Abstract

The surfactant and colloidal nanoparticles has been considered for various applications because of interaction of both complex mixtures. The hydrophilic SiO2 nanoparticle could not be surface active behavior at the liquid/air interface. In this study, the SiO2 nanoparticles have been modified with 3-isocyanatopropyltriethoxy-silane (ICP), and the effect of foam stability has been investigated. The physical properties of surface modified SiO2 nanoparticle were analyzed by XRD, TGA, FT-IR, and SEM. After surface modification of SiO2 nanoparticles, the contact angle of SiO2 nanoparticle was also increased from 62° to 82° with increased ICP concentration. The experimental result has shown that SiO2 nanoparticle with ICP was positive effect and improved foam stability could be obtained at proper ICP concentration compared with un-modified SiO2 nanoparticle.

Similar content being viewed by others

Introduction

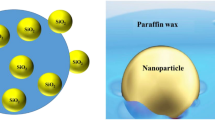

The surfactant and nanoparticles has been considered for various applications because of interaction of both complex mixtures, which could influence the dynamic and static behavior1,2,3,4. Silica (SiO2) nanoparticles have been widely used in various applications such as catalyst, biomolecule separations, chromatographic supports5,6. SiO2 nanoparticles are also used as foam stabilizers for the foams and emulsion applications7,8. Generally, aqueous foams are thermodynamically unstable because of breaking of the film or irreversible drainage of the liquid. It is reported that colloidal hydrophobic particles are able to significantly improve the foam stability8. These approaches are being used for the stable foam applications. However, as synthesized mesoporous silica nanoparticles have hydrophilic properties, which is not adsorb and surface active behavior at the liquid/air interface. Therefore, the use of hydrophilic SiO2 nanoparticles has been disadvantageous. In order to enhance the foam stability, the surface modification of SiO2 nanoparticle should be needed. Normally, the modified SiO2 nanoparticles could stabilized the foam by interfacial elasticity9. A number of methods surface modification of SiO2 nanoparticles have been developed by using organic or in inorganic additives10,11,12. The SiO2 nanoparticle surface has been changed from hydrophilic to hydrophobic properties, resulting from incorporation with functional groups. It is reported that the hydrophobic SiO2 nanoparticle has enhanced affinity to organic compound10.

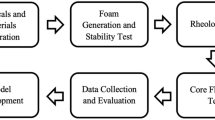

In this study, the surface modification of SiO2 nanoparticles has been prepared by copolymerization with organic-silica precursors in the presence of a cetyltrimethylammonium bromide. Our approach has shown in a one-pot synthesis method and did not add any co-solvent or additives during the synthesis of SiO2 nanoparticles. After modification of the SiO2 nanoparticle, the morphology and structure were analyzed by SEM and XRD. Foam stability has been improved with SiO2 nanoparticles modified by 3-isocyanatopropyltriethoxy-silane.

Result and discussion

Figure 1a shows the small-angle XRD patterns of SiO2 and SiO2-ICP samples synthesized according to the ICP concentration. All SiO2-ICP samples show an intense (100) peak and two weak (110, 200) peaks, indicating that the presence of three peaks is common in SiO2 materials and 2D hexagonally ordered structure. The intensity of d(100) in the XRD peaks were decreased as a function of the ICP concentration. It is indicating that the addition of ICP did not influence the SiO2 structure, but resulted in well-ordered structure when ICP was added during the synthesis13. Moreover, the addition of ICP resulted in the decrease of SiO2 nanoparticle size, but not in the collapse in the SiO2 mesoporous structure13. The TGA profiles of as-synthesized SiO2 particles are depicted in Fig. 1b. The first region from room temperature to 150 °C is attributed to the release of absorbed water on the silica surface. The drastic weight loss (37%) caused by decomposition of organic molecule and CTAB in the SiO2 matrix was observed in the temperature range of 150–300 °C. The weight loss after 550 °C was decreased, indicating that the pure SiO2 particles can be obtained. And further weight loss was observed after 500 °C according to the ICP concentration, which is decomposed of ICP modification.

