Abstract

Finding out robust active and sustainable catalyst towards alcohol electro-oxidation reaction is major challenges for large-scale commercialization of direct alcohol fuel cells. Herein, a robust Pt nanowires (NWs)/Ti0.7W0.3O2 electrocatalyst, as the coherency of using non-carbon catalyst support and controlling the morphology and structure of the Pt nanocatalyst, was fabricated via an effortless chemical reduction reaction approach at room temperature without using surfactant/stabilizers or template to assemble an anodic electrocatalyst towards methanol electro-oxidation reaction (MOR) and ethanol electro-oxidation reaction (EOR). These observational results demonstrated that the Pt NWs/Ti0.7W0.3O2 electrocatalyst is an intriguing anodic electrocatalyst, which can alter the state-of-the-art Pt NPs/C catalyst. Compared with the conventional Pt NPs/C electrocatalyst, the Pt NWs/Ti0.7W0.3O2 electrocatalyst exhibited the lower onset potential (~0.1 V for MOR and ~0.2 for EOR), higher mass activity (~355.29 mA/mgPt for MOR and ~325.01 mA/mgPt for EOR) and much greater durability. The outperformance of the Pt NWs/Ti0.7W0.3O2 electrocatalyst is ascribable to the merits of the anisotropic one-dimensional Pt nanostructure and the mesoporous Ti0.7W0.3O2 support along with the synergistic effects between the Ti0.7W0.3O2 support and the Pt nanocatalyst. Furthermore, this approach may provide a promising catalytic platform for fuel cell technology and a variety of applications.

Similar content being viewed by others

Introduction

Low-temperature fuel cell systems have been attracted more and more attention as a promising green power technology to overcome environmental and energy issues in the 21st century. Compared to hydrogen-oxidation fuel cells, direct alcohol fuel cells (DAFCs) exhibited many advantages; namely, high conversion efficiency, high power density, and readily storage as well as facile transportation1. Up to now, carbon-supported Pt catalysts have widely utilized for both anode and cathode2, however, electrochemical corrosion of the carbon support3 causes the dissolution/detachment, Ostwald ripening, aggregation4,5 of the Pt nanocatalysts and thus the fuel cell performance is drastically deteriorated in long-term operation. In view of the above issues, numerous efforts have been devoted to designing non-carbon catalyst supports, which possess high corrosion resistance and strong interplay with the Pt nanocatalyst. Recently, M-doped TiO2 materials have emerged as a robust catalyst support in fuel cell applications owing to the synergistic effects with platinum catalyst leading to the improvement of both electrocatalytic stability and activity of the Pt-based electrocatalysts2,6,7,8,9,10.

At this juncture, the Pt nanoparticles (zero-dimensional) structures were commonly utilized in fuel cell systems11, however, the zero-dimensional possess some restrictions; namely, a high number of low coordination atoms and surface defects11,12 that directly affect their electrocatalytic activity and durability. To date, tuning the morphology and structure of the Pt catalyst has been proven to be a forward-looking approach to enhance both the activity and durability of the electrocatalyst5,13,14. Compared with the zero-dimensional structures, the one-dimensional structure like nanowires possessed many advantages; namely, the high surface-area-to-volume ratio, low number of surface defects, smooth single-crystalline and ability to prevent the particle agglomeration and coalescence of the Pt nanocatalysts11,13,14, resulting in good sensitivity and activity of the Pt-based electrocatalyst.

To be the best of our knowledge, there are a limited number of researches on the coherency of the non-carbon catalyst support and one-dimensional Pt nanowires to develop a robust electrocatalyst towards alcohol electro-oxidation reaction. In this work, we demonstrated the Pt NWs/Ti0.7W0.3O2 catalyst toward methanol electro-oxidation and ethanol electro-oxidation which was successfully fabricated via the simple chemical reduction route at room temperature, only using formic acid (HCOOH) as reducing agents. These observational results indicated that the Pt NWs/Ti0.7W0.3O2 is promising anodic catalysts for methanol electro-oxidation reaction (MOR) and ethanol electro-oxidation reaction (EOR), which can alter the conventional Pt NPs/C electrocatalysts. For instance, the robust Pt NWs/Ti0.7W0.3O2 electrocatalyst exhibited the lower onset potential (~0.1 V vs. NHE for MOR and ~0.2 V vs. NHE for EOR), higher mass activity (~355.29 mA/mgPt for MOR and ~325.01 mA/mgPt for EOR) and higher If/Ib ratio (~2.70 for MOR and ~1.35 for EOR) as well as much higher electrochemical stability relative to the Pt NPs/C catalyst. The high mass activity and superior stability of the robust Pt NWs/Ti0.7W0.3O2 electrocatalyst could be derived from combining the merits of the one-dimensional Pt nanostructures and the mesoporous Ti0.7W0.3O2 catalyst support, as well as the synergistic effect between the mesoporous Ti0.7W0.3O2 catalyst support to the Pt nanoforms. Finally, this research can provide robust catalysts platforms for fuel cell technologies and other applications such as solar cells, water splitting.

