. https://doi.org/10.1016/j.bmcl.2007.09.095 (2007).

Armesto, D., Horspool, W. M., Martin, N., Ramos, A. & Seoane, C. Synthesis of cyclobutenes by the novel photochemical ring contraction of 4-substituted 2-amino-3, 5-dicyano-6-phenyl-4H-pyrans. J. Org. Chem. 54, 3069–3072. https://doi.org/10.1021/jo00274a021 (1989).

Reynolds, G. A. & Drexhage, K. H. New coumarin dyes with rigidized structure for flashlamp-pumped dye lasers. Opt. Commun. 13, 222–225. https://doi.org/10.1016/0030-4018(75)90085-1 (1975).

Azizi, N., Mariami, M. & Edrisi, M. Greener construction of 4H-chromenes based dyes in deep eutectic solvent. Dyes Pigments 100, 215–221. https://doi.org/10.1016/j.dyepig.2013.09.007 (2014).

Bissell, E. R., Mitchell, A. R. & Smith, R. E. Synthesis and chemistry of 7-amino-4-(trifluoromethyl) coumarin and its amino acid and peptide derivatives. J. Org. Chem. 45, 2283–2287. https://doi.org/10.1021/jo01300a003 (1980).

Ellis, G. P. Chromenes, chromanones, and chromones. In The Chemistry of Heterocyclic Compounds (eds Weissberger, A. & Taylor, E. C.) 11–139 (Wiley, 1977).

Singha, R., Islam, A. & Ghosh, P. One-pot three-component tandem annulation of 4-hydroxycoumarine with aldehyde and aromatic amines using graphene oxide as an efficient catalyst. Sci. Rep. 11, 1–9. https://doi.org/10.1038/s41598-021-99360-3 (2021).

Baghbanian, S. M., Rezaei, N. & Tashakkorian, H. Nanozeolite clinoptilolite as a highly efficient heterogeneous catalyst for the synthesis of various 2-amino-4 H-chromene derivatives in aqueous media. Green Chem. 15, 3446–3458. https://doi.org/10.1039/C3GC41302K (2013).

Khazaee, A., Jahanshahi, R., Sobhani, S., Skibsted, J. & Sansano, J. M. Immobilized piperazine on the surface of graphene oxide as a heterogeneous bifunctional acid–base catalyst for the multicomponent synthesis of 2-amino-3-cyano-4 H-chromenes. Green Chem. 22, 4604–4616. https://doi.org/10.1039/D0GC01274B (2020).

Nagaraju, S., Paplal, B., Sathish, K., Giri, S. & Kashinath, D. Synthesis of functionalized chromene and spirochromenes using l-proline-melamine as highly efficient and recyclable homogeneous catalyst at room temperature. Tetrahedron Lett. 58, 4200–4204. https://doi.org/10.1016/j.tetlet.2017.09.060 (2017).

Khazaei, A., Gholami, F., Khakyzadeh, V., Moosavi-Zare, A. R. & Afsar, J. Magnetic core–shell titanium dioxide nanoparticles as an efficient catalyst for domino Knoevenagel–Michael-cyclocondensation reaction of malononitrile, various aldehydes and dimedone. RSC Adv. 5, 14305–14310. https://doi.org/10.1039/C4RA16300A (2015).

Esmaeilpour, M., Javidi, J., Dehghani, F. & Dodeji, F. N. A green one-pot three-component synthesis of tetrahydrobenzo [b] pyran and 3,4-dihydropyrano [c] chromene derivatives using a Fe 3 O 4@ SiO2–imid–PMA n magnetic nanocatalyst under ultrasonic irradiation or reflux conditions. RSC Adv. 5, 26625–26633. https://doi.org/10.1039/C5RA01021G (2015).

Rostami, A., Atashkar, B. & Gholami, H. Novel magnetic nanoparticles Fe3O4-immobilized domino Knoevenagel condensation, Michael addition, and cyclization catalyst. Catal. Commun. 37, 69–74. https://doi.org/10.1016/j.catcom.2013.03.022 (2013).

Moosavi-Zare, A. R. et al. Tandem Knoevenagel–Michael-cyclocondensation reactions of malononitrile, various aldehydes and dimedone using acetic acid functionalized ionic liquid. New J. Chem. 38, 2342–2347. https://doi.org/10.1039/C3NJ01509B (2014).

