Abstract

The heterotrophic cultivation of microalgae has a number of notable advantages, which include allowing high culture density levels as well as enabling the production of biomass in consistent and predictable quantities. In this study, the full potential of Chlorella sp. HS2 is explored through optimization of the parameters for its heterotrophic cultivation. First, carbon and nitrogen sources were screened in PhotobioBox. Initial screening using the Plackett-Burman design (PBD) was then adopted and the concentrations of the major nutrients (glucose, sodium nitrate, and dipotassium phosphate) were optimized via response surface methodology (RSM) with a central composite design (CCD). Upon validation of the model via flask-scale cultivation, the optimized BG11 medium was found to result in a three-fold improvement in biomass amounts, from 5.85 to 18.13 g/L, in comparison to a non-optimized BG11 medium containing 72 g/L glucose. Scaling up the cultivation to a 5-L fermenter resulted in a greatly improved biomass concentration of 35.3 g/L owing to more efficient oxygenation of the culture. In addition, phosphorus feeding fermentation was employed in an effort to address early depletion of phosphate, and a maximum biomass concentration of 42.95 g/L was achieved, with biomass productivity of 5.37 g/L/D.

Similar content being viewed by others

Introduction

Microalgae have been highlighted as a renewable biomass resource for biofuel over the last few decades due to a number of advantages they have over terrestrial biomass1. They are also a promising alternative energy source due to their potentially higher oil content, growth rate, and ability to accumulate high amounts of lipids in comparison to conventional crops and lignocellulosic types of biomass. Today, autotrophic growth is the most common procedure for cultivating microalgae due to their photosynthetic ability and the added benefit of sequestering atmospheric carbon dioxide.

Although microalgae-based biofuels have many advantages, further research and development are necessary to overcome the current problems of low productivity and high cost. The commonly studied process for algal biomass production is outdoor photoautotrophic cultivation, due to the ease of scalability and the added benefit of CO2 sequestration. The primary bottleneck that limits the productivity of all photoautotrophic cultivation systems is the light penetration2 and absence of light at night3. Light penetration is often poor inside photobioreactors (PBR) and open raceway ponds (ORP), and the penetration further falls with increasing cell density and depth due to self-shading effects. Light/dark cycle is also inevitable for outdoor cultivation, and it was reported that respiratory effect at night causes a decrease in the biomass produced in the day period3. In addition, the outdoor cultivation systems also suffer from inconsistent biomass productivity due to the fluctuations of light intensity and temperature across the day/night cycle and seasonal changes4,5. Furthermore, most common outdoor cultivation systems such as open raceway ponds frequently suffer from contamination problems. Due to the nature of open systems, it is nearly impossible to maintain a monoculture of a single target microalgal strain due to the high susceptibility of these systems to be contaminated with undesirable foreign species6. Lastly, concentration of cell culture dictates the costs of harvest, extraction, and purification process of the product, in which case the higher culture density of heterotrophic cultivation provides further advantages of reduced downstream processing costs7.

In this light, heterotrophic cultivation has been proposed as an alternative method for industrial-scale algal biomass and biofuel production1. One of the major advantages of heterotrophic cultivation is that the culture can achieve more reliable and predictable biomass productivity in comparison to the photoautotrophic systems, due to the consistent availability of the energy source in the form of organic carbon uptake8,9. Moreover, additional advantages of heterotrophic cultivation include a cost-effective and relatively simple mode of operation. While additional costs would occur for the usage of carbon sources, there have been many researches which use waste and wastewater containing the massive amount of organic carbon for simultaneously reducing the costs of both algal cultivation and wastewater treatment8,10,11. Of course, contamination issues would occur in the outdoor cultivation using organic carbon sources, however, it could be controlled and minimized by using extremophiles12. With successful cultivation using the techniques above, it is possible to obtain a high-density culture that is unobtainable under photoautotrophic modes, which allows economic harvesting and easier downstream processing for large-scale production13. In some cases, fed-batch cultivation can achieve culture density of over 70 g/L, far exceeding that of the photoautotrophic cultures8 and considering that centrifugation which is one of the common harvesting methods brings about 100 g/L cell density, then it surely saves the costs for the harvests14,15. Lastly, heterotroph based massive cultivation could make it possible to produce value-added products which have higher prices at least greater more than biofuel9,16,17,18. While it has been estimated that the costs of carbon sources account for up to 80% of the total operating costs in the heterotrophic cultivation, the above-mentioned advantages can easily compensate for the increased costs19.

Chlorella sp. HS2 was recently isolated from Jeongbang falls in Jeju, Korea. It has the ability to achieve extraordinary culture density (5.91 g/L) and biomass productivity (656.7 mg/L/D) under photoautotrophic conditions20. In addition, it is capable of tolerating high-level of salinity (0–5%), and being able to proliferate under a wide range of temperature (14–46 °C) and pH (3.0–10.5)21. Due to these outstanding growth and environmental resistance characteristics compared to other microalgae, investigating how this strain would perform under heterotrophic fermentation holds significant interest.

Statistical analysis has been applied on algal biomass and lipid production a lot, because it is an efficient way to optimize complex and various culture conditions including nutrient, temperature, pH and so on22,23,24. However, statistical optimizations were limited to phototrophic cultivation of microalgae, and the application for heterotrophic cultivation has been seldom reported. Most of the previous statistical analyses on heterotrophic cultivation were mainly for producing value-added products instead of focusing on general biomass productivity25,26.

Thus, in this study, we optimized the heterotrophic cultivation of promising strain of Chlorella sp. HS2 in order to explore the potential of green algae fermentation for biomass and biofuel production using Plackett-Burman design (PBD)27 and the response surface methodology (RSM) with the central composite design (CCD)26,28,29. The optimized parameters were then experimentally verified on the flask scale and then on the final scale, a 5-L fermenter, for further optimization. Lastly, biomass and lipid productivity was further improved by enhancing the nutrient uptake using a P-feeding strategy.

