Abstract

In the present study, the Fe3O4@Glycerol-Cu complex supported magnetically as a nanoparticle was prepared by grafting. Firstly, Fe3O4 NPs were synthesized by FeCl3.6H2O and FeCl2.4H2O according to the reported method, and subsequently, the prepared MNP with 3-chloropropyltrimethoxysilane. After that, the support-glycerol was functionalized on the surface of MNP-(CH2)3Cl for graft and stabilization of copper metal. Our purpose is to use the Fe3O4@Glycerol-Cu as a green, recoverable, novel, and affordable nanocatalyst in the effective synthesis of 2-amino-4H-chromenes. FT-IR, XRD, TGA, BET, VSM, TEM, and SEM–EDX techniques were examined to characterize this nanocatalyst. This result demonstrates that copper and organic compounds have appropriately reacted, with the support of MNP-(CH2)3Cl, and the crystalline structure have preserved in the MNP-(CH2)3Cl/Glycerol-Cu nanocatalyst confirmed the formation of the base Cu complex grafted on the surface of the nanoparticles. Finally, as can be seen, the nanoparticle size is 5–15 nm. This heterogeneous nanocatalyst illustrated excellent recyclable behavior, and can be used several times without notable reduction of its activity.

Similar content being viewed by others

Introduction

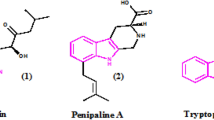

The researchers have considerably worried about the environmentally safe and health Issues of manufacturing from processes that include catalysts (catalytic processes). They have made significant endeavors to expand of environmentally pleasant recyclable catalysts for natural and organic variation, including multi-component reactions in the industrial and combinatorial fields1,2,3,4. In addition, the stabilization of diverse homogeneous catalysts onto different nanoparticles has appeared as a promising approach for amending stability and catalytic performance5. In recent decades, the stabilizing of diverse homogeneous catalysts onto different nanoparticles has transpired as a hopeful method to improve stability and catalytic performance6. The last few years have evidenced a significant advance in the expansion of different magnetic nanoparticles (MNPs) as effective and stable supports for catalysts in widely used fields owing to their interesting chemical and physical characteristics, including easy segregating of magnetic, large surface to volume ratio, and high performance of recyclability7,8,9,10,11. The application of diverse and combined magnetic metal oxide nanoparticles such as Fe2O3, Fe3O4, Al2O3, etc., has fascinated extensive regard in organic reactions as catalysts support12. Fe3O4 nanoparticles have appeared as excellent support for the stabilizing of different ligands and functional groups due to the attendance of high superficial density OH groups, high stability, easy magnetic separation, and biocompatibility13,14,15,16,17,18.

The recent rise in the popularity of biodiesel has significantly increased the demand for glycerol, an important oleochemical commodity. Glycerol forms complexes with many metal ions. It has been reported that copper ions through a reaction hydroxyl group glycerol (copper-glycerol complex) can be an intermediate product for certain chemical reactions19,20,21.

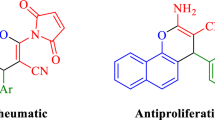

Amongst the heterocyclic scaffolds, chromenes are essential compounds of pharmacological and pharmacological significance that carried out anti-HIV, diuretic, antimalarial, and anticancer virtues22,23,24,25. Some of the chromenes have been extensively utilized as remedial and therapeutically beneficial factors, including acenocoumarol which functions as an anticoagulant26. As well, a wide diversity of chromenes are natural products found in many secondary metabolites such as anthocyanin, pigments, and flavonoids27,28. Also, a wide diversity of chromenes has been found in extensive applications such as cosmetics, pigments, and biocompatible agrochemicals29.

