Abstract

Solar photovoltaic (PV) energy has met great attention in the electrical power generation field for its many advantages in both on and off-grid applications. The requirement for higher proficiency from the PV system to reap the energy requires maximum power point tracking techniques (MPPT). This paper presents an adaptive MPPT of a stand-alone PV system using an updated PI controller optimized by harmony search (HS). A lookup table is formed for the temperature and irradiance with the corresponding voltage at MPP (VMPP). This voltage is considered as the updated reference voltage required for MPP at each temperature and irradiance. The difference between this updated reference voltage at MPP and the variable PV voltage due to changing the environmental conditions is used to stimulate PI controller optimized by HS to update the duty cycle (D) of the DC–DC converter. The temperature, irradiance, and corresponding duty cycle at MPP are utilized to convert this MPP technique into an adaptive one without the PI controllers' need. An experimental implementation of the proposed adaptive MPPT is introduced to test the simulation results' validity at different irradiance and temperature levels.

Similar content being viewed by others

Introduction

Due to the environmental difficulties and the significant increase in energy demands, there has become a global and urgent need to generate power from renewable energy sources (RESs). This urgent need to use and implement RESs is due to several factors, including but not limited to clean and non-polluted production of energy, continuity generations as these RESs will not be depleted. Many RESs with significant penetration into the electrical networks were used and implemented based on many RESs types. Wind energy, fuel cell and photovoltaic (PV) were used in many applications, either on or off-grid applications1,2,3. Some of these RES may be connected to form hybrid RES. These hybrid systems are used for on and off-grid applications4.

PV systems are widely spread as one of the RESs. Growth of PV systems and solar energy PV systems had become common in many off and on-grid applications with expected generating level PV up to 1 TW in 20215.

The initial cost and the subsequent generating unit (kW.hr) cost of PV systems is still relatively high compared to the classical fuel. This increase in costs has led to a significant tendency to use the available output power from PV without directions to create new PV systems, if possible. One of the well-known techniques for using the available power extracted from PV systems is maximum power point tracking (MPPT).

MPPT of PV systems means controlling and adapting the output of generated power from PV to MPP available from PV at certain surrounding environmental conditions. MPPT is based on control and drive the duty cycle (D) of the DC-DC converter connecting the DC output of PV system, feeding the load in off-grid applications or feeding an inverter in on-grid applications. A new PV-MPPT based on the control of the DC-DC chopper as in Ref.6. A modified adaptive hill climbing PV-MPPT was introduced in Ref.7. A sensorless single-cell MPP for vehicle solar arrays applications was proposed8. The parallel connection of PV systems for standalone configuration was modeled and conducted in Ref.9. A comparison between different MPPT techniques was presented in Ref.10.

The output power of the PV system mainly relies on the surrounding temperature and the irradiance. MPPT techniques are to force the PV system's characteristics to operate at the MPP to exploit the available energy from PV at a certain temperature and irradiance conditions by regulating the DC–DC converter's duty cycle. Fractional open circuit and fractional short circuit, the conventional solutions for MPPT were presented, but they were not accurate to track the maximum operating point11. Different MPPT algorithms were proposed; from them, perturb and observation (P&O) was used in many applications3. P&O is a very simple technique and easy to be implemented12. P&O is affected mainly by the perturb step value for both transient and steady-state operating conditions. That calls for adaptive regulation of the perturbation step as in Refs.13,14. Different procedures were applied to convert the MPPT into adaptive MPPT15,16,17,18. These adaptive techniques suffered from high computational load and the users' well-known to adapt the perturb step size.

