Abstract

The coupling between electric, magnetic and elastic features in multiferroic materials is an emerging field in materials science, with important applications on alternative solid-state cooling technologies, energy harvesting and sensors/actuators. In this direction, we developed a thorough investigation of a multiferroic composite, comprising magnetocaloric/magnetostrictive Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) microparticles blended into a piezo- and pyroelectric poly(vinylidene) fluoride (PVDF) matrix. Using a simple solvent casting technique, the formation and stabilization of PVDF electroactive phases are improved when the filler content increases from 2 to 12 weight fraction (wt.%). This effect greatly contributes to the magnetoelectric (ME) coupling, with the ME coefficient \({\alpha }_{ME}\) increasing from 0.3 V/cm.Oe to 2.2 V/cm.Oe, by increasing the amount of magnetic material. In addition, magnetic measurements revealed that the ME-coupling has influenced the magnetocaloric effect via a contribution from the electroactive polymer and hence leading to a multicaloric effect. These results contribute to the development of multifunctional systems for novel technologies.

Similar content being viewed by others

Introduction

Recently, efforts to find materials simultaneously presenting more than one primary ferroic ordering - multiferroic materials - have intensified with the aim of exploring novel and interesting features, like multicaloric effect and magnetoelectric (ME) coupling1,2. Through a theoretical approach, Vopson demonstrated that multiferroic systems fulfil the requirements to present giant caloric effects which rises from the coupling between its intrinsic ferroic orderings3. Therefore such systems have a great potential in magnetic refrigeration technology which is at the forefront to substitute the conventional vapour compression cooling/heating technology. Experimental studies have revealed that the use of multiple-stimuli during each cycle can improve the system caloric efficiency and device operation4,5,6. However, a complete understanding on the interplay between phase transitions on reversible caloric effects of multiferroic materials is still at an early stage7.

The ME-coupling in hybrid systems is a product effect which is known to be stronger than in single-phase multiferroic materials8. For composites, the ME-coupling rises from interfacial interactions between a piezoelectric and a magnetostrictive phase9. Extensive research on these multiple-phase systems revealed that their ME response is strongly dependent on the shape, composition and the connectivity type between the components10,11. Among the different designs of multiphase systems presenting large ME responses, it is possible to mention the particulate-matrix composites, bulk and fibers/rods/wires with different shapes and geometries8. This feature allows to tune the composite features by choosing the correct components for practical applications. For instance, ME composites can be used as high sensitive magnetic sensors, current/voltage converters and energy harvesters12. Considering practical applications, the optimization of the ME response at room temperature is a critical issue towards the design of a real-life device.

The aim of this study is to evaluate the morphological, crystallographic, magnetoelectric and magnetocaloric properties of a micrometric composite obtained by the dilution of magnetostrictive \(G{d}_{5}(Si,Ge{)}_{4}\) into a piezoelectric poly(vinylidene) fluoride (PVDF) matrix using a simple chemical route. The concentrations of 2 and 12 weight fraction (wt.%) of magnetic material were chosen for being below the percolation threshold while simultaneously allowing to study the effect of changing one order of magnitude in the magnetic material amount inside the electroactive polymer. Gadolinium silicides germanides have already shown their potential for applications on multi-energy conversion and energy harvesting when implemented into polymeric matrix13,14,15. Ozaydin and Liang demonstrated that the energy conversion from magnetic energy to electrical power is more effective for the crushed Gd\({}_{5}\)Si\({}_{2}\)Ge\({}_{2}\) alloy blended with PVDF than for pure PVDF and magnetic material itself13. More recently, Harstad et al. evaluated the enhancement in the generation of voltage output through mechanical stimulation of PVDF loaded with small amounts (\(\le \)5 wt.%) of 470 nm Gd\({}_{5}\)Si\({}_{4}\) particles14. The tests performed by the authors revealed a power density of 14.3 mW/cm\({}^{3}\), being more efficient than pure PVDF that presented 3.25 mW/cm\({}^{3}\) in the same experimental conditions. These important observations are a consequence of the ME-coupling in composites with magnetostrictive and piezoelectric phases. The evaluation of the ME behavior can be used to improve its response aiming future applications12. For instance, the combination of magnetic and electric fields in FeRh thin film deposited into a BaTiO\({}_{3}\) substrate revealed a 96% reduction on the magnetic hysteresis losses arising from the strong magnetoelectric coupling2. From first principles calculations, it was shown that the ME-coupling for multiferroic systems can be enhanced indirectly by the pyroelectric and magnetocaloric features of the material16. In this sense, the results and conclusions presented herein demonstrate the effect of PVDF pyroelectricity on the Gd\({}_{5}\)(Si,Ge)\({}_{4}\) magnetocaloric effect leading to the observation of a multicaloric effect; thus, enabling the advancement of device engineering1,17,18.

Results

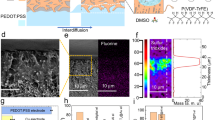

The SEM micrograph shown in Fig. 1 revealed that, by sieving the Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) (GSG) milled ingot, a thin powder with an average particle size of 3.4 \(\pm \) 0.7 \(\mu \)m is achieved, as obtained through the histogram of Fig. 1(b). These microparticles were blended with 2 and 12 wt.% concentration into PVDF through solvent casting technique. From the cross-section image of freeze-fractured GSG/PVDF composite, depicted in Fig. 1(c), it is noticeable the well dispersed magnetic microparticles along the polymer volume. As can be seen from Fig. 1(d,e), the polymer morphology does not suffer significant changes when GSG concentration is increased, which is in agreement with the observed for undrawn PVDF membranes19,20,21. Furthermore, from pure PVDF to 12 wt.% composite, the cross-section images reveal that the thickness remains unaltered at around 200 \(\mu \)m.

