Abstract

Microalgae are a diverse group of microorganisms, the majority of which are photosynthetic in nature. Microalgae have different applications, the most important of which is the biological treatment of wastewater. Microalgae grow in various types of wastewater, such as wastewater polluted by Azo dyes, due to microalgae using wastewater as a culture medium, which contains many nutrients like nitrogen, phosphate, and carbon sources. Microalgae grow in various types of wastewater, such as wastewater polluted by Azo dyes, due to microalgae using wastewater as a culture medium, which contains many nutrients like nitrogen, phosphate, and carbon sources. So, microalgae are used for bioremediation of wastewater due to the efficiency of growing in wastewater and for the high production of lipids followed by trans-esterification to biodiesel. Face-centered central composite design (FCCCD) was used to determine the factors that have the most significant impact on the simultaneous decolorization of methyl red and lipid production by the fresh green alga Scenedesmus obliquus. The predicted results indicated that the alga decolorized 70.15% methyl red and produced 20.91% lipids by using 1 g/L nitrogen, an incubation time of 10 days, a pH of 8, and the concentration of methyl red is 17.65 mg/L. The dry biomasses of S. obliquus were also examined by SEM and FTIR before and after treatment with methyl red. SEM and FTIR showed that the properties of dry S. obliquus were altered after the biosorption of methyl red. According to GC–MS analysis of hexane extracts of S. obliquus, the lipid profile differed before and after methyl red decolorization. The results proved that it is possible to use S. obliquus to remove dyes and produce renewable fuels such as biodiesel. The novelty of this study is that this is the first time in which the effect of nitrogen concentrations in the medium used for algal growth on the removal of dye has been studied.

Similar content being viewed by others

Introduction

The dramatic increase in the global population and hence projects will exceed 9 billion in 2050, which will cause energy shortages and negative effects on the environment due to huge fossil fuel consumption and hence the emission of greenhouse gases1,2. Researchers have focused on reducing the requirements of fossil fuels, reducing greenhouse gas emissions, and conserving environmental sustainability3,4,5,6. Huge quantities of Azo dye are lost during textile industries and other industries, such as pharmaceuticals, cosmetics, food, and paper printing, which lose approximately 10 to 15% of consumed Azo dyes7,8. A large amount of wastewater is produced every day because textile industries use several hundred thousand gallons of water every day, which contains many dyes and some heavy metals that cause environmental problems9,10. Due to the huge usage of Azo dyes in different industries, Azo dyes are the major compounds of effluents11. The occurrence of Azo dyes in aquatic bodies can cause serious disorders and adversely affect human health12. Azo dyes cause carcinogenic and mutagenic activities and can cause allergic reactions13. Azo dye treatments are a major challenge because they encompass aromatic rings, azonic linkages, and amino groups, which cause multiple damage to the receiving environment14. A variety of microorganisms (algae, yeast, fungi, and bacteria) have been investigated for their potential for textile dye bioremediation15,16. Algae are used in bioremediation for the following reasons, high growth rates17,18, having the ability to sequester CO217,19, algal growth is not affected by stress conditions19, no competition with food crops18, can grow in wastewater and seawater, and can be used in wastewater treatment with both live and dead algae18,20.

The efficacy of various algal strains in dye degradation potential has already been shown21. Industrial textile wastewater contains necessary nutrients for algae cultivation, including organic dyes as potential sources of carbon, nitrates, and metals as micronutrients22. Therefore, textile wastewater seems to be a promising and inexpensive microalgal growing medium23,24. Despite their adverse effects on fish, azo dyes in wastewater do not obstruct the progress of certain algal species. However, a few other algal strains in water are very sensitive to azo dyes25. In contrast to bacteria, Liu et al.26 showed a greater impact of the marine alga Shewanella in decolorizing azo dyes even in saline environments. Algal bioremediation seems to have become a promising technology for the treatment of textile wastewater27. Since algae are photosynthetic, they obtain energy from sunlight, carbon dioxide, and wastewater nutrients and perform photosynthesis processes28. Algae can consume coloured water during their growth, potentially decolorizing dye-contaminated wastewater, and the resulting algal biomass can be processed further for bioenergy and algal-based bioproduct production. Algae fulfil most of the criteria for an applicable dye elimination tool and have the possibility to serve as an encouraging dye removal method in the future29.

However, microalgae have recently gained considerable attention because of their capacity for carbon dioxide fixation and bioremediation of textile wastewater6. Microalgae can be used simultaneously, first for the bioremediation of textile wastewater and then to accumulate lipids30. Some microalgae biomasses contain up to 70% total extractable lipids (g/g dry weight). Biodiesel is derived from lipids produced by microalgae through the transesterification process31. Therefore, biodiesel can be used as an environmentally friendly, sustainable fuel in electricity production and can meet the energy needs of the textile sector32. Microalgae can use carbon dioxide from the diesel generator atmosphere and organic dyes to photosynthesize it into carbohydrates33. Compared with other organic diesel raw materials, microalgae have certain advantages, as their growth rate is rapid, they can be developed approximately everywhere, including sewage, wastewater, saltwater, and arid land, and they do not need fertile agricultural land. Microalgae production is not seasonal and can be harvested daily. Its waste can be used as feed for animals or for other purposes34. Various microalgae are considered to have a strong effect on the growth of biomass and the metabolism of fatty acids and lipids35. Microalgal oils can be transformed using current technologies into jet fuel, gasoline, and diesel31. Many microalgae organisms can be stimulated to produce large amounts of lipids, which leads to high oil production36. The most effective stress factor that influences microalgae lipid yield is nitrogen starvation, and the total lipid content of microalgae increases from 25.5 to 45.7% (g/g) under stress conditions37. Total and triacylglycerol lipid concentrations were increased when algae biofilms were grown on porous membrane material under nitrogen starvation38. The most critical factor that affects microalgal metabolism is pH39. In accordance with the pH changes, the production of lipids and biomass changes40.

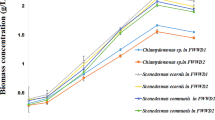

Microalgae, Chlorella vulgaris FACHB-8 and Chlorella sp. FACHB-31 have been used to remediate anaerobically treated swine wastewater (ADSW), and production biodiesel production, the results showed that both strains were good candidates for biodiesel production and bio-remediate of wastewater41.

The objectives of this work were to evaluate the capacity of the live alga Scenedesmus obliquus to biodegrade dye (methyl red) and to determine the production of lipids by the algal biomass for future possible applications in biodiesel production and statistical optimization of process variables by face-centered central composite design (FCCCD) for biodegradation of methyl red by Scenedesmus obliquus. SEM and FTIR analyses were used to characterize the biomass. GC–MS analysis was also used to determine the profile of the lipids.

Material and methods

Material

Scenedesmus obliquus microgreen alga was acquired from the “Microbial Biotechnology Department, Genetic Engineering and Biotechnology Research Institute (GEBRI), University of Sadat City, Egypt”. Methyl red was obtained from Sigma–Aldrich, formula as shown in Fig. 1

Alga culture

S. obliquus was grown on a modified Bischoff and bold42 basal medium (all components were purchased from sigma Sigma-Aldrich in Egypt)42.

Optimization of process variables by face-centered central composite design (FCCCD)

Ten millilitres of alga at log phase were inoculated in 90 mL of medium using FCCCD to appraise the influence of four factors and investigate their optimum levels on methyl red decolorization and lipid production. Table 1 presents thirty runs with four variables, each of which varies from − 1 (low level), 0 (zero or middle level), and + 1 (high level). The selected independent factors were initial concentration of KNO3 as nitrogen source (X1: 0.5, 1, 1.5 g/L), incubation time (X2: 6, 10, 14 days), initial pH (X3: 7, 8, 9), methyl red concentration (X4: 10, 20, 30 mg/L) with an intensity of 80 μE m–2 s–1 continuous light. The relations among the four independent factors in addition to the responses (% methyl red (X4) decolorization, biomass and lipid contents were determined using the following second-order polynomial equation:

The symbol Y is the predicted methyl red decolorization (%) or lipid biosorption percentage, the linear coefficient (βi), quadratic coefficients (βii), the regression coefficients (β0), the coded values of the independent variables (Xi), and the interaction coefficients (βij).

