Abstract

A carefully designed ammonium sulfate precipitation will simplify extraction of proteins and is considered to be a gold standard among various precipitation methods. Therefore, optimization of ammonium sulfate precipitation can be an important functional step in protein purification. The presence of high amounts of ammonium sulphate precludes direct detection of many enzymatically active proteins including reducing sugar assays (e.g. Nelson-Somogyi, Reissig and 3,5-dinitrosalicylic acid methods) for assessing carbohydrases (e.g. laminarinase (β (1–3)-glucanohydrolase), cellulases and chitinases). In this study, a simple method was developed using laminarin infused agarose plate for the direct analysis of the ammonium sulphate precipitates from Streptomyces rimosus AFM-1. The developed method is simple and convenient that can give accurate results even in presence of ammonium sulfate in the crude precipitates. Laminarin is a translucent substrate requiring the use of a stain to visualize the zones of hydrolysis in a plate assay. A very low-cost and locally available fluorescent optical fabric brightener Tinopal CBS-X has been used as a stain to detect the zones of hydrolysis. We also report simple methods to prepare colloidal chitin and cell free supernatant in this manuscript.

Similar content being viewed by others

Introduction

β-glucans are non-starch polysaccharides which serve a nutritional as well as structural role in algae, plants and fungi. β-glucanases are the enzymes which act upon β-glucans. Laminarin, a type of β-glucan, is the long-term carbon storage polysaccharide found in marine brown macroalgae and consists of β-(1–3) linked glucose molecules interspersed with β-(1–6) intrachain linkages, and 6-O-branching1. Laminarin is structurally and chemically similar to the β-glucans found in the fungal cell wall and is used to immunize plants against fungal pathogens2,3. Consequently, laminarin is often used as a substrate to evaluate the fungal cell wall-active enzymes4.

Glucanases are important in biological pest control, bioremediation, food industry, production of fungal spheroplast and to produce ethanol5,6,7,8,9. Further, β-glucanases, especially the ones that hydrolyze laminarin (Laminarinase; EC 3.2.1.6) have been shown to be an integral part of antifungal defense and offense mechanisms of plants and microbes10,11,12,13. Additionally, many microbial biocontrol agents are laminarinase producers14. Therefore, detection and measurement of laminarinase activity is an important activity for research and commercial purposes.

Ammonium sulfate (AS), a member of the Hofmeister series, continues to be the gold standard among various protein precipitation methods. Except for a few exceptions, AS precipitation is the mildest protein precipitation methods available and does not cause large scale denaturation/loss of activity of proteins15. Also, the presence of AS has a stabilizing effect on the proteins and is germicidal. Thus, AS precipitation is often used as a preliminary step in majority of protein purification schemes. This step concentrates the target protein, thereby reducing the sample volume by several folds16.

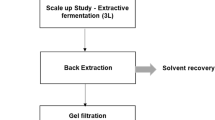

Historically, AS had been the reagent of choice for the precipitation and extraction of laminarinase8,17,18,19,20,21,22. Consequently, a large bulk of literature describe AS precipitation as the preliminary step in protein purification. In the recent times, there is a predictable shift towards cloning of laminarinase gene in recombinant hosts1,22,23,24,25. Based on a survey of the literature, the strategies for the extraction and purification of laminarinase can broadly be classified into the following categories:

-

(i)

AS precipitation of the supernatant followed by chromatographic methods of purification (gel filtration, ion exchange, affinity and hydrophobic interaction)8,17,18,19,20,21,22.

-

(ii)

Concentration of the supernatant using membrane-based concentrators (e.g. tangential flow filtration device and stirred cell concentrators) followed by chromatographic methods of purification26,27,28,29,30,31.

-

(iii)

Recombinant protein expression and purification by chromatographic methods1,22,23,24,25.

All the three strategies have their own advantages and disadvantages, but strategies (ii) and (iii) stand out for their substantial weaknesses. For example, in strategy (ii), a substantial investment must be made for acquiring and operating the tangential flow filter and stirred cells with ultrafiltration membrane. The devices are expensive and, also require repeated purchase of membrane material and tangential flow capsule (TFC). Similarly, substantial time, skilled manpower and investment are required for strategy (iii). Despite the drawbacks, recombinant expression of proteins is an unavoidable and most preferred step in protein structural studies by X-ray crystallography or protein NMR spectroscopy1,32.

Being a non-specific low-resolution method, AS precipitation results in the co-precipitation of contaminating proteins along with the target protein33,34. A certain degree of selectivity could be achieved with AS precipitation if the precipitation profile of the target protein at various salt concentrations is known16. Although, enzymes can easily be analyzed using plate assays, direct evaluation of enzyme precipitates containing AS using a plate assay was not attempted until now.

