Abstract

High quality FeySe1−xTex epitaxial thin films have been fabricated on TiO2-buffered SrTiO3 substrates by pulsed laser deposition technology. There is a significant composition deviation between the nominal target and the thin film. Te doping can affect the Se/Te ratio and Fe content in chemical composition. The superconducting transition temperature Tc is closely related to the chemical composition. Fe vacancies are beneficial for the FeySe1−xTex films to exhibit the higher Tc. A 3D phase diagram is given that the optimize range is x = 0.13–0.15 and y = 0.73–0.78 for FeySe1−xTex films. The anisotropic, effective pining energy, and critical current density for the Fe0.72Se0.94Te0.06, Fe0.76Se0.87Te0.13 and Fe0.91Se0.77Te0.23 films were studied in detail. The scanning transmission electron microscopy images display a regular atomic arrangement at the interfacial structure.

Similar content being viewed by others

Introduction

In 2008, Kamihara et al.1 first discovered the iron-based superconductor LaO1−xFxFeAs, which has a superconducting critical temperature of 26 K. Subsequently, Hsu et al.2 reported that the binary superconductor FeSe with antifluorite planes has the transition temperature of 8 K. Through the applied pressure on the samples, the transition temperature can reach ~ 37 K3,4. Ge et al.5 reported a superconducting transition temperature above 100 K in single-layer FeSe film grown on Nb-doped SrTiO3 (STO) substrate by molecular beam epitaxy method. Due to its simple crystal structure, this binary FeSe system with higher Tc is available, which has attracted tremendous interest in exploring the mechanism of high-temperature superconductivity6,7,8. Generally, the FeSe layer is responsible for the superconductivity and the paired electrons are mainly 3d electrons of Fe ions. Meanwhile, the FeSe layers exhibit electrical neutrality, and the atoms between the layers are bonded together by van der Waals9,10. However, the same structure as FeTe does not show superconducting behavior. Yeh et al.11 found that when Te atoms are replaced by partially substituted Se atoms, the antiferromagnetic can be suppressed and its superconductivity is induced with a superconducting transition temperature of 15 K. In bulk crystals, the optimal Te content to achieve the highest Tc is considered to be x ≈ 0.6, and phase separation occurs in the region of 0.1 ≤ x ≤ 0.312. Liu et al.13 have studied the electronic and magnetic phase diagram of Fe1.02SexTe1−x single crystal superconductors. They showed that the phase diagram contains three regions, namely long-range antiferromagnetic order with a wave vector (π, 0) in region I (0 ≤ x < 0.09), neither long-range antiferromagnetic order nor bulk superconductivity in Region II (0.09 < x < 0.29) and the evidence of bulk superconductivity with the Tc about 14.5 K in Region III (x ≥ 0.29). The phase diagram of FeSe1−xTex films on CaF2 substrates showed that the maximum value of Tc is as high as 23 K at x = 0.2, and a sudden suppression of Tc is observed at 0.1 < x < 0.2, whereas Tc increases with decreasing x for 0.2 ≤ x < 114. The interface effect between film and substrate makes it possible to obtain the FeySe1−xTex films with high transition temperature in a metastable phase. Although researchers have done many studies on superconducting mechanism of Fe(Se, Te) films that prepared by pulsed laser deposition (PLD), the bidirectional effect of chemical composition on the superconductivity of FeySe1−xTex films is uncertain15,16,17,18,19. In this paper, we have prepared polycrystalline targets with different nominal composition to grow FeySe1−xTex films and did a detailed investigation on the superconducting properties and its phase diagram. The experimental results show that there is a significant deviation between the nominal composition of targets and the real composition of films. The increase of Te doping can have an impact not only on Se/Te ratio but also Fe content. The electrical transport results indicate that the optimal range of Te and Fe content is x = 0.13–0.15 and y = 0.73–0.78 for FeySe1−xTex films with excellent superconductivity. As x = 0.13, y = 0.76, the maximum of zero-resistivity temperature Tc0max of film is over 17 K and the critical current density Jc is higher than 106 A/cm2 at 4 K. Moreover, STEM images reveal that the interface region of FeySe1−xTex/TiO2/SrTiO3 heterostructure is sharp and clean, and no obvious atomic diffusion and migration are detected.

