Abstract

Obstacles to widespread deployments of direct air capture of CO2 (DAC) lie in high material and energy costs. By grafting quaternary ammonium (QA) functional group to mesoporous polymers with high surface area, a unique DAC adsorbent with moisture swing adsorption (MSA) ability and ultra-high kinetics was developed in this work. Functionalization is designed for efficient delivery of QA group through mesopores to active substitution sites. This achieved ultra-high kinetics adsorbent with half time of 2.9 min under atmospheric environment, is the highest kinetics value reported among DAC adsorbents. A cyclic adsorption capacity of 0.26 mmol g−1 is obtained during MSA process. Through adsorption thermodynamics, it is revealed that adsorbent with uniform cylindrical pore structure has higher functional group efficiency and CO2 capacity. Pore structure can also tune the MSA ability of adsorbent through capillary condensation of water inside its mesopores. The successful functionalization of mesoporous polymers with superb CO2 adsorption kinetics opens the door to facilitate DAC adsorbents for large-scale carbon capture deployments.

Similar content being viewed by others

Introduction

Limiting global warming to less than 1.5 °C over preindustrial levels with limited or no overshoot projects the Negative Emission Technologies (NETs)1, which is expected to remove CO2 on the order of 100 Gt by midcentury2. As an important component of NETs portfolio, direct air capture (DAC) of CO2 by chemicals has advantages of low environmental risk, convenient feedstock for CO2 utilization and unlimited capacity in reducing atmospheric CO2 level3,4. However, NETs are always challenged by low kinetics issues under the ultra-low CO2 partial pressure of 40 Pa in air. Under this atmospheric environment, the rates of CO2 uptake by photosynthesis and ocean absorption are on the order of 10–6 and 10–8 mol m−2 s−1, respectively5,6.

Kinetics of artificial material of DAC can be hundreds of times higher than that of natural process. Decades of sorbents development for flue gas capture provides various functional parts referenced to DAC, ranging from alkali hydroxides to solid amines4,7. As both functionalization and CO2 adsorption need channels for molecule diffusion, porous DAC adsorbents have aroused extensive concerns. During functional group impregnation, researchers found that amine molecules are prone to first filling small pores (< 10 nm) due to their relatively high surface potential8,9. This would result in complete filling of pore channels and limiting CO2 diffusion after functionalization, especially for adsorbents with microporous. To avoid this outcome, low functional group loading (e.g. < 9 mmol N g−1) is suggested to keep a certain amount of mesopores (e.g. 1 cm3 g−1 for aerogel10, 0.35 cm3 g−1 for mesoporous alumina11). In situ polymerization with amine-containing monomers, e.g., linear poly-l-alanine8 or hyperbranched aminosilica12, is also a preference for keeping the mesoporous structure of adsorbents.

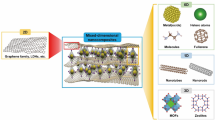

Of particular interest to this work is chemically grafting quaternary ammonium (QA) groups on mesoporous material for DAC adsorption. The QA groups possess the ability of moisture swing adsorption (MSA) which employs water to trigger the desorption, rather than heat or electrical energy. Therefore, the MSA could have a lower energy consumption than temperature-swing adsorption (TSA) process13. The pore structures are introduced to MSA adsorbent in this work to enhance its molecular diffusivity. The grafting of QA cations with strong ionic bonding towards anions can avoid the overlap of functional groups inside mesopores14. Also, the mesopores can provide more surface area for functionalization, compared to macroporous supports4,7,15,16 or cellulose fiber with limited pore structure17. This further provides sufficient channels for CO2 diffusion and high efficiency ammonium sites for CO2 to be captured. On the other hand, moisture swing adsorption (MSA) is known as water can distinctly alter the binding energy of QA ion pair to CO2 through the Brønsted base mechanism15,18. Thus, water behavior in mesopores, such as diffusion and capillary condensation, will ultimately project on the performance of moisture swing adsorbents.

Results

Design and fabrication of QMPRs

Quaternary ammonium functionalized mesoporous adsorbents (QMPRs) are produced though a three-step process illustrated in Fig. 1a. Using this approach, three types of porous QMPRs based on MPRs with similar particle size (500–600 µm as shown in Fig. 1b,c) have been prepared (FTIR analysis and surface morphology are shown in Supplementary Fig. 1). During synthesis process, dichloromethane and methanol were selected as swelling agents, as they can overcome steric hindrance and permeate reagents into active substitution sites at a sufficiently swelled state19. Carbonate is selected as the counter anion to QA group to build a strong interaction with CO2 in air15.