Results

Characterization of the Pt NWs/Ti0.7W0.3O2 electrocatalysts

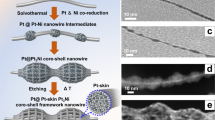

The mesoporous Ti0.7W0.3O2 support was prepared via the one-pot solvothermal route without employing surfactant/stabilizer or further heat treatment8 (see Figs S1–S6, Supplementary Information). In this work, the one-dimensional (1D) Pt nanocatalysts were directly grown on the mesoporous Ti0.7W0.3O2 support via a facile and simple chemical reduction approach at room temperature, only utilizing formic acid (HCOOH) as reducing agents (Fig. 1a). The formed structure lattice of platinum nanowires (NWs) over the Ti0.7W0.3O2 support was investigated by means of X-ray diffraction (XRD) measurement. As can be seen in Fig. 1b, three typical diffraction peaks of face-centered cubic (fcc) structure (JDCPS 04-0802) of the platinum metal were clearly observed at 39.76°; 46.24° and 67.45° with respect to the crystal (111), (200) and (220) facets. Importantly, the strongest peak of platinum metal was located at 39.76° correspond to crystal (111) facets, which implied that the platinum nanocatalysts were formed along the (111) direction. Interestingly, no signal of the segregation of tungsten and titanium dioxide (TiO2) was detected in the XRD pattern (Fig. 1b), suggesting that the mesoporous Ti0.7W0.3O2 catalyst support possessed the highly stable structure in reduction media with the long reaction time. Furthermore, the transmission electron microscopy (TEM) was implemented to investigate the morphology of the Pt nanoforms on the mesoporous Ti0.7W0.3O2 support. Figure 1c,d shows the morphology of Pt nanocatalyst to be the wire-like shape with the length ~40 nm and ~5 nm in diameter. The disuniform size of particles could be interpreted due to the agglomeration phenomena when growing the PtNWs on the surface of the Ti0.7W0.3O2 supports. Besides, TEM images (Fig. S7, Supplementary Information) exhibited the catalyst morphology to be the rhombus and sphere that could be explained due to the agglomeration of support materials and one-dimensional (1D) Pt nanocatalyst which maybe covers overall the surface of Ti0.7W0.3O2 support due to the high Pt loading (50 wt%) on the support. Moreover, HR-TEM image (see Fig. 1e) exhibited the fringe with a lattice spacing of ~2.3 Å corresponding to the (111) crystal plane of fcc Pt, confirming the oriented formation of Pt toward (111) facets on the surface of the supports. The mechanism of the growth of the Pt nanowires (NWs) on the Ti0.7W0.3O2 support could occur in a similar manner to that of Pt NWs on carbon spheres, CNT or other supports that reported in previous works14,15,16,17,18,19. Typically, Pt nuclei are deposited on the surface of support during the reduction of H2PtCl6 by HCOOH. Next, the freshly formed Pt nuclei act as sites for further nucleation via the continual absorption and reduction of Pt (IV) ions resulting in the formation of clustered particles. The very low reduction rate of the formic acid (HCOOH) at room temperature, which environmental favors for the anisotropic development of platinum nuclei along the (111) direction15,16. From this mechanism, Pt nuclei are deposited on the surface of Ti0.7W0.3O2 support during the reduction of H2PtCl6 by HCOOH to form Pt nuclei that act as sites for further nucleation via the continual absorption and reduction of Pt (IV) ions resulting in the formation of clustered particles and form the Pt NWs on the surface of Ti0.7W0.3O2 supports under the very low reduction rate and long-time reaction (72 hours) at room temperature. These outcomes suggest that the simple chemical reduction route using formic acid is a suitable approach to design the Pt NWs/Ti0.7W0.3O2 electrocatalyst.