AS interferes with most of the biochemical assays like total reducing sugar assays, colorimetric protein estimation assays and SDS-PAGE. Dialysis step is thus an unavoidable hindrance after AS precipitation16. The AS precipitation profile of a new/novel protein is usually unknown. Hence, optimization of the AS concentration would involve a large number of samples that need to be dialyzed35. This is an impediment, especially for the untrained workers.

In this study, it is demonstrated that the laminarin plate assay is not perturbed by the presence of AS in the non-dialyzed samples. This was achieved by comparing the plate assay results with that of the reducing sugar assay (3,5-Dinitrosalicylic acid (DNS) assay) of the dialyzed samples. An easily available optical fabric brightener (OFB) Tinopal CBS-X (Disodium 4,4′-bis (2-sulfostyryl) biphenyl) has been used to stain the laminarin plate. Congo red (CR) staining, which has been the cornerstone of polysaccharide-based plate assays, is compared with the OFB staining36.

To the best of our knowledge, this is the first report for the use of OFB for staining laminarin infused agarose plate using the laminarinase enzyme from an actinomycete (Streptomyces rimosus AFM-1).

Materials and methods

Materials

Ammonium sulphate, 3,5-dinitrosalicylic acid (DNS), powdered shrimp chitin, yeast extract powder, malt extract powder and other ingredients used in the preparation of colloidal chitin minimal salts (CCMS) broth were purchased from HiMedia laboratories Pvt. Ltd., Mumbai, India. Laminarin derived from Laminaria digitata and 12 kDa cutoff dialysis tubing were procured from Sigma-Aldrich chemicals Pvt. Ltd., Bengaluru, India. Concentrated hydrochloric acid was procured from Merck life science Pvt. Ltd., Mumbai, India. Carboxymethyl cellulose (CMC) was procured from Sisco Research Laboratories Pvt. Ltd., Mumbai, India. An actinomycete strain AFM-1 isolated from marine sediment sample from Udupi district, Karnataka, India was used in this study. AFM-1 was identified as Streptomyces rimosus based on phenotypic and 16SrDNA sequencing by National Chemical Laboratory (NCL), Pune, India (GenBank accession No. MT604984). Tinopal CBS-X (generic) and 280 g per square meter (GSM) 65/35 polyester-cotton blend laboratory coat clothing material (LCCM) were procured from the local market. Erma ESM11 stage micrometer and eye-piece graticule were procured from Erma Inc., Tokyo, Japan.

Methods

Determination of average Feret’s pore diameter of LCCM

Stage micrometer and an eyepiece graticule were used to calibrate a compound microscope at 40X magnification. The stage micrometer was replaced with the LCCM and pictures were taken. ImageJ software (National Institutes of Health (NIH), USA) was used to analyze the images37. The picture with stage micrometer and eyepiece graticule aligned with each other was used to set the scale (“known distance” function with μm as the unit) in ImageJ. Oval or freehand selection tools were used to manually select the pores in the LCCM pictures. The Feret’s diameters and other dimensional parameters were calculated using the “measure” function of ImageJ38.

Three different pictures of LCCM and 97 individual pores were analyzed in a similar manner. The results were compiled and the final average Feret’s diameter and standard deviation were calculated.

Preparation of colloidal chitin (CC)

To circumvent the requirement for large volume centrifugation, a filtration apparatus assembled from locally available materials was used for the preparation of CC and cell free supernatant (CFS). LCCM of 280 GSM was used as the filter element. 10 g of powdered shrimp chitin was treated with 100 mL of concentrated 37% w/w hydrochloric acid in a glass beaker kept in a tray filled with cold water. The resultant highly viscous mixture was manually stirred every 5 min with a glass rod for 30 min. The slurry was slowly added to two liters of chilled distilled water with concomitant mixing for 15 min39. This thick suspension was passed through the filtering apparatus with LCCM as the filtering element (Fig. 1A,B). The filtration apparatus was setup as depicted in Fig. 1A. The filtration element of the apparatus comprised of a piece of LCCM of sufficient dimensions. A porcelain Buchner funnel (5.6″ diameter) with fixed perforated plate was used for the preparation of CC. The LCCM was fixed to the Buchner funnel using rubber bands.

Apparatus used for the preparation of colloidal chitin (CC) and cell free supernatant (CFS). (A) The components of the lab coat clothing material (LCCM) based filtration apparatus. (B) Filtration setup used for the preparation of CC. Note: A tray was used to collect the liquid dripping from the LCCM due to wicking. (C) Buchner funnel was replaced with a glass funnel for the preparation of CFS.

After the water was drained, the CC paste was collected from the LCCM and resuspended in distilled water and filtered as before. This process was repeated till the pH of CC was near neutral. Then the paste was sterilized by autoclaving and stored at 4 °C until further use.