Characterization of pore structure

N2 adsorption and desorption isotherms of different MPRs are shown in Fig. 2a. All MPRs exhibit type IV isotherms with hysteresis loops, which is associated with capillary condensation of nitrogen taking place in mesopores. The H2 hysteresis loop of MRP-1 indicates special ink-bottle-like mesopores with narrow opening, while H1 hysteresis loops of MRP-2 and MPR-3 generally suggesting cylindrical pores with more uniform size of resins20. As for MPR-3, it should have a certain amount of macropores (> 50 nm), as the isotherms showed no obvious adsorption saturation at large P/P0 where fits the zone of multilayer adsorption. Quaternization didn’t change the pore type of MPRs and QMPRs based on the same type of isotherms. However, the pore volumes of QMPR-2 and QMPR-3 drop significantly compared to MPRs, especially between the pore size of 30 and 50 nm (Fig. 2b). This could be primarily contributed by the swelling process, where it generally induce a 15–25% increase in bulk volume and squeeze mesopores of resins21,22. On the other hand, the swelling effect also result in higher surface area (Table 1) and higher amination efficiency, as the grafting of TMA may barely affect the pore structure of resin due to the small molecular size (0.66 nm) and monolayer grafting23. The decreasing surface area of QMPR-3 compare to MPR-3 may be due to the combined effect of swelling and amination.

Quaternization with pore structure of MPRs

The CO2 capacity of QMPRs can be predicted by nitrogen content (QN) or charge density (Qc) through Eq. (1) below13,24, which the results are listed in Table 2.

The ion exchange efficiency of functional group (FG), η1, is employed to measure the availability of QA group. Only the QA cations electrostatic interacting with carbonate ions are effective for CO2 adsorption. Gel type ion exchange resins (IER) generally have a high η1 of over 98%25. Compared with that, the relatively lower η1 of QMPR should be due to the uneven distribution of QA groups inside the mesopores. Ion exchange for carbonate requires two QA cations with proper distance. Cation distance larger or shorter than the size of one carbonate molecule between two adjacent cations will result in increased potential energy of ion exchange26. For gel type IER, as illustrated in Fig. 2c, the cations are randomly distributed in the three-dimensional network of crosslinked polymer. The strong repulsion between cations will result in a uniform cation distance of about 0.8 nm for IER with charge density of 3.4 mmol g−1, which provides proper space for counter anions with multivalence, e.g. carbonate, acetate, or phosphate anion15,18. During quaternization of QMPR, the diffusion of acyl group through micropores in gel type resins would have large resistance compared to diffusion through mesopores. The QA group would be concentrated inside the pores which can be indicated by the poor content of nitrogen, or large value of C/N. Uneven spatial distribution of cations, or cations with distance of far smaller or larger than the size of carbonate ion will result in poor ion exchange efficiency26. For QMPRs, the η1 should also be related to the pore shape. Compared to QMRP-1 with ink-bottle pores and QMPR-3 with macropores, QMPR-2 with cylindrical mesopores is expected to have QA cations with more uniform spatial distance. This should be the reason why QMPR-2 has relatively higher ion exchange efficiency.

Mechanism of water effect on capacity of QMPRs

CO2 adsorption isotherms of QMPR adsorbents are plotted in Fig. 3a, which exhibited Langmuir isotherm characteristics (Supplementary Fig. 3). No CO2 adsorption is detected in MPRs (Supplementary Fig. 4). QMPR-2 exhibits the largest CO2 capacity of 0.28 mmol g−1 under relative humidity (RH) of 21% and CO2 concentration of 400 ppm, while QMPR-1 and QMPR-3 have relatively lower CO2 capacity. This adsorption results consist with the ion exchange capacity of QMPRs. Table 2 shows that, for all the quaternized adsorbents, the functional group efficiencies at 400 ppm, η2, are close to 60%. Although η2 is larger than that of most solid amines11,27, it is still lower than that of gel type IER13. From thermodynamic point of view, the functional group efficiency under a certain CO2 partial pressure is determined by the equilibrium constant, which reflects the binding ability of adsorbents with CO2. For moisture swing adsorbents, the CO2 binding energy should be primarily affected by environmental humidity24 and hydrophilicity of material17. Due to the hydrophilic feature of QA groups27, QMPR has higher water sorption capacity compared to MPR (Supplementary Table 1). One can assume that the increased water content after amination is concentrated around the functional groups. Therefore, it is not surprising to find that QMPR and gel IER have similar hydrophilicity, or water content per functional group.