SEM micrographs for (a) Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) powder with average particle size of 3.4 \(\mu \)m, as obtained through the log-normal distribution shown in (b). The cross-section micrograph for 2 wt.% sample in (c) reveals the powder distribution along PVDF thickness. (d) 2 wt.% and (e) 12 wt.% PVDF/GSG composite surface images reveal a good dispersion of the 3.4 \(\mu \)m Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) powder.

The XRD patterns obtained for all samples are shown in Fig. 2(a). The GSG powder presents 76.2% of orthorhombic-I [O(I)] and 22.6% of distorted monoclinic (M) structures and less than 2% of eutectic 5:3-phase (Mn\({}_{5}\)Si\({}_{3}\)-type), a common product of the fast cooling after melting22. Such phase analysis was performed through Rietveld calculations and the obtained lattice parameters for O(I), M and 5:3 phases are displayed in the Supplementary Fig. S1, in agreement with Reference 23. The main diffraction peak of spurious 5:3 is positioned at 31.2\({}^{o}\) corresponding to (210) diffraction plane - identified with an asterisk in Fig. 2(a). As for the pure PVDF and blended systems, the patterns reveal a good crystallinity degree for the polymeric matrix. PVDF is a semi-crystalline plastic formed by C-H-F chains with arrangements mainly observed in three different crystalline structures: \(\alpha \)-, \(\beta \)- and \(\gamma \)-phase24. A LeBail calculation for pure PVDF pattern was performed and is presented in the Supplementary Fig. S2, revealing a majority formation of electroactive (EA) \(\beta \)- and \(\gamma \)-phases. For the composite samples, due to the large amount of crystallographic phases from filler and polymeric matrix and reduced peak intensities, a reliable pattern fitting was not possible to be performed. Furthermore, the absence of additional peaks suggests that there was no contamination during powder manipulation for the composite preparation.

(a) XRD patterns of GSG powder, pure PVDF and the composite samples with 2 and 12 wt.%. The main peaks of O(I) and the secondary M structure are highlighted, which are also observed for the composites. The Bragg positions of PVDF crystallographic \(\alpha \)-, \(\beta \)- and \(\gamma \)-type structures are indicated for the composite samples. (b) FTIR absorption curves for PVDF and composite samples with the modes of vibration indexed for each \(\alpha \)-, \(\beta \)- and \(\gamma \)-phases.

Fourier-transform infrared spectroscopy (FTIR) measurements were performed to quantify the amount of EA-phases in the pure PVDF and composite samples, shown in Fig. 2(b), where the exclusive peak for each crystal structure will be used to distinguish their formation25. These peaks are identified in Fig. 2(b) for the three main phases \(\alpha \), \(\beta \) and \(\gamma \) at 763 cm\({}^{-1}\), 1275cm\({}^{-1}\) and 1234cm\({}^{-1}\), respectively, confirming the XRD analysis on the formation of these C-H-F chains for all samples.

The normalized magnetization \(M/{M}_{S}\) curves as a function of temperature, for low values of applied magnetic fields, are shown in Fig. 3(a). The thermal hysteresis between cooling (blue arrow) and heating (red arrow) M-T curves for the GSG starting powder is an evidence of a first order magnetic transition (FOMT) attributed to the M-phase of the Gd\({}_{5}\)(Si,Ge)\({}_{4}\) compounds family26. This is translated into a bump on the temperature derivative curves of magnetization for the powder and for the composite samples, as highlighted in Fig. 3(b). When the powder is implemented into PVDF, the M-phase transition is conserved with the same T\({}_{C}\) around 254 K. The ferro- to paramagnetic (FM-PM) transition of the O(I)-phase occurs at 308 K and is in accordance with previous reports on this composition23,27. Figure 3(c–e) shows the M(T,H) map for each sample, focusing on the evaluation of the magnetocaloric properties. As observed for magnetic composites, the dilution of the ferromagnetic powder in the diamagnetic polymer matrix leads to a reduction in the saturation magnetization values28.

(a) Normalized magnetization \(M/{M}_{S}\) curves as a function of temperature and (b) its temperature derivative curves with the indication on the M-phase transition region and the O(I)-phase Curie temperature. Magnetization isotherms curves for (c) 2 wt.%, (d) 12 wt.% PVDF/GSG composites and (e) for the powder.

