Abstract

Bancha is a popular type of green tea in Japan, rich in tea polyphenols (TPs) and has a more astringent aroma with a less aromatic and strong character that complements functional foods. The blanching process is used to extract TPs and remove unwanted microorganisms, as well as inhibit phenolic oxidation. This study proposed a green tea blanching process followed by spray drying the extracts with maltodextrin. Furthermore, it is focused on maximizing the major chemical components of green tea (i.e., catechins, caffeine, and phenolic contents) based on powder particle size obtained through Multiple Response Surface Methodology optimizations. The results show that the proposed model accurately predicts leached-spray dried green tea’s total catechin and caffeine content, with a coefficient of 0.9475 and 0.8692, respectively. This process yielded composite desirability of 0.9751, while individual desirability yielded excellent results of 1.0000, 0.9188, 1.0000, and 0.9839 for catechin, caffeine, phenol content, and powder. The settings appear to yield functional results for entire responses. Due to the concerns in tropical skin nutrition applications, smaller particle size green tea can promote better adsorption than larger sizes.

Similar content being viewed by others

Introduction

Green tea contains many bioactive compounds dominated by polyphenols such as flavonoids, phenolic acids and tannins1,2, and methylxanthines such as caffeine3. These components confirm broad spectrum activities such as anticancer, cancer, anti-inflammation, cardiovascular disease prevention and anticarcinogens4. Some of the most common types of green tea in Japan are Sencha and Bancha5. Sencha is the first or second flush of green tea (first seasonal picking), while Bancha is the third or fourth flush (late seasonal picking)6. Bancha green tea has a more astringent aroma due to catechins and condensed tannins. It is much appreciated in Japan for its robust flavor and because the strong character goes well with food7. The process inactivating enzymes, such as polyphenol oxidase, laccase, lipoxygenase and hydro peroxidase, was performed through a blanching process. The process is also used to remove unwanted microorganisms and inhibit phenolic oxidation, known as browning. Meanwhile, browning is also known as the Maillard reaction, which results in melanoidin formation and degradation of green tea bioactive compounds4.

Undesired browning of food products due to enzyme activity could be effectively prevented by suppressing the activity of tyrosinase, a multifunctional glycosylated and copper-containing oxidase. Tyrosinase inhibitors are classified into natural, semi-synthetic and synthetic ones8,9. Natural tyrosinase inhibitors isolated from various sources such as mycological metabolites, plants, and marine algae offer myriad captivating benefits, thus promoting the research on the isolation and applications8,10. Quercetin, kaempferol and morin are some flavonoids showing potential inhibitory activity against tyrosinase. Moreover, tea polyphenol (TPs) such as epicatechin gallate is a natural active compound reported as a safe and promising tyrosinase activity suppressor9, but the inhibitory mechanism of TPs is still ambiguous. However, research on investigating the inhibition mechanism is performed. Molecular docking of tyrosinase and TPs was performed, and the dominant role in the binding of ECG to tyrosinase is played by hydrophobic and hydrogen bonding forces9,10. It was also stated that poly-condensate aldehyde of catechin reduces the tyrosinase activity by chelating the active sites10. Furthermore, through a cresolase-like pathway, epicatechin gallate (ECG) and catechin (C) make tyrosinase irreversibly inactivated due to their catechol group (ring B) being catalyzed by tyrosinase. Epigallocatechin gallate (EGCG) inhibits the activity of tyrosinase by competing with or delaying the oxidation of substrate2.

Epigallocatechin gallate, epicatechin, epigallocatechin and epicatechin gallate are the primary polyphenols present in green tea11. The most effective attribute in scavenging the alkyl peroxyl radical was EGCG, which performed 10 times better than vitamin C and -carotene12,13. Caffeine was also reported as a significant tyrosinase inhibitor, and microencapsulation using a spray dryer is important in the pharmaceutical and food industries. This process is suitable for sensitive and volatile materials and can increase product stability14. Therefore, TPs of bancha were separated by the applied blanching process and followed by spray drying of the green tea extracts. Maltodextrin was utilized as wall material in the spray dying, focusing on maximizing the major chemical components of green tea on the powder particle size obtained by using multiple response surface methodology optimizations.