In line with our ongoing attempts in the field of catalysts30,31,32,33,34, in the present research, our purpose is the novel nanocatalyst production in the effective preparation of 2-amino-4H-chromenes. Fe3O4@Glycerol-Cu as a green nanocatalyst was employed for the first time with the effective formation of 2-amino-4H-chromenes through a one-pot, three-component reaction of malononitrile, cyclic 1,3-dicarbonyl compounds, and arylglyoxals. According to the results obtained, offered a plan for the preparation of 2-amino-4H-chromenes utilizing Fe3O4@Glycerol-Cu leads to favorable compounds with excellent efficiency and low reaction time, as well as, this green nanocatalyst under mild reaction demonstrated recyclable demeanor 6 times with the minor loss of its activity. According to our information, we presented an interesting magnetic nanocatalyst Fe3O4@Glycerol-Cu, a novel magnetic reusable nanocatalyst in the obtaining of 2-amino-4H-chromenes.

Experimental section

Materials and methods

All precursors and solvents for the synthesis were bought from Sigma-Aldrich and Merck and utilized without excess purification. FT-IR spectra were done using KBr pellets on the Nexus 670 apparatus. Nanostructure patterns were characterized by XRD measurement with a wavelength of 1.54 Å while these patterns were recorded in the range 10–80. The BET technique used nitrogen as the adsorption gas to measure the specific surface area. The properties measurement of the magnetic catalyst was performed by VSM. The morphology images of the nanocatalyst were recorded through a field-emission scanning electron microscope (FE-SEM). Elemental compositions of the nanocatalysts were affirmed using energy-dispersive X-ray (EDX) analysis.

Synthesis Fe3O4 nanoparticles

One of the best methods for separating nanomaterials from a solution is magnetizing them. Magnetic nanoparticles have been synthesized with the following reaction:

Various solutions of FeCl2.4H2O (ferric chloride tetrahydrate) and FeCl3.6H2O (ferrous chloride hexahydrate) were provided with a molar ratio of 1 to 2. In this, the usual method, FeCl2.4H2O (1.5 g) and FeCl3.6H2O (3 g), were mixed in deionized water (50 mL). Next, NH4OH (ammonium hydroxide, 10 mL of 25% solution) was added dropwise to the above solution and stirred vigorously (50 min, 80 °C, and 700 rpm). A black precipitate is the result of the reaction. The obtained nanoparticles were washed with EtOH and eventually dried (under vacuum conditions at 60 °C for 24 h).

Preparation of MNP-(CH2)3Cl

The prepared MNP (1.6 g) with 3-chloropropyltrimethoxysilane (1.7 g) was added to ethanol (35 mL), and the compound was stirred under reflux conditions at 70 °C for 24 h. Afterward, the obtained solid was washed with ethanol, and eventually, the solid was dried (under vacuum) to acquire MNP–(CH2)3–Cl.

Preparation of support-glycerol

The prepared MNP-(CH2)3Cl (1.2 g) in a 50 mL round-bottom flask with glycerol (25 mL) and EtOH (40 mL) were refluxed at 70 °C for 24 h. Then, the obtained product was separated by the magnet and frequently washed with EtOH. Eventually, the product was dried at 70 °C for 20 h in an oven.

Synthesis of Fe3O4@Glycerol-Cu

The made support-glycerol (1.5 g) was combined with CuSO4.5H2O (0.7 g) in EtOH (40 mL) and reflux conditions at 70 °C for 24 h. As soon as the reaction was completed, the Fe3O4@Glycerol-Cu nanoparticles were collected by an external magnet. Finally, the separated product was washed frequently with EtOH and DW to eliminate the unwanted excess materials and then dried at 70 °C for 15 h.

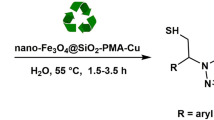

Preparation of 2-amino-4H-chromenes

First, a combination of arylglyoxals (1 mmol), malononitrile (1.1 mmol), cyclic 1,3-dicarbonyl compounds (1 mmol), and magnetic nanocatalyst (10 mg) were added to a flask containing ethanol (10 mL) and the reaction contents were stirred at room temperature (Table 2, appropriate reaction time in the range of 15–20 min) and then the reaction progression was evaluated using thin-layer chromatography. After completing the reaction, the nanocatalyst was segregated by a magnet and washed with acetone or water until the following reaction. Finally, 1H-NMR spectroscopy and FT-IR analysis were used to identify the products, and the precipitate was filtered and recrystallized from ethanol to get the desired 2-amino-4H-chromenes in high yields.

