Abstract

In this approach, thin spikes (NSs) of ternary nano-formulated mixed CuO/MnO2/Gd2O3 were synthesized by the hydrothermal approach for efficient detection of 3-methoxyphenyl hydrazine (3-MPHyd) chemical from various environmental samples. The NSs were systematically characterized by using XPS, EDS, TEM, FTIR, UV/vis, and XRD. The fabricated NSs onto the glassy carbon electrode (GCE) was successfully applied for the selective and sensitive detection of 3-MPHyd in the phosphate buffer system (PBS), which displayed the highest sensitivity, good selectivity with ultra-trace detection limit, high stability, good reproducibility, and quick response time. The real environmental samples were tested for validation from stand point of the ternary doped nanomaterials for sensing in the practical applications using by electrochemical method.

Similar content being viewed by others

Introduction

As strong reducing agents, generally the phenyl hydrazine and their derivatives are well-known, and they have various industrial applications such as blooming agent for plastics, corrosion inhibitor insecticides, and oxygen scavenger in the boiler as rocket fuel, photographic chemicals, aerospace fuel and explosives1. Due to exposure of these chemicals by human even at trace amount, may cause the hostile effect to human such as liver and kidney injury, haemolytic anaemia, skin irritation and dermatitis, etc. and the phenyl hydrazine and their derivatives are considered as a carcinogenic2,3,4. Then it is necessary to capture of 3-MPHyd at ultra-trace level to safe the human, environment, and the eco-system. The literatures have been described the detection methods of phenyl hydrazine and their derivatives such as fluorimetry, capillary electrophoresis, chromatography, spectrophotometry, photometry and photometric titrations, electrochemical technique5,6,7. But most of them, the electrochemical methods are widely implemented technique due to its high sensitivity, lower detection limit, greater simplicity, lower cost and long-term stability in chemical environment. Except few articles, the most of reported studies have been suffering in sensitivity, reproducibility and stability. To the phenyl hydrazine and their derivatives, the higher potential is required for GCE. Therefore, the modified GCE needs easy to fabricate for increasing the electrons transferring-rate as well as improving the sensitivity with lower detection limit8.

To reduce the over potential and increase the electron transfer rate, the various transition material such as copper oxides are used as detecting or capturing materials to the phenyl hydrazine and their derivatives9. Recently, the un-doped metal oxides (specially, transition) such as iron oxide, tungsten oxide, manganese oxide, and copper oxide are also studied as a detecting material of hydrazine and the derivatives of hydrazine10. Among them, MnO2 is the potential electron arbitrator as exhibited the high catalytic activity, precise surface area, lower resistances and pleasant electrochemical properties11. The CuO is a good electro mediator with better electro-chemical property with large surface area, which can enhance the electron transferring12. Generally, nanostructure materials have given significant attention for various organic as well as inorganic components, which is attracted owing to the binding affinity at optimum working conditions13,14,15,16.

A successful hydrazine derivative material with zinc oxide nano-urchins is reported and exhibited the good sensitivity as well as lower detection limit17. Another hydrazine derivate material based on silver-doped zinc oxide was reported, which was successful with high sensitivity and detection limit18. It is already established that CuO and MnO2 are efficient sensing elements to monitor the toxins for the safety of environment. Therefore, the ternary combination of CuO/MnO2/Gd2O3 NSs may be an effective detection material to detect environmental toxins due to the large active surface area in their interior or exterior surfaces. Various toxic analytes such as phenols and their derivatives, alcohol, acetone, ammonium hydroxide, dichloromethane, heavy-metal ions, hydrazine, aliphatic and aromatic compounds have been detected by various compositions of metal oxide/sulphides with the doped or un-doped, mixed/dual combinations19. The nanostructure materials prepared by sol–gel method have been shown elsewhere with the higher surface area for good adsorption of chemicals and ions20,21,22,23. From the specific advantage of the active surface area with ternary metal oxides compared to single or dual/doped combination, it is highly demanded to introduce new doped materials with metal oxides.

Generally, mixed doped metal oxide exhibits promising results for the detection and quantification of hazardous chemicals by various detection approaches. Besides this, as enhancing of electrochemical properties of CuO/MnO2/Gd2O3 NS nanostructure material by converting it to a doped mixed oxides with other materials is also cost-effective. Here, CuO/MnO2/Gd2O3 NS nanostructured materials have employed a great deal of consideration due to their chemical, structural, physical, and optical properties in terms of large-active surface area, high-stability, and high porosity. These properties are directly depend on the structural morphology prepared by reactant precursors for making the CuO/MnO2/Gd2O3 porous materials in the basic medium at low-temperature. This CuO/MnO2/Gd2O3 NSs material was synthesized by a facile solution method using NaOH solution. This technique has several advantages including facile preparation, accurate control of reactant temperature, easy to handle, one-step reaction. Optical, morphological, electrical, and chemical properties of the CuO/MnO2/Gd2O3 NS nanomaterials are of huge significance from the scientific aspect, compared to other undoped materials. The non-stoichiometry, mostly oxygen vacancies, Gd2O3 makes it conducting nature in the doped nanostructured materials24,25,26,27,28,29. The formation energy of oxygen vacancies and metal interstitials in the semiconductor is very low and thus these defects form eagerly, resulting the increased conductivity of CuO/MnO2/Gd2O3 NS materials compared to other undoped materials. CuO/MnO2/Gd2O3 NS materials have also attracted considerable interest due to their potential applications in fabricating optoelectronic, electro-analytical, selective detection of assays, chemical sensor devices, hybrid-composites, electron-field emission sources for emission exhibits, biochemical detections, and surface-enhanced Raman properties, etc. CuO/MnO2/Gd2O3 NS material offers improved performance due to the large-active surface area, which increased conductivity and current responses of the CuO/MnO2/Gd2O3 NSs/Nafion/GCE assembly during the electrochemical investigation.

The most reliable hydrothermal process was applied to synthesize CuO/MnO2/Gd2O3 NSs. The fabricated NSs were practice for the coating onto a GCE, and the binding properties between these were enhanced by the addition of nafion solution. The resulted GCE was investigated for efficient capturing of 3-MPHyd in the aqueous media. The analytical capturing performances were studies very carefully, and the outcome of the 3-MPHyd chemical material was high sensitivity with the low detection limits. Here, it is introduced a significant material in this approach for selective and sensitive monitoring and capturing of selective 3-MPHyd with CuO/MnO2/Gd2O3 NSs sensor probe.

