Abstract

Immiscible semiconductors are of premier importance since the source of lighting has been replaced by white light-emitting-diodes (LEDs) composed of thermodynamically immiscible InxGa1−xN blue LEDs and yellow phosphors. For realizing versatile deep-ultraviolet to near-infrared light-emitters, Al1−xInxN alloys are one of the desirable candidates. Here we exemplify the appearance and self-formation sequence of compositional superlattices in compressively strained m-plane Al1−xInxN films. On each terrace of atomically-flat m-plane GaN, In- and Al-species diffuse toward a monolayer (ML) step edge, and the first and second uppermost < \(\stackrel{-}{1}\stackrel{-}{1}20\)> cation-rows are preferentially occupied by Al and In atoms, respectively, because the configuration of one In-N and two Al-N bonds is more stable than that of one Al-N and two In-N bonds. Subsequent coverage by next < \(\stackrel{-}{1}\stackrel{-}{1}20\)> Al-row buries the < \(\stackrel{-}{1}\stackrel{-}{1}20\)> In-row, producing nearly Al0.5In0.5N cation-stripe ordering along [0001]-axis on GaN. At the second Al0.72In0.28N layer, this ordinality suddenly lessens but In-rich and In-poor < \(\stackrel{-}{1}\stackrel{-}{1}20\)>-rows are alternately formed, which grow into respective {0001}-planes. Simultaneously, approximately 5-nm-period Al0.70In0.30N/Al0.74In0.26N ordering is formed to mitigate the lattice mismatch along [0001], which grow into approximately 5-nm-period Al0.70In0.30N/Al0.74In0.26N {\(10\stackrel{-}{1}2\)} superlattices as step-flow growth progresses. Spatially resolved cathodoluminescence spectra identify the emissions from particular structures.

Similar content being viewed by others

Introduction

Incandescent bulbs and fluorescent tubes are progressively replaced by compact and high-efficiency white light-emitting-diodes (LEDs)1 composed of InxGa1-xN quantum-well (QW) blue LEDs2 and yellow phosphors, thanks to the threading dislocation (TD)-tolerant radiation probability3,4,5 of localized excitons in low InN mole fraction (x) InxGa1-xN alloys. Consequently the research fields of thermodynamically immiscible III-nitride alloys6,7,8,9,10 have been exciting more than 25 years. For realizing high-efficiency light sources for high color-rendering-index lighting, curing, skin therapy, and sterilization/disinfection, near- to far-ultraviolet light-emitters of similarly high radiative efficiency as InxGa1−xN are indispensable. Especially, deep ultraviolet (DUV) LEDs are a key device for biochemical detection, non-line-of-sight communications, and disinfection of viruses.

For the urgent development of DUV LEDs, AlxGa1−xN alloys have been studied and great strides have been achieved11,12,13,14,15,16,17,18,19. Beyond AlxGa1−xN, the use of immiscible7,10,20,21,22 Al1−xInxN alloys is an exotic way for realizing light-emitters23,24 operating in DUV to infrared wavelengths, because their bandgap energies (Eg) cover from DUV (Eg = 6.01 eV for AlN) to infrared (Eg = 0.65 eV for InN) wavelengths. However, c-plane Al0.82In0.18N epilayers lattice-matched to GaN have been exclusively investigated as auxiliary components such as Al0.82In0.18N/GaN distributed Bragg reflectors25 and an Al0.82In0.18N barrier for GaN heterostructure field-effect transistors26. The major reason why Al1−xInxN have scarcely been investigated as light-emitting media includes the difficulties in growing Al1−xInxN containing low concentration of nonradiative recombination centers (NRCs), NNRC, as follows. Because AlN and InN have large lattice mismatch (Δa/a) of approximately 14%, the delta-lattice-parameter (DLP) model27 predicts nonmiscible of Al1-xInxN alloys7,10,20,21,22. Also, because optimum film growth temperatures (Tg) for metalorganic vapor phase epitaxy (MOVPE) of AlN (> 1600 °C) and InN (< 400 °C) are significantly different, Al1-xInxN alloys suffer from kinetic phase separation due to instantaneous evaporation of In or InN from the surface7. Consequently, there have been few reported results on a near-band-edge (NBE) emission of Al1−xInxN films5,23,28,29,30,31,32,33,34 and QWs24,35, and the NBE emission exhibited large full-width at half-maximum (FWHM) value of a few hundred meV5,23,24,28,29,30,31,32,33,34,35 and Stokes’ shifts (SSs) larger than several hundred meV or nearly 1 eV, which is the energy difference between the absorption and emission. From a different perspective, large SS29,30,32,34, weak thermal quenching23,32, and morphology-insensitive cathodoluminescence (CL) intensity mapping images23 for the NBE emission owing to short minority-carrier (hole) diffusion length (Lp) likely suggest that the NBE emission originates from certain localized states. Such localized states may have advantages3,4,5 in obtaining high quantum efficiencies (QE). However, insufficient photoluminescence (PL) lifetimes (\({\tau }_{\mathrm{PL}}\)) at room temperature, which nearly represents the nonradiative lifetime (\({\tau }_{\mathrm{NR}}\)), shorter than 80 ps23,29,33 indicates the difficulties in decreasing NNRC. Moreover, there have been limited publications23,31,32,34 on an NBE emission of nonpolar-plane Al1-xInxN, although (Al,In,Ga)N grown in off-polar orientations36,37 are a promising candidate for opto- and electronic devices of ultimate performance: as summarized in Refs.5,23,36,37, nonpolar planes are electrically-neutral and polarization discontinuity normal to heterointerfaces does not exist since the c-axis is parallel to the interface. Such QWs do not suffer the deleterious polarization-induced electric field5,23,36,37,38 and therefore regular conduction- and valence-band profiles result in well-overlapped electron–hole wavefunctions5,23,36,37,38,39.