The temperature dependence of ME coefficient for 2 wt.% and 12 wt.% PVDF/GSG composite samples is presented in Fig. 4(a,b), respectively. A maximum in the ME coefficient is observed around \( \sim \)305 K which shifts by increasing \({H}_{DC}\) bias magnetic field. As can be noted, from 2 to 12 wt.% of filler content, there is a 10\(\times \) enhancement in the ME coefficient. These maxima in the \({\alpha }_{ME}\)-T curves can be attributed to strong magnetoelectric ordering near \({T}_{C}\). In Fig 4, by increasing \({H}_{DC}\) bias magnetic field, the ME effect increases and reaches the maximum value at a bias field of 5 kOe; then the ME coefficient decreases slowly as the magnetic \({H}_{DC}\) increases. The ME-coupling is closely related to the magnetostrictive behavior of the GSG component26. The initial gain in ME coefficient can be attributed to the enhancement of the domain wall movement and the rotation of GSG particles, which facilitates the magnetostriction in the GSG phase. When the bias field approaches 10 kOe, the magnetic field induced strain in GSG micropowders begin to reach saturation. As a result, above 5 kOe, the ME output voltage generated from the mechanical interaction between the phases decreases.

Discussion

As aforementioned, the coupling between the magnetic and electric orderings of a multicomponent system rises from interfacial interactions8. For this reason, the morphology of the produced samples was first analysed through microscope imaging, where the formation of pores for the composites reveals that PVDF nucleates around the particles into a complex structure, with formation of air gaps19,29,30. The observed surface profile for the pure PVDF films, however, is in good agreement with previous systems submitted to thermal treatments to improve \(\beta \)-phase formation with lower porosity levels31. This evidence can be related to the chemical ratio quantities and the temperature control during the solvent evaporation32.

In this regard, it is important to evaluate the crystallographic and magnetic features of the constituents. The structural characterization of the magnetic filler revealed the formation of magnetostrictive M-phase on the 3.4 \(\mu \)m powder, that is required for the ME-coupling. As for the electroactive polymer, the XRD analysis has shown a majority formation of EA-phases, responsible for the piezo- and pyroelectric effects of PVDF. However, since PVDF usually presents \( \sim \)50% of crystallinity degree21, the amount of EA-phase formation will be inferred from the FTIR measurements presented in Fig. 2(b). This can be performed by considering the exclusive peaks of \(\alpha \)-phase at 763 cm\({}^{-1}\) and the common peak associated with the vibration modes of the EA-phases, namely, \(\beta \) and \(\gamma \), placed at 839cm\({}^{-1}\)25. The quantification of EA-phase is then calculated using the relative intensities through the following equation25:

where \({I}_{EA}\) and \({I}_{763}\) are the absorbance intensity of each phase. The constants \({K}_{763}\) and \({K}_{840}\) are related to the absorption coefficients associated with each wavenumber with values of 7.7\(\times \)10\({}^{-4}\) cm\({}^{2}\)mol\({}^{-1}\) and 6.1\(\times \)10\({}^{-4}\) cm\({}^{2}\)mol\({}^{-1}\), respectively25. The obtained results are shown in Fig. 5(a) revealing a slight increase in the amount of EA-phases from pure PVDF to 12 wt.% GSG/PVDF composite, corroborating XRD analysis. The enhancement of EA-phases formation and stabilization on PVDF due to the presence of fillers has been reported previously14,19,20,24,33. The piezoelectric \({d}_{33}\) coefficient for the pure PVDF and composite samples is also depicted in Fig. 5(a), revealing the same increasing trend of the electroactive phases in the material. We observe therefore an enhancement of the piezoelectric response by increasing the filler content, in agreement with previous reports14,30,32. Such observations will be important for the evaluation of the ME-coupling on the produced multiferroic samples.

(a) (left axes) The amount of electroactive phases obtained through the FTIR measurements using Eq. 1 and (right axes) the d\({}_{33}\) piezoelectric coefficient measured for pure PVDF and composites. Atomic force microscopy for 12 wt.% composite obtained at both sides (b) top and (c) bottom revealing that PVDF chains nucleates around the magnetic grains.

It is important to highlight that the pyroelectricity of PVDF - where the temperature change leads to polarization variations - affects the caloric response of the composite34. In fact, from the morphology evaluation, it was observed the formation of air gaps around the grains that, for MCE applications, favours the heat exchange during machine operation35,36. Despite the formation of porous, there is a good bonding between grains and matrix; however, due to the different scattering of each component, it is not possible to ensure a complete covering of the fillers. In order to observe the connections between the grains and the matrix, atomic force microscopy (AFM) measurements were carried out, shown in Fig. 5(b,c). The obtained 3D map for 12 wt.% composite in a selected area of 25 × 25 \(\mu \)m\({}^{2}\) shows a continuous view over the polymer surface where the magnetic particles are covered by PVDF. Images of the opposite side in Fig. 5(c) confirm that all the particles are completely hidden by the polymer. The larger structures present diameters around \( \sim \)8 \(\mu \)m, indicating that the polymer layer surrounding the micropowders must be around \( \sim \)3 \(\mu \)m in thickness. As illustrated in Fig. 5, the C-H-F chains of the PVDF arrange around the GSG grains during the cast, suggesting that the presence of a magnetic material is influencing the polymer matrix nucleation kinetics24,30. This fact will be of great matter for the ME-coupling, where the electric polarization in the piezoelectric phase is driven by the grains displacement during magnetization8.