Niknam, K., Khataminejad, M. & Zeyaei, F. Diethylene glycol-bis (3-methylimidazolium) dihydroxide as a dicationic ionic liquid catalyst for the synthesis of 4H-pyrane derivatives in aqueous medium. Tetrahedron Lett. 57, 361–365. https://doi.org/10.1016/j.tetlet.2015.12.034 (2016).

Sharma, P., Gupta, M., Kant, R. & Gupta, V. K. One-pot synthesis of various 2-amino-4 H-chromene derivatives using a highly active supported ionic liquid catalyst. RSC Adv. 6, 32052–32059. https://doi.org/10.1039/C6RA06523F (2016).

Gupta, M., Gupta, M. & Gupta, V. K. Salicyldimine-based Schiff’s complex of copper(II) as an efficient catalyst for the synthesis of nitrogen and oxygen heterocycles. New J. Chem. 39, 3578–3587. https://doi.org/10.1039/C4NJ02391A (2015).

Anamika, Yadav, C. L., Drew, M. G., Kumar, K. & Singh, N. Ferrocene-functionalized dithiocarbamate zinc(II) complexes as efficient bifunctional catalysts for the one-pot synthesis of chromene and imidazopyrimidine derivatives via Knoevenagel condensation reaction. Inorg. Chem. 60, 6446–6462. https://doi.org/10.1021/acs.inorgchem.1c00162 (2021).

Jafari-Moghaddam, F., Beyramabadi, S. A., Khashi, M. & Morsali, A. Three VO2+ complexes of the pyridoxal-derived Schiff bases: Synthesis, experimental and theoretical characterizations, and catalytic activity in a cyclocondensation reaction. J. Mol. Struct. 1153, 149–156. https://doi.org/10.1016/j.molstruc.2017.10.007 (2018).

Dekamin, M. G. & Eslami, M. Highly efficient organocatalytic synthesis of diverse and densely functionalized 2-amino-3-cyano-4 H-pyrans under mechanochemical ball milling. Green Chem. 16, 4914–4921. https://doi.org/10.1039/C4GC00411F (2014).

Shirini, F. & Daneshvar, N. Introduction of taurine (2-aminoethanesulfonic acid) as a green bio-organic catalyst for the promotion of organic reactions under green conditions. RSC Adv. 6, 110190–110205. https://doi.org/10.1039/C6RA15432H (2016).

Azath, I. A., Puthiaraj, P. & Pitchumani, K. One-pot multicomponent solvent-free synthesis of 2-amino-4 H-benzo [b] pyrans catalyzed by per-6-amino-β-cyclodextrin. ACS Sustain. Chem. Eng. 1, 174–179. https://doi.org/10.1021/sc3000866 (2013).

Tufail, F. et al. A practical green approach to diversified spirochromene/spiropyran scaffolds via a glucose–water synergy driven organocatalytic system. New J. Chem. 42, 17279–17290. https://doi.org/10.1039/C8NJ03028F (2018).

Zaharani, L., Khaligh, N. G., Mihankhah, T. & Johan, M. R. Application of nitrogen-rich porous organic polymer for the solid-phase synthesis of 2-amino-4H-benzo [b] pyran scaffolds using ball milling process. Mol. Divers. 25, 323–332. https://doi.org/10.1007/s11030-020-10092-4 (2021).

Babaei, P. & Safaei-Ghomi, J. l-proline covered N doped graphene quantum dots modified CuO/ZnO hexagonal nanocomposite as a robust retrievable catalyst in synthesis of substituted chiral 2-amino-4H-chromenes. Mater. Chem. Phys. 267, 124668. https://doi.org/10.1016/j.matchemphys.2021.124668 (2021).

Ataie, F., Davoodnia, A. & Khojastehnezhad, A. Graphene oxide functionalized organic-inorganic hybrid (GO–Si–NH2–PMo): An efficient and green catalyst for the synthesis of tetrahydrobenzo [b] pyran derivatives. Polycycl. Aromat. Compd. 41, 781–794. https://doi.org/10.1080/10406638.2019.1622137 (2021).

Madasamy, K., Kumaraguru, S., Sankar, V., Mannathan, S. & Kathiresan, M. A Zn based metal organic framework as a heterogeneous catalyst for C–C bond formation reactions. New J. Chem. 43, 3793–3800. https://doi.org/10.1039/C8NJ05953E (2019).

Azizi, N., Dezfooli, S., Khajeh, M. & Hashemi, M. M. Efficient deep eutectic solvents catalyzed synthesis of pyran and benzopyran derivatives. J. Mol. Liq. 186, 76–80. https://doi.org/10.1016/j.molliq.2013.05.011 (2013).

