Abstract

An amorphous TaxMnyOz layer with 1.0 nm thickness was studied as an alternative Cu diffusion barrier for advanced interconnect. The thermal and electrical stabilities of the 1.0-nm-thick TaxMnyOz barrier were evaluated by transmission electron microscopy (TEM) and current density–electric field (J–E) and capacitance–voltage (C–V) measurements after annealing at 400 °C for 10 h. X-ray photoelectron spectroscopy revealed the chemical characteristics of the TaxMnyOz layer, and a tape peeling test showed that the TaxMnyOz barrier between the Cu and SiO2 layers provided better adhesion compared to the sample without the barrier. TEM observation and line profiling measurements in energy-dispersive X-ray spectroscopy after thermal annealing revealed that Cu diffusion was prevented by the TaxMnyOz barrier. Also, the J–E and C–V measurements of the fabricated metal-oxide-semiconductor sample showed that the TaxMnyOz barrier significantly improved the electrical stability of the Cu interconnect. Our results indicate that the 1.0-nm-thick TaxMnyOz barrier efficiently prevented Cu diffusion into the SiO2 layer and enhanced the thermal and electrical stability of the Cu interconnect. The improved performance of the TaxMnyOz barrier can be attributed to the microstructural stability achieved by forming ternary Ta-Mn-O film with controlled Ta/Mn atomic ratio. The chemical composition can affect the atomic configuration and density of the Ta-Mn-O film, which are closely related to the diffusion behavior. Therefore, the 1.0-nm-thick amorphous TaxMnyOz barrier is a promising Cu diffusion barrier for advanced interconnect technology.

Similar content being viewed by others

Introduction

A copper (Cu) interconnect can transmit clock and other signals for providing power/ground functions to various microelectronic devices. Cu interconnects require a liner/barrier to improve the adhesion between the Cu and silicon-based interlayer dielectric (ILD) materials and to block the diffusion of Cu into the ILD materials1. A dual Ta/TaN barrier formed by physical vapor deposition (PVD) is generally used as a diffusion barrier as it leads to good adhesion between Cu and the ILD materials, in addition to ensuring thermal stability and blocking the diffusion of Cu into the ILD material2,3. However, the dual Ta/TaN barrier is naturally thicker than a single barrier and can increase the electrical resistivity because it occupies a larger portion of Cu line volume in the Cu interconnect. In addition, with the scaling down expected by Moore’s Law4, the conventional dual Ta/TaN diffusion barrier faces technological limitations5, including poor step coverage by PVD methods6 and an inability to form a barrier layer with a thickness of 1 nm or less. Recently, thinner TaN barriers prepared by atomic layer deposition (ALD) have been investigated, but their performance as barriers is not yet perfect, making them difficult to apply in practice7.

Instead of a dual Ta/TaN barrier which has polycrystalline structure with inherent grain boundary diffusion pathways, an amorphous Ta2O5 barrier was investigated as a potential single barrier for Cu interconnects8,9. This oxide has a high thermal stability and is not reactive with Cu or SiO2. Salaum et al.8,9 reported that a 20-nm-thick amorphous Ta2O5 barrier showed a good performance as a diffusion barrier up to 600 °C, but it failed at higher temperatures, corresponding to the beginning of crystallization. Moreover, although amorphous Ta2O5 layers have some advantages as diffusion barriers, a Ta2O5 layer with a thickness less than 20 nm is not suitable for use as a Cu diffusion barrier because it is deposited as a discontinuous layer8.

A notable progress in Cu interconnects is a self-forming barrier proposed by Koike et al.10 The self-forming barrier was realized by spontaneously reacting the Cu–X alloying element with O and Si elements in the ILD material during post-metallization annealing5. Among the Cu–X alloying elements used11,12,13,14,15,16, an Mn alloying element17,18 is widely used because the self-formed Mn oxide or Mn silicate has good reliability and is thinner than the dual Ta/TaN barrier. The thickness of the self-forming barrier is determined by the temperature of post-metallization annealing and the type of deposition method, such as PVD, chemical vapor deposition (CVD), or ALD19,20,21,22. Although the CVD method yields good step coverage, Nguyen et al.23 reported that it is difficult to control the barrier thickness due to the high reactivity of the Mn precursor with the SiO2 layer, and thus amorphous MnSixOy diffusion barriers with thicknesses of less than 2.0 nm are not suitable for use as Cu diffusion barriers. Moreover, the self-forming barrier is very sensitive to the processing conditions such as temperature, annealing time, and alloying concentration.

On the other hand, a MnOx layer formed by ALD was considered a good candidate because of its thickness controllability. However, it was found to act as a Cu diffusion barrier only when its thickness was greater than 1.2 nm20. Furthermore, the thickness of the ALD–MnOx layer is affected by the adsorbed moisture on the substrate. The ALD–MnOx layer was very thin on the hydrophobic surface of a low-k SiOCH substrate, whereas it was thicker on a TEOS–SiO2 substrate24. Thus, the surface conditions of the ILD material are very important in terms of controlling the thickness of the ALD–MnOx layer.