Concerning the magnetic behavior, there is no shift in \({T}_{C}\) of the powder for the 2 wt.% and 12 wt.% composites, as observed for other blended systems, revealing no major influence from the ferroelectric polymer on the filler intrinsic magnetic features13,14,37. The Gd\({}_{5}\)(Si,Ge)\({}_{4}\) family compounds have a strong magnetic and structural coupling and, for this reason, magnetic analysis can be used to infer the amount of each phase22,38. This was performed through the reciprocal magnetic susceptibility curves, considering the contribution of each phase - as detailed in the Supplementary Information Document, based on the References22,38. The best fittings to the data are presented in Fig. 6(a) and the corresponding free parameters listed in Table 1. As can be noted from the reciprocal magnetic susceptibility (\({\chi }^{-1}\)), the diamagnetic contribution of PVDF (\({\chi }_{0}\)) is more evident for the sample with lower GSG content, due to the ferromagnetic dilution. The \({\theta }_{P}\) values for the main phases in Table 1 suffer a slight reduction from powder to 2 wt.% composite, because of the grains dilution along the polymeric chain. It is worth pointing out that the glass transition temperature (T\({}_{g}\)) for the amorphous phase of PVDF is around 233 K, where the matrix deformations during melting must be affecting the system magnetic response39. PVDF is a diamagnetic material; however, the \(\beta \)-phase presents a net nonzero dipole moment which can interact with the embedded particles that can be the responsible for the associated errors of the fit parameters40. Furthermore, the paramagnetic effective moment (\({\mu }_{eff}\)) values - obtained through the relation \(C={\mu }_{eff}^{2}/3{k}_{B}\) - are within the error for the theoretical expected for Gd\({}^{3+}\) for the main O(I)-phase and for reported values on 5:3 binary phase22,35,41. Gd\({}_{5}\)(Si,Ge)\({}_{4}\) compositions with a M-structure present high sensitivity to external parameters and, for this reason, there is a reduction in the \({\mu }_{eff}\) values that can be an effect of PVDF walls on the grains surface during the FM-PM transition37. Nevertheless, from the data obtained at low temperature (5 K), we could extract the saturation magnetization (\({\mu }_{sat}\)) values by extrapolating the M versus 1/H curve. For the O(I)-phase, the \({\mu }_{sat}\) value is expected to be 7.41 \({\mu }_{B}\) due to the extra contribution from 5d orbitals of Si and Ge38; however, due to the formation of M and 5:3 phase there is a reduction in \({\mu }_{sat}\) for the powder. The \({\mu }_{sat}\) lower values for the composite samples are a result of magnetic material dilution that can generate dipolar interactions between the smaller grains inside the electroactive polymer40,42.

(a) Reciprocal magnetic susceptibility curves for the free powder and composite samples with the best fittings of the modified Curie-Weiss law by considering the contribution of each crystallographic structure. The ME voltage coefficient \({\alpha }_{ME}\) as a function of DC magnetic field for (b) 2 wt.% and (c) 12wt.% PVDF/GSG composite samples at 305 K with the fitted curve considering the thermally mediated mechanism on the ME coupling given by Eq. 6.

The ME effect in a 0-3 type multiferroic composite is strongly dependent on the connection between magnetostrictive and piezoelectric components. Some interesting theoretical and experimental results were obtained in Reference9 for multiferroic PVDF based composite spheres, where it was concluded that particles with 1.4 \(\mu \)m size have higher ME-coupling. In this study, since the GSG particles have random shapes, the described models cannot be applied for a clear explanation of interfacial effects. Therewith, it should be noted that our magnetic component, Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\), is a material with large magnetocaloric effect around the Curie temperature that can also contribute to the total ME effect34. From first-principle calculations, it was demonstrated that the intrinsic thermodynamic features of a hybrid system can be used to tune the ME-coupling16. To understand this mechanism, we should first write the ME-coupling in terms of the adiabatic temperature change \(\Delta T\) - from the magnetocaloric effect - and the temperature, as follows:

For the GSG magnetocaloric material, the adiabatic temperature change (\(\Delta T\)) can be given by the Belov-Goryaga equation34,43:

where the phenomenological coefficients are \({a}_{1}={a}_{T}({T}_{C}-T)\) and a2, \(k={a}_{T}T/C\), with aT being a temperature independent constant and \(C\), the heat capacity. Thus, at low DC applied magnetic field regime, the dominant term is \(\Delta T\propto \)\({H}^{2}\); and, for high magnetic fields, \({H}^{2/3}\) is the predominant one34. In this way, the main derivative terms considering different regimes of applied DC field regimes can be written as follows:

Hence, given the thermally mediated mechanism, the ME coefficient can be described by the following relation:

with \({c}_{1}\) and \({c}_{2}\) being the constants related to the two first derivative terms in Eq. 2.

To confirm this behavior, a curve fit on the field dependence of \({\alpha }_{ME}\) was performed considering the above function, that is shown in Fig. 6(b,c) for the 2 wt.% and 12 wt.% composites, respectively. As can be noted, the higher coefficient below the saturation is associated with the linear term (\({c}_{2}\)) and at the high DC field regime, the \({c}_{1}\) parameter that is related to the power term of Eq. 6 has the larger value, confirming the mechanism description given above. Finally, with these phenomenological observations, it should be concluded that the ME effect in PVDF/GSG composites is a result of the elastic cooperation between magnetostrictive and piezoelectric components behavior with a contribution from a thermal mediation arising from the components magnetocaloric and pyroelectric features.

