Abstract

The movement of the ferrous nanoparticles is random in the base fluid, and it will be homogeneous under the enforced magnetic field. This phenomenon shows a significant impact on the energy transmission process. In view of this, we inspected the stream and energy transport in magnetohydrodynamic dissipative ferro and hybrid ferrofluids by considering an uneven heat rise/fall and radiation effects. We studied the Fe3O4 (magnetic oxide) and CoFe2O4 (cobalt iron oxide) ferrous particles embedded in H2O-EG (ethylene glycol) (50–50%) mixture. The flow model is converted as ODEs with suitable similarities and resolved them using the 4th order Runge-Kutta scheme. The influence of related constraints on transport phenomena examined through graphical illustrations. Simultaneous solutions explored for both ferro and hybrid ferrofluid cases. It is found that the magnetic oxide and cobalt iron oxide suspended in H2O-EG (ethylene glycol) (50–50%) mixture effectively reduces the heat transfer rate under specific conditions.

Similar content being viewed by others

Introduction

The fluid flows across a stretching surface have attained plentiful implications in the analysis of boundary layer flow owing to its great solicitations in medical, industrial, and mechanical engineering applications. Food dispensation, silicon wafer process, hot rolling, cooling of reactors, design of precious stone, tinning of wires, continuous casting of metals, paper production, making of microchips, glass industry, crystal growth, space vehicles, polymer physics are some applications of such motion in a time-dependent liquid film flow across a surface. Anderson et al.1 discussed the problem of liquid film movement of a Newtonian fluid through a strained surface. The influence of radiative heat and variable thermal conductivity on shear thickening fluid drive of a liquid film on the unsteady permeable extending superficial inspected by Khan et al.2 and Shah et al.3 It clinched that the distribution of heat and the variable temperature parameter are linearly proportional beside the surface. Idrees et al.4 studied an elucidation of the problem of an unsteady MHD thin-film flow owing to stressed sheet in the appearance of mutable viscosity. Recently, Kumar et al.5 bestowed dual elucidations for micropolar conducting fluid flow past an overextended sheet in the presence of second-order velocity slip.

The frictional heat mechanism has an active role in industrial and scientific implications such as electric coffee fabricators, rock forms, cuisine diet, and sanitization. Chen6 considered a problem of an unsteady two-dimensional shear-thickening film flow over an elongated geometry to examine the influence of viscous dissipation. Later, Chen7 extended the problem with Joule’s heat and gave a result with the support of the numeric Keller-Box scheme. The effect of frictional heat on the natural convective 2D drive of hybrid nano liquid over a circular tube was discussed by Suresh et al.8 Numerical scrutiny was accompanied by Ramandevi et al.9 for the comparison of the heat transfer mechanism in both viscoelastic and Casson fluid flow using new heat flux under the action of and viscous dissipation. Recently, the authors10 discussed the impact of Joule heating on fluid motion owing to the extending sheet in the occurrence of Biot number.

Newly, scientists and researchers made an immense effort to examine the significance and separation of hybrid ferrofluids due to their applications in many branches of natural, engineering, and physical sciences. A magnetic colloid is well-known as a ferrofluid. A ferrofluid is a colloidal interruption of single-domain ferromagnetic elements in a base liquid. It has several medicinal and biological solicitations like amplifiers, revolving shaft seals, vacuum chambers, computer drives, dissipation of radiation, medicine delivery, cell parting, etc. A nanofluid consists of a single nanomaterial, whereas the hybrid nanofluid consists of more than one unlike nanoparticles with ordinary fluid. The determination behind the invention of a mixture of ferrofluids is to knob the transport phenomena. Madhesh and Kalaiselvam11 discussed the rheological appearances and temperature transmission of hybrid nanofluids. The magnetohydrodynamic time-dependent liquid film flow of grapheme nanoparticles embedded nanofluid under various thermal transport aspects can be viewed in ref. 12 The influence of drag force on the flow over an expanding surface was discussed by Sheikholeslami et al.13 Later on, the researchers14,15 investigated the transport phenomena of Newtonian and non-Newtonian hybrid nanoliquids under various physical effects. Kumar et al.16 discussed the effect of Brownian moment on bio convective stagnated motion of nanoliquid and presented dual solutions. It was clinched that the measure of thermal transport is high in the case of hybrid nanofluid when matched with another liquid. Sandeep17 deliberated the influence of drag force and variable viscosity on the hybrid nanofluid drive of liquid film over a fraught sheet.

