Abstract

We have investigated the crystal structures and mechanical properties of osmium diboride (OsB2) based on the density functional theory. The structures of OsB2 from 0 to 400 GPa were predicted using the particle swarm optimization algorithm structure prediction technique. The orthorhombic Pmmn structure of OsB2 (oP6-OsB2) was found to be the most stable phase under zero pressure and it will transfer to the hexagonal P63/mmc structure (hP6-OsB2) around 12.4 GPa. Meanwhile, we have discovered a new stable orthorhombic Immm structure (oI12-OsB2) above 379.6 GPa. After that, a thorough and comprehensive investigation on mechanical properties of different OsB2 phases is performed in this work. Further studies showed that the hardness of oP6-OsB2 and hP6-OsB2 at zero pressure is 15.6 and 20.1 GPa, while that for oI12-OsB2 under 400 GPa is 15.4 GPa, indicating that these three phases should be potentially hard materials rather than superhard materials. Finally, the pressure–temperature phase diagram of OsB2 is constructed for the first time by using the quasi-harmonic approximation method. Our results showed that the transition pressures of oP6-OsB2 → hP6-OsB2 and hP6-OsB2 → oI12-OsB2 all decreases appreciably with the increase of temperature.

Similar content being viewed by others

Introduction

Hard and superhard materials have attracted considerable attention because of their excellent performance as cutting tools and abrasives. Diamond is an excellent superhard material, but it is difficult to synthesize artificially1,2. Therefore, a lot of efforts have been invested to seek new hard materials in the past several decades. So far, one of the design principle of synthetic hard materials is to add light elements B, C, and N to electron-rich transition metals3, such as ReB24,5,6,7, OsB28,9,10,11,12, WB413,14, PtC15, Re2C16, OsN217, PtN218,19, etc. Among them, the transition-metal borides have attracted considerable attention because of their excellent physicochemical property20,21.

OsB2 as a potential hard material, its structure and internal physical properties have been extensively studied in resent years8,9,10,11,12,22,23,24,25,26,27. To our best knowledge, OsB2 was first synthesized by Cumberland et al.8 through resistive heating method. They found that OsB2 possess the orthorhombic Pmmn structure (oP6-OsB2) at ambient condition, and it is an ultra-incompressible and hard material. It was soon confirmed by Gou et al.22 using first-principles total energy calculations, and showed that oP6-OsB2 is not a superhard material. Later, Gu et al.9 synthesized oP6-OsB2 compounds by arc melting and subsequent annealing method. They found that oP6-OsB2 does not belong to the superhard materials, and its stability can reach up to 34 GPa. Except the oP6-OsB2 phase, other structures of OsB2 have also been predicted by theoretical studies. For example, Hao et al.28 reported that the orthorhombic Pnma structure of OsB2 is thermodynamically and mechanically stable under environmental conditions. Moreover, using first-principles total energy calculations, Chen et al.20 predicted that two hexagonal structures of P63/mmc and P6/mmm were also exist under pressure. Unfortunately, these phases have never been reported experimentally. Until 2014, Xie et al.11 successfully synthesized hP6-OsB2 phase by means of mechanochemical method, and it was found to be stable at ambient conditions. Then, Ren et al.23 investigated the structure stability of OsB2 under pressure through first-principles calculations. It is found that oP6-OsB2 is thermodynamically more stable than hP6-OsB2 at 0 GPa. With the increase of pressure, oP6-OsB2 will transfer to the hP6-OsB2 at 10.8 GPa. Most recently, by using particle swarm optimization algorithm, Feng et al.27 predicted two new high pressure phases Fddd and Cmcm of OsB2 under pressure of 0–100 GPa. But, it is worth noting that the two high-pressure phases were both metastable structures.