Results and discussion

In the published papers14,20,21,22,23, authors usually defined the nominal composition of the targets as the real composition of FeySe1−xTex films. However, the deviation between the nominal composition and the real composition may affect the study on the mechanism of superconductivity for FeySe1−xTex films. We determined the real composition of films by EDX mapping in SEM technology. Our experimental results show that there is a significant deviation between the nominal composition and the real composition in two groups, as shown in Tables 1 and 2. At the first, we fixed the content of Fe and adjusted the amount of Te doping in targets (nominal composition in Table 1). EDX results show that Te doping can have an impact not only on Se/Te ratio but also the Fe content in films. The optimal chemical composition may play an important role in films with the excellent superconducting property. Base on this result, we measured the superconducting properties of these films and gave them in the following text. To explore the effect of Fe content on the superconductivity of FeySe1−xTex films, we fixed the Se/Te ratio and change the Fe doping in the nominal composition, as shown in Table 2. It can be seen that the change of Fe doping in the nominal composition also affects the Fe content in the real composition, but has little influence on the ratio of Se/Te. During the deposition, the transfer and growth rate of Fe/Se/Te elements are different, which may result in the obvious deviation of chemical composition between target and film. Therefore, we think that it is inaccurate to directly define the nominal composition of the targets as the real composition of the films.

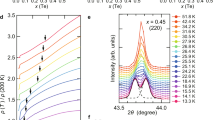

The semilogarithmic XRD patterns of FeySe1−xTex films are shown in Fig. 1. From Fig. 1, only FeySe1−xTex and TiO2 peaks are observed along the c-axis (00l), which indicates the FeySe1−xTex films to be the single tetragonal phase. Our previous work confirmed that TiO2 as a buffer layer could increase the lattice match between Fe(Se, Te) film and STO substrate, so as to enhance the superconducting property of Fe(Se, Te) film24. We find that with increasing Te doping, the (00l) peaks significantly shift to a low angle. The c-axis lattice parameters for FeySe1−xTex films are obtained by fitting the (001) peak, as listed in Table 1. The ionic radius of Te (Te2−, 221 pm) is larger than that of Se (Se2−, 198 pm)25. Te doping can increase the distance between the Fe plane and Se/Te atom (hFe-Se/Te), which increases the c-axis lattice parameters. Zhuang et al.26 and Imai et al.27 have reported the effect of chemical composition on the structure in FeSe1−xTex films. In our results, the increase of Te doping in targets can also raise the Fe content in FeySe1−xTex films. For y > 1 in Table 1, we think that the additional Fe may be incorporated in the inter-layer of Fe-Se/Te space. Thus, Fe content plays a part in the change of lattice parameter. Zhuang et al.22 assumed that two key factors affected the lattice parameters of thin films under the Fe-deficient conditions. The ionic radius of Fe is smaller than that of Se and Te. Fe vacancy phase leads to a smaller c-axis lattice parameter, while Se/Te interstitial phase leads to a larger c-axis in comparison with the stoichiometric phase. For Table 2, with increasing the Fe doping, the c-axis lattice parameter of films increases. The above results show that the superconducting structures of FeySe1−xTex films are not changed with 0.63 < y < 1.43, whereas Te and Fe doping jointly influence the c-axis lattice parameter.