Results and discussions

Our study on the application of novel retrievable and heterogeneous magnetic nanocatalysts in organic transformations encouraged us to report a new heterogeneous catalyst (Fe3O4@Glycerol-Cu) and to study its utilization in the preparation of 2-amino-4H-chromenes. Figure 1, represents a concise route of the magnetic catalyst preparation process.

Catalyst characterization

The newly prepared nanocatalyst structure was characterized using various techniques, including FT-IR (Fourier transform infrared), TGA (Thermogravimetric analysis), XRD (X-ray diffraction), BET (Brunauer–Emmett–Teller), VSM (vibrating-sample magnetometer), EDX (energy dispersive X-ray spectroscopy) and SEM (scanning electron microscopy).

FT-IR analysis

Figure 2, illustrates the FT-IR spectra acquired for Fe3O4 (curve a), MNP–(CH2)3Cl (curve b), MNP–(CH2)3Cl/Glycerol (curve c), and MNP–(CH2)3Cl/Glycerol-Cu (curve d). Curve a, shows the FT-IR spectrum of Fe3O4, and peaks that appeared at 562, 1618, and 3436 cm−1 are attributed to Fe–O vibrations, O–H bending, and O–H stretching, respectively. Curve b, represents the characteristic absorption bands at 2955, 800–1200 cm−1 correspond to aliphatic C–H stretching, Si–O stretching, and Si–O–Si symmetric and asymmetric stretching, respectively. The peaks in the region of 3390, 1239 and 1270 cm−1 correspond to vibrations of O–H stretching vibrations (Change the peak size compared to a and b) and C–O stretching vibrations relating to glycerol (curve c). Moreover, the peak observed at 482 cm−1 in the spectrum (curve d) can be assigned to Cu–O vibration. The advent of the characteristic absorption bands in all the curves a–d, illustrates the successful immobilization of Cu and the organic moieties on the surface of Fe3O4 nanoparticles.

XRD analysis

The nanoparticle's size and crystalline nature of MNP-(CH2)3Cl/Glycerol-Cu were characterized by XRD. Figure 3a, exhibits the XRD pattern of MNP–(CH2)3Cl that Bragg's peaks were observed at 2θ = 31, 36, 43.5, 53.9, 57.5 and 63, that these angles correspond to the (220), (311), (400), (422), (511) and (440) crystal planes, respectively. These peaks indicate the presence of Fe3O4 in the compound. Figure 3b shows the XRD pattern of MNP–(CH2)3Cl/Glycerol-Cu that Bragg's peaks were observed at 2θ = 18, 21, 43.5, 53.9, 57.5 and 63. Also, the peak intensity at common angles (Fig. 3a,b) has been reduced. This result demonstrates that copper and organic compounds have adequately reacted, with the support (MNP–(CH2)3Cl), and the crystalline structure has preserved in the MNP–(CH2)3Cl/Glycerol-Cu nanocatalyst. Also, the average crystallite size of nanoparticles by utilizing the Debye–Scherer equation which is shown in Eq. (1), can be analyzed by the XRD pattern.

D in the mentioned equation represents the average crystalline, and K shows a dimensionless shape factor of about 0.9, λ is the X-ray wavelength; β is the line broadening at half the maximum intensity, as well as θ, is the Bragg angle35.

TGA analysis

TGA (Thermal gravimetric analysis) was utilized on the Fe3O4@Glycerol-Cu nanocatalyst to study its thermal stability. According to Fig. 4, the first weight loss happens below 200 °C because of the removal of the structure O–H and remaining organic solvents. The next weight loss in the range of 150–450 °C is likely attributed to the removal of the Cu complex and the Fe3O4-grafted organic materials. In the final thermal step beyond 450 °C the change of the crystal phase and complete dissociation of the catalyst occurs.