Statistical analysis

For experimental design and statistical analysis, the software Design Expert “Version 7 for Windows” was used. STATISTICA Software “Version 8.0, StatSoft Inc., Tulsa, USA” was used to generate three-dimensional surface plots.

Analytical methods

For each trial of FCCCD, thirty millilitres of algal suspensions were centrifuged, and the filtrates were analysed with a UV–Vis Dual Beam Spectrophotometer UVS-2700 by determining the absorption variations at 430 nm wavelengths to reveal the residual concentrations of MR dye. The efficiency of the fresh alga S. obliquus for MR decolorization was verified as a percentage using the following equation:

where C1 is the initial concentration of MR and C2 is the final concentration after treatments with algal biomass.

Dry weight estimation

After the limited time (6, 10, and 14 days) was finished, aliquots of 100 ml were centrifuged, and the residue was dried until constant weight in an oven at 60 °C.

Lipids determination

For each trial of FCCCD, one gram of algal dry weight was mixed with 50 mL of hexane and then stirred with a magnetic stirrer bar for 20 min. The residue was then separated by filtration, and the solvent was evaporated. The extracted lipid was determined as a percentage by using the following equation43:

where G1 lipids weight, G2 dry weight.

Preparation of fatty acid methyl ester (FAME) content and analysis by GC–MS

20 mg of the lipid extract were weighted and then 0.5 N methanol KOH (2.805 gm KOH in 100 mL methanol) was added, vortexed, and heated at 50 °C for 15 min. The mixture was then cooled and vortexed to mix well. Then, 5 mL of 4 N HCl (3, 4 ml HCl in 100 mL of water) was added and vortexed. Petroleum ether and hexane 1:1, were then added. The upper layer (FAME) was transferred to another tube and dried at 40 °C. 1 mL of hexane was then added to the dried FAME. The FAMEs were then injected and analysed by GC–MS. The sample was injected into GC–MS with a silica capillary column, HP-5MS, and the carrier gas was helium. The GC–MS temperature programme was initiated at 60 °C (2 min) and then increased to 280 °C at an ionizing rate of 8 °C/min. To evaluate the different peaks, Wiley and Wiley Nist mass spectral databases were applied.

Fourier transform infrared (FTIR) spectroscopy

FTIR spectroscopy is a crucial method for assessing the changes in the active groups present in the algal biomass after and prior to MR decolorization. Dry algal biomass samples were blended with potassium bromide pellets. Then, FTIR spectra were analysed at 400–4000 cm−1 using a Thermo Fisher Nicolete IS10 spectrophotometer (USA).

Scanning electron microscopy (SEM)

To study the cell surface of S. obliquus, the dry biomass was examined with SEM after and prior to MR decolorization. Using an accelerated beam voltage of 30 keV, the gold-coated dry biomass was examined at different magnifications.

Results and discussion

In this study, the impact of four variables, namely, nitrogen source conc. (g/L), incubation time (days), initial pH level, and methyl red concentration (mg/L) on simultaneous methyl red decolorization and lipid production (as a response) using the microalga S. obliquus was investigated.

Statistical optimization of lipid production and MR removal by the fresh alga, S. obliquus

The fermentation medium contents and various environmental conditions (i.e., nutrients, pH, etc.) required for microbial growth play an incredible role in achieving maximum metabolite production44,45. The conventional strategy for culture medium optimization (single variable optimization method) has been expanded for optimization of the process, but this method not only takes a long time, is expensive and laborious, but also ignores the effects of independent factor interactions46,47.

The statistical designs of experiments have been used for the optimization of process parameters and can be performed in two key steps: first, screening of the significant variables and second, optimization of those variables. These designs have several advantages, including fewer experimental runs for multiple parameters; avoiding misinterpretation of the results that occurs with the conventional strategy; assisting in determining the optimum level of each variable; exploring the individual, quadratic, and interaction effects between different variables; and predicting the optimum conditions for maximum response48. To determine the effects of four process variables and to obtain their optimum values for maximum simultaneous lipid production and decolorization of MR using fresh alga, S. obliquus, an overall number of thirty experimental runs of FCCCD were done. Table 1 shows the observed and predicted results for both lipid production and decolorization of MR. The results indicate substantial variations in both lipid production and MR decolorization percentages by S. obliquus according to the combinations of the four variables. Based on the data collected, the percentage of methyl red decolorization varied significantly from 29.63 to 70.56%.

These results agree with those of Abou-El-Souod et al.49, in which the decolorization percentage of methyl red (20 ppm) by S. obliquus was 48.60%. The decolorization percentage of methyl red (20 ppm) by C. vulgaris was in the range of 71%21. The result demonstrated that lipid production by S. obliquus ranged from 14.52 to 21.29% of dry weight, as shown in Table 1. The lipid production percentage of dry weight S. obliquus ranged from 11 to 55%19, 15.2 to 24.4%50, 21 to 42%35, 20.4 to 25.2%51. The lipid yield percentage of dry weight Scenedesmus dimorphus was 2635, Scenedesmus rubescens ranged from 18.5 to 23.2%52, Scenedesmus quadricauda was 18.453. The highest levels of methyl red decolorization (70.56%) were obtained in run no. 16 when all the tested variables were at their central value: the nitrogen source concentration was set at 1 g/L, the incubation time (10 days), initial pH level (8), and methyl red concentration (20 mg/L). Meanwhile, the highest levels of lipid production (21.29%) were shown in run no. 13, when the nitrogen source concentration was set at 1 g/L, the incubation time (10 days), initial pH level (10), and methyl red concentration (10 mg/L). The minimum methyl red decolorization (29.63%) was obtained in run no. 1 when the nitrogen source concentration was set at 0.5 g/L, the incubation time (6 days), initial pH level (7) and the methyl red concentration was 10 mg/L. The minimum lipid production was 14.58% when the nitrogen source concentration was set at 0.5 g/L, the incubation time (6 days), initial pH level (9) and methyl red concentration (30 mg/L).

Multiple regression analysis and ANOVA for methyl red decolorization by fresh S. obliquus

The FCCCD results for methyl red decolorization by fresh S. obliquus were analysed statistically, employing multiple regression analysis and analysis of variance (ANOVA), and the results of the analyses are presented in Tables 2, 3. Statistical regression analysis data such as adj R2 value, coefficient (R2) value, predicted R2 value, the main influence of each variable, lack of fit, F-value, and probability P-value were investigated to determine the model reliability. Individual, interactions and quadratic effects of the different variables were also evaluated.

The model determination coefficient (R2) for methyl red decolorization by fresh S. obliquus was 0.9944, meaning that 99.44% of the variance in methyl red decolorization was explained by the independent aspects used, and the model could not elucidate just 0.56% of the overall variance. A regression model with a high R2 value above 0.9 is considered to have the strongest significant correlation54,55. In addition, the Adj R2 value of the methyl red decolorization % by fresh S. obliquus (Adj R2 0.9893) was very high, which verified that the model is very significant, as shown in Table 2. On the other hand, there is reasonable agreement between the predicted R2 value of 0.9819 and the Adj R2 value of 0.9893, meaning a strong agreement between the predicted and experimental values of methyl red decolorization percentages. The model used in this study is therefore appropriate to predict methyl red decolorization by fresh S. obliquus in the range of independent parameters.

A considerably small value of the coefficient of variation % (C.V. = 1.86%) displays the high accuracy and consistency of the experimental values of methyl red decolorization percentages56. Adequate precision determines the level of noise; a level higher than 4 is superior and implies model consistency. The current adequate precision ratio for methyl red decolorization by the fresh S. obliquus model is 53.34, which implies model reliability. The standard deviation (SD) of methyl red decolorization by the fresh S. obliquus model was 1.09. The PRESS (expected residual sum of squares) value was 57.76, and the mean value of the methyl red decolorization model was 58.30 (Table 2).