As mentioned above, previous studies9,27,28 have predicted several stable OsB2 structures under different pressures. However, the reported stable phases of OsB2 were not in agreement with each other. Furthermore, most of the studies on this problem mainly concentrated in the low pressure stage, and few studies have done on high pressures23,27. So far, the phase stability of OsB2 under pressure up to 400 GPa is still unknown. As a fundamental topic in condensed matter physics, revealing and elucidating the trend and mechanism of material high-pressure structural transformation is of great significance for its potential applications. Therefore, a thorough and comprehensive investigation on the phase stability of OsB2 under high pressure is really necessary. In this work, we explored the crystal structures of OsB2 from 0 to 400 GPa using particle swarm optimization (PSO) algorithm29,30 structure prediction technique. It is found that oP6-OsB2 is the most stable structure at 0 GPa and it will transition to hP6-OsB2 at low pressure range. Meanwhile, the orthorhombic Immm structure (oI12-OsB2) is predicted for the first time under high pressure, and it will be the most stable phase above 379.6 GPa. Furthermore, a comprehensive investigation on mechanical properties of different OsB2 phases also be performed in this work.

Computational details

We performed the structure prediction of OsB2 at selected pressures of 0, 100, 200, 300, and 400 GPa using PSO algorithm29 as implemented in the CALYPSO code30. This method can predict stable or metastable crystal structures based on a given chemical compositions under specific external conditions. So far, it has been successfully applied not only to element solids, but also to binary and ternary compounds31,32,33,34. Moreover, the ab initio optimizations and mechanical properties calculations for every structure generated by the CALYPSO code were performed using the VASP package35 with the PBE generalized gradient approximation36. The electron–ion interactions was dealt with PAW pseudopotentials37 with 5p65d56s2 and 2s22p1 valence configuration for Os and B, respectively. To achieve absolute convergences, the kinetic energy cutoff was set to 800 eV, and the Monkhorst–Pack k-point meshes38 was selected to 8 × 13 × 9 for oP6-OsB2, 16 × 16 × 6 for hP6-OsB2, 15 × 15 × 3 for R-3 m structure (hR9-OsB2), 12 × 12 × 5 for I4/mmm structure (tI6-OsB2), 15 × 15 × 6 for P4/nmm structure (tP6-OsB2), 13 × 15 × 7 for Cmcm structure (oC12-OsB2), and 5 × 15 × 10 for oI12-OsB2. In addition, the phonon dispersion curves were calculated by using the finite displacement method39 within the PHON code40. To ensure that the force calculations were fully convergent, we used 2 × 4 × 3, 3 × 3 × 2, 3 × 3 × 3 supercells for oP6-OsB2, hP6-OsB2, oI12-OsB2 in the calculations. Meanwhile, the 3 × 4 × 3, 4 × 4 × 2, and 3 × 5 × 5 Γ-centered k-point meshes were chosen for oP6-OsB2, hP6-OsB2, and oI12-OsB2 supercells, respectively.

Results and discussion

Structure prediction and dynamical stability

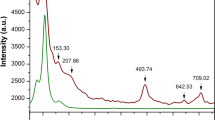

According to the structure search results, oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, and oC12-OsB2 all possess lower enthalpy values under environmental pressure. Among them, oP6-OsB2 (Fig. 1a) is the most stable phase at 0 GPa, which is consistent with previous experimental8,9,26 and theoretical22,23,27 results. Moreover, we found that hP6-OsB2 (Fig. 1b) possesses the lowest enthalpy at the pressures of 100, 200 and 300 GPa. As the pressure increases further, a new oI12-OsB2 (Fig. 1c) structure is discovered for the first time, which is the most stable structure under 400 GPa. The predicted structural parameters of different OsB2 phases under pressure are listed in Table 1. For comparison the available experimental9,26 and theoretical24,25,27 data are also included. As shown, our obtained results agree well with other data, which proves the reliability of this research. In addition, we further evaluated the formation enthalpies of different OsB2 phases at ambient condition by the equation: ∆H = H(OsB2)—H(Os)—2H(B), in which the R-3 m phase for B and the Fm-3 m phase for Os were selected as the reference structures. Our obtained formation enthalpies of oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, oC12-OsB2, and oI12-OsB2 at zero pressure are -0.775, -0.751, -0.531, -0.476, -0.567, -0.633, and 0.910 eV/f.u., respectively. Among them, oP6-OsB2 possesses the minimum formation enthalpy. Moreover, except for the high-pressure phase tI12-OsB2, the formation enthalpies of other structures is all negative, indicating that they are potential metastable structures of OsB2 under environmental conditions.