Results and Discussion

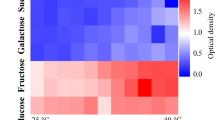

Initial screening of the carbon and nitrogen sources

In order to determine the substrate that is most favored by Chlorella sp. HS2, glucose, sucrose, sodium acetate, and lactic acid were tested. Glucose was chosen as the candidate because it is the most common substrate in industrial fermentation processes2,30. Sucrose is an inexpensive carbon from waste molasses8. Acetate and lactate were one of the most common carbon sources for growing many microorganisms, including microalgae1,2. Cell growth using four different carbon sources with 1, 5, 10, and 20 g/L concentrations were examined with optical density at 680 nm and it was calculated as dry cell weight (DCW, g/L) using Eq. 2, as presented in Fig. 1a. Among the various concentrations of carbon sources that were tested, the best performance was achieved with 20 g/L of glucose (0.41 g/L), followed by 10 and 5 g/L of glucose (0.39 and 0.36 g/L, respectively). The second best growth performance was observed with sucrose, but the performance was relatively lower than the result with the same concentration of glucose (20 g/L sucrose showed 0.26 g/L). It could be assumed that degradation of sucrose was not processed well because of the neutral pH of the medium31 and cells had lower efficiency to use sucrose directly or degraded fructose than glucose. As a result, Chlorella sp. HS2 has less capability to use sucrose in this condition and resulted in just half the growth compared to that obtained with the same concentration of glucose. Sodium acetate and lactic acid were the third and fourth carbon source for Chlorella sp. HS2. In the case of sodium acetate, it has the ability to buffer the pH32, but a high dosage of it could modify the pH to an undesirable range for Chlorella sp. HS2. In a similar manner, lactic acid could modify the pH below the optimum range for Chlorella sp. HS2 and showed almost no growth. As a result, among the carbon sources, glucose has been utilized as the primary carbon source in microorganism based industries because it is metabolized in the form of energy and a carbon source with minimal cost. Chlorella sp. HS2 appeared to easily metabolize glucose and thereupon provide good biomass production. In terms of economic feasibility, glucose is relatively more cost-effective than the other carbon sources because it is produced on a large scale industrially and has a high substrate yield in the cultivation industry33. In addition, glucose constitute large part of reasonable carbon sources from agricultural and food waste water1,34. Therefore, optimization study based on glucose will help better understand the cultivation using various reasonable carbon sources also35. Thus, under these circumstances, glucose was selected as a heterotrophic carbon source for Chlorella sp. HS2.

Effects of various concentrations of (a) carbon (glucose, sucrose, sodium acetate, and lactic acid) and (b) nitrogen sources (sodium nitrate, urea, ammonium chloride, and yeast extract) on the cell growth (calculated dry cell weight, DCW) under heterotrophic cultivation of Chlorella sp. HS2. Asterisks (*P <0.05, **P <0.01, ***P <0.001) refers to significant differences when compared with each glucose or nitrate concentrations.

In addition to the carbon source, sodium nitrate, urea, ammonium chloride, and yeast extract were tested for the heterotrophic cultivation of Chlorella sp. HS2. Sodium nitrate was chosen as the candidate because it is commonly used as a nitrogen source for Chlorella cultivation36. Urea is one of the cheapest nitrogen sources and is considered a valuable nitrogen source to achieve high lipid productivity37. Ammonium chloride is meanwhile the preferred nitrogen source for most microalgae, as all other forms of nitrogen must be converted to ammonium for accessible nitrogen forms38. Finally, yeast extract is an important nitrogen source for all microorganism growth as well as microalgae growth39. Each nitrogen source (125, 250, 500, and 750 mg/L) were added to a BG11 medium containing 10 g/L of glucose and cell growth was examined. The results are provided in Fig. 1b. Among the tested conditions, the highest cell growth performance was obtained with 750 mg/L of sodium nitrate (0.58 g/L), whereas 500, 250, and 125 mg/L showed decreasing cell growth (0.46, 0.37, and 0.27 g/L, respectively). Interestingly, the other nitrogen sources showed similar cell growth over different dosages. In the case of ammonium chloride, ammonium ions make hydrogen ions when they are consumed and decrease the pH, and therefore could impede cell growth. In the case of urea, it contains two ammonium ions in the molecules, but it has a smaller effect on pH changes than ammonium chloride2. However, different concentrations of dosages did not show significant differences in cell growth and the highest cell growth (0.25 g/L growth with 750 mg/L urea) was even less than the minimum result of sodium nitrate (0.28 g/L growth with 125 mg/L sodium nitrate). Yeast extract contains not only nitrogen source in the form of amino acids but also carbon and phosphorus sources, therefore it usually yields higher cell density than the other nitrogen sources. However, in this screening test, maximum cell growth was achieved under 500 mg/L yeast extract, and further additions reduced the cell growth. Therefore, considering the substrate yield and economic feasibility of nitrogen sources, sodium nitrate was selected for the heterotrophic cultivation of Chlorella sp. HS2.

Screening of key nutrients using the PBD

Based on the results of the carbon and nitrogen screening test described above, glucose and sodium nitrate were selected as the main nutrients for BG11 application on heterotrophic Chlorella sp. HS2. In addition, all eleven nutrient sources in glucose added BG11 media with sodium nitrate were evaluated in twelve combinations via PBD27. Tables S1 and S2 illustrate the candidate variables (nutrients), the high- and low-end ranges used, and the responses (dry cell weight) under the given conditions on the flask scale. The results summarized in Table 1 show that glucose, sodium nitrate, both phosphate sources, MgSO4∙7H2O, Na2CO3, and ferric citrate all positively influenced cell growth. However, CaCl2, citric acid, and Na2 EDTA were found to have negative effects. Although some of the trace metal solutions displayed a negative effect, the error range is considerably large due to the very low concentrations of the trace metals. Trace metals were not removed from the list of media components given that their presence is still necessary for cell growth. While the choice of phosphorus source did not have a critical effect on the overall cell growth, monopotassium phosphate was observed to have a greater influence on the response (indicated by a higher t value) in comparison to dipotassium phosphate. Additional comparison between monopotassium phosphate and dipotassium phosphate was conducted in the flask scale (Fig. S1) because dipotassium phosphate is the only phosphate source in the modified BG11 medium. As a result, it showed no significant difference (P value (0.33)> 0.05) in cell growth. Theoretically, both monopotassium phosphate and dipotassium phosphate were dissociated into dihydrogen phosphate and monohydrogen phosphate, respectively, in the solution and these dihydrogen phosphate and monohydrogen phosphate are in the equilibrium state. And their distribution at the equilibrium state was determined by pH or the other ions in the medium40. Though two different monopotassium phosphate and dipotassium phosphate were tested, their pHs were adjusted to pH 7 and the same concentrations of other nutrients were supplied, therefore, the distributions of monohydrogen phosphate and dihydorgeon phosphate ions might be same for both conditions. That is why, we assumed, both phosphate sources showed almost same growth and glucose consumption results as Fig. S1. Therefore, dipotassium phosphate which is usually used in the ordinary BG11 medium was selected. Based on these observations, glucose, sodium nitrate, and dipotassium phosphate were chosen as the carbon, nitrogen, and phosphorus sources, respectively, for the remainder of the study. The minor nutrient components in BG11 were identical to the earlier selections, with the exception of MgSO4∙7H2O, which was added at a higher concentration (increased from 0.075 g/L to 1 g/L). MgSO4∙7H2O plays an important role in the formation of the chloroplast of green algae, and therefore MgSO4∙7H2O was included in the initial RSM. However, when it was present above a certain concentration, MgSO4∙7H2O was found to not have a remarkable influence on cell growth and was hence excluded as the main factor. Ferric citrate was also shown to have a relatively large effect according to the PBD results, but it had less meaning to find the optimal concentration due to its low concentration in the medium. Therefore, dipotassium phosphate was chosen as a key nutrient for optimization along with glucose and sodium nitrate.