The ANOVA of the regression model of methyl red decolorization indicates that the model terms are highly significant, as is apparent from the F (Fisher’s variance) value (F value = 483.09) and a very minor probability value [P-value˂ 0.0001] (Table 3). P-values were manipulated as a tool to evaluate the significance of each variable. In this study, the variables with P-values of less than 0.05 were found to have significant effects57,58. Meanwhile, the lack of fit for methyl red decolorization % was not significant (P-value = 0.4053 and F-value = 1.31) (Table 3).

The negative coefficient values of the linear, mutual interactions and quadratic effects of the selected process variables denote an antagonistic correlation among the selected process parameters and methyl red decolorization by fresh S. obliquus (the variables exert a negative effect). However, the positive coefficient values indicate a synergistic correlation between the selected process parameters and methyl red decolorization by fresh S. obliquus. It can be investigated from the values of coefficients that the linear coefficients of X1, X2, X3, and X4 are highly significant. The P-values of the coefficients indicate that the relations between X1, and X2; X1X3; X1X4; X2X3; X2X4; X3X4; X12, X22, X32, and X42 had a very significant impact on methyl red decolorization (P-value < 0.05).

The polynomial regression equation expressed in terms of coded levels of the variables reveals the mathematical relationships between the independent variables and can be used to make predictions of methyl red decolorization by S. obliquus (Y) for given levels of each variable. The mathematical relationship is assumed by the following polynomial equation of the second order:

where Y is the predicted value of methyl red decolorization % by vital S. obliquus. X1 is the coded value of the nitrogen source conc., (g/L), X2 is the coded value of incubation time (days), X3 is the coded value of initial pH level, and X4 is the coded value of methyl red concentration (mg/L).

The summary fit results in Table 3 demonstrate that the quadratic polynomial model has the most significant model terms with a very low P-value < 0.0001 and a nonsignificant lack of fit with a high probability value (P-value = 0.4053) and F-value = 1.09.

Multiple regression analysis and ANOVA for lipid production by fresh S. obliquus

Multiple regression analysis and analysis of variance (ANOVA) were used to analyse the FCCCD results for lipid production by fresh S. obliquus. The results are shown in Tables 4, 5. The model determination coefficient (R2) for lipid production by fresh S. obliquus was 0.9978, meaning that 99.78% of the variance in lipid production was explained by the independent factors used, and the model could not elucidate just 0.22% of the overall variance. In addition, the Adj R2 value of lipid production by fresh S. obliquus (Adj R2 0.9958) was very sharp, which verified great model significance, as shown in Table 4. On the other hand, there was reasonable agreement between the predicted R2 value of 0.9938 and the Adj R2 value of 0.9958, indicating great harmony between the predicted and experimental values of lipid production by the fresh alga S. obliquus. The model used in this study is therefore appropriate to predict lipid production by fresh S. obliquus in the range of independent parameters.

A considerably small value of the coefficient of variation % (C.V. = 0.80%) displays the high accuracy and consistency of the experimental values of lipid production. The current adequate precision ratio for lipid production by the fresh S. obliquus model is 64.67, which implies the high precision and reliability of the model. The Std. Dev. of lipid production by the fresh S. obliquus model was 0.15. The PRESS value was 0.94, and the mean value of the lipid production model was 18.42 (Table 4).

The ANOVA of the regression model of lipid production indicates that the model terms are highly significant, as is apparent from the F (Fisher’s variance) value (F-value = 483.09) and a very minor probability value [P-value˂ 0.0001] (Table 5). Meanwhile, the lack of fit for lipid production was not significant (P-value = 0.9157 and F-value = 0.37) (Table 5).

It can be seen from the coefficients that the linear coefficients of X1, X2, X3, and X4 are highly significant. The P-values of the coefficients indicate that the relationships between X1 and X3; X1X4; X2X4; X3X4; X12, X22, X32, and X42 had a very significant impact on lipid production (P-value < 0.05). The P-value of coefficients indicates that the relations between X1 and X2 and X2X3 had a nonsignificant impact on lipid production (P-value ˃ 0.05).

Table 5 shows the fit summary results, which indicate that the quadratic polynomial model has the most significant model terms with a very low P-value < 0.0013 and a nonsignificant lack of fit with an elevated probability value (P-value = 0.9157) and an F-value = 0.37. The quadratic polynomial model has the highest R2(0.9978), adjusted R2(0.9958), and predicted R2 (0.9938).

The polynomial regression equation in terms of coded levels of the variables indicates the mathematical relations between the independent variables and can be used to make predictions of lipid production by S. obliquus (Y) for given levels of each variable. The mathematical relationship is assumed by the following polynomial equation of the second order:

where Y is the predicted value of lipid production by vital S. obliquus. X1: is the coded value of the nitrogen source conc. (g/L), X2 is the coded value of the incubation time (days), X3 is the coded value of the initial pH level, and X4 is the coded value of the methyl red concentration (mg/L).

The adequacy of the model fit for methyl red decolorization (%) by using S. obliquus results

The normal probability plot of internally studentized residuals (NPP) is an important statistical tool for detecting the appropriateness of the model and clarifying whether a set of data is normal or deviates from normality59,60. Figure 2A shows the NPP of internally studentized residuals for methyl red decolorization (%) by using S. obliquus results in data analysis, which indicates that the residuals are normally disseminated; they are located along the straight diagonal line of the normal distribution of methyl red decolorization (%) by using S. obliquus, which reveals suitability of the model, and the predicted results of methyl red decolorization (%) by using S. obliquus were well fitted with the experimental results. Figure 2B shows the predicted values of methyl red decolorization (%) by using S. obliquus versus the internally studentized residuals as determined by a second-order polynomial equation. Figure 2B shows that the residual data is distributed equally above and below the x-axis, confirming the validity of the model.

The adequacy of the model fit for lipid production (%) by using S. obliquus

Figure 3A displays the graph of the box-Cox plot of the model alteration of lipid production (%) by using S. obliquus determined by a second-order polynomial equation. As shown in Fig. 3A, the best value of lambda (λ = 0.46) is located between the two vertical red lines so that no data alteration is necessitated. The red lines indicate the minimum and maximum 95% confidence interval values. Figure 3B presents a plot of predicted versus experimental (actual) values of lipid production (%) by using S. obliquus. The graph shows the points adjacent to the diagonal line, revealing a good correlation between the predicted and actual experimental values.

Three-dimensional surface plots to imagine the effects of independent process factors on methyl red decolorization by using S. obliquus

The three-dimensional (3D) surface plots were generated to recognize the optimum conditions for the highest percentage of methyl red decolorization by using S. obliquus and to visualize the effects of the interactions between the selected process factors on the percentage of methyl red decolorization. 3D graphs for the four variables combined in pairs (nitrogen sources conc. (X1), incubation time (X2), initial pH level (X3) and methyl red concentration (X4) were created by plotting the percentage of methyl red decolorization on the Z-axis versus two process factors, while other independent process factors were fixed at their center levels. The 3D graph (Fig. 4) illustrates the effect of the nitrogen source conc. (X1) and incubation time (X2) on methyl red decolorization on the Z-axis, whereas the initial pH level (X3) and methyl red concentration (X4) were maintained at their center levels.