The authors grew m-plane Al1−xInxN on m-plane freestanding (FS)-GaN substrates by MOVPE32, which exhibited predominant NBE emission bands ranging from 5.81 to 2.39 eV with increasing x. By installing these films, planar vacuum fluorescent display (VFD) devices emitting polarized UV-C, blue, and green lights were trial-manufactured23. In Fig. 1, polarized emission spectra of our Al0.68In0.32N green VFD device at 300 K are shown23. The insets show the configuration of crystal axes and a photograph of the device under operation. Although the magnitude of polarization (\(\rho\)) was not unity, the electric field (E) component of the light was polarized parallel to the c-axis (E//c). However, little is known about the luminescence mechanisms of Al1−xInxN alloys5,23,24,28,29,30,31,32,33,34,35 and it is worth clarifying the reason why Al1−xInxN exhibits defect-tolerant radiation probability. In this article, two distinct length-scale cation orderings are exemplified to explain the appearance and self-formation sequence of compositional superlattices (CSLs) in m-plane Al0.72In0.28N films, in which excitons are confined in Al0.70In0.30N layers. Then, so-called composition-pulling21,40 phenomenon is described. Finally, cross-sectional spatially resolved cathodoluminescence (SRCL) spectra are correlated with these particular zones.

Partially reproduced with permission from Chichibu et al.23.

Polarized emission spectra of the green-light-emitting VFD device comprising of m-plane Al0.68In0.32N epitaxial nanoboards operated at 300 K. Although the magnitude of polarization (ρ) was not unity, the emission is essentially E//c polarized. Insets show the configuration of crystal axes and a photograph of the device under operation, taken from the surface through the grid electrodes: the shadows of the grids are superimposed on the emitting patterns.

Results: compositional superlattices (CSLs) in a pseudomorphic Al0.72In0.28N film

Figure 2 shows the structures of our m-plane Al0.7In0.3N epilayer32 used in the VFD device23 in Fig. 1. Its surface is composed of elliptic grains with the major axes almost parallel to < \(\stackrel{-}{1}\stackrel{-}{1}20\) > a-axis, as shown in the surface atomic-force microscopy (AFM) image23,32 in Fig. 2a. For observing slight changes in crystallographic orientation and/or chemical composition, cross-sectional high-angle annular dark-field (HAADF) images were taken using a scanning transmission-electron microscopy (STEM). In Fig. 2a, the directions of visions for Fig. 2b from (0001) and Fig. 2c,d from {\(11\stackrel{-}{2}0\)} cross-sections are indicated schematically by eyes. These images (Fig. 2b,c) indicate that the epitaxial Al1−xInxN structure comprises of three zones, namely (I) approximately 60-nm-thick “Pseudomorphic zone”, (II) approximately 100 to 150-nm-thick nonuniform zone named “Transition zone”, and (III) approximately 500-nm-thick “Nanoboards zone”, as defined in Fig. 2c. The nanoboards are the elliptic grains seen in Fig. 2a. Corresponding magnified images are shown in Figs. 2d, 3f,g, Fig. 3c–e and a, respectively. As shown in Fig. 2c,d, Pseudomorphic zone is a three-dimensional (3D) film with regularly aligned stripes with bright and dim contrasts parallel to an {\(10\stackrel{-}{1}2\)} plane. The continuous film growth seems to terminate in Transition zone at the areas encircled in Fig. 3c,d, and a dense array of 80 to 100-nm-thick Al1−xInxN nanoboards23, which are divided by spatial gaps, align on {\(10\stackrel{-}{1}3\)} facets in Nanoboards zone, as shown in Fig. 2c. As similar samples32 have been characterized by using x-ray diffraction (XRD) measurements to have an epitaxial relationship with GaN underlayer, these Al1−xInxN structures are called as epitaxial nanoboards.

Panels (a), (c), and (d) are reproduced with permission from Chichibu et al.23.

(a) Surface AFM image for the m-plane Al0.7In0.3N epitaxial structure grown on m-plane GaN substrate. Cross-sectional HAADF-STEM images taken from (b) (0001) and (c, d) {\(11\stackrel{-}{2}0\)} cross-sections. In (a), the directions of visions for (b) and (c, d) are schematically indicated by eyes beside the image.

(a, c, d, e, f, g) Cross-sectional HAADF-STEM images for the m-plane Al0.7In0.3N epitaxial structure taken from {\(11\stackrel{-}{2}0\)} cross-section. In (a), exact locations where nanoprobe EDX composition analyses were carried out in “Nanoboards zone” are indicated, and corresponding local InN mole fractions x are shown using a frequency histogram in (b). In (c, d), the areas where the continuous film growths terminated in “Transition zone” are indicated by circles. In (e), high-resolution HAADF image taken around the starting area of the gap is shown. As indicated by triangles, slight changes in crystal orientations are observed. Local x values measured at the locations indicated by rectangles in (f) and (g) are summarized in frequency histograms shown in (h) and (i) for the bright (high x) and dim (low x) stripe-areas, respectively.

In order to quantify local x, nanometer-probe energy-dispersive x-ray (EDX) composition analyses were carried out. In Fig. 3a, exact locations where the nanoprobe EDX measurements were carried out are indicated by closed rectangles on the HAADF-STEM image. The frequencies of local x are shown using a histogram in Fig. 3b, where the colors of rectangles in Fig. 3a indicate the x values given in Fig. 3b. As shown, local x distributes from 0.26 ± 0.03 to 0.35 ± 0.03 with average x of about 0.315. Although the error in x for the present EDX analysis is estimated to be ± 0.03, the finite extent in x being about 0.10 (0.26–0.36) is significant. In the bulk of nanoboards, remarkable accumulation of In is not found. These results mean that average x of the nanoboards are almost homogeneous but x has remarkable inhomogeneity with the length scale shorter than a few nm. This local inhomegeneity produces remarkable Eg inhomogeneity, because Al1−xInxN alloys of low to middle x have high derivative dEg(x)/dx value, which causes large alloy broadening23,24,28,29,30,31,32,33,34,35. In the present nanoboards, Eg for x = 0.26 and 0.35 are estimated according to Refs.20,23,28,29,30,32,34,41,42,43,44,45,46 to be approximately 3.42 and 2.75 eV, respectively, which account for SS of about 0.67 eV. This value reproduces the experimental result being 0.7 eV23,32. Therefore, such a few nm-scale inhomogeneity in x can explain the large SS and also large FWHM value of the NBE peak (approximately 0.3 eV in these Al0.68In0.32N nanoboards)32. We note that the VFD device shown in Fig. 1 is operated under the acceleration voltage (Vacc) of 3.5 kV, and hence CL is generated in these nanoboards.

