Abstract

We determined the effects of biochar on starch properties and the activities of enzymes and expression levels of genes related to starch in two Japonica rice cultivars. The two rice varieties were subjected to five biochar treatments (0, control; and 5, 10, 20, and 40 t/hm2). In both rice varieties, the content of apparent amylose and resistant starch were lower in biochar treatments than in the control. The proportion of fa chains was higher and that of fb3 chain was lower in the biochar treatments than in the control. Starch viscosity and cooking taste quality were improved by the biochar treatments. In both rice varieties, the activity of granule-bound starch synthase was significantly decreased by biochar treatments, and the activities of soluble starch synthase, starch branching enzyme, and starch debranching enzyme were significantly increased. The transcript levels of genes encoding starch synthases and starch branching enzymes were significantly increased by biochar treatments. We conclude that biochar at a dose of 5–10 t/hm2 can regulate the activity of starch-related enzymes, and this affects the type, content, and fine structure of starch. Therefore, the addition of biochar to soil can improve the viscosity and taste quality of rice starch.

Similar content being viewed by others

Introduction

Biochar, generally refers to the carbon-rich solid product when biomass is thermally decomposed under anoxic conditions1. Most previous studies on biochar have focused on its interactions with soils, crops, and other factors in the environment. Research in many countries has shown that biochar can significantly improve soil structure and soil physical and chemical properties, modify the soil microbial community, and increase crop yields, and contribute to the prevention and control of air pollution, reductions in carbon dioxide emissions, and the sustainable development of agriculture2,3,4. Many studies have explored the effects of adding biochar to rice fields on yield, soil and greenhouse gases, but few have focused on its effects on rice quality and the related mechanisms.

Starch is the most important component of rice grains, and and the main factor affecting rice cooking and eating quality5,6. Starch accumulates in rice grains via a series of complex enzymatic processes. Rice starch is formed in the chloroplast as a product of photosynthesis, and then is decomposed into dihydroxy-phosphate, which is transported from the chloroplast to the matrix where it is transformed into sucrose via the activities of sucrose phosphate synthase (SPS), sucrose synthase (SuSy), and acid invertase (AI). The sucrose is then transported to reservoir organs to provide materials for starch synthesis. The sucrose entering the grain cell sap forms adenosine diphosphate glucose (ADPG) through glycolysis, then amylose is formedvia the activity of granule-bound starch synthase (GBSS). Then, amylopectin is formed via the combined activities of soluble starch synthase (SSS), starch branching enzyme (SBE) and starch debranching enzyme (SDBE). Starch synthases can be divided into four types: SS I–IV. The SS I-type mainly combines A and B1 chains with very short external segments with a degree of polymerization (DP) of 6–7 to form DP 8–12 segments7. The SS IIa-type is responsible for the formation of medium-length branch chains (i.e., the addition of DP 6–11 to DP 13–28 chains)8, while SS IIIa participates in the formation of long chains (DP ≥ 30), particularly B2 and B3 chains9. Previous studies have shown that the expression levels of genes encoding products related to starch synthesis and metabolism are regulated by environmental factors and cultivation conditions, and that changes in the composition of amylose and amylopectin affect the cooking and taste qualities of rice10,11. In this experiment, two Japonica rice varieties, SN265 and Japanese Akihikari were used to study the effects of adding biochar to soil at different concentrations on the activities of key enzymes involved in sucrose metabolism in seeds and on the relationship between starch quality and the transcript levels of starch-related genes (SS I, SS IIa, SS IIIa, SBE I, SBE IIb, ISA I and GBSS I). The overall aim of this research was to explore the molecular mechanism by which biochar affects the properties of rice starch.