Optimization of the medium composition by the RSM

After the initial profiling of the major and minor nutrients, the concentrations of glucose, sodium nitrate, and dipotassium phosphate were optimized by employing the RSM and CCD. For the CCD, a second-order polynomial RSM model consists of 23 factorial design points with six-star points and six replicates at the central points, thus requiring 20 experiments in total41. The coded and natural values of the variables are shown in Table S3. After selecting glucose, sodium nitrate, and dipotassium phosphate as the three key nutrients, the CCD was applied to identify the effects of these nutrients on cell growth and thus to determine their optimal concentrations (Table S4). For the determination of the significance, t-tests were conducted, with the p-values presented in Table 242. The interrelationships between the dry cell weight (g/L) and the levels of key nutrients were found to be well represented by the following quadratic equation with a correlation coefficient R2 of 0.9050,

where G, N, and P represent glucose, sodium nitrate, and dipotassium phosphate, respectively.

Respective contour plots and three-dimensional response surface curves described by the regression model are presented to explain the effects of the key nutrients (Fig. 2). Each response surface curve represents the effect of two of the three nutrient factors, while the third variable is set at the baseline level. The contour plot of G and N appeared to be elliptical, which indicates some degree of mutual interaction among the nutrients. Based on the regression equation, the optimum concentrations were calculated to be 72 g/L glucose, 8 g/L sodium nitrate, and 0.22 g/L dipotassium phosphate.

Validation of the RSM model via flask cultivation

Next, Chlorella sp. HS2 was cultivated under the proposed optimum concentrations of glucose, sodium nitrate, and dipotassium phosphate, which were tested in order to validate the RSM model. Under non-optimized conditions containing 72 g/L glucose in BG11 medium, the maximum biomass of 5.85 g/L was obtained (Fig. S2a). In comparison, according to the model, the maximum dry cell weight (DCW) of the microalgae was predicted to be 18.63 g/L under the optimized conditions. After the microalgae were cultivated for seven days in the optimized medium on the baffled flask, a total DCW of 18.13 g/L was obtained (Fig. S2b). This result was close to the model's prediction of 18.63 g/L.

The accuracy of the RSM model (Eq. 3) was analyzed further by the analysis of variance (ANOVA) approach, and these results are summarized in Table S5. In the flask scale validation, the F-value (Fstatistic(9,10)=10.56) was three times greater than the tabulated F(9,10)(=3.14), which shows that the model is a good predictor of the experimental results43,44. Furthermore, the relatively high correlation coefficient (R2 = 0.9050) and low P-value (P <0.001) provided strong evidence of the high significance of the regression model45.

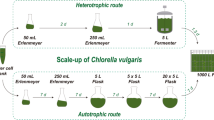

Optimized fermentation of Chlorella sp. HS2 in the 5-L fermenter

The earlier validation experiment on the flask showed that Chlorella sp. HS2 cultivated in the optimized BG11 medium presented a remarkable increase in DCW from 5.85 to 18.13 g/L. However, considering that cells were not able to fully utilize all the glucose in the medium (Fig. S2b) and cell growth was limited by the flask scale condition (limited oxygen and changing pH)46,47, fermenter scale cultivation should be examined. Therefore, in order to investigate the full potential of Chlorella sp. HS2 under heterotrophic conditions, the cultivation was scaled up to a 5-L jar fermenter.

As expected, Chlorella sp. HS2 in the optimized BG11 medium achieved a maximum DCW of 35.3 ± 0.6 g/L after 10 days with a better glucose consumption rate (6.5 g/L/D) (Fig. 3a). However, even in the fermenter scale, cells failed to use all the glucose. The reason was found in the nutrient profile, as presented in Fig. 3b. Dipotassium phosphate was depleted on the second day and it appears that the depleted phosphate disturbed the cell growth and cell could not utilize all the glucose. According to48, the C:N:P ratio is important for harmonized utilization of each carbon, nitrogen, and phosphate source, and it also can be exploited such that the cells achieve greater biomass yield. Even though the concentration of glucose continued to decrease until the end of the experiment, the growth rate of Chlorella sp. HS2 was decreased after the third day from 6.47 g/L/D to 2.23 g/L/D, and the cells appear to be in an abnormal condition, showing low activity. In the same manner, the consumption of an optimized amount of sodium nitrate was limited to 2.5 g/L for 10 days (Fig. 3b). Phosphate was depleted quickly and this has a negative effect on nitrate consumption. Limited nitrate consumption caused more lipid accumulation (Fig. 3c). The total lipid productivity continued to decrease throughout the cultivation process due to the increase in the cultivation time. However, the total lipid content increased gradually from 20.2% when the phosphate was depleted to 26.28% on day 8. This increase in the lipid content indicates that the growth was being inhibited by nutrient limitation37,49,50. Lipid productivity kept decreasing from 1.42 g/L/D (2nd day) to 0.81 g/L/D (7th day) and subsequently showed a similar value (0.90 g/L/D). This decrease was mainly because cells showed less biomass productivity than changes in lipid content, which showed an increase.