In order to further investigate the surface characterization of the as-prepared Pt NWs/Ti0.7W0.3O2, Pt NWs/C and Pt NPs/C electrocatalysts, the X-ray photoelectron spectroscopy (XPS) measurement was performed. These XPS results (see Fig. 2) indicated that the Pt 4f5/2 and Pt 4f7/2 peaks of the Pt NWs/C and Pt NPs/C electrocatalyst were located at 74.08 eV and 70.80 eV, respectively, which could be which assigned to zero-valent of Pt20,21. Interestingly, the Pt NWs/Ti0.7W0.3O2 exhibited the Pt 4f5/2 and Pt 4f7/2 at 73.75 eV and 70.47 eV, respectively. It means that the negative shift to the low binding energy of Pt 4 f5/2 and Pt 4f7/2 in the Pt NWs/Ti0.7W0.3O2 catalyst are ascribable to the electronic transfer from Ti0.7W0.3O2 support to the Pt catalysts that carbon support can not exhibit the mechanism2,6,10,22. This results in the downshift d-band center of Pt nanocatalyst6,22, which normally found out in the conventional Pt-M alloy implying that the mesoporous Ti0.7W0.3O2 catalyst support could play a key role as co-catalyst for the Pt metal that a simple carbon support cannot6. The downshift d-band of the Pt nanocatalyst leading to the weak accumulation of absorbed carbonaceous species on platinum catalysts’ active sites2,6 and therefore can significantly enhance the electrocatalytic activity and stability of the Pt NWs/Ti0.7W0.3O2 electrocatalyst versus that of the conventional Pt NPs/C catalyst.

Application of the Pt NWs/Ti0.7W0.3O2 towards methanol electro-oxidation reaction (MOR)

The electrochemical properties of the Pt NWs/Ti0.7W0.3O2 electrocatalysts were investigated and compared to the Pt NWs/C and the traditional Pt NPs/C in N2-purged 0.5 M H2SO4 aqueous solution via the cyclic voltammetry measurements. As can be seen in Fig. 3a, these catalysts show the multiple peaks in the hydrogen adsorption/desorption regions, implying that the high crystallinity of these electrocatalysts11,14,18. The electrochemical surface area (ECSA) of the Pt NWs/Ti0.7W0.3O2, Pt NWs/C, and conventional Pt NPs/C electrocatalysts, calculated from the charge of hydrogen adsorption, are around 63.48 m2/g; 56.73 m2/g, respectively, which is approximate half that of the conventional Pt/C electrocatalyst (~130.32 m2/g) (Fig. 3b). The low ECSA values of the Pt NWs/Ti0.7W0.3O2 and the Pt NWs/C catalysts versus that of the Pt NPs/C could be accounted for the reducing boundaries of the 1D morphology of the nanowires relative to the 0D morphology of the nanoparticles23. Besides, the accelerated durability test (ADT) in N2-purged 0.5 M H2SO4 at a scan rate of 50 mV/s was also employed to investigate the electrochemical stability of as-prepared electrocatalysts. After the 5000 cycling test, the ECSA loss of the Pt NWs/Ti0.7W0.3O2 catalysts was estimated to be 11.89% of initial ECSA value, meanwhile, the ECSA value of Pt NWs/C and conventional Pt NPs/C was significantly degraded to be ~19.33% and ~27.45% of initial ECSA value, respectively (Fig. 3c–e). The enhanced stability of the Pt NWs/Ti0.7W0.3O2 catalyst could be ascribed to the inherent structural and chemical durability and the superior corrosion resistance of the TiO2-based oxide in acidic and oxidative environments6.