Materials and methods

Plant materials and experimental design

We conducted a pot experiment using the rice varieties ShenNong265 (hereafter, SN265) and Japanese Akihikari (hereafter, Akihikari). This experiment was carried out at Shenyang, Liaoning Province, China, from 2018 to 2019. Rice husk biochar was added to soil at five rates: 0 t/hm2 (B1, control), 5 t/hm2 (B2), 10 t/hm2 (B3), 20 t/hm2 (B4) and 40 t/hm2 (B5). The bulk density of the soil in this area is 1.34 g/cm3, and the soil quality was calculated for soil in the top 15-cm layer. When 10 t/hm2 of biochar was applied, the mass ratio in the soil was 5‰. Based on this calculation, the amounts of soil and biochar in the control and treatments were as follows: Control (B1): 15 kg soil per pot ; B2: 75 g biochar + 14.93 kg soil per pot; B3: 150 g biochar + 14.85 kg soil per pot; B4: 225 g biochar + 14.78 kg soil per pot; B5: 300 g biochar + 14.70 kg soil per pot. The soil and biochar were mixed before adding to each pot (pot diameter × height = 35 cm × 30 cm). The rice seeds were sown on April 15, with two seeds in per hole for plate seedling cultivation. The seedlings were raised in a greenhouse, and were transplanted at the 3.5-leaf stage. At this stage, seedlings with the same height were planted with equal spacing in the pots, with 1 seedling per hole, 3 holes per pot, and 16 pots per treatment. In total, 15 kg of nitrogen fertilizer (calculated based on pure nitrogen) was applied in three applications (basal: tiller: ear, 5:4:1). Irrigation was managed as per the normal practices in the area. The biochar was made from rice husk (particle size 1.5–2.0 mm), and was produced and provided by the Liaoning Jinhefu Agricultural Development Co., Ltd. The physical and chemical properties of potting soil and biochar are shown in Table 1. Samples with uniform growth length were taken from every treatment at 10 days after heading. All samples were stored at − 80 °C until use. At harvest, all samples from one pot were mixed as one replicate before threshing. The brown rice grains were dried naturally for 3 months and then processed. After sieving through a 1.7 mm classifier, the polished rice was ground with a full-automatic rice mill.

Measurement of physical and chemical properties of rice

The rice appearance quality was determined using Wanshen SCE rice appearance detection analysis software. The eating quality was measured using a Satake rice taste analyzer (SATAKE Corp., Hiroshima, Japan)., The amylose content in rice was determined by the sulfuric acid anthracene copper method12. The amylopectin side chain branch content was determined using the method of Nakamura et al.17. A Rapid Visco Analyzer (RVA; NEWPORT SCIENTIFIC Pty. Ltd, Warriewood, Australia) was used to test the viscosity of rice flour starch in the samples in accordance with the standards13 specified by the regulated by American Association of Cereal Chemists, Analyses were conducted using TCW (Thermal Cycle Windows) software.

Activities of starch-related enzymes and transcript levels of their encoding genes

The activities of GBSS, SSS, SBE and DBE in rice grains were measured using the methods described by Jin Zhengxun et al.14. To measure gene transcript levels, total RNA was extracted by the Trizol method from the rice grains stored at − 80 °C. Then, the total RNA was treated with DNase I to eliminate DNA and cDNA was synthesized using a reverse transcription kit (Nova, purchased from Jiangsu Yugong Biolabs Inc). According to the gene RNA sequence published at the NCBI (https://www.ncbi.nlm.nih.gov), qRT-PC primers (Table 2) were designed with software Premier 5.0, and BLAST comparisons were made at the NCBI website to ensure the specificity of the primers. With cDNA as the template and Actin1 as the internal reference gene, qRT-PCR analyses were conducted using a Taq SYBR Green qPCR kit. Each sample was analyzed three times. The relativetranscript levels of the target genes were calculated using the ΔCt method15.

Data analysis

The data were processed and analyzed using GraphPad Prism 8 and SPSS 18 statistical software. ANOVA and Duncan’s tests were used to detect significant differences among treatments.

Results and analysis

Effect of biochar on rice appearance and processing quality

As shown in Table 3 the biochar treatments directly affected the rate of chalky rice and the chalkiness degree of rice in both SN265 and Akihikari. For both varieties, the rate of chalky rice and the chalkiness degree were significantly lower in the B2 and B3 treatments than in the control. There was no significant difference in the length–width ratio of the seeds among treatments. For both rice varieties, the rate of the coarse was higher in B2 and especially B3, but the differences among the other treatments and between B2/B3 and the control were small. For SN265, the rates of polished rice and head rice were significantly higher in the B2 and B3 treatments than in the control, but not significantly different between the other treatments and the control. For Akihikari, the rates of polished rice and head rice rate were also higher in the B2 and B3 treatments than in the control and the other treatments, but this difference was not statistically significant.