Production of laminarinase

Streptomyces rimosus AFM-1 was used to co-produce chitinase and laminarinase enzymes by submerged fermentation. Spore suspensions were prepared from 15 days old yeast extract malt extract glucose (YEME) agar slants. The sporulated slats were gently washed with 5 mL of sterile distilled water containing 0.01% Tween 20 and the suspension was filtered through a sterile custom-made glass wool filter to remove large particles. Custom-made glass wool filter consisted of a 15 mL polypropylene tube filled with glass wool and with a small hole in the bottom of the tube to collect the filtrate. Final spore count was adjusted to 1 × 106 spore mL−1 using a Neubauer chamber under light microscope. The inoculum size was 1% and fermentation was carried out in 500 mL Erlenmeyer flasks containing 150 mL of CCMS broth medium with the following composition (L−1) 2.803 g K2HPO4, 1.893 g KH2PO4, 1.5 g NaCl, 3 g yeast extract, 0.5 g MgSO4.5H2O, 0.01 g FeSO4.7H2O, 0.001 g ZnSO4, 25 g moist CC and pH 7.0. The fermentation was carried out for 5 days at 28 °C in a shaker incubator set at 150 RPM. CFS was prepared by separating the cell mass using the LCCM based filtering apparatus as described earlier. A glass funnel was used for the preparation of CFS (Fig. 1C). Filtration apparatus and LCCM used for the preparation of CFS were sterilized in an autoclave for 20 min before use.

Ammonium sulfate precipitation and dialysis

All steps were performed at 4 °C unless otherwise stated. Fifty milliliters of CFS was used for precipitation with different concentrations of AS. Required quantity of solid AS was slowly added with concomitant mixing using a magnetic stirrer. The AS treated solutions were kept undisturbed for either 20 min (short term incubation; STI) or 3 h (long time incubation; LTI) or 8 h (extended time incubation; XTI). Protein pellet was collected by centrifugation at 4032xg for 30 min. The resultant protein pellets were dissolved in 800 μl of 50 mM potassium phosphate buffer (pH6.5) and either directly used for plate assay (laminarin and carboxy methyl cellulose (CMC)) or dialyzed for the reducing sugar assay. For the dialyzed samples, protein solutions containing AS were dialyzed against 50 mM potassium phosphate buffer (pH6.5) with three successive buffer changes over the period of 12 h using a 12 kDa cutoff membrane tubing. The dialyzed solutions were carefully collected, and their volumes measured.

Estimation of laminarinase activity by reducing sugar assay

The laminarinase activity was estimated using a modified protocol of Zhu et al., 2008 with 0.3% laminarin in 50 mM potassium phosphate buffer (pH 6.5) as the substrate40. The activity was analyzed after 37 °C for 180 min incubation of reaction mixture containing 0.25 mL of substrate and 0.25 mL of enzyme solution. Formation of reducing sugars was quantified by the 3,5-dinitrosalicylic acid (DNS) method by measuring the color change at 540 nm using a microplate reader41. Non incubated reaction mixture served as the blank. Assays were carried out in triplicates. One unit of laminarinase activity is defined as the amount of enzyme that catalyzes the liberation of reducing sugar equivalent to 1 µM d-glucose per minute under standard assay conditions. One unit of chitinase activity is defined as the amount of enzyme that catalyzes the liberation of reducing sugar equivalent to 1 µM N-acetyl-d-glucosamine (GlcNAc) per minute under standard assay conditions.

Estimation of laminarinase by plate assay

Plate assays were carried out in petri dish of either 3.9″ (Figs. 2A,B, 3A,B) or 5.9″ diameter (Figs. 2C, 4A,B). Two plate assay methods were used. For laminarin infused agarose method, plates were prepared as per Michalko et al., 2013 with modifications42. The following components (100 mL−1) were prepared in 50 mM potassium phosphate buffer (pH 6.5) and used for the plate assay: 0.15 g laminarin and 0.8 g agarose. For CMC plate assay method, laminarin was replaced with 0.5% CMC. The agarose was melted by heating and poured into petri dish to achieve a thickness of approximately 5 mm. After cooling, wells of 6 mm diameter were cut into the agarose gel using a cork borer and 50 μl of protein precipitate solutions from various AS treatment groups were added to the wells. The plates were incubated at 37 °C for 4 h. After the incubation period, the plates were stained for 15 min with freshly prepared 0.15% Tinopal CBS-X in distilled water. The plates were destained with distilled water for 20 min and observed under UV light (365 nm). Assays were carried out in triplicates. CR staining of the laminarin plate was performed with a 0.1% solution of CR for 15 min, destained twice for 15 min with 1 M NaCl and observed under white light43.