Experimental section

Materials and method

In this research work, the required chemicals were used as received without further purification. The inorganic salts of transition metals such as copper(II) chloride (CuCl2), manganese(II) chloride (MnCl2), gadolinium(III) chloride, and ammonium hydroxide (NH4OH) were purchased from well-known Sigma-Aldrich, which was deployed to prepare ternary CuO/MnO2/Gd2O3 NSs. As a part of these studies, the analytical grade chemicals 2,4-DNP (2,4-dinitrophenol), 3,4-DAT (3,4-diaminotoluene), pyridine, BH (benzaldehyde), 3-chlorophenol, THF (tetrahydrofuran), methanol, 3-MPHyd (3-methoxyphenylhydrazine), AH (ammonium-hydroxide), coating agent nafion (in 5% ethanol), NaH2PO4, and Na2HPO4 were also bought from the Sigma-Aldrich and deployed as-received. For the details characterization of synthesized CuO/MnO2/Gd2O3 NSs, conventional XRD, XPS, FTIR, UV/Vis and FESEM were implemented to evaluate the structural, crystalline, functional, optical, morphological and elemental analyses. The reliable current versus potential (electrochemical method) was used to determine 3-MPHyd with active CuO/MnO2/Gd2O3 NSs material by using Keithley electrometer (6517A, USA) at room conditions.

Hydrothermally synthesis of CuO/MnO2/Gd2O3 NSs

The inorganic salts copper chloride (CuCl2), manganese chloride (MnCl2), gadolinium chloride (GdCl3) and alkali ammonium hydroxide (NH4OH) were used to prepare CuO/MnO2/Gd2O3 NSs by solvo/hydrothermal method at low temperature. The solvothermal process was widely used efficient method to fabricate nanomaterials of metal oxides, and the resultant guest or doped metal oxides are smaller in size as well as phase formation. Following this method, 100.0 mL of 0.10 M CuCl2, 100.0 mL of 0.10 M MnCl2, 100.0 mL of 0.10 M GdCl3 and 100.0 mL of 0.10 M NH4OH were prepared in a different four 200.0 mL beaker with de-ionized water and resultant solutions were kept with continuous magnetic stirring. Another 250.0 mL of conical flask was taken and 50.0 mL of each prepared metallic salt solution was added. Then the mixture was shacked with continuous magnetic stirring onto the hot plate. To obtain the co-precipitation of metal hydroxides, the prepared 0.10 M NH4OH was added slowly and at the pH value 10.5, all metal hydroxides were precipitated out in conical flask. Then the total solution was kept at 80 °C on the hot plate with continuous magnetic stirring around 6 h. As-prepared participate of metal hydroxides were washed thoroughly by de-ionized water and kept it to dry at room condition for overnight. Consequently, the powdered sample was heated for calcination at 510 °C for 6 h. Under higher temperature, the metal oxides is transform to crystalline metal oxide i.e., CuO/MnO2/Gd2O3 nanostructure shapes, which contains the higher metallic-ions. The prepared material was properly grained into fine powder of nano-sized materials for details characterization. The following reactions may happen:

In the aqueous medium:

In furnace:

The Ks was low (Ks = 2.2 × 10–20 in Cu(OH)2, 2.0 × 10–13 for Mn(OH)2 and 1.88 × 10–23 for Gd(OH)330. Metal ions were precipitated out quantitatively as various oxides. The crystal formation was happened initially, where an aggregation to the Gd(OH)3 was started. In the reaction system, pH was continued to enhance, then the Cu(OH)2 was started to precipitate, which was re-aggregated onto the Gd(OH)3 crystallites. Further increasing of pH, Mn(OH)2 is also participated out to form aggregation with other two metal hydroxides. The formation of NSs is similar with the previously reported article31. The synthesized NSs were characterized in terms of elemental composition, crystallinity, optical property, morphology, structure, and functional properties. Later, CuO/MnO2/Gd2O3 NSs were applied to detect 3-MPHyd by reliable electrochemical method at room conditions. This is the first time, the produced CuO/MnO2/Gd2O3 NSs were implemented for the selective determination of 3-MPHyd for environmental safety by electrochemical method.

Fabrication of CuO/MnO2/Gd2O3/Nafion/GCE sensor probe

The ternary doped materials based on the NSs of CuO/MnO2/Gd2O3 was successively implemented to determine the target environmentally unsafe 3-MPHyd in reaction medium. To prepare the working electrode for 3-MPHyd detection, the ethanolic slurry of CuO/MnO2/Gd2O3 NSs was put onto the GCE. Platinum wire (Pt-wire) was used as a counter electrode. The dispersed materials was attached between NSs of ternary metal oxides and GCE by air dry initially. It was fabricated on the flat GCE and dried in air for complete thin-film formation. Later, after drying completely, 1.0 μL of 5.0% Nafion (ethanolic) was dropped onto the fabricated electrode surface and waited until dry it completely. Here, nafion is used as a chemical glue for the stable attachment of ternary materials onto the surface of flat-GCE. Then the dried fabricated electrode was used as working electrode in this investigation. The electrochemical cell was composed by CuO/MnO2/Gd2O3/binders/GCE sensor probe as working electrode. The fabrication scheme is presented in the Fig. 1. The target analyte 3-MPHyd was used to prepare the solution in di-ionized water on the concentration range from 1.0 mM to 1.0 pM and this formulated solutions of 3-MPHyd (lower to higher concentration) were investigated into electrochemical cell (chemical material). Then the linearity was calculated from the linear plot by using regression co-efficient (r2). The other analytical properties of 3-MPHyd chemical sensor such as LDR and LOD were estimated according to ratio of 3 N/S.