The inspiration for radiating heat on convective movements shows a massive role in many engineering and scientific procedures like space technology, paper bowls production, freezing of metal bits, satellites, design of electronic chips, and fuel wells. The radiation is either or nonlinear depends on temperature ratio parameter values. The mechanism of asymmetrical heat rise or fall has well-known uses in drug industries and numerous manufacturing happenings like freezing of metal strips and crude oil recovery, etc. Devi and Devi18 considered a problem to investigate a numerical explanation for MHD flow of nanoliquid across a penetrable sheet with heat rise/fall. Kandelousi and Ellahi19 scrutinized a time-independent, two-dimensional ferrohydrodynamic flow through a square cavity in the occurrence of drag force. The well-known Lattice Boltzmann technique is utilized to resolve the equations of motion. Afrand et al.20 contemplated a problem to examine the Power-law fluid. The stimulus of radiation on the hydrodynamic drive of shear thickening over a stretched surface was scrutinized by Ramzan et al.21 Ghadikolaei22 deliberated the magnetohydrodynamic free convective motion of two different hybrid nanofluids across an overextended surface. The impact of thermic heat on MHD flow of micropolar shear-thickening nanoliquid thru a nonlinear stretched sheet was examined by Lu et al.23 numerically with the help of the Matlab package. Kumar et al.24 discussed the inspiration of asymmetrical heat generation or absorption and nonlinear thermic heat on slanting stagnated motion of shear thickening fluid across a vertical sheet in conducting field. The impact of non-linear thermal radiation and resistive heating on MHD shear-thickening nanoliquid flow over an inclined penetrable stretched sheet was reported by Ghadikolaei et al.25 Discrete heating effect on free convection flow past a vertical annulus was studied by the researchers26,27,28,29. Sankar et al.30 performed a numerical investigation to analyze the heat and mass transfer rates in the presence of discrete heat source.

In all the afford studies, scientists scrutinized the transport phenomena of nanoliquids past a solid geometry with numerous physical aspects. The main motto of this exploration is to provide a numerical examination of the stream and energy transport in magnetohydrodynamic dissipative ferro and hybrid ferrofluids by considering an uneven heat rise/fall and radiation effects. We studied the Fe3O4 (magnetic oxide) and CoFe2O4 (cobalt iron oxide) ferrous particles embedded in H2O-EG (ethylene glycol) (50–50%) mixture. The flow model is converted as ODEs with suitable similarities and resolved them using the 4th order Runge-Kutta scheme. The influence of related constraints on transport phenomena examined through graphical illustrations. Simultaneous solutions are explored for both ferrous and hybrid ferrofluid cases.

Modelling

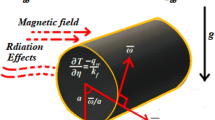

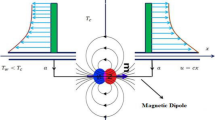

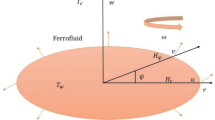

Consider a time dependent flow of EG-H2O based magnetic and cobalt iron oxide mixture hybrid ferrofluid past an extending sheet as depicted in Fig. 1. Here, the surface is placed lengthways x-axis with the temperature and momentum respectively taken as \({T}_{w}={T}_{0}-{T}_{re}\sqrt{{b}^{2}{x}^{4}/4{v}_{f}^{2}(1-\alpha t)},\,0\le {T}_{re}\le {T}_{0},\) \({\rm{and}}\,{u}_{w}=bx/(1-\alpha t)\) and \(y\)- axis is normal to it (where \(b,\alpha \) are constants and \({T}_{0},{T}_{re}\) are slit, reference temperatures)

An electromagnetic field of forte \(B={B}_{0}\sqrt{1/(1-\alpha t)}\) is measured normal to the drive. Thermal radiation, asymmetrical heat rise/fall and viscous dissipation possessions are engaged. The slip between the particles is neglected. With the above conventions, the leading transport equalities are as follows:

Frontier limitations:

where

where, the dynamic viscosity, density, electrical conductivity, thermal conductivity, specific heat capacitance, Stefan–Boltzmann constant, uneven heat source/sink parameters and radiative absorption coefficient are respectively given by \(\mu ,\rho ,\sigma ,k,{c}_{p},{\sigma }^{\ast },{A}^{\ast },{B}^{\ast }\,and\,{k}^{\ast }\). Here, the suffix \(nf\,{\rm{and}}\,hnf\) denotes the nano and hybrid nanoliquid.