The fermenter scale cultivation gave 1.57 times more biomass yield and 10 g/L higher consumption of glucose. Although screened and optimized conditions were applied, cells could not completely consume the glucose, mainly because of the depletion of phosphate. It is noteworthy that even though screening and statistical optimization were applied, additional optimization is required at a specific scale. Therefore, further optimization was conducted in the form of phosphate feeding.

P-feeding fermentation for improved carbon-nitrogen utilization

RSM data showed that the optimum dipotassium phosphate feeding amount was 0.22 g/L. In microalgae, phosphates are commonly known to be depleted first due to microalgae quickly uptaking any excess phosphorus in the environment for sequestration in the form of phosphate granules51. This phenomenon makes it difficult to precisely determine the amount of phosphate that is used and to control the balance among the C, N, and P sources48. In addition, RSM data showed that more addition of dipotassium phosphate led to lower biomass yield, and therefore a phosphate feeding strategy was applied. Although most fed-batch fermentation processes involve the feeding of a carbon source, the P-feeding process is feasible for fed-batch fermentation52. The initial medium used was BG11, which is identical to that in the previous experiment, and 1 mL of concentrate containing 0.22 g/L of phosphorus was pulse-fed every two days until the glucose was depleted.

The dipotassium phosphate feeding fermentation resulted in similar growth rate (5.37 g/L/D) over the cultivation, as shown in Fig. 4a. The final dry cell weight increased to 42.95 g/L and glucose was completely depleted by the end of the cultivation (8th day) as the glucose consumption rate increased from 6.4 g/L/D (without phosphate feeding) to 9.0 g/L/D (with phosphate feeding). Enhanced glucose utilization could be explained by the fact that greater phosphate availability under pulse-feed culture conditions allowed cells to increase nitrogen uptake (Fig. 4b). All the supplied phosphate with pulse feed was consumed within a day and nitrate consumption was maintained at a constant rate (0.61 g/L/D). Indeed, the total amount of nitrate consumed increased from 2.47 to 4.91 g/L only for 8 days. The previous study also reported that the nitrogen source uptake rate is greatly influenced by the phosphate availability51 and it was closely related to the optimum N:P ratio.

By adopting pulse-feeding cultivation of phosphate, the overall dry cell weight and the consumption rates of glucose, nitrate, and phosphate were enhanced. However, better nitrate consumption led to less lipid content during the cultivation (Fig. 4c). The observed decrease most likely resulted from the decrease in the overall C:N ratio within the biomass. While the amount of glucose consumed in the pulse-feeding cultivation of phosphate was slightly greater than that during batch cultivation, and the consumed amount of nitrogen nearly doubled. This may indicate two possible underlying mechanisms; one is easy consumption of the nitrogen source caused by better phosphate availability removes the nitrogen limitation condition from cells and this results in better growth compared to the case of concentrating on the lipid accumulation48. The other is that more of the carbon flux was involved in de novo protein synthesis and cellular growth than in lipid accumulation (Fig. S3). Through the pulse-feeding cultivation of phosphate, the lipid content increased from 11.86% (day 3) to 16.02% (day 8), although it is substantially lower than cultivation without pulse feed of phosphate (26.28%). As a result, total lipid productivity was also similar to the cultivation without pulse feed of phosphate, but it was kept at around 0.86 g/L/D during the whole cultivation period and this was mostly because of better growth.

The overall performance of biomass production from the system that used Chlorella sp. HS2 with the optimized BG11 medium and the P feeding fermentation mode was found to be vastly superior to the performance in the majority of previous works involving the heterotrophic fermentation of green algae (Table 3). In terms of pure DCW yields, the current study achieved the highest biomass concentration among the studies that were surveyed39,49,53,54. Most importantly, the biomass yield per substrate input (0.60 g DCW/g substrate) was among the highest ever reported. However, the overall lipid content was found to be noticeably lower (16.0%) than that in other studies (26.3–72.0%).

It is noteworthy that different C:N ratio within the biomass (based on the consumption) results in different lipid content and biomass yield even within the same system as shown in Figs. 3c and 4c. As expected, the various culture conditions and strains across different studies resulted in a wide range of response (Table 3). While both batch and P feeding cultivation of Chlorella sp. HS2 had identical C:N ratio (21.8) in the medium, different biomass yields (35.3 and 43.0 g/L) and lipid contents (26.3 and 16.0 g/L) were obtained. As for two studies involving Chlorella vulgaris and Chlorella sorokiniana, the C:N ratios in the medium were comparable (19.2 and 17.6 each), but they reported totally different biomass yields (4.27 and 1.75 g/L) and lipid contents (30.0 and 39.2%). In the case of Chlorella protothecoides, Li et al. and Chen & Walker used different C:N ratio in the medium, but obtained showed similar biomass yields (13.9 and 15.3 g/L) and lipid contents (72.0 and 64.1%). Therefore, it appears that C:N ratio in the medium alone is a poor indicator to predict the biomass and lipid yields, and specific optimization is needed for each target product and selected strain under given conditions. In this study, BG11 medium (originally a phototrophic medium) has been optimized using PBD and RSM with the primary objective of maximizing the rate of biomass productivity. While the lipid content was lower than the values reported in most instances of heterotrophic fermentation, the possibility of increasing the lipid content further can be explored with Chlorella sp. HS2. These steps would involve a potential two-stage cultivation mode with nutrient starvation after supplemental glucose fed-batch fermentation, combined with increased delivery of disolved oxygen (DO) for more effective utilization of the supplemental glucose.

Conclusion

In this study, PBD was employed to determine the effects of various nutrients contained in BG11 on the heterotrophic growth of Chlorella sp. HS2. An RSM analysis based on CCD successfully determined the optimal concentrations of glucose, sodium nitrate, and dipotassium phosphate, which were 72 g/L, 8 g/L, and 0.22 g/L, respectively. A subsequent scale-up of the model to a 5-L fermenter showed that the culture underwent possible phosphorus deficiency, resulting in incomplete utilization of the carbon and nitrogen sources. This problem was addressed via P feeding fermentation using pulse-supplementation of phosphorus, which resulted in a maximum biomass concentration of 42.95 ± 0.05 g/L. This led to the conclusion that the heterotrophic cultivation of Chlorella sp. HS2 is a highly promising method for the production of high-density algal cultures.