Chen, L., Zhang, X., Tan, L., Zhang, M. & Li, Y. Catalyst-free visible-light induced synthesis of nitrogen-and oxygen-containing heterocycles from 1, 3-diketones. Environ. Chem. Lett. 19, 1831–1837. https://doi.org/10.1007/s10311-020-01150-2 (2021).

Bakherad, M. et al. Catalyst-free green synthesis of tetrahydro-benzo [b] pyrans in magnetized water: Experimental aspects and molecular dynamics simulation. Res. Chem. Intermed. 45, 2981–2997. https://doi.org/10.1007/s11164-019-03774-8 (2019).

Khan, K. M. et al. Tetraketones: A new class of tyrosinase inhibitors. Bioorg. Med. Chem. 14, 344–351. https://doi.org/10.1016/j.bmc.2005.08.029 (2006).

Qiao, Y. F. et al. Isolation and characterization of a new pyrano [4′, 3′: 6, 7] naphtho [1, 2-b] xanthene antibiotic FD-594. J. Antibiot. 51, 282–287. https://doi.org/10.7164/antibiotics.51.282 (1998).

Jamison, J. M., Krabill, K., Hatwalkar, A., Jamison, E. & Tsai, C. C. Potentiation of the antiviral activity of poly r (AU) by xanthene dyes. Cell Biol. Int. Rep. 14, 1075–1084. https://doi.org/10.1016/0309-1651(90)90015-Q (1990).

Nie, D. & Honn, K. V. Cyclooxygenase, lipoxygenase and tumor angiogenesis. Cell. Mol. Life Sci. 59, 799–807. https://doi.org/10.1007/s00018-002-8468-9 (2002).

Schneider, I. & Bucar, F. Lipoxygenase inhibitors from natural plant sources. Part 2: Medicinal plants with inhibitory activity on arachidonate 12-lipoxygenase, 15-lipoxygenase and leukotriene receptor antagonists. Phytother. Res. 19, 263–272. https://doi.org/10.1002/ptr.1604 (2005).

Ion, R. M., Planner, A., Wiktorowicz, K. & Frackowiak, D. The incorporation of various porphyrins into blood cells measured via flow cytometry, absorption and emission spectroscopy. Acta Biochim. Pol. 45, 833–845. https://doi.org/10.18388/abp.1998_4279 (1998).

Banerjee, A. & Mukherjee, A. K. Chemical aspects of santalin as a histological stain. Stain Technol. 56, 83–85. https://doi.org/10.3109/10520298109067286 (1981).

To, Q. H., Lee, Y. R. & Kim, S. H. Efficient one-pot synthesis of acridinediones by indium(III) triflate-catalyzed reactions of β-enaminones, aldehydes, and cyclic 1, 3-dicarbonyls. Bull. Korean Chem. Soc. 33, 1170–1176. https://doi.org/10.5012/bkcs.2012.33.4.1170 (2012).

Jung, D. H., Lee, Y. R., Kim, S. H. & Lyoo, W. S. New and general methods for the synthesis of arylmethylene bis (3-hydroxy-2-cyclohexene-1-ones) and xanthenediones by EDDA and In (OTf) 3-catalyzed one-pot domino Knoevenagel/Michael or Koevenagel/Michael/cyclodehydration reactions. Bull. Korean Chem. Soc. 30, 1989–1995. https://doi.org/10.5012/bkcs.2009.30.9.1989 (2009).

Li, J. T., Li, Y. W., Song, Y. L. & Chen, G. F. Improved synthesis of 2, 2′-arylmethylene bis (3-hydroxy-5, 5-dimethyl-2-cyclohexene-1-one) derivatives catalyzed by urea under ultrasound. Ultrason. Sonochem. 19, 1–4. https://doi.org/10.1016/j.ultsonch.2011.05.001 (2012).

Ilangovan, A. et al. Simple and cost effective acid catalysts for efficient synthesis of 9-aryl-1, 8-dioxooctahydroxanthene. Tetrahedron Lett. 54, 491–494. https://doi.org/10.1016/j.tetlet.2012.11.058 (2013).

Tajbakhsh, M., Heidary, M. & Hosseinzadeh, R. Nano Fe/NaY zeolite: An efficient and reusable solid-supported catalyst for synthesis of 1-oxo-hexahydroxanthene and tetraketone derivatives. Res. Chem. Intermed. 42, 1425–1439. https://doi.org/10.1007/s11164-015-2094-2 (2016).