Results and discussion

Materials properties

The crystallographic studies of prepared CuO/MnO2/Gd2O3 NSs were carried out by the implementation of XRD. As shown in Fig. 2a, the fabricated NSs were consisting of diversified crystalline mediums of CuO, MnO2 and Gd2O3. The resultant XRD spectra is represented the Bragg planes of CuO indices as θ such as (110), (111), (200), (202), (113), and (022), which has the similarities with JCPDS No. 72-0629 and earlier published articles32,33. The other diffracted peaks created from MnO2 indices as ß are (101), (110), (111), (200), (210), (211), (002) and (310). This XRD pattern of MnO2 is agreed with the JCPDS Card, No. 24-0735 and literatures34,35. The additional sharpest peaks of Gd2O3 indices as λ are (211), (222), (411), (442), (611) and (622), which are agreed with those reported for gadolinium oxide nanoparticles36 and JCPDS No. 43-1015. There is a provision for measuring the crystallinity by the XRD pattern through Scherer’s expectation (vii).

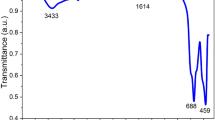

where λ is wavelength (1.5418 Å) and β is width at half, according to the apex peak, and θ is the diffracting edge37. Here, the determined crystallinity was 43.31 nm. Additionally, it is also compared the XRD spectrum of individual CuO, MnO2, and CuO/MnO2/Gd2O3 NSs and presented in the Fig. 2b. FTIR investigation of synthesized CuO/MnO2/Gd2O3 NSs is depicted in Fig. 2c and obtained peaks are at 539, 1402, 3370 and 3622 cm−1. The main characteristic absorption peak is at 539 cm−1 which is corresponding to Mn–O or Cu–O stretching modes38 and the identical peak at 1402 cm−1 is responsible for C−O stretching39. The other two peaks at 3370 and 3622 are corresponding to the OH group40. The visual spectra of CuO/MnO2/Gd2O3 NSs were completed at the range between 200.0 and 800.0 nm wavelengths. As judged from Fig. 2d, the maximum intensity was inspected at 306 nm and this was the evaluated absorption band of prepared CuO/MnO2/Gd2O3 NSs41. According to the Eq. (8), the defined energy band-gap (Ebg) was 4.05 eV of the CuO/MnO2/Gd2O3 NSs.

where Ebg = energy band-gap and λ = maxima absorbed area.

Structural analyses

The structural analyses of the fabricated NSs were evaluated by FESEM images. The resultant FESEM of CuO/MnO2/Gd2O3 NSs from higher to lower magnifying images are depicted in Fig. 3a,b and it is clearly shown a uniform aligned of CuO/MnO2/Gd2O3 nanospikes. From Fig. 3c,d, the EDS define of CuO/MnO2/Gd2O3 demonstrated the existence of Cu, Mn, Gd and O and the elemental arrangements of calcined co-doped metal oxides are nanospikes in shape. The atomic compositions (wt%) of CuO/MnO2/Gd2O3 NSs are as O 3.58%, Cu 2.17%, Gd 84.1% and Mn 10.15%. Any additional peaks are not detected, which is associated with impurities. Therefore, the synthesized NSs are consisted only Cu, Mn, Gd and O.

Binding energy analysis

The XPS is defined in Fig. 4 are also investigated to evaluate the chemical composition, electronic and valance states of prepared CuO/MnO2/Gd2O3 NSs. As it is shown the full spectrum (Fig. 4a), Cu2p, Mn2p Gd3d and O1s core level of spin orbitals are investigated. The observed O1s peak at 530.0 eV, which was presented in Fig. 4b and assigned to the O2−42,43. The Cu2p spin orbital ruptures into Cu2p3/2 and Cu2p1/2 as depicted in Fig. 4c. Here, it displays the high resolution spectrum of Cu 2p, separated into Cu 2p3/2 and Cu 2p1/2 at 930.5 eV and 952.1 eV, respectively (Fig. c1 and c2). The distance between these Cu 2p main peaks positions is 21.6 eV, which agrees well with previous reports about CuO spectrum. It is also denoted to the existence of Cu2+ chemical state as an indication of the formation of CuO, which is matched to the reported literatures44,45,46,47,48,49,50,51,52. Moreover, additional confirmation of CuO state was seen with the broad satellite peaks at a higher binding energy than the main peaks. The main peak of Cu 2p3/2 at 930.5 eV was accompanied by satellite peaks on the higher binding energy side at 939.2 eV, 941.5 eV and 943.1 eV, which suggests the existence of CuO. From the full spectrum, we can clearly see that the main peak of Cu 2p1/2 at 952.1 eV, which also confirms the presence of CuO. The XPS spectrum is also exhibited the two major peaks of Mn2p orbital and the resultant spectrum of Mn2p is represented in Fig. 4d. As evaluated, the spin energy of Mn2p3/2 (641.2 eV) and Mn2p1/2 (653.1 eV) are also the adjacent position with the reported data for MnO245,46, which is presented separately in Fig. 4d1,d2. In Gd3d spectra (Fig. 4e), two peaks are found, where the binding-energy of strong peak at ~ 1186.0 eV is responsible for Gd3d5/2, and the binding-energy of weak peak at ~ 1221.4 eV is responsible for Gd3d3/2. It is associated with the oxidation state of Gd3+, which is represented in the Fig. 4e1, e249,50.

Sensing of 3-MPHyrd by CuO/MnO2/Gd2O3 NSs

The proposed application of 3-MPHyrd chemical material was to detect 3-MPHyrd in environmental real samples. The chemical material based on CuO/MnO2/Gd2O3 NSs is first stage, and any report regarding phenyl hydrazine analyte is not available. Here the conducting binder of nafion is used to enhance the stability with high conductivity and electron transfer51,52. During the sensing performances of proposed 3-MPHyd chemical material, electrochemical responses of CuO/MnO2/Gd2O3 NSs were increased with increasing of 3-MPHyd amount. In presence of higher concentration of target analyte, the resultant current is gradually increased by oxidation of 3-MPHyd onto CuO/MnO2/Gd2O3 NSs. In this investigation, the flat GCE was coated with the ethanolic slurry of CuO/MnO2/Gd2O3 NSs and dried it in the ambient temperature. Later, the fabricated CuO/MnO2/Gd2O3 NSs/Nafion/GCE electrode was employed to sensing the 3-MPHyd by electrochemical approach at room conditions. The 3-MPHyd sensing mechanism onto CuO/MnO2/Gd2O3 NS probe is based on the ternary metal oxides, owing to adsorption/absorption of aqueous oxygen onto the exterior or interior surface of CuO/MnO2/Gd2O3 NSs, according to the dissolved O2 in bulk-solution or surface-air of the surrounding atmosphere (Eqs. 9–11). These reactions are taken place in bulk-solution or air/liquid interface or surrounding air due to the low carrier concentration, which probably increased the resistance of ternary material surface as well as decreased the conductivity53,54,55,56. The anlayte 3-MPHyd sensitivity towards CuO/MnO2/Gd2O3 NSs could be attributed to the high oxygen deficiency and defect the density leads to increase the oxygen adsorption for form active as O2-, then O- and finally OH-. Larger the amount of oxygen adsorbed on the mixed CuO/MnO2/Gd2O3 NSs surface, larger would be the oxidizing capability and faster would be the oxidation of 3-MPHyd.