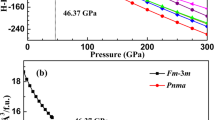

To evaluate the transition pressures of OsB2 at zero Kelvin, the calculated enthalpy differences of hP6-OsB2, hR9-OsB2, tP6-OsB2, and oI12-OsB2 with respect to oP6-OsB2 phase under pressure are provided in Fig. 2. As shown, oP6-OsB2 has lower enthalpy than other structures at 0 GPa, indicating that it is the most stable structure under ambient conditions. Moreover, the pressure-induced transformation from oP6-OsB2 to hP6-OsB2 occurs at about 12.4 GPa, which is in good agreement with the theoretical result of 10.8 GPa23. After that, hP6-ReB2 possesses structure stability in a wide pressure range. As the pressure increases further, the stability of oI12-OsB2 gets enhanced gradually, and it becomes the most stable phase above 379.6 GPa. Thus, the phase transition sequence of OsB2 under pressure should be oP6-OsB2 → hP6-OsB2 → oI12-OsB2. Moreover, the vibrational phonon dispersion curves under a series of pressures are further calculated to assess their dynamic stability. The obtained results at selected pressures are presented in Fig. 3. We found that oP6-OsB2, hP6-OsB2, and oI12-OsB2 do not show any imaginary frequencies under pressure of 0–200, 0–440, and 200–440 GPa, respectively, indicating that these phases should be dynamically stable within the corresponding pressure range. In addition, the equations of state of OsB2 under pressure up to 450 GPa is further evaluated, as shown in Fig. 4. It is obvious that the volume decreases of 1.18% from oP6-OsB2 to hP6-OsB2 and 3.63% from hP6-OsB2 to oI12-OsB2, which means that the pressure-induced structure transitions of OsB2 are first-order rather than continuous.

Mechanical properties

The elastic properties of OsB2 under different pressures are investigated by strain–stress method. Our calculated elastic constants of oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, and oC12-OsB2 under zero pressure are given in Table 2. It is obvious that our obtained results are consistent well with the available theoretical data24,25,27,41. Moreover, the obtained elastic constants of oI12-OsB2 at 400 GPa are also included in Table 2, but unfortunately there is no data can be compared with them. In addition, we can judge the mechanical stability of crystals based on their elastic constant42,43. For hexagonal structures of hP6-OsB2 and hR9-OsB2,

For tetragonal crystals of tI6-OsB2 and tP6-OsB2,

For orthorhombic phases of oP6-OsB2, oC12-OsB2 and oI12-OsB2,

where \(\tilde{C}_{ii} = C_{ii} - P\) (i = 1, 2, 3, 4, 5, 6), \(\tilde{C}_{ij} = C_{ij}\) (i = 1, 2, 3; j = 4, 5, 6), \(\tilde{C}_{12} = C_{12} + P,\) \(\tilde{C}_{13} = C_{13} + P,\) \(\tilde{C}_{23} = C_{23} + P,\) \(\tilde{C}_{45} = C_{45} ,\) \(\tilde{C}_{46} = C_{46} ,\) \(\tilde{C}_{56} = C_{56} .\) After careful check, the calculated elastic constants of oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, oC12-OsB2, and oI12-OsB2 all meet their mechanical stability conditions, which means that these structures should be mechanically stable under the corresponding pressure.

In addition, for all OsB2 structures, the calculated C11, C22, and C33 are obviously larger than other elastic constants, indicating that they should be hard to compress on the a, b, and c axes. As the hardest natural minerals, diamond possesses a high elastic constant C11 of 1079 GPa at ambient conditions44. Interestingly, our obtained C33 of hP6-OsB2 is about 887 GPa at zero pressure, close to the C11 value of diamond, which implies that hP6-OsB2 may also be a hard material. For this reason, we further evaluated the hardness of different OsB2 structures by an empirical model45, which can be expressed as

in which k is equal to G/B. Through Voigt-Reuss-Hill approximation46, the bulk modulus B, and shear modulus G can be calculated by the elastic constants Cij. The obtained results, along with the other theoretical data24,25,27,41, are presented in Table 3. It is obvious that our calculated B and G agree with the available calculated results. Moreover, we can judge the ductility or brittleness of a material by the B/G ratio47. Usually, a material is ductile if B/G > 1.75, or else it is brittle. Under zero pressure, our calculated B/G of oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, and oC12-OsB2 is 1.90, 1.71, 1.50, 1.30, 1.62, and 1.54, respectively. This indicates that oP6-OsB2 is ductile, and the other phases are all brittle under environmental conditions. Meanwhile, the high-pressure phase oI12-OsB2 should be ductile at 400 GPa, because its B/G ratio is greater than the critical value under this pressure.