Materials and Methods

Microalgal strain and culture maintenance

Green alga Chlorella sp. HS2 was isolated by Dr. Hee-Sik Kim at the Korea Research Institute of Bioscience and Biotechnology (KRIBB) in Korea. The culture was maintained in a BG11 medium containing (g/L) 1.5 NaNO3, 0.04 K2HPO4∙2H2O, 0.075 MgSO4∙7H2O, 0.036 CaCl2∙2H2O, 0.006 citric acid, 0.02 Na2CO3, 0.006 ferric ammonium citrate, 0.001 Na-EDTA, and 1 mL of the trace metal A5. The trace metal A5 solution consisted of (g/L) 2.86 H3BO3, 1.81 MnCl2∙4H2O, 0.22 ZnSO4∙7H2O, 0.39 NaMoO4∙2H2O, 0.079 CuSO4∙5H2O, and 0.05 CoCl2∙6H2O. The seed culture, which used BG11 medium with 10 g/L glucose, was maintained in a dark condition at 32 °C and 120 rpm.

Carbon and nitrogen screening using PhotoBiobox

Screening of carbon and nitrogen sources for heterotrophic Chlorella sp. HS2 was conducted using PhotoBiobox (Sinhwascience, Korea)55. Photobiobox is an incubator invented to keep the same condition (temperature and air supply) for all wells on 96 well plate and it makes possible to compare the effect of certain additives precisely. For the carbon source screening, glucose, sucrose, sodium acetate, and lactic acid were tested. Glucose, sucrose, sodium acetate, and lactic acid, with respective concentrations of 1, 5, 10, and 20 g/L, were added into each 1 L BG11 medium containing 1.5 g sodium nitrate and sterilized with an autoclave. For the nitrogen source screening, sodium nitrate, urea, ammonium chloride, and yeast extract were tested. Each nitrogen source, where the concentrations were 125, 250, 500, and 750 mg/L, was added into each BG11 medium containing 10 g/L glucose and sterilized with an autoclave. Microalgal culture was inoculated in 250 μL wells of a 96-well glass plate (working volume: 200 μL) and it was covered to prevent evaporation55. Cells were cultivated for 120 hours under a dark condition at 37 °C and mixed using the auto-mixing function in Photobiobox. Cell growth was initially measured by optical density at 680 nm (OD680 nm) using Plate reader (SpectraMax M2; Molecular Devices, Sunnyvale, CA, USA). And dry cell weight (DCW) was calculated based on the predetermined calibration curve using the correlation between dry cell weight and OD680 nm, which is represented by Eq. 2.

For the correlation, cells were cultivated in the flask scale and then OD and DCW were measured three times daily based using plate reader and method below, respectively.

Statistical optimization

The Plackett-Burman Design (PBD) was used to select the statistically significant factors that are considered to influence the biomass concentration of Chlorella sp. HS236. After the selection of three significant factors using the PBD, a factorial response surface methodology (RSM) was utilized to obtain information about the important effects and the interactions between the selected variables with a positive influence on cell growth. In this study, the central composite design (CCD) was employed for the RSM. In RSM, glucose, sodium nitrate, and dipotassium phosphate was used to obtain the respective optimum concentration. Glucose concentration ranges from 25.36 g/L to 94.64 g/L and sodium nitrate concentration ranges from 5.07 g/L to 18.93 g/L and dipotassium phosphate concentration ranges from 0.06 g/L to 0.24 g/L.

Statistical analysis

During the carbon and nitrogen source selection, P-values were obtained via a Student's t-test between glucose and different carbon sources at the same concentrations, and a Student's t-test between nitrate and different nitrogen sources at the same concentrations. All the experiments were carried out in duplicate. The results were expressed as mean values and standard deviation (SD) between experiments. The analysis of variance (ANOVA) method was used for the statistical analysis of the model. The analysis includes a Fisher test (F-test), a related probability P (F) assessment, and the coefficient of determination (R2), which measures the fit of the regression model. The response surface and contour plots of the model were used to evaluate the interactions between the important variables.

Validation of heterotrophic cultivation in flask and fermenter

For flask-scale cultivation, the cells were grown in a 250 mL flask using 100 mL of modified BG11, containing 72 g glucose, 8 g NaNO3, 0.22 g K2HPO4∙2H2O, 0.075 g MgSO4∙7H2O, 0.02 g Na2CO3, 0.006 g ferric ammonium citrate, and 1 mL of the trace metal A5 per 1 L. The trace metal A5 solution consisted of 2.86 g H3BO3, 1.81 g MnCl2∙4H2O, 0.22 g ZnSO4∙7H2O, 0.39 g NaMoO4∙2H2O, 0.079 g CuSO4∙5H2O, and 0.05 g CoCl2∙6H2O per 1 L. For cultivation in a shaking incubator, the temperature and agitation were kept at 37 °C and at 120 rpm, respectively. The initial pH of the medium was adjusted with 1 N HCl solution to 7.0.

For a fermentation test, the cells were grown in a 5-L jar fermenter (CNS Co. Ltd., Korea) containing 3 L of the modified BG11. The filtered air was supplied at a 1.67 vvm flow rate, and temperature and agitation were kept at 37 °C and 300 rpm, respectively. The culture pH was held constant at 7 via the automatic addition of 1 N HCl. The initial concentration of the inoculum was 7.4 ×106 cells/mL, and the total cultivation periods were 10 days (batch) and 8 days (P-feeding). In the P-feeding cultivation, dipotassium phosphate was initially 0.22 g/L and 0.11 g/L per feed.

Biomass and total lipid analysis

To measure the dry cell weight (DCW), 1 mL of culture was centrifuged at 13,000 rpm for 3 min. The pellets were washed twice with DI water and dried at 90 °C for 24 h in an oven. To measure the total lipid amount, 30 mg of the cell was centrifuged at 4,000 rpm for 10 min. The pellets were washed twice with DI water and stored at −70 °C for two days and lyophilized for three days.

