Abstract

In this work we report the white light emission in transparent Cr:YAG ceramic pellet upon irradiation with focused beam of CW infrared laser diode. It was found that this phenomenon is specifically related to interaction of laser beam with a surface of the pellet. The white light was emitted outside an irradiated spot at the surface of the pellet and did not penetrate inside the pellet. Moreover, the red emission related to two-photon absorption along the laser beam penetrating the Cr3+:YAG pellet was observed. Interaction of the laser beam with the surface of the pellet leads to an efficient white light emission from an outer side of the pellet. The resulting white light emission did not entry back the pellet. Multiphoton ionization leading to intervalence charge transfer followed by light emission was proposed as the mechanism of experimentally observed white light emission.

Similar content being viewed by others

Introduction

Laser induced white emission (LIWE) in rare earth doped oxides excited by focused laser beam in vacuum was reported by Wang and Tanner1. Since then, LIWE was observed in different materials placed in vacuum ambient2,3,4,5,6,7,8. An increase in the ambient pressure was accompanied by a decrease of LIWE intensity, which remained stable up to critical point9,10. The excitation power dependence of LIWE intensity demonstrated a threshold behavior for multiphoton avalanche processes1. Numerous models have been proposed for white light generation in lanthanide-based systems including the intervalence charge transfer (IVCT)9,11, multiphoton absorption12, thermal avalanche13 and others2,14.

Recently we have reported LIWE in transparent Cr:YAG ceramics15,16. In a course of studies we have found that an occurrence of white emission was closely related to the interaction of focused laser beam with the surface of ceramics. In the present study we study the LIWE process in Cr:YAG transparent ceramics under CW IR laser excitation. It was shown that LIWE is the surface related phenomenon and the light is emitted only out of the interaction spot of laser beam and does not penetrate the ceramics.

Experimental

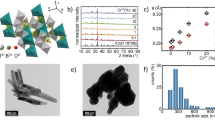

The Cr4+:YAG ceramics was made in Institute for Single Crystals, Kharkiv, Ukraine. The Cr:YAG samples were sintered in vacuum furnace by solid state reaction. High purity High purity reagents: Al2O3 (purity > 99.99%, Baikowski, d = 0.15–0.3 μm), Y2O3 (purity > 99.999%, Alfa Aesar, d = < 10 μm), Cr2O3 (purity > 99.97%, Alfa Aesar, d = < 100 nm), CaO (purity > 99.999%, Sigma Aldrich, d = < 0.1 μm) were used as starting materials. Powders were taken in stoichiometric ratio, concentrations of Ca and Cr were taken in order to replace Y and Al, respectively. Cr2O3 and CaO powders were weighted precisely to obtain chromium and calcium content of 0.1 and 0.5 at.%, respectively9. Homogenization was performed by ball milling for 15 h using high purity Al2O3 balls. The milled slurry was dried for 1 day in air and sieved through a 200-mesh screen. The compacts were prepared by applying isostatic pressing at P = 250 MPa. Sintering was performed at 1750 °C for 50 h using solid state reaction (SSR) in vacuum furnace.

Scheme of the LIWE measurement setup is shown in the Fig. 1. The samples were placed in a vacuum cell connected to EXT75DX turbo molecular vacuum pump with TIC controller (Edwards) to achieve the pressure of 10–4 mbar. To collect the emission spectra, the AVS-USB2000 Avantes Spectrometer was used. Emission spectra were measured using an infrared continuous wave Nd:YAG laser 3,4 W as an excitation source. The spectra were not corrected to the detector sensitivity. In order to protect the CCD camera, FGS900S filter was used for measurement of the power dependence of LIWE intensity. LIWE was measured under P -10–4 Pa. The effect of pressure on the LIWE intensity of Cr:YAG ceramics was studied in our previous work15.

Results and discussion

The measurements of laser induced emission spectra of Cr:YAG ceramics were carried out by exciting the sample in vacuum in different places with a focused laser beam. Round Cr:YAG ceramics pellets with thickness of 1 mm and diameter of 8 mm were taken. The experiments demonstrated that the characteristics of the emission resulting from irradiation of the ceramic pellet depended on the excitation laser power density on the illuminated pellet surface. The photos demonstrating interaction of laser beam with the edge of the pellet for different excitation power densities are shown in Fig. 2. The experiments were also performed for the rectangular sample plate ceramic (see Fig. S1 in Supplementary).

In experiment we have used a focused laser beam with a diameter of excitation spot of 175 µm. For 3.4 W laser power the excitation power density is close to ~ 108 W/m216. In a course of experiments it was found that Cr:YAG ceramics is able to generate the bright LIWE for excitation power density threshold of 0.7 W for focused CW laser beam (1064 nm)15,16. Intense LIWE can be generated at relatively low temperature of the sample (below 50 °C)4. Therefore, the sample temperature can not be responsible for white colour black body emission. LIWE intensity depends sufficiently on the excitation density. A tuning of the laser beam by several tens of micrometers can cause a decrease in the emission intensity by an order of magnitude or its complete disappearance. However, the intense LIWE can be successfully observed over an entire surface of the sample.