Incremental conductance (IC) method with endeavors to overcome the problems that appear when using P&O MPPT technique was presented in Refs.19,20,21. IC gave a better performance than P&O in the transient periods associated with rapid changes in the environmental conditions. Some modifications are applied to improve the IC method by adjusting PI controllers with the capability to modify the duty cycle of the DC–DC converters. The challenges in these modifications are to determine the PI controller parameters and how to adapt them quickly with variations in the environmental conditions. Many other artificial techniques were presented to overcome the MPPT problems that emerged when using P&O and IC techniques. Fuzzy logic controller is proposed to update the control signal instead of a fixed signal when using static PI controller parameters for PI controllers22. Another artificial technique is used to update the duty cycle control signal to achieve the MPPT of PV system, artificial neural network23,24. Despite the advantages of using both Fuzzy logic controllers and artificial neural network22,23,24, over static PI controllers, they are more complex than PI controllers, along with their implementation difficulty. Besides, fuzzy logic controller was used alone and a hybrid with firefly for achieving MPPT25,26,27.

For tuning the PI controller parameters, many optimization techniques were introduced. Genetic algorithms, particle swarm optimization, cuckoo search and harmony search (HS), elephant herding optimization were introduced to optimize PI controller parameters for many power systems applications28,29,30,31,32. Hybridization of two or more optimization techniques was presented for MPPT. Hybrid PSO and gray-wolf optimization techniques was presented and compared to single optimization techniques for MPPT33. Another hybrid optimization technique based Jaya optimization is proposed for MPPT in Ref.34. These optimization techniques succeed at the optimal tuning of the PI controller parameters off-line. With varying operating conditions, the optimized PI controller parameters could not condemn the optimality, if they are not returned. Adaptive algorithms should be introduced to convert PI controller into an optimal one. Artificial neural network was introduced to convert adaptive PI controllers into adaptive one as in Ref.34. Another adaptive control technique was presented to convert the PI controller parameters (static gains) into adaptive ones through adaptive reference PI controllers. This adaptive control was presented to enhance the PV system performance by updating the voltage reference based on the variable environmental operating conditions35. However, these techniques acquire high experience for users, and much training data to assure the systems' accuracy.

In this paper, a robust and straightforward adaptive MPPT technique is proposed. The PV curve of the PV system is plotted and verified practically. A lookup table is formed for different values of irradiance, temperature and the corresponding voltage at MPP (VMPP_ref). This MPP voltage is taken as the updated reference and compared to the varied PV voltage due to the variation of irradiance and temperature. The error between the reference updated voltage and the PV voltage represents the input to the PI controller. This error is minimized using HS optimization. This process is repeated 30 times to obtain the optimized PI controller parameters with the corresponding duty cycles required for MPPT at each temperature and irradiance. The irradiances, temperatures and the corresponding optimized duty cycles required for MPPT are used achieve MPPT at each operating condition. With these data (irradiance, temperature and the duty cycle), the system is converted to adaptive MPPT without using PI controller. These data were used to build up a practical circuit to achieve the adaptive MPPT technique proposed. A simple microcontroller is used with the second table data to dive the DC-DC converter with the updated duty cycle at each irradiance and temperature to assure adaptive MPPT at different temperatures and irradiances.

Problem formulation

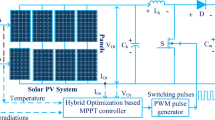

The proposed system, Fig. 1, comprises a PV module connected to a DC–DC converter feeding a load. The DC–DC converter's duty cycle ratio is controlled using an optimized PI controller to maintain MPP of the PV system. A lookup table (Table 1) consists of the temperature, irradiance and the corresponding voltage at MPP obtained from the characteristics is formed. This table is used for updating the reference voltage (VMPP_ref) for MPP at each temperature and irradiance. The PV voltage (Vpv) is sensed and compared to the updated reference voltage. This error is minimized by HS optimization technique and used to stimulate the DC-DC chopper to track MPP36,37,38,39.

PV modeling

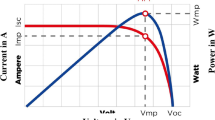

The PV equivalent circuit is given in Fig. 2. This circuit comprises a light-dependent current source with a shunted diode6,7. The current produced by this current source is directly proportional to the light dropped on the PV. RS and Rp are series and shunt resistances of PV, respectively.

In this paper, the EBS solar module is used and the specifications of this module are given in Table 1 at standard conditions of 25 °C temperature and irradiance of 1000 W/m2.