Methods

Materials

The dried bancha green tea leave was obtained from one Indonesian Tea Board member, PT. Kabepe Chakra (Bandung, Indonesia). The production process by Kapebe Cakra was in line with the Indonesian National Standard (SNI no 3945:2016), Ethical Tea Partnership, Rainforest Alliance and Halal Assurance System. The chemicals used during the analysis were Folin–Ciocâlteu reagent (FCR), carbon tetrachloride (CCl4), chloroform (CHCl3), and sodium carbonate (Na2CO3), which were all purchased from Merck & Co., Inc. (New Jersey, US). Furthermore, Sigma-Aldrich Fine Chemicals supplied the gallic acid (Missouri, US). The experimental research on plants (tea) complied with the relevant institutional, national, and international guidelines and legislation. Plants of tea applied in this research did not involving species at risk of extinction.

General procedure

Fifty grams of dried bancha green tea leave were weighed and leached regarding the designed variables of temperature, leave-to-water ratio and time. Response Surface Methodology was applied to obtain the optimal condition during leaching. Furthermore, the leached bancha tea was spray dried at 30 °C and 80 °C of liquid and hot air inlet temperature. The obtained powder analyzed the major chemical contents of catechin, caffeine and phenol by conducting duplicate absorbance measuring of UV Vis spectrophotometer (GENESYS™ 10 Series, Massachusetts, US). The powder particle size was analyzed using a particle size analyzer (Horiba LA-960, Japan). Furthermore, the experimental research on bancha tea conformed to the Good Agriculture Practices/GAP on Tea15 and Compendium of Guidelines for Tea16.

Determination of caffeine content

Ten millilitres of distilled water were added to 5 mg of sample, followed by 1 mL of 20% Na2CO3 solution and 20 mL of CCl4. The extraction of caffeine was obtained by forming a non-polar layer of CCl4. Subsequently, CCl4 (20 mL) was added to the mixture solution and separated by forming a non-polar layer of CCl4. This stage was repeated until it reached 50 mL of solvent. The separated solvent was then analyzed for the caffeine content using the UV–Vis spectrophotometer (GENESYS™ 10 Series, Massachusetts, US) at 270 nm. This procedure was employed in duplicate measurements17.

Determination of total catechin content

Fifty milligrams of powder were dissolved in 40 mL of distilled water. Furthermore, 40 mL of CHCl3 was employed for washing to remove the non-polar impurities, including caffeine and pigments. This washing procedure was repeated four times, following the extract’s absorbance analysis at 274 nm by conducting UV–Vis Spectrophotometry (GENESYS™ 10 Series, Massachusetts, US)13.

Determination of total phenol content

The FCR method was applied for total phenol content determination. One milligram of powder was dissolved on 1 mL of distilled water and mixed with a gallic acid standard of 100 µg/mL. This was followed by adding 5 mL of distilled water, 0.5 mL of FCR, 1.5 mL of 20% Na2CO3 and distilled water until it reached a total volume of 10 mL. After 2 h of incubation and the dark blue color of the solution was obtained, the absorbance was determined using a UV–Vis Spectrophotometer (GENESYS™ 10 Series, Massachusetts, US) at 750 nm18,19.

Determination of powder particle size

In dry form, the particles obtained were analyzed using a particle size analyzer (Horiba LA-960, Japan). Twenty grams of sample was fed into a dry cell chamber in the auto mode set up with 97–98% transmittance. The particles were air scattered with purified air at 0.3 MPa, and the measurement was conducted in three replications20.

Surface structure determination

The surface morphology of samples was observed under scanning electron microscopy (SEM) (Thermo Scientific Quattro S, Germany) without any coating. A pinch of sample powder was placed on the double taped stubs, and then the SEM was operated at a high vacuum with a voltage of 2 kV at the magnification of 250 × , 500 × , and 1500 × .