Effect of biochar on rice starch properties and eating quality

Effect of biochar on rice starch composition and viscosity

As shown in Table 4 that the apparent amylose and resistant starch content of the two rice varieties decreased to a certain extent in response to biochar treatments. The apparent amylose and resistant starch contents of Akihikari were higher in the B4 treatment than in the control, but tended to be lower in other treatments, especially those in B3, than in the control. In both rice varieties, the proportion of Fa chains was significantly increased in the biochar treatments compared with the control, with only small differences among the biochar treatments. The proportion of Fb3 chains was lower in the biochar treatments than in the control, with only small differences among the biochar treatments. Therefore, in most cases, the Fa/Fb3 ratio was significantly higherin the biochar treatments than in the control. The Fa/Fb3 ratio was significantly higher in the B3 treatment than in the other treatments in Akihikari, but not in SN265.

Table 5 shows the viscosity, hot pulp viscosity, disintegration value and cold glue viscosity of starch from the two rice varieties in the various treatments. The values of these parameters tended to be higher in the biochar treatments, especially B2 and B3, than in the control. The differences in these values among the other treatments and between the other treatments and the control were small. There were no significant differences in peak time and gelatinization temperature among the different biochar treatments among the treatments and between the treatments and the control.

Effect of biochar on taste quality of rice

As shown in Table 6, for SN265, the treatments could be ranked, from highest to lowest eating value, appearance, viscosity and balance degree, as follows: B3 > B2 > B1, B4 and B5. The hardness was significantly lower B3 than in B2, and the hardness of B3 and B2 was significantly lower than that of the control and the other treatments. The hardness of B4 and B5 was similar to that of the control. For Akihikari, the treatments could be ranked, from highest to lowest taste value, appearance and balance degree, as follows: B3, B2 > B4, B5 > B1. For the viscosity, the treatments were ranked as follows: B3 > B2 > B5, B4, B1. The hardness showed no significant difference among the biochar treatments, but was significantly lower in the biochar treatments than in the control.

Effect of biochar on activity of rice starch related enzymes and transcript levels of their encoding genes

Effects of biochar on starch-related enzyme activity

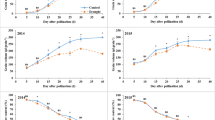

The treatments could be ranked, from highest GBSS activity to lowest, as follows: B5 > B4 > B1 > B2 > B3 (SN265) and B1 > B5 > B2, B4 > B3 (Akihikari). The common feature was that GBSS activity was significantly lower in B3 and B2 than in the control, and lower in B3 than in B2 (Fig. 1). The activity of SSS was significantly higher in B2, B3 and B4 than in the control and B5, and significantly higher in B2 and B3 than in B4. The trends in SBE and SDBE activities in both rice varieties were similar to that of SSS, but in Akihikari, the activity of SDBE was slightly higher in B2 and B3 than in B4.

Effects of biochar on activities of starch-related enzymes in grains of two Japonica rice varieties, SN265 and Akihikari. Abbreviations: GBSS, granule-bound starch synthase; SSS, soluble starch synthase; SBE, starch branching enzyme; SDBE, starch debranching enzyme. Biochar treatments: 0 t/hm2 (B1, control), 5 t/hm2 (B2), 10 t/hm2 (B3), 20 t/hm2 (B4) and 40 t/hm2 (B5). Different letters indicate significant difference at 5% level.