The adiabatic entropy change was calculated with the M(T,H) maps using the Maxwell-relation \(\partial M/\partial T=\partial S/\partial H\), due to the absence of irreversibility between the magnetization curves by increasing and decreasing the applied magnetic field23,27,44,45. Therewith, the \(\Delta {S}_{M}(T)\) curves for all samples, considering the weight fraction of magnetic material and for a field variation of 5 T, could be obtained as shown in Fig. 7(a). The maximum values (\(\Delta {S}_{M}^{max}\)) range from 2.88 to 3.10 J/kg.K from powder to 2 wt.% composite, indicating no effect of PVDF matrix on the FM-PM transition at 308 K. However, the \(\Delta S\) curve profile suffers a drastic change in the [230–295]K temperature range: for the powder, there is a lump due to the thermal hysteresis of M-phase; 12 wt.% composite shows a deviation from the powder curve at 265 K and 2 wt.% curve has a linear growth above 230 K. Such differences strongly suggest that indeed there is a coupling between the ferroelectric phases of PVDF and the magnetic phase of GSG, which enlarges the ME-coupling presented in the previous section. The glass transition of amorphous \(\alpha \)-phase occurs around 220 K, that leads to relaxation of semicrystalline chains with a small associated pyroelectric effect that vanishes around 275 K34,46. For 2 wt.% sample, due to the low amount of filler, the effect is nearly null at the 200-300 K temperature range. With higher filler contents, however, the pyroelectricity contribution to the \(\Delta S\) curve becomes more evident, implying the interaction between the electroactive PVDF and the grains8,34. For engineering applications, the most effective unit for the change in entropy is the volumetric one \(\Delta {S}_{V}\)47, depicted in Fig. 7(b). The \(\Delta {S}_{V}^{max}\) values naturally decrease from \( \sim \)24 mJ/cm\({}^{3}\)K for the starting powder to \( \sim \)6.62 mJ/cm3 K and 0.10 mJ/cm3 K when implemented into PVDF with 12 and 2 wt.%, respectively. Nevertheless, the relative cooling power - which is a more effective parameter for device implementation - calculated at the 220–330K temperature interval is 9.50 mJ/cm\({}^{3}\) and 638 mJ/cm\({}^{3}\) for the 2 and 12 wt.% composites, respectively.

The combination of materials with multiple caloric effects, the so-called multicaloric materials, is a new topic of research for improving alternative cooling technologies1. As pointed out by Vopson, systems presenting two primary ferroic orderings simultaneously, the multiferroic materials, are the main candidates to present giant caloric effects3. Among the required conditions, the materials must present low heat capacity, large ME-coupling coefficient and low magnetic/electric hysteresis. For the present case, the \({\alpha }_{ME}\) of 2.2 V/cm.Oe obtained for 12 wt.% composite is among the largest ME responses when compared with other 0-3 type composites reported on literature48, which is affecting the system MCE response. In this way, the cross-coupling effect should be taken into account for the isothermal entropy change of the system under the influence of an applied magnetic field. The alignment of magnetic particles along the polymeric matrix induces an electric polarization (\({P}_{ind}\)) and, consequently, an internal electrical field (\({E}_{ind}\)). If we assume a linear ME-effect, the induced field in the system is3:

with \({\epsilon }_{0}\) being the vacuum permittivity and \({\chi }^{e}\), the electrical susceptibility. In this way, the total entropy change of the multicomponent system, when a magnetic field is applied, derived from the generalized Maxwell relations in Reference3, is given as follows:

The curves presented in Fig. 7 were indirectly obtained through the first term of Eq. 8, that can be simply denoted as \(\Delta {S}_{M}\). Rearranging this relation for the calculated \(\Delta {S}_{M}\) we obtain:

The polarization derivative term represents the pyroelectric effect that, in the present system, rises from the PVDF electroactive phase relaxation3,46. Hence, the polymer ferroelectricity is contributing to the magnetic entropy change which justifies the deviation from the powder curve observed around 270 K for 12 wt.% composite. It is important to point out the dependence on the ME coefficient, which is also affecting the composite caloric behavior. For this reason, the understanding on the mechanisms between each phase in a multiferroic composite system is relevant from a fundamental point of view aiming prototype development. In this sense, in order to completely understand the mechanism behind the coupling between magnetic and electric phase orderings on the multicomponent system, an evaluation of the electrocaloric response of the samples should be performed2. Nevertheless, these results reveal that the cross-coupling effects play a role on the MCE behaviour of GSG/PVDF composites which can be used to tune these features for future applications3,28,40.

Conclusions

In this study we have experimentally demonstrated that the introduction of Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) microparticles into an electroactive PVDF with a volume fraction of 2 and 12 wt.% gives rise to a magnetoelectric coupling and, consequently, a multicaloric effect. Morphological and structural characterization revealed an improvement in the polar \(\beta \)- and \(\gamma \)-phases on the PVDF due to the magnetic filler, that is responsible for the piezo- and pyroelectric effects. As a result, a large ME response of 2.2 V/cm.Oe is observed for 12 wt.% of powder concentration. Similarly, this strong coupling between magnetic and electric orderings on the produced composites lead to unexpected variations in the magnetic entropy change curves when compared with the pure magnetic material. The change of the powder magnetocaloric response can be attributed to the pyroelectricity character of the polymer, where the increase of temperature induces polarization variations in the polymeric matrix3. These results reveal the great potential of Gd\({}_{5}\)(Si,Ge)\({}_{4}\) family for applications as sensors and energy harvesting by the combination with polymeric matrices even with low magnetic material concentration.