An alternative Cu diffusion barrier is required to meet various requirements such as good adhesion between Cu and the SiO2 layer, back-end-of-line (BEOL)-compatible deposition processes, and reliability in advanced Cu interconnects25,26. It is desirable to avoid forming polycrystalline films with inherent grain boundaries which dominates diffusion especially at low temperatures. Therefore, the amorphous structure is still beneficial at preventing the atomic diffusion27,28. The incorporation of an additive element in existing transition metal oxide may offer a promising method for maintaining amorphous state by interrupting the polycrystalline phase formation. In this regard, the ternary Ta-Mn-O system is of potential interest for Cu interconnects. In addition to the ability to form an amorphous structure, the electrical resistivity of the barrier layer is another important property because it has substantial influence on the effective resistivity of the Cu interconnect. However, the resistivity of the Cu interconnect is more affected by grain boundary scattering, surface scattering, and an increasing portion of the conventional barrier in the Cu interconnect than the resistivity of the barrier layer itself26,29. In that sense, it is very important to minimize the thickness of the barrier layer to reduce the resistivity of the Cu interconnect. Although industry-friendly Ta-based and Mn-based barriers exhibit excellent performance in Cu interconnects, it is still challenging to fabricate a Cu diffusion barrier with a thickness less than 1.2 nm that completely prevents Cu diffusion into the ILD material.

In this study, we developed an amorphous TaxMnyOz layer as an ultrathin diffusion barrier for advanced Cu interconnects that had excel`lent barrier properties, such as high thermal stability and good adhesion. A 1.0-nm-thick amorphous TaxMnyOz layer was prepared by using the conventional PVD method because it allows easy and systematic investigation of the fundamental properties by changing the film thickness and chemical composition. To evaluate the thermal and electrical stability of the TaxMnyOz barrier, we investigated its ability to prevent Cu diffusion into the ILD material by annealing it at 400 °C for 10 h and by applying bias thermal stress under 6 MV/cm and 150 °C for 30 min. The results of this study demonstrate that the amorphous TaxMnyOz layer is a promising diffusion barrier for advanced Cu interconnects.

Results and Discussion

Figure 1a shows plan-view transmission electron microscopy (TEM) images of the as-deposited TaxMnyOz barrier and selected-area electron diffraction patterns (SADPs). The TaxMnyOz film was in amorphous form, as seen in the plan-view TEM image, and the SADP in the inset reveals only a halo-ring pattern, indicating a perfectly amorphous structure. The thickness of the deposited TaxMnyOz barrier was determined from the cross-sectional high-resolution (HR)-TEM images of the metal-oxide-semiconductor (MOS) structure with the TaxMnyOz barrier and the intensity profile (Fig. 1b,c). The intensities of the Cu, the TaxMnyOz barrier, and the SiO2 layers were different in the HR-TEM image as shown in Fig. 1c, and the TaxMnyOz barrier was clearly distinguished between the Cu and SiO2 layer. The thickness of the barrier was 1.0 nm and it was an amorphous phase. To confirm the elemental distribution in the as-deposited MOS capacitor with the TaxMnyOz barrier, the scanning TEM-electron energy loss spectroscopy (STEM-EELS) spectrum was obtained in the energy loss range for each region with Cu (L2,3 edge:931 eV), Ta (O1 edge:71 eV), Mn (L3 edge:640 eV), O (K edge:532 eV), and Si (K edge:99 eV). As shown in the Ta map ranging from 69.5 to 79.5 eV and the Mn map ranging from 637.5 to 647.5 eV, the TaxMnyOz film was a thin layer between the Cu and SiO2 layers (Fig. 1d).

(a) Plan-view HR-TEM image showing the amorphous TaxMnyOz layer. The SADP is shown in the inset. (b) Cross-sectional HR-TEM image of the as-deposited MOS capacitor sample with the amorphous TaxMnyOz barrier. (c) Intensity profile for the thickness measurement of the initial TaxMnyOz barrier. (d) STEM-EELS elemental maps of the as-deposited MOS capacitor sample with the amorphous TaxMnyOz barrier.