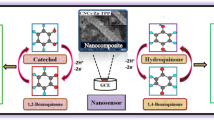

The pictographic representation (Fig. 5a) and mechanism (Fig. 5b) of the CuO/MnO2/Gd2O3 NSs modified electrode of 3-MPhyd chemical material is depicted in Fig. 5. As clarified in Fig. 5c, the electrochemical signalling data was illustrated with prepared NS of CuO/MnO2/Gd2O3, which is exhibited the higher current response compared to pure CuO and MnO2. Here, the oxidation reaction of 3-MPHyd onto surface of CuO/MnO2/Gd2O3 NSs/Nafion/GCE into the buffer system is proposed and presented below according to Eq. (12). According to the electrochemical oxidation process, targeted 3-MPHyd molecule is oxidized, hence released the electrons. Thus it is increased the electrochemical response with the CuO/MnO2/Gd2O3 NSs/Nafion/GCE sensor probe in the electrochemical system during measurement of resultant current. As a result, in contact with the CuO/MnO2/Gd2O3 NS surface, the target analyte 3-MPHyd is directly oxidized by releasing two electrons onto the sensor surface of CuO/MnO2/Gd2O3 NSs/Nafion/GCE probe, which is measured during the electrochemical measurement at room conditions. During the oxidation of 3-MPHyd, the resultant current is significantly increased by producing ammonia, water, and carbon dioxide into the electrochemical process.

Schematic diagram of sensor fabrication and probable mechanism. Possible bonding mechanism of 3-MPHyd by capturing of the thin nanospikes in electrochemical approach. (a) GCE fabrication with CuO/MnO2/Gd2O3 NSs and conducting nafion-coating binders; (b) Possible mechanism of 3-MPHyd capturing onto CuO/MnO2/Gd2O3 NSs surfaces; (c) 3-MPHyd detection by electrochemical method using CuO/MnO2/Gd2O3 NSs modified GCE.

The synthesized CuO/MnO2/Gd2O3 NSs/binder/GCE is not equally given electrochemical response in the full range in buffer system. The invented working electrode was investigated in alkaline and acidic media, and it was observed that the chemical material was exhibited the maximum electrochemical response in pH 7.0. The pH optimization performance is illustrated in Fig. 6a. To obtain the selectivity, the fabricated working electrode based on CuO/MnO2/Gd2O3/binder/GCE was performed in presence of various toxins such as 2,4-DNP (2,4-dinitrophenol), 3,4-DAT, pyridine, BH, 3-CP, THF, methanol, 3-MPHyd, and AH. As it is depicted in Fig. 6b, 3-MPHyd was displayed with the highest electrochemical responses. Also the most important analytical characteristic of chemical material is the ability to reproducible performance repeatedly. This performance of sensor was executed in 0.1 nM concentration of 3-MPHyd solution. The outstanding reproducibility was observed, which is shown in Fig. 6c.

The calculated RSD (relative standard deviation) is 1.10%, which is measured at + 1.0 V. The response time with the fabricated working electrode based on CuO/MnO2/Gd2O3/binder/GCE is 9.25 s. It was evaluated under the certain amount of 0.1 nM of 3-MPHyd solution, which is shown in Fig. 6d. The fabricated sensor is very fast response towards the target analyte with CuO/MnO2/Gd2O3/binder/GCE sensor probe by electrochemical method. After the 9.25 s, signal become sensor response become stable and flat, due to the saturation of contact surface with target analyte. The fabricated materials CuO/MnO2/Gd2O3/binder/GCE was studied and compared in presence of various hydrazine derivatives (Fig. 7a). It was found that 3-MPHyd shows the highest electrochemical response (Fig. 7a) compared to blank solution (without 3-MPHyd), only hydrazine and phenylhydrazine derivatives in the identical conditions. Additionally, a control experiment has been performed with the only GCE, GCE/Nafion, and GCE/Nafion/CuO/MnO2/Gd2O3 electrodes in the identical conditions in presence of target 3-MPHyd chemical, which is presented in the Fig. 7b. It is observed that the CuO/MnO2/Gd2O3 fabricated glassy carbon electrode is showed the highest electrochemical current compared to only GCE and GCE/Nafion electrodes.

Control experiment of fabricated chemical sensor probe. (a) Comparative study of different derivatives of hydrazine such as hydrazine, phenylhydrazine, 3-methoxyphenlyhydrazines. (b) Comparative study of various fabricated GCE, GCE/Naifon, CuO/MnO2/Gd2O3/Nafion/GCE electrodes. Analyte concentration: 0.1 nM; Holding time: 1.0 s; Electrochemical method; Potential ranges: 0 to + 1.5 V.

The materials fabricated CuO/MnO2/Gd2O3/binder/GCE sensor probe intra-day reproducibility (Fig. 8a) and inter-day validity (Fig. 8b) have been also studied and presented in Fig. 8. According to these studies, the sensor probe is reproduced almost the similar response in the same day in different measurements in the identical conditions. On the other hand, fabricated CuO/MnO2/Gd2O3/binder/GCE sensor probe is exhibited the almost similar reproducible responses in different inter-day measurement in the identical conditions, which is presented in the Fig. 8b.