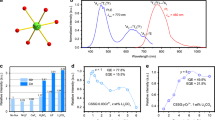

The laser path highlighted in red in the Fig. 2 is caused by Cr3+ emission. When the excitation light was focused on a surface of the sample and its power exceeded certain threshold, the samples generated LIWE. The LIWE was observed on both unpolished (see Fig. 2) and polished (see Fig. S2 in Supplementary) surfaces of the sample. The average intensity of LIWE on the unpolished side was higher than on the polished one. The SEM images of polished and unpolished surfaces have been added to the paper (see Fig. S6). It suggests that the intensity of LIWE depends on the surface roughness. Moreover, when the incident laser beam spot was larger than the spot of incident focused laser beam, the white light emission was not observed. The laser beam entered the pellet leading to red emission with the spectrum assigned to the 4T2g → 4A2g transitions of Cr3+ ions (see Fig. 3). Beforehand, it was shown that when the Cr3+:YAG single crystal was irradiated by a focused infrared laser, strong red emission was observed along direction of irradiation in the volume of the sample12.

The broadband emission spectra for different excitation powers were reported by us earlier12, LIWE spectra under 3.4 W of 1064 nm excitation see on Fig. S5. The excitation power density of the focused laser beam at the excitation spot with diameter D = 0.175 mm was estimated to be 108 W/m2. This value is consistent with the thickness of the red line (0.16 ± 0.03 mm) near the beam entry where LIWE is generated. The shift of the focus deeper into the sample leads to decrease in the excitation density and the disappearance of the white emission at the entry point and, at the same time, increase in the power density at the exit point and the appearance of the white emission after exceeding the threshold. In addition, self-focusing leads to additional focusing of the laser beam in the bulk (see Fig. 3 and relevant text in Supplementary).The thickness of the red line at the entry and exit points is 0.34 ± 0.03 mm and 0.11 ± 0.03 mm, respectively (Fig. S3).

The interaction of the laser beam with the surface of the sample leads to ionization with simultaneous emission of photons and free photoelectrons17. Emission of free electrons is preceded by the multiphoton (N-photon) absorption ionization process. The electron emission rate J related to multiphoton absorption necessary for ionization is described by a simple formula J \(\propto \) IN, where I is the intensity of the incident laser beam18,19. An ionization process is more complex since apart from multiphoton absorption, an avalanche ionization plays a significant role20. Broadband laser induced white emission may be described by intervalence charge transfer (IVCT) transitions following the ionization of Cr3+ ion15 Cr3+ + N ћω → Cr4+ + e- and then IVCT transitions generating the broadband laser induced white emission ν(LIWE) (Cr4+, Cr3+) → (Cr3+, Cr4+) + ν(LIWE) (see Fig. 4)10. A detailed explanation of the role of LIWE phenomenon in the white light emission was reported earlier15,16. The white light was emitted only in an irradiation spot at the side surface of pellet and was emitted off the side surface of pellet, it does not penetrate the pellet. No white light was observed inside the pellet (see Fig. S4 and the video file in the Supplement).

To conclude the emission of white light is surface related phenomenon. The following features of emitted light due to interaction of incident laser beam with the ceramic pellet can be mentioned:

-

1.

Laser beam passing through a pellet leads to the white light emission only from the outer side of pellet.

-

2.

LIWE occurred in opposite direction to laser beam.

-

3.

The self-focusing occurs before the geometrical focus. Laser beam propagating through transparent medium with an effective refractive index determined by nonlinear index of refraction n2 (Kerr effect) n = n0 + n2 I, where I is the intensity of laser beam. The index n2 is positive.

-

4.

Intensity of LIWE strongly depends on the surface roughness being higher for higher roughness.

-

5.

Self-focused laser beam inside the ceramic approaches its edge and becomes a point source of white light emission outside. Such behavior is due to the fact that ionization responsible for white light is preceded by emission of electrons.

The surface plays an important role in inducing LIWE, however, many questions still need more elaborated studies. The IVCT mechanism does not take into account the role of the surface in the LIWE phenomenon. To discuss the role of surface we propose the following model: The laser beam interacts with the surface of the pellet leading to multiphoton ionization assisted by emission of photons and hot electrons. It is known that a number of emitted electrons is higher than a number of emitted phonons. Since electrons cannot penetrate inside the pellet, the ionization process may occur only outside the sample. The processes occurring in the system may be schematically depicted as a sequence of the following processes: multiphoton ionization of Cr3+ → emission of free electrons and formation of Cr4+ → IVCT (Cr3+, Cr4+) → V(LIWE). Moreover, the multiphoton ionization process can lead to generation of the plasma at the LIWE spot via ejection of free electrons preceding photon emission. In conclusion, the main statement of the present work, that LIWE is caused by the ionization process, can occur only outside the bulk, while various possible mechanisms of multiphoton absorption can be proposed for different materials2.