In contrast to Nanoboards zone, HAADF-STEM images of Pseudomorphic zone exhibit regularly aligned stripes with bright and dim contrasts parallel to {\(10\stackrel{-}{1}2\)} r-planes, as shown in Figs. 2c,d,3c,f,g. The magnified images of Fig. 2d are shown in Fig. 3f,g, in which exact locations for EDX measurements are indicated by open rectangles. In Fig. 3h,i, the frequencies of local x in the bright and dim stripes, respectively, in Fig. 3f,g are shown using histograms. As shown, the average x in the bright and dim stripes are obtained as 0.30 ± 0.03 and 0.26 ± 0.03, respectively, with finite extent of about 0.13. The result that brighter stripes in the HAADF images exhibit higher x is reasonable, because the brightness of HAADF images of a crystal structure is essentially proportional to square of the atomic number (Z). Although the estimated error value in x for the present EDX analysis is ± 0.03, Fig. 2c,d, 3c,f,g prove the presence of CSLs, and the accuracy of EDX seems sufficient. Accordingly, this Al0.72In0.28N pseudomorphic film is nothing but approximately 5-nm-period {\(10\stackrel{-}{1}2\)} Al0.74In0.26N/Al0.70In0.30N CSLs.

We note that x in the brighter zone within Transition zone in Fig. 2b,c is not higher than the other areas: i.e. the brightness change is likely due to slight changes in crystallographic orientations. In Fig. 3e, significant perturbations in lattice images are indicated by triangles. Also, the presence of a gap that is similar to deficiency of the material makes the images dim, as shown in Figs. 2c, 3c–e. Anyhow, the observed increase in average x from Al0.72In0.28N in Pseudomorphic zone to Al0.68In0.32N in partially strain-relaxed Nanoboards zone is known as the “composition-pulling effect”21,40 that stems from the presence of a lattice-mismatched substrate. The reason for the change in x under the same growth conditions includes the change in growing surface morphology triggered by lattice relaxation21,40, which takes place when the accumulated stress exceeds the elastic limit. In the present sample, the continuous film growth terminates at approximately 50–60 nm in Transition zone (Fig. 3c,d), where the spatial gaps are introduced instead of TDs.

Discussion 1: cation-ordered Al1−xInxN on GaN and In-rich/In-poor c-planes in Al0.72In0.28N

In order to elucidate the origin of {\(10\stackrel{-}{1}2\)} Al0.74In0.26N/Al0.70In0.30N CSLs, high-resolution cross-sectional HAADF-STEM images of the pseudomorphic Al0.72In0.28N/GaN heterointerface are shown in Figs. 4 and 5. There are two distinct length-scale orderings, as follows. In the HAADF image taken from (0001) cross-section, well-aligned hexagonal-shaped cation images are observed, as shown in Fig. 4a. Because cation and nitrogen atoms align on <0001>-axes, cation images are predominantly seen. Consistent with the magnitude of average Z, hexagons in GaN are brighter than those in Al0.72In0.28N. However, the brightest horizontal row is found at very Al0.72In0.28N/GaN interface, indicating the highest x at the first Al1−xInxN layer. This interface segregation of In is further evidenced by HAADF-STEM observation from {\(11\stackrel{-}{2}0\)} cross-section. As shown in Fig. 4b, brightest dots appear every 0.52 nm (two cation planes) at the first Al1−xInxN layer, which maintains ML atomic steps with terrace widths of approximately 70 nm (Fig. 3c). The results indicate that cation sublattices along <0001>-axis are alternately occupied by In atoms (or extremely In-rich Al1−xInxN) and Al atoms (or extremely Al-rich Al1−xInxN). At the second Al1−xInxN layer, the ordinality suddenly lessens but there still exists a 0.52-nm-period ordering: fin-shaped In-rich (bright) and In-poor (dim) (0001)-planes alternately appear every 0.52 nm along <0001> direction, as shown by magenta and dark blue triangles in Fig. 4b. For quantitatively observing such orderings, brightness profiles for this image enclosed by rectangles in Fig. 4b are shown in Fig. 4c–e. For underlying GaN, a 0.26-nm-period oscillating brightness profile is found in Fig. 4d. Its peaks correspond to the signals from Ga and valleys to unextinguished background signals. We note that the spatial resolution for our electron diffraction was insufficient to resolve closely located N signals from that of cations. Diffrent from GaN, brightness profiles for the first layer and the bulk of Al1−xInxN exhibit higher and lower, two-level peaks alternately with common valleys, as shown in Fig. 4e. The intensity ratio for the two levels in the first layer profile (top trace in Fig. 4e) is larger than that in the Al0.72In0.28N epilayer profile (bottom trace in Fig. 4e), indicating higher ordinality at the first layer. In Fig. 4c, a vertical brightness profile across the interface is displayerd. Although slight differences are recognized, cation signals in GaN, the first layer, and Al0.72In0.28N epilayer exhibit corresponding brightness features. We note that the brightness of the first layer cation is much higher than those in GaN or Al0.72In0.28N zones, indicating significantly large Z.