Total lipids were determined using the modified Folch method56. The dried cell was grounded into a powder using a bead beater. Thirty mg of biomass was added into 10 mL of chloroform/methanol (2:1, v/v) and sonicated for 4 h. For the phase separation, 2.5 mL of DI water was then added and vortexed for 5 min and centrifuged at 4,000 rpm for 10 min. The lower hydrophobic phase was transferred to another glass vial through an organic solvent filter (PTFE membrane filters 0.2 µm, Sartorius, Germany) using a syringe. Four mL of filtered hydrophobic phase was transferred to a pre-weighed aluminum weighing dish and underwent natural evaporation in the hood. The lipid content was calculated using Eq. 3.

WD: weight of the aluminum dish, WL: weight of aluminum dish with lipid, WS: weight of sample, VC: volume of chloroform, VP: volume of chloroform in the aluminum dish.

Glucose, nitrate, and phosphate analysis

The sugar concentrations were measured using a high-pressure liquid chromatograph (HPLC, Waters, USA) equipped with a refractive index detector (RI). The Aminex HPX-87H column (300 mm ×7.8 mm; Bio-Rad, USA) was maintained at 65 °C with a mobile phase (0.01 N H2SO4). The supernatant was passed through a 0.2 μm syringe filter (Sartorius Stedim Biotech, Gottingen, Germany), and the nitrate concentration was measured using ion chromatography (883 Basic IC plus, Metrohm, Switzerland). An anion column (Metrosep A Supp 5) was used to analyze the nitrate (NO3-) and the phosphate (PO4−) ions remaining in the culture medium. The eluent, which consisted of 3.2 mM Na2CO3 and 1 mM NaHCO3, was supplied at a flow rate of 0.7 mL/min into the column for the analysis55,57.

References

Lowrey, J., Brooks, M. S. & McGinn, P. J. Heterotrophic and mixotrophic cultivation of microalgae for biodiesel production in agricultural wastewaters and associated challenges—a critical review. J. Appl. Phycol. 27, 1485–1498, https://doi.org/10.1007/s10811-014-0459-3 (2014).

Perez-Garcia, O., Escalante, F. M. E., de-Bashan, L. E. & Bashan, Y. Heterotrophic cultures of microalgae: Metabolism and potential products. Water Res. 45, 11–36, https://doi.org/10.1016/j.watres.2010.08.037 (2011).

Edmundson, S. J. & Huesemann, M. H. The dark side of algae cultivation: Characterizing night biomass loss in three photosynthetic algae, Chlorella sorokiniana, Nannochloropsis salina and Picochlorum sp. Algal Res. 12, 470–476, https://doi.org/10.1016/j.algal.2015.10.012 (2015).

De Bhowmick, G., Subramanian, G., Mishra, S. & Sen, R. Raceway pond cultivation of a marine microalga of Indian origin for biomass and lipid production: A case study. Algal Res. 6, 201–209, https://doi.org/10.1016/j.algal.2014.07.005 (2014).

Pérez-López, P. et al. Comparative life cycle assessment of real pilot reactors for microalgae cultivation in different seasons. Appl. Energy 205, 1151–1164, https://doi.org/10.1016/j.apenergy.2017.08.102 (2017).

Xu, L., Weathers, P. J., Xiong, X. R. & Liu, C. Z. Microalgal bioreactors: Challenges and opportunities. Eng. Life Sci. 9, 178–189, https://doi.org/10.1002/elsc.200800111 (2009).

Singh, M., Shukla, R. & Das, K. Harvesting of microalgal biomass. Biotechnological applications of Microalgae, 77-88 (2013).

Yan, D., Lu, Y., Chen, Y. F. & Wu, Q. Y. Waste molasses alone displaces glucose-based medium for microalgal fermentation towards cost-saving biodiesel production. Bioresour. Technol. 102, 6487–6493, https://doi.org/10.1016/j.biortech.2011.03.036 (2011).

Morales-Sánchez, D., Martinez-Rodriguez, O. A. & Martinez, A. Heterotrophic cultivation of microalgae: Production of metabolites of commercial interest. J. Chem. Technol. Biotechnol., https://doi.org/10.1002/jctb.5115 (2016).

Sibi, G. Low cost carbon and nitrogen sources for higher microalgal biomass and lipid production using agricultural wastes. J. Environ. Sci. Technol. 8, 113 (2015).

Pleissner, D. & Rumpold, B. A. Utilization of organic residues using heterotrophic microalgae and insects. Waste Manage. 72, 227–239 (2018).

D’Alessandro, E. B. & Antoniosi Filho, N. R. Concepts and studies on lipid and pigments of microalgae: A review. Renew. Sustain. Energy Rev. 58, 832–841, https://doi.org/10.1016/j.rser.2015.12.162 (2016).

Lee, Y. K. Algal Nutrition‒Heterotrophic Carbon Nutrition. Handbook of microalgal culture: Biotechnology and Applied Phycology, 116–124 (2004).

Palabhanvi, B., Muthuraj, M., Mukherjee, M., Kumar, V. & Das, D. Process engineering strategy for high cell density-lipid rich cultivation of Chlorella sp. FC2 IITG via model guided feeding recipe and substrate driven pH control. Algal Res. 16, 317–329, https://doi.org/10.1016/j.algal.2016.03.024 (2016).

Zheng, Y. et al. High-density fed-batch culture of a thermotolerant microalga chlorella sorokiniana for biofuel production. Appl. Energy 108, 281–287, https://doi.org/10.1016/j.apenergy.2013.02.059 (2013).

Gong, M. & Bassi, A. Carotenoids from microalgae: a review of recent developments. Biotechnol. Adv. 34, 1396–1412 (2016).

Doshi, A., Pascoe, S., Coglan, L. & Rainey, T. The financial feasibility of microalgae biodiesel in an integrated, multi‐output production system. Biofuels Bioprod. Bioref. 11, 991–1006 (2017).

Hoffman, J., Pate, R. C., Drennen, T. & Quinn, J. C. Techno-economic assessment of open microalgae production systems. Algal Res. 23, 51–57 (2017).