CO2 adsorption performance and cycling of QMPRs. (a) Adsorption isotherms at 20 °C and 21% RH. (b) Local relative humidity of pores caused by capillary condensation of water. (c) Adsorption isotherms of QMPR-2 at different RH. A stable swing capacity of 0.26 mmol g−1 can be obtained by adsorbing at 21% RH and desorbing at 100% RH. (d) Multiple cycles for CO2 adsorption by QMPR-2 at 400 ppm and desorbed at 100% RH.

More influential effect goes to the capillary condensation of water taking place inside the pore channels, which changes the environmental humidity in local pores. The capillary condensation under equilibrium conditions is given by Kelvin’s equation:

VL is the molar volume of water, γ is the surface tension of water, and R is the gas constant. For a hydrophilic surface (contact angle, θ, < 90°), the saturation vapor pressure inside the pores (p), as a function of pore width (d) and temperature (T), is smaller than that in bulk phase (p0). Condensation can, therefore, take place under higher relative humidity28. As illustrated in Fig. 3b, under water vapor partial pressure of 500 Pa at 20 °C (21% RH in ambient air), the local relative humidity in pores smaller than 10 nm could be over 30%. The increased number of water molecules surrounding by QA groups will increase the free energy of water dissociation for hydroxide ion and lead to decreased binding ability of adsorbents with CO224. The moisture swing adsorption property of QMPR-2 is depicted by the CO2 adsorption isotherms at different relative humidity (Fig. 3c). By adsorbing 400 ppm CO2 at 21% RH, and desorbing at RH of 100%, a stable swing capacity of 0.26 mmol g-1 can be obtained (cyclic adsorption shown in Fig. 3d).

Adsorption kinetics of QMPRs

Figure 4a demonstrates that CO2 adsorption kinetics of QMPRs is governed by the surface area of adsorbent. QMRP-3, which owns the smallest surface area among adsorbents, has the lowest adsorption rate. QMPR-1 and QMPR-2 have similar surface area and their adsorption rates are also close at initial state. Meanwhile, it is interesting to find that the adsorption rate of QMPR-1 drops more rapidly with increased CO2 saturation. This should be due to the special ink-bottle-like micro-pore structure as indicated by the hysteresis loop of QMRP-1. Previous isothermal studies24 revealed that quaternary ammonium adsorbent will release part of hydrated water during CO2 adsorption, e.g. 2.7 to 3.7 mol H2O mol−1 CO2. During CO2 adsorption of QMPR-1, the released water could be gradually trapped by the ink-bottle-like microstructure. This would result in fast accumulation of humidity in local pores, and ultimately deteriorate its adsorption kinetics.

Adsorption half time of QMPRs, which is defined as the time to reach half of CO2 capacity, could be calculated through a mixed 1,2-order equation29 (Fitting result is shown in Supplementary Table 2). QMPR-2 exhibits an exciting feature of kinetics with half time of 2.9 min (Fig. 4b), which is the highest kinetics value reported among DAC adsorbents. Enhanced kinetics of MSA gives great opportunities to facilitate the deployment of direct air capture in large-scale carbon capture. Adsorption quadrantal diagram with two indicators of adsorption capacity and adsorption half-time is employed to evaluate the state-of-the-art MSA adsorbents for DAC. Due to the high extent of quaternization during sol–gel fabrication of commercial resin24, the MSA adsorbents based on commercial quaternized resins generally have CO2 capacity as high as 1.5 mmol g−1, and are scattered at quadrant I. Recently synthesized MSA adsorbents have high kinetics and located in quadrant III as they are bottom-up designed based on backbone with porous structure. The ideal MSA adsorbent, which has both high capacity and high kinetics, can be expected by grafting functional group into mesoporous resins during sol–gel fabrication process.