Demonstration of selectivity and reliability of laminarin plate assay. (A) 90% saturation ammonium sulfate (AS) precipitate heat treated for 20 min in a boiling water bath (1); 90% saturation AS precipitate non-heat treated (2). (B) Heat treated (1) and non-heat treated (2) 90% saturation AS precipitate in a 0.5% carboxymethyl cellulose (CMC) agarose plate. (C) Precipitates from various treatment groups (40%-90% AS) tested in a 0.5% CMC agarose plate. 40% (1); 50% (2); 60% (3); 70% (4); 80% (5) and 90% (6). Staining protocol and other parameters for CMC plate assay were same as the laminarin plate assay.

Superior resolution of optical fabric brightener (OFB) vs. congo red (CR) as a stain for the laminarin plate assay. Short Time Incubation (STI) samples (60%-90% AS treatment) were used as the enzyme source. (A) Plate stained with OFB and observed under UV light. Boiled sample 90% (1); 60% (2); 70% (3); 80% (4); and 90% (5). (B) Plate stained with CR and observed under white light. Boiled sample 90% (1); 60% (2); 70% (3); 80% (4); and 90% (5).

Representative images of laminarinase plate assay for Short Time Incubation (STI) samples (30%-90% AS treatment). (A) Laminarinase plate under visible white light. 30% (1); 40% (2); 50% (3); 60% (4); 70% (5); 80% (6) and 90% (7). (B) Laminarinase plate under UV light (365 nm). 30% (1); 40% (2); 50% (3); 60% (4); 70% (5); 80% (6) and 90% (7).

The zones of hydrolysis were measured using a scale ruler. Pictures of the laminarin and CMC plates (white light and UV) were captured. Heat denatured samples prepared by boiling the AS protein precipitate solution at 100 °C for 20 min was used as control.

Results

Preparation of CC and CFS

The 280 GSM 65/35 polyester-cotton blend LCCM was analyzed using ImageJ tool and its average Feret’s diameter was found to be 94.63 ± 7.04 μm37.

LCCM had excellent filtering properties, was rugged and could be reused indefinitely for the preparation of CC and CFS. It took approximately 5 min to filter 1liter of CFS and 20 min to filter 2 L of CC slurry. The need for large volume centrifugation facility was avoided by using the LCCM based filtering apparatus. The resultant creamy white colored CC had a soft, pasty consistency with a moisture content of 92–95%. The Buchner funnel was replaced with a glass funnel for the preparation of CFS. A single layer of LCCM was sufficient for the filtration of CC and the fermented broth. The yields of CC and CFS were 93 ± 1.25% and 90 ± 1.47% respectively.

Production of laminarinase, ammonium sulfate precipitation, dialysis and reducing sugar assay

Streptomyces rimosus AFM-1 exhibited pellet growth during submerged fermentation. The productivity of chitinase and laminarinase on the 5th day of fermentation were 11.76 ± 0.86 UmL−1 and 13.66 ± 1.24 UmL−1 respectively.

The volume of the dialyzed samples increased with increasing AS concentration. The volumes of 90% AS samples were approximately double that of the 40% AS samples. The highest enzyme titers were obtained at 90% AS saturation in STI samples. The enzyme titers across the treatment groups reduced with increasing AS precipitation time and this pattern was similar in both plate assay as well as the reducing sugar assay (Figs. 5, 6).

Estimation of laminarinase by plate assay

The selectivity and reliability of laminarin plate assay was tested by incubating the AS precipitates in CMC infused plates that were stained with the OFB. No zones of hydrolysis could be detected with either the native or the boiled samples (Fig. 2B,C). Further, boiled enzyme solutions failed to induce zones of hydrolysis in the laminarin plate (Fig. 2A).

The OFB staining protocol used in this study was compared with the CR staining method43. Laminarin plates stained with CR had very poor contrast and the bright yellow colored zones of hydrolysis as described in other works of research were missing (Fig. 3B)42,44. OFB stain in the laminarin plates was stable for at least 48 h at room temperature. The activity pattern of the various AS treatment groups was clearly represented in the laminarin plate assay (Fig. 4B) and was confirmed by the reducing sugar assay of the dialyzed samples (Fig. 5). The loss of activity with increasing AS precipitation incubation times resulted in reduced zones of hydrolysis (Fig. 6).

Discussion

Preparation of CC and CFS usually involve large volumes of liquids which need to be centrifuged45,46. Large volume centrifugation facilities may not be available in many research laboratories. Filtration is an economical operation compared to large volume centrifugation.