Summary

In the present work we have investigated the laser induced white emission upon irradiation of Cr:YAG transparent ceramic pellet. It was found that the white light was emitted only on the outer side of the pellet surface from a spot irradiated by focused laser beam. The emitted white light did not penetrate inside the ceramic pellet and being emitted from the outer side of pellet surface. For slightly larger excitation spots no white light emission was observed, but only the red light emission assigned to the 4T2g → 4A2g fluorescence of Cr3+ ions due to two photon absorption of 1064 nm laser light. The transmitted laser beam demonstrated self-focusing and an intense white light emission was observed in the exit point.

References

Wang, J. & Tanner, P. A. Upconversion for white light generation by a single compound. J. Am. Chem. Soc. 132(3), 947–949 (2010).

Wu, J., Zheng, G., Liu, X. & Qiu, J. Near-infrared laser driven white light continuum generation: Materials, photophysical behaviours and applications. Chem. Soc. Rev. 49(11), 3461–3483 (2020).

Stefanski, M., Lukaszewicz, M., Hreniak, D. & Strek, W. Laser induced white emission generated by infrared excitation from Eu3+:Sr2CeO4 nanocrystals. J. Chem. Phys. 146(10), 104705 (2017).

Strek, W. et al. White emission of lithium ytterbium tetraphosphate nanocrystals. Opt. Express 19(15), 14083–14092 (2011).

González, F., Khadka, R., López-Juárez, R., Collins, J. & Di Bartolo, B. Emission of white-light in cubic Y4Zr3O12:Yb3+ induced by a continuous infrared laser. J. Lumin. 198, 320–326 (2018).

Tomala, R., Hreniak, D. & Strek, W. Influence concentration of Nd3+ ion on the laser induced white emission of Y2Si2O7:Nd3+. Opt. Mater. 74, 135–138 (2017).

Tomala, R. & Strek, W. Emission properties of Nd3+:Y2Si2O7 nanocrystals under high excitation power density. Opt. Mater. 96, 109257 (2019).

Strek, W., Oleszko, M., Wiewiórski, P., Tomala, R. & Hanulia, T. Coherent white emission of graphene. Appl. Phys. Lett. 116(17), 171105 (2020).

Chaika, M. et al. Influence of Cr doping on the phase composition of Cr, Ca:YAG ceramics by solid state reaction sintering. J. Am. Ceram. Soc. 102(4), 2104–2115 (2019).

Strek, W., Marciniak, L., Hreniak, D. & Lukowiak, A. Anti-Stokes bright yellowish emission of NdAlO3 nanocrystals. J. Appl. Phys. 111(2), 024305 (2012).

Chaika, M., Tomala, R. & Strek, W. Laser induced broadband Vis and NIR emission from Yb: YAG nanopowders. J. Alloys Compd. 865, 158957 (2021).

Chaika, M. et al. Upconversion luminescence in Cr3+:YAG single crystal under infrared excitation. J. Luminesc. 226, 117467 (2020).

Zhu, S. et al. High-efficiency broadband anti-Stokes emission from Yb 3+-doped bulk crystals. Opt. Lett. 41(10), 2141–2144 (2016).

Bilir, G. et al. Broadband visible light emission from nominally undoped and Cr3+ doped garnet nanopowders. IEEE Photonics J. 6(4), 1–11 (2014).

Chaika, M. A., Tomala, R. & Strek, W. Infrared laser stimulated broadband white emission of transparent Cr:YAG ceramics obtained by solid state reaction sintering. Opt. Mater. 111, 110673 (2021).

Chaika, M. & Strek, W. Laser induced broad band white emission from transparent Cr4+:YAG ceramics: Origin of broadband emission. J. Luminesc. 233, 117935 (2021).

Brodeur, A. & Chin, S. L. Ultrafast white-light continuum generation and self-focusing in transparent condensed media. JOSA B 16(4), 637–650 (1999).

Marburger, J. H. Self-focusing: theory. Prog. Quantum Electron. 4, 35–110 (1975).

Shen, Y. R. Self-focusing: experimental. Prog. Quantum Electron. 4, 1–34 (1975).

Keldysh, L. V. Ionization in the field of a strong electromagnetic wave. Sov. Phys. JETP 20(5), 1307–1314 (1965).

Acknowledgements

The authors are grateful to Dr. A.G. Doroshenko and Dr. S.V. Parkhomenko for their help in sintering of the sample. This work was supported by Polish National Science Centre, grant: PRELUDIUM-18 2019/35/N/ST3/01018.

Author information

Authors and Affiliations

Contributions

M.C.: Conceptualization, Methodology, Formal analysis, Investigation, Visualization, Writing—Original Draft, Review & Editing R.T.: Methodology, Writing—Review & Editing W.S.: Writing—Conceptualization, Review & Editing, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary Video 1.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chaika, M., Tomala, R. & Strek, W. Surface related laser induced white emission of Cr:YAG ceramic. Sci Rep 11, 14063 (2021). https://doi.org/10.1038/s41598-021-93638-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-93638-2

This article is cited by

-

Preparation of monophasic YAG raw material by multi-stage process

Discover Applied Sciences (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.