Similarity transmutations26

The ferrofluid restrictions are taken as

Using Eqs. (5) to (7), the Eqs. (2) to (4) can be distorted as

Transformed boundaries:

where, \({\phi }_{1},{\phi }_{2}\) denotes the nanoparticle volume fraction and the suffixes \(f,s\) denotes the fluid and solid particles. And the dimensionless magnetic field parameter, Prandtl number, Radiation parameter, Unsteadiness parameter, Eckert number and film thickness quantities are specified by

The reduced Nusselt number \(N{u}_{x}\) is specified as

with the Reynolds number \({\mathrm{Re}}_{x}=\frac{{u}_{w}x}{{v}_{f}}\).

Results and Discussion

The Eqs. (8) and (9) with the constraints in Eq. (10) are resolved by the RK-shooting scheme. The assets of non-dimensional restrictions on the drive, energy fields along with Nusselt number are elucidated explicitly. The results are displayed for (H2O-EG-Fe3O4) water-EG-magnetic oxide ferrofluid (solid lines), (H2O-EG-CoFe2O4) water-EG-cobalt iron oxide ferrofluid (dashed lines) and water-EG- magnetic/cobalt iron oxide hybrid ferrofluid (dotted lines) cases. For computing purpose, the dimensionless quantities can be considered as \(M=3,R=1,{\phi }_{1}={\phi }_{2}=0.1;Ec=S=\lambda ={A}^{\ast }={B}^{\ast }=0.5,\Pr =30.\) Table 1 predicts the physical properties, and Table 2 discusses the authentication of the outputs.

Figure 2 explains the impression of \(M\) on the drive and thermal fields along with Nusselt number. The momentum boundary layer of water-EG-magnetic/cobalt iron oxide hybrid ferrofluid is less influenced by \(M\) when equated with water-EG-magnetic oxide and water-EG-cobalt iron oxide ferrofluids. And the opposite trend has been noticed in the thermal boundary layer as displayed in Fig. 2(a). The reason for these trends is the drag force developed against the flow due to the imposing of external magnetic force. As a rise in the resultant temperature, we noticed a fall in the Nusselt number, as shown in Fig. 2(c). Notably, it is less in H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid when compared to other two ferrofluids.

Figure 3 explicate the influence of \(R\) and uneven heat rise/fall on \(\theta (\eta )\,{\rm{and}}\,N{u}_{x}\). As per the general nature of \(R,\,{A}^{\ast }\,{\rm{and}}\,{B}^{\ast }\), a rise in the heat input primes to upsurge in the heat field. A similar drift was followed by Fig. 4. However, we observed a significant hike in the thermal field of H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid when compared to the other two ferrofluids. These may be due to the enhanced heat conduction between the Fe3O4-CoFe2O4 solid particles. As a result, we found decay in \(N{u}_{x}\) in all cases for growing numbers of \(R,\,{A}^{\ast }\,{\rm{and}}\,{B}^{\ast }\) (see Figs. 3(b) and 4(b)).

Figure 5 expounds the result of \(\lambda \) on \(f\text{'}(\eta ),\theta (\eta )\,{\rm{and}}\,N{u}_{x}\). We perceived a depreciation in momentum and thermal arenas for boosting values of \(\lambda \). Notably, we noticed that the impact of \(\lambda \) is high on the thermal filed of H2O-EG-CoFe2O4 ferrofluid when equated to water-EG-magnetic oxide ferrofluid and water-EG-magnetic/cobalt iron oxide hybrid ferrofluid. Generally, a rise in the film thickness leads to enlarging the flow filed and hence reduces the heat transfer. Cobalt may be the reason for the additional reduction in the heat transfer of H2O-EG-CoFe2O4 ferrofluid.

Figure 6 illustrate the control of viscous dissipation on \(f\text{'}(\eta ),\theta (\eta )\,{\rm{and}}\,N{u}_{x}\). It is profound that the growing values of \(Ec\) effectively escalate the thermal and drive boundary layers. Physically, drive force can be converted as heat energy in viscous fluids. If the viscosity of the fluid is high, then more internal heat energy will generate and hence the heat transfer. Interestingly, enhancing the fluid viscosity commendably enhancing the flow and thermal fields of H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid when equated to the other two ferrofluids. Figures 7 and 8 exemplify the impression of \(M,\lambda ,\,{A}^{\ast }\,{\rm{and}}\,{B}^{\ast }\) on Nusselt number. It is evident that the boosting standards of \(M,\lambda ,\,{A}^{\ast }\,{\rm{and}}\,{B}^{\ast }\) decline the heat transfer rate in all cases. Mainly, this influence is high on H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid.