Effect of biochar on transcript levels of starch-related genes in rice grains

As shown in Fig. 2, the transcript levels of SS I were higher in B3 than in B2, and higher in both of those treatments than in the other biochar treatments. The differences in SS I transcript levels between B1 and B4 and between B4 and B5 were not significant. The trends in SS II transcript levels were similar to those of SS I, but there was no significant difference in SS II transcript levels between B5 and B3. The treatments could be ranked, from highest SS III transcript level to lowest, as follows: B5 > B1, B2, B4 > B3. For SBE I, its transcript levels were higher in the biochar treatments than in the control, and those differences were significant for all treatments except for B4. The treatments could be ranked, from highest transcript level of SBE IIb to lowest, as follows: B2 > B3 > B4 > B1, B5. The transcript levels of ISA were significantly higher in B2 than in the other treatments, but the differences among the other treatments were not statistically significant. The transcript levels of GBSS I were significantly lower in the biochar treatments, especially B3, than in the control. The rank order of the treatments in terms of AGPS2 transcript levels was B2 > B1 > B3 > B4, B5, and in terms of AGPL2 transcript levels it was B2, B3 > B1, B4 > B5.

Effect of biochar on transcript levels of starch-related genes in rice grains. Gene transcript levels were calculated relative to that of Actin1. Biochar treatments: 0 t/hm2 (B1, control), 5 t/hm2 (B2), 10 t/hm2 (B3), 20 t/hm2 (B4) and 40 t/hm2 (B5). Different letters indicate significant difference at 5% level.

Conclusion and discussion

The key to the eating quality of rice is viscoelasticity and other texture characteristics of rice. The starch content in the rice endosperm plays an important role in rice cooking and eating quality16,17. Endosperm starch consists of two kinds of α-glucose chains with different structures, namely amylose and highly branched amylopectin14. Rice with low amylose content is sticky and soft, while rice with high amylose content is relatively loose and hard after cooking18,19,20,21. The proportions of amylose and amylopectin and the fine structure of amylopectin affect the physical and chemical properties and RVA characteristics of starch, thereby affecting the processing quality and eating quality of rice grains. Amylopectin can be classified according to branch length into short-chain Fa, medium-chain Fb1 and Fb2, and long-chain Fb3. Many studies have shown that amylose content is the most important factor in rice quality18, and it has been used to predict the cooking and eating quality of rice for many years16. Most high-quality rice varieties have a low or medium amylose content. According to previous studies, the lower the AAC%, the greater the viscosity and the lower the hardness of rice, which result in better the palatability is. Allahholipour22 found that rice varieties with good palatability have a low AAC%, a high disintegration value, and low a cooling value. Li18 showed that a high proportion of amylose and long amylopectin branches lead to greater elasticity and lower viscosity; a high proportion of long amylopectin Fb3 increases hardness, and an increase in Fa content and Fa/Fb3 lead to higher viscosity. In our study, we found that biochar can reduce the apparent amylose content of SN265 and Akihikar, and increase the Fa content and Fa/Fb3 ratio in rice starch, especially the 10 t/hm2 biochar treatment. This ultimately improved the viscosity and taste quality of both rice varieties.

Starch accumulates via a complex series of enzymatic processes. Rice starch is formed in the chloroplast from the products of photosynthesis, and amylose is formed via the activity of GBSS, the key enzyme for amylose synthesis in the endosperm23,24,25. It is encoded by GBSS I whose transcript levels directly affect amylose content. Thus, inhibiting GBSS I expression can reduce the amylose content in seeds26. Amylopectin is produced under the combined actions of SSS, SBE, and DBE. SSS extends glucose chain linked by α-1,4 glucoside, and then branches are added by the activity of SBE. Finally, DBE removes the unsuitable branches to synthesize amylopectin. In the rice endosperm, SBE I and SBE II are responsible for the synthesis of 70% and 30% of amylopectin, respectively27,28,29. SBE I and SBE IIIb play different roles in the formation of the two types of branches: SBE I tends to transfer longer branched chains, and provides the substrate for SS IIIa to generate medium-sized and long chains, In contrast, SBE IIb tends to utilize short chains (DP 6–7) , which are subsequently extended by SS I17,29. The starch de-branching enzyme ISA uses amylopectin as its specific substrate, which is directly involved in the synthesis of amylopectin. ISA I is one of the most important genes determining starch structures in rice grains10,30,31. In this study, we found that biochar treatments affected the fine structure and content of starch by regulating the expression of genes encoding products related to starch synthesis and modification. This ultimately affected the viscosity and eating quality of rice. With increasing amounts of biochar added to soil, the transcript levels of GBSS I first decreased and then increased, and the activity of GBSS also first decreased and then increased. Consequently, the amylose content was significantly lower in B3 than in the other treatments. The transcript levels of SS IIa and SS IIIa affected the activity of amylase. The transcript level of SS IIa was significantly higher in B3 than in the control.The transcript level of SS IIIa was lowest in B3, resulting in the highest proportion of Fa chains and the lowest proportion of Fb3 chains, which affected the Fa/Fb3 ratio. The highest relative transcript levels of SBE I, SBE IIb and ISA I were in B2, much higher than in the control.