Park, W. K. et al. Economical DHA (Docosahexaenoic acid) production from Aurantiochytrium sp KRS101 using orange peel extract and low cost nitrogen sources. Algal Res. 29, 71–79, https://doi.org/10.1016/j.algal.2017.11.017 (2018).

Nayak, M., Suh, W. I., Chang, Y. K. & Lee, B. Exploration of two-stage cultivation strategies using nitrogen starvation to maximize the lipid productivity in Chlorella sp. HS2. Bioresour. Technol., https://doi.org/10.1016/j.biortech.2018.12.111 (2019).

Yun, J.-H. et al. Evaluation of the potential of Chlorella sp. HS2, an algal isolate from a tidal rock pool, as an industrial algal crop under a wide range of abiotic conditions. J. Appl. Phycol. 31, 2245–2258, https://doi.org/10.1007/s10811-019-1751-z (2019).

Kim, M. et al. Increased biomass and lipid production of Ettlia sp. YC001 by optimized C and N sources in heterotrophic culture. Sci. rep. 9, 6830 (2019).

Lee, T. H., Jang, J. K. & Kim, H. W. Optimal temperature and light intensity for improved mixotrophic metabolism of Chlorella sorokiniana treating livestock wastewater. J. Microbiol. Biotechnol. 27, 2010–2018, https://doi.org/10.4014/jmb.1707.07007 (2017).

Chen, T. & Wang, Y. Optimized astaxanthin production in Chlorella zofingiensis under dark condition by response surface methodology. Food Sci. Biotechnol. 22, 1–8, https://doi.org/10.1007/s10068-013-0221-7 (2013).

Wang, Y. et al. Optimization of Chlorella vulgaris and bioflocculant-producing bacteria co-culture: enhancing microalgae harvesting and lipid content. Lett. Appl. Microbiol. 60, 497–503, https://doi.org/10.1111/lam.12403 (2015).

Jeon, J. Y. et al. Optimization of culture media for large-scale lutein production by heterotrophic Chlorella vulgaris. Biotechnol. Progr. 30, 736–743, https://doi.org/10.1002/btpr.1889 (2014).

Plackett, R. L. & Burman, J. P. The design of optimum multifactorial experiments. Biometrika 33, 305–325 (1946).

Wang, Y. H., Fang, X. L., An, F. Q., Wang, G. H. & Zhang, X. Improvement of antibiotic activity of Xenorhabdus bovienii by medium optimization using response surface methodology. Microb. Cell Fac. 10, doi:Artn 9810.1186/1475-2859-10-98 (2011).

Park, J., Hong, S. K. & Chang, Y. K. Production of DagA, a beta-agarase, by Streptomyces lividans in glucose medium or mixed-sugar medium simulating microalgae hydrolysate. J. Microbiol. Biotechnol. 24, 1622–1628, https://doi.org/10.4014/jmb.1405.05019 (2014).

Venkata Mohan, S., Rohit, M. V., Chiranjeevi, P., Chandra, R. & Navaneeth, B. Heterotrophic microalgae cultivation to synergize biodiesel production with waste remediation: Progress and perspectives. Bioresour. Technol. 184, 169–178, https://doi.org/10.1016/j.biortech.2014.10.056 (2015).

Eggleston, G. & Vercellotti, J. R. Degradation of Sucrose, Glucose and Fructose in Concentrated Aqueous Solutions Under Constant pH Conditions at Elevated Temperature. J. Carbohydrate Chemistry 19, 1305–1318, https://doi.org/10.1080/07328300008544153 (2000).

Yu, H. & Huang, G. H. Effects of sodium acetate as a pH control amendment on the composting of food waste (vol 100, pg 2005, 2009). Bioresour. Technol. 100, 2745–2745, https://doi.org/10.1016/j.biortech.2008.10.007 (2009).

Vassilev, N. & Vassileva, M. Biotechnological solubilization of rock phosphate on media containing agro-industrial wastes. Appl. Microbiol. Biotechnol. 61, 435–440, https://doi.org/10.1007/s00253-003-1318-3 (2003).

Pleissner, D., Lam, W. C., Sun, Z. & Lin, C. S. K. Food waste as nutrient source in heterotrophic microalgae cultivation. Bioresour. Technol. 137, 139–146, https://doi.org/10.1016/j.biortech.2013.03.088 (2013).

Morales‐Sánchez, D., Martinez‐Rodriguez, O. A. & Martinez, A. Heterotrophic cultivation of microalgae: production of metabolites of commercial interest. J. Chem. Technol. Biot. 92, 925–936 (2017).

Dayana Priyadharshini, S. & Bakthavatsalam, A. K. Optimization of phenol degradation by the microalga Chlorella pyrenoidosa using Plackett-Burman Design and Response Surface Methodology. Bioresour. Technol. 207, 150–156, https://doi.org/10.1016/j.biortech.2016.01.138 (2016).

Li, Y., Yuan, Z., Mu, J., Chen, D. & Feng, B. Proteomic analysis of lipid accumulation in chlorella protothecoides cells by heterotrophic N deprivation coupling cultivation. Energy Fuels 27, 4031–4040, https://doi.org/10.1021/ef4000177 (2013).

Wang, H. Y., Xiong, H. R., Hui, Z. L. & Zeng, X. B. Mixotrophic cultivation of Chlorella pyrenoidosa with diluted primary piggery wastewater to produce lipids. Bioresour. Technol. 104, 215–220, https://doi.org/10.1016/j.biortech.2011.11.020 (2012).

Kumar, V., Muthuraj, M., Palabhanvi, B., Ghoshal, A. K. & Das, D. High cell density lipid rich cultivation of a novel microalgal isolate Chlorella sorokiniana FC6 IITG in a single-stage fed-batch mode under mixotrophic condition. Bioresour. Technol. 170, 115–124, https://doi.org/10.1016/j.biortech.2014.07.066 (2014).

Van Veen, H. W., Abee, T., Kortstee, G., Konings, W. N. & Zehnder, A. Substrate specificity of the two phosphate transport systems of Acinetobacter johnsonii 210A in relation to phosphate speciation in its aquatic environment. J. Biol. Chem. 269, 16212–16216 (1994).