A wide array of filtration elements were used by researchers for the preparation of CC and CFS. Some of the commonly used filtration elements are filter paper, cheesecloth, Miracloth (Calbiochem) and coffee filter paper47,48. Filter paper is fragile, non-reusable and has very low filtration rate. When compared to the LCCM, cheese cloth has relatively larger pore size and a small portion of CC is lost during the filtration48. Also, cheesecloth does not have the durability of the LCCM. Although perfectly suited for the filtration job, Miracloth costs approximately US$89 for a 4.5 m roll in India. Just like the filter paper, coffee filter paper is fragile and cannot be reused. Moreover, coffee filter paper is not widely available in India48.

Under these circumstances, a filtration apparatus made from locally available materials was assembled to circumvent the large volume centrifugation step in the preparation of CC and CFS (Fig. 1). The most important component of this apparatus is the filtering element which is a piece of laboratory coat clothing material (LCCM) of sufficient dimensions to completely cover the funnel. A wide variety of fabric materials are used in the manufacturing of laboratory coat including 100% cotton, cotton-synthetic blends of various proportions and 100% synthetic fabric. Propriety synthetic fibers (e.g. Nomex) are also used for specific purposes. Although, 65/35 polyester-cotton blend was used in this study, LCCM made of 40/60 and 80/20 polyester-cotton blend are also commonly used as they are lightweight, resist wrinkles, and durable57.

Buchner funnel was replaced with a glass funnel as it is bulky and consumed more space during sterilization. The use of LCCM for the preparation of CFS is more suitable for fungi and actinomycetes which have pelleted growth in submerged fermentation49,50. A single layer of LCCM was found to be sufficient for filtering CC and the fermented broth. Although, not used in this study, a vacuum pump could optionally be used to expedite the process. Some of the advantages of LCCM are as follows:

-

i)

Durability and rugged nature

-

ii)

Very high filtration rate

-

iii)

Reusable

-

iv)

Economical

-

v)

No leakage of CC and microbial cell mass (no bleeding)

The superior functionality of the LCCM as a filter element was abundantly demonstrated not only by the observations listed above, but also a simple wash with soap and water was enough to rejuvenate the LCCM for reuse.

A major disadvantage with the optimization of AS precipitation is that it requires careful handling while dispensing protein solution into and out of the dialysis bag. Any discrepancies will result in either the accidental loss of sample or dilution of the protein solution with buffer. Consequently, the results will be inaccurate. Additionally, performing dialysis for a large number of samples is laborious. Performing a reducing sugar assay after the dialysis step adds to the complexity and time factor of the scheme16.

Plate assays can be used to evaluate enzymes, but the use of translucent substrates, such as laminarin, requires the use of a stain to detect the zone of hydrolysis42,51,52,53. Traditionally, CR has been used as a stain to detect the zone of hydrolysis in (1–3) (1–4)-β-d-glucans, O-(hydroxyethyl) cellulose (HEC), and xyloglucan. Surprisingly, CR is a poor stain for CMC and laminarin due to narrow bathochromic shift (< 20 nm)36,54. So, a robust and highly selective staining method for laminarin plate assay is required.

An easily available OFB Tinopal CBS-X has been used as a stain in this study. Generic, 99% pure, OFB used in this study costs just US$2 for 100 g. Tinopal CBS-X in the form of a commercial formulation (Ranipal) had been previously used to detect chitinase activity in agarose plate52. Ranipal is an admixture of bluing agent and Tinopal CBS-X manufactured by Pidilite Industries Ltd., Mumbai, India. Ranipal is not suitable for staining laminarin plate as the bluing agent reduces the contrast55.

A plate assay which is not affected by the presence of AS would simplify the optimization process. Such an idea was the primary motivation for this work. We have demonstrated the reliability and usability of laminarin infused agarose plate assay for the direct quantification of the laminarinase enzyme without the dialysis step. A simple and economical OFB stain was used to visualize the zones of hydrolysis. CR staining is the method of choice for the staining of carbohydrate polymers, but is not recommended for the quantification of laminarin due to narrow bathochromic shift36. Consequently, our initial study with CR staining provided poor contrast and inability to properly measure the zones of hydrolysis (Fig. 3B). The OFB used in this study provides better resolution in comparison to CR staining (Fig. 3A). Recently, chromogenic laminarin substrate has also been synthesized56. A summary and comparison of various assay methods for laminarinase enzyme is provided in Table 1.

The correlation between the zone sizes and enzyme titer was confirmed by reducing sugar assay of the dialyzed samples (Fig. 5). Further, boiled enzyme solution failed to induce zones of hydrolysis in the laminarin plate (Fig. 2A), thus clearly demonstrating its usability. As discussed earlier, Ranipal is not a good choice for the staining of the laminarin plate and is difficult to procure due to limited availability.