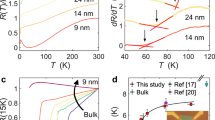

Figure 2a shows the temperature dependence of the normalized resistivity ρ/ρ300K (ρ-T) for the FeySe1−xTex films. For 0.03 ≤ x ≤ 0.23 in Fig. 2a, as the temperature above the superconducting transition, the films only display metallic behavior. However, for x > 0.23, the resistivity of films changes from semiconducting to metallic before superconducting transition. This change may attribute to the structural phase transition and magnetic phase transition caused by Te doping. If we define the point of intersection of the two lines as the normal-state resistivity ρn, as shown in the inset of Fig. 2a, the onset transition temperature Tconset and zero-resistivity temperature Tc0 are obtained from these ρ-T curves where the resistivity is 90% and 1% of the normal state resistivity ρn, respectively. The values of Tconset and Tc0 for these films are listed in Table 1 and plotted in the 3D phase diagram, as shown in Fig. 2c. With increasing the Te doping, the Tc rises at first and then decreases. From Fig. 2c, the Fe0.76Se0.87Te0.13 film exhibits the higher Tconset and Tc0 about 18.95 K and 17.34 K, respectively. Surprising us, the composition of the Fe0.76Se0.87Te0.13 film is not consistent with that of the single crystal, where the highest Tc is considered x ≈ 0.6 in Fe(Se1−xTex)0.82 polycrystal sample, and located at the phase separation region of 0.1 ≤ x ≤ 0.312. They argued that the single-phase of Fe(Se1−xTex)0.82 single crystals with the region of 0.1 ≤ x ≤ 0.3 were not easy to obtain. However, Imai et al.14 assumed that the single-phase epitaxial films of FeSe1−xTex with 0.1 ≤ x ≤ 0.4 could be successfully prepared on CaF2 substrates, attributing to the strain effect between film and substrate. Due to the different substrates, there is a difference in the suppression of phase separation and giant enhancement of Tc for FeySe1−xTex films. Our experimental results display that the sudden suppression of Tc is observed at 0.03 ≤ x < 0.13, whereas Tc increases with decreasing x for 0.13 ≤ x < 0.56. The superconductivity is related to the Te and Fe content in FeySe1−xTex films. Therefore, we must consider the effects of Fe vacancies on the superconductivity of FeySe1−xTex films. Figure 2b shows the temperature dependence of the normalized resistivity ρ/ρ300K (ρ-T) near the optimal composition FeySe1−xTex films, where x ~ 0.15 and y ~ 0.76. The results demonstrate the effects of Fe vacancies on the superconductivity of FeySe1−xTex films. The Tconset and Tc0 are listed in Table 2 and plotted in the 3D phase diagram of Fig. 2b. Although we do not know why the Tconset and Tc0 increase with decreasing the Fe content near y = 0.76, the transition width broadens much more. This result further confirms that the optimal range is x = 0.13–0.15 and y = 0.73–0.78 for the FeySe1−xTex films.

(a,b) Temperature dependence of resistivity from 2 to 300 K for FeySe1−xTex thin films. (a) (x, y) = (0.03, 0.63), (0.06, 0.72), (0.13, 0.76), (0.23, 0.91), (0.34, 1.09) and (0.56, 1.43). Inset: enlarged plot for the definition of normal-state resistivity ρn. (b) (x, y) = (0.15, 0.73), (0.13, 0.76) and (0.16, 0.78). Inset: the enlarged ρ-T curve near Tc. (c) Sketch of the proposed temperature doping 3D phase diagram for FeySe1−xTex superconducting system, showing regions of superconductivity (SC), flux flow (FF) and normal state (NS).

Figure 2c is a new 3D phase diagram for the FeySe1−xTex films. The blue open symbols are the projection of experimental points on the xy-plane at Tc ≈ 1 K. The 3D phase diagram can be divided into three regions by Tconset(x, y) and Tc0(x, y) curved surfaces, which are superconductivity (SC), flux flow (FF), and normal state (NS), respectively. Above the Tconset(x, y) curved surfaces, the FeySe1−xTex film is in the normal state. Below the Tc0(x, y) curved surfaces, the FeySe1−xTex film is in a superconducting state. Between the Tconset(x, y) and Tc0(x, y) curved surfaces, the FeySe1−xTex film is in the flux flow state. The 3D phase diagram demonstrates that the phase separation is absent, and that the optimal composition for the FeySe1−xTex film on STO substrate is not x ≈ 0.5 and y = 1 but x ~ 0.13 and y ~ 0.76. It should be noted that the dependence of Tc on x suddenly changes at the boundary defined by 0.03 ≤ x < 0.13 in our experiment. Thus, not only the decrease of Tc with x ≥ 0.13 can be explained by the empirical law that shows the relation between Tc and structural parameters, but also the sudden suppression of Tc in films with 0.03 ≤ x < 0.13 can be explained by the orthorhombic distortion results in a suppression of Tc. As reported by Imai et al.14, the orthorhombic distortion is applicable to the behavior of films, if a large orthorhombic distortion is observed only in films with 0 < x < 0.1, which is consistent with our result of 0.03 ≤ x < 0.13. Chen et al.28 and Bendele et al.29 pointed out that a few Fe vacancies were beneficial to improve the superconductivity and raised the superconducting transition temperature for FeySe1−xTex films. The inhomogeneous distribution of Fe vacancies can induce the Fe disorder effect in FeySe1−xTex films with y < 1. The first-principles calculation also showed that the Fe vacancies could effectively increase the number of electron carriers and change the electronic properties in samples22. Therefore, in this experiment, the highest Tconset and Tc0 occur near y = 0.76. When the Te and Fe content exceed the optimal composition, the Tconset and the Tc0 of FeySe1−xTex films decrease. For example, as x = 0.56, y = 1.43, the ρ does not down to 1% ρn, so the Fe1.43Se0.44Te0.56 film only has the Tconset about 8.03 K.