Bandi, S., Kim, Y. J., Sa, S. O. & Chang, Y. K. Statistical approach to development of culture medium for ansamitocin P-3 production with Actinosynnema pretiosum ATCC 31565. J. Microbiol. Biotechnol. 15, 930–937 (2005).

Box, G. E. P. & Hunter, J. S. Multi-Factor Experimental Designs for Exploring Response Surfaces. Ann. Stat. 28, 195–241 (1957).

Yu, T. W. et al. The biosynthetic gene cluster of the maytansinoid antitumor agent ansamitocin from Actinosynnema pretiosum. PNAS. 99, 7968–7973, https://doi.org/10.1073/pnas.092697199 (2002).

Rao, K. J., Kim, C. H. & Rhee, S. K. Statistical optimization of medium for the production of recombinant hirudin from Saccharomyces cerevisiae using response surface methodology. Process Biochem. 35, 639–647, https://doi.org/10.1016/S0032-9592(99)00129-6 (2000).

Himmelblau, D. M. Experiment Optimization in Chemistry and Chemical-Engineering - Akhnazarova,S. Kafarov,V. Am. Sci. 72, 638–638 (1984).

Garcia-Ochoa, F. & Gomez, E. Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol. Adv. 27, 153–176, https://doi.org/10.1016/j.biotechadv.2008.10.006 (2009).

Garcia-Ochoa, F., Gomez, E., Santos, V. E. & Merchuk, J. C. Oxygen uptake rate in microbial processes: An overview. Biochem. Eng. J. 49, 289–307, https://doi.org/10.1016/j.bej.2010.01.011 (2010).

Vrede, T., Dobberfuhl, D. R., Kooijman, S. A. L. M. & Elser, J. J. Fundamental connections among organism C: N: P stoichiometry, macromolecular composition, and growth. Ecology 85, 1217–1229, https://doi.org/10.1890/02-0249 (2004).

Shen, X. F., Chu, F. F., Lam, P. K. S. & Zeng, R. J. Biosynthesis of high yield fatty acids from Chlorella vulgaris NIES-227 under nitrogen starvation stress during heterotrophic cultivation. Water Res. 81, 294–300, https://doi.org/10.1016/j.watres.2015.06.003 (2015).

Griffiths, M. J., van Hille, R. P. & Harrison, S. T. L. The effect of nitrogen limitation on lipid productivity and cell composition in Chlorella vulgaris. Appl. Microbiol. Biotechnol. 98, 2345–2356, https://doi.org/10.1007/s00253-013-5442-4 (2014).

Chu, F. F., Chu, P. N., Shen, X. F., Lam, P. K. & Zeng, R. J. Effect of phosphorus on biodiesel production from Scenedesmus obliquus under nitrogen-deficiency stress. Bioresour. Technol. 152, 241–246, https://doi.org/10.1016/j.biortech.2013.11.013 (2014).

Yzturk, S., Yalik, P. & Yzdamar, T. H. Fed-Batch Biomolecule Production by Bacillus subtilis: A State of the Art Review. Trends Biotechnol. 34, 329–345, https://doi.org/10.1016/j.tibtech.2015.12.008 (2016).

Li, Y. et al. Production of biomass and lipid by the microalgae Chlorella protothecoides with heterotrophic-Cu(II) stressed (HCuS) coupling cultivation. Bioresour. Technol. 148, 283–292, https://doi.org/10.1016/j.biortech.2013.08.153 (2013).

Chen, Y. H. & Walker, T. H. Biomass and lipid production of heterotrophic microalgae Chlorella protothecoides by using biodiesel-derived crude glycerol. Biotechnol. Lett. 33, 1973–1983, https://doi.org/10.1007/s10529-011-0672-y (2011).

Heo, J., Cho, D. H., Ramanan, R., Oh, H. M. & Kim, H. S. PhotoBiobox: A tablet sized, low-cost, high throughput photobioreactor for microalgal screening and culture optimization for growth, lipid content and CO2 sequestration. Biochem. Eng. J. 103, 193–197, https://doi.org/10.1016/j.bej.2015.07.013 (2015).

Folch, J., Lees, M. & Sloane Stanley, G. H. A simple method for the isolation and purification of total lipides from animal tissues. J. Biol. Chem. 226, 497–509 (1957).

Sung, M. G., Lee, B., Kim, C. W., Nam, K. & Chang, Y. K. Enhancement of lipid productivity by adopting multi-stage continuous cultivation strategy in Nannochloropsis gaditana. Bioresour. Technol. 229, 20–25, https://doi.org/10.1016/j.biortech.2016.12.100 (2017).

Acknowledgements

This work was supported by the Advanced Biomass R&D Center (ABC) of the Global Frontier Project funded by the Ministry of Science, ICT and Future Planning of Korea (ABC-2010-0029728).

Author information

Authors and Affiliations

Contributions

H.S.K. and W.-K.P. conducted most of the experiments and data collection and interpreted the data and prepared the draft of the article. G.S. helped with data analysis and interpretation. W.I.S. and B.L. revised the manuscript. M.M. and Y.K.C. conceived the study and consolidated the aim of this study. All authors gave final approval for publication.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, H.S., Park, WK., Lee, B. et al. Optimization of heterotrophic cultivation of Chlorella sp. HS2 using screening, statistical assessment, and validation. Sci Rep 9, 19383 (2019). https://doi.org/10.1038/s41598-019-55854-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-55854-9

This article is cited by

-

Large-scale production of myco-fabricated ZnO/MnO nanocomposite using endophytic Colonstachys rosea with its antimicrobial efficacy against human pathogens

Scientific Reports (2024)

-

Maximizing biomass productivity of cyanobacterium Nostoc sp. through high-throughput bioprocess optimization and application in multiproduct biorefinery towards a holistic zero waste

Biomass Conversion and Biorefinery (2024)

-

Nutrient Removal by Algae-Based Wastewater Treatment

Current Pollution Reports (2022)

-

Experimental and optimization studies on phycoremediation of dairy wastewater and biomass production efficiency of Chlorella vulgaris isolated from Ganga River, Haridwar, India

Environmental Science and Pollution Research (2022)

-

Insights into the physiology of Chlorella vulgaris cultivated in sweet sorghum bagasse hydrolysate for sustainable algal biomass and lipid production

Scientific Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.