Figure 4A shows that methyl red decolorization increases with increasing nitrogen source conc., and incubation time. The highest percentage of methyl red decolorization was apparently placed close to the central level of the nitrogen source concentration and incubation time. The center level nitrogen (X1) causes a high degradation value of methyl red by S. obliquus. Lower and higher concentrations of nitrogen (X1) and incubation time (X2) resulted in lower methyl red decolorization percentages. By solving the Eq. (1) and analysing Fig. 4A, the maximum methyl red decolorization predicted value of 70.56% could be achieved at the optimal predicted levels of nitrogen source conc. of 1 g/L, and incubation time of 10 days by using S. obliquus at initial pH level 8, and 20 mg/L methyl red. Figure 4B represents the influence of nitrogen concentration (X1) and initial pH (X3) levels on the methyl red decolorization percentages, where the incubation time (X2) and methyl red concentrations (X4) were maintained at their centre levels. Figure 4C denotes the influence of nitrogen concentration (X1) and methyl red concentration (X4) on the methyl red decolorization percentages. When the other two variables were at the centre levels, the high and low levels of the tested variables did not affect the methyl red decolorization percentages when using fresh S. obliquus. The influence of incubation time (X2) and initial pH (X3) on the methyl red decolorization percentages is shown in Fig. 4D. As shown in Fig. 4D, the center value of incubation time (X2) and initial pH (X3) caused the elevation of methyl red decolorization, while the other two variable factors were also at the center value. Figure 4E shows the influence of both incubation time (X2) and methyl red concentration (X4) on methyl red decolorization percentages by using fresh S. obliquus. The highest decolorization was obtained when the nitrogen concentration (X1) and initial pH (X3) were at their center values. The effect of initial pH (X3) and methyl red concentrations (X3) on the methyl red decolorization percentages by using fresh S. obliquus is shown in Fig. 4F. The low and high values of the initial pH and methyl red concentrations did not increase the percentage of methyl red decolorization when nitrogen concentration and incubation time were maintained at their center levels.

Three-dimensional surface plots to envision the effects of independent process factors on lipid production % by using S. obliquus

Figure 5 demonstrates the three-dimensional plots for lipid production percentages as a function of nitrogen source conc. (X1), incubation time (X2), initial pH level (X3), and methyl red concentration (X4). Figure 5A validates that higher and lower levels of nitrogen concentrations and incubation time decrease the lipid production percentage by S. obliquus when the initial pH is at the center value and methyl red concentrations are at lower values. Figure 5B demonstrates that the centre value of nitrogen concentrations and initial pH increased the lipid production percentage by S. obliquus when the incubation time was at the center value and methyl red concentrations were at low values. Figure 5C demonstrates the effect of nitrogen concentrations and methyl red concentrations on the lipid production percentage by S. obliquus. The results prove that the centre value of nitrogen concentrations and low value of methyl red concentrations promote the lipid production percentage by S. obliquus when two other variables are maintained at their centre levels. Figure 5D represents the effect of incubation time and pH on the lipid production percentage by S. obliquus. The results proved that when nitrogen concentrations were at center levels and methyl red at low levels, the results proved that the high and low levels of the incubation time and initial pH values decreased the lipid production percentage by S. obliquus when the nitrogen concentration was at its center level and methyl red concentrations were at their low levels. Figure 5E shows that the centre level of incubation time and low level of methyl red concentrations increase the lipid production percentage by S. obliquus at their center levels of both nitrogen concentrations and initial pH. Figure 5F denotes the effect of pH and methyl red concentrations on the lipid production percentage by S. obliquus. The results indicated that high and central levels of methyl red concentrations and high and low levels of pH decreased lipid production by S. obliquus when the nitrogen concentrations and incubation time were maintained at their center levels.

The desirability functions

One of the key targets of the experimental design analysis is to identify the optimum conditions predicted to maximize the response. Due to its simplicity, the desirability function (DF) approach has been commonly employed to determine the optimum predicted conditions for the optimization of multi-response processes61. The DF strategy is used to determine the optimum predicted conditions that can provide the "most desirable" response values. The use of DF will effectively contribute to the optimization of biotechnological processes with a reduced number of replicates. The function of desirability ranged between zero (indicating an undesirable response) and one (indicating a completely desirable response). For the optimization process, the DF option in Design Expert Software (version 7) was used. The optimum predicted conditions reached with a desirability function of 0.98 for the maximum decolorization of methyl red % and lipid production (70.15 and 20.91%; respectively) by S. obliquus (Fig. 6) were obtained by using nitrogen concentrations of 1.05 g/L medium, an incubation time of 10.82, the initial pH level of 8.11, and methyl red concentrations of 17.65 mg/L. These optimum values were confirmed experimentally, which resulted in methyl red decolorization of 70.15% and lipid production by S. obliquus of 20.91% dry weight.

Bisht et al.62 reported that one g/L sodium nitrate was added to BG11 medium to show better biomass growth and lipid productivity of Scenedesmus sp. DBTKU. The lipid contents of Chlorella sorokiniana DOE1412 were not affected by pH levels63. El‑Naggar et al.64 used Face-centered central composite design (FCCCD) to find out the optimum levels and to analyze the combined effects of initial pH, contact time, Hg2+, Remazol brilliant blue (RBB), and biomass concentrations on the biosorption process of Hg2+ and RBB dye simultaneously from the binary mixture by Gelidium corneum biomass. FCCCD design of experiments resulted in a maximum removal percentage of RBB of 89.18% which was obtained using 200 mg/L Hg2+, 100 mg/L RBB, pH 5, 4 g/L algal biomass and 180 min of contact time. As well, El‑Naggar et al.61 used a FCCCD based optimization to investigate the efficiency of the Gracilaria seaweed biomass as a sustainable biosorbent for bioremoval of methylene blue from aqueous solution. The highest bioremoval percentage of methylene blue was 94.86%, obtained under optimum experimental conditions: 6 g/L Gracilaria seaweed biomass, initial pH 8, 20 mg/L of methylene blue, 150 mg/L of Ni2+ and 180 min of contact time. On the other hand, El‑Naggar et al.59 used FCCCD to optimize the process variables levels and analyze their combined effects on Congo red dye removal percentage. The highest removal percentage of Congo red dye (97.89%) was achieved using 100 mg/L Congo red dye, 200 mg/L Pb2+, 3 g/L algal biomass, initial pH 6 and contact time was 120 min at 30 °C.

Infrared of biomass of S. obliquus

Infrared analysis of S. obliquus biomass was applied to identify the structural variation of the biomass after and before treatments with MR. Seventeen peaks were present in the control, and 18 peaks were present in the treated alga (Fig. 7). The peaks in control are 3865.48, 3745.88, 3425.69, 2926.11, 2862.46, 2395.67, 1727.31, 1654.01, 1543.1, 1449.55, 1255.7, 1140.93, 1079.21, 1044.49, 698.25, 600.85 and 478.36 cm−1, the peaks are shifted to 3910.8, 3859.69, 3747.81, 3436.3, 2929, 2388.92, 1923.09, 1654.01, 1546.96, 1449.55, 1402.3, 1315.5,1242.2, 1105.25, 683.79, 617.24, 538.16 and 479.33 cm−1 after treatments with MR.

Peak at 3425 cm−1 assigned OH stretching of alcohols and phenols65. The peak at 3436.3 cm−1 was due to the stretching vibration of OH66. The peaks at 2926 cm−1 and 2929 cm-1 correspond to aliphatic C–H stretching67. The peak at 2395 cm−1 represents weak absorption HPO468. The peak at 2388 cm−1 denoted O–H···O–P modes (strong H-bonds)69. The peak at 1727 cm−1 was due to the stretching vibration of O–H70. The peak at 1923 cm−1 represents asymmetric stretching of alkene71. Peaks at 1664, 1546, 1543, 1255, and 1242 cm−1 correspond to amide groups72,73. The peak at 1449 cm−1 represents asymmetric CH3 bending of the methyl groups of proteins74. The peak at 1402 cm−1 represents CH3 symmetric deformation75, 1315 cm−1 amino groups76. Peaks at 1105 cm−1 represent carbohydrates77, and those at 1079 cm−1 represent phosphate groups78. The peak at 1044 cm−1 may be due to the residual 70 inorganic sulfate ions. Peaks ranged 800 to 600 represent C-Cl79. It is evident that there was due to the stretching vibration of the azo bond diminishes in 1654 cm−1, The intensity shifted after treatment by methyl red from 46.272 before treatment by methyl red to 44.541 (after treatment by methyl red), there is a new peak in the azo range (after treatment by methyl red) is 1727.31 cm−1, there is a little shift in the peak 1546 cm−1 (before treatment) to 1543 cm−1 (after treatment by methyl red) and the intensity peak shifted from 49.426 (before treatment) to 49.114 after treatment by methyl red.