Discussion

The moisture swing separation process, which adsorb CO2 at dry atmosphere and desorb CO2 at high relative humidity, provides a promising approach to low cost CO2 capture from air. In this work, the quaternary ammonium functional group was grafted onto mesoporous polymers to develop MSA adsorbent with high kinetics. In order to provide sufficient mass transfer channels for diffusion of functional group during grafting, Dichloromethane and methanol were selected as swelling agents as they can overcome steric hindrance and permeate reagents into active substitution sites at a sufficiently swelled state. The swelling effect also results in increased surface area and amination efficiency which are quite different from traditional amine functionalized adsorbents. Furthermore, cylindrical mesopores, which exhibits type IV isotherms with H1 hysteresis loops, are expected to have quaternary ammonium functional group with more uniform spatial distance and higher amination efficiency. The adsorbent synthesis employing proper swelling agents and polymer support with optimized mesoporous structure achieved adsorption half time of 2.9 min under atmospheric environment. This is the highest kinetics value reported among DAC adsorbents. Moreover, the behavior of water is significantly affected by mesopores, which further alters the binding energy of quaternary ammonium ion pair to CO2. Mesopores have lower saturation vapor pressure according to Kelvin’s equation capillary and have higher environmental humidity in local pores. The increased hydration water can distinctly decrease the binding energy of quaternary ammonium ion pairs to CO2 through the Brønsted base mechanism. This can result in poor functional group efficiencies at 400 ppm, or moisture swing ability, compared to gel type ion exchange resin. Further improvement of MSA adsorbent with high capacity and kinetics can be expected by grafting quaternary ammonium into mesoporous matrix with hydrophobic groups.

Methods

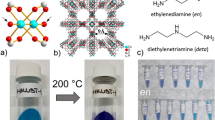

Fabrication of QMPRs

Commercial nonpolar porous resins (XAD-4, XAD-16, and XAD-1180N, purchased from Aladdin, China) were pretreated by 0.1 M HCl, 5 wt.% NaOH and deionized (DI) water to remove the impurities. After dried at 60 °C under vacuum, 4.00 g mesoporous resin (MPR) sample was placed in a four-necked flask (equipped with constant pressure funnel, reflux condenser, thermometer, and mechanical stirring). 20 mL dichloromethane (CH2Cl2) was added as solvent and the mixture was stirred for 12 h to fully swell the microspheres. Chloroacetyl chloride (reagent) and powdered anhydrous aluminum chloride (Lewis catalyst) were slowly added to the mixture under N2 protection (molar ratio of MPR to reagent to catalyst is 1:1:1). After 4.5 h room-temperature reaction, the mixture was suction-filtered and washed with tetrahydrofuran, 0.1 M HCl, and DI water in sequence, until chlorine ion could not be detected in the solution. The resulting light-brown microspheres were named as MPR-CA-1, MPR-CA-2, and MPR-CA-3, respectively.

The 4.00 g MPR-CA then swelled in 20 mL MeOH for 6 h at room temperature. Accompanied with 60 wt.% trimethylamine (TMA, 3.0 e.q. based on chloroacetyl chloride), the mixture was reacted in the flask with an oil bath (fitted reflux) pre-heated to 70 °C. After 4 h, the obtained resin microspheres (MPR-Cl) were packed in a column, washing with MeOH and DI water to remove the residuals. The obtained product was dried under vacuum at 60 °C for 12 h. After ion-exchange with 1 M Na2CO3 solution, the synthesized quaternary ammonium anion exchange mesoporous resins (QMPRs) were produced.

Characterization

Pore characteristics of MPRs and QMPRs were analyzed using N2 adsorption/desorption isotherms (ASAP2020, Micromeritics, USA). Total pore volume was based on the adsorbed amount of N2 at P/P0 = 0.99. The specific surface area was calculated using Brunauer–Emmett–Teller (BET) method (0.01 < P/P0 < 0.1), and pore-size distribution was obtained by density functional theory (DFT). Chemical structure of resin samples was identified by a Fourier transform infrared spectrometer (FTIR, Digilab BioRad FTS 6000 spectrometer, ATR mode), which scans from 4000 to 400 cm−1. The element contents, including carbon, hydrogen, and nitrogen of resins, were determined though vario MAX cube and Elementar equipment. Surface morphology of resin samples were observed by a Hitachi SU-8010 scanning electron microscope (SEM) with an accelerating voltage of 20 kV. The Mohr titration was used to quantify the chloride ion amount in exchanging residue of QMPRs. By getting charge density (Qc) of QMPR, an ideal CO2 capacity can be calculated from it. Thus, it further gives the ion exchange efficiencies (η1) of functional group (FG) and FG efficiencies at 400 ppm (η2) of QMPRs.