High-resolution cross-sectional HAADF-STEM images for the m-plane pseudomorphic Al0.72In0.28N/GaN heterointerface taken from (a) (0001) and (b) {\(11\stackrel{-}{2}0\)} cross-sections. In (b), In-rich (0001) plane (brighter row) and In-poor (0001) plane (dimmer row) are indicated by magenta and dark blue triangles, respectively. The location of a ML atomic step is indicated by the arrow. In (c–e), brightness profiles for the HAADF image enclosed by rectangles in (b) are shown. (c) A vertical brightness profile across the interface. (d) A lateral brightness profile for underlaying GaN. (e) Lateral profiles at the first layer (top trace) and in the bulk of Al1−xInxN (bottom trace).

(a) A schematic drawing of the model striped ordering of <\(\stackrel{-}{1}\stackrel{-}{1}20\)> In- and Al-rows along the <0001> direction on the GaN surface. (b) A picture in perspective and theoretically simulated HAADF image for cation ordered m-plane (AlN)(InN) superlattices (Al0.5In0.5N film) on GaN. (c) Detuned and contrast adjusted HAADF image of (b) by adding finite beam defocus to reproduce the experimental brightness data of pure binary GaN (Fig. 4b). (d) The brightness profiles drawn for GaN and the first Al0.5In0.5N layer using the image in (c).

For explaining the formation dynamics of these orderings, the surface atomic structure near the step-edge is schematically drawn in Fig. 5a. Here, the step-flow growth appears to proceed toward [0001] direction, judging from the shape of the ML atomic step in Fig. 4b. The striped ordering of < \(\stackrel{-}{1}\stackrel{-}{1}20\) > In- and Al-rows (or extremely In-rich Al1-xInxN-row and extremely Al-rich Al1-xInxN-row) on GaN along [0001]-axis is most likely formed by site-selection of cation species at the growth front, as follows. On each terrace of atomically-flat m-plane GaN, In and Al species diffuse toward the ML step-edge. Because large molar flow ratio (CH3)3In: (CH3)3Al = 8:1 was used to obtain7 solid-phase x of 0.3 (Ref.32), In species tend to cover the surface. However, uppermost and second uppermost < \(\stackrel{-}{1}\stackrel{-}{1}20\) > cation-rows, which are indicated by A and B in Fig. 5a, are most probably occupied by Al and In, respectively. This site selection can be understood, as follows. Because the cohesive energies of AlN and InN, respectively, are − 5.83 and − 3.99 eV/atom (experimental)47 and − 5.853 and − 4.195 eV/atom (first-principles calculations)48, the configuration “two Al-N bonds at A and one In-N bond at B” is more stable than that of “one Al-N bond at B and two In-N bonds at A”. These adatoms are temporally pinned by N-bridges, and subsequent growth of the next involatile < \(\stackrel{-}{1}\stackrel{-}{1}20\)> Al-row (A) buries the volatile < \(\stackrel{-}{1}\stackrel{-}{1}20\) > In-row (B) at the second from the top. Consistent with this model, < \(\stackrel{-}{1}\stackrel{-}{1}20\)> Al-rows on the In-poor (0001) planes in Fig. 4b are found at slightly below and more slightly above < \(\stackrel{-}{1}\stackrel{-}{1}20\)> In-rows.

In Fig. 5b, a picture in perspective and theoretically simulated HAADF image for a model m-plane, c-directional (AlN)(InN) superlattices (Al0.5In0.5N film) on GaN are shown to assess the perfection of Al/In ordering at the first layer. Figure 5c shows the detuned HAADF image of Fig. 5b by applying finite beam defocus to reproduce the experimental brightness profile of pure binary GaN (Fig. 4b). The brightness profiles drawn for GaN and the first Al0.5In0.5N layer of Fig. 5c are given in Fig. 5d. For Al0.5In0.5N, the ratio of the two peak levels is slightly larger than that in Fig. 4e, implying that the first layer is an essentially but not necessarily pure self-formed Al0.5In0.5N. At the second Al0.72In0.28N layer, the ordinality suddenly lessens in comparison with the first layer (Fig. 4b), because the influences of Ga bonds are not so significant at the second nearest neighbor cation site. However, In-rich/In-poor < \(\stackrel{-}{1}\stackrel{-}{1}20\)> rows are still alternately formed, which grow into respective {0001} planes resulting in their fin-shaped ordering along [0001]-direction (Fig. 4b).

Discussion 2: {\(10\stackrel{-}{1}2\)} Al0.74In0.26N/Al0.70In0.30N CSLs

Simultaneously to the lattice parameter scale ordering, the other length-scale ordering, namely approximately 5-nm-period {\(10\stackrel{-}{1}2\)} Al0.74In0.26N/Al0.70In0.30N CSLs, is initiated at the second Al0.72In0.28N layer on m-plane GaN: a few-nm-wide two-tone stripes, namely a few-nm-wide InN-rich (Al0.70In0.30N) and InN-poor (Al0.74In0.26N) < \(\stackrel{-}{1}\stackrel{-}{1}20\)> zones, are observed at the second Al0.72In0.28N layer, as shown in Figs. 4b and 6a–d. The locations of boundary-lines of these CSLs seem to be independent of step-edge locations, indicating that the Al0.70In0.30N/Al0.74In0.26N zones are most likely formed to mitigate gross lattice-mismatch between Al0.72In0.28N and GaN because the lattice mismatch (Δc) between InN and GaN (11%) is much larger than that of AlN and GaN (3%) and hence InN-poor zones are periodically formed on the m-plane Al0.5In0.5N (or x close to 0.5) ML on GaN structure. We note that Al0.74In0.26N lattice-matches to GaN along <0001>-axis. Because step-flow growth progresses toward <0001> Ga-polar direction, a-few-nm-period Al0.70In0.30N/Al0.74In0.26N progresses toward upper left on {\(10\stackrel{-}{1}2\)} plane, which gives rise to the formation of approximately 5-nm-period Al0.70In0.30N/Al0.74In0.26N CSLs along the <\(20\stackrel{-}{2}1\)>-axis, as seen in Figs. 2c,d, 3c,f,g, 4b and 6.