Conclusions

Due to the numerous applications of ferrofluid fluids in the heat transfer process, a computational analysis is performed to investigate the drive and heat transport in EG-H2O/Fe3O4 ferroliquid, water-EG/CoFe2O4 ferroliquid and water-EG-magnetic oxide/cobalt iron oxide ferrofluid hybrid ferrofluid in the presence of thermal radiation, dissipation and uneven energy generation/fall. Observations of the current analysis are listed below:

The drive of water-EG-magnetic oxide/cobalt iron oxide hybrid ferrofluid is effectively controlled by \(M\).

Thermal radiation and asymmetrical heat rise/fall regulates the energy transport in

H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid.

Enhancement in film thickness and addition of cobalt leads to a gradual decline in the thermal boundary layer thickness.

CoFe2O4 may works like an insulator by increasing the concentration of cobalt.

H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid may be used as a coolant by balancing the cobalt levels.

By monitoring the viscous levels, we can control the internal heat transfer of H2O-EG-Fe3O4/CoFe2O4 hybrid ferrofluid.

References

Anderson, H. I., Aarseth, J. B. & Dandpat, B. S. Heat transfer in a liquid film on an unsteady stretching surface. Int. Heat Mass Transf 43, 69–74 (2000).

Khan, Y., Wu, Q., Faraz, N. & Yildirim, A. The effects of variable viscosity and thermal conductivity on a thin film flow over a shrinking/stretching sheet. Comp. Math. Appl. 61, 3391–3399 (2011).

Shah, Z., Bonyah, E., Islam, S., Khan, W. & Ishaq, M. Radiative MHD thin film flow of Williamson fluid over an unsteady permeable stretching sheet. Heliyon 4, e00825 (2018).

Idrees, M., Rehman, S., Shah, R. A., Ullah, M. & Abbas, T. A similarity solution of time dependent MHD liquid film flow over stretching sheet with variable physical properties. Res. Phys 8, 194–205 (2018).

Kumar, K. A., Sugunamma, V., Sandeep, N. & Mustafa, M. T. Simultaneous solutions for first order and second order slips on micropolar fluid flow across a convective surface in the presence of Lorentz force and variable heat source/sink. Sci. Rep. 9, 14706 (2019).

Chen, C. H. Effect of viscous dissipation on heat transfer in a non-Newtonian liquid film over an unsteady stretching sheet. J. Non-Newt. Fluid Mech 135, 128–135 (2006).

Chen, C. H. Combined effects of Joule heating and viscous dissipation on magnetohydrodynamic flow past a permeable stretching surface with free convection and radiative heat transfer. J. Heat Transf 132, 064503 (2010).

Suresh, S., Venkitaraj, K. P., Selvakumar, P. & Chandrasekar, M. Effect of Al2O3-Cu/water hybrid nanofluid in heat transfer. Exp. Therm. Fluid Sci. 38, 54–60 (2012).

Ramandevi, B., Reddy, J. V. R., Sugunamma, V. & Sandeep, N. Combined influence of viscous dissipation and non-uniform heat source/sink on MHD non-Newtonian fluid flow with Cattaneo-Christov heat flux. Alex. Eng. J 57, 1009–1018 (2018).

Srinivasacharya, D. & Jagadeeshwar, P. Effect of Joule heating on the flow over an exponentially stretching sheet with convective thermal condition. Math. Sci 13, 201–2011 (2019).

Madhesh, D. & Kalaiselvam, S. Experimental study on heat transfer and rheological characteristics of hybrid nanofluids for cooling applications. J. Exp. Nanosci. 10(15), 1194–1213 (2015).

Sandeep, N. & Malvandi, A. Enhanced heat transfer in liquid thin film flow of non-Newtonian nanofluids embedded with graphene nanoparticles. Adv. Powder Tech 27, 2448–2456 (2016).

Sheikholeslami, M., Mustafa, M. T. & Ganji, D. D. Effect of Lorentz forces on forced-convection nanofluid flow over a stretched surface. Particuology 26, 108–113 (2016).

Afridi, M. I., Tlili, I., Goodarzi, M., Osman, M. & Khan, N. A. Irreversibility Analysis of Hybrid Nanofluid Flow over a Thin Needle with Effects of Energy Dissipation. Symmetry 11, 663 (2019).

Subhani, M. & Nadeem, S. Numerical investigation of unsteady MHD flow of micropolar hybrid nanofluid in porous medium, Physica Scripta, 94, https://doi.org/10.1088/1402-4896/ab154a (2019).

Kumar, K., Sugunamma, V., Sandeep, N. & Reddy, J. V. R. Impact of Brownian motion and thermophoresis on bio-convective flow of nanoliquids past a variable thickness surface with slip effects. Mult. Mod. in Mat. and Stru 15, 103–132 (2018).