According to the obtained B and G, we can further calculated Young’s modulus E and Poisson’s ratio σ by

As shown in Table 3, our calculated results are consistent well with the available experimental4 or other calculated data24,25,27,41. Generally, a higher value of E indicates that the material is stiffer, while a smaller value of σ indicates that the covalent bond is more directional. Accordingly, the order of stiffness of OsB2 is tI6 > tP6 > hR9 > hP6 > oC12 > oP6, while the directionality degree of covalent bonds of OsB2 should be tI6 > hR9 > oC12 > tP6 > hP6 > oP6 under ambient conditions. Furthermore, our calculated hardness of oP6-OsB2, hP6-OsB2, hR9-OsB2, tI6-OsB2, tP6-OsB2, and oC12-OsB2 under zero pressure is 15.6, 20.1, 26.0, 34.7, 23.5, and 22.5 GPa, respectively, which agree well with the available experimental4 and theoretical24,25,27,41 results. Meanwhile, the high-pressure phase oI12-OsB2 possesses the hardness of 15.9 GPa at 400 GPa. Usually, the hardness of superhard materials should be higher than 40 GPa48,49. Accordingly, all the OsB2 phases studied above can be used as the candidate for hard materials rather than superhard materials.

Pressure–temperature phase diagram

After established the phase transition sequence of oP6-OsB2 → hP6-OsB2 → oI12-OsB2 under pressure at zero Kelvin. We further investigated the stable region of each phases under high pressure and high temperature through the quasi-harmonic approximation (QHA)50 method. In which, the Helmholtz free energy is given by

where E(V) is the static energy, Fvib(V,T) is the nonequilibrium vibrational Helmholtz free energy

in which g(ω,V) represents phonon density of state. Then, we can get the Gibbs free energy by

Our phonon frequencies calculations in Sect. 3.1 indicates that oP6-OsB2, hP6-OsB2, and oI12-OsB2 are dynamically stable within a large pressure range. Thus, according to the calculated Gibbs free energies of these three phases under different temperatures and pressures, the phase diagram of OsB2 is constructed for the first time, as shown in Fig. 5. It can be seen that temperature has a significant effect on the structural stability of OsB2. With the increase of temperature, the transition pressures of oP6-OsB2 → hP6-OsB2, and hP6-OsB2 → oI12-OsB2 all decreases appreciably. Moreover, oP6-OsB2 is located only in a very small region at the lower left corner of phase diagram, and it will transition to hP6-OsB2 with a temperature of ~ 1000 K at zero pressure. This is consistent with the previous experimental results of 873 K12. Meanwhile, the phase transformation of hP6-OsB2 → oI12-OsB2 occurs at 374.5 GPa under room temperature of 300 K.

Conclusions

We have investigated the structure stability of OsB2 from 0 to 400 GPa through the ab initio PSO algorithm. The phase transition sequence of oP6-OsB2 → hP6-OsB2 → oI12-OsB2 under pressure was established. Through high precision calculations, the transition pressures were determined as 12.4 and 379.6 GPa at zero Kelvin. Phonon frequencies calculations show that oP6-OsB2, hP6-OsB2, and oI12-OsB2 possess dynamical stability under 0–200, 0–440, and 200–440 GPa, respectively. Moreover, the elastic constants and elastic-dependent properties of OsB2 are also successfully investigated. Our calculated hardness suggests that oP6-OsB2, hP6-OsB2, and oI12-OsB2 are both potential hard materials rather than superhard materials. Furthermore, the phase diagram of OsB2 at high pressure and high temperature was constructed for the first time based on the QHA method. Our result shows that the transition pressures of oP6-OsB2 → hP6-OsB2 and hP6-OsB2 → oI12-OsB2 all decreases with the increase of temperature.

References

Brookes, C. A. Plastic deformation and anisotropy in the hardness of diamond. Nature 228, 660 (1970).

Sumiya, H., Toda, N. & Satoh, S. Mechanical properties of synthetic type IIa diamond crystal. Diam. Relat. Mater. 6, 1841 (1997).

