Abstract

Trans-oxanes are important liquid crystals. The commonly used techniques for the synthesis were to react 2-substituted propylene glycols with substituted formaldehydes. Such process produces toxic cis-oxanes, which are harmful to the environment. The cis to trans isomerization of wasted cis-oxanes was studied in the presence of p-toluenesulfonic acid as catalyst. The yield of cis to trans conversion was over 70%, which was much higher than 42–69% when traditional methods were employed. The total yield of the new method was increased to 90%. Further investigation of effects of catalysts, reaction times, temperatures on the cis-trans conversion was carried out. Proposed mechanism of this process for the conversion was discussed.

Similar content being viewed by others

Introduction

One feature of trans-oxane materials is easy to synthesize, which is a key requirement for the applications in TN/STN and TFT modes of liquid crystal display1,2. The class of trans oxane is among the key materials for liquid crystal display. During the past decades, the research on oxane liquid crystals, especially trans-oxanes, has attracted increasing attention in the field3,4. The commonly used synthesis was to react substituted formaldehydes (a) with 2-substituted propylene glycols (b) for mixed cis-trans oxanes (e)5,6, followed by separation and purification to give pure trans-oxane monomer (d) (Fig. 1).

Liquid crystal display requires highly pure trans-oxanes, and its cis-isomers have to be removed from their mixtures. The routine purification was to extract trans-isomers by recrystallization. However, such strategy was unsatisfactory7,8. Some amount of trans-isomers remained in the mother liquor with cis-isomers, therefore the yield of trans-oxanes was relatively low (about 50% as calculated based on alkyl benzaldehyde). After recrystallization a large amount of mother liquor (f) was left over containing mainly cis-trans mixtures. There is no literature on recycling the mixtures and purifying the trans isomers, so mixture f was usually discarded causing not only environmental pollution, but also high cost of the trans isomers.

Although cis-trans isomerization was reported9,10, there has been no reports on converting cis-oxanes (c) into trans-oxanes so far. In order to improve the yield of trans-oxanes and reduce the environmental pollution, a new synthetic route (Fig. 2) was employed to give trans-oxanes (d). As shown in Fig. 2, the cis-trans mixtures of oxanes (e) were synthesized by docking p-alkyl benzaldehyde (a) directly with 2-substituted propylene glycol (b). Pure trans-oxanes (d) monomers were obtained by either high vacuum distillation, chromatography or recrystallization. The latter left a large amount of cis-trans mixtures (f) with cis configuration dominant. The cis-trans mixture with trans configuration dominant (g) was obtained in the presence of p-toluenesulfonic acid as catalyst. Then the mixture (g) was purified further as shown in Fig. 2 to give pure trans-configuration of oxanes (d). The process was repeated several times until cis isomers were completely converted into trans ones.

Obviously the overall yield of trans-oxanes in Fig. 2 reached up to 78–88% (calculated based on alkyl benzaldehyde), which was significantly higher than that in Fig. 1 (about 42–69%). Due to the repeated conversion and purification of the mixture f, the mother liquor generated in the process was reused in site repeatedly to reduce environmental pollution. This improves the utilization rate of the starting materials and reduces the cost of products. Since the syntheses of corresponding compounds a and b were previously reported11,12, this paper will only deal with how to carry out the catalytic conversion of the key cis to trans isomers. The synthesis of representative mixture e was also selected to describe the conversion of cis-trans mixture f. The factors and mechanism of conversion were analyzed throughout the experiments in order to provide an example for the optimization of the process, and a reference for the synthesis of similar oxanes.

Results

The effect of the reaction conditions on the conversion

Reaction temperature

The effects of the reaction temperature on the cis to trans oxane conversion of mother liquors (f) were shown in Table 1. The temperatures of cis to trans isomerization of 2-p-cyanophenyl-5-ethyl-1,3-dioxane and 5-(4-n-propyl) cyclohexyl-2-p-ethylphenyl-1,3-dioxane were around 98 °C (n-heptane as solvent) to 110 °C (toluene as solvent). The corresponding trans isomers were obtained by recrystallization and the ratio of cis/trans conversion maintained at 25:75 as temperatures were increased.