Our results show that biochar affected the expression of genes related to starch synthesis, which led to changes in the activities of enzymes involved in the synthesis of amylose and amylose, thereby changing the quality of rice. We propose two possible mechanisms for this effect: (1) There are many water-soluble active molecules on the surface of biochar. These include organic compounds such as carboxylic acid, acetoxy acid, benzoic acid, glycol, triol and phenolic substances32. Active molecules enter the plant body directly through the root system. After the active molecule enters the plant, it binds to the key protein/gene involved in starch synthesis, and then activates/inhibits a new metabolic pathway that ultimately affects grain quality. Previous studies have found that water-soluble molecules from biochar can alter the transcript levels of genes to improve drought and salt resistance in rice33,34. To explore this idea, we intend to use modern molecular biology techniques to screen and detect target genes or new metabolic pathways in further studies. (2) Biological carbon (especially rice husk carbon) contains abundant silicon that can be used directly and indirectly by plants. Many studies have shown that silicon can improve photosynthesis and promote carbohydrate synthesis and transport35. Silicon can also improve grain appearance quality and total starch content, and reduce amylose content and chalkiness to improve grain quality36,37,38,39. Based on the results of this study, we propose that an appropriate amount of biochar can increase the expression of genes and the activity of enzymes related to starch synthesis, which affects the types and content of starch and ultimately affects rice quality. The specific mechanism of its upstream function is unknown, and will be explored in further research.

Under the conditions of this study, the addition of 5–10t/hm2 biochar to improved the taste quality of rice, and also improved its appearance and processing quality. To reduce costs while still achieving tangible benefits, the rate of 5t/hm2 biochar is recommended. According to the estimated 30–40% yield of biochar from straw, 5 t/hm2 biochar is approximately equivalent to the carbonization of the full amount of straw, which is feasible for production. Given the stable long-term effectiveness of biochar, measures such as carbonizing straw every other year, or reducing the amount of biochar after continuous application, are proposed.

Conclusion

A certain amount of biochar can regulate the activities of enzymes related to starch synthesis and metabolism by affecting the transcript levels of their encoding genes. These changes affect the content and fine structure of starch in rice grains, and ultimately improve the viscosity characteristics and taste quality of starch, as well as the appearance and processing quality of rice grains. Our results indicate that an appropriate rate of biochar addition is 5–10 t/hm2. Further studies are required to clarify the detailed physiological, biochemical, and molecular biological mechanisms underlying the effect of biochar to improve the taste, appearance and processing of rice.

References

Chen, W. F., Meng, J., Han, X. R., Lan, Y. & Zhang, W. M. Past, present, and future of biochar. Biochar. 1, 75–87 (2019).

Chen, J. H., Liu, X. Y., Zheng, J. W., Zhang, B. & Lu, H. F. Biochar soil amendment increased bacterial but decreased fungal gene abundance with shifts in community structure in a slightly acid rice paddy from Southwest China. Appl. Soil. Ecol. 71, 33–44 (2013).

Dong, D. et al. Responses of methane emissions and rice yield to applications of biochar and straw in a paddy field. J. Soils Sediments 13(8), 1450–1460 (2013).

Liu, Y. X., Lu, H. H., Yang, S. M. & Wang, Y. F. Impacts of biochar addition on rice yield and soil properties in a cold waterlogged paddy for two crop seasons. Field Crops Res. 191, 161–167 (2016).