To obtain the chemical information of the TaxMnyOz diffusion barrier, X-ray photoelectron spectroscopy (XPS) analysis was performed and the results are shown in Fig. 2. The experimental XPS spectra were deconvoluted using Gaussian–Lorentzian peaks after background extraction. As shown in Fig. 2a, the Ta 4f spectrum revealed that Ta 4f5/2 and Ta 4f7/2 existed at peak values of 25.8 eV and 27.7 eV, respectively, and the loss feature for Ta2O5 appeared at 36.8 eV. These peaks corresponded to the binding energy of fully oxidized stoichiometric Ta2O5, which was in good agreement with previous work30. Fig. 2b shows the XPS spectrum of Mn 2p in the TaxMnyOz diffusion barrier. The main two peaks with binding energies at 641.2 eV and 653.4 eV corresponded to Mn 2p3/2 and Mn 2p1/2, respectively. Peak fitting was conducted for Mn 2p3/2, which was deconvoluted into Mn2+, Mn3+, and Mn4+, with characteristic binding energies at 640.7 eV, 641.8 eV, and 643.1 eV, respectively31,32. The Mn 2p3/2 peak also demonstrated an MnO satellite feature at 646.2 eV. The Mn metal in the TaxMnyOz barrier consisted of MnO, MnO2, and Mn2O3 based on the obtained binding energy at the Mn 2p3/2 peak. In Fig. 2c, there were three O 1 s peaks at 530.1 eV, 531.2 eV, and 532.9 eV, indicating metal–oxide (M–O), metal–oxygen vacancy (M–Ovac), and metal–hydrogen lattice (M–OH) bonds, respectively33. The M–O, M–Ovac, and M–OH bonds were formed by binding with the Ta and Mn metals in the TaxMnyOz diffusion barrier.

Because the rough surface of the diffusion barrier can provide a fast diffusion pathway for Cu migration across the liner, the surface roughnesses of the 1.0-nm-thick TaxMnyOz layer and the SiO2 layer without the barrier (reference) were measured using atomic force microscopy (AFM). A smooth surface with a root mean square (RMS) value of 0.20 nm was obtained for the 1.0-nm-thick TaxMnyOz barrier, which was similar to the RMS of the 10-nm-thick SiO2 layer (0.19 nm), as shown in Fig. 3a,b. To examine the Cu adhesion to the SiO2 surface resulting from the TaxMnyOz barrier, 3 M Scotch tape peeling tests were performed for the MOS capacitor samples with and without the TaxMnyOz barrier. As shown in Fig. 4a,b, the MOS capacitor sample without the barrier failed the tape peeling test owing to poor adhesion, which was apparent from the removal of the Cu dot electrodes. In contrast, for the TaxMnyOz barrier sample, the Cu dot electrodes deposited on the SiO2 layer did not change after the tape peeling test, as shown in Fig. 4c,d, despite multiple attempts to tear off the Cu dot electrodes. These results indicate that the TaxMnyOz barrier had good adhesion between the Cu and SiO2 layers.

To investigate the thermal stability of the 1.0-nm-thick TaxMnyOz barrier, we annealed the MOS capacitor samples with and without the TaxMnyOz barrier at 400 °C for 10 h. Figure 5 shows the cross-sectional HR-TEM images and the line profile of the chemical composition for each element after annealing at 400 °C for 10 h. To compare the results with and without the TaxMnyOz barrier, a MOS capacitor sample without a barrier was prepared as a reference. For the sample without the TaxMnyOz barrier, the interface between the Cu and SiO2 layer showed a noticeable difference because of Cu diffusion into the SiO2 layer during annealing, as shown in Fig. 5a. The initial SiO2 layer with a thickness of 10 nm was reduced to approximately 5.8 nm owing to Cu diffusion. Conversely, the annealed sample with the TaxMnyOz barrier was identical to the initial interface between the Cu and SiO2 layers and had a uniform thickness of 1.0 nm, which was consistent with the as-deposited TaxMnyOz barrier before annealing, as shown in Fig. 5b,c. In addition, the STEM-energy dispersive X-ray spectroscopy (STEM-EDS) line profile, shown in Fig. 5d,e, was used to accurately evaluate the Cu diffusion. For the sample without the TaxMnyOz barrier (see Fig. 5d), Si and O were detected in the SiO2 layers, as shown in the high-angle annular dark-field (HAADF) STEM image, and the distribution of Cu showed that the Cu atoms diffused into the SiO2 layer. The annealed TaxMnyOz diffusion barrier showed the same chemical binding states as the as-deposited TaxMnyOz barrier, as shown in Fig. S1 of the SI. In the STEM-EDS line profile of the annealed sample with the TaxMnyOz barrier shown in Fig. 5e, Cu was not detected inside the SiO2 layer, which indicated no diffusion of Cu into the SiO2 layer. However, the Ta and Mn in the diffusion barrier were not properly detected in the barrier region between the Cu and the SiO2 layers, despite the presence of the TaxMnyOz barrier. In fact, the quantitative analysis using STEM-EDS for Ta in the MOS capacitor sample was difficult because the Ta Mα (1.71 keV) and Ta Lα (8.14 keV) X-ray energies overlapped with the Si Kα (1.74 keV) and Cu Kα (8.04 keV) X-ray energies, respectively. In addition, Mn was difficult to detect in the line profile owing to the damage caused by the 200-keV e-beam during the STEM-EDS analysis. To complement STEM-EDS, Ta and Mn were confirmed using STEM-EELS. As shown in Fig. 5f, Ta and Mn were detected at the interface between the Cu and SiO2 layers. In addition, the TaxMnyOz barrier prevented the diffusion of Cu toward the SiO2 layer, which was consistent with the Cu distribution in the STEM-EDS line profile. However, the detection of trace elements that may have affected the device characteristics was difficult because the detection limits of STEM-EDS and -EELS are approximately 0.1–3.0 wt.%34. Therefore, to determine the presence of a few Cu atoms in amounts as low as 109 atoms/cm3 35, the current density-electric field (J–E) and capacitance-voltage (C–V) characteristics were evaluated.