Saha, M., Pal, A. K. & Nandi, S. Pd (0) NPs: A novel and reusable catalyst for the synthesis of bis (heterocyclyl) methanes in water. RSC Adv. 2, 6397–6400. https://doi.org/10.1039/C2RA20445B (2012).

Nemati, F., Heravi, M. M. & Rad, R. S. Nano-Fe3O4 encapsulated-silica particles bearing sulfonic acid groups as a magnetically separable catalyst for highly efficient Knoevenagel condensation and Michael addition reactions of aromatic aldehydes with 1, 3-cyclic diketones. Chin. J. Catal. 33, 1825–1831. https://doi.org/10.1016/S1872-2067(11)60455-5 (2012).

Maleki, B., Raei, M., Alinezhad, H., Tayebee, R. & Sedrpoushan, A. Chemoselective synthesis of tetraketones in water catalyzed by nanostructured diphosphate Na2CaP2O7. Org. Prep. Proced. Int. 50, 288–300. https://doi.org/10.1080/00304948.2018.1462055 (2018).

Kantevari, S., Bantu, R. & Nagarapu, L. HClO4–SiO2 and PPA–SiO2 catalyzed efficient one-pot Knoevenagel condensation, Michael addition and cyclo-dehydration of dimedone and aldehydes in acetonitrile, aqueous and solvent free conditions: Scope and limitations. J. Mol. Catal. A Chem. 269, 53–57. https://doi.org/10.1016/j.molcata.2006.12.039 (2007).

Hafez, H. N., Hegab, M. I., Ahmed-Farag, I. S. & El-Gazzar, A. B. A. A facile regioselective synthesis of novel spiro-thioxanthene and spiro-xanthene-9′, 2-[1, 3, 4] thiadiazole derivatives as potential analgesic and anti-inflammatory agents. Bioorg. Med. Chem. Lett. 18, 4538–4543. https://doi.org/10.1016/j.bmcl.2008.07.042 (2008).

Chen, X., Pradhan, T., Wang, F., Kim, J. S. & Yoon, J. Fluorescent chemosensors based on spiroring-opening of xanthenes and related derivatives. Chem. Rev. 112, 1910–1956. https://doi.org/10.1021/cr200201z (2012).

Li, J., Tang, W., Lu, L. & Su, W. Strontium triflate catalyzed one-pot condensation of β-naphthol, aldehydes and cyclic 1, 3-dicarbonyl compounds. Tetrahedron Lett. 49, 7117–7120. https://doi.org/10.1016/j.tetlet.2008.09.129 (2008).

Shankarling, G. S. & Jarag, K. J. Laser dyes. Resonance 15, 804–818. https://doi.org/10.1007/s12045-010-0090-9 (2010).

Hajela, K. & Kapil, R. S. Synthesis and post-coital contraceptive activity of a new series of substituted 2, 3-diaryl-2H-1-benzopyrans. Eur. J. Med. Chem. 32, 135–142. https://doi.org/10.1016/S0223-5234(97)87540-X (1997).

Frédérick, R. et al. Mechanism-based thrombin inhibitors: Design, synthesis, and molecular docking of a new selective 2-oxo-2 h-1-benzopyran derivative. J. Med. Chem. 50, 3645–3650. https://doi.org/10.1021/jm061368v (2007).

Okazaki, H., Kishi, T., Beppu, T. & Arima, K. A new antibiotic, baciphelacin. J. Antibiot. 28, 717–719. https://doi.org/10.7164/antibiotics.28.717 (1975).

Heravi, M. M., Alinejhad, H., Bakhtiari, K. & Oskooie, H. A. Sulfamic acid catalyzed solvent-free synthesis of 10-aryl-7, 7-dimethyl-6, 7, 8, 10-tetrahydro-9H-[1, 3]-dioxolo [4, 5-b] xanthen-9-ones and 12-aryl-9, 9-dimethyl-8, 9, 10, 12-tetrahydro-11H-benzo [a] xanthen-11-ones. Mol. Divers. 14, 621–626. https://doi.org/10.1007/s11030-009-9196-y (2010).

Kupwade, R. V., Pandit, K. S., Desai, U. V., Kulkarni, M. A. & Wadgaonkar, P. P. Diethylamine-catalyzed environmentally benign synthesis of 1-oxo-hexahydroxanthenes and bis-coumarins at ambient temperature. Res. Chem. Intermed. 42, 6313–6325. https://doi.org/10.1007/s11164-016-2464-4 (2016).