Shen, P., Jin, Z. X., Luo, Q. X., Jin, X. Y. & Sun, Y. L. Relationship between activity of key starch synthetic enzymes during grain filling and quality of eating and cooking in rice. Chin J. Rice Sci. 20(1), 58–64 (2016).

Xie, L. H. et al. Proteins affect rice eating quality properties and its mechanism. Chin. J. Rice Sci. 27(1), 91–96 (2013).

Hanashiro, I., Higuchi, T., Aihara, S. & Nakamura, Y. Structures of starches from rice mutants deficient in the starch synthase isozyme SSI or SSIIIa. Biomacromol 12, 1621–1628 (2011).

Nakamura, Y., Aihara, S., Crofts, N. & Sawada, T. In vitro studies of enzymatic properties of starch synthases and interactions between starch synthase I and starch branching enzymes from rice. Plant Sci. 224, 1–8 (2014).

Fujita, N. et al. Characterization of SSIIIa-deficient mutants of rice: the function of SSIIIa and pleiotropic effects by SSIIIa deficiency in the rice endosperm. Plant Physiol. 144, 2009–2023 (2007).

Zhu, L. N. et al. Analysis of expression characteristics of isoamylase and the correlation with starch content during grain filling in rice. Chin. J. Rice Sci. 29(5), 528–534 (2015).

Du, X. D. et al. Changes in starch accumulation and activity of enzymes associated with starch synthesis under different nitrogen applications in japonica rice in cold region. Acta Agron. Sin. 38(1), 159–167 (2012).

He, Z. F. A review of the separation and test methods of cereal starch. Grain Stor. 65(6), 32–38 (1985).

American Association of Cereal Chemist (AACC). Approved methods of analysis. 11th edn. Methods 61-02. 01. Determination of the Pasting Properties of Rice with the Rapid Visco Analyser. The Association: St. Paul, MN (1999).

Jin, Z. X., Zhu, F. X., Guo, X. D. & Zhang, Z. C. Effect of different nitrogen application methods on metabolism correlation enzymes and quality in rice. J. Northeast Agric. Univ. 47(6), 1–7 (2016).

Rajeevan, M. S., Ranamukhaarachchi, D. G., Vernon, S. D. & Unger, E. R. Use of real-time quantitative PCR to validate the results of cDNA array and differential display PCR technologies. Methods 25(4), 443–451 (2001).

Zhou, L. J. et al. Differential expressions among five Waxy alleles and their effects on the eating and cooking qualities in specialty rice cultivars. J. Integrative Agric. 14(6), 1153–1162 (2015).

Nakamura, S., Satoh, H. & Ohtsubo, K. Development of formulae for estimating amylose content, amylopectin chain length distribution, and resistant starch content based on the iodine absorption curve of rice starch. J. Agric. Chem. Soc. Jpn. 79(3), 443–455 (2015).

Li, H. Y., Prakash, S., Nicholson, T. M., Fitzgerald, M. A. & Gilbert, R. G. Instrumental measurement of cooked rice texture by dynamic rheological testing and its relation to the FNE structure of rice starch. Carbohyd. Polym. 146, 253–263 (2016).

Li, H. Y., Prakash, S., Nicholson, T. M., Fitzgerald, M. A. & Gilbert, R. G. The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem. 196, 702–711 (2016).

Nakamura, S. et al. Comparison of eating quality and physico chemical properties between Japanese and Chinese rice cultivars. Biosci. Biotechnol. Biochem. 80, 2437–2449 (2016).

Huang, S. J. et al. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Integr. Agric. 19(4), 988–998 (2020).

Allahgholipour, M., Ali, A. J., Alinia, F., Nagamine, T. & Kojima, Y. Relationship between rice grain amylose and pasting properties for breeding better quality rice varieties. Plant Breeding 125(4), 357–362 (2006).

Yan, P., Shen, W. T., Li, X. Y. & Zhou, P. Progress in construction of hpRNA vector for plant RNAi. Biotechnol. Bull. 9, 7–12 (2013).

Sasaki, T., Yasui, T. & Matsuki, J. Effect of amylose content on gelatinization, retrogradation, and pasting properties of starches from waxy and nonwaxy wheat and their F1 seeds. Cereal. Chem. 77(1), 58–63 (2000).