As indicated in Fig. 9a, the electrochemical response of CuO/MnO2/Gd2O3 NSs/binder/GCE electrode is the maximum at the lowest concentration of 3-MPHyd. To execute this performance, a range of 3-MPHyd solution was prepared based on the concentration (full range 1.0 mM to 1.0 pM) and electrochemical measurement was carried out in the range from 0.0 to + 1.5 V. The linearity (r2: 0.9919) of the calibration plot (Fig. 9b,c was drawn as current versus concentration of 3-MPHyd). The analytical parameters have been calculated from the calibration plot (Fig. 9b) such as sensitivity (24.05 µA µM−1 cm−2), LOD (0.4 ± 0.02 pM at SNR of 3), LDR (1.0 pM to 0.1 mM), and Response time (9.25 s). Sensitivity was calculated from the slope of the calibration plot. It was calculated from the slope of the calibration plot by considering the active surface area of fabricated electrode (0.0316 cm2). During the sensing performances of 3-MPHyd chemical, the electrochemical current responses with CuO/MnO2/Gd2O3 NSs were increased with increasing of the target 3-MPHyd concentration. In presence of higher concentration of target analyte, the resultant current is gradually increased due to the oxidation of 3-MPHyd during electrochemical process with CuO/MnO2/Gd2O3 NSs. During the addition of analyte into the electrochemical solution, the oxidation current is increased gradually until 0.1 nM. After that the current response is found stable until 1.0 pM. No significant increase of current is occurred. A comparison between the electrodes fabricated on binary MnO/CuO, and ternary combinations of CuO/MnO2/Gd2O3 NSs were studied, and it was found that CuO/MnO2/Gd2O3 NSs/binder/GCE electrode was exhibited the highest electrochemical responses (Fig. 9d).

Detection of target chemical with the fabricated sensor probe. (a) Effect of concentration of 3-MPHyd compound based on CuO/MnO2/Gd2O3 NSs by electrochemical method, (b) calibration curve (Inset: log [3-MPHyd. Conc.] vs. Current), and (d) the comparison of electrochemical responses based on various electrodes. Analyte concentration: 0.1 nM; Holding time: 1.0 s; electrochemical method; Potential ranges: 0 to + 1.5.

The possible reaction mechanism of the capturing under optimum condition is depicted in Fig. 5. The metal oxides nanomaterials are investigated as potential materials with various electroanalytical methods57,58,59. The significant application of CuO/MnO2/Gd2O3 NSs materials was employed in the capturing of environmentally toxic compound. The CuO/MnO2/Gd2O3 NSs materials are nontoxic, long-term stability, consistence, high electrochemical activity, nontoxicity and easy-to-use. The electrochemical method for the CuO/MnO2/Gd2O3 NSs is considerably changed during the adsorption of 3-MPHyd as the target agent. Here, Table 1, it is presented about the materials for capturing of hydrazine and their derivatives by various electrochemical approaches60,61,62,63,64,65,66,67,68,69,70,71,72. In this nano-formulated ternary CuO/MnO2/Gd2O3 NS materials have accomplished great deal of attention owing to their structural, chemical, optical, electrochemical, and morphological properties in terms of large-active surface area, high-stability as well as good porosity, and permeability73,74,75,76,77,78. This method has numerous benefits including easy and facile preparation, accurate control of the reactants temperature, easy to handle, one-step reaction, and high-porosity as well as porous natures79,80,81,82. Finally, this mixed CuO/MnO2/Gd2O3 NSs material have also attracted substantial attention owing to their impending applications in fabricating chemical devices, opto-electronics, electro-analytical, selective detection of chemical and biochemical assays, hybrid-composites, electron-field emission sources for emission exhibits, and biochemical detections etc.

Real sample analysis

The ternary CuO/MnO2/Gd2O3 NS materials fabricated electrode probe is potentiality depended on the real sample treating and others feasibility parameters62,63,64,65. To measure the 3-MPHyd in the real environmental sample with various concentrations, the fabricated material based on CuO/MnO2/Gd2O3 NSs was used to detect in the industrial effluent (collected from the Jeddah Industrial Area, Saudi Arabia) and extracted samples. The collected industrial effluent was initially filtered to remove the floating large particles and then filtered sample was directly used for analysis. The extracted sample from plastic baby bottle, plastic water bottle, and PVC food packaging bags were also filtered and analysed with CuO/MnO2/Gd2O3 NSs/Nafion/GCE sensor probe by electrochemical method. The analysis report is presented in the Table 2. The results clarified that the proposed NSs has high possibility to selective detection of 3-MPHyd significantly and efficiently.

Conclusions

In this study, selective 3-MPHyd chemical material based on nano-formulated CuO/MnO2/Gd2O3 spike was fabricated and reported in details. The NSs of transition metal oxides were prepared by the hydrothermal approach in alkaline phase at low-temperature. The fabricated nanospikes were totally characterized by using FTIR, UV–Vis, XRD, XPS and FESEM. The slurry of ternary CuO/MnO2/Gd2O3 NSs was coated onto GCE as a layer of thin-film with conducting binder of nafion solution for selective and sensitive electrochemical detection of 3-MPHyd toxic compounds. The important experimental parameters such as sensitivity, low limit of detection, quantification, reaction time, sensitivity and reusability were performed systematically. The obtain results were good and satisfactorily enough to determine the target 3-MPHyd in short response time by electro-chemical approach. Here, CuO/MnO2/Gd2O3 NSs materials are an effective and potential for the selective detection of 3-MPHyd. Thus the materials can be used in broad scales for the efficient detection of selective 3-MPHyd by electrochemical method at room conditions for environmental remediation.

References

Tiwari, I., Gupta, M., Sinha, P. & Banks, C. E. Simultaneous determination of hydrazine and phenyl hydrazine using 4′-(4-carboxyphenyl)-2,2′:6′,2″ terpyridine diacetonitrile triphenylphosphine ruthenium(II) tetrafluoroborate complex functionalized multiwalled carbon nanotubes modified electrode. Mater. Res. Bull. 60, 166–173 (2014).

World Health Organization. Guidelines for Drinking-Water Quality. 2nd edn (World Health Organization, Geneva, 1993).

US Department of Health. Human Services (National Library of Medicine, Bethesda, 1993).

NIOSH, Method 3518, Phenyl hydrazine, Manual of Analytical Methods, 4th ed., (National Institute for Occupational Safety and Health, Cincinnati 1994).

Safavi, A. & Karimi, M. A. Flow injection chemiluminescence determination of hydrazine by oxidation with chlorinated isocyanurates. Talanta 58, 785–792 (2002).