To understand the new phase diagram, we have measured the electrical transport and magnetization properties for FeySe1−xTex films in magnetic field. Here, we choose some typical results in the next part. Figure 3a,b present the temperature dependence of resistivity of Fe0.76Se0.87Te0.13 film in various magnetic fields up to 9 T applied perpendicular and parallel to the c-axis. With increasing the applied magnetic field, the resistive transition is broadened. At the same field, the width of superconducting transition ΔTc for H//c is larger than that for H//ab. This result indicates that the FeySe1−xTex films are anisotropic near Tc.

If we define the onset transition temperature Tconset as the critical temperature Tc, namely the field is the upper critical field Hc2, we can get the temperature of the upper critical field near Tc. The H-T phase diagram for Fe0.72Se0.94Te0.06, Fe0.76Se0.87Te0.13 and Fe0.91Se0.77Te0.23 films is shown in Fig. 4a. The temperature dependence of the upper critical field Hc2 near Tc follows the formula \(H_{c2} (T) = H_{c2} (0)(1 - T/T_{c} )^{n}\), where Hc2 (0) and n are parameters obtained from the experimental data. The parameters Hc2(0) and n near Tc for (1) Fe0.72Se0.94Te0.06, (2) Fe0.76Se0.87Te0.13 and (3) Fe0.91Se0.77Te0.23 films, respectively, are (1) 67.9 T and 0.63 for H//ab, 46.6 T and 0.78 for H//c; (2) 91.8 T and 0.54 for H//ab, 82.5 T and 0.57 for H//c; and (3) 77.4 T and 0.71 for H//ab, 60.2 T and 0.53 for H//c. The result implies that the upper critical field Hc2 depends on Te and Fe content. The higher upper critical field Hc2 located at x = 0.13–0.15 and y = 0.73–0.78 for FeySe1−xTex films. From Fig. 4a, we can get the temperature dependence of the anisotropic factor γ = Hc2ab/Hc2c near Tc, as shown in Fig. 4b. We can see that the γ value decreases with decreasing temperature. \(\gamma_{{T_{c} }}\) for Fe0.72Se0.94Te0.06, Fe0.76Se0.87Te0.13 and Fe0.91Se0.77Te0.23 films are estimated about 3.3, 1.9 and 1.6, respectively. Increasing Te doping can inhibit its anisotropy and enhance the correlation between Fe-Se/Te layers, leading to the increasing the dimensionality of Fermi surface, which is conducive to the transmission of electrons along the c-axis direction.