PI controller design

The updated reference voltage, VMPP_ref represents the voltage at which MPP is attained is used and compared to the current PV voltage, Vpv. The difference between these two voltages ev represents the error used to drive PI controller. An objective function, J is formed based on the integral square of error of ev that can be defined as:

The HS optimization technique is used to minimize this objective function and determine the optimal PI control parameters at each irradiance and temperature.

Harmony search optimization

The first step in HS is the initialization of the two PI control parameters by supposing random values of them. Then the fitness function J, given in (1) is determined with these random values. Then the Harmony Memory (HM) is set as in (2)

The HM matrix contains two columns for the PI controller parameters (Kp, Ki). Each row in this matrix is the enhanced harmony vector based on the harmony memory considering rate (HMCR) and pitch adjusting rate (PAR). The updated harmony vector \({x}_{i}^{n+1}\) of the current harmony vector \({x}_{i}^{n}\) is calculated as:

where rand is a random value between (0, 1) and BW is an arbitrary distance bandwidth.

The updating process is done again till reaching the minimum possible value for the objective function J or reaching the maximum search iteration numbers, Fig. 336.

Simulation results

Harmony search optimization technique

Due to the temperature and irradiance variations, the PV output voltage will change to new values different from the required values for MPP. These variables PV voltages will be compared to the voltage required for MPPT at these environmental conditions as in Table 2. The error between the PV voltage and the updated reference voltage based on Table 2 is used to drive PI controller to produce the duty cycle required for the converter. The HS optimization algorithm is used to minimize the objective function given in (1) and then determine the optimal PI controller parameters. HS optimization is used 30 times to obtain the optimal PI controller parameters for each case. The convergences of the first three cases are given in Fig. 4.

The optimized PI controller parameters using HS for the 30 cases proposed are given in Table 2.

Adaptive maximum power technique proposed

The proposed technique PI-HS for MPPT will be compared to P&O and IC methods to study the proposed method's effectiveness. At the standard conditions of 25 °C and 1000 W/m2 (point 26 in the table), the MPP with P&O, IC and PI-HS are plotted in Fig. 6. The performance of the PV system with the proposed technique surplus the performance with P&O and IC methods. There are fluctuations between 33.4 and 34.9 W in power generated from the PV were obtained when using P&O; slight improvement in these fluctuations was attained when using IC as in Fig. 5. The proposed HS-PI reached to the maximum power value of 35 W without any fluctuations.

The performance of the proposed system will be investigated with some changes in environmental conditions. A sudden change in the temperature from 37 to 31 °C and a sudden change in irradiance from 1000 to 800 W/m2 (change from point 30 to point 22 in Table 2) occurs at 1.17 s. The proposed technique gives better performance than P&O and IC techniques in both steady-state and transient intervals, Fig. 6.

MPP with change from point 30 to point 22, defined in Table 2.

The PI controller introduced in this article succeeded in achieving the MPPT with better performance. Another test case will be presented to check if the optimal PI controller parameters determine at certain conditions will satisfy the optimality at other operating conditions or not.

The standard test case (point 26) will be tested with two different values for the optimal PI controllers. The first PI controller, PI-HS-1 is the optimal controller parameters determined at the standard condition (2.497, 13.986), while the second controller PI-HS-2 is the PI control parameters at another point, point 24 as an example, with PI controller parameters of (8.486, 12.548). The PI controller parameters obtained for this case showed better performance and tracking the MPP to a higher level when using PI-HS-1 at which the operating conditions are considered than using PI-HS-2. This calls for changing the PI control parameters for each operating condition Fig. 7. In other words, convert the fixed PI controller parameters into variable ones based on the environmental conditions. This transformation is difficult to be applied practically. This issue had been addressed by adding another technique to the system and implement it practically.