Kaner, R. B., Gilman, J. J. & Tolbert, S. H. Designing superhard materials. Science 308, 1268 (2005).

Chung, H. Y. et al. Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure. Science 316, 436 (2007).

Levine, J. B. et al. Preparation and properties of metallic, superhard rhenium diboride crystals. J. Am. Chem. Soc. 130, 16953 (2008).

Zang, C., Sun, H., Tse, J. S. & Chen, C. Indentation strength of ultraincompressible rhenium boride, carbide, and nitride from first-principles calculations. Phys. Rev. B 86, 014108 (2012).

Wang, Y. X., Yan, Z. X., Liu, W. & Zhou, G. L. Novel high pressure structures and mechanical properties of rhenium diboride. J. Appl. Phys. 126, 135901 (2019).

Cumberland, R. W. et al. Osmium diboride, an ultra-incompressible, hard material. J. Am. Chem. Soc. 127, 7264 (2005).

Gu, Q., Krauss, G. & Steurer, W. Transition metal borides: superhard versus ultra-incompressible. Adv. Mater. 20, 3620 (2008).

Yang, J., Sun, H. & Chen, C. Is Osmium Diboride An Ultra-Hard Material?. J. Am. Chem. Soc. 130, 7200 (2008).

Xie, Z. et al. Novel high pressure hexagonal OsB2 by mechanochemistry. J. Solid State Chem. 215, 16 (2014).

Long, Y. et al. Effects of Re addition on phase stability and mechanical properties of hexagonal OsB2. J. Am. Chem. Soc. 101, 151 (2018).

Mohammadi, R. et al. Tungsten tetraboride, an inexpensive superhard material. Proc. Natl. Acad. Sci. U.S.A. 108, 10958 (2011).

Li, X., Tao, Y. & Peng, F. Pressure and temperature induced phase transition in WB4: a first principles study. J. Alloys Compd. 687, 579 (2016).

Ono, S., Kikegawa, T. & Ohishi, Y. A high-pressure and high-temperature synthesis of platinum carbide. Solid State Commun. 133, 55 (2005).

Juarez-Arellano, E. A. et al. Stability field of the high-(P, T) Re2C phase and properties of an analogous osmium carbide phase. J. Alloys Compd. 481, 577 (2009).

Young, A. F. et al. Synthesis of novel transition metal nitrides IrN2 and OsN2. Phys. Rev. Lett. 96, 155501 (2006).

Crowhurst, J. C. et al. Synthesis and characterization of the nitrides of platinum and iridium. Science 311, 1275 (2006).

Gregoryanz, E. Synthesis and characterization of a binary noble metal nitride. Nat. Mater. 3, 294 (2004).

Chen, X. Q., Fu, C. L., Krcmmar, M. & Painter, G. S. Electronic and Structural origin of ultraincompressibility of 5d transition-metal diborides MB2 (M=W, Re, Os). Phys. Rev. Lett. 100, 196403 (2008).

Levine, J. B., Tolbert, S. H. & Kaner, R. B. Advancements in the search for superhard ultra-incompressible metal borides. Adv. Func. Mater. 19, 3519 (2009).

Gou, Y. et al. First-principles study of low compressibility osmium borides. Appl. Phys. Lett. 88, 221904 (2006).

Ren, F. Z., Wang, Y. X. & Lo, V. C. Pressure induced structural phase transition of OsB2: First-principles calculations. J. Solid State Chem. 183, 915 (2010).

Wang, Y. C. et al. Structural and relative stabilities, electronic properties and possible reactive routing of osmium and ruthenium borides from first-principles calculations. Dalton Trans. 42, 7041 (2013).

Zhong, M. M. et al. Phase stability, physical properties, and hardness of transition-metal diborides MB2 (M = Tc, W, Re, and Os): first-principles investigations. J. Phys. Chem. C 117, 10643 (2013).

Zheng, X. et al. Role of MgO on densification and mechanical properties in spark plasma sintered Os0.9Re0.1B2 ceramic. Ceram. Int. 44, 16302 (2018).

Feng, S. et al. Structural, elastic, electronic and hardness properties of osmium diboride predicted from first principles calculations. J. Alloys Compd. 844, 156098 (2020).