The effective pining energy is an important parameter to enhance the capacity of carrying current for superconducting materials. According to the thermally activated flux flow (TAFF) theory, the lnρ–1/T in the TAFF region can be described using an Arrhenius relation30, \(\rho = \rho_{0} \exp \left( { - \frac{{U_{0} }}{{{\rm K}_{B} {\rm T}}}} \right)\) where U0 is the effective pinning energy. Figure 5a,b shows the linear relationship between lnρ and 1/T of the Fe0.76Se0.87Te0.13 film. From the absolute slope of lnρ − 1/T curves, we can obtain the effective pinning energy U0 of Fe0.72Se0.94Te0.06, Fe0.76Se0.87Te0.13 and Fe0.91Se0.77Te0.23 films, respectively, as shown in Fig. 5c. It can be found that the U0 value of Fe0.76Se0.87Te0.13 is larger than that of Fe0.72Se0.94Te0.06 and Fe0.91Se0.77Te0.23 in the same field. What’s more, U0 values for H//ab plane are much higher than that for H//c, indicating the flux pinning is anisotropic. The magnetic field dependence of U0 follows a power low U0 (H) ~ H-α. When H//ab, the parameter α decreases with increasing the Te doping. The parameter α for the Fe0.76Se0.87Te0.13 and Fe0.91Se0.77Te0.23 films is close. For H//c, there is an obvious crossover occurred at H ≈ 2 T. Below 2 T, the parameter α is close to 0.15. Above 2 T, α is close to 0.5. Similar behavior has been observed in other superconductors30,31,32,33,34. In the field below 2 T, the pinning energy U0 is weakly dependent on the applied magnetic field H. It can be considered that the number of magnetic flux lines is much less than the number of pinning centers. The single vortex pinning dominates in this region35. As the magnetic field increases above 2 T, more flux lines enter the superconductor and the flux spacing becomes smaller, which leads to the pinning energy being inhibited. The pinning energy U0 becomes strongly dependent on the field H. and the collective creep pinning is dominant in this region36,37.

The critical current density Jc is also an important parameter for high quality epitaxial superconducting films. To study the effect of chemical composition on the critical current density of FeySe1−xTex films, we have measured the magnetization hysteresis loops in fields parallel to the c-axis from 0 to ± 9 T. Figure 6 shows the M-H loops of Fe0.91Se0.77Te0.23 film at various temperatures. The M-H loops show symmetric field dependence. As the field increases, the magnetization of film decreases. The critical current density Jc is estimated from the M-H loops by the Bean critical state model38: \(J_{c} = 20\frac{\Delta M}{{a(1 - a/3b)}}\). Where △M = M(+) − M(−), M( +) and M(−) are the magnetizations when sweeping fields up and down, respectively. a and b (a < b) are the FeySe1−xTex film’s cross-sectional dimension. The field dependence of the critical current density Jc at various temperatures is shown in Fig. 7. From Fig. 7a–c, we can see that with increasing the Te doping, the field dependence of the critical current density Jc improves at higher field region. In addition, the measured critical temperature Tc in Fe0.76Se0.87Te0.13 is higher than that in Fe0.91Se0.77Te0.23. The calculated Jc at 4 K and 0 T for Fe0.72Se0.94Te0.06, Fe0.76Se0.87Te0.13, Fe0.91Se0.77Te0.23 films are about 4.46 × 105 A/cm2, 4.51 × 106 A/cm2 and 4.05 × 106 A/cm2, respectively. This result displays that the higher Tc also contributes to improving the magnetic field dependence of Jc at 4 K. Therefore, the optimal composition is beneficial for FeySe1−xTex films exhibiting excellent superconductivity in lower field region.

Magnetic field dependence of critical current density Jc at various temperatures for (a) Fe0.72Se0.94Te0.06, (b) Fe0.76Se0.87Te0.13, and (c) Fe0.91Se0.77Te0.23 thin films. (d) Normalized flux pinning force versus reduced magnetic field at 11, 12 and 13 K for Fe0.76Se0.87Te0.13 thin film. Solid line is the fitting curve using the Dew-Hughes model.

Flux pinning force can provide a very efficient route to descript the vortex dynamics in superconductors39,40. Furthermore, we calculated the field dependence of the flux pinning force Fp = μ0H × Jc for temperatures at 11, 12 and 13 K, respectively. Based on the theory of Dew-Hughes41, the field dependence of the normalized vortex pinning force fp should follow the expression \(f_{p} = Ah^{p} (1 - h)^{q}\), where h = H/Hirr, p and q are parameters that depend on the pinning centers. Figure 7d gives the relationship of normalized vortex pinning force fp and reduced magnetic field h for Fe0.76Se0.87Te0.13 film. By fitting the fp-h curves, we obtain p = 0.67, q = 2.45, and hmax = 0.21, indicating that the flux pinning centers in film may be dominant by the core normal surface pinning (p = 0.5, q = 2, and hmax = 0.2)42.