The morphology of SiO2 and SiO2-ICP particles was observed by FE-SEM and TEM. Figure 2 shows the SEM and TEM images of pristine SiO2 and SiO2-ICP particles. As shown in Fig. 2, SEM and TEM image is clearly reveal that the morphology of SiO2-ICP nanoparticles was transformed from kidney-bean-shape to spherical shape according to the ICP concentration. It also observed that the particle size of SiO2 decreased with higher ICP concentration (500 nm < Fig. 2d,h). Moreover, the mesopore structures of SiO2 are also observed in spite of their different particle size (Fig. 2e–h). From the XRD, SEM, and TEM, the addition of ICP could modify the morphology and size of SiO2 particles during SiO2 synthesis.

The surface modification of SiO2 particles was investigated by FT-IR. Figure 3 shows the FT-IR spectra of SiO2 and SiO2-ICP samples. The peak at 1060 cm−1 was attributed to the Si–O–C asymmetry stretching vibration and Si–OH stretching vibration14. After modification of ICP, the new peaks were observed at 2974 and 3700 cm−1, which is assigned to C–H stretching vibration in CH2 and CH3 and the 1387 cm−1 peak was corresponding to the vibration of C–H, which was not observed in SiO2 particles but were in SiO2-ICP particles15. This is the fact that the ICP was effectively grafted on the SiO2 surface. The intensity peak of at 1060 cm−1 was decreased as a function of ICP concentration, indicating the surface modification of SiO2 particles by ICP.

For the foam stability measurement, the aqueous foam was generated and its stability was recorded by using Foamscan analyzer. The N2 gas was used to produce the foam volume of 200 ml. After that, the gas flow was stopped and foam volume was monitored according to time. Figure 4 shows the decay of the foam volume of surfactant which contained 1 wt% SiO2 particles (EM 100, 1 wt%) at pH 2. All the samples show the similar foam volume properties and the foam stability of SiO2-ICP particles and exhibit higher foam stability than SiO2 particles without ICP. The foam stability was improved with increasing ICP concentration. It is considered that the hydrophobic particles can be attached on the liquid–gas interfaces and stabilize the foam bubbles in surfactant-free diluted suspensions16,17,18,19. Moreover, it is reported that the smaller particle leads to higher viscosity of the suspension under identical particle geometry and type20. Therefore, the high ICP concentration could be favor the foam stability because of modification of wettability of SiO2 particles at the air–water interface and aqueous solution.

In order to clarify the improvement of foam stability of SiO2 nanoparticles, we have evaluated the contact angles of SiO2-ICP samples in air. The particle-stabilized silica nanoparticle depends on significantly on the particle hydrophobicity at the water–air interface in terms of the contact angle21. It is reported that the hydrophilicity/hydrophobicity have been determined by contact angle method, which is important evidence for affecting properties of the particle surface22. Figure 5 shows the contact angle of SiO2 nanoparticles with increasing ICP concentration. As shown in Fig. 5, in the absence of ICP, the contact angle is 62°. However, the ICP concentration is increased, contact angle was also increased from 62° to 82°. The result of contact angle of SiO2-ICP nanoparticle matched well with the foam stabilities. The SiO2 nanoparticle surface thus undergo transition more hydrophobic wettability, indicating that more ICP molecules are adsorbed on the SiO2 nanoparticle surface. It can be concluded that the organic groups of ICP affect the surface properties in the SiO2 nanoparticles.

Conclusion

In this study, we synthesized SiO2 nanoparticles through sol–gel process and modified its surface by adjusting ICP concentration. The surface modification of SiO2 nanoparticles was analyzed by XRD, TGA, SEM, TEM, FT-IR and contact angle. The morphology of silica nanoparticle transformed from kidney-bean-shape to spheres according to the ICP concentration and contact angle was increased as the ICP amount was increased, which became more hydrophobic. The results of TGA and FT-IR have shown the interaction between the SiO2 nanoparticle surface and ICP after the surface modification. The foam stability was gradually increased with increasing ICP amount, which means that the hydrophobic properties of SiO2 nanoparticle affect the foam stability and foam stabilization.