Multiple response surface methodology

The alpha’s central composite design (CCD) for orthogonality is used to analyze the multiple response surface experiments (Minitab 19 Statistical Software, Pennsylvania, US). The independent variables of the leaching process of bancha green tea were temperature (X1), leave-to-water ratio (X2) and leaching time (X3). Each optimized variable was coded at five levels, namely − α, − 1, 0, + 1 and + α, regarding the range of leaching process of bancha green tea, as shown in Table 1. The multiple responses obtained were caffeine content (FC), total catechin content (TC), total phenolic content (PC) and powder particle size (PS).

Results and discussion

Effect of extraction parameter on the major chemical components and physical properties of bancha leached-spray dried green tea

The leaching process of bancha was conducted by using a central composite design with alpha for the orthogonality. The parameters were leaching temperature, leave-to-water ratio, and leaching time. A set of 16 experiments and the observed responses of spray-dried powder of the extract obtained are tabulated in Table 2. Green tea extractions for functional foods are commonly conducted using water. It is cost-effective, in batch or continuous processes on a commercial scale, to remove undesirable constituents and centralize bioactive compounds21,22. The extraction efficiency is proportional to the solvent-to-water ratio and is heavily influenced by the polarity of the constituent compounds and the solvent type23.

Leaching temperature and time are critical in the major chemical components, varying efficiency depending on the compound24. The experimental outcomes show that these variables impacted the content of caffeine, catechin, and phenolic. This is also supported by the research25 that optimized leaching conditions from green tea bags and total phenolic content increase with temperature and time. Another study conducted by26 where caffeine was water leached from Turkish tea, found that leaching temperature affects the caffeine content, with the maximum yield obtained at its boiling point. Heat makes tea cell walls more permeable to solvent penetration, thus increasing the components’ solubility and diffusion coefficients. However, applying higher extraction temperature can also impact solvent viscosity reduction and catechins’ degradation27,28,29. The ratio of leaves to water significantly affects the catechin content. Similarly, the higher the solvent used for extraction, the more catechin is extracted30,31. To visualize the relationship amongst the response and experimental results of the independent variables for the leaching condition, a response surface profile based on the quadratic polynomial model equation was generated, as seen in Table 4.

Effect of particle size on the catechins contents, caffeine contents and phenol content

The particle size of bancha green tea powder was determined by an analyzer (Fig. 2A–P). The distribution of major chemical contents is separated into caffeine, catechin, and phenol. As can be seen in Fig. 1 that dried bancha green tea performed the highest caffeine compared to the catechin content and provided the lowest minimum content for all variables. The particle size was completely affected by the air temperature, proofed in larger particles in the inlet air temperature at 132 °C than 180 °C32. Increasing the drying air temperature results in increased particle size due to ballooning or puffing33. Caffeine content was found as the highest component in bancha green tea, with a particle size of 337 μm (Fig. 2G) in the amount of 63.51 g/mL. Meanwhile, catechin content was the second-place major chemical content of bancha green tea with a particle size of 435 μm (Fig. 2J) in the amount of 2.279 g/mL total catechin content. Particle size significantly affected total catechin concentration34. The concentration of caffeine and total catechins were greatly affected by the particle size of green tea. However, as particle size increased from 433 μm (Fig. 2C) to 467 μm (Fig. 2N), all the major content levels decreased, especially catechin (0.875 g/mL). It is supported by the report of35 that catechin contents decreased as particle size increased because of the contact surface between O2 and particles resulting in catechin oxidation. The tea powder’s particle size influences the solute’s mass transfer and the total surface area for contact between the solvent and the sample34.