The interface structure plays a vital role in determining the superconducting properties for FeySe1−xTex films. Using the STEM analysis, we could reveal the Fe0.76Se0.87Te0.13/TiO2/STO microstructure and determine the morphology of the interface. The thicknesses of Fe0.76Se0.87Te0.13 and TiO2 film are about 32.4 nm and 29.5 nm, respectively. Figure 8a shows the overview image of the Fe0.76Se0.87Te0.13/TiO2/STO interface. It can be seen that the heterostructure interface is sharp and clean. The TiO2 buffer was successfully deposited between the Fe0.76Se0.87Te0.13 film and STO substrate. Figure 8b shows the high-magnification HAADF image of Fe0.76Se0.87Te0.13/TiO2. The Fe, Se, Te, Ti and O atoms are arranged neatly at the interface. In this case, the Fe0.76Se0.87Te0.13 structure with a tetragonal space group P4/nmm is very simple, and each unit cell contains 3 quintuple layers (QLs), which are bonded by van der Waals (vdW)9. The TiO2 unit cell has two Ti–O triple layers, which grow on STO along the (00l) direction. From Fig. 8b, a nanoscale damaged layer (or transition layer) was formed between the TiO2 and Fe0.76Se0.87Te0.13 interface. To determine the formation of this transition layer, the Atomic resolution EDX mapping was conducted in this area. The chemical elemental maps of Fig. 8c confirm the suggestion from HAADF image that the atoms are arranged regularly without obvious diffusion and migration. Such high quality heterostructure has a significant influence on the enhancement of superconductivity for FeySe1−xTex films.

Conclusion

In summary, we successfully prepared the FeySe1−xTex thin films with 0.03 ≤ x ≤ 0.56 and 0.63 ≤ y ≤ 1.43 by PLD. Our experimental results confirm the significant deviation between the nominal compositions of targets and the real compositions of FeySe1−xTex films. Chemical composition does affect the superconducting properties such as the superconducting transition temperature and the critical current density in FeySe1−xTex films. A new 3D phase diagram is presented from the experimental results of electrical transport, which reveals that the optimal composition for FeySe1−xTex films is x = 0.13–0.15 and y = 0.73–0.78. The field dependence of flux pinning energy displays that the increase of Te doping can enhance the flux pinning in FeySe1−xTex films. STEM investigation shows that the Fe0.76Se0.87Te0.13/TiO2/STO heterostructure has a sharp interface and exhibits almost no atomics intermixing. Our study results provide some further understanding on the mechanism of superconducting properties for FeySe1−xTex films, which has a certain guiding significance and reference value for the potential application of iron-based superconductors.

Methods

The PLD targets were prepared by the self-flux method with high purity materials (Fe 99.99%, Te 99.999% and Se 99.999%) in the stoichiometric proportion. Fe, Se and Te were fully ground and squeezed into a 3/4 in. block, and then encapsulated in a vacuum quartz tube. The vacuum quartz tube was calcined in a muffle furnace at 850 °C for 72 h, then slowly cooled down to room temperature at the rate of 3 °C/min. The FeySe1−xTex epitaxial films were deposited on STO single crystalline substrates at 300 °C by PLD in a high vacuum (~ 10–7 mbar). The distance between target and substrate was set at ~ 70 mm. A KrF excimer laser (248 nm) was used for deposition with an energy density of 2.0 J/cm2 and a repetition frequency of 2 Hz. The size of the STO substrate is 5 mm × 5 mm. TiO2 film as a buffer layer was firstly deposited on STO substrate by PLD to improve the lattice matching between FeySe1−xTex film and STO substrate. The deposition temperature and deposition time for FeySe1−xTex and TiO2 films were 300 °C and 15 min, 600 °C and 4.5 min, respectively. After deposition, the films were annealed to room temperature at the rate of 5 °C/min.

X-ray diffraction (XRD) patterns using the θ/2θ method were measured by Bruker D8 with CuKα radiation (λ = 1.54 Å). The Φ-scan of (101) peak from the Fe0.76Se0.87Te0.13 thin film is shown in Supplementary SFig. 1. The chemical composition of FeySe1−xTex films was determined by energy dispersive x-ray spectroscopy (EDX) in a Gemini 500 scanning electron microscope (SEM) mapping. The measurements of electrical transport were carried out via the physical property measurement system (PPMS-9T, Quantum Design). Magnetization measurements on films with 100 Oe/s of sweep rate were performed in vibrating sample magnetometer (VSM). The microstructures of FeySe1−xTex films were examined by scanning transmission electron microscopy (STEM, FEI Titan G2 60–300 aberration). Samples for the STEM were cut and milled in a focused ion beam (FIB, FEI Helios Nanolab 600) according to the so-called micro-bridge sampling technique.