Rawat, J. P. & Bhattacharjee, P. Spectrophotometric determination of phenylhydrazine with ammonium molybdate. Microchim. Acta 66, 619–624 (1976).

Tangy, W., Jiang, G. & Cai, Z. Determination of atrazine and its deethylated degradation product in water and sediment by using gas chromatography/ion trap mass spectrometry. Int. J. Environ. Anal. Chem. 85, 1117–1125 (2005).

Tiwari, I., Gupta, M., Sinha, P. & Aggarwal, S. K. Electro-oxidation of phenyl hydrazine on a modified electrode constructed using nanocomposite of ruthenium terpyridyl complex, multiwalled carbon nanotubes and nafion. Electrochim. Acta 76, 106–111 (2012).

Wang, G. et al. Copper oxide nanoarray based on the substrate of Cu applied for the chemical sensor of hydrazine detection. Electrochem. Commun. 11, 631–634 (2009).

Shukla, S., Chaudhary, S., Umar, A., Chaudhary, G. R. & Mehta, S. K. Tungsten oxide (WO3) nanoparticles as scaffold for the fabrication of hydrazine chemical sensor. Sens. Actuator B Chem. 196, 231–237 (2014).

Dai, Y., Huang, J., Zhang, H. & Liu, C. C. Highly sensitive electrochemical analysis of tunnel structured MnO2 nanoparticle-based sensors on the oxidation of nitrite. Sens. Actuator B Chem. 281, 746–750 (2019).

Khan, S. B. et al. Highly sensitive and stable phenyl hydrazine chemical sensors based on CuO flower shapes and hollow spheres. New J. Chem. 37, 1098–1104 (2013).

Rahman, M. M. et al. Fabrication of highly sensitive phenyl hydrazine chemical sensor based on as-grown ZnO–Fe2O3 microwires. Int. J. Electrochem. Sci. 8, 520–534 (2013).

Rahman, M. M., Khan, A., Marwani, H. M. & Asiri, A. M. Hydrazine sensor based on silver nanoparticle-decorated polyaniline tungstophosphate nanocomposite for use in environmental remediation. Microchim. Acta 183, 1787–1796 (2016).

Rahman, M. M., Balkhoyor, H. B. & Asiri, A. M. Ultrasensitive and selective hydrazine sensor development based on Sn/ZnO nanoparticles. RSC Adv. 6, 29342–29352 (2016).

Sheikh, T. A. et al. Trace electrochemical detection of Ni2+ ions with bidentate N,N′-(ethane-1,2-diyl)bis(3,4-dimethoxybenzenesulfonamide) [EDBDMBS] as a chelating agent. Inorg. Chim. Acta 464, 157–166 (2017).

Umar, A. et al. Enhanced photocatalytic degradation of harmful dye and phenyl hydrazine chemical sensing using ZnO nanourchins. Chem. Eng. J. 262, 588–596 (2015).

Ibrahim, A. A. et al. Growth and properties of Ag-doped ZnO nanoflowers for highly sensitive phenyl hydrazine chemical sensor application. Talanta 93, 257–263 (2012).

Rahman, M. M., Ahmed, J. & Asiri, A. M. Thiourea sensor development based on hydrothermally prepared CMO nanoparticles for environmental safety. Biosens. Bioelectron. 99, 586–592 (2018).

Awual, M. R., Hasan, M. M. & Khaleque, M. A. Efficient selenium(IV) detection and removal from water by tailor-made novel conjugate adsorbent. Sens. Actuators B Chem. 209, 194–202 (2015).

Awual, M. R. et al. Inorganic-organic based novel nano-conjugate material for effective cobalt(II) ions capturing from wastewater. Chem. Eng. J. 324, 130–139 (2017).

Awual, M. R. et al. Ligand field effect for Dysprosium(III) and Lutetium(III) adsorption and EXAFS coordination with novel composite nanomaterials. Chem. Eng. J. 320, 427–435 (2017).

Hussain, M. M., Rahman, M. M., Asiri, A. M. & Awual, M. R. Non-enzymatic simultaneous detection of L-glutamic acid and uric acid using mesoporous Co3O4 nanosheets. RSC Adv. 6, 80511–80521 (2016).

Xiao, H., Li, P., Jia, F. & Zhang, L. General non-aqueous sol-gel synthesis of nanostructured Sm2O3, Gd2O3, Dy2O3, and Gd2O3:Eu3+ phosphor. J. Phys. Chem. C 113, 21034–21041 (2009).

Rahman, M. M., Alam, M. M. & Asiri, A. M. Fabrication of an acetone sensor based on facile ternary MnO2/Gd2O3/SnO2 nanosheets for environmental safety. New J. Chem. 41, 9938–9946 (2017).

Abdullah, M. M. et al. Fabrication of ethanol chemical sensors based on as-prepared Gd2O3 nanorods by facile hydrothermal routes. J. Colloidal Sci. Biotechnol. 2, 322–327 (2013).

Abdullah, M. M. et al. Sensitive and fast response ethanol chemical sensor based on as-grown Gd2O3 nanostructures. J. Rare Earths. 33, 214–220 (2015).

Rahman, M. M., Hussain, M. M., Asiri, A. M., Alamry, K. A. & Hasnat, M. A. An enzyme free detection of L-Glutamic acid using deposited CuO.GdO nanospikes on a flat glassy carbon electrode. Surf. Interfaces 20, 100617 (2020).

Zheng, W. et al. Low power high purity red upconversion emission and multiple temperature sensing behaviors in Yb3+, Er3+ codoped Gd2O3 porous nanorods. ACS Sustain. Chem. Eng. 8, 9578–9588 (2020).

Xiao, F. E. N. G., Jun-song, G. A. O. & Zu-cheng, W. U. Removal of copper ions from electroplating rinse water using electrodeionization. J. Zhejiang Univ. Sci. A. 9, 1283–1287 (2008).

Rahman, M. M., Alam, M. M., Asiri, A. M. & Islam, M. A. Ethanol sensor development based on ternary-doped metal oxides (CdO/ZnO/Yb2O3) nanosheets for environmental safety. RSC Adv. 7, 22627–22639 (2017).