CO2 adsorption measurements

CO2 adsorption isotherms and kinetics were performed in a self-made system (Supplementary Fig. 5). CO2 leakage was tested before each measurement. By repeatedly injecting 0.5 ml of CO2 using syringe, the leakage rate was tested as 1.4 × 10–4 ppm s−1 under a CO2 concentration difference of 500 ppm. This verifies that CO2 leaking issue could be negligible compared to the injected amount.

Isothermal and kinetics models

4.00 g QMPR was loaded in the reaction chamber, dried by ultra-high-purity (UHP) N2 before adsorption. Relative humidity (RH) was controlled at 21% under 20 °C. CO2 was injected into chamber repeatedly once adsorption equilibrium was reached. An isotherm related between CO2 concentration and adsorbed amount can be obtained as:

where Qe and Qinj are CO2 adsorbed and injected volume. ce is the CO2 concentration at equilibrium. Vs is the volume of the system (8 L). mad is the adsorbent weight. Vm is the molar volume.

Langmuir, Freundlich, and Temkin isotherm models are employed to fit the MSA equilibrium. These models can be reformed by linear relationship between monotonic function of Qe and P.

where Qe and Qmax are CO2 adsorbed amount at equilibrium and 100% saturation, respectively. A1, B1, A2, and B2 are adsorption parameters calculated by linear fitting. K’ is the effective equilibrium constant of adsorption.

The normalized adsorption rate at a certain CO2 concentration is determined by calculating the slope of θt ~ t curve. By measuring the CO2 concentration (Ct) at time t, the saturation of adsorbent (θt) can be calculated as:

Pseudo-first-order (PFO), pseudo-second order (PSO), and mixed 1,2-order (MOE) rate models are employed to investigate the adsorption kinetics, which expressed as:

where Qt (mmol g−1) is CO2 adsorbed amount at time t, k1 and k2 are rate constants for PFO and PSO models, respectively. f2 is the percentage of PSO equation in MOE rate model.

H2O adsorption analysis

H2O adsorption capacity of MPRs and QMPRs were obtained using a gravimetric method. Sample of resin (~ 1.00 g) were first dried in the chamber using UHP N2, note md (g) as its dry mass. Humid N2 (N2 pass through humidity controller) was then introduced to the chamber, and record mw (g) as the mass of sample saturated at a certain RH. This process was operated multiple times until mw obtained from the electronic balance was stable. H2O adsorbed amount of each sample, Qw (mmol g−1), was expressed as:

References

Rogelj, J. et al. Mitigation pathways compatible with 1.5°C in the context of sustainable development. Glob. Warm. 1.5°C. An IPCC Spec. Rep. (2018).

National Academies of Sciences, Engineering, and Medicine Report. Negative emissions technologies and reliable sequestration: a research agenda. The National Academies Press. https://www.nap.edu/catalog/25259/negative-emissions-technologies-and-reliable-sequestration-a-research-agenda (2018).

Bui, M. et al. Carbon capture and storage (CCS): the way forward. Energy Environ. Sci. 11, 1062–1176 (2018).

Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct capture of CO2 from ambient air. Chem. Rev. 116, 11840–11876 (2016).

Vicca, S. Global vegetation’s CO2 uptake. Nat. Ecol. Evol. 2, 1840–1841 (2018).

Keppler, L. & Landschützer, P. Regional wind variability modulates the southern ocean carbon sink. Sci. Rep. 9, 1–10 (2019).

D’Alessandro, D. M., Smit, B. & Long, J. R. Carbon dioxide capture: prospects for new materials. Angew. Chem. Int. Ed. 49, 6058–6082 (2010).

Chen, Z. et al. Polyethylenimine-impregnated resin for high CO2 adsorption: an efficient adsorbent for CO2 capture from simulated flue gas and ambient air. ACS Appl. Mater. Interfaces 5, 6937–6945 (2013).

Liu, F. Q. et al. Amine-tethered adsorbents based on three-dimensional macroporous silica for CO2 capture from simulated flue gas and air. ACS Appl. Mater. Interfaces 6, 4371–4381 (2014).

Kong, Y., Shen, X., Cui, S. & Fan, M. Facile synthesis of an amine hybrid aerogel with high adsorption efficiency and regenerability for air capture via a solvothermal-assisted sol-gel process and supercritical drying. Green Chem. 17, 3436–3445 (2015).

Chaikittisilp, W., Kim, H. J. & Jones, C. W. Mesoporous alumina-supported amines as potential steam-stable adsorbents for capturing CO2 from simulated flue gas and ambient air. Energy Fuels 25, 5528–5537 (2011).