Parameters effect on catechins, caffeine and phenolic contents

The optimization studies of biomolecule component extraction of catechin36,37, caffeine38,39 and phenolic contents40,41 were conducted and observed using the response surface methodology (RSM). Table 3 shows the variance analysis of caffeine, catechin, phenolic contents and powder particle size against temperature, leaves-to-water, and time. The error on the degree of freedom (DF) was found at 10 consisting of 5 lack-of-fit and 5 pure errors. This indicates the independent information which can estimate the coefficients, and the error of DF is directly proportional to the precision of the coefficient verified in regression. Applied Fisher’s F test evaluated the model’s regression coefficient’s significance. The F0, the computed value of F, of the model for catechin, caffeine, phenolic, and powder particle size were 20.05, 1.67, 7.38 and 1.18, respectively. The computed value of F of catechin and phenolic content exceed 4.96 (the value of F0.05,1,10), indicating the significance of both models. Furthermore, Table 3 serves information of terms in four models that have significant effect on the response. The information is in form of its p-value indicated with star sign next to the adjusted sum of squares. The p-value less than 0.05 represent that the terms of model have a significant effect on the response. In case of catechin content model, the linear terms which include temperature, leave-water ratio and time were statistically significant. The quadratic term of temperature × temperature as well as leave-water ratio × leave water ratio was also statistically significant. It was also found that 2- way interaction of leave-water ratio × time is also significant for catechin content model. The significant effect of linier term of temperature, time and leave – water ratio on catechin separation from peanut red skin was also reported42. Variance analysis also shows that the 2-way interaction of temperature × leave-water ratio was the only term statistically significant on caffeine content model. The liner term of temperature, leave-water ratio and time were statistically significant. Furthermore, 2- way interaction of temperature × leave-water ratio and leave-water ratio × time were statistically significant on phenolic content model. The significance of temperature and sample-solvent ratio on phenolic substance extraction was also reported43. They mention that sample—solvent ratio was the most significant single factor in influencing the antioxidant capacity of the phenolic extract of ground ivy obtained from microwave assisted extraction process.

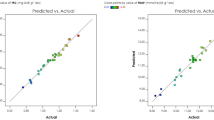

Table 4 presents the surface responses of the quadratic polynomial model equation, the standard error of the regression (S) and the coefficient of determination (R2). The coefficient of determination (R-square) was obtained at 0.9475, 0.8692, 0.6007 and 0.5169 for contents of catechin, caffeine, total phenolic and powder particle size. The R-square (in the range of 0–1) of a model should be larger than 0.8 to be a good predictive model44. Therefore, the R-square significantly fits the catechin and caffeine content models. These prediction values were strengthened by the standard error of the regression (0.1626, 5.2709, 0.0148 and 95.5433 of each response variable). The closer fitting line indicators and the smaller standard error values are preferable.

The response variables and the interaction effect on the contour plots are shown in Fig. 3A–L. The interactive effect of catechin content was regarding the leaching temperature and leave-to-water ratio at 7.5 min of leaching time, as represented in Fig. 3A. The maximum catechin content was obtained at the highest leaching temperature and time. Regarding the leaching temperature and time at 0.15 of leave-to-water ratio, Fig. 3B shows the maximum catechin content. It was obtained at the highest leaching temperature, regardless of the time. Figure 3C depicts the plot of catechin content regarding the leaching time vs. leave-to-water ratio at 80 °C of leaching temperature. The maximum catechin was achieved at the lowest leave-to-water ratio with the longest leaching time. The minimum bancha green tea needed a longer time to diffuse in the water as a solvent. Increasing the bancha green tea by more than 0.2 of the leave-to-water ratio provided the maximum catechin content at a faster time up to 7 min. The high temperature could increase the permeability of green tea cell walls for solvent and constituent27. However, the high temperature could degrade these contents because epimerization can change their structure45. Due to water efficiency and cost-effectiveness, a low leaves-to-water ratio is desirable for extracting catechins46. The longer the leaching duration, the greater the chance of catechin thermal decomposition into other chemicals27. The decrease of catechin content indicates this after 7 min of leaching time.

Response surface and profile of total catechin content (A–C), caffeine content (D–F), total phenolic content (G–I) and powder particle size (J–L) regarding temperature-L/W ratio at 7.5 min of leaching time (A, D, G, J), temperature–time at L/W ratio 0.15 (B, E, H, K), L/W ratio-time at 80 °C (C, F, I, L).