Chen, W. et al. Peroxidase-like activity of water-soluble cupric oxide nanoparticles and its analytical application for detection of hydrogen peroxide and glucose. Analyst 137, 1706–1712 (2012).

Kumar, P. P. N. V., Shameem, U., Kollu, P., Kalyani, R. L. & Pammi, S. V. N. Green synthesis of copper oxide nanoparticles using Aloe vera leaf extract and its antibacterial activity against fish bacterial pathogens. Biol. Nano. Sci. 5, 135–139 (2015).

Wang, G. S., Nie, L. Z. & Yu, S. H. Tunable wave absorption properties of β-MnO2 nanorods and their application in dielectric composites. RSC Adv. 2, 6216–6221 (2012).

Feng, L. et al. MnO2 prepared by hydrothermal method and electrochemical performance as anode for lithium-ion battery. Nanoscale Res. Lett. 9, 290 (2014).

Khan, S. A., Gambhir, S. & Ahmad, A. Extracellular biosynthesis of gadolinium oxide (Gd2O3) nanoparticles, their biodistribution and bioconjugation with the chemically modified anticancer drug taxol. Beilstein J. Nanotechnol. 5, 249–257 (2014).

Jenkins, R. & Snyder, R. L. Introduction to X-Ray Powder Diffractometry Vol. 138, 750–950 (Wiley, New York, 1994).

Huang, M. et al. Merging of Kirkendall growth and Ostwald Ripening: CuO@MnO2 Core-shell architectures for asymmetric supercapacitors. Sci. Rep. 4, 4518–4527 (2014).

Padil, V. V. T. & Cerník, M. Green synthesis of copper oxide nanoparticles using gum karaya as a biotemplate and their antibacterial application. Int. J. Anomed. 8, 889–898 (2013).

Dubal, D. P., Dhawale, D. S., Salunkhe, R. R., Jamdade, V. S. & Lokhande, C. D. Fabrication of copper oxide multilayer nanosheets for supercapacitor application. J. Alloys Compd. 492, 26–30 (2010).

Rahman, M. M., Jamal, A., Khan, S. B. & Faisal, M. CuO co-doped ZnO based nanostructured materials for sensitive chemical sensor applications. ACS Appl. Mater. Interfaces 3, 1346–1351 (2011).

Huang, M. et al. Merging of Kirkendall Growth and Ostwald Ripening: CuO@MnO2 core–shell architectures for asymmetric supercapacitors. Sci. Rep. 4, 4518–4526 (2014).

Li, L. et al. Controlled growth of CuS on electrospun carbon nanofibers as an efficient counter electrode for quantum dot-sensitized solar cells. J. Phys. Chem. C 118, 16526–16535 (2014).

Akhavan, O., Azimirad, R., Safa, S. & Hasani, E. CuO/Cu(OH)2 hierarchical nanostructures as bactericidal photocatalysts. J. Mater. Chem. 21, 9634–9640 (2011).

Wang, J. G., Yang, Y., Huang, Z. H. & Kang, F. Rational synthesis of MnO2/conducting polypyrrole@ carbon nanofiber triaxial nano-cables for high-performance supercapacitors. J. Mater. Chem. 22, 16943–16949 (2012).

Xia, H. et al. Hierarchically structured Co3O4@ Pt@ MnO2 nanowire arrays for high-performance supercapacitors. Sci. Rep. 3, 2978–2985 (2013).

Wang, C. et al. Controlled synthesis of micro/nanostructured CuO anodes for lithium-ion batteries. Nano. Energy 9, 334–344 (2014).

Pawar, S. M. et al. Multi-functional reactively-sputtered copper oxide electrodes for supercapacitor and electro-catalyst in direct methanol fuel cell applications. Sci. Rep. 6, 21310–21318 (2016).

Patel, S. K. S. et al. Structural and magnetic properties of Co-doped Gd2O3 nanorods. J. Magn. Magn. Mater. 403, 155–160 (2016).

Devi, A. et al. Rare-earth substituted HfO2 thin films grown by metalorganic chemical vapor deposition. Thin Solid Films 520, 4512–4517 (2012).

Ren, S. et al. Surface modification of sulfonated poly (ether ether ketone) membranes using Nafion solution for direct methanol fuel cells. J. Membr. Sci. 247, 59–63 (2005).

Wang, Z., Liu, G., Zhang, L. & Wang, H. Electrochemical detection of trace cadmium in soil using a Nafion/stannum film-modified molecular wire carbon paste electrodes. Ionics 19, 1687–1693 (2013).

Rahman, M. M., Alam, M. M. & Alamry, K. A. Sensitive and selective m-Tolylhydrazine sensor development based on CdO nanoparticles decorated multi-walled carbon nanotubes. J. Ind. Eng. Chem. 77, 309–316 (2019).

Rahman, M. M., Jamal, A., Khan, S. B., Faisal, M. & Asiri, A. M. Fabrication of phenyl-hydrazine chemical sensor based on Al-doped ZnO nanoparticles. Sens. Transducers J. 134, 32–44 (2011).

Akhter, H. et al. Fabrication of hydrazine sensor based on silica-coated Fe2O3 magnetic nanoparticles prepared by a rapid microwave irradiation method. J. Alloys Compd. 698, 921–929 (2017).

Rahman, M. M., Ahmed, J. & Asiri, A. M. Development of creatine sensor based on antimony-doped tin oxide (ATO) nanoparticles. Sens. Actuators B Chem. 242, 167–175 (2017).

Dong, B. et al. High dispersion and electrocatalytic activity of Pd/titanium dioxide nanotubes catalysts for hydrazine oxidation. J. Power Source 175, 266–271 (2008).

Lu, W., Shu, J., Wang, Z., Haung, N. & Song, W. The intrinsic oxidase-like activity of Ag2O nanoparticles and its application for colorimetric detection of sulfite. Mater. Lett. 154, 33–36 (2015).

Yue, X., Yang, W., Xu, M., Liu, X. & Jia, J. High performance of electrocatalytic oxidation and determination of hydrazine based on Pt nanoparticles/TiO2 nanosheets. Talanta 144, 1296–1300 (2015).

Umar, A., Rahman, M. M., Kim, S. H. & Hahn, Y. B. Zinc oxide nanonail based chemical sensor for hydrazine detection. Chem. Commun. (Camb.) 2, 166–168 (2008).