Methods

The SiO2 nanoparticles were synthesized by following a published procedure23. Typically, the cetyltrimethylammonium bromide (CTAB, 2.0 g) and 2 M sodium hydroxide solution (NaOH, 7.0 ml) were added in deionized water and the mixture was stirred and heated at 80 °C. To clear this solution, tetraethylorthosilicate (TEOS, 9.3 ml) and desired 3-isocyanatopropyltriethoxy-silane (ICP) were added to the solution via rapid injection. The withe precipitation was observed after 3 min and the solution was maintained at 80 °C for 2 h. After the reaction time, the as-synthesized particles were washed by water and methanol, and dried under vacuum oven.

The morphology of SiO2 nanoparticles were analyzed by a field emission scanning electron microscopy (FE-SEM, Hitachi), a high resolution transmission electron microscope (HR-TEM, JEOL). Small angle X-ray diffraction (XRD, PANalytical) analysis was conducted by using Cu Kα radiation (λ = 1.5405) in a range of 0.5°–5° 2θ. Thermogravimetric analysis (TGA, Mettler-Toledo) was carried out to measure the concentration of CTAB in SiO2 nanoparticles under flowing N2 with a heating rate of 5 °C min−1. The fourier transform infrared spectroscopy (FT-IR) spectra of SiO2 nanoparticles was recorded in FT-IR spectrophotometer (VERTEX 80). Contact angle of water drops on SiO2 nanoparticles was determined using Phoenix series.

The foam stability was analyzed with commercially available Foamscan instrument (Teclis/IT Concept). Foamscan is commercially available instrument to measure foamability, foam stability, and foam drainage24. For the foam stability, Elotant™ Miloside 100 (EM 100, LG Household and Health Care) was used as surfactant and as-synthesized SiO2 nanoparticles (1 wt%) were added to the surfactant solution to investigate the effect of foam stability which contains as-synthesized SiO2 nanoparticles according to the ICP concentration.

References

Hunter, T. N., Wanless, E. J., Jameson, G. J. & Pugh, R. J. Non-ionic surfactant interactions with hydrophobic nanoparticles: Impact on foam stability. Colloids Surf. A: Physicochem. Eng. Asp. 347, 81–89 (2009).

Whitby, C. P., Fornasiero, D., Ralston, J., Liggieri, L. & Ravera, F. Properties of fattyamine-silica nanoparticle interfacial layers at the hexane-water interface. J. Phys. Chem. C 116, 3050–3058 (2012).

Jiang, L. et al. Interfacial study on the interaction between hydrophobic nanoparticles and ionic surfactants. Colloids Surf. A: Physicochem. Eng. Asp. 488, 20–27 (2016).

ShamsiJazeyi, H., Miller, C. A., Wong, M. S., Tour, J. M. & Verduzco, R. Polymer-coated nanoparticles for enhanced oil recovery. Appl. Polym. Sci. 131, 40576 (2014).

Hoppe, R., Ortlam, A., Rathousky, J., Schulz-Ekloff, G. & Zukal, A. Synthesis of titanium-containing MCM-41 mesoporous molecular sieves in the presence of zinc phthalocyanine and rhodamine B. Microporous Mater. 8, 267–273 (1997).

Chomski, D., Dag, O., Kuperman, A., Coombs, N. & Ozin, G. A. New forms of luminescent silicon: Silicon-silica composite mesostructures. Chem. Vap. Dopos. 2, 8–13 (1996).

Binks, B. P. & Rodrigues, J. A. Influence of surfactant structure on the double inversion of emulsions in the presence of nanoparticles. Colloids Surf. A: Physicochem. Eng. Asp. 345, 195–201 (2009).

Zhu, Y., Pei, X., Jiang, J., Cui, Z. & Binks, B. P. Responsive aqueous foams stabilized by silica nanoparticles hydrophobized in situ with a conventional surfactant. Langmuir: ACS J. Surf. Colloids 31, 12937–12943 (2015).