N2-physical adsorption studies

Figure 5, illustrates the nitrogen adsorption/desorption isotherms of the Fe3O4@Glycerol-Cu magnetic nanocatalyst. The hole property was evaluated by nitrogen adsorption–desorption. The particular surface area was computed using the BET for the synthesized Fe3O4@Glycerol-Cu nanocatalyst, and its value was 10.785 m2g−1. The hole volume is 2.4779 cm3g−1. The related hole size spread of the magnetic nanocatalyst was determined as 14.119 nm, using the BJH technique. These results indicate that the Fe3O4@Glycerol-Cu magnetic nanocatalyst was acquired as a mesoporous type (2 < Dv < 50 nm, Dv is the particle diameter of the volume distribution).

VSM analysis

Figure 6, shows the magnetization behavior and Feature of Fe3O4@Glycerol-Cu, with a vibrating sample magnetometer (VSM) at room temperature. Also, Fig. 6, illustrates the VSM data obtained for MNP–(CH2)3Cl and Fe3O4@Glycerol-Cu in curves a and b, respectively. The specific saturation magnetizations of MNP–(CH2)3Cl and Fe3O4@Glycerol-Cu are measured to be 30 and 20 emu/g−1 respectively. The Negligible reduction (10 emu/g−1) observed in Ms of the Fe3O4@Glycerol-Cu nanoparticles in comparison to the Ms value of the bare MNP–(CH2)3Cl nanoparticles was most likely related to the presence of the coated materials on the surface of the Fe3O4 nanoparticles.

EDX analysis

The EDX data illustrate the presence of Fe, Si, C, O, and Cu in Fe3O4@Glycerol-Cu (Fig. 7). As is evident from the spectrum, the existence of Cu, Fe, O, C, and Si elements with wt% of 8.19, 47.82, 25.83, 6.69 and 11.47 were detected in MNP-(CH2)3Cl/Glycerol-Cu, respectively. The advent of the peaks related to the O and Cu atoms confirmed the formation of the base Cu complex grafted on the surface of the nanoparticles.

SEM analysis

Figure 8, shows the morphology and particle size of Fe3O4@Glycerol-Cu using SEM (scanning electron microscopy). These images indicate the spherical structure and demonstrate that the nanocatalyst was made of uniform nanometer particles. Finally, as can be seen, the nanoparticle size is 18 nm.

TEM analysis

Transmission electron microscopy (TEM) has shown to be a useful tool for analyzing the size and shape distribution of particles. TEM image of Fe3O4@Glycerol-Cu exhibits that the diameter size of the as-prepared sample is in the range of 5–15 nm (Fig. 9). Furthermore, distinct structures in which the Fe3O4 spherical cores are visible as dark regions coated by bright outer shells can be detected, also, the distances show the cross links that caused the holes to appear.

Synthesis of 2-amino-4H-chromenes by amounts of Fe3O4@Glycerol-Cu

After obtaining and evaluating the magnetic nanocatalyst structure, it was investigated that the catalytic activity of Fe3O4@Glycerol-Cu as an effective catalyst in the direct formation of 2-amino-4H-chromenes. Thus, to find out a simple and biocompatible method for the synthesis of target products in the presence of Fe3O4@Glycerol-Cu as a recyclable and stable nanocatalyst in the reaction of 4-fluoroarylglyoxal (1b), malononitrile (2), and cyclohexane-1,3-dione (3a) with molar ratio: 1:1.1:1 was explored to create optimal conditions. Optimization of the nanocatalyst in the synthesis of product 4b, using different catalytic amounts of Fe3O4@Glycerol-Cu, is demonstrated in Table 1. Outstanding results were obtained with 4-fluoroarylglyoxal (1 mmol), malononitrile (1.1 mmol), cyclohexane-1,3-dione (1 mmol) in the presence of Fe3O4@Glycerol-Cu (10 mg) and ethanol (5 mL) at room temperature (Table 1, entry 3). The use of lower and higher amounts of nanocatalyst (5 and 15 mg) had not affected the result (Table 1, entries 2 and 4, respectively). The optimal time for the reaction is 15 min. TLC results confirmed that no impurities were observed in the reaction.

The reaction was carried out with 95% yield. As indicated in Table 2, the suggested method is generalizable and includes different functional groups.