In the AS infused CFS, a pattern of progressive reduction in the enzyme activity was seen with the increasing incubation period (i.e. 20 min > 3 hr > 8 hr). This pattern was clearly documented in both plate assay as well as the reducing sugar assay (Figs. 5, Fig. 6). Reduction of the laminarinase activity with increasing AS incubation time indicates possible aggregation or denaturation of the laminarinase15. This is an important parameter in deciding the optimal time of precipitation for AS infused samples.

Conclusion

A set of simple, robust and economical methods for the preparation of CC, CFS and for the direct quantification of laminarinase was developed.

References

Qin, H. M. et al. Laminarinase from Flavobacterium sp. reveals the structural basis of thermostability and substrate specificity. Sci. Rep. 7, 11425 (2017).

Aziz, A. et al. Laminarin elicits defense responses in grapevine and induces protection against Botrytis cinerea and Plasmopara viticola. Mol. Plant-Microbe Interact. 16, 1118–1128 (2003).

Klarzynski, O. et al. Linear β-1,3 glucans are elicitors of defense responses in tobacco. Plant Physiol. 124, 1027–1037 (2000).

Nagpure, A., Choudhary, B., Kumar, S. & Gupta, R. K. Isolation and characterization of chitinolytic Streptomyces sp. MT7 and its antagonism towards wood-rotting fungi. Ann. Microbiol. 64, 531–541 (2014).

Ueki, A., Takehara, T., Ishioka, G., Kaku, N. & Ueki, K. Production of β-1,3-glucanase and chitosanase from clostridial strains isolated from the soil subjected to biological disinfestation. AMB Express 9, 114 (2019).

Yang, S. Q., Xiong, H., Yang, H. Y., Yan, Q. J. & Jiang, Z. Q. High-level production of β-1,3–1,4-glucanase by Rhizomucor miehei under solid-state fermentation and its potential application in the brewing industry. J. Appl. Microbiol. 118, 84–91 (2015).

Scott, J. H. & Schekman, R. Lyticase : Endoglucanase and protease activities that act together in yeast cell lysis. J. Bacteriol. 142, 414–423 (1980).

Jose, D., Jayesh, P., Gopinath, P., Mohandas, A. & Bright Singh, I. S. Potential application of beta-1, 3 glucanase from an environmental isolate of Pseudomonas aeruginosa MCCB 123 in fungal DNA extraction. Indian J. Exp. Biol. 52, 89–96 (2014).

Harun, R. & Danquah, M. K. Enzymatic hydrolysis of microalgal biomass for bioethanol production. Chem. Eng. J. 168, 1079–1084 (2011).

Gupta, P., Ravi, I. & Sharma, V. Induction of β-1,3-glucanase and chitinase activity in the defense response of Eruca sativa plants against the fungal pathogen Alternaria brassicicola. J. Plant Interact. 8, 155–161 (2013).

DelaCruz, J., Pintor-Toro, J. A., Benitez, T., Llobell, A. & Romero, L. C. A novel endo-β-1,3-glucanase, BGN13.1, involved in the mycoparasitism of Trichoderma harzianum. J. Bacteriol. 177, 6937–6945 (1995).

Choudhary, B., Nagpure, A. & Gupta, R. K. Fungal cell-wall lytic enzymes, antifungal metabolite(s) production, and characterization from Streptomyces exfoliatus MT9 for controlling fruit-rotting fungi. J. Basic Microbiol. 54, 1295–1309 (2014).

Lee, S. Y. et al. Biocontrol of anthracnose in pepper using chitinase, β-1,3 glucanase, and 2-furancarboxaldehyde produced by Streptomyces cavourensis SY224. J. Microbiol. Biotechnol. 22, 1359–1366 (2012).

Lim, H. S., Kim, Y. S. & Kim, S. D. Pseudomonas stutzeri YPL-1 genetic transformation and antifungal mechanism against Fusarium solani, an agent of plant root rot. Appl. Environ. Microbiol. 57, 510–516 (1991).

Rahman, M. A., Choi, Y. H., Pradeep, G. C. & Yoo, J. C. An ammonium sulfate sensitive chitinase from Streptomyces sp. CS501. Arch. Pharm. Res. 37, 1522–1529 (2014).

Duong-Ly, K. C. & Gabelli, S. B. Chapter Seven- Salting out of proteins using ammonium sulfate precipitation. Methods Enzymol. 541, 85–94 (2014).

Holten, V. Z. & Bartnicki-Garcia, S. Intracellular β-glucanase activity of Phytophthora palmivora. BBA Enzymol. 276, 221–227 (1972).

Sena, A. R. et al. Production, purification and characterization of a thermostable β-1,3-glucanase (laminarinase) produced by Moniliophthora perniciosa. An. Acad. Bras. Cienc. 83, 599–609 (2011).

Kumagai, Y. & Ojima, T. Isolation and characterization of two types of β-1,3-glucanases from the common sea hare Aplysia kurodai. Comp. Biochem. Physiol. 155, 138–144 (2010).