Methods

Samples production

Tri-arc melting technique was used for the preparation of magnetic material with Gd\({}_{5}\)Si\({}_{2.4}\)Ge\({}_{1.6}\) (GSG) stoichiometry, as described in Reference27. The microparticles were produced by sifting the as-cast ingot powder through a sequence of strainers with hole sizes from 50 \(\mu \)m to 5 \(\mu \)m. The obtained powder was blended with poly(vinylidene) fluoride (PVDF) using the solvent casting technique. For this procedure, PVDF powder (acquired from Alfa Aesar, 44080) was dissolved in dimethylformamide (DMF) (from Sigma, 227056-1L) with a weight ratio of 1:30 in a hot plate at 310 K to obtain a final solution with a volume of 1 ml. The amount of magnetic material dispersed on the suspension was weighted with 2% and 12% weight fractions of PVDF. Subsequently, the solution dried for a day in exhaust hood.

Characterization techniques

SEM micrographs were carried using a Phyllips-FEI/Quanta 400 with 500-10 000\(\times \) magnification with an energy of 15 kV at Material Centre of Porto University (CEMUP). For cross-section imaging, all the composite films were fractured after being frozen in liquid Nitrogen. Structural characterization was performed by means of X-ray Diffraction (XRD) at room temperature using a Rigaku Smartlab with a Cu-K\(\alpha \) radiation, 45 kV and 200 mA at IFIMUP and analyzed using the FullProf Suite Software49. The amount of each crystal phases on the polymorphic PVDF film was obtained through FTIR measurement. Data were collected in the range of 550-1400 cm\({}^{-1}\) at room temperature using a Jasco Deutschland, (Model FT/IR-6100 type A) spectrometer at the absorption mode with a 2 cm\({}^{-1}\) resolution at LAMULT-Unicamp. The piezoelectric coefficient measurements were carried out using a d\({}_{33}\) meter (Model YE2730). All samples were coated with Ag contacts on both sides and were polled by applying an electric field of 20 kV/mm for 1 hour at 50 °C. During poling, the samples were placed in an oil bath with a thermo controller. Magnetic characterization and MCE evaluation were performed using a Superconducting Quantum Interference Device (SQUID) Magnetometer with data collected within the range of [5,350] K under applied magnetic fields up to 5 T at IFIMUP facility.

Magnetoelectric (ME) measurements

Using a custom designed setup in a 77-350 K temperature range at Amirkhanov Institute of Physics, Daghestan Scientific Center. ME effect was studied by measuring a voltage U generated across the sample under superimposed alternating magnetic field \({H}_{AC}\) and static bias magnetic field \({H}_{DC}\), as described in Reference50. The ME signal was measured by a lock-in amplifier (Stanford research system, Model SR830) and AC magnetic field was generated by internal waveform generator of SR830. The amplitude of AC magnetic field was \( \sim \)10 Oe with 50–70 kHz of frequency, as pointed in Fig. S3, and DC magnetic field was applied in 0-18 kOe range. The ME coefficient \({\alpha }_{ME}\) is defined using the relation:

where \({U}_{AC}\) is the magnetically induced AC output voltage across the plane of the sample, \({H}_{AC}\) is the amplitude of the AC magnetic field and \(b\) is the sample thickness. ME coefficient was measured in mode, where the applied bias magnetic field \({H}_{DC}\) is parallel to the direction of ME voltage (\({H}_{DC}\)\(\parallel \) U) and perpendicular to the plane of sample. The samples used for magnetoelectric measurements have the shape of thin rectangular plates with sizes of 0.26 \(\times \)4 \(\times \) 7 mm and 0.17 \(\times \) 4 \(\times \) 3 mm, for 2 wt.% and 12 wt.% composites, respectively.

Data availability

All data generated or analysed during this study are included in this published article (and its Supplementary Information files).

References

Stern-Taulats, E. et al. Multicaloric materials and effects. MRS Bulletin 43, 295–299 (2018).

Liu, Y. et al. Large reversible caloric effect in FeRh thin films via a dual-stimulus multicaloric cycle. Nature Communications 7, 11614 (2016).

Vopson, M. M. Theory of giant-caloric effects in multiferroic materials. Journal of Physics D: Applied Physics 46, 345304 (2013).

Ursic, H. et al. A multicaloric material as a link between electrocaloric and magnetocaloric refrigeration. Scientific reports 6, 26629 (2016).

Gottschall, T. et al. A multicaloric cooling cycle that exploits thermal hysteresis. Nature Materials 17, 929 (2018).

Li, B. et al. Colossal barocaloric effects in plastic crystals. Nature 567, 506 (2019).

Liu, Y. et al. Towards multicaloric effect with ferroelectrics. Physical Review B 94, 214113 (2016).

Fiebig, M. Revival of the magnetoelectric effect. Journal of Physics D: Applied Physics 38, R123 (2005).

Fernández, C. L., Pereira, N., Lanceros-Mendez, S. & Martins, P. Evaluation and optimization of the magnetoelectric response of CoFe2O4 /poly (vinylidene fluoride) composite spheres by computer simulation. Composites Science and Technology 146, 119–130 (2017).