As shown in Fig. 10, an appropriate pathway for forming of compounds 4a–h in the presence of prepared Fe3O4@Glycerol-Cu nanocatalyst is proposed. Initially, the oxygen atom in carbonyl groups of arylgloxals 1a–h coordinated with Cu in the head of the nanocatalyst. Then Knoevenagel condensation of the activated formyl group of arylglyoxals 1a-h, with malononitrile (2), leads to form the intermediate I by the removal of the water molecule. After that, intermediate II is created via the Michael addition of cyclic 1,3-dicarbonyl compounds 3a,b with intermediate I. Subsequently, heterocyclization occurred and the corresponding products 4a-h were produced.

The efficiency and capability of the Fe3O4@Glycerol-Cu system in synthesizing of chromenes were compared with the obtained result from other data (Table 3). As illustrated, Fe3O4@Glycerol-Cu is the best nanocatalyst in synthesizing compounds 4a–h in a green solvent under moderate conditions. This nanocatalyst has significant features such as biocompatibility, selectivity, low cost, and chemically stable materials.

Recyclability of the nanocatalyst

The reuse of nanocatalysts is a significant benefit to industrial applications. We checked out the reusability of the Fe3O4@Glycerol-Cu nanocatalyst for the reaction between arylglyoxals, malononitrile, and cyclic 1,3-diketones under optimal reaction conditions. The separated nanocatalyst (by a magnet) was washed with EtOH several times and dried at 70 °C. Finally, the produced nanocatalyst was used six consecutive times without loss of reactivity (Fig. 11).

Considering the similarity of the FT-IR spectra obtained from the catalyst of the first stage and the 6th stage of catalyst recycling, with the peaks of the spectrum of the newly synthesized catalyst, it can be concluded that the efficiency decreases in the last stages of recycling due to the change in the ligand structure and other related factors. It is not related to the reduction of efficiency, but it is related to the reduction of copper as a result of washing in the recycling cycle. The yield of the product obtained in the final cycle was approximately 88%, which indicates that the leaching of copper from the recovered catalyst was negligible.

Hot filtration

The hot filtration was carried out for the preparation of products 4a–h with using of arylglyoxals, malononitrile, and cyclic 1,3-diketones. In the first twenty minutes of the reaction, the yield is 33%. Then, the nanocatalyst was isolated, and the filtrate was allowed to react more. In the end, no other reaction was observed (Fig. 12).

Conclusion

Briefly, in the present study, the Fe3O4@Glycerol-Cu nanocatalyst was synthesized utilizing the grafting technique. The prepared product (Fe3O4@Glycerol-Cu) was structurally evaluated by XRD, FT-IR, TGA, BET, VSM, TEM, and SEM–EDX. The advent of the characteristic absorption bands in all the curves of FT-IR analysis illustrates the successful immobilization of Cu and the organic moieties on the surface of Fe3O4 nanoparticles. The EDX data illustrate related to the O, and Cu atoms confirmed the formation of the base Cu complex grafted on the surface of the nanoparticles. The catalytic activity of these nanoparticles prepared as Lewis acid heterogeneous catalysts for the preparation of 2-amino-4H-chromenes was investigated through one-pot green synthesis. Therefore, the suggested route for obtaining 2-amino-4H-chromenes using Fe3O4@Glycerol-Cu gives favorable products with higher yields and short reaction times. Finally, this green nanocatalyst is helpful for the synthesis of these kinds of compounds based on availability and selectivity (Supplementary information S1).

Data availability

All data generated or analyzed during this study are included in this published article.

References

Nasir Baig, R. B. & Varma, R. S. Copper on chitosan: a recyclable heterogeneous catalyst for azide-alkyne cycloaddition reactions in water. Green Chem. 15, 1839–1843 (2013).

Someshwar, D. D., Vedavati, G. P. & Yeon, T. J. Supported copper triflate as an efficient catalytic system for the synthesis of highly functionalized 2-naphthol Mannich bases under solvent free condition. Tetrahedron Lett. 53, 4376–4380 (2012).

Rambhau, P. G. & Ambarsing, P. R. A. A review on recent progress in multicomponent reactions of pyrimidine synthesis. Drug Invention Today. 5, 148–152 (2013).