The influence of reaction time

The influence of reaction time onthe cis to trans oxane conversion of mother liquors (f) was shown in Table 2. The cis-trans isomerization was completed in 1 h at 98 °C or 110 °C and there was no change of the cis-trans ratio when reaction time was increased. The proportion of cis-trans product remained at the level of 25:75 even though prolonged reaction time was applied.

Discussion

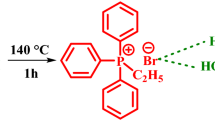

It was known that the conversion of the cis-trans isomer might be a chemical dynamic equilibrium process13, which was generally divided into three categories: photoisomerzation, thermoisomerization and catalytic isomerization. As the final cis-trans equilibrium was decided by the thermodynamic stability of each isomer, thermoisomerization and catalytic isomerization were classified into one group during the synthesis14. The isomerization was mainly focused on C=C, C=N15. The studies on the catalytic isomerization of cycloalkanes and heterocycles16 were mainly concentrated on how to control cis-generation in ring-closure. However, the mechanism of how cis-isomers are converted into trans-ones is still unknown. It is also difficult to study the mechanism of catalytic isomerization because of the electronic and spatial effects of substituents on isomer molecules. Currently, only CNDO/2, SCF-MO and FSGO are used to roughly determine whether the mechanism of catalytic isomerization is based on the plane lateral displacement mechanism or the torsion mechanism under acid-base catalysis. We propose that the conversion process and the mechanism of the cis-trans isomerization of oxanes are as follows (Fig. 3):

Oxanes undergo ring opening in the presence of p-toluenesulfonic acid to go through a planar intermediate state h, followed by the aldol condensation for ring closure to give cis (c) an d trans (d) acetal, respectively. The rearrangement process favors trans configuration as it is more stable thermodynamically. The experimental results showed the ratio of cis-trans compounds in the system was 25:75, and it was basically unchanged (Tables 1 and 2). This means experimental results supported the proposed mechanism.

Methods

Materials and equipments

SY 25000-type high-pressure liquid chromatograph (HPLC, methanol as mobile phase, C218 as the stationary phase, a flow rate of 1 mL·min-1); 1102 gas chromatograph (GC); HP 5989B mass spectrometer analyzer. p-cyanobenzaldehyde, toluene, calcium chloride and 2-ethyl propylene glycol were from Shanghai Reagent Factory (analytical grade). The anhydrous magnesium sulfate was also analytical grade from Tianjin Sitong Chemical Plant.

Preparation of the cis-trans mixture (e1) of 2-p-cyanophenyl-5-ethyl-1,3-dioxane

Toluene 130 mL, 2-ethylpropylene glycol 26.5 g (255 mM), p-cyanobenzaldehyde 32.8 g (250 mM), calcium chloride 0.5 g were successively added into the 500 mL reaction flask equipped with mechanical stirrer and reflux condenser. They were then stirred, and heated to reflux. Heating stopped when no water was generated. Analysis of the sample was performed on the gas chromatography (GC). When GC online results showed the content of p-cyanobenzaldehyde was less than 0.05%, the reaction was quenched. The mixture was cooled with water 150 ml. The aqueous phase was extracted with toluene 20 mL. The organic phases were combined and washed with water to neutral, then dried with anhydrous magnesium sulfate 5 g for 8 hrs and filtered. The filter cake was washed with toluene 10 mL twice. After distillation, the cis-trans mixture (e1) 52.2 g of 2-p-cyanophenyl-5-ethyl-1,3-dioxane was obtained. GC analysis showed that the content of the cis-2-p-cyanophenyl-5-ethyl-1,3-dioxane (c1) was ≥20% and the trans -2-p-cyanophenyl-5-ethyl-1,3-dioxane (d1) was ≥79%, respectively.

How to prepare the trans -2-p-cyanophenyl-5-ethyl-1,3-dioxane

The e1 prepared from above was recrystallized from ethanol at the ratio of 1 g/1.8 mL twice. The product was 34.6 g, and the purity of d1 was ≥99.5%, analyzed by gas chromatography (GC) and the purified yield was about 65%. The cis-trans mixture containing 2-p-cyanophenyl-5-ethyl-1,3-dioxane (f1) 17.4 g was obtained from the combined recrystallization mother liquor and the solvent was removed by distillation. Analysis of the sample by GC showed that the content of c1 was ≥58%, and d1 was ≥39%. f1 was directly used in following reaction.