Figure 3D illustrates the caffeine content concerning leave-to-water ratio and leaching temperature at 7.5 min of leaching time. The total catechin content was obtained at the maximum level of leave-to-water ratio and temperature. Regarding the time and temperature of leaching at a 0.15 leave-to-water ratio, the maximum catechin content was obtained at the maximum temperature, disregarding the leaching time (Fig. 3E). From the other point of view, Fig. 3F represents the leaching temperature at 80 °C and found the highest catechin content at the highest leave-to-water ratio regarding shorter time than 6 min.

The maximum phenol content was observed at the low temperature (< 77 °C) with regards to the high leave-water ratio (> 0.21) at a hold time value of 7.5 min (Fig. 3G). Figure 3H indicates the phenol content (0.05 mg/g) in the range of 5.4–6.7 min with regards to a lower temperature than 79.5 °C. Meanwhile, Fig. 3I depicts the phenol content at 80 °C, showing that the maximum phenol content (0.08 mg/g) was found at a leave-water ratio of 0.2 during leaching time for 7 min. The longer leaching time than 7.5 min decreases the phenol content due to thermal degradation.

Subsequently, the particle size (< 400 μm) was obtained at a higher temperature than 87 °C in the range of 0.13–0.20 of leave-water ratio for 7.5 min (Fig. 3J). At a 0.15 leave-water ratio, the minimum particle size of 250 μm was determined at leaching conditions of 72.5 °C and 4 min (Fig. 3K). Figure 3L depicts the minimum powder particle size (< 400 μm) on the leaching time (< 4.5 min) and the range of leave-water ratio at 0.10–0.17.

According to the findings, the temperature is directly proportional to the caffeine content in the extracted green tea47,48. Raising the temperature to 95 °C reduces the total catechins content, and this explains why it undergoes thermal degradation and epimerization48,49. The temperature was raised above 90 °C, decreasing total phenolic content50.

Response of optimization of phenolic, catechins, caffeine contents and powder particle size

The optimization response of bancha green tea components and powder particle size obtained during spray-dried was defined. The observation comprises the maximum values of catechin, caffeine, and phenolic contents on the minimum value of powder particle size (Table 5). The prediction of the multiple responses obtained the setting variable at 86.4 °C, 0.0895 of leaves-to water ratio and 10.72 min of leaching time for the fit solution (2.699 mg/mL, 60.31 mg/mL, 0.0862 mg/g and 343 μm for catechin, caffeine, phenolic contents and powder particle size, respectively).

Figure 4 shows the individual and composite desirability of the response parameter. The individual and composite desirability reported how much the variable optimized the single and the entire response. The desirability approach transforms each predicted response’s measured properties into a dimensionless value of d. The scale of the desirability function ranges between 0–1, and a value of zero (d = 0) implies that the response is completely unacceptable. In contrast, when the desirability value is unity, the response is exactly of the targeted value51. The desirability values were tabulated in Table 5, and the composite desirability was found to be 0.9751. The individual desirability was found at 1.000, 0.9188, 1.000, and 0.9839 for each catechin, caffeine, phenolic contents and powder particle size response.

In conclusion, the variables obtained favorable results for all responses and are more effective at maximizing the catechin and phenolic contents yield. Figure 5 presents SEM micrographs of the predicted setting variables. The powder showed dents surface structure without cracks, confirming the extended film formulation during the early phase under low temperature drying52,53.

Conclusion

The proposed model satisfies the leached-spray dried green tea prediction, consisting of 0.9475 and 0.8692 total catechin and caffeine content on the coefficient of determination. The process provided the composite of 0.9751, and the individual desirability provided excellent results of 1.0000, 0.9188, 1.0000 and 0.9839 for catechin, caffeine, phenol contents and powder particle size. Therefore, the settings appear to obtain the functioning results for whole responses. The individual desirability indicates that the settings are shown potentially to maximize catechin and phenol contents (1.000) by minimizing the powder particle size (0.9839) than maximizing caffeine content (0.9188). Since powder particle size plays the main role in topical skin nutrition, it can promote better adsorption of the main component of green tea.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Radeva-Ilieva, M. P. et al. Protective effect of methylxanthine fractions isolated from bancha tea leaves against doxorubicin-induced cardio- and nephrotoxicities in rats. Biomed. Res. Int. 2020 (2020).