Yunyun, L., Rihui, Z. & Jie-Ping, W. Water-promoted synthesis of enaminones: Mechanism investigation and application in multicomponent reactions. Synth. Commun. 43, 2475–2483 (2013).

Wu, X. et al. Green synthesis and formation mechanism of cellulose nanocrystal-supported gold nanoparticles with enhanced catalytic performance. Environ. Sci. Nano. 1, 71–79 (2014).

Sajjadifar, S., Rezayati, S., Arzehgar, Z., Abbaspour, S. & Torabi Jafroudi, M. Applications of iron and nickel immobilized on hydroxyapatite-core-shell γ-Fe2O3 as a nanomagnetic catalyst for the chemoselective oxidation of sulfides to sulfoxides under solvent-free conditions. J. Chin. Chem. Soc. 65, 960–969 (2018).

Taghavi Fardood, S., Ramazani, A., Moradnia, F., Afshari, Z., Ganjkhanlu, S. & Yekke Zare, F. Green synthesis of ZnO nanoparticles via sol-gel method and investigation of its application in solvent-free synthesis of 12-aryl-tetrahydrobenzo[α]xanthene-11-one derivatives under microwave irradiation. Chem. Methodol. 3, 632–642 (2019).

Dálaigh, C. Ó., Corr, S. A., Gun’ko, Y. & Connon, S. J. A Magnetic-nanoparticle-supported 4-N, N-dialkylaminopyridine catalyst: Excellent reactivity combined with facile catalyst recovery and recyclability. Angew Chem. Int. Ed. 46, 4329–4332 (2007).

Shi, F. et al. Tuning catalytic activity between homogeneous and heterogeneous catalysis: Improved activity and selectivity of free Nano-Fe2O3 in selective oxidations. Angew. Chem. Int. Ed. 46, 8866–8868 (2007).

Clark, J. H. & Macquarrie, D. J. Handbook of Green Chemistry and Technology (Blackwell, 2002).

Zheng, X., Luo, S., Zhang, L. & Cheng, J.-P. Magnetic nanoparticle supported ionic liquidcatalysts for CO2 cycloaddition reactions. Green Chem. 11, 455–458 (2009).

Azarifar, A., Nejat-Yami, R., Al Kobaisi, M. & Azarifar, D. Magnetic La0.7Sr0.3MnO3 nanoparticles: Recyclable and efficient catalyst for ultrasound-accelarated synthesis of 4H-chromenes, and 4H-pyrano[2,3-c]pyrazoles. J. Iran. Chem. Soc. 10, 439–446 (2013).

Govan, J. E. & Gun’ko, Y. K. Recent advances in the application of magnetic nanoparticles as a support for homogeneous catalysts. Nanomaterials 4, 222–241 (2014).

Chng, L. L., Erathodiyil, N. & Ying, J. Y. Nanostructured catalysts for organic transformations. Acc Chem. Res. 46, 1825–1837 (2013).

Baig, R. N. & Varma, R. S. Magnetically retrievable catalysts for organic synthesis. Chem. Commun. 49, 752–770 (2013).

Kooti, M., Karimi, M. & Nasiri, E. A novel copper complex supported on magnetic reduced graphene oxide: an efficient and green nanocatalyst for the synthesis of 1-amidoalkyl-2-naphthol derivatives. J. Nanopart Res. 16, 20–34 (2018).

Ghorbani-Choghamarani, A., Tahmasbi, B. & Moradi, Z. S-Benzylisothiourea complex of palladium on magnetic nanoparticles: A highly efficient and reusable nanocatalyst for synthesis of polyhydroquinolines and Suzuki reaction. Appl. Organomet. Chem. 31, e3665 (2017).

Wang, D. & Astruc, D. Fast-growing field of magnetically recyclable nanocatalysts. Chem. Rev. 114, 6949–6985 (2014).

Ashraf, M. A., Liu, Z., Peng, W.-X. & Zhou, L. Glycerol Cu(II) complex supported on Fe3O4 magnetic nanoparticles: A new and highly efficient reusable catalyst for the formation of aryl-sulfur and aryl-oxygen bonds. Catal. Lett. 150, 1128–1141 (2020).