Testing the proposed MPPT algorithm

Experimental verification of P–V and I–V characteristics

Experimental test rig outdoor atrium in is shown Fig. 8. A solar panel is mounted at an optimum angle to get the maximum light at peak hours. An irradiance sensor is mounted at the same angle as the solar panel to get an accurate response. A temperature sensor is placed on the solar panel to get the panel's current temperature and find out its dependency on the temperature.

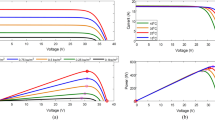

The experimental verification of P–V and I–V characteristics of the solar cell used is given in Fig. 9a,b at 25 °C and 1000 W/m2. This experimental verification is used to verify the simulation and will be used many times at different environmental conditions to determine the voltage at MPP, which is, in turn, the updating the reference voltage (VMPP_ref).

The experimental set-up contains a solar panel, sensors for temperature and irradiance, buck converter, PWM generation and lab-view front panel. The updated duty cycle at MPP and the corresponding temperatures and irradiances are used and added to the Lab-view. At any values of irradiances and temperatures, the optimized duty cycle at MPP is the output from the PWM generation to make the PV system operates at the MPP conditions.

Adaptive MPPT verification

The model is simulated for 30 cases, and each case has a certain temperature and irradiance to get the voltage at MPP from the P–V characteristics. The temperature is taken from 22 to 37 °C with a step of 3 °C while the irradiance is taken from 200 to 1000 W/m2 with a step of 200 W/m2, Table 2. From these data, the reference voltage is updated at each irradiance and temperature.

The modification technique is applied practically by determining the duty cycle required for MPPT corresponding to each operating condition. In other words, the output of PI-HS is determined at each point in Table 2. A new table is formed with the temperature, irradiance and the corresponding duty cycle. This technique is working without using PI controllers, which simplify the system and make it easy to implement.

In order to test the proposed technique for adaptive MPPT, a test setup was developed that was capable of data acquisition in real-time with parameter recording functionality. The block diagram of the system is shown the Fig. 10.

The block diagram shows the logical connections of different blocks of the system. Si-420TC irradiance sensor is used to sense light, which provides 4–20 mA current output, and is compensated by a built-in thermal compensator. Moreover, it has a wide range of spectral responses from 0 to 1200 W/m2. Besides, three-wire RTD is used to monitor solar panels' temperature in a wide range with high accuracy. Furthermore, National Instruments robust and precise current and voltage sensing modules NI9217 and NI9225 are used to monitor input and output parameters. PWM National Instrument X-series card is used for high frequency, which has 100 MHz on board time base for accurate duty cycle control and frequency generation.

The switching circuit is based on a single MOSFET DC-DC buck topology. N-Channel MOSFET is used on high side. Since the gate is at a higher voltage level, a gate driver circuit is used to drive the MOSFET with respect to floating ground. Line fuses are used on both sides of the circuit for protection. A voltage sensor was placed to put recording the input and output values. The schematic is shown in Fig. 11.

The list of components used along with their values is given in Table 3.

LabVIEW is used to develop the main software to test the proposed adaptive algorithm. LabVIEW Front panel shows input and output voltage; temperature, irradiance and power.

The test ring is left for 1 day for about 3 min outdoor, the irradiance and the temperature are recorded as in Fig. 12 using the temperature and irradiances sensors used in the experimental setup shown in Fig. 8.

The system is tested with the proposed adaptive MPPT with an adaptive duty cycle and compared to a fixed duty cycle for driving the DC–DC chopper.

The input and output power for the same environmental conditions, Fig. 13 are given in Fig. 13. The system efficiency with this adaptive duty cycle is improved with values greater than 90%.

Another practical test case for fixed duty cycles is applied and the efficiency of the system will be investigated. For a certain period, the input, output power of PV and the efficiency are recorded. The duty cycle in this case is kept at fixed values not adapted according to the proposed technique. Five values of duty cycles of 0.5, 0.6, 0.7 0.8 and 0.9 are adjusted at each interval, Fig. 14. The system’s maximum efficiency is 84% compared to the range of efficiencies between 91 and 93% when using the adaptive duty cycle as in Fig. 13.