Lee, K. C. et al. Purification and characterization of a thermostable laminarinase from Penicillium rolfsii c3–2(1) IBRL. BioResources 9, 1072–1084 (2014).

Kobayashi, T., Uchimura, K., Kubota, T., Nunoura, T. & Deguchi, S. Biochemical and genetic characterization of β-1,3 glucanase from a deep subseafloor Laceyella putida. Appl. Microbiol. Biotechnol. 100, 203–214 (2016).

Mitsuya, D. et al. Enzymatic properties and the gene structure of a cold-adapted laminarinase from Pseudoalteromonas species LA. J. Biosci. Bioeng. 126, 169–175 (2018).

Badur, A. H., Ammar, E. M., Yalamanchili, G., Hehemann, J. H. & Rao, C. V. Characterization of the GH16 and GH17 laminarinases from Vibrio breoganii 1C10. Appl. Microbiol. Biotechnol. 104, 161–171 (2020).

Westphal, A. H., Geerke-Volmer, A. A., van Mierlo, C. P. M. & van Berkel, W. J. H. Chaotropic heat treatment resolves native-like aggregation of a heterologously produced hyperthermostable laminarinase. Biotechnol. J. 12, 1700007 (2017).

Becker, S., Scheffel, A., Polz, M. F. & Hehemann, J. H. Accurate quantification of laminarin in marine organic matter with enzymes from marine microbes. Appl. Environ. Microbiol. 83, e03389-e3416 (2017).

Yang, J., Xu, Y., Miyakawa, T., Long, L. & Tanokura, M. Molecular basis for substrate recognition and catalysis by a marine bacterial laminarinase. Appl. Environ. Microbiol. 86, e01796-e1820 (2020).

Méndez-Líter, J. A., De Eugenio, L. I., Prieto, A. & Martínez, M. J. The β-glucosidase secreted by Talaromyces amestolkiae under carbon starvation: A versatile catalyst for biofuel production from plant and algal biomass. Biotechnol. Biofuels 11, 123 (2018).

Villalba, M. L., Mazzucco, M. B., Lopes, C. A., Ganga, M. A. & Sangorrín, M. P. Purification and characterization of Saccharomyces eubayanus killer toxin: Biocontrol effectiveness against wine spoilage yeasts. Int. J. Food Microbiol. 331, 108714 (2020).

Hemavathi, A. B. & Raghavarao, K. S. M. S. Membrane processing for purification and concentration of β-glycosidases from barley (Hordeum vulgare). Biotechnol. Bioprocess Eng. 16, 282–290 (2011).

Fiske, M. J., Tobey-Fincher, K. L. & Fuchs, R. L. Cloning of two genes from Bacillus circulans WL-12 which encode 1,3-β-glucanase activity. J. Gen. Microbiol. 136, 2377–2383 (1990).

Ventom, A. M. & Asenjo, J. A. Purification of the major glucanase of Oerskovia xanthineolytica LL-G109. Biotechnol. Tech. 4, 165–170 (1990).

Ilari, A. et al. Crystal structure of a family 16 endoglucanase from the hyperthermophile Pyrococcus furiosus: Structural basis of substrate recognition. FEBS J. 276, 1048–1058 (2009).

Okur, H. I. et al. Beyond the Hofmeister series: Ion-specific effects on proteins and their biological functions. J. Phys. Chem. B 121, 1997–2014 (2017).

Green, A. A. & Hughes, W. L. Protein fractionation on the basis of solubility in aqueous solutions of salts and organic solvents. Methods Enzymol. 1, 67–90 (1955).

Park, S. R., Lim, C. Y., Kim, D. S. & Ko, K. Optimization of ammonium sulfate concentration for purification of colorectal cancer vaccine candidate recombinant protein GA733-Fck isolated from plants. Front. Plant Sci. 6, 1040 (2015).

Wood, P. J., Erfle, J. D. & Teather, R. M. Use of complex formation between congo red and polysaccharides in detection and assay of polysaccharide hydrolases. Methods Enzymol. 160, 59–74 (1988).

Rueden, C. T. et al. Image J2: ImageJ for the next generation of scientific image data. BMC Bioinformatics 18, 529 (2017).

Mazzoli, A. & Favoni, O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technol. 225, 65–71 (2012).

Hsu, S. C. & Lockwood, J. L. Powdered chitin agar as a selective medium for enumeration of actinomycetes in water and soil. Appl. Microbiol. 29, 422–426 (1975).

Zhu, B. W. et al. Purification and partial characterization of a novel β-1,3-glucanase from the gut of sea cucumber Stichopus japonicus. Process Biochem. 43, 1102–1106 (2008).