Sandeep, N. Effect of aligned magnetic field on liquid film flow of magnetic-nanofluid embedded with graphene nanoparticles. Adv. Powder Tech. 28, 865–875 (2017).

Devi, S. P. A. & Devi, S. S. U. Numerical Investigation of Hydromagnetic Hybrid Cu – Al2O3/Water Nanofluid Flow over a Permeable Stretching Sheet with Suction. Int. J. Nonlinear Sci. Numer. Simul 17, 149–257 (2016).

Kandelousi, M. S. & Ellahi, R. Simulation of ferrofluid flow for magnetic drug targeting using the lattice Boltzmann method. Zeitschrift für Naturforschung A 70, 115–124 (2015).

Afrand, M., Oghraie, D. & Ruhani, B. Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nanofluid: an experimental study. Exp.Ther. and Fluid Sci. 77, 38–44 (2016).

Ramzan, M., Ullah, N., Chung, J. D., Lu, D. & Farooq, U. Buoyancy effects on the radiative magneto Micropolar nanofluid flow with double stratification, activation energy and binary chemical reaction. Sci. Rep. 7, 12901 (2017).

Ghadikolaei, S. S., Yassari, M., Sadeghi, H., Hosseinzadeh & Ganji, D. D. Investigation on thermophysical properties of Tio2–Cu/H2O hybrid nanofluid transport dependent on shape factor in MHD stagnation point flow. Powder Tech. 322, 428–438 (2017).

Lu, D., Ramzan, M., Ahmad, S., Chung, J. D. & Farooq, U. A numerical treatment of MHD radiative flow of Micropolar nanofluid with homogeneous-heterogeneous reactions past a nonlinear stretched surface. Sci. Rep. 8, 12431 (2018).

Kumar, K. A., Sugunamma, V. & Sandeep, N. Impact of non-linear radiation on MHD non-aligned stagnation point flow of micropolar fluid over a convective surface. J. Non-Equilib. Thermo. 43, 327–345 (2018).

Ghadikolaei, S. S., Hosseinzadeh, K., Ganji, D. D. & Jafari, B. Nonlinear thermal radiation effect on magneto Casson nanofluid flow with Joule heating effect over an inclined porous stretching sheet. Case Stud. in Ther. Eng. 12, 176–187 (2018).

Xu, H., Pop, I. & You, X. Flow and heat transfer in a nano-liquid film over an unsteady stretching surface. Int. J. Heat Mass Transf 60, 646–652 (2013).

Sankar, M., Park, Y., Lopez, J. M. & Do, Y. Numerical study of natural convection in a vertical porous annulus with discrete heating. Int. J. Heat Mass Transf 54, 1493–1505 (2011).

Sankar, M. & Do, Y. Numerical simulation of free convection heat transfer in a vertical annular cavity with discrete heating. Int. Comm. Heat Mass Transf 37, 600–606 (2010).

Sankar, M. & Park, J. Younghae Do. Natural convection in a vertical annuli with discrete heat sources. Num. Heat Transfer, Part A: Applications 59, 594–615 (2011).

Sankar, M., Beomseok, K., Lopez, J. M. & Do, Y. Thermosolutal convection from a discrete heat and solute source in a vertical porous annulus. Int. J. Heat Mass Transf. 55, 4116–4128 (2012).

Acknowledgements

Authors acknowledge the UGC-India for start-up grant No. 30-489/2019(BSR).

Author information

Authors and Affiliations

Contributions

I.T. explored the graphical results, K.A. did the literature survey, N.S. formulated the problem and explored the results. M.T.M discussed the results. All authors look over the final script and approved.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tlili, I., Mustafa, M.T., Kumar, K.A. et al. Effect of asymmetrical heat rise/fall on the film flow of magnetohydrodynamic hybrid ferrofluid. Sci Rep 10, 6677 (2020). https://doi.org/10.1038/s41598-020-63708-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-63708-y

This article is cited by

-

Enhancement of thermal energy transfer behind a double consecutive expansion utilizing a variable magnetic field

Scientific Reports (2024)

-

On-demand ferrofluid droplet formation with non-linear magnetic permeability in the presence of high non-uniform magnetic fields

Scientific Reports (2022)

-

An approach based on the porous media model for multilayered flow in the presence of interfacial surfactants

Pramana (2022)

-

Assessment of the local thermal non-equilibrium condition for nanofluid flow through porous media: a comparative analysis

Indian Journal of Physics (2022)

-

Mathematical Study of Heat Transfer in a Stagnation Flow of a Hybrid Nanofluid over a Stretching/Shrinking Cylinder

Journal of Engineering Physics and Thermophysics (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.