Cross-sectional HR-TEM images of the MOS capacitor sample (a) without the barrier and (b) with the TaxMnyOz barrier. Image (c) shows the intensity profile for the thickness measurement after annealing at 400 °C for 10 h. The HAADF-STEM images and the STEM-EDS line profiles of the MOS capacitor sample are shown (d) without the barrier and (e) with the TaxMnyOz barrier after annealing at 400 °C for 10 h. Image (f) shows the HAADF-STEM image and the STEM-EELS line profile of the MOS capacitor sample with TaxMnyOz barrier after annealing at 400 °C for 10 h.

Figure 6 shows the dielectric breakdown field of a statistical time-zero dielectric breakdown (TZDB) histogram obtained using 20 J–E curves, as shown in the inset of Fig. 6 for the as-deposited and annealed MOS capacitor samples. In the statistical results of the TZDB histogram, three modes, referred to as A-, B-, and C-modes, were observed when the breakdown fields were composed of low (<1 MV/cm), intermediate, and high (>14 MV/cm) fields, respectively36. The A- and B-mode failures could be attributed to localized defect spots, such as Cu+ ion transport, referred to as an extrinsic breakdown, and the C-mode failure corresponded to an approximately defect-free oxide sample, was referred to as an intrinsic breakdown. As shown in Fig. 6a,b, the MOS capacitor sample without the barrier exhibited the C-mode failure ranged from 14.25 MV/cm to 16.25 MV/cm before annealing, whereas the A- and B-mode failures ranged from 3.25 MV/cm to 12.25 MV/cm after annealing at 400 °C for 10 h. Thus, the MOS capacitor sample without the barrier exhibited extrinsic breakdown because of the Cu+ ions that diffused into the SiO2 layer during annealing. Conversely, in Fig. 6c,d, the TaxMnyOz barrier samples exhibited C-mode failure regardless of annealing, unlike the reference sample without the barrier, and the breakdown field before and after thermal annealing ranged from 15.45 MV/cm to 16.95 MV/cm and from 15.55 MV/cm to 16.55 MV/cm, respectively. These results provide evidence that the penetration of Cu+ ions into the SiO2 layer did not occur, which is consistent with the TEM results shown in Fig. 5.

In addition, a correlative analysis of the XPS and J–E measurements was carried out to evaluate the performance of the 1.0-nm-thick TaxMnyOz barrier layer according to the content of Ta and Mn. The Ta/Mn ratio (i.e., the normalized chemical composition of the metals) of the as-deposited TaxMnyOz layer was estimated by the wide-scan XPS survey spectra, and the TZDB histogram was measured to evaluate the Cu-blocking capability of the TaxMnyOz barrier after annealing at 400 °C for 10 h. Three 1.0-nm-thick TaxMnyOz barriers, each with a different Ta/Mn ratio, were prepared by controlling only the deposition time during DC sputtering. As shown in Fig. S2 of the SI, the 1.0-nm-thick TaxMnyOz barrier with a normalized Ta content of 91.5% (balance Mn) could not completely block Cu diffusion into the SiO2 layer during annealing. Conversely, for the TaxMnyOz barrier with normalized Ta content range from 56.5% to 62.6%, the TZDB results showed that the penetration of Cu+ ions into the SiO2 layer did not occur. Therefore, the chemical composition (Ta/Mn ratio) can affect the performance of TaxMnyOz barrier. The incorporation of an additive element in existing binary system can lead to a change in atomic configuration and density of the barrier and contribute to maintain a high thermal stability by suppressing the polycrystalline phase formation37,38,39. Fig. S3 of the SI shows the detailed Ta 4f XPS spectrum of TaxMnyOz barrier with the normalized Ta content of 91.5% in Fig. S2a. This deconvoluted Ta 4f XPS spectrum revealed that the Ta 4f7/2 and 4f5/2 binding energies corresponded to the metallic Ta as well as the amorphous Ta2O5, unlike TaxMnyOz barrier containing the normalized Ta content of 46.55% (Fig. 2a). Therefore, the poor barrier property of the TaxMnyOz layer with a high Ta/Mn ratio can be attributed to a lack of Mn and O atoms to bind Ta and the presence of metallic Ta atoms. Bassiri et al.40 reported that the Ta-Ta and Ta-O bonding distances were determined as 3.1 Å and less than 2 Å, respectively, by analyzing high-quality EXAFS spectra of ion beam sputtered amorphous tantala. This implies that the amount of Ta-Ta and Ta-O bonds is closely related to the atomic configuration and density of the TaxMnyOz film. Therefore, the performance of 1.0 nm-thick TaxMnyOz barrier can be affected by the binding states between Ta, Mn and O, depending on the Ta/Mn ratio.