La Penna, G. et al. Cu(II)–glycerol–N-ethylmorpholine complex stability revealed by X-ray spectroscopy. J. Phys. Chem. C. 125, 1483–1492 (2021).

Yee, C. M., Hassan, H. A., Hassan, Z. A. A. & Ismail, H. Zinc glycerolate: potential active for topical application. J. Oil Palm. Res. 24, 1287–1295 (2012).

Khaksar, S., Rouhollahpour, A. & Talesh, S. M. A facile and efficient synthesis of 2-amino-3-cyano-4H-chromenes and tetrahydrobenzo[b]pyrans using 2,2,2-trifluoroethanol as a metal-free and reusable medium. J. Fluorine Chem. 141, 11–15 (2012).

Gao, S., Tsai, C. H., Tseng, C. & Yao, C. F. Fluoride ion catalyzed multicomponent reactions for efficient synthesis of 4H-chromene and N-arylquinoline derivatives in aqueous media. Tetrahedron 64, 9143–9149 (2008).

Kumar, D., Sharad, V. B., Dube, S. U. & Kapur, S. A facile one-pot green synthesis and antibacterial activity of 2-amino-4H-pyrans and 2-amino-5-oxo-5,6,7,8-tetrahydro-4H-chromenes. J. Eur. Med. Chem. 44, 3805–3809 (2009).

Bolognese, A., Correale, G., Manfra, M., Lavecchia, A., Mazzoni, O., Novellino, E., La Colla, P., Sanna, G. & Loddo, R. Antitumor agents. 3. Design, synthesis, and biological evaluation of new pyridoisoquinolindione and dihydrothienoquinolindione derivatives with potent cytotoxic activity. J. Med. Chem. 47, 849–858 (2004).

Joule, J. A., Mills, K. & Smith, G. F. Heterocyclic Chemistry, 3rd ed (Chapman & Hall, 1995).

Morita, N. & Arisawa, M. Flavonoids: Chemistry and biochemistry. Heterocycles 4, 373–392 (1976).

Schmid, H. Natürlich vorkommende chromone. Chem. Org. Naturst. 11, 124–179 (1954).

Peng, Y. & Song, G. Amino-functionalized ionic liquid as catalytically active solvent for microwave-assisted synthesis of 4H-pyrans. Catal. Commun. 8, 111–114 (2007).

Kafi-Ahmadi, L. Poursattar Marjani, A. & Nozad, E. Ultrasonic‐assisted preparation of Co3O4 and Eu‐doped Co3O4 nanocatalysts and their application for solvent‐free synthesis of 2‐amino‐4H‐benzochromenes under microwave irradiation. Appl. Organomet. Chem. 35, e6271 (2021)

Majidi Arlan, F., Poursattar Marjani, A., Javahershenas, R. & Khalafy, J. Recent developments in the synthesis of polysubstituted pyridines via multicomponent reactions using nanocatalysts. New J. Chem. 45, 12328–12345 (2021)

Azimi, F., Poursattar Marjani, A. & Keshipour, S. Fe(II)-phthalocyanine supported on chitosan aerogel as a catalyst for oxidation of alcohols and alkyl arenes. Sci. Rep. 11, 23769 (2021).

Khashaei, M. Kafi-Ahmadi, L. Khademinia, S. Poursattar Marjani, A. & Nozad. E. A facile hydrothermal synthesis of high-efficient NiO nanocatalyst for preparation of 3,4-dihydropyrimidin-2(1H)-ones. Sci. Rep. 12, 8585 (2022).

Kafi‑Ahmadi, L., Khademinia, S. Poursattar Marjani, A. & Nozad, E. Microwave‑assisted preparation of polysubstituted imidazoles using Zingiber extract synthesized green Cr2O3 nanoparticles. Sci. Rep. 12, 19942 (2022).

Safari, J., Zarnegar, Z. & Heydarian, M. Magnetic Fe3O4 nanoparticles as efficient and reusable catalyst for the green synthesis of 2-amino-4H-chromene in aqueous media. Bull. Chem. Soc. Jpn. 85, 1332–1338 (2012).