Cross-sectional HAADF-STEM images for the m-plane pseudomorphic Al0.72In0.28N/GaN heterointerface taken from the {\(11\stackrel{-}{2}0\)} cross-section. In panels (a) and (b), the location of the ML atomic step is indicated by the arrow. The step-flow growth proceeds toward the left side. The starting points of Al0.74In0.26 N (dim) and Al0.70In0.30N (bright) stripes parallel to the {\(10\stackrel{-}{1}2\}\) plane are independent of the locations of surface ML steps.

Discussion 3: lattice relaxation and generation of Al0.68In0.32N nanoboards

The pseudomorphic growth of CSLs lasts approximately 50 to 60 nm until the accumulated stress exceeds the elastic limit of the film. This value is close to what has been reported for c-plane lattice-matched Al0.82In0.18N film growth on GaN21. Then lattice relaxation takes place in Transition zone: the continuous film growth appears to terminate at the areas encircled in Fig. 3c,d. As most of the spatial gaps are initiated in the dim (In-poor) Al0.74In0.26N stripe, In-desorption or Al-precipitation may interfere the film growth. Once the gaps appear, the nanoboards having {\(10\stackrel{-}{1}3\)} facets start growing. The reason for the appearance of {\(10\stackrel{-}{1}3\)} facets can be understood from Fig. 5a that the lack of an In atom would stop growing {\(10\stackrel{-}{1}2\)} and skip to {\(10\stackrel{-}{1}3\)} facets. Above Transition zone, a random compositional inhomogeneity shown in Fig. 3a,b is introduced in the Al0.68In0.32N nanoboards.

Discussion 4: correlation between the structural and optical properties

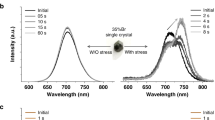

Cross-sectional HAADF-STEM image and room temperature SRCL spectra of the m-plane Al0.7In0.3N/GaN epitaxial structure are compared in Fig. 7 to identiy the origins of particular CL peaks. The HAADF-STEM image shown in Fig. 2c is reloaded in Fig. 7a for easy comparison. Figure 7b shows the spatially integrated CL spectrum measured for the area including GaN, Pseudomorphic zone, Transision zone, and nearly half of Nanoboards zone in Fig. 7a. In Fig. 7c, cross-sectional SRCL spectra measured at 200 points along the arrow labeled “CL linescan” in Fig. 7a are shown using a 3D representation: CL spectra of the m-plane GaN, pseudomorphic Al0.72In0.28N zone (CSLs), and Al0.68In0.32N nanoboards are found at front to back of the figure. For GaN, an NBE emission originating from the recombination of free excitons (FX)49 at 3.41 eV dominates the spectra, while the intensity of the broad luminescence band at around 2.2 eV named “yellow luminescence (YL) band”50,51,52,53 is more than an order of magnitude weaker than the FX peak. Because YL band has two independent origins, namely carbon on nitrogen site (CN)53 and defect complex comprises of a Ga-vacancy (VGa) and oxygen on nitrogen site (ON), VGaON51, the CL result indicates that our GaN homoepitaxial epilayer is of good purity with low CN and VGa concentrations. As the focused electron beam (e-beam) position moves from GaN to the pseudomorphic Al0.72In0.28N zone, FX peak of GaN dissapears and a new peak at around 2.96 eV appears. According to the relationship between Eg and x in Al1-xInxN20,23,28,29,30,32,34,41,42,43,44,45,46, Eg of the In-rich stripe in the CSLs (Al0.70In0.30N) is estimated to be approximately 3.0 eV. Therefore, the peak at 2.96 eV is assigned as an NBE emission of the CSLs. We note that Eg of the In-poor counterpart (Al0.74In0.26N) is estimated from the Eg-x relationship20,23,28,29,30,32,34,41,42,43,44,45,46 to be about 3.4 eV. Accordingly, SS of at least 0.4 eV will be produced in the present CSLs. The YL band of GaN is also observed when Pseudomorphic zone is excited. Because the diameter of an excitation volume using a 5 keV e-beam is about 100 nm, the result implies that some carriers excited in GaN are trapped by the origin of YL band50,51,52,53. In addition, the NBE emission of Pseudomorphic zone (2.96 eV) likely excites YL (2.2 eV) in the transparent GaN (Eg = 3.43 eV). Nevertheless, spot-excitation CL made it possible to detect the emission from the 50-nm-thick CSL layer. Finally, Al0.68In0.32N Nanoboards zone exhibits a predominant green emission band at around 2.36 eV, the energy agrees with the emission peak of our VFD device (Fig. 1). As x in Nanoboards zone distributes from 0.26 to 0.35, as shown in Fig. 3b, it is reasonable that the NBE emission in the nanoboards exhibits SS of about 0.7 eV29,30,32. As can be seen in Fig. 1, the emission from Nanoboards zone is sufficiently visible under the fluorescent lamp illumination. The use of the 50-nm-thick Pseudomorphic CSLs on GaN as a light-emitting medium is more attractive, since the CSLs contain low densities of TDs.

Panel (a) is reproduced with permission from Chichibu et al.23.

Spatially resolved CL spectra of the m-plane Al0.7In0.3N epitaxial structure. (a) Cross-sectional HAADF-STEM image of the m-plane Al0.7In0.3N epitaxial structure observed from {\(11\stackrel{-}{2}0\)} cross-section. (b) Spatially integrated cross-sectional CL spectra measured at 295 K for the area including GaN, Pseudomorphic zone, Transision zone, and nearly half of Nanoboards zone in (a). (c) Cross-sectional SRCL spectra measured at 200 points along the arrow labeled “CL linescan” in (a) using a 3D representation. The CL spectra in the m-plane GaN, pseudomorphic Al0.72In0.28N zone, and Al0.68In0.32N nanoboards are found from front to back of the figure. The intensities are shown by a contour map.