Scanning electron microscopy (SEM)

SEM micrographs of S. obliquus biomass after and before treatments with MR are shown in Fig. 8. The results indicated that the untreated alga was relatively smooth and no impurities were present, but in the case of alga treated with MR, there were large amounts of impurities and shrinkage. When Chlorella sp. absorbed lower concentrations of dyes, the cell surface became less smooth80.

Lipid’s profile

Twenty compounds appeared in the lipid extract from the alga (S. obliquus) grown with M.R., but in the case of the control, there were only 10 compounds. This was because alga was grown with methyl red under mixotrophic conditions and used the carbon present in dye as the sole carbon source, but the control alga was grown under autotrophic conditions and CO2 assimilation. The results in Figs. 9 and 10 indicate that the chemical composition of the methyl esters of fatty acids extracted from S. obliquus was grown under mixotrophic and phototrophic conditions, respectively. Compounds are present in GC–MS profiles after methylations of hexane extracts of S. obliquus were grown with methyl red (mixotrophic conditions): hexanoic acid, cyclopropane, octyl-, 2,4-decadienal, (E, E)-, 2,4-nonadienal, (E, E)-, diethyl phthalate. Nonadecane, 2-bromotetradecane, 1-chloroeicosane, 9,12-octadecanoic acid (Z, Z)-, hexadecane, 2,6,11,15-tetramethyl-, hexadecane, 2-bromo dodecane, heptadecane, 2,6,10,15-tetramethyl-, tetratriacontane, hentriacicontane, tetrapententacontane, 1,54-dibromo-, (R)-(−)-14-methyl-8-hexadecyn-1-ol, propylenegal monoleate, 2,6-bis(3,4-methylenedioxyphenyl)-3,7-dioxabicyclo (3.3.0) octan, and cyclopropanebutanoic acid, 2-[[2-[[2-[(2-pentylcyclopropyl) were met. Compounds were present after hexane extract from S. obliquus was grown under photoautotrophic conditions were diethyl Phthalate, 9,12-octadecadienoic acid (Z, Z)-, Z, Z-3,13-octadecedien-1-ol, 9-octadecenoic acid (Z)-, 2-hydroxy-3-[(1-oxohexadecyl) oxy]pr, 1-octadecyne, 13-tetradecynoic acid, methyl ester, hexanoic acid, 2-tetradecyl ester, octanoic acid, hexadecyl ester, 2-octanol, pentafluoropropionate, and tricyclo [20.8.0.0] triacontane, 1(22),7(16)-diepoxy-. Five major fatty acids in Scenedesmus dimorphus were oleic acid, linolenic acid, palmitic acid and 2-methy tetracosane 16.12%, 12.68%, 10.14%, 10.11% and 6.83%, Scenedesmus quadricauda lipids components were palmitic acid, oleic acid, linoleic acid, 3, 7, 11- trimethyl-2,4-dodecadiene and linolenic acid (16.36%, 15.60%, 11.67%, 9.67% and 6.21%, respectively81. The polyunsaturated essential fatty acid 9,12-octadecadienoic acid methyl ester (Z, Z) (linoleic acid) is present in the lipid profile of S. obliquus when grown under autotrophic conditions and that grown under mixotrophic conditions, but the percentage of contents were differ.

The maximum amount is present in the lipids of alga grown under autotrophic conditions and represents 78.26, but in the case of alga grown in mix-trophic conditions, it represents 45.92. Therefore, the lipid composition and its percentage of alga grown with MR differed from the lipid profile of the same alga when grown under autotrophic conditions. Alga grown with methyl red had a lot of different compounds in their lipid profile than those grown under photoautotrophic conditions. This could be due to alga grown with methyl red has a different metabolism for producing fatty acids. Under mixotrophic conditions, algae use methyl red as the sole carbon source. Fazal et al.30 reported that microalgae utilize dyes as a carbon source and transform them into metabolites. Microalgae also work as biosorbents because dyes can be absorbed onto their surface82. The low amount of unsaturated fatty acids in the lipid profile of alga cultivated with methyl red may be due to the nitrogen content of the dye elevating the available nitrogen to alga. When the nitrogen deficiency reached day 10, the lipid content of Scenedesmus sp. increased from 14 to 31%83. Numerous other hydrocarbons were detected in addition to fatty acids due to the algae's metabolism being distinct from that of phototrophic algae. The microgreen algae Chlorella pyrenoidosa and Chlorella vulagris degrade dyes into simple aromatic amines and decolorize dye wastewater84. Therefore, it is possible to use the fatty acids extracted from alga grown with methyl red to produce biodiesel and simultaneously remove dyes.

An engine fuelled with biodiesel containing superior oxygen content can lead to lower CO emissions with increasing blend ratio due to complete combustion in the diesel engine. An engine fuelled with biodiesel containing superior cetane number and higher lubricity is more effective.

Biodiesel with higher gross calorific value produces higher power. Biodiesel has a higher viscosity, which causes fuel flow and ignition problems in engines and decreases power output85. Lipid yields by microalgae are controlled by various culturing conditions, such as nitrogen deprivation86, harvesting times87, and pH88. Additionally, the methods and solvents used to extract lipids affect lipid yields and contents43. The oxidation state of the nitrogen source (i.e., NH4 or NO3) can promote the influence of biomass yield89. Musa et al.90 reported that the use of NO3 as a nitrogen source requires high energy and diminishes biomass yield. The results indicated that unsaturated fatty acids were more abundant than saturated fatty acids. Saturated acid components in algal biomass are in the range of 25–45%, while unsaturated fatty acid contents account for 50–55% of total fatty acids91. Xin et al.83 reported the potential production of biodiesel from lipids extracted from Scenedesmus sp. grown in wastewater treatment. Mata et al.92 stated the possible production of biodiesel from Scenedesmus obliquus that was grown in brewery wastewater. The lipid percentage of Scenedesmus obliquus grown with total wastewater was 22.7, whereas the lipid percentage of algae grew in BBM 25.251. Mata et al.92 reported that Scenedesmus sp. Z-4 displayed great potential to realize simultaneous wastewater treatment and lipid production at low temperatures. Table 6 reported the various factors affecting the decolorization of methyl red dye from aqueous solutions by using different sorbents (algae and bacteria). There was variation in factors (incubation time, pH, methyl red conc., temperature) influencing the decolorization of methyl red according to the biosorbents. The incubation times were 60 h, 20 m, 60 m, 24 h, 48 h and 6 h with the biosorbents Chara vulgaris, Neplhelium lappaceum seeds, Galactomyces geotrichum MTCC 1360, Rhodococcus strain UCC 0016, Bacillus megaterium ITBHU01 and Spirulina-C11; respectively at pH 5, 3, 7, 7.21 and 8 with Chara vulgaris, Neplhelium lappaceum seeds, Rhodococcus strain UCC 0016, Bacillus megaterium ITBHU01 and Aeromonas jandaei strain93,94,95,96,97,98,99,100; respectively. Many studies used algae to remove dyes and heavy metals from wastewater29,101,102. The lipid yields by algae can be stimulated by some factors such as ultrasonication103 and addition of iron oxide nanoparticles to the algae growth media104,105,106,107.

Conclusions

This study demonstrates a novel approach that uses the microgreen alga Scenedesmus obliquus to decolorize methyl red and produce lipids for possible transesterification to biodiesel. Experimentally, the maximum methyl red removal and lipid production were 70.015 and 20.91%; respectively. The methyl red concentration was 17.95 mg/L, nitrogen concentration was 1.05 mg/L, incubation time was 10 days, and pH was 8.11. Fresh algal biomass from S. obliquus can be used to remove methyl red from wastewater efficiently, making lipids that can be transesterified into biodiesel and solving both fuel and environmental problems. Algae can be used in simultaneous bioremediation of wastewater and production of biofuels like biodiesel that is derived from lipid content and bio-methanol that is derived from carbohydrate content. Extensive study should be required to determine the optimal conditions for production and harvesting of high lipid content algae to make algae fuel for future energy.

References

Dutta, K., Daverey, A. & Lin, J.-G. Evolution retrospective for alternative fuels: First to fourth generation. Renew. Energy. 69, 114–122 (2014).

Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 123, 230–241 (2017).

Phwan, C. K. et al. Overview: Comparison of pretreatment technologies and fermentation processes of bioethanol from microalgae. Energy Convers Manag. 173, 81–94 (2018).

Hu, Y. et al. Copyrolysis and cohydrothermal liquefaction of seaweeds and rice husk: Comparative study towards enhanced biofuel production. J. Anal. Appl. Pyrolysis. 129, 162–170 (2018).

Kiran, B., Kumar, R. & Deshmukh, D. Perspectives of microalgal biofuels as a renewable source of energy. Energy Convers. Manag. 88, 1228–1244 (2014).

Singh, A., Nigam, P. S. & Murphy, J. D. Renewable fuels from algae: An answer to debatable land-based fuels. Bioresour. Technol 102, 10–16 (2011).

Ananthashankar, R. Treatment of Textile Effluent Containing Reactive Red 120 Dye Using Advanced Oxidation, M.Sc. A Thesis, Dalhousie University, Halifax, Nova Scotia, 145p (2012).

Hassaan, M. A. & Nemr, A. E. Advanced oxidation processes for textile wastewater treatment. Int. J. Photochem. Photobiol. 2, 85–93 (2017).

Bhuiyan, R. M. A., Mizanur, R. M., Shaid, A., Bashar, M. M. & Khan, M. A. Scope of reusing and recycling the textile wastewater after treatment with gamma radiation. J. Clean. Prod. 112, 3063–3071 (2016).

Khatri, A., Peerzada, M. H., Mohsin, M. & White, M. A review on developments in dyeing cotton fabrics with reactive dyes for reducing effluent pollution. J. Clean. Prod. 87, 50–57 (2015).

Hassaan, M. A., El Nemr, A. & Hassaan, A. Health and environmental impacts of dyes: Mini review. Am. J. Environ. Sci. Eng. 1(3), 64–67 (2017).

Achwal, W. B. Problems during analysis of textile as per ecostandards and the customer articles ordinance (Part I)”. Colourage 44, 29–31 (1997).

Gičević, A., Hindija, L. & Karačić, A. Toxicity of azo dyes in pharmaceutical industry. In International Conference on Medical and Biological Engineering, 581–587 (Springer, 2019).

de Campos Ventura-Camargo, B. & Marin-Morales, M. A. Azo dyes: Characterization and toxicity-a review. Textiles Light Ind. Sci. Technol. 2(2), 85–103 (2013).

Ayaden, B. et al. Natural mordenite-rich tuff as an alternative for removing textile dyes (Asucryl red): Adsorption properties, kinetic and equilibrium studies. Clay Miner. 54(4), 349–355 (2019).

Lellis, B., Fávaro-Polonio, C. Z., Pamphile, J. A. & Polonio, J. C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 3(2), 275–290 (2019).

Chen, G., Zhao, L. & Qi, Y. Enhancing the productivity of microalgae cultivated in wastewater toward biofuel production: A critical review. Appl. Energy 137, 282–291. https://doi.org/10.1016/j.apenergy.2014.10.032 (2015).

Suganya, T., Varman, M., Masjuki, H. H. & Renganathan, S. Macroalgae and microalgae as a potential source for commercial applications along with biofuels production: A biorefinery approach. Renew. Sustain. Energy Rev. 55, 909–941. https://doi.org/10.1016/j.rser.2015.11.026 (2016).

Mata, T. M., Martins, A. A. & Caetano, N. S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 14(1), 217–232 (2010).

Fu, Y. & Viraraghavan, T. Fungal decolorization of dye wastewaters: A review. Bioresour. Technol. 79, 251–262. https://doi.org/10.1016/S0960-8524(01)00028-1 (2001).

El-Sheekh, M. M., Gharieb, M. M. & Abou-El-Souod, G. W. Biodegradation of dyes by some green algae and cyanobacteria. Int. Biodeterior. Biodegrad. 63(6), 699–704 (2009).

Cai, T., Park, S. Y. & Li, Y. Nutrient recovery from wastewater streams by microalgae: Status and prospects. Renew. Sustain. Energy Rev. 19, 360–369 (2013).

Abdel-Raouf, N., Al-Homaidan, A. A. & Ibraheem, I. Microalgae and wastewater treatment. Saudi J. Biol. Sci. 19(3), 257–275 (2012).

Zhang, Y. et al. The effect of bacterial contamination on the heterotrophic cultivation of Chlorella pyrenoidosa in wastewater from the production of soybean products. Water Res. 46(17), 5509–5516 (2012).

Novotný, Č et al. Comparative use of bacterial, algal and protozoan tests to study toxicity of azo-and anthraquinone dyes. Chemosphere 63(9), 1436–1442 (2006).

Liu, T. et al. Attached cultivation technology of microalgae for efficient biomass feedstock production. Bioresour. Technol. 127, 216–222 (2013).

Taştan, B. E., Ertuğrul, S. & Dönmez, G. Effective bioremoval of reactive dye and heavy metals by Aspergillus versicolor. Bioresour. Technol. 101(3), 870–876 (2010).

Shen, Y. Carbon dioxide biofixation and wastewater treatment via algae photochemical synthesis for biofuels production. RSC Adv. 4(91), 49672–49722 (2014).

Sarkar, P. & Dey, A. Phycoremediation—An emerging technique for dye abatement: An overview. Process Saf. Environ. Prot. 147, 214–225 (2021).

Fazal, T. et al. Bioremediation of textile wastewater and successive biodiesel production using microalgae. Renew. Sustain. Energy Rev. 82, 3107–3126 (2018).

Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 25(3), 294–306 (2007).

Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 86, S108–S117 (2009).

Demirbas, A. Biodiesel from oilgae, biofixation of carbon dioxide by microalgae: A solution to pollution problems. Appl. Energy 88(10), 3541–3547 (2011).

Culley, D. D. Jr., Rejmánková, E., Květ, J. & Frye, J. B. Production, chemical quality and use of duckweeds (Lemnaceae) in aquaculture, waste management, and animal feeds. J. World Mariculture Soc. 12(2), 27–49 (1981).

Griffiths, M. J. & Harrison, S. T. Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J. Appl. Phycol. 21(5), 493–507 (2009).

Sharma, K. K., Schuhmann, H. & Schenk, P. M. High lipid induction in microalgae for biodiesel production. Energies 5(5), 1532–1553 (2012).

Hu, Q. et al. Microalgal triacylglycerols as feedstocks for biofuel production: Perspectives and advances. Plant J. 54(4), 621–639 (2008).

Shen, Y., Zhang, H., Xu, X. & Lin, X. Biofilm formation and lipid accumulation of attached culture of Botryococcus braunii. Bioprocess Biosyst. Eng. 38(3), 481–488 (2015).

Chen, C. Y. & Durbin, E. G. Effects of pH on the growth and carbon uptake of marine phytoplankton. Mar. Ecol.-Prog. Ser. 109, 83–83 (1994).

Moheimani, N. R. Inorganic carbon and pH effect on growth and lipid productivity of Tetraselmis suecica and Chlorella sp. (Chlorophyta) grown outdoors in bag photobioreactors. J. Appl. Phycol. 25(2), 387–398 (2013).

Chen, Z. et al. Exploration of microalgal species for nutrient removal from anaerobically digested swine wastewater and potential lipids production. Microorganisms 9, 2469. https://doi.org/10.3390/microorganisms9122469 (2021).

Bischoff, H. W. & Bold, H. C. Some soil algae from enchanted rock and related algal species. Phycol. Stud. IV. Univ. Texas Publ. 6318, 1–95 (1963).

El-Sheekh, M. M. & Hamouda, R. A. Lipids extraction from the green alga Ankistrodesmus falcatus using different methods. Rendiconti Lincei. 27(3), 589–595 (2016).

El-Naggar, N. E., El-Bindary, A. A. & Nour, N. S. Statistical optimization of process variables for antimicrobial metabolites production by Streptomyces anulatus NEAE-94 against some multidrug-resistant strains. Int. J. Pharmacol. 9, 322–334 (2013).