Tang, H., Cui, F., Li, H., Huang, Q. & Li, Y. Understanding the inhibitory mechanism of tea polyphenols against tyrosinase using fluorescence spectroscopy, cyclic voltammetry, oximetry, and molecular simulations. RSC Adv. 8, 8310–8318 (2018).

Georgiev, K., Zhelev, I. & Georgieva, S. Total phenolic compounds and tannins content of Bancha green tea (Camellia sinensis) depending on extraction conditions. Scr. Sci. Pharm. 1, 48 (2014).

Minatel, I. O. et al. Phenolic compounds: Functional properties, impact of processing and bioavailability. Phenolic Compd. Biol. Act. https://doi.org/10.5772/66368 (2017).

Horie, M., Nara, K., Sugino, S., Umeno, A. & Yoshida, Y. Comparison of antioxidant activities among four kinds of Japanese traditional fermented tea. Food Sci. Nutr. 5, 639–645 (2017).

Iwasaki, M. et al. Green tea drinking and subsequent risk of breast cancer in a population to based cohort of Japanese women. Breast Cancer Res. 12, R88 (2010).

Culture, J., Types, M. & Tea, J. G. A complete guide to Japanese tea. 1–5 (2020).

Lee, S. Y., Baek, N. & Nam, T. G. Natural, semisynthetic and synthetic tyrosinase inhibitors. J. Enzyme Inhib. Med. Chem. 31, 1–13 (2015).

Song, X. et al. Inhibitory mechanism of epicatechin gallate on tyrosinase: Inhibitory interaction, conformational change and computational simulation. Food Funct. 11, 4892–4902 (2020).

Obaid, R. J. et al. Natural and synthetic flavonoid derivatives as new potential tyrosinase inhibitors: a systematic review. RSC Adv. 11, 22159–22198 (2021).

Anand, J., Upadhyaya, B., Rawat, P. & Rai, N. Biochemical characterization and pharmacognostic evaluation of purified catechins in green tea (Camellia sinensis) cultivars of India. 3 Biotech 5, 285–294 (2015).

He, J., Xu, L., Yang, L. & Wang, X. Epigallocatechin gallate is the most effective catechin against antioxidant stress via hydrogen peroxide and radical scavenging activity. Med. Sci. Monit. 24, 8198–8206 (2018).

Ibrahim, Y. M., Musa, Y. A. & Yakasai, A. Spectrophotometric method for determination of catechins in green tea and formulations. Niger. J. Pharm. Sci 16, 25–30 (2017).

Paramita, V., Furuta, T. & Yoshii, H. Microencapsulation efficacy of d-limonene by spray drying using various combinations of wall materials and emulsifiers. Food Sci. Technol. Res. 16, 365–372 (2010).

Suswono. Good agriculture practices/GAP on tea. Kementan 518, 1–65 (2014).

European Tea Committee & European Herbal Infusions Association. Compendium of guidelines for tea (Camellia sinensis). THIE 5, 1–49 (2018).

Amos-Tautua, W. & Diepreye, E. Ultra-violet spectrophotometric determination of caffeine in soft and energy drinks available in Yenagoa, Nigeria. Adv. J. Food Sci. Technol. 6, 155–158 (2014).

Bhalodia, N. R., Acharya, R. N. & Shukla, V. J. Evaluation of in vitro antioxidant activity of hydroalcoholic seed extratcs of Cassia fistula linn. Free Radic. Antioxid. 1, 68–76 (2011).

Kamtekar, S., Keer, V. & Patil, V. Estimation of phenolic content, flavonoid content, antioxidant and alpha amylase inhibitory activity of marketed polyherbal formulation. J. Appl. Pharm. Sci. 4, 61–065 (2014).

Septiyanti, M. Manual Book, Standard Operating Procedure Horiba LA-960 (Indonesian Institute of Sciences (LIPI), 2016).