Fang, X. W., Jiang, D., Dai, T. B. & Cao, W. X. Accumulation regularity of starch components in wheat varieties. Jiangsu J. Agric. Sci. 18(3), 139–142 (2002) ((in Chinese)).

Miao, H. X., Sun, P. G., Zhang, K. X., Jin, Z. Q. & Xu, B. Y. Research progress on expression regulation mechanism of genes encoding granule-bound starch synthase in plants. Biotech. Bull. 32(3), 18–23 (2016).

Nishi, A., Nakamura, Y., Tanaka, N. & Satoh, H. Organ Specificity of isoforms of starch branching enzyme (Q-enzyme) in rice. Plant Cell Physiol. 33(7), 985–991 (1992).

Mizuno, K. et al. Alteration of the structural properties of starch components by the lack of an isoforms of starch branching enzyme in rice seeds. J. Biol. Chem. 268(25), 19084–19091 (1993).

Wang, K. et al. The biosynthesis, structure and gelatinization properties of starches from wild and cultivated African rice species (Oryza barthii and Oryza glaberrima). Carbohyd. Polym. 129, 92–100 (2015).

Satoh, H. et al. Starch-branching enzyme I deficient mutation specifically affects the structure and properties of starch in rice endosperm. Plant Phys. 133, 1111–1121 (2003).

Utsumi, Y., Utsumi, C., Sawada, T., Fujita, N. & Nakamura, Y. Functional diversity of isoamylase oligomers: the ISA1 homo-oligomer is essential for amylopectin biosynthesis in rice endosperm. Plant Physiol. 156(1), 61–77 (2011).

Graber, E. R. et al. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 337(1), 481–496 (2010).

Zhen, X. X., Xu, F., Jiang, T. Y., Gao, J. P. & Zhang, W. Z. Mechanism of the regulating effect on biochar-leach liquor to rice seedlings under salt stress. J. Shenyang Agric. Univ. 46(04), 471–475 (2015).

Jiang, T. Y. et al. Water-soluble active molecule on biochar surface could ehance the tolerance to drought stress in rice. Mol. Plant Breed. 6, 1223–1232 (2015).

Kim, S. G. et al. Silicon-induced cell wall fortification of rice leaves: a possible cellular mechanism of enhanced host resistance to blas. Phytopathology 92(10), 1095–1103 (2002).

Shang, Y. et al. Effect of silicon fertilizer application on yield and grain quality of japonica rice from Northeast China. Chin. J. Rice Sci. 23, 661–664 (2009).

Ahmad, A. et al. Effect of silicon and boron foliar application on yield and quality of rice. Pak. J. Life Soc. Sci. 1, 161 (2012).

Kargbo, M. B. et al. Physiological basis of improved performance of super rice (Oryza sativa) to deep placed fertilizer with precision hill-drilling machine. Int. J. Agric. Biol. 18, 797–804 (2016).

Mo, Z. W. et al. Silicon fertilization modulates 2-acetyl-1-pyrroline content, yield formation and grain quality of aromatic rice. J. Cereal. Sci. 75, 17–24 (2017).

Acknowledgments

The authors thank Zhengjin Xu and Guijin Dai for assistance in managing these experiments. We thank Jennifer Smith, PhD, from Liwen Bianji, Edanz Group China (www.liwenbianji.cn/ac), for editing the English text of a draft of this manuscript.

Funding

This work was supported by the Earmarked Fund for National Key Research and Development Program-Northern Japonica Rice High-quality, High-yield and National key research and development program (2017YFD0100500) and China Agriculture Research System (CARS-01-50).

Author information

Authors and Affiliations

Contributions

Funding acquisition, Z.X. and G.D.; Data collection and writing—original draft, D.G.; Writing—review and editing, Z.X., W.Z., X.X., L.W.; All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gong, D., Xu, X., Wu, L. et al. Effect of biochar on rice starch properties and starch-related gene expression and enzyme activities. Sci Rep 10, 16917 (2020). https://doi.org/10.1038/s41598-020-73888-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-73888-2

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.