Conclusions

This paper introduced a new adaptive MPP technique for a standalone PV system. This technique is based on updating the reference voltage for MPPT based on the environmental changes including irradiance and temperature. This updated voltage is compared to the PV output voltage and the error is used to drive the DC–DC converter. This error is minimized by harmony search optimization technique. The proposed technique updated the PI controller parameters and consequently the duty cycle required for the converter. The proposed adaptive technique gave a better performance than P&O and IC techniques in terms of system efficiency. An experimental setup is used to simplify the controller by lookup table consisting of the temperature, irradiance, and corresponding duty cycle required for each operating condition to achieve MPPT. Compassion between the proposed adaptive and some fixed values for the duty cycles necessary for MPPT was introduced at every operating point. This comparison proved the effectiveness of the proposed method in MPPT with higher efficiencies.

Abbreviations

- BW :

-

Arbitrary distance bandwidth

- D:

-

Duty cycle

- ev:

-

Error in the voltage between PV voltage and the reference value

- HM:

-

Harmony memory

- HMCR:

-

Harmony memory considering rate

- IC:

-

Incremental conductance

- Isc :

-

Short circuit current

- Im :

-

Current at max. power

- Kp, Ki :

-

PI controller parameters gainn

- MPPT:

-

Maximum power point tracking

- Pm :

-

Maximum power

- PV:

-

Photovoltaic

- P&O:

-

Perturb and observation

- PI:

-

Proportional-integral contoller

- PAR:

-

Pitch adjusting rate

- RES:

-

Renewable energy sources

- rand :

-

Random value between (0, 1)

- RS:

-

Series resistances of PV

- Rp:

-

Shunt resistances of PV

- VOC :

-

Open circuit voltage

- Vm :

-

Voltage at max. power

- VMPP_ref:

-

Updating the reference voltage

References

Tawfiq, A.A.E., El-Raouf, M.O.A., Mosaad, M. I., El-Gawad, A.F.A. & Farahat, M. A. E. Optimal reliability study of grid-connected PV systems using evolutionary computing techniques. IEEE Access. 9, 42125–42139. https://doi.org/10.1109/ACCESS.2021.3064906 (2021).

Samy, M. M., Mosaad, M. I. & Barakat, S. Optimal economic study of hybrid PV-wind-fuel cell system integrated to unreliable electric utility using hybrid search optimization technique. Int. J. Hydrogen Energy 46(20), 11217–11231 (2021).

Abdelsalam, A. K., Massoud, A. M., Ahmed, S. & Enjeti, P. N. High-performance adaptive perturb and observe MPPT technique for photovoltaic-based microgrids. IEEE Trans. Power Electron. 26(4), 1010–1021 (2011).

Hassanein, W. S., Ahmed, M. M., Osama Abed El-Raouf, M., Ashmawy, M. G. & Mosaad, M. I. Performance improvement of off-grid hybrid renewable energy system using dynamic voltage restorer. Alexandria Eng. J. 59(3), 1567–1581 (2020).

PV Power Plants Industry Guide [Online], Solar PV world Expo, China, 16-18 August 2021. http://www.PVresources.com.

Kuo, Y. C., Liang, T. J. & Chen, J. F. Novel maximum-power point tracking controller for photovoltaic energy convertion system. IEEE Ind. Electron. Trans. 48(3), 594–601 (2001).

Xiao, W. & Dunford, W.G. A modified adaptive hill climbing MPPT method for photovoltaic power systems. in Proc.35 Th Annu. IEEE Power Electron. Spec. Conf., 1957–1963 (2004).

Wolfs, P.J. & Tang, L. A single cell maximum power point tracking converter without a current sensor for high performance vehicle solar arrays. in Proc. IEEE 36th Power Electron. Spec. Conf., 165–171 (2005).

Gules, R., De Pellegrin Pacheco, J., Hey, H. L. & Imhoff, J. A maximum power point tracking system with parallel connection for PV standalone applications. IEEE Trans. Ind. Electron. 55(7), 2674–2683 (2008).