Di Zhao, Y., De Zhang, W., Chen, H. & Luo, Q. M. Anodic oxidation of hydrazine at carbon nanotube powder microelectrode and its detection. Talanta 58, 529–534 (2002).

Kumar, R. et al. Ag-doped ZnO nanoellipsoids: potential scaffold for photocatalytic and sensing applications. Talanta 137, 204–213 (2015).

Salimi, A., Miranzadeh, L. & Hallaj, R. Amperometric and voltammetric detection of hydrazine using glassy carbon electrodes modified with carbon nanotubes and catechol derivatives. Talanta 75, 147–156 (2008).

Ni, Y., Zhu, J., Zhang, L. & Hong, J. Hierarchical ZnO micro/nanoarchitectures: hydrothermal preparation, characterization and application in the detection of hydrazine. CrystEngComm 12, 2213–2218 (2010).

Liu, J., Li, Y., Jiang, J. & Huang, X. C@ ZnO nanorod array-based hydrazine electrochemical sensor with improved sensitivity and stability. Dalton Trans. 39, 8693–8697 (2010).

Sultana, W., Ghosh, S. & Eraiah, B. Zinc oxide modified au electrode as sensor for an efficient detection of hydrazine. Electroanalysis 24, 1869–1877 (2012).

Han, K. N., Li, C. A., Bui, M. P. N., Pham, X. H. & Seong, G. H. Control of ZnO morphologies on carbon nanotube electrodes and electrocatalytic characteristics toward hydrazine. Chem. Commun. (Camb). 47, 938 (2011).

Fang, B., Zhang, C., Zhang, W. & Wang, G. A novel hydrazine electrochemical sensor based on a carbon nanotube-wired ZnO nanoflower-modified electrode. Electrochim. Acta 55, 178–182 (2009).

Zhang, C. et al. Enhancement in analytical hydrazine based on gold nanoparticles deposited on ZnO-MWCNTs films. Sens. Actuators B Chem. 150, 247–253 (2010).

Rahman, M. M., Alam, M. M., Asiri, A. M. & Awual, M. R. Fabrication of 4-aminophenol sensor based on hydrothermally prepared ZnO/Yb2O3 nanosheets. New J. Chem. 41, 9159–9169 (2017).

Rahman, M. M., Alam, M. M., Asiri, A. M. & Islam, M. A. 3, 4-Diaminotoluene sensor development based on hydrothermally prepared MnCoxOy nanoparticles. Talanta 176, 17–25 (2018).

Arshad, M. N. et al. Fabrication of cadmium ionic sensor based on (E)-4-Methyl-N′-(1-(pyridin-2-yl) ethylidene) benzenesulfonohydrazide (MPEBSH) by electrochemical approach. J. Organomet. Chem. 827, 49–55 (2017).

Awual, M. R. et al. Facile mercury detection and removal from aqueous media involving ligand impregnated conjugate nanomaterials. Chem. Eng. J. 290, 243–251 (2016).

Sheikh, T. A., Rahman, M. M., Asiri, A. M., Marwani, H. M. & Awual, M. R. 4-Hexylresorcinol sensor development based on wet-chemically prepared Co3O4@Er2O3 nanorods: a practical approach. J. Ind. Eng. Chem. 66, 446–455 (2018).

Awual, M. R. et al. Efficient detection and adsorption of cadmium(II) ions using innovative nano-composite materials. Chem. Eng. J. 343, 118–127 (2018).

Rahman, M. M. Selective capturing of phenolic derivative by a binary metal oxide microcubes for its detection. Sci. Rep. 9, 19234 (2019).

Rahman, M. M. et al. Facile and efficient 3-chlorophenol sensor development based on photolumenescent core-shell CdSe/ZnS quantum dots. Sci. Rep. 10, 557 (2020).

Rahman, M. M. & Ahmed, J. Cd-doped Sb2O4 nanostructures modified glassy carbon electrode for efficient detection of melamine by electrochemical approach. Biosens. Bioelectron. 102, 631–636 (2018).

Rahman, M. M. Efficient formaldehyde sensor development based on Cu-codoped ZnO nanomaterial by an electrochemical approach. Sens. Actuators B Chem. 305, 127541 (2020).

Rahman, M. M. Label-free Kanamycin sensor development based on CuONiO hollow-spheres: food samples analyses. Sens. Actuators: B Chem. 264, 84–91 (2018).

Rahman, M. M., Wahid, A. & Asiri, A. M. Development of highly sensitive 1, 4-dioxane sensor with semiconductor NiO-doped Nd2O3 nanostructures by electrochemical approach. New J. Chem. 43, 17395–17402 (2019).

Alam, M. M., Asiri, A. M. & Rahman, M. M. Fabrication of phenylhydrazine sensor with V2O5 doped ZnO nanocomposites. Mater. Chem. Phys. 243, 122658 (2020).

Acknowledgements

This project was funded by the National Plan for Science, Technology and Innovation (MAARIFAH)—King Abdulaziz City for Science and Technology—the Kingdom of Saudi Arabia—Award No. (14-BIO1978-03). The authors also, acknowledge with thanks Science and Technology Unit, King Abdulaziz University for technical support.

Author information

Authors and Affiliations

Contributions

M.M.R. Designed and performed the experiments and wrote the manuscript text; M.M.A. Performed all sensor applications with fabricated sensor material; A.M.A. Revised the manuscript and provided the technical supports; F.A.D.M.O. Performed the optical characterization of ternary nanostructure materials. Finally, all the authors are revised and approved the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rahman, M.M., Alam, M.M., Asiri, A.M. et al. Fabrication of selective and sensitive chemical sensor probe based on ternary nano-formulated CuO/MnO2/Gd2O3 spikes by hydrothermal approach. Sci Rep 10, 20248 (2020). https://doi.org/10.1038/s41598-020-76662-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-76662-6

This article is cited by

-

Highly sensitive sensor probe development with ZCCO nano-capsule composites for the selective detection of unsafe methanol chemical by electrochemical technique

Applied Nanoscience (2022)

-

A reliable electrochemical approach for detection of testosterone with CuO-doped CeO2 nanocomposites-coated glassy carbon electrode

Journal of Materials Science: Materials in Electronics (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.