Conversion of c1 to d1 under catalystic isomerization in the presence of p-toluenesulfonic acid

The cis-trans mixture (f1) 17.4 g (82 mM), p-toluenesulfonic acid 1.7 g (10 mM) and toluene 100 mL were successively added into 250 mL reaction flask equipped with mechanical stirrer, reflux condenser. The reaction mixture was heated under stirring. Analysis of the sample was carried out every 0.5 h and reflux continued for 3 h. When GC online results showed the cis-trans ratio remained unchanged, the reaction was quenched. The mixture was cooled and water 50 mL was added. The aqueous phase was extracted with toluene 20 mL. The organic phases were combined, washed with water to neutral, dried over anhydrous magnesium sulfate 5 g for 8 hrs and filtered. The filter cake was washed with toluene 10 mL twice. The cis-trans mixture (g1) 17.4 g was obtained after solvent removal and distillation.

Analysis of the sample by GC showed that c1 was ≥21%, and d1 was ≥78%. After recrystallization for purification, the product (d1) was 12.1 g with purity ≥99.5% analyzed by GC, and the yield was ≥69%. The mother liquor from recrystallization (f1) was collected and extracted. The overall yield of compound d1 based on p-cyanobenzaldehyde was ≥93% following the procedure of Fig. 2.

Conversion of cis-5-(4-n-propyl) cyclohexyl-2-p-ethylphenyl-1,3-dioxane (c6) to its corresponding trans configuration (d6) in the presence of p-toluenesulfonic acid

The cis-trans mixture (f6) 23 g containing 5-(4-propyl) cyclohexyl-2-p-ethylphenyl-1,3-dioxane was obtained following the same experimental procedure as above. Analysis of the sample by GC showed that c6 was ≥87% and d6 was ≥12%. In 250 mL reaction flask equipped with mechanical stirrer, reflux condenser and addition funnel, 23 g (73 mM) of cis-trans mixture of f6, 1.1 g (7 mM) of p-toluenesulfonic acid and 100 mL of n-heptane were added to the reaction flask. Then reaction mixture was heated under stirring. Analysis of the sample was carried out every 0.5 h and reflux continued for 3 hrs. When GC online results showed the cis-trans ratio was unchanged, the reaction was quenched. Then the reaction mixture was cooled and water 50 mL was added. The aqueous phase was extracted with n-heptane 20 mL. The organic phases were combined and washed with water to neutral, dried over anhydrous magnesium sulfate 5 g for 8 hrs and filtered, then washed with n-heptane 10 mL twice. The cis-trans mixture (g6) was obtained after distillation. Analysis of the sample by GC showed that cis-5-(4-n-propyl) cyclohexyl-2-p-ethylphenyl-1, 3-dioxane (c6) ≥23%, and trans-5-(4-n-propyl) cyclohexyl-2-p-ethylphenyl-1, 3-dioxane (d6) was ≥76%. After recrystallization and purification, the product (d6) was 14.8 g, the purity of d6 analyzed by GC was ≥99.5%, and the yield was ≥65%. The mother liquor from recrystallization was collected and extracted with the method described in Fig. 2. The overall yield of d6 was ≥70%.

References

Han, Y., Wang, K., Zhang, J., Li, Z. & Zhang, F. Synthesis and properties of 3, 5-difluorotolane liquid crystal compounds. Chin. J. Liq. Cryst. Displays. 28, 683–687 (2013).

Yun, G., Zheng, C. C. & Hua, R. Preparation and characteristics of terminal alkeny-bearing lateral fluoro-benzene negative liquid crystals. Chin. J. Liq. Cryst. Displays. 28, 510–515 (2013).

Hirata, K. Production of tetrahydro-2H-pyran derivative used as component of liquid crystal medium, involves applying oxane compound as intermediate. EP3228617-A1 (2017).