References

Kamihara, Y. et al. Iron-based layered superconductor La[O1−xFx]FeAs (x = 0.05–0.12) with Tc = 26 K. J. Am. Chem. Soc. 130, 3296–3297 (2008).

Hsu, F. C. et al. Superconductivity in the PbO-type structure α-FeSe. Proc. Natl. Acad. Sci. USA 105, 14262–14264 (2008).

Medvedev, S. et al. Electronic and magnetic phase diagram of β-Fe1.01Se with superconductivity at 36.7 K under pressure. Nat. Mater. 8, 630–633 (2009).

Margadonna, S. et al. Pressure evolution of the low-temperature crystal structure and bonding of the superconductor FeSe (Tc = 37 K). Phys. Rev. B 80, 064506 (2009).

Ge, J. F. et al. Superconductivity above 100 K in single-layer FeSe films on doped SrTiO3. Nat. Mater. 14, 285–289 (2015).

Hanzawa, K. et al. Electric field-induced superconducting transition of insulating FeSe thin film at 35 K. Proc. Natl. Acad. Sci. USA 113, 3986–3990 (2016).

Zhang, H. et al. Origin of charge transfer and enhanced electron-phonon coupling in single unit-cell FeSe films on SrTiO3. Nat. Commun. 8, 1–7 (2017).

Zhou, G. Y. et al. Interface enhanced superconductivity in monolayer FeSe films on MgO (001): Charge transfer with atomic substitution. Sci. Bull. 63, 747–752 (2018).

Sims, H. et al. Intrinsic interfacial van der Waals monolayers and their effect on the high-temperature superconductor FeSe/SrTiO3. Phys. Rev. B 100, 144103 (2019).

Li, F. S. et al. Atomically resolved FeSe/SrTiO3 (001) interface structure by scanning transmission electron microscopy. 2D Mater. 3, 024002 (2016).

Yeh, K. W. et al. Tellurium substitution effect on superconductivity of the α-phase iron selenide. Europhys. Lett. 84, 37002 (2008).

Fang, M. H. et al. Superconductivity close to magnetic instability in Fe(Se1−xTex)0.82. Phys. Rev. B 78, 224503 (2008).

Liu, T. J. et al. From (π, 0) magnetic order to superconductivity with (π, π) magnetic resonance in Fe1.02Te1−xSex. Nat. Mater. 9, 718–720 (2010).

Imai, Y. et al. Suppression of phase separation and giant enhancement of superconducting transition temperature in FeSe1−xTex thin films. Proc. Natl. Acad. Sci. USA 112, 1937–1940 (2015).

Bellingeri, E. et al. Tc = 21 K in epitaxial FeSe0.5Te0.5 thin films with biaxial compressive strain. Appl. Phys. Lett. 96, 102512 (2010).

Huang, S. X. et al. Control of tetrahedral coordination and superconductivity in FeSe0.5Te0.5 thin films. Phys. Rev. Lett. 104, 217002 (2010).

Iida, K. et al. Generic Fe buffer layers for Fe-based superconductors: Epitaxial FeSe1−xTex thin films. Appl. Phys. Lett. 99, 202503 (2011).

Bellingeri, E. et al. Tuning of the superconducting properties of FeSe0.5Te0.5 thin films through the substrate effect. Supercond. Sci. Technol. 25, 084022 (2012).

Iida, K. et al. Intrinsic pinning and the critical current scaling of clean epitaxial Fe(Se, Te) thin films. Phys. Rev. B 87, 104510 (2013).

Ichinose, A. et al. Microscopic analysis of the chemical reaction between Fe(Te, Se) thin films and underlying CaF2. Supercond. Sci. Technol. 26, 075002 (2013).

Zhuang, J. C. et al. Pauli-limited effect in the magnetic phase diagram of FeSexTe1−x thin films. Appl. Phys. Lett. 107, 222601 (2015).