The cyclic voltammetry measurement was carried out in N2-purged 10 v/v % CH3OH/0.5 M H2SO4 at a scan rate of 50 mV/s to evaluate the electrocatalytic activity towards methanol electro-oxidation reaction (MOR) of the Pt NWs/Ti0.7W0.3O2 catalyst. Figure 4a compares the CV curves of the Pt NWs/Ti0.7W0.3O2, the Pt NWs/C and the conventional Pt NPs/C electrocatalysts. Compared with other as-obtained electrocatalysts, the Pt NWs/Ti0.7W0.3O2 catalyst exhibited the highest mass activity (355.29 mA/mgPt), which is ~1.23-fold and ~1.57-times higher than those of the Pt NWs/C (288.79 mA/mgPt) and conventional Pt NPs/C (226.40 mA/mgPt) catalysts, respectively, albeit it’s the low electrochemical surface area (ECSA) value. The great electrocatalytic activity of the Pt NWs/Ti0.7W0.3O2 catalysts is ascribable to the formed Pt nanoforms along the (111) orientation, which possessed the most activity towards methanol electro-oxidation owing to the low poisoning rate24. Furthermore, the potential at which the methanol oxidation starts (i.e., the onset potential, Eonset) of the Pt NWs/Ti0.7W0.3O2 catalyst was found to be the lowest (~0.1 V vs. NHE), which is negatively shifted about 200 mV and 350 mV with respect to the Pt NWs/C (~0.3 V vs. NHE) and the conventional Pt NPs/C (~0.45 V vs. NHE) (see Fig. 4b), implying that the methanol electro-oxidation reaction (MOR) on the Pt NWs/Ti0.7W0.3O2 catalyst was performed easier and faster than the Pt NWs/C and Pt NPs/C electrocatalyst. Consequently, the ratio of the forward peak current density (If) and a negative-going current density (Ib) is generally represented the resistance to the poisoning of the accumulation of carbonaceous species2,25. Interestingly, the Pt NWs/Ti0.7W0.3O2 catalyst exhibited the highest If/Ib values in comparison with the Pt NWs/C and the conventional Pt NPs/C electrocatalyst. The If/Ib ratio of three different catalysts are shown in order: Pt NWs/Ti0.7W0.3O2 (~2.70) > Pt NWs/C (~1.03) > Pt NPs/C (0.97), suggesting that the Pt NWs/Ti0.7W0.3O2 electrocatalysts possessed the best CO-tolerance in comparison with the Pt NWs/C and the conventional Pt NPs/C catalysts towards MOR. The high If/Ib value of the Pt NWs/Ti0.7W0.3O2 electrocatalyst compared to that of the Pt NWs/C electrocatalyst could be explained due to the strong interaction between Pt nanocatalyst and Ti0.7W0.3O2 support, resulting in making weak adsorption of CO-like species on the sites of Pt nanocatalyst2,6,26 (Table 1). For the Pt NPs/C electrocatalyst, the high If/Ib value of the Pt NWs/Ti0.7W0.3O2 electrocatalyst was attributable to the strong interaction between Pt nanocatalyst and Ti0.7W0.3O2 support as well as the advantages of one-dimensional (1D) structure of Pt nanocatalyst such as (i) long segments of smooth crystal planes, (ii) a low number of surface defects, leading to good sensitivity and and activity for methanol electro-oxidation reaction11,18 and (iii) unique one-dimensional (1D) Pt morphology, resulting in improving mass transport and electron transfers during electrocatalytic reactions11,17,18,27,28.

In order to examine the durability of the Pt NWs/Ti0.7W0.3O2 catalyst towards MOR, the 5000 potential cycling measurement was conducted in N2-purged 10 v/v % CH3OH/0.5 M H2SO4 solution at a scan rate of 50 mV/s. Figure 4c–e show the CVs of three different electrocatalysts before and after the test. As results indicated that the Pt NWs/Ti0.7W0.3O2 electrocatalysts exhibited superior stability in comparison with the Pt NWs/C, and the conventional Pt NPs/C catalysts. Particularly, the Pt NWs/Ti0.7W0.3O2 catalyst demonstrated the deterioration of the mass activity to be around 12.05% of the initial mass activity, which was ~2.18-times and ~3.06-fold lower than those of the Pt NWs/C (~26.36%), and the conventional Pt NPs/C electrocatalysts (~36.83%), respectively (see Fig. 4f). It can be concluded that the stability of the Pt NWs/Ti0.7W0.3O2 was greatly enhanced towards the MOR.

Application of the Pt NWs/Ti0.7W0.3O2 towards ethanol electro-oxidation reaction (EOR)