Blumberg, J. B., Bolling, B. W., Chen, C. Y. O. & Xiao, H. Review and perspective on the composition and safety of green tea extracts. Eur. J. Nutr. Food Saf. https://doi.org/10.9734/EJNFS/2015/12712 (2015).

Bart, H.-J. & Pilz, S. Industrial Scale Natural Products Extraction (Wiley, 2011).

Kassing, M., Jenelten, U., Schenk, J. & Strube, J. A new approach for process development of plant-based extraction processes. Chem. Eng. Technol. Ind. Chem. Equip. Process Eng. 33, 377–387 (2010).

Ziaedini, A., Jafari, A. & Zakeri, A. Extraction of antioxidants and caffeine from green tea (Camelia sinensis) leaves: Kinetics and modeling. Food Sci. Technol. Int. 16, 505–510 (2010).

Jang, M.-J., Ha, H.-J., Yoon, S.-R., Noh, J.-E. & Kwon, J.-H. Prediction of optimal leaching conditions for green tea. J. Korean Soc. Food Sci. Nutr. 35, 747–753 (2006).

Gürü, M. & Icen, H. Obtaining of caffeine from Turkish tea fiber and stalk wastes. Bioresour. Technol. 94, 17–19 (2004).

Vuong, Q., Golding, J., Nguyen, M. & Roach, P. Extraction and isolation of catechins from tea. J. Sep. Sci. 33, 3415–3428 (2010).

Chen, Z.-Y., Zhu, Q. Y., Wong, Y. F., Zhang, Z. & Chung, H. Y. Stabilizing effect of ascorbic acid on green tea catechins. J. Agric. Food Chem. 46, 2512–2516 (1998).

Santos-Buelga, C. & Williamson, G. Methods in Polyphenol Analysis (Royal Society of Chemistry, 2003). https://doi.org/10.1021/ja033571a.

Perva-Uzunalić, A. et al. Extraction of active ingredients from green tea (Camellia sinensis): Extraction efficiency of major catechins and caffeine. Food Chem. 96, 597–605 (2006).

Pinelo, M., Rubilar, M., Jerez, M., Sineiro, J. & Núñez, M. J. Effect of solvent, temperature, and solvent-to-solid ratio on the total phenolic content and antiradical activity of extracts from different components of grape pomace. J. Agric. Food Chem. 53, 2111–2117 (2005).

Villegas-Santiago, J. et al. Effect of spray-drying conditions on moisture content and particle size of coffee extract in a prototype dryer. Rev. Mex. Ing. Química 19, 767–781 (2020).

Walton, D. E. The morphology of spray-dried particles a qualitative view. Dry. Technol. 18, 1943–1986 (2000).

Sun, Q.-L. et al. Decaffeination of green tea by supercritical carbon dioxide. J. Med. Plants Res. 4, 1161–1168 (2010).

Zaiter, A., Becker, L., Karam, M.-C. & Dicko, A. Effect of particle size on antioxidant activity and catechin content of green tea powders. J. Food Sci. Technol. 53, 2025–2032 (2016).

Vuong, Q. V., Golding, J. B., Nguyen, M. H. & Roach, P. D. Production of caffeinated and decaffeinated green tea catechin powders from underutilised old tea leaves. J. Food Eng. 110, 1–8 (2012).

Chen, J., Thilakarathna, W. P. D. W., Astatkie, T. & Rupasinghe, H. P. V. Optimization of catechin and proanthocyanidin recovery from grape seeds using microwave-assisted extraction. Biomolecules 10, 243 (2020).

Hariyadi, D. M., Tedja, C. A., Zubaidah, E., Yuwono, S. S. & Fibrianto, K. Optimization of brewing time and temperature for caffeine and tannin levels in dampit coffee leaf tea of Robusta (Coffea canephora) and liberica (Coffea liberica). Potravin. Slovak J. Food Sci. 14, 58–68 (2020).