Martins, P. & Lanceros-Méndez, S. Polymer-based magnetoelectric materials. Advanced Functional Materials 23, 3371–3385 (2013).

Laletin, V., Filippov, D. & Firsova, T. The nonlinear resonance magnetoelectric effect in magnetostrictive-piezoelectric structures. Technical Physics Letters 40, 237–240 (2014).

Nan, C.-W., Bichurin, M., Dong, S., Viehland, D. & Srinivasan, G. Multiferroic magnetoelectric composites: historical perspective, status, and future directions. Journal of Applied Physics 103, 1 (2008).

Ozaydin, M. & Liang, H. Multi-energy conversion of Gd5(Si2Ge2)-Poly(vinylidene fluoride), a hybrid material. Applied Physics Letters 105, 062903 (2014).

Harstad, S. et al. Enhancement of β-phase in PVDF films embedded with ferromagnetic Gd5Si4 nanoparticles for piezoelectric energy harvesting. AIP Advances 7, 056411 (2017).

Nersessian, N. et al. Gd5Si2Ge2 composite for magnetostrictive actuator applications. Applied physics letters 84, 4801–4803 (2004).

Chang, C.-M., Mani, B., Lisenkov, S. & Ponomareva, I. Thermally mediated mechanism to enhance magnetoelectric coupling in multiferroics. Physical Review Letters 114, 177205 (2015).

Franco, V. et al. Magnetocaloric effect: from materials research to refrigeration devices. Progress in Materials Science 93, 112–232 (2018).

Belo, J. et al. Critical magnetic behavior of magnetocaloric materials with the Gd5Si4-type structure. Journal of Applied Physics 113, 133909 (2013).

Kim, G. H., Hong, S. M. & Seo, Y. Piezoelectric properties of poly(vinylidene fluoride) and carbon nanotube blends: β-phase development. Physical Chemistry Chemical Physics 11, 10506–10512 (2009).

Ong, W., Gao, M. & Ho, G. Hybrid organic PVDF-inorganic M-rGO-TiO2 (M = Ag, Pt) nanocomposites for multifunctional volatile organic compound sensing and photocatalytic degradation-H2 production. Nanoscale 5, 11283–11290 (2013).

Ducrot, P.-H., Dufour, I. & Ayela, C. Optimization of PVDF-TrFE processing conditions for the fabrication of organic MEMS resonators. Scientific reports 6, 19426 (2016).

Belo, J. et al. Phase control studies in Gd5Si2Ge2 giant magnetocaloric compound. Journal of Alloys and Compounds 529, 89–95 (2012).

Misra, S. & Miller, G. J. On the distribution of tetrelide atoms (Si, Ge)in Gd5(SixGe1-x)4. Journal of Solid State Chemistry 179, 2290–2297 (2006).

Salimi, A. & Yousefi, A. Conformational changes and phase transformation mechanisms in PVDF solution-cast films. Journal of Polymer Science Part B: Polymer Physics 42, 3487–3495 (2004).

Cai, X., Lei, T., Sun, D. & Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Advances 7, 15382–15389 (2017).

Pecharsky, V. K. & Gschneidner, K. A. Jr Gd5(SixGe1 -x)4 : an extremum material. Advanced Materials 13, 683–686 (2001).

Pecharsky, V. & Gschneidner, K. Phase relationships and crystallography in the pseudobinary system Gd5Si4-Gd5Ge4. Journal of Alloys and Compounds 260, 98–106 (1997).

Imamura, W. et al. A new type of magnetocaloric composite based on conductive polymer and magnetocaloric compound. Journal of Magnetism and Magnetic Materials 425, 65–71 (2017).

Mago, G., Kalyon, D. M. & Fisher, F. T. Membranes of polyvinylidene fluoride and PVDF nanocomposites with carbon nanotubes via immersion precipitation. Journal of Nanomaterials, 200817.2008.

Elmezayyen, A. S., Reicha, F. M., El-Sherbiny, I. M., Zheng, J. & Xu, C. Significantly enhanced electroactive β phase crystallization and UV-shielding properties in PVDF nanocomposites flexible films through loading of ATO nanoparticles: synthesis and formation mechanism. European Polymer Journal 90, 195–208 (2017).

Gregorio, R. Jr Determination of the α, β, and γ crystalline phases of poly(vinylidene fluoride) films prepared at different conditions. Journal of Applied Polymer Science 100, 3272–3279 (2006).

Soin, N. et al. Exclusive self-aligned β-phase PVDF films with abnormal piezoelectric coefficient prepared via phase inversion. Chemical Communications 51, 8257–8260 (2015).

Gomes, J., Nunes, J. S., Sencadas, V. & Lanceros-Méndez, S. Influence of the β-phase content and degree of crystallinity on the piezo-and ferroelectric properties of poly(vinylidenefluoride). Smart Materials and Structures 19, 065010 (2010).

Lu, S. et al. Thermally mediated multiferroic composites for the magnetoelectric materials. Applied Physics Letters 96, 102902 (2010).

Reis, M. Fundamentals of magnetism (Elsevier, 2013).

Kitanovski, A. & Egolf, P. W. Innovative ideas for future research on magnetocaloric technologies. International Journal of Refrigeration 33, 449–464 (2010).