The normalized C–V characteristics of MOS capacitor samples with and without the TaxMnyOz barrier upon annealing at 400 °C for 10 h are shown in Fig. 7. In Fig. 7a, the MOS capacitor sample without the barrier shows a negative flatband voltage shift (indicated by the green arrow) from −0.94 V to −2.54 V upon annealing owing to Cu+ ion transport into the SiO2 layer, which indicates a buildup of positive charge within the SiO2 layer during annealing18. In addition, the hysteresis in the C–V curve indicates movement of the Cu+ ion within the dielectric film during the C–V sweep. It was noted that the flatband voltage of the MOS capacitor with the TaxMnyOz barrier before annealing was more negative than that of the as-deposited reference sample without the TaxMnyOz barrier (Cu/SiO2/Si). This can be attributed to intrinsic defects (positive charge was calculated as 4.63 × 10−11 C) such as charges in SiO2 or oxygen vacancies in the TaxMnyOz layer18,41,42,43. The flatband voltage moved to the positive region from −2.25 V to −0.49 V (indicated by the purple arrow) upon annealing owing to the removal of the intrinsic defects in the MOS capacitor sample and not from the diffusion of Cu+ ions into the SiO2 layer18. In other words, there was no flatband voltage shift toward the negative region, and no hysteresis curve was observed in the MOS capacitor with the TaxMnyOz barrier, as shown in Fig. 7b, indicating that the Cu+ ions were effectively prevented from diffusing into the SiO2 layer by the TaxMnyOz barrier.

The normalized C–V characteristics before and after bias thermal stress (BTS) were also measured. Figure 8 shows the normalized C–V curves for MOS capacitor with and without the TaxMnyOz barrier after BTS at 6 MV/cm and 150 °C for 30 min. As shown in Fig. 8a, for the MOS capacitor without a barrier, the normalized C–V curve presented a roughly −1.0 V observable shift of flatband voltage toward the negative region under an electrical field of 6 MV/cm, which is consistent with the normalized C–V sweep after thermal annealing. Conversely, the MOS capacitor with the TaxMnyOz barrier showed no negative shift in flatband voltage, as shown in Fig. 8b. A positive shift of flatband voltage in the C–V curve occurred because of the removal of intrinsic defects during annealing.

Consequently, these results provide direct evidence that the 1.0-nm-thick amorphous TaxMnyOz layer is suitable for use as an ultrathin diffusion barrier that can improve the reliability and lifetime of advanced Cu interconnects.

Conclusions

We investigated the effectiveness of an amorphous TaxMnyOz layer as an ultrathin diffusion barrier for advanced Cu interconnects. A 1.0-nm-thick TaxMny layer was oxidized by exposure to air to obtain an amorphous TaxMnyOz film. Ta and Mn were present as Ta2O5, MnO, MnO2, and Mn2O3 in the amorphous TaxMnyOz film. The tape peeling test for the MOS capacitor sample showed no delamination in the presence of the TaxMnyOz layer, which improved the adhesion between the Cu and the SiO2 layers. To evaluate the diffusion barrier properties of the 1.0-nm-thick amorphous TaxMnyOz film, MOS capacitor samples with and without the barrier were annealed at 400 °C for 10 h. HR-TEM and STEM-EDS/EELS analyses showed that the amorphous TaxMnyOz barrier had a stable microstructure and chemical composition, even after thermal annealing. The J–E, C–V and TZDB results showed that the diffusion of Cu was effectively blocked by the amorphous TaxMnyOz barrier. The correlative analysis of XPS and TZDB revealed that, with a comparable O concentration, the Ta/Mn atomic ratio affected the atomic configuration and density of Ta–Mn–O films. To prevent the Cu diffusion into the Ta–Mn–O film, the Ta/Mn ratio needs to be high to ensure a high atomic density. However, the Ta/Mn ratio cannot be too high because a lack of Mn and O atoms to bind Ta and the presence of the metallic Ta atoms deteriorates the barrier performance. In conclusion, a 1.0-nm-thick amorphous TaxMnyOz layer serves as an adhesion promotor and excellent diffusion barrier, and it can be used as a single liner/barrier material for advanced Cu interconnects.