Rosenholm, J. M., Duchanoy, A. & Lindén, M. Hyperbranching surface polymerization as a tool for preferential functionalization of the outer surface of mesoporous silica. Chem. Mater. 20, 1126–1133 (2008).

Wang, T., Lackner, K. S. & Wright, A. Moisture swing sorbent for carbon dioxide capture from ambient air. Environ. Sci. Technol. 45, 6670–6675 (2011).

Shi, R. & Wang, Y. Dual ionic and organic nature of ionic liquids. Sci. Rep. 6, 1–12 (2016).

Wang, T. et al. Designing moisture-swing CO2 sorbents through anion screening of polymeric ionic liquids. Energy Fuels 31, 11127–11133 (2017).

Song, J. et al. Quaternized chitosan/PVA aerogels for reversible CO2 capture from ambient air. Ind. Eng. Chem. Res. 57, 4941–4948 (2018).

Hou, C., Wu, Y., Wang, T., Wang, X. & Gao, X. Preparation of quaternized bamboo cellulose and its implication in direct air capture of CO2. Energy Fuels 33, 1745–1752 (2019).

Wang, T. et al. Spontaneous cooling absorption of CO2 by a polymeric ionic liquid for direct air capture. J. Phys. Chem. Lett. 8, 3986–3990 (2017).

Gao, B., Wang, L. & Du, R. Studies on chloroacylation reaction process of crosslinked polystyrene microspheres with ω-chloroacyl chloride as reagent. J. Macromol. Sci. Part A Pure Appl. Chem. 47, 927–934 (2010).

Henderson, M. A. & Irwin, M. G. High humidity affects HemoCue microcuvette function. Anaesth. Intensive Care 23, 407 (1995).

Zaleski, R., Krasucka, P., Skrzypiec, K. & Goworek, J. Macro- and nanoscopic studies of porous polymer swelling. Macromolecules 50, 5080–5089 (2017).

Zhou, W. Q., Gu, T. Y., Su, Z. G. & Ma, G. H. Synthesis of macroporous poly(styrene-divinyl benzene) microspheres by surfactant reverse micelles swelling method. Polymer (Guildf) 48, 1981–1988 (2007).

Lioe, H., Barlow, C. K. & O’Hair, R. A. J. How does acetylcholine lose trimethylamine? A density functional theory study of four competing mechanisms. J. Am. Soc. Mass Spectrom. 20, 238–246 (2009).

Wang, T., Lackner, K. S. & Wright, A. B. Moisture-swing sorption for carbon dioxide capture from ambient air: a thermodynamic analysis. Phys. Chem. Chem. Phys. 15, 504–514 (2013).

Pepper, K. W., Paisley, H. M. & Young, M. A. 833. Properties of ion-exchange resins in relation to their structure. Part VI. Anion-exchange resins derived from styrene-divinyl-benzene copolymers. J. Chem. Soc (Resumed), 4097–4105 (1953).

Shi, X. Study of a humidity-swing carbon dioxide sorbent (2017).

Shishatskiy, S., Pauls, J. R., Nunes, S. P. & Peinemann, K. V. Quaternary ammonium membrane materials for CO2 separation. J. Memb. Sci. 359, 44–53 (2010).

Morishige, K., Kawai, T. & Kittaka, S. Capillary condensation of water in mesoporous carbon. J. Phys. Chem. C 118, 4664–4669 (2014).

Marczewski, A. W. Application of mixed order rate equations to adsorption of methylene blue on mesoporous carbons. Appl. Surf. Sci. 256, 5145–5152 (2010).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 51676169) and Natural Science Funds for Distinguished Young Scholar of Zhejiang Province (LR19E060002).

Author information

Authors and Affiliations

Contributions

T.W. conceived the research, X.R.W. and C.L.H. designed experiments. X.R.W., C.L.H. and J.L. analyzed the data. T.W. and X.R.W. wrote the manuscript. All authors discussed and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, T., Wang, X., Hou, C. et al. Quaternary functionalized mesoporous adsorbents for ultra-high kinetics of CO2 capture from air. Sci Rep 10, 21429 (2020). https://doi.org/10.1038/s41598-020-77477-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-77477-1

This article is cited by

-

Dual-templating-derived porous carbons for low-pressure CO2 capture

Carbon Letters (2023)

-

Progress and current challenges for CO2 capture materials from ambient air

Advanced Composites and Hybrid Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.