Zhang, P., Yu, Y. D. & Zhang, Z. H. 2, 4, 6-Trichloro-1, 3, 5-triazine as an efficient catalyst for synthesis of benzopyran derivatives under solvent-free conditions. Synth. Commun. 38, 4474–4479. https://doi.org/10.1080/00397910802369604 (2008).

Nagarapu, L., Karnakanti, S., Bantu, R. & Sridhar, B. Efficient, high-yield protocol for the one-pot synthesis of benzopyran derivatives catalyzed by p-TSA in aqueous media. Synth. Commun. 42, 967–974. https://doi.org/10.1080/00397911.2010.533804 (2012).

He, F., Li, P., Gu, Y. & Li, G. Glycerol as a promoting medium for electrophilic activation of aldehydes: Catalyst-free synthesis of di (indolyl) methanes, xanthene-1, 8 (2 H)-diones and 1-oxo-hexahydroxanthenes. Green Chem. 11, 1767–1773. https://doi.org/10.1039/B916015A (2009).

Dwivedi, K. D., Reddy, M. S. & Chowhan, L. R. Isatin N, N′-cyclic azomethine imine 1, 3-dipole mediated regio and diastereoselective synthesis of isoxazole-containing spirooxindoles by an abnormal [3+2] cycloaddition. Tetrahedron Lett. 61, 152664. https://doi.org/10.1016/j.tetlet.2020.152664 (2020).

Reddy, M. S., Kumar, N. S. & Chowhan, L. R. Heterogeneous graphene oxide as recyclable catalyst for azomethine ylide mediated 1, 3 dipolar cycloaddition reaction in aqueous medium. RSC Adv. 8, 35587–35593. https://doi.org/10.1039/C8RA06714G (2018).

Satish Kumar, N. et al. Zinc oxide nanoparticles as efficient catalyst for the synthesis of novel di-spiroindolizidine bisoxindoles in aqueous medium. Environ. Chem. Lett. 17, 455–464. https://doi.org/10.1007/s10311-018-0772-1 (2019).

Borah, B., Bora, J., Ramesh, P. & Chowhan, L. R. Sonochemistry in an organocatalytic domino reaction: An expedient multicomponent access to structurally functionalized dihydropyrano [3, 2-b] pyrans, spiro-pyrano [3, 2-b] pyrans, and spiro-indenoquinoxaline-pyranopyrans under ambient conditions. RSC Adv. 12, 12843–12857. https://doi.org/10.1039/D2RA01917E (2022).

Jiménez-González, C., Constable, D. J. & Ponder, C. S. Evaluating the “Greenness” of chemical processes and products in the pharmaceutical industry—A green metrics primer. Chem. Soc. Rev. 41, 1485–1498. https://doi.org/10.1039/C1CS15215G (2012).

Calvo-Flores, F. G. Sustainable chemistry metrics. ChemSusChem 2, 905–919. https://doi.org/10.1002/cssc.200900128 (2009).

Sheldon, R. A. Metrics of green chemistry and sustainability: Past, present, and future. ACS Sustain. Chem. Eng. 6, 32–48. https://doi.org/10.1021/acssuschemeng.7b03505 (2018).

Jimenez-Gonzalez, C., Ponder, C. S., Broxterman, Q. B. & Manley, J. B. Using the right green yardstick: Why process mass intensity is used in the pharmaceutical industry to drive more sustainable processes. Org. Process Res. Dev. 15, 912–917. https://doi.org/10.1021/op200097d (2011).

Augé, J. A new rationale of reaction metrics for green chemistry. Mathematical expression of the environmental impact factor of chemical processes. Green Chem. 10, 225–231. https://doi.org/10.1039/B711274B (2008).

Constable, D. J., Curzons, A. D. & Cunningham, V. L. Metrics to ‘green’ chemistry—Which are the best?. Green Chem. 4, 521–527. https://doi.org/10.1039/B206169B (2002).

Acknowledgements

BB and BK thank UGC-India for the fellowship. BB thanks Central Instrumentation Facility (CIF), Central University of Gujarat. Author thanks the Central University of Gujarat for the infrastructure to carry out the work.

Author information

Authors and Affiliations

Contributions

B.B. wrote the main manuscript text, and performed the experiments. S.S. and K.K.P. performed the experiments. M.P. and B.K. and R.B. supported the study. V.R. performed DFT calculations and R.C. supervised the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Borah, B., Swain, S., Patat, M. et al. Brønsted acid catalyzed mechanochemical domino multicomponent reactions by employing liquid assisted grindstone chemistry. Sci Rep 13, 1386 (2023). https://doi.org/10.1038/s41598-023-27948-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-27948-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.