Esram, T. & Chapman, P. L. Comparison of photovoltaic array maximum power point tracking techniques. IEEE Trans. Energy Conv. 22(2), 439–449 (2007).

Nicola, F., Giovanni, P. & Giovanni, S. Optimization for perturb and observen maximum power point racking method. IEEE Trans. Power Electron. 20(4), 963–973 (2005).

Patel, H. & Agarwal, V. Investigations into the performance of photovoltaics-based active filter configurations and their control schemes under uniform and non-uniform radiation conditions. IET Renew. Power Gener. 4(1), 12–22 (2010).

Zhang, L., Al-Amoudi, A., & Bai, Y. Real-time maximum power point tracking for grid-connected photovoltaic systems. in Proc. 8th Int. Conf. Power Electron. Variable Speed Drives (IEE Conf. Publ. No. 475), 124–129 (2000).

Patel, H. & Agarwal, V. MPPT scheme for a PV-fed single-phase singlestage grid-connected inverter operating in CCM with only one current sensor. IEEE Trans. Energy Convers. 24(1), 256–263 (2009).

Chiang, M.-L., Hua, C.-C., & Lin, J.-R. Direct power control for distributed PV power system. in Proc. Power Convers. Conf., Osaka, Japan, 311–315 (2002).

Xiao, W. & Dunford, W. G. A modified adaptive hill climbing MPPT method for photovoltaic power systems. in Proc. IEEE 35th Annu. Power Electron. Spec. Conf. Vol. 3, 1957–1963 (2004).

Wolfs, P. J. & Tang, L. A single cell maximum power point tracking converter without a current sensor for high performance vehicle solar arrays. in Proc. IEEE 36th Power Electron. Spec. Conf., 165–171 (2005).

Pandey, A., Dasgupta, N. & Mukerjee, A. K. High-performance algorithms for drift avoidance and fast tracking in solar MPPT system. IEEE Trans. Energy Convers. 23(2), 681–689 (2008).

Easter Selvan, S., Subramanian, S., Theban Solomon, S. Novel Technique for PID Tuning by Particle Swarm Optimization. in Proc.7th Annul. Swarm Users/Researchers Conf. (Swarm Fest 2003) (Notre Dame, 2003).

Markvart, T. Solar Electricity (Wiley, 1994).

Walker, G. Evaluating MPPT converter topologies using a MATLAB PV model. J. Electr. Electron. Eng. Aust. IEAust. 21(1), 49–56 (2001).

Chiu, C. T-S Fuzzy maximum power point tracking control of solar power generation systems. IEEE Energy Conv. Trans. 25, 1123–1132. https://doi.org/10.1109/TEC.2010.2041551 (2010).

Alabedin, A.M.Z., El-Saadany, E.F. & Salama, M.M.A. Maximum power point tracking for photovoltaic systems using fuzzy logic and artificial neural networks. In Proc. 2011 IEEE Power and Energy Society General Meeting 1–9. https://doi.org/10.1109/PES.2011.6039690 (2011).

Bouselham, L., Hajji, M., Hajji, B. & Bouali, H. A new MPPT-based ANN for photovoltaic system under partial shading conditions energy. Procedia 111, 924–933 (2017).

Priyadarshi, N., et al. A fuzzy SVPWM based inverter control realization of grid integrated PV-wind system with FPSO MPPT algorithm for a grid-connected PV/wind power generation system: hardware implementation. IET Electric Power Appl. 12, 962–971 (2018).

Priyadarshi, N., Sharma, A. K. & Azam, F. A hybrid firefly-asymmetrical fuzzy logic controller based MPPT for PV-wind-fuel grid integration. Int. J. Renew. Energy Res. (IJRER) 7(4), 1546–1560 (2017).

Priyadarshi, N., Azam, F., Bhoi, A. K. & Alam, S. An artificial fuzzy logic intelligent controller based MPPT for PV grid utility. In Proceedings of 2nd International Conference on Communication, Computing and Networking. Lecture Notes in Networks and Systems Vol. 46 (eds Krishna, C. et al.) (Springer, 2019). https://doi.org/10.1007/978-981-13-1217-588.