Zhang, H. et al. Mechanical properties and magnetocaloric effects in La(Fe, Si)13 hydrides bonded with different epoxy resins. Journal of Applied Physics 117, 063902 (2015).

Andrade, V.M.et al. Lanthanum dilution effects on the giant magnetocaloric Gd5Si1.8Ge2.2 compound. Physica Status Solidi (b) (2018).

Stolbov, O. V., Raikher, Y. L. & Balasoiu, M. Modelling of magnetodipolar striction in softmagnetic elastomers. Soft Matter 7, 8484–8487 (2011).

Ouyang, Z.-W., Chen, E.-C. & Wu, T.-M. Thermal stability and magnetic properties of polyvinylidene fluoride/magnetite nanocomposites. Materials 8, 4553–4564 (2015).

Roger, J., Babizhetskyy, V., Hiebl, K., Halet, J.-F. & Guérin, R. Structural chemistry, magnetism and electrical properties of binary Gd Silicides and Ho3Si4. Journal of Alloys and Compounds 407, 25–35 (2006).

Kechrakos, D. & Trohidou, K. Competition between dipolar and exchange interparticle interactions in magnetic nanoparticle films. Journal of Magnetism and Magnetic Materials 262, 107–110 (2003).

Franco, V. et al. Field dependence of the adiabatic temperature change in second order phase transition materials: Application to Gd. Journal of Applied Physics 106, 103911 (2009).

Amaral, J. & Amaral, V. The effect of magnetic irreversibility on estimating the magnetocaloric effect from magnetization measurements. Applied Physics Letters 94, 042506 (2009).

Andrade, V. et al. Magnetocaloric functional properties of Sm0.6Sr0.4MnO3 manganite due to advanced nanostructured morphology. Materials Chemistry and Physics 172, 20–25 (2016).

Stavrakas, I., Triantis, D., Photopoulos, P., Kanapitsas, A. & Tsonos, C., Thermally stimulated discharge current (TSDC) characteristics in PVDF-graphene nanocomposites International Conference ’Science inTechnology’ SCinTE 2015 2.

Gschneidner, K. A. Jr, Pecharsky, V. & Tsokol, A. Recent developments in magnetocaloric materials. Reports on Progress in Physics 68, 1479 (2005).

Leung, C. M., Li, J., Viehland, D. & Zhuang, X. A review on applications of magnetoelectric composites: from heterostructural uncooled magnetic sensors, energy harvesters to highly efficient power converters. Journal of Physics D: Applied Physics 51, 263002 (2018).

Rodríguez-Carvajal, J. Recent developments of the program FULLPROF. Commission on powder diffraction (IUCr).Newsletter 26, 12–19 (2001).

Calisir, I., Amirov, A. A., Kleppe, A. K. & Hall, D. A. Optimisation of functional properties in lead-free BiFeO3-BaTiO3 ceramics through La3 substitution strategy. Journal of Materials Chemistry A 6, 5378–5397 (2018).

Acknowledgements

This work is funded by FEDER funds through the COMPETE 2020 Programme and National Funds throught FCT - Portuguese Foundation for Science and Technology under the projects POCI-01-0145-FEDER-029454, POCI-01-0145-FEDER-032527 and UID/FIS/04564/2016. This work was also supported by NECL with the project NORTE-01-0145-FEDER-022096 and by the European Union Horizon - 2020 research and innovation program under the Marie Sklodowska-Curie Grant Agreement No. 734801. The authors acknowledge K. Pirota and F. Beron for the FTIR measurements performed at Unicamp in Brazil. Special thanks to Dr. A. Aliev for help in automatizing the ME experiments at Amirkhanov Institute of Physics and the helpful discussions. Federal Fluminense University, Brazil, permanent address for MSR; Aveiro University, Portugal, temporary address during this work for MSR. VMA thanks the CNPq for the Grant No. 203180/2014-3. A.A. acknowledges Russian Science Foundation for support magnetoelectric studies (grant No. 18-79-10176). J.H. Belo thanks FCT for Grant No. SFRH/BD/88440/2012, Project PTDC/FISMA/31302/2017, and his contract No. DL57/2016 reference SFRH-BPD-87430/2012. Finally, the discussion of results has been made possible through the mobility grant provided by the 5 top 100 Russian Academic Excellence Project at the Immanuel Kant Baltic Federal University.

Author information

Authors and Affiliations

Contributions

N.B., A.L.P., J.H.B. and A.M.P. produced the powder and composite samples. V.M.A. performed the structural, magnetic and magnetocaloric measurements and analyses. B.P. prepared figure 3. A.A. and D.Y. performed the ME-measurements and analysis. V.M.A., A.A. and M.S.R. wrote the main text. M.A.V and J.P.A. contributed with expertise on multiferroic and magnetocaloric materials, discussing special issues of the work. All authors attended to scientific meetings and, in addition, delivered a comprehensive and detailed reading of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Andrade, V.M., Amirov, A., Yusupov, D. et al. Multicaloric effect in a multiferroic composite of Gd5(Si,Ge)4 microparticles embedded into a ferroelectric PVDF matrix. Sci Rep 9, 18308 (2019). https://doi.org/10.1038/s41598-019-54635-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-54635-8

This article is cited by

-

Materials, physics and systems for multicaloric cooling

Nature Reviews Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.