Methods

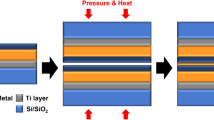

The substrates for barrier deposition were 10-nm-thick SiO2 films on p-type doped silicon (100) wafers and were cleaned using a piranha solution of 3:1 sulfuric acid (H2SO4) and hydrogen peroxide (H2O2). Then, the Mn layer was deposited first, followed by Ta layer deposition on the SiO2/Si substrate by direct current (DC) magnetron sputtering using a Mn target (purity 99.9%) and Ta target (purity 99.99%) under a power of 5W at an Ar gas pressure of 5.5 mTorr (see Fig. S4 of the SI for the deposition process and the formation of the TaxMnyOz layer). The DC sputtering chamber was pumped down to a base pressure less than 4.0 × 10−7 Torr and pre-sputtering was conducted at 10 W higher than the processing power for 20 min before deposition. The sequentially deposited ultrathin Mn and Ta films were intermixed to form a TaxMny film. The 1.0-nm-thick TaxMny film was oxidized by atmospheric exposure for the ex-situ sputtering to deposit the Cu film. Fig. S4 of the SI shows a schematic of the oxidation mechanism of the TaxMny film. The oxidized TaxMny film is referred to as the TaxMnyOz layer. It was found that this intermixing and oxidation mechanism was valid only for sequentially deposited ultrathin Mn and Ta films with a total thickness less than 2.5 nm (see Fig S5 of the SI).

To fabricate the MOS capacitor structure, 150-nm-thick Cu films were then deposited on the TaxMnyOz film by DC magnetron sputtering with dots of 100 µm diameter through a shadow mask, and a 50-nm-thick Ta film was coated as the capping layer. MOS capacitor samples with and without the 1.0-nm-thick TaxMnyOz layer were prepared using the same deposition method. To evaluate the thermal stability of the TaxMnyOz layer as a diffusion barrier, the as-deposited MOS capacitor samples were annealed at 400 °C for 10 h in a tube furnace under Ar + 10% H2 gas flow. XPS (ESCALAB250Xi, Thermo-Scientific, UK) was used to determine the chemical characteristics of the deposited TaxMnyOz layer. Samples for cross-sectional transmission electron microscopy (TEM) were fabricated using a focused ion beam (FIB, NX2000, Hitachi). The TEM samples were milled using a high-energy Ga+ ion beam from 30 keV to 5 keV and a low-energy Ar+ ion beam of 1 keV after the electron beam-induced deposition of the W material as a protective layer to minimize damage to the surface layers during the FIB milling process44,45. TEM (JEOL ARM-200F) analysis at 200 kV with EDS and EELS were used to analyze the microstructure and to obtain the line profiles for the chemical composition of the Cu, Ta, Mn, Si, and O elements in the two types of samples before and after annealing. The surface morphology of the 1.0-nm-thick TaxMnyOz layer was analyzed by AFM (Park System Co.), and the adhesion strength between the Cu and SiO2 layers depending on the presence of the TaxMnyOz barrier was examined using a 3M Scotch tape peeling test46.

To evaluate the Cu diffusion barrier performance of TaxMnyOz after annealing at 400 °C for 10 h, the J–E characteristics were evaluated using a microprobe system connected to an Agilent B1500A parametric analyzer. The J–E curves were measured by applying voltage ranging from 0 V to −20 V in −50-mV steps. The BTS tests were performed by using a microprobe system capable of annealing and applying a high electric field to the MOS capacitor in a controlled environment. For the BTS tests, a bias field of 6 MV/cm was applied on the MOS capacitor at 150 °C for 30 min. After a given time period, the samples were cooled to room temperature. The C–V characteristics before and after thermal annealing and BTS were evaluated using a probe station with an Agilent E4980A precision LCR meter with an AC frequency of 100 kHz. For all C–V measurements, a voltage ranging from +4 V to −4 V was applied in 0.1-V steps, and the hysteresis was scanned by applying a reverse voltage of −4 V to +4 V.

References

Baklanov, M., Ho, P. S., & Zschech, E. Advanced Interconnects for ULSI Technology. (John Wiley & Sons: Hoboken, 2012).

Hubner, R. et al. Structure and thermal stability of graded Ta-TaN diffusion barriers between Cu and SiO2. Thin Solid Films 437, 248–256 (2003).

Xie, Q. et al. Superior thermal stability of Ta/TaN bi-layer structure for copper metallization. Appl. Surf. Sci. 253, 1666–1672 (2006).

Schaller, R. R. Moore’s law: Past, present, and future. IEEE Spectrum 34, 53–59 (1997).

Koike, J., Haneda, M., Iijima, J. & Wada, M. Cu Alloy metallization for self-forming barrier process. 2006 International Interconnect Technology Conference, Burlingame, CA, USA, New York: IEEE (2006, June 5–7).

Tsai, M. H., Sun, S. C., Tsai, C. E., Chuang, S. H. & Chiu, H. T. Comparison of the diffusion barrier properties of chemical-vapor-deposited TaN and sputtered TaN between Cu and Si. J. Appl. Phys. 79, 6932–6938 (1996).

Wu, Z. et al. PVD-treated ALD TaN for Cu interconnect extension to 5 nm node and beyond. 2018 IEEE International Interconnect Technology Conference - IITC, Santa Clara, CA, USA, New York: IEEE (2018, June 4–7).

Salaun, A. L., Mantoux, A., Blanquet, E., Djurado, E. & ESD, A. L. D. depositions of Ta2O5 thin films investigated as barriers to copper diffusion for advanced metallization. J. Electrochem. Soc. 156(5), H311–315 (2009).