El-Naggar, N. E. A. A. & Hamouda, R. A. Antimicrobial potentialities of Streptomyces lienomycini NEAE-31 against human pathogen multidrug-resistant Pseudomonas aeruginosa. Int. J. Pharmacol. 12(8), 769–788 (2016).

E-A El-Naggar, N. Extracellular production of the oncolytic enzyme, l-asparaginase, by newly isolated Streptomyces sp. strain NEAE-95 as potential microbial cell factories: Optimization of culture conditions using response surface methodology. Curr. Pharm. Biotechnol. 16(2), 162–178 (2015).

El-Naggar, N. E. A., Haroun, S. A., Oweis, E. A. & Sherief, A. A. Identification of newly isolated Talaromyces pinophilus and statistical optimization of β-glucosidase production under solid-state fermentation. Prep. Biochem. Biotechnol. 45(7), 712–729 (2015).

El-Naggar, N. E. A., El-Khateeb, A. Y., Ghoniem, A. A., El-Hersh, M. S. & Saber, W. I. Innovative low-cost biosorption process of Cr6+ by Pseudomonas alcaliphila NEWG-2. Sci. Rep. 10(1), 1–18 (2020).

Abou-El-Souod, G., Hamouda, R. A. & El-Sheekh, M. Influence of heavy metal as cocontamination on biodegradation of dyes by free and immobilized Scenedesmus obliquus. Desalin. Water Treat. 182, 351–358 (2020).

Tang, D., Han, W., Li, P., Miao, X. & Zhong, J. CO2 biofixation and fatty acid composition of Scenedesmus obliquus and Chlorella pyrenoidosa in response to different CO2 levels. Bioresour. Technol. 102(3), 3071–3076 (2011).

Eida, M. F., Darwesh, O. M. & Matter, I. A. Cultivation of oleaginous microalgae Scenedesmus obliquus on secondary treated municipal wastewater as growth medium for biodiesel production. J. Ecol. Eng. 19(5), 38–50 (2018).

Hakalin, N. L., Paz, A. P., Aranda, D. A. & Moraes, L. M. P. Enhancement of cell growth and lipid content of a freshwater microalga Scenedesmus sp. by optimizing nitrogen, phosphorus and vitamin concentrations for biodiesel production. Nat. Sci. 2014, 1044–1054 (2014).

Rodolfi, L. et al. Microalgae for oil: Strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol. Bioeng. 102(1), 100–112 (2009).

El-Naggar, N. E. A., Moawad, H. & Abdelwahed, N. A. Optimization of fermentation conditions for enhancing extracellular production of L-asparaginase, an anti-leukemic agent, by newly isolated Streptomyces brollosae NEAE-115 using solid-state fermentation. Ann. Microbiol. 67(1), 1–15 (2017).

El-Naggar, N. E. A., Hamouda, R. A., Mousa, I. E., Abdel-Hamid, M. S. & Rabei, N. H. Statistical optimization for cadmium removal using Ulva fasciata biomass: Characterization, immobilization and application for almost-complete cadmium removal from aqueous solutions. Sci. Rep. 8(1), 1–17 (2018).

Box, G. E. P., Hunter, W. G. & Hunter, J. S. Statistics for Experimenters (Wiley, 1978).

Mohamedin, A., El-Naggar, N. E. A., Shawqi Hamza, S. & Sherief, A. A. Green synthesis, characterization and antimicrobial activities of silver nanoparticles by Streptomyces viridodiastaticus SSHH-1 as a living nanofactory: Statistical optimization of process variables. Curr. Nanosci. 11(5), 640–654 (2015).

El-Naggar, N. E., Mohamedin, A., Hamza, S. S., & Sherief, A. Extracellular biofabrication, characterization, and antimicrobial efficacy of silver nanoparticles loaded on cotton fabrics using newly isolated Streptomyces sp. SSHH-1E. J. Nanomater. 2016, 3257359 (2016).

El-Naggar, N. E. A., Rabei, N. H. & El-Malkey, S. E. Eco-friendly approach for biosorption of Pb2+ and carcinogenic Congo red dye from binary solution onto sustainable Ulva lactuca biomass. Sci. Rep. 10(1), 1–22 (2020).

El-Naggar, N. E. A., El-Shweihy, N. M. & El-Ewasy, S. M. Identification and statistical optimization of fermentation conditions for a newly isolated extracellular cholesterol oxidase-producing Streptomyces cavourensis strain NEAE-42. BMC Microbiol. 16(1), 1–20 (2016).

El-Naggar, N. E. A. & Rabei, N. H. Bioprocessing optimization for efficient simultaneous removal of methylene blue and nickel by Gracilaria seaweed biomass. Sci. Rep. 10(1), 1–21 (2020).

Bisht, T. S., Pandey, M. & Pande, V. Impact of different nitrogen sources on biomass growth and lipid productivity of Scenedesmus sp. for biodiesel production. J. Algal Biomass Utln 7(4), 8–36 (2016).

Qiu, R., Gao, S., Lopez, P. A. & Ogden, K. L. Effects of pH on cell growth, lipid production and CO2 addition of microalgae Chlorella sorokiniana. Algal Res. 28, 192–199 (2017).

El-Naggar, N. E., Hamouda, R. A., El-Khateeb, A. Y. & Rabei, N. H. Biosorption of cationic Hg2+ and Remazol brilliant blue anionic dye from binary solution using Gelidium corneum biomass. Sci. Rep. 11(1), 1–24 (2021).

Daphedar, A. & Taranath, T. C. Characterization and cytotoxic effect of biogenic silver nanoparticles on mitotic chromosomes of Drimia polyantha (Blatt. & McCann) Stearn. Toxicol. Rep. 5, 910–918 (2018).

Sreenivasulu, G. et al. Organic matter from benthic foraminifera (Ammonia beccarii) shells by FT-IR spectroscopy: A study on Tupilipalem, South east coast of India. MethodsX. 4, 55–62 (2017).

Saha, R. et al. Removal of hexavalent chromium from water by adsorption on mosambi (Citrus limetta) peel. Res. Chem. Intermed. 39(5), 2245–2257 (2013).

Suryawanshi, V. B. & Chaudhari, R. T. Growth and characterization of agar gel grown brushite crystals. Indian J. Mater. Sci. 2014, 1–6 (2014).

Röska, B. et al. Determination of the hydrogen-bond network and the ferrimagnetic structure of a rockbridgeite-type compound. J. Phys. Condens. Matter 30(23), 235401 (2018).

Peng, S., Fan, X., Li, S. & Zhang, J. Green synthesis and characterization of graphite oxide by orthogonal experiment. J. Chil. Chem. Soc. 58(4), 2213–2217 (2013).

Shulga, E. et al. Functionalisation of aligned carbon nanotubes with nitric acid vapour. Micro Nano Lett. 6(8), 704–708 (2011).

Chiriboga, L. et al. Infrared spectroscopy of human tissue. I. Differentiation and maturation of epithelial cells in the human cervix. Biospectroscopy 4(1), 47–53 (1998).

Lucassen, G. W., Van Veen, G. N. & Jansen, J. A. Band analysis of hydrated human skin stratum corneum attenuated total reflectance Fourier transform infrared spectra in vivo. J. Biomed. Opt. 3(3), 267–280 (1998).

Yano, K. et al. Direct measurement of human lung cancerous and noncancerous tissues by Fourier transform infrared microscopy: Can an infrared microscope be used as a clinical tool?. Anal. Biochem. 287(2), 218–225 (2000).

Frank, C. J., Redd, D. C., Gansler, T. S. & McCreery, R. L. Characterization of human breast biopsy specimens with near-IR Raman spectroscopy. Anal. Chem. 66(3), 319–326 (1994).

Long, Q. W. & Wang, Y. Sodium tetraethylenepentamine heptaacetate as novel draw solute for forward osmosis—synthesis, application and recovery. Energies 8(11), 12917–12928 (2015).