In conclusion, the appearance and self-formation sequence of 0.52-nm-period striped ordering of <\(\stackrel{-}{1}\stackrel{-}{1}20\)> In/Al (or extremely In- and Al-rich Al1−xInxN) cation-rows at the first layer on m-plane GaN and fin-shaped In-rich/In-poor {0001}-planes from the second Al0.72In0.28N layer, as well as approximately 5-nm-period {\(10\stackrel{-}{1}2\)} Al0.70In0.30N/Al0.74In0.26N CSLs in 50 to 60-nm-thick pseudomorphic m-plane Al0.72In0.28N film23,32 during MOVPE were exemplified. Then, so-called composition-pulling21,40 phenomenon was described from the viewpoints of surface kinetics and strain relaxation in lattice-mismatched heteroepitaxy for explaining the growth of strain-relaxed Al0.68In0.32N nanoboards23 with random compositional inhomogeneity. Finally, cross-sectional SRCL spectra were correlated with these particular zones to explain large SSs and short Lp. The use of pseudomorphic CSLs as light-emitting media was proposed.

Methods

Samples

Approximately 700-nm-thick unintentionally-doped m-plane Al0.7In0.3N epilayer was grown32 subsequently to a 1000-nm-thick GaN homoepitaxial buffer layer by MOVPE on a 8 × 20-mm2-area, 325-μm-thick m-plane FS-GaN substrate54, which was grown by hydride vapor phase epitaxy using GaCl and NH3. The TD and basal-plane stacking fault densities of the GaN epilayer grown using (CH3)3 Ga and NH3 were lower than our detection limits (< 1 × 106 cm−2 and < 1 × 103 cm−1, respectively). The nominaly x = 0.3 (Al0.7In0.3N) epilayer was grown using (CH3)3Al, (CH3)3In, and NH3 at Tg = 660 °C. The reactor pressure was 2.7 × 104 Pa. A large molar flow rate ratio of (CH3)3In: (CH3)3Al = 8:1 was used to obtain the solid phase x = 0.3. The structural properties such as crystal mosaics, surface morphologies and strains are given in Ref. 32. Residual concentrations of oxygen, [O], carbon, [C], and silicon, [Si], in Al0.7In0.3N were semi-quantitatively determined by secondary-ion mass spectrometry using an AlN (x = 0) reference due to the lack of an Al0.7In0.3N reference. Consequently, their concentrations are generally overestimated because the corresponding ion signals in In-containing matrix are stronger than true values. For example, [O], [C], and [Si] in Al0.7In0.3N estimated in this way were about 1021, 1020, and 1019 cm−3, respectively. However, these values are of course too high and unreliable. Because electron concentration, n, in the FS-GaN substrate is as high as 2 × 1018 cm−3, correct characterization of n and electron mobility in overgrown Al0.7In0.3 N layer was not possible. We therefore speculate n in the Al0.7In0.3N layer to be higher than 1019 cm−3.

Vacuum fluorescent display (VFD) devices

The information of the green VFD comprising of Al0.7In0.3N nanoboards displayed in Fig. 1 can be found in Ref.23.

Scanning transmission electron microscopy (STEM) and high-angle annular dark field (HAADF) images

Bright-field and dark-field STEM images were taken using JEM-ARM200F operated at Vacc = 200 kV. The InN mole fraction x was evaluated by using nanoprobe EDX measurements using the same STEM equipped with JED-2300T detector. The EDX data were analyzed using the software implemented in the microscope named NSS Ver. 3.3.113 (Thermo Fisher Scientific), and chemical compositions were estimated using the Cliff-Lorimer method without standard samples. The overall error in the InN mole fraction x excluding the effects of x-ray absorption in our Al0.7In0.3N film was approximately \(\pm\) 0.03. For example, x will be expressed as 0.30 \(\pm\) 0.03. By using the same STEM, HAADF images were taken to observe slight changes in crystallographic orientation and/or chemical composition. For quantitative analysis of HAADF images, ideal images were simulated using the software named xHREM (HREM Research, Inc.)55. After calculating the image created for tightly focused e-beam with nearly zero broadening, the contrast was adjusted by adding finite beam defocus to reproduce experimental brightness profile of pure binary GaN.

Spatially resolved cathodoluminescence (SRCL) measurement

Cross-sectional SRCL measurement was carried out to record local CL spectra using a detection system composed of a 14-cm-focal-length grating spectrometer (MicroHR) and a 1024 × 256 thermoelectrically-cooled open-electrode charge-coupled device (CCD) array, which are equipped on a scanning electron microscopy (JSM-880 modified)5,56. Designated line-scanning and spatially integrated CL spectra were measured using the external beam-scanning module. The Vacc and current of the e-beam were 5 kV and 500 pA, respectively. The corresponding excited carrier concentration is calculated to be lower than 1015 cm−3 when the average carrier lifetime is 30 ps. All SRCL measurements were carried out at 295 K.

Data availability

The data that support the findings of this study are available in this manuscript.

References

Nakamura, S. & Fasol, G. The Blue Laser Diode (Springer, Berlin, 1997).

Nakamura, S., Senoh, M., Iwasa, N. & Nagahama, S. High-brightness InGaN blue, green and yellow light-emitting diodes with quantum well structures. Jpn. J. Appl. Phys. Part 2 34, L797-799 (1995).

Chichibu, S., Azuhata, T., Sota, T. & Nakamura, S. Spontaneous emission of localized excitons in InGaN single and multiquantum well structures. Appl. Phys. Lett. 69, 4188–4190 (1996).