Masahiro, H. Manufacture of compound containing oxane and dihalophenyl groups used in N-type liquid crystal material, involves coupling compound containing oxane group and compound containing dihalophenyl group in presence of transition metal catalyst. WO2019035408-A1 (2019).

LI, Y., Song, Y., Zhou, H. & Wang, X. Anhydrous offset sprinkle ink printing plate manufacturing method, involves covering silicon rubber layer with ink area to prepare anhydrous offset sprinkle ink printing plate, and removing water-soluble high polymer or waste liquid. CN104742491-A; CN104742491-B[P] (2015).

Hu, Y. & Lin, H. Energy-saving and environmentally-friendly light aggregate concrete block used for preparing formaldehyde adsorbent, comprises eg. polycaprolactone, lanthanum citrate, liquid crystal elastomer, propylene glycol alginate and monazite powder. CN108911592-A[P] (2018).

LI, Q., Zhang, S., Yu, Q., Sun, W. & Jiang, D. Preparation of alkylcyclohexyl-phenol compound useful as liquid-crystal compound intermediate, involves preparing (benzyloxy-phenyl)-bicyclohexylol from benzyloxy bromobenzene compound, hydrogenating, isomerizing, and acid hydrolyzing. CN103553878-A; CN103553878-B[P] (2014).

Sun, H., Xiao, C. & Zou, Y. Preparation of E-3,5-dimethoxy-4′-hydroxy diphenylethene and its derivatives, comprises methylating 3,5-dihydroxyacetophenone, doing Willgerodt-Kindler Rearrangement Reaction, hydrolyzing, extracting, and recrystallizing. CN101665418-A; CN101665418-B[P] (2010).

Miniewicz, A., Orlikowaska, H., Sobolewaska, A. & Bartkiewicz, S. Kinetics of thermal cis-trans isomerization in a phototropic azobenzene-based single-component liquid crystal in its nematic and isotropic phases. Phys. Chem. Chem. Phys. 20, 2904–2913 (2018).

Lee, C. et al. Optically controllable photonic crystals and passively tunable Terahertz metamaterials using dye-doped liquid crystal cells. J. Mater. Chem. C. 6, 4959–4966 (2018).

Vanderpool, S. H. Para-alkyl benzaldehyde prodn. from alkylbenzene-by reacting with carbon mon:oxide over hydrogen fluoride and metal penta:fluoride. US4218403-A (1980).

Schrader, T. O. et al. Complementary asymmetric routes to (R)-2-(7-hydroxy-2,3-dihydro-1H-pyrrolo[1,2-a]indol-1-yl)acetate. Org. Lett. 14, 6306–6309 (2012).

Wang, S. et al. Ultrafast dynamics of UV-excited trans- and cis-ferulic acid in aqueous solutions. Phys. Chem. Chem. Phys. 19, 30683–30694 (2017).

Qi, Z., Zhang, F., Yao, R., Liu, J. & Zhang, X. Mixed CoN4Cl2 and CoCl4 units versus two CoN2Cl3 units in [Co2(Htbi)2Cl4] isomers. Inorg. Chem. Commun. 39, 21–25 (2014).

Goodby, J. W. The Nanoscale engineering of nematic liquid crystals for displays. Liq. Cryst. 38, 1363–1387 (2011).

Chianese, A. R. et al. Acceptorless alkane dehydrogenation catalyzed by iridium CCC-pincer complexes. Organometallics. 33, 457–464 (2014).

Acknowledgements

Financial support for this work was received from National Natural Science Foundation of China (grant number 81673115), Huimin project of Ministry of Science and Technology of China (grant number 2012GS610101), Department of Health of Shaanxi Province (grant number 2018D050), and International Cooperation Foundation of Shaanxi province(2020KW-057). Editorial help of Prof Zuoquan Wang is acknowledged.

Author information

Authors and Affiliations

Contributions

Zhaoheng Dong and Qun chen conceived the research, Ping Fan and Zhaoheng Dong performed some experiments and analysis, Chen Chen and Qun Chen discussed and wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Dong, Z., Fan, P., Chen, Q. et al. Facile conversion of cis into trans oxane as liquid crystals. Sci Rep 10, 6936 (2020). https://doi.org/10.1038/s41598-020-63902-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-63902-y

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.