Hao, X., Xu, Y. & Gao, F. Electronic and elastic properties of new semiconducting oP12-type RuB2 and OsB2. J. Phys. Condens. Matter 23, 125501 (2011).

Wang, Y. C., Lv, J., Zhu, L. & Ma, Y. M. Crystal structure prediction via particle-swarm optimization. Phys. Rev. B 82, 094116 (2010).

Wang, Y. C., Lv, J., Zhu, L. & Ma, Y. M. CALYPSO: a method for crystal structure prediction. Comput. Phys. Commun. 183, 2063 (2012).

Deng, J., Guo, J. G. & Chen, X. L. Molecular Oxygen-induced ferromagnetism and half-metallicity in α-BaNaO4: a first-principles study. J. Am. Chem. Soc. 142, 5234 (2020).

Zhu, L. Carbon-boron clathrates as a new class of sp3-bonded framework materials. Sci. Adv. 6, 8361 (2020).

Li, X. F. & Peng, F. Superconductivity of pressure-stabilized vanadium hydrides. Inorg. Chem. 56, 13759 (2017).

Zhang, H. Y. First-Principles predictions of phase transition and mechanical properties of tungsten diboride under pressure. J. Phys. Chem. C 121, 7397 (2017).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6, 15 (1996).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Parlinski, K., Li, Z. Q. & Kawazoe, Y. First-principles determination of the soft mode in cubic ZrO2. Phys. Rev. Lett. 78, 4063 (1997).

Alfè, D. PHON: A program to calculate phonons using the small displacement method. Comput. Phys. Commun. 180, 2622 (2009).

Zhang, M. G., Yan, H. Y., Zhang, G. T. & Wang, H. Ultra-incompressible orthorhombic phase of osmium tetraboride (OsB4) predicted from first principles. J. Phys. Chem. C 116, 4293 (2012).

Wu, Z. J. Crystal structures and elastic properties of superhard IrN2 and IrN3 from first principles. Phys. Rev. B 76, 054115 (2007).

Sin’ko, G. V. & Smirnov, N. A. Relative stability and elastic properties of hcp, bcc, and fcc beryllium under pressure. Phys. Rev. B 71, 214108 (2005).

McSkimin, H. J., Andreatch, P. & Glynn, P. The elastic stiffness moduli of diamond. J. Appl. Phys. 43, 985 (1972).

Chen, X., Niu, H., Li, D. & Li, Y. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics 19, 1275 (2011).

Hill, R. The elastic behaviour of a crystalline aggregate. Proc. Phys. Soc. A 65, 349 (1952).

Pugh, S. F. X. C. I. I. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos. Mag. 45, 823 (1954).

Solozhenko, V. L. & Gregoryanz, E. Synthesis of superhard materials. Mater. Today 8, 44 (2005).

Gilman, J. J. Chemistry and Physics of Mechanical Hardness (Wiley, 2009).

Otero-de-la-Roza, A., Abbasi-Pérez, D. & Luaña, V. Gibbs2: A new version of the quasiharmonic model code: II: models for solid-state thermodynamics, features and implementation. Comput. Phys. Commun. 182, 2232 (2011).

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant Nos. 11904282, 11805151, and 12005166, the Doctoral Scientific Research Foundation of Xi’an University of Science and Technology under Grant No. 2018QDJ029, and the Natural Science Foundation of Shaanxi Provincial Department of Education under Grant No. 20JK0764.

Author information

Authors and Affiliations

Contributions

Y.-X.W. conceived the research. Y.-X.W. and Y.-Y.L. performed atomic and electronic structure calculations. Y.-X.W., Y.-Y.L., Z.-X.Y., W.L., G.-L.Z., and K.-Z.X. analyzed the numerical results. Y.-X.W. wrote the manuscript and all the authors commented on it.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Y.X., Liu, Y.Y., Yan, Z.X. et al. Crystal structures and mechanical properties of osmium diboride at high pressure. Sci Rep 11, 5754 (2021). https://doi.org/10.1038/s41598-021-85334-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-85334-y

This article is cited by

-

Ceramic transition metal diboride superlattices with improved ductility and fracture toughness screened by ab initio calculations

Scientific Reports (2023)

-

Phase stability, mechanical properties and thermal conductivity of technetium diborides in different crystal structures

Applied Physics A (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.