Narukawa, Y. et al. Role of self-formed InGaN quantum dots for exciton localization in the purple laser diode emitting at 420 nm. Appl. Phys. Lett. 70, 981–983 (1997).

Chichibu, S. F. et al. Origin of defect-insensitive emission probability in In-containing (Al, In, Ga)N alloy semiconductors. Nat. Mater. 5, 810–816 (2006).

Ho, I. & Stringfellow, G. B. Solid phase immiscibility in GaInN. Appl. Phys. Lett. 69, 2701–2703 (1996).

Koukitu, A. & Seki, H. Unstable region of solid composition in ternary nitride alloys grown by metalorganic vapor-phase epitaxy. Jpn. J. Appl. Phys. Part 2 35, L1638–1640 (1996).

Scholz, F. Metalorganic vapour phase epitaxy of GaN and GaInN/GaN heterostructures and quantum wells. Prog. Cryst. Growth Charact. Mater. 35, 243–262 (1997).

Caetano, C., Teles, L. K., Marques, M., Dal Pino, A. & Jr. & Ferreira, L. G. Phase stability, chemical bonds, and gap bowing of InxGa1−xN alloys: comparison between cubic and wurtzite structures. Phys. Rev. B 74, 045215 (2006).

Mohamad, R. et al. A Theoretical investigation of the miscibility and structural properties of InxAlyGa1−x−yN alloys. Phys. Status Solidi B 255, 1700394 (2018).

Adivarahan, V. et al. Sub-milliwatt power III-N light emitting diodes at 285 nm. Jpn. J. Appl. Phys. Part 2 41, L435-436 (2002).

Allerman, A. A. et al. Growth and design of deep-UV (240–290 nm) light emitting diodes using AlGaN alloys. J. Cryst. Growth 272, 227–241 (2004).

Hirayama, H. Quaternary InAlGaN-based high-efficiency ultraviolet light-emitting diodes. J. Appl. Phys. 97, 091101 (2005).

Fujioka, A., Misaki, T., Murayama, T., Narukawa, Y. & Mukai, T. Improvement in output power of 280-nm deep ultraviolet light-emitting diode by using AlGaN multi quantum wells. Appl. Phys. Express 3, 041001 (2010).

Pernot, C. et al. Improved efficiency of 255–280 nm AlGaN-based light-emitting diodes. Appl. Phys. Express 3, 061004 (2010).

Grandusky, J. R. et al. High output power from 260 nm pseudomorphic ultraviolet light-emitting diodes with improved thermal performance. Appl. Phys. Express 4, 082101 (2011).

Wunderer, T. et al. Pseudomorphically grown ultraviolet C photopumped lasers on bulk AlN substrates. Appl. Phys. Express 4, 092101 (2011).

Kneissl, M. et al. Advances in group III-nitride-based deep UV light-emitting diode technology. Semicond. Sci. Technol. 26, 014036 (2011).

Kinoshita, T. et al. Deep-ultraviolet light-emitting diodes fabricated on AlN substrates prepared by hydride vapor phase epitaxy. Appl. Phys. Express 5, 122101 (2012).

Teles, L. K., Scolfaro, L. M. R., Furthmüller, J., Bechstedt, F. & Leite, J. R. Phase separation, gap bowing, and structural properties of cubic InxAl1-xN. Phys. Status Solidi B 234, 956–960 (2002).

Redondo-Cubero, A. et al. Depth-resolved analysis of spontaneous phase separation in the growth of lattice-matched AlInN. J. Phys. D Appl. Phys. 43, 055406 (2010).

Zhao, G. et al. The immiscibility of InAlN ternary alloy. Sci. Rep. 6, 26600 (2016).

Chichibu, S. F., Kojima, K., Uedono, A. & Sato, Y. Defect-resistant radiative performance of m-plane immiscible Al1-xInxN epitaxial nanostructures for deep-ultraviolet and visible polarized light emitters. Adv. Mater. 29, 1603644 (2017).

Pampili, P. et al. InAlN-based LEDs emitting in the near-UV region. Jpn. J. Appl. Phys. 58, SCCB33 (2019).

Carlin, J.-F. & Ilegems, M. High-quality AlInN for high index contrast Bragg mirrors lattice matched to GaN. Appl. Phys. Lett. 83, 668–670 (2003).

Higashiwaki, M. & Matsui, T. InAlN/GaN heterostructure field-effect transistors grown by plasma-assisted molecular-beam epitaxy. Jpn. J. Appl. Phys. 43, L768-770 (2004).

Stringfellow, G. B. Calculation of regular solution interaction parameters in semiconductor solid solutions. J. Phys. Chem. Solids 34, 1749–1751 (1973).

Yamaguchi, S. et al. Observation of photoluminescence from Al1-xInxN heteroepitaxial films grown by metalorganic vapor phase epitaxy. Appl. Phys. Lett. 73, 830–832 (1998).

Onuma, T. et al. Recombination dynamics of localized excitons in Al1-xInxN epitaxial films on GaN templates grown by metalorganic vapor phase epitaxy. J. Appl. Phys. 94, 2449–2453 (2003).

Wang, K. et al. Optical energies of AlInN epilayers. J. Appl. Phys. 103, 073510 (2008).

Laskar, M. R. et al. Anisotropic structural and optical properties of a-plane (1120) AlInN nearly-lattice-matched to GaN. Appl. Phys. Lett. 98, 181108 (2011).

Chichibu, S. F. et al. High internal quantum efficiency ultraviolet to green luminescence peaks from pseudomorphic m-plane Al1-xInxN epilayers grown on a low defect density m-plane freestanding GaN substrate. J. Appl. Phys. 116, 213501 (2014).

Marcinkevicius, S., Sztein, A., Nakamura, S. & Speck, J. S. Properties of sub-band edge states in AlInN studied by time-resolved photoluminescence of a AlInN/GaN heterostructure. Semicond. Sci. Technol. 30, 115017 (2015).