Salaun, A. L., Mantoux, A., Djurado, E. & Blanquet, E. Atomic layer deposition of tantalum oxide thin films for their use as diffusion barriers in microelectronic devices. Microelectron. Eng. 87, 373–378 (2010).

Koike, J. & Wada, M. Self-forming diffusion barrier layer in Cu–Mn alloy metallization. Appl. Phys. Lett. 87, 041911, https://doi.org/10.1063/1.1993759 (2005).

Cao, F., Wu, G. H., Jiang, L. T. & Chen, G. Q. Application of Cu-C and Cu-V alloys in barrier-less copper metallization. Vacuum 122, 122–126, https://doi.org/10.1016/j.vacuum.2015.09.011 (2015).

Hu, C. K. et al. Electromigration in Cu(Al) and Cu(Mn) damascene lines. J. Appl. Phys. 111, https://doi.org/10.1063/1.4711070 (2012).

Tsukimoto, S., Morita, T., Moriyama, M., Ito, K. & Murakami, M. Formation of Ti diffusion barrier layers in thin Cu(Ti) alloy films. J. Electron. Mater. 34, 592–599, https://doi.org/10.1007/s11664-005-0070-0 (2005).

Frederick, M. J. & Ramanath, G. Kinetics of interfacial reaction in Cu-Mg alloy films on SiO2. J. Appl. Phys. 95, 363–366, https://doi.org/10.1063/1.1630355 (2004).

Wang, Y., Tang, B. H. & Li, F. Y. The properties of self-formed diffusion barrier layer in Cu(Cr) alloy. Vacuum 126, 51–54, https://doi.org/10.1016/j.vacuum.2016.01.019 (2016).

Park, J. H. et al. Self-forming VOx layer as Cu diffusion barrier for low-k dielectrics. Surf. Coat. Tech. 259, 252–256, https://doi.org/10.1016/j.surfcoat.2014.04.003 (2014).

Neishi, K. et al. Formation of a manganese oxide barrier layer with thermal chemical vapor deposition for advanced large-scale integrated interconnect structure. Appl. Phys. Lett. 93, https://doi.org/10.1063/1.2963984 (2008).

Byrne, C. et al. In situ XPS chemical analysis of MnSiO3 copper diffusion barrier layer formation and simultaneous fabrication of metal oxide semiconductor electrical test MOS structures. ACS Appl. Mater. Interfaces 8, 2470–2477, https://doi.org/10.1021/acsami.5b08044 (2016).

Dixit, V. K., Neishi, K., Akao, N. & Koike, J. Structural and electronic properties of a Mn oxide diffusion barrier layer formed by chemical vapor deposition. IEEE Trans. Device Mater. Reliab. 11, 295–302, doi:10.1109/TDMR.2011.2141671 (2011).

Matsumoto, K., Maekawa, K., Nagai, H., & Koike, J. Deposition behavior and substrate dependency of ALD MnOx diffusion barrier layer. 2013 IEEE International Interconnect Technology Conference – IITC, Kyoto, Japan, New York: IEEE (2013, June 13–15).

Park, J. H. et al. Self-forming Mn-based diffusion barriers on low-k substrates. Jpn. J. Appl. Phys. 53, https://doi.org/10.7567/Jjap.53.08nl01 (2014).

Haneda, M., Iijima, J., & Koike, J. Growth behavior of self-formed barrier at Cu-Mn/SiO2 interface at 250-450 degrees C. Appl. Phys. Lett. 90, https://doi.org/10.1063/1.2750402 (2007).

Nguyen, M. P., Sutou, Y. & Koike, J. Diffusion barrier property of MnSixOy layer formed by chemical vapor deposition for Cu advanced interconnect application. Thin Solid Films 580, 56–60, https://doi.org/10.1016/j.tsf.2015.03.007 (2015).

Koike, J., Hosseini, M., Hai, H. T., Ando, D., & Sutou, Y. Material innovation for MOL, BEOL, and 3D intergration. 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, New York: IEEE (2017, December 2–6).

Lo, C.-L. et al. Large-area, single-layer molybdenum disulfide synthesized at BEOL compatible temperature as Cu diffusion barrier. IEEE Electron Device Lett. 39, 873–876, https://doi.org/10.1109/led.2018.2827061 (2018).

Lo, C.-L. et al. Enhancing interconnect reliability and performance by converting tantalum to 2D layered tantalum sulfide at low temperature. Adv. Mater. 31, 1902397, https://doi.org/10.1002/adma.201902397 (2019).

Cao, Z. H., Hu, K. & Meng, X. K. Diffusion barrier properties of amorphous and nanocrystalline Ta films for Cu interconnects. J. Appl. Phys. 106, 113513 (2009).

Kaloyeros, A. E. & Eisenbraun, E. Ultrathin diffusion barriers/liners for gigascale copper metallization. Annu. Rev. Mater. Sci. 30, 363–385 (2000).