Fukuyama, Y., Yoshida, S., Yanagisawa, S. & Shimizu, M. A study on the differences between oral squamous cell carcinomas and normal oral mucosas measured by Fourier transform infrared spectroscopy. Biospectroscopy 5(2), 117–126 (1999).

Khalid, K., & Hanafiah, M. A. K. M. Kinetic and isotherm adsorption studies of methylene blue on sulfuric acid treated spent grated coconut (Cocos nucifera). In Advanced Materials Research. Vol. 970, 192–197 (2014)

Hamouda, R. A., El-Naggar, N. E., Doleib, N. M. & Saddiq, A. A. Bioprocessing strategies for cost-effective simultaneous removal of chromium and malachite green by marine alga Enteromorpha intestinalis. Sci. Rep. 10(1), 1–19 (2020).

Doshi, H., Ray, A., Kothari, I. L. & Gami, B. Spectroscopic and scanning electron microscopy studies of bioaccumulation of pollutants by algae. Curr. Microbiol. 53(2), 148–157 (2006).

Gour, R. S., Chawla, A., Singh, H., Chauhan, R. S. & Kant, A. Characterization and screening of native Scenedesmus sp. isolates suitable for biofuel feedstock. PLoS ONE 11(5), e0155321 (2016).

Chu, W. L., See, Y. C. & Phang, S. M. Use of immobilized Chlorella vulgaris for the removal of colour from textile dyes. J. Appl. Phycol. 21(6), 641–648 (2009).

Xin, L., Hong-Ying, H. & Jia, Y. Lipid accumulation and nutrient removal properties of a newly isolated freshwater microalga, Scenedesmus sp. LX1, growing in secondary effluent. New Biotechnol. 27(1), 59–63 (2010).

Forgacs, E., Cserhati, T. & Oros, G. Removal of synthetic dyes from wastewaters: A review. Environ. Int. 30(7), 953–971 (2004).

McCarthy, P., Rasul, M. G. & Moazzem, S. Comparison of the performance and emissions of different biodiesel blends against petroleum diesel. Int. J. Low-Carbon Technol. 6(4), 255–260 (2011).

Illman, A. M., Scragg, A. H. & Shales, S. W. Increase in Chlorella strains calorific values when grown in low nitrogen medium. Enzyme Microb. Technol. 27(8), 631–635 (2000).

Zhila, N. O., Kalacheva, G. S. & Volova, T. G. Effect of salinity on the biochemical composition of the alga Botryococcus braunii Kütz IPPAS H-252. J. Appl. Phycol. 23(1), 47–52 (2011).

Tzovenis, I., De Pauw, N. & Sorgeloos, P. Effect of different light regimes on the docosahexaenoic acid (DHA) content of Isochrysis aff. galbana (clone T-ISO). Aquac. Int. 5(6), 489–507 (1997).

González-Garcinuño, Á., Tabernero, A., Sánchez-Álvarez, J. M., Del Valle, E. M. M. & Galán, M. A. Effect of nitrogen source on growth and lipid accumulation in Scenedesmus abundans and Chlorella ellipsoidea. Bioresour. Technol. 173, 334–341 (2014).

Musa, M. et al. Factors affecting microalgae production for biofuels and the potentials of chemometric methods in assessing and optimizing productivity. Cells 8(8), 851 (2019).

Subramaniam, R., Dufreche, S., Zappi, M. & Bajpai, R. Microbial lipids from renewable resources: Production and characterization. J. Ind. Microbiol. Biotechnol. 37(12), 1271–1287 (2010).

Mata, T. M. et al. Potential of microalgae Scenedesmus obliquus grown in brewery wastewater for biodiesel production. Chem. Eng. Trans. 32(1), 901–906 (2013).

Ma, C. et al. Molasses wastewater treatment and lipid production at low temperature conditions by a microalgal mutant Scenedesmus sp. Z-4. Biotechnol. Biofuels. 10(1), 1–13 (2017).

Mahajan, P. & Kaushal, J. Phytoremediation of azo dye methyl red by macroalgae Chara vulgaris L.: Kinetic and equilibrium studies. Environ. Sci. Pollut. Res. 27(21), 26406–26418 (2020).

Zein, R., Astuti, A. W., Wahyuni, D., Furqani, F. & Munaf, E. Removal of methyl red from aqueous solution by Neplhelium lappaceum. Res. J. Pharm. Biol. Chem. Sci. 6(3), 86–97 (2015).

Jadhav, S. U., Kalme, S. D. & Govindwar, S. P. Biodegradation of methyl red by Galactomyces geotrichum MTCC 1360. Int. Biodeterior. Biodegrad. 62(2), 135–142 (2008).

Maniyam, M. N., Ibrahim, A. L. & Cass, A. E. Decolorization and biodegradation of azo dye methyl red by Rhodococcus strain UCC 0016. Environ. Technol. 41(1), 71–85 (2020).

Tripathi, A., Singh, Y., Verma, D. K., Ranjan, M. R. & Srivastava, S. K. Bioremediation of hazardous azo dye methyl red by a newly isolated Bacillus megaterium ITBHU01: Process improvement through ANN-GA based synergistic approach. Indian J. Biochem. Biophys. 53, 112–125 (2016).

Ansari, M. K. A., Khatib, U. M., Owens, G. & Fatma, T. Evaluation of methyl red tolerant cyanobacteria for simultaneous laccase production and dye decolorization. Int. J. Waste Resour 6, 2252–5211 (2016).

Sharma, S. C. D. et al. Decolorization of azo dye methyl red by suspended and coimmobilized bacterial cells with mediators anthraquinone-2,6-disulfonate and Fe3O4 nanoparticles. Int. Biodeterior. Biodegrad. 112, 88–97 (2016).

Singh, A. et al. Biological remediation technologies for dyes and heavy metals in wastewater treatment: New insight. Bioresour. Technol. 343, 126154 (2022).

Rana, M. S. & Prajapati, S. K. Stimulating effects of glycerol on the growth, phycoremediation and biofuel potential of Chlorella pyrenoidosa cultivated in wastewater. Environ. Technol. Innov. 24, 102082 (2021).

Ren, H. Y. et al. Ultrasonic enhanced simultaneous algal lipid production and nutrients removal from non-sterile domestic wastewater. Energy Convers. Manag. 180, 680–688 (2019).

Rana, M. S., Bhushan, S. & Prajapati, S. K. New insights on improved growth and biogas production potential of Chlorella pyrenoidosa through intermittent iron oxide nanoparticle supplementation. Sci. Rep. 10(1), 1–13 (2020).

Bhandari, M. & Prajapati, S. K. Use of reverse osmosis reject from drinking water plant for microalgal biomass production. Water Res. 210, 117989 (2021).

Rana, M. S., Bhushan, S., Sudhakar, D. R. & Prajapati, S. K. Effect of iron oxide nanoparticles on growth and biofuel potential of Chlorella spp. Algal Res. 49, 101942 (2020).

Ren, H. Y. et al. Enhanced microalgal growth and lipid accumulation by addition of different nanoparticles under xenon lamp illumination. Bioresour. Technol. 297, 122409 (2020).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

N.E.E. carried out all analyses and experimental instructions, collected the data, performed and explained the statistical analysis, and contributed to revision, rephrasing, and editing of the final version of the manuscript. R.A.H. proposed the research topic, interpreted the results, and wrote and revised the manuscript. G.A.E. carried out the experiments, provided necessary tools for experiments and contributed to the writing and revision of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El‑Naggar, N.E., Hamouda, R.A. & Abou-El-Souod, G.W. Statistical optimization for simultaneous removal of methyl red and production of fatty acid methyl esters using fresh alga Scenedesmus obliquus. Sci Rep 12, 7156 (2022). https://doi.org/10.1038/s41598-022-11069-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-11069-z

This article is cited by

-

Green synthesis of collagen nanoparticles by Streptomyces xinghaiensis NEAA-1, statistical optimization, characterization, and evaluation of their anticancer potential

Scientific Reports (2024)

-

Artificial intelligence-based optimization for chitosan nanoparticles biosynthesis, characterization and in‑vitro assessment of its anti-biofilm potentiality

Scientific Reports (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.