Poursattar Marjani, A., Ebrahimi Saatluo, B. & Nouri, F. An efficient synthesis of 4H-chromene derivatives by a one-pot, three-component reaction. Iran J. Chem. Chem. Eng. 37, 149–157 (2018).

Ovchinnikova, A. & Andin, A. N. Recyclization of dimedone adduct with 2-(2-oxo-2-phenylethylidene)propanedinitrile in the reaction with N-nucleophiles. Russ. J. Org. Chem. 49, 1067–1071 (2013).

Hasaninejad, A., Golzar, N., Beyrati, M., Zare, A. & Doroodmand, M. M. Silica-bonded 5-n-propyl-octahydro-pyrimido[1,2-a]azepinium chloride (SB-DBU)Cl as a highly efficient, heterogeneous and recyclable silica-supported ionic liquid catalyst for the synthesis of benzo[b]pyran, bis(benzo[b]pyran) and spiro-pyran derivatives. J. Mol. Catal. A: Chem. 372, 137–150 (2013).

Khoshneviszadeh, M., Najmeh, E., Miri, R., Foroumadi, A. & Hemmateenejad, B. QSAR study of 4-aryl-4H-chromenes as a new series of apoptosis inducers using different chemometric tool. Chem. Biol. Drug Des. 79, 442–458 (2012).

Khan, T. A., Lal, M., Ali, S. & Khan, M. M. One-pot three-component reaction for the synthesis of pyran annulated heterocyclic compounds using DMAP as a catalyst. Tetrahedron Lett. 52, 5327–5332 (2011).

Hasaninejad, A., Shekouhy, M., Golzar, N., Zare, A. & Doroodmand, M. M. Silica bonded n-propyl-4-aza-1-azoniabicyclo[2.2.2]octane chloride (SB-DABCO): A highly efficient, reusable and new heterogeneous catalyst for the synthesis of 4H-benzo[b]pyran derivatives. Appl. Catal. A: Gen. 402, 11–22 (2011).

Kargar Behbahani, F. & Sadeghi, M. On water CuSO4.5H2O-catalyzed synthesis of 2-amino-4H-chromenes. J. Korean Chem. Soc. 57, 357–360 (2013).

Moradi Gorji, F. & Monadi, N. Synthesis and characterization of Cu(II) Schiff base complex immobilized on graphene oxide/α-Fe2O3 as heterogeneous catalyst for the three-component synthesis of 2-amino-4H-chromenes derivatives and dye reduction. Synth. Met. 258, 0379–6779 (2019).

Acknowledgements

The authors would like to acknowledge the support received from the Research Council of Urmia University.

Author information

Authors and Affiliations

Contributions

A.P.M.: conceptualization, investigation, project administration, supervision, writing—review and editing. F.A.: data curation, investigation, methodology, writing—original draft. A.D.A.: data curation, formal analysis, investigation, methodology, writing—original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Poursattar Marjani, A., Asadzadeh, F. & Danandeh Asl, A. Fe3O4@Glycerol-Cu as a novel heterogeneous magnetic nanocatalyst for the green synthesis of 2-amino-4H-chromenes. Sci Rep 12, 22173 (2022). https://doi.org/10.1038/s41598-022-26769-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-26769-9

This article is cited by

-

Carbon-based catalysts: advances in synthesizing N-heterocyclic compounds using graphene family and graphite oxide

Research on Chemical Intermediates (2024)

-

Development of CuMnxOy (x = 2, and y = 4)-GO heterostructure for the synthesis of pyranoquinoline derivatives

Scientific Reports (2023)

-

Magnetically retrievable nanocatalyst Fe3O4@CPTMO@dithizone-Ni for the fabrication of 4H-benzo[h]chromenes under green medium

Scientific Reports (2023)

-

Synthesis of new magnetic nanocatalyst Fe3O4@CPTMO-phenylalanine-Ni and its catalytic effect in the preparation of substituted pyrazoles

Scientific Reports (2023)

-

Synthesis of Highly Heterocyclic Fluorescent Molecules: 2-imino-2H-pyrano[3,2-c] Pyridin-5(6H)-ones Derivatives

Journal of Fluorescence (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.