Cheng, Y. L., Lee, C. Y. & Huang, Y. L. Copper Metal for Semiconductor Interconnects. In Noble and Precious Metals – Properties, Nanoscale Effects and Applications (IntechOpen, 2018).

Abbas, Y. et al. Compliance-free, digital SET and analog RESET synaptic characteristics of sub-tantalum oxide-based neuromorphic device. Sci Rep 8, 1228, https://doi.org/10.1038/s41598-018-19575-9 (2018).

Du, Y. et al. Mesostructured amorphous manganese oxides: facile synthesis and highly durable elimination of low-concentration NO at room temperature in air. Chem. Commun. 51, 5887–5889, https://doi.org/10.1039/c5cc00269a (2015).

Ramirez, A. et al. Evaluation of MnOx, Mn2O3, and Mn3O4 electrodeposited film for the oxygen evolution reaction of water. J. Phys. Chem. C 118, 14073–14081 (2014).

Kim, W. G. et al. High-pressure gas activation for amorphous indium-gallium-zinc-oxide thin-film transistors at 100 degrees C. Sci Rep 6, 23039, https://doi.org/10.1038/srep23039 (2016).

Bart, J. C. J. Plastics Additives: Advanced Industrial Analysis. (IOS Press, 2006).

Pierret, R. F. Semiconductor Device Fundamentals. (Addison-Wesley Press, 1996).

Hori, T. Gate Dielectrics and MOS ULSIs (Springer, 1997).

Lai, L. W. & Chen, J. S. Influence of Ta/Si atomic ratio on the interdiffusion between Ta-Si-N and Cu at elevated temperature. J. Appl. Phys. 94, 5396 (2003).

Yan, H. et al. Formation and characterization of magnetron sputtered Ta-Si-N-O thin films. Thin Solid Films 517, 5207–5211 (2009).

Consiglio, S. et al. Atomic Layer Deposition of Ultrathin TaN and Ternary Ta1-xAlxNy Films for Cu Diffusion Barrier Applications in Advanced Interconnects. ECS Transactions 69(7), 181–189 (2015).

Bassiri, R. et al. Order within disorder: The atomic structure of ion-beam sputtered amorphous tantala (a-Ta2O5). APL. Materials 3, 036103 (2015).

McIntyre, P. C. Bulk and interfacial oxygen defects in HfO2 gate dielectric stacks: a critical assessment. ECS Transactions 11(4), 235–249 (2007).

Bentarzi, H. Transport in metal-oxide-semiconductor structures: mobile ions effects on the oxide properties. (Springer-Verlag, 2011).

Hosseini, M., Ando, D., Sutou, Y. & Koike, J. Co and CoTix for contact plug and barrier layer in integrated circuits. Microelectron. Eng. 189, 78–84 (2018).

An, B. S., Shin, Y. J., Ju, J. S. & Yang, C. W. Transmission electron microscopy specimen preparation for two-dimensional material using electron beam-induced deposition of a protective layer in the focused ion beam method. Applied Microscopy 48, 122–125, https://doi.org/10.9729/AM.2018.48.4.122 (2018).

Kato, N. I. Reducing focused ion beam damage to transmission electron microscopy samples. J. Electron. Microsc. 53, 451–458, https://doi.org/10.1093/jmicro/dfh080 (2004).

Strong, J. On the cleaning of surfaces. Rev. Sci. Instrum. 6, 97–98, https://doi.org/10.1063/1.1751951 (1935).

Acknowledgements

This study was supported by the Ministry of Trade, Industry & Energy (MOTIE) [Project Number 10080625], the Korea Semiconductor Research Consortium (KSRC) support program for the development of future semiconductor devices funded by the Korean government (MSIP). This work was also supported in part by the Korea Basic Science Institute (KBSI) National Research Facilities & Equipment Center (NFEC) grant funded by the Korea government (MOE) (No. 2019R1A6C1010031), and Samsung Electronics. The authors are grateful for support from the Cooperative Center for Research Facilities (CCRF) at Sungkyunkwan University.

Author information

Authors and Affiliations

Contributions

B.S.A. contributed to the device fabrication, characterization, and data analysis and to writing the manuscript. Y.K. and J.S.O. contributed to the TEM analysis and the data analysis. M.L. and S.P. discussed the results and commented on the manuscript. C.W.Y. supervised the project, along with advising and reviewing the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

An, BS., Kwon, Y., Oh, JS. et al. Amorphous TaxMnyOz Layer as a Diffusion Barrier for Advanced Copper Interconnects. Sci Rep 9, 20132 (2019). https://doi.org/10.1038/s41598-019-56796-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-56796-y

This article is cited by

-

Bipolar Resistive Switching Characteristics of Ta/TaxMnyOz/Pt Structure for ReRAM Application with Large Resistance Window

Electronic Materials Letters (2024)

-

Robust Co alloy design for Co interconnects using a self-forming barrier layer

Scientific Reports (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.