Tfouni, S. A. V., Camara, M. M., Kamikata, K., Gomes, F. M. L. & Furlani, R. P. Z. Caffeine in teas: Levels, transference to infusion and estimated intak. Food Sci. Technol. 38, 661–666 (2018).

Abdeltaif, S. A., Sirelkhatim, K. A. & Hassan, A. B. Estimation of phenolic and flavonoid compounds and antioxidant activity of spent coffee and black tea (processing) waste for potential recovery and reuse in Sudan. Recycling 3, (2018).

Skrypnik, L. & Novikova, A. Response surface modeling and optimization of polyphenols extraction from apple pomace based on nonionic emulsifiers. Agronomy 10, (2020).

Zhang, H., Liu, M., Han, S. & Wei, Y. Optimizing the extraction of catechin from peanut red skin optimizing the extraction of catechin from peanut red skin using response surface methodology and its antioxidant activity. IERI Procedia 5, 312–320 (2013).

Šeremet, D. et al. Optimization of heat-, microwave-assisted and subcritical water extraction of phenolic compounds from ground ivy (Glechoma hederacea L.) using response surface methodology. J. Appl. Res. Med. Aromat. Plants 25, (2021).

Rheem, S., Rheem, I. & Oh, S. Response surface methodology using a fullest balanced model: A re-analysis of a dataset in the Korean journal for food science of animal resources. Korean J. Food Sci. Anim. Resour. 37, 139–146 (2017).

Saklar, S., Ertas, E., Ozdemir, I. & Karadeniz, B. Effects of different brewing conditions on catechin content and sensory acceptance in Turkish green tea infusions. J. Food Sci. Technol. 52, 6639–6646 (2015).

Vuong, Q., Golding, J., Stathopoulos, C., Nguyen, M. & Roach, P. Optimizing conditions for the extraction of catechins from green tea using hot water. J. Sep. Sci. 34, 3099–3106 (2011).

Nhan, P. P. & Phu, N. T. Effect of time and water temperature on caffeine extraction from coffee. Pak. J. Nutr. 11, 100–103 (2012).

Donlao, N. & Ogawa, Y. The influence of processing conditions on catechin, caffeine and chlorophyll contents of green tea (Camelia sinensis) leaves and infusions. LWT 116, 108567 (2019).

Forester, S. C. & Lambert, J. D. The role of antioxidant versus pro-oxidant effects of green tea polyphenols in cancer prevention. Mol. Nutr. Food Res. 55, 844–854 (2011).

Chang, M.-Y. et al. Effects of infusion and storage on antioxidant activity and total phenolic content of black tea. Appl. Sci. 10, 2685 (2020).

Eun Lee, K., Bharadwaj, S., Yadava, U. & Gu Kang, S. Evaluation of caffeine as inhibitor against collagenase, elastase and tyrosinase using in silico and in vitro approach. J. Enzyme Inhib. Med. Chem. 34, 927–936 (2019).

Tambade, P. B., Sharma, M., Singh, A. K. & Surendranath, B. Flaxseed oil microcapsules prepared using soy protein isolate and modified starch: Process optimization, characterization and in vitro release behaviour. Agric. Res. 9, 652–662 (2020).

Carneiro, H. C. F., Tonon, R. V., Grosso, C. R. F. & Hubinger, M. D. Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray drying using different combinations of wall materials. J. Food Eng. 115, 443–451 (2013).

Acknowledgements

The authors are grateful to the Higher Education Ministry, Indonesia [No. 521-04/UN7.6.1/PP/2021] for supporting this scientific research.

Author information

Authors and Affiliations

Contributions

V.P. wrote the main manuscript text; N.M., M.E.Y., and E.Y provided the whole data; H.D.A., Y.W.W, I.H., and B.P. designed the experimental method; F.H. provided the bancha tea; T.S. and B.W. responsible for running parameters.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paramita, V., Masruchin, N., Wirohadidjojo, Y.W. et al. Multiple response optimizations on the leached-spray-dried bancha green tea towards healthy ageing. Sci Rep 12, 21347 (2022). https://doi.org/10.1038/s41598-022-25644-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-25644-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.