Ghose, T. K. Measurement of cellulase activities. Pure Appl. Chem. 59, 257–268 (1987).

Michalko, J. et al. Glucan-rich diet is digested and taken up by the carnivorous sundew (Drosera rotundifolia L.): Implication for a novel role of plant β-1,3-glucanases. Planta 238, 715–725 (2013).

Teather, R. M. & Wood, P. J. Use of Congo red-polysaccharide interactions in enumeration and characterization of cellulolytic bacteria from the bovine rumen. Appl. Environ. Microbiol. 43, 777–780 (1982).

Li, X. H., Bhaskar, R., Yang, H. J., Wang, D. & Miao, Y. G. Screening and identification of new isolate: Thermostable Escherichia coli with novel thermoalkalotolerant cellulases. Curr. Microbiol. 59, 393–399 (2009).

Agrawal, T. & Kotasthane, A. S. Chitinolytic assay of indigenous Trichoderma isolates collected from different geographical locations of Chhattisgarh in Central India. Springerplus 1, 73 (2012).

Yamashita, Y. & Okazaki, K. Purification and antifungal activity of recombinant chitinase from Escherichia coli carrying the family 19 chitinase gene of Streptomyces sp. J-13–3. Biosci. Biotechnol. Biochem. 68, 2193–2196 (2004).

Li, H. M., Sullivan, R., Moy, M., Kobayashi, D. Y. & Belanger, F. C. Expression of a novel chitinase by the fungal endophyte in Poa ampla. Mycologia 96, 526–536 (2004).

Murthy, N. & Bleakley, B. Simplified method of preparing colloidal chitin used for screening of chitinase- producing microorganisms. Internet J. Microbiol. 10, 1–5 (2012).

Kim, J. H. & Hancock, I. C. Pellet forming and fragmentation in liquid culture of Streptomyces griseus. Biotechnol. Lett. 22, 189–192 (2000).

Veiter, L., Rajamanickam, V. & Herwig, C. The filamentous fungal pellet—relationship between morphology and productivity. Appl. Microbiol. Biotechnol. 102, 2997–3006 (2018).

Velasquez, L. & Hammerschmidt, R. Development of a method for the detection and quantification of total chitinase activity by digital analysis. J. Microbiol. Methods 59, 7–14 (2004).

Anil, K., Seshagirirao, K. & Podile, A. R. A simple, rapid and yet less expensive method to detect chitinase in agarose plates. J. Biochem. Biophys. Methods 70, 683–684 (2007).

Meddeb-Mouelhi, F., Moisan, J. K. & Beauregard, M. A comparison of plate assay methods for detecting extracellular cellulase and xylanase activity. Enzyme Microb. Technol. 66, 16–19 (2014).

Wood, P. J. The use of dye-polysaccharide interactions in β-d-glucanase assay. Carbohydr. Res. 94, 19–23 (1981).

Sashidhar, R. B., Kosuri, T. & Nayak, S. Rapid detection of proteins on one-dimensional polyacrylamide gel electrophoresis using an inexpensive fluorescent optical brightener. Biochem. Anal. Biochem. 5, 293 (2016).

Kračun, S. K. et al. A new generation of versatile chromogenic substrates for high-throughput analysis of biomass-degrading enzymes. Biotechnol. Biofuels 8, 70 (2015).

University of Alabama in Huntsville (UAH). UAH Laboratory Personal Protective Equipment. https://www.uah.edu/images/administrative/policies/support-documents/07.07.04_Lab_PPE_2013.pdf (2013).

Acknowledgements

We acknowledge Manipal College of Pharmaceutical Sciences (MCOPS), Manipal Academy of Higher Education (MAHE), Manipal, India for infrastructure and support. We also acknowledge the help rendered by Ms. Aboli Bhingarkar, an undergraduate student in our department for her help in the initial stages of this research work.

Funding

The study was supported by Department of Biotechnology, Ministry of Science and Technology, Government of India (project ID: BT/PR10827/AAQ/3/661/2014).

Author information

Authors and Affiliations

Contributions

A.K. conceptualized the work, conducted experiments, analysed results, and drafted the manuscript. N.V.P. analysed samples and results. J.M.A. provided critical biochemicals, analysed results, and participated in the conception of the work. R.C.H. Provided critical suggestions and thoroughly reviewed the manuscript. S.V.M. reviewed the manuscript and provided the funding. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Koteshwara, A., Philip, N.V., Aranjani, J.M. et al. A set of simple methods for detection and extraction of laminarinase. Sci Rep 11, 2489 (2021). https://doi.org/10.1038/s41598-021-81807-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-81807-2

This article is cited by

-

Antibiotic resistance profiling and valorization of food waste streams to starter culture biomass and exopolysaccharides through fed-batch fermentations

Food Science and Biotechnology (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.