Until now, ethanol has emerged as green fuel sources, which can alter for methanol because of lower toxicity and market cost, however, one of the most major challenges is the development of the electrocatalyst with the great electrocatalytic stability and activity towards ethanol electro-oxidation reaction (EOR)11. With the unique electrocatalytic properties towards MOR, we also further evaluated the catalytic activity and stability of the Pt NWs/Ti0.7W0.3O2 electrocatalyst for the EOR. Figure 5a shows the CV curves of three different electrocatalysts in N2-purged 10 v/v % C2H5OH/0.5 M H2SO4 solution at a scan rate of 50 mV/s. By comparing the positive-going and negative-going EOR waves in terms of the peak potential and peak current, the Pt NWs anchored over the mesoporous Ti0.7W0.3O2 catalyst support exhibited the higher electrocatalytic activity than the Pt NWs/C and the conventional Pt NPs/C electrocatalyst. On the positive-going sweep, both the onset potential and ethanol electro-oxidation potential of the Pt NWs/Ti0.7W0.3O2 catalyst were negatively shifted compared to those of the conventional Pt NPs/C to be ~300 mV and ~40 mV, respectively (see Fig. 5a), implying the better CO-tolerance of the as-prepared Pt NWs/Ti0.7W0.3O2 catalyst due to the facile removal of the adsorbed carbonaceous intermediate species14,29. Moreover, the mass activity of the Pt NWs/Ti0.7W0.3O2 catalyst was found to be around 325.01 mA/mgPt, which was ~1.91-fold and ~2.35-times higher than those of the Pt NWs/C (~169.73 mA/mgPt), and the traditional Pt NPs/C (~137.98 mA/mgPt), respectively (Fig. 5b), suggesting that the catalytic activity towards ethanol electro-oxidation reaction (EOR) of the Pt NWs/Ti0.7W0.3O2 catalyst was drastically improved. The great mass activity of the as-obtained Pt NWs/Ti0.7W0.3O2 catalyst could result from the strong interaction between the Pt nanocatalyst and Ti0.7W0.3O2 support which provides active species for catalytic reaction resulting in enhancing the dehydrogenation of ethanol30,31,32,33. For the negative-going waves, the anodic peak corresponds to the continuous oxidation of ethanol when the adsorbed intermediate species on the catalyst’s surface in the forward sweep are removed34. Importantly, the Pt NWs/Ti0.7W0.3O2 catalyst possessed the highest If/Ib values, which showed in order: Pt NWs/Ti0.7W0.3O2 (~1.35) > Pt NWs/C (~0.87) > Pt NPs/C (~0.83), suggesting that the Pt NWs/Ti0.7W0.3O2 possessed the high resistance to poisoning of the accumulation of carbonaceous species (Table 2). Besides the advantages of the one-dimensional Pt morphology, the electronic transfer from the mesoporous Ti0.7W0.3O2 support to the Pt nanocatalyst (so-called “electronic effect”) making the downshift d-band center of the Pt nanocatalyst and lower the adsorption energy of COads, facilitating the oxidation of COads at a lower potentials2,24, resulting in the significant enhancement of both the electrocatalytic activity and stability of the Pt NWs/Ti0.7W0.3O2 catalyst.

The electrocatalytic stability of the Pt NWs/Ti0.7W0.3O2 towards EOR was further investigated via the accelerated durability test (ADT) in N2-purged 10 v/v % C2H5OH/0.5 M H2SO4 aqueous solution. These outcomes indicated that the Pt NWs/Ti0.7W0.3O2 catalyst possessed the superior stability towards ethanol electro-oxidation in comparison with the Pt NWs/C and the conventional Pt NPs/C electrocatalysts. For instance, after 5000 cycling test, the mass activity of the Pt NWs/Ti0.7W0.3O2 electrocatalyst was found to be around 283.89 mA/mgPt with respect to the deterioration to be ~12.65% of the initial mass activity (~325.01 mA/mgPt), meanwhile, the Pt NWs/C and conventional Pt NPs/C electrocatalysts showed the decay to be around ~30.09% (from 169.73 mA/mgPt dropped to 118.66 mA/mgPt) and ~45.36% (from 137.98 mA/mgPt to 75.41 mA/mgPt), respectively (see Fig. 5c–f). The significant degradation of the Pt NWs/C and the conventional Pt NPs/C electrocatalyst is attributable to the poor durability of the carbon-based support resulting in the detachment/dissolution, Ostwald ripening of the Pt nanocatalyst2.