Dinh, D. V., Hu, N., Honda, Y., Amano, H. & Pristovsek, M. Indium incorporation and optical properties of polar, semipolar and nonpolar InAlN. Semicond. Sci. Technol. 35, 035004 (2020).

Zubialevich, V. Z. et al. Enhanced UV luminescence from InAlN quantum well structures using two temperature growth. J. Lumin. 155, 108–111 (2014).

Waltereit, P. et al. Nitride semiconductors free of electrostatic fields for efficient white light-emitting diodes. Nature 406, 865–868 (2000).

Speck, J. S. & Chichibu, S. F. Nonpolar and semipolar group III nitride-based materials. MRS Bull. 34, 304–312 (2009) (and papers cited therein).

Takeuchi, T. et al. Quantum-confined stark effect due to piezoelectric fields in GaInN strained quantum wells. Jpn. J. Appl. Phys. Part 2 36, L382–L385 (1997).

Durand, C. et al. M-plane GaN/InAlN multiple quantum wells in core-shell wire structure for UV emission. ACS Photonics 1, 38–46 (2014).

Shimizu, M., Kawaguchi, Y., Hiramatsu, K. & Sawaki, N. MOVPE growth of thick homogeneous InGaN directly on sapphire substrate using AlN buffer layer. Solid-State Electron. 41, 145–147 (1997).

Kim, K. S., Saxler, A., Kung, P., Razeghi, M. & Lim, K. Y. Determination of the band-gap energy of Al1-xInxN grown by metal-organic chemical-vapor deposition. Appl. Phys. Lett. 71, 800–802 (1997).

Sakalauskas, E. et al. J. Phys. D Appl. Phys. 43, 365102 (2010).

Aschenbrenner, T. et al. Optical and structural characterization of AlInN layers for optoelectronic applications. J. Appl. Phys. 108, 063533 (2010).

Schulz, S. et al. Composition-dependent band gap and band-edge bowing in AlInN: A combined theoretical and experimental study. Appl. Phys. Express 6, 121001 (2013).

Zubialevich, V. Z. et al. Strongly nonparabolic variation of the band gap in InxAl1-xN with low indium content. Semicond. Sci. Technol. 31, 025006 (2016).

Kawamura, T. et al. First-principles calculation of bandgaps of Al1-xInxN alloys and short-period Al1-xInxN/Al1-yInyN superlattices. Phys. Status Solidi B 257, 1900530 (2019).

Edgar, J. H. (ed.) Properties of Group III Nitrides EMIS Data reviews Series No. 11 (The Institution of Electrical Engineering, London, 1994).

Akiyama, T. Section 3, Fundamental properties of III-nitrides compounds. In Epitaxial Growth of III-Nitride Compounds: Computational Approach. Springer Series in Materials Science, 269 (eds Matsuoka, T. & Kangawa, Y.) 35–53 (Springer, Springer, Berlin, 2018).

Chichibu, S., Azuhata, T., Sota, T. & Nakamura, S. Excitonic emissions from hexagonal GaN epitaxial layers. J. Appl. Phys. 79, 2784–2786 (1996).

Ogino, T. & Aoki, M. Mechanism of yellow luminescence in GaN. Jpn. J. Appl. Phys. 19, 2395–2405 (1980).

Neugebauer, J. & van de Walle, C. G. Atomic geometry and electronic structure of native defects in GaN. Phys. Rev. B 50, 8067-8070(R) (1994).

Reshchikov, M. A. & Morkoç, H. Luminescence properties of defects in GaN. J. Appl. Phys. 97, 061301 (2005).

Lyons, J. L., Janotti, A. & Van de Walle, C. G. Carbon impurities and the yellow luminescence in GaN. Appl. Phys. Lett. 97, 152108 (2010).

Fujito, K. et al. High-quality nonpolar m-plane GaN substrates grown by HVPE. Phys. Status Solidi A 205, 1056–1059 (2008).

Kimoto, K. et al. Local crystal structure analysis with several picometer precision using scanning transmission electron microscopy. Ultramicroscopy 110, 778–782 (2010).

Chichibu, S., Wada, K. & Nakamura, S. Spatially resolved cathodoluminescence spectra of InGaN quantum wells. Appl. Phys. Lett. 71, 2346–2348 (1997).

Acknowledgements

S. F. C. would like to thank Dr. Y. Sato of Futaba Corporation for installing our Al1-xInxN nanostructures on the VFD device, Dr. H. Ikeda and K. Fujito of Mitsubishi Chemical Corporation for providing the m-plane FS-GaN substrate, Dr. T. Onuma for help with the growth experiment, Y. Inatomi for the discussion on the growth, and T. Miyazaki of Foundation for Promotion of Material Science and Technology of Japan for HAADF-STEM and nanoprobe EDX measurements. This work was supported in part by the Cooperative Research Program of “Network Joint Research Center for Materials and Devices” and “Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials” and JSPS KAKENHI (Grant Nos. JP16H06418, JP16H06427, and JP17H02907) by the Ministry of Education, Culture, Sports, Science and Technology, Japan.

Author information

Authors and Affiliations

Contributions

K.S. carried out the simulation of HAADF images and SRCL measurement, Y.K. carried out theoretical calculations of the surface structure and growth instability of AlInN alloys, K.K. carried out polarized CL measurement. S.F.C. grew the Al0.7In0.3N/GaN structure by MOVPE, carried out SRCL measurement with K.S., analyzed all data for constructing the discussion, and organized this research project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Chichibu, S.F., Shima, K., Kojima, K. et al. Self-formed compositional superlattices triggered by cation orderings in m-plane Al1−xInxN on GaN. Sci Rep 10, 18570 (2020). https://doi.org/10.1038/s41598-020-75380-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-75380-3

This article is cited by

-

Nonpolar AlxGa1−xN/AlyGa1−yN multiple quantum wells on GaN nanowire for UV emission

Nano Research (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.