Yang, X.-S., Deb, S. Multi-objective cuckoo search for design optimization. Comput. Oper. Res. 40(6), 1616–1624 https://doi.org/10.1016/j.cor.2011.09.026 (2011).

Yang, X. S. Nature-Inspired Metaheuristic Algorithms (Luniver, 2008).

Viagundamoorthi, M. & Ramesh, R. Experimental investigation of chaos in input regulated solar PV powered buck converter. Int. J. Comput. Appl. 34, 11–16 (2012).

El-Raouf, M.O.A., Mosaad, M.I., Mallawany, A., Al-Ahmar, M.A. & Bendary, F.M.E. MPPT of PV-wind-fuel cell of off-grid hybrid system for a new community. in 2018 Twentieth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 480–487. https://doi.org/10.1109/MEPCON.2018.8635165 (2018).

El-Naggar, M. F., Mosaad, M. I., Hasanien, H. M., AbdulFattah, T. A. & Bendary, A. F. Elephant herding algorithm-based optimal PI controller for LVRT enhancement of wind energy conversion systems. Ain Shams Eng. J. 12(1), 599–608 (2021).

Pervez, I., Malick, I.H., Tariq, M., Sarwar, A. & Zaid, M. A maximum power point tracking method using a hybrid PSO and grey wolf optimization algorithm. in 2019 2nd International Conference on Power Energy, Environment and Intelligent Control (PEEIC), 565–569. https://doi.org/10.1109/PEEIC47157.2019.8976741 (2019).

Pervez, I. et al. Rapid and robust adaptive Jaya (Ajaya) based maximum power point tracking of a PV-based generation system. IEEE Access. 9, 48679–48703. https://doi.org/10.1109/ACCESS.2020.3028609 (2021).

Alhejji, A. & Mosaad, M. I. Performance enhancement of grid-connected PV systems using adaptive reference PI controller. Ain Shams Eng. J. 12(1), 541–554 (2021).

El-Raouf, M. O. A., Mosaad, M. I., Mallawany, A., Al-Ahmar, M. A. & Bendary, F. M. E. MPPT of PV-Wind-Fuel Cell of Off-Grid Hybrid System for a New Community. In 2018 Twentieth International Middle East Power Systems Conference (MEPCON), pp. 480–487 https://doi.org/10.1109/MEPCON.2018.8635165 (2018).

Park, S.-H., Cha, G.-R., Jung, Y.-C. & Won, C.-Y. Design and application for PV generation system using a soft-switching boost converter with SARC. IEEE Trans. Ind. Electron. 57(2), 515–522 (2010).

Mosaad, M. I., Osama Abed El-Raouf, M., Al-Ahmar, M. A. & Banakher, F. A. Maximum power point tracking of PV system based cuckoo search algorithm; review and comparison. Energy Procedia 162, 117–126 (2019).

Mosaad, M. I., Abu-Siada, A. & Elnaggar, M. Application of superconductors to improve the performance of DFIG-based WECS. IEEE Access J. 7(1), 103760–103769 (2019).

Author information

Authors and Affiliations

Contributions

M.I.M. prepare the idea, simulation and results. F.A.B. prepare the practical part.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Banakhr, F.A., Mosaad, M.I. High performance adaptive maximum power point tracking technique for off-grid photovoltaic systems. Sci Rep 11, 20400 (2021). https://doi.org/10.1038/s41598-021-99949-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-99949-8

This article is cited by

-

Arithmetic optimization algorithm based maximum power point tracking for grid-connected photovoltaic system

Scientific Reports (2023)

-

An Intelligent Improvement Based on a Novel Configuration of Artificial Neural Network Model to Track the Maximum Power Point of a Photovoltaic Panel

Journal of Control, Automation and Electrical Systems (2023)

-

Photo-supercapacitors based on nanoscaled ZnO

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.