Zhuang, J. C. et al. Enhancement of transition temperature in FexSe0.5Te0.5 film via iron vacancies. Appl. Phys. Lett. 104, 262601 (2014).

Tarantini, C. et al. Significant enhancement of upper critical fields by doping and strain in iron-based superconductors. Phys. Rev. B 84, 184522 (2011).

Huang, J. F. et al. Linear correlation between the c-axis lattice constant and superconducting critical temperature in FeSe0.5Te0.5 thin films. Mater. Res. Express 7, 046002 (2020).

Wu, Z. F. et al. Anisotropic flux pinning energy in FeSexTe1−x single crystals. Phys. C 528, 39–47 (2016).

Zhuang, J. C. et al. Unabridged phase diagram for single-phased FeSexTe1−x thin films. Sci. Rep. 4, 1–6 (2014).

Imai, Y. et al. Control of structural transition in FeSe1−xTex thin films by changing substrate materials. Sci. Rep. 7, 1–6 (2017).

Chen, T. K. et al. Fe-vacancy order and superconductivity in tetragonal β-Fe1−xSe. Proc. Natl. Acad. Sci. USA 111, 63–68 (2014).

Bendele, M. et al. Tuning the superconducting and magnetic properties of FeySe0.25Te0.75 by varying the iron content. Phys. Rev. B 82, 212504 (2010).

Palstra, T. T. M. et al. Thermally activated dissipation in Bi22Sr2Ca0.8Cu2O8+δ. Phys. Rev. Lett. 61, 1662 (1988).

Ge, J. et al. Superconducting properties of highly oriented Fe1.03Te0.55Se0.45 with excess Fe. Solid State Commun. 150, 1641–1645 (2010).

Lei, H. et al. Thermally activated energy and flux-flow Hall effect of Fe1+y(Te1+xSx)z. Phys. Rev. B 82, 134525 (2010).

Lei, H. et al. Critical fields, thermally activated transport, and critical current density of β-FeSe single crystals. Phys. Rev. B 84, 014520 (2011).

Xing, X. Z. et al. Thermally activated flux flow, vortex-glass phase transition and the mixed-state Hall effect in 112-type iron pnictide superconductors. Sci. China Phys. Mech. 61, 1–8 (2018).

Blatter, G. et al. Vortices in high-temperature superconductors. Rev. Mod. Phys. 66, 1125 (1994).

Tinkham, M. Resistive transition of high-temperature superconductors. Phys. Rev. Lett. 61, 1658 (1988).

Mao, R. et al. Effect of Te-doping on the superconducting characteristics of FeSe single crystal. J. Alloy. Compd. 809, 151851 (2019).

Bean, C. P. Magnetization of high-field superconductors. Rev. Mod. Phys. 36, 31 (1964).

Kramer, E. J. Scaling laws for flux pinning in hard superconductors. J. Appl. Phys. 44, 1360–1370 (1973).

Willa, R. et al. Strong-pinning regimes by spherical inclusions in anisotropic type-II superconductors. Supercond. Sci. Tech. 31, 014001 (2017).

Dew-Hughes, D. Flux pinning mechanisms in type II superconductors. Philos. Mag. 30, 293–305 (1974).

Wang, A. et al. Critical current density and vortex pinning in tetragonal FeS1−xSex (x = 0, 0.06). Phys. Rev. B 94, 094506 (2016).

Acknowledgements

The authors are grateful for the financial support of the National Natural Science Foundation of China (12174182), the Ministry of Science and Technology of China (2017YFA0303200), and the National Key Research and Development Program of China (2016YFA0300401).

Author information

Authors and Affiliations

Contributions

Y.Z., T.W., Z.W. and Z.X. conceived the experiments; Y.Z. conducted the experiments; Y.Z., Z.W., and Z.X. analysed the results; Y.Z. and Z.W. wrote the paper. All authors have reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, Y., Wang, T., Wang, Z. et al. Effects of Te- and Fe-doping on the superconducting properties in FeySe1−xTex thin films. Sci Rep 12, 391 (2022). https://doi.org/10.1038/s41598-021-04403-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-04403-4

This article is cited by

-

Effect of sputtering pressure on the superconducting properties of Fe(Te,Se) films

Journal of Materials Science (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.