Vatanparast, H., Samiee, A., Bahramian, A. & Javadi, A. Surface behavior of hydrophilic silica nanoparticle-SDS surfactant solutions: I. Effect of nanoparticle concentration on foamability and foam stability. Colloids Surf. A: Physicochem. Eng. Asp. 513, 430–441 (2017).

Kang, T., Jang, I. & Oh, S.-G. Surface modification of silica nanoparticles using phenyl trimethoxy silane and their dispersion stability in N-methyl-2-pyrrolidone. Colloids Surf. A: Physicochem. Eng. Asp. 501, 24–31 (2016).

Ma, X. et al. Surface modification and characterization of highly dispersed silica nanoparticles by cationic surfactant. Colloids Surf. A: Physicochem. Eng. Asp. 358, 172–176 (2010).

Zhu, Y., Jiang, J., Cui, Z. & Binks, B. P. Responsive aqueous foams stabilized by silica nanoparticles hydrophobised in situ with a switchable surfactant. Soft Matter 10, 9739–9745 (2014).

Zeng, W., Qian, X.-F., Yin, J. & Zhu, Z.-K. The drug delivery system of MCM-41 materials via co-condensation synthesis. Mat. Chem. Phys. 97, 437–441 (2006).

Liu, H. et al. Preparation of porous hollow SiO2 spheres by a modified stober process using MF microspheres as templates. J. Clust. Sci 23, 273–285 (2012).

Yilgor, E., Atilla, G. E., Ekin, A., Kurt, P. & Yilgor, I. Isopropyl alcohol: An unusual, powerful, ‘green’ solvent for the preparation of silicone-urea copolymers with high urea contents. Polymer 44, 7787–7793 (2003).

Binks, B. P. Particles as surfactant-similarities and differences. Curr. Opin. Colloid Interface Sci. 7, 21–41 (2002).

Du, Z. P. et al. Outstanding stability of particle-stabilized bubbles. Langmuir 19, 3106–3108 (2003).

Dickinson, E., Ettelaie, R., Kostakis, T. & Murry, B. S. Factors controlling the formation and stability of air bubbles stabilized by partially hydrophobica silica nanoparticles. Langmuir 20, 8517–8525 (2004).

Binks, B. P. & Horozov, T. S. Aqueous foams stabilized solely by silica nanoparticles. Angew. Chem. Int. Ed. 44, 3722–3725 (2005).

Kadoi, K. & Nakae, H. Relationship between foam stabilization and physical properties of particles on aluminum foam production. Mater. Trans. 52, 1912–1919 (2011).

Binks, B. P., Duncumb, B. & Murakami, R. Effect of pH and salt concentration on the phase inversion of particle-stabilized foams. Langmuir 23, 9143–9146 (2007).

Mahltig, B. & Bottcher, H. Modified silica sol coatings for water-repellent textiles. J. Sol-Gel Sci. Technol. 27, 43–52 (2003).

Huh, S., Wiench, J., Yoo, J.-C., Pruski, M. & Lin, V.S.-Y. Orgarnic functionalization and morphology control of mesoporous silica via co-condensation synthesis method. Chem. Mater. 15, 4247–4256 (2003).

Yoon, I.-H. et al. Effect of silica nanoparticles on the stability of decontamination foam and their application for oxide of corroded specimens. Ann. Nucl. Energy 73, 168–174 (2014).

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020M2A8A5079107).

Author information

Authors and Affiliations

Contributions

M.C. conducted the most of experiments and wrote the manuscript. W.K.C., C.H.J. and S.B. Kim have reviewed the manuscript and given the suggestions for the study.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Choi, M., Choi, WK., Jung, CH. et al. The surface modification and characterization of SiO2 nanoparticles for higher foam stability. Sci Rep 10, 19399 (2020). https://doi.org/10.1038/s41598-020-76464-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-76464-w

This article is cited by

-

Non-isothermal crystallization analysis of recycled high-density polyethylene/black shale composites

Journal of Thermal Analysis and Calorimetry (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.