The chronoamperometry measurement in N2-purged 10 v/v % C2H5OH/0.5 M H2SO4 aqueous solution at the immobilized potential of 0.7 V for 7200 s was carried out to investigate the electrocatalytic stability of the Pt NWs/Ti0.7W0.3O2 electrocatalyst towards EOR. As can be seen in Fig. 6, the Pt NWs/Ti0.7W0.3O2 catalyst exhibited the initial mass activity to be 187.04 mA/mgPt, which is higher than those of the Pt NWs/C (~178.99 mA/mgPt) and the conventional Pt NPs/C (~175.21 mA/mgPt). After 7200 s test, the mass activity of the Pt NWs/Ti0.7W0.3O2 electrocatalyst was remained to be around 116.80 mA/mgPt, which is ~1.54-fold and ~8.44-fold higher than those of the Pt NWs/C (75.90 mA/mgPt) and the Pt NPs/C (13.84 mA/mgPt) at the same time, respectively. The decay rate of the as-prepared catalysts is showed in order: Pt NWs/Ti0.7W0.3O2 (~0.59 mA/mgPt.min) < Pt NWs/C (~0.86 mA/cm2.min) < Pt NPs/C (~1.34 mA/mgPt.min). The superior durability of the Pt NWs/Ti0.7W0.3O2 electrocatalyst relative to the conventional Pt NPs/C could be interpreted due to the lower vulnerability to dissolution, Ostwald ripening and aggregation of the 1D Pt structure (nanowires) than 0D Pt structure (nanoparticles)11,13,14. In addition, the high corrosion resistance of TiO2-based oxide in acidic and oxidative environments14 as well as the electronic effect between the mesoporous Ti0.7W0.3O2 support and the Pt nanocatalysts, which results in the weak adsorption of carbonaceous intermediate species on the active sites of the Pt nanocatalysts and, consequently, improve the catalytic stability of the Pt NWs/Ti0.7W0.3O2 catalyst.

Discussion

In brief, we introduce the robust Pt NWs/Ti0.7W0.3O2 electrocatalyst, which was prepared via a simple chemical reduction route at room temperature without utilizing surfactant/stabilizers or template. The experimental outcomes demonstrated that the robust Pt NWs/Ti0.7W0.3O2 catalyst is a promising electrocatalyst towards the methanol electro-oxidation and ethanol electro-oxidation. For instance, the Pt NWs/Ti0.7W0.3O2 electrocatalyst exhibited the lower onset potential (~0.1 V vs. NHE for MOR and ~0.2 V vs. NHE for EOR), higher mass activity (~355.29 mA/mgPt for MOR and ~325.01 mA/mgPt for EOR), and the greater If/Ib ratio (~2.70 for MOR and ~1.35 for EOR) along with the superior stability in acidic and oxidative environment related to the conventional Pt/C catalyst. These enhancements of the Pt NWs/T0.7W0.3O2 catalyst are attributable to the merits of the one-dimensional Pt structure and the mesoporous Ti0.7W0.3O2 catalyst support, as well as the electron transfers from the Ti0.7W0.3O2 catalyst support to the Pt nanowires, which was evidenced via the XPS spectroscopy, leading to the weak linkage of intermediate carbonaceous species on the active surface of the Pt nanocatalyst. Furthermore, this approach may provide a robust catalytic platform for fuel cell technologies and a variety of applications.

Methods

Fabrication of the Pt NWs/Ti0.7W0.3O2 electrocatalyst

In this work, the simple chemical reduction route was utilized to produce the Pt NWs/Ti0.7W0.3O2 catalyst consisted of using the chloroplatinic acid hydrate (H2PtCl6.xH2O) and the as-prepared Ti0.7W0.3O2 catalyst support as starting precursors as well as the formic acid (HCOOH) as reducing agent. Briefly, a mixture of 8 mL H2O and 0.62 mL 0.05 M H2PtCl6 aqueous solution and 1.2 mL HCOOH was stirred for 15 min to generate a homogenous solution. Next, 6 mg Ti0.7W0.3O2 supports were ultrasonically dissolved into the above solution for 15 min to create a homogeneous suspension. Afterward, the as-prepared suspension was stored at room temperature for 72 hours to fabricate the 50 wt % Pt NWs/Ti0.7W0.3O2 catalyst. Finally, the obtained product was rinsed copiously with purified water and then dried at 80 °C overnight for further analysis. For comparison, the 50 wt % Pt NWs were grown on Vulcan XC-72 support at the same condition.

Material characterization

The structure information of the formed Pt nanowires over the mesoporous Ti0.7W0.3O2 support was measured via the X-ray diffraction (XRD) measurement operated on a D2 PHASER-Brucker using Cu Kα radiation at 30 kV. The transmission electron microscopy (TEM) measurement was conducted on the JEOL-LEM 1400 microscope at an accelerating voltage of 3800 V to examine the morphology of the as-prepared Pt NWs/Ti0.7W0.3O2 catalyst. Furthermore, the X-ray photoelectron spectroscopy (XPS) was implemented to investigate the surface properties of the as-obtained Pt NWs/Ti0.7W0.3O2 electrocatalyst.

Electrochemical properties

An EC-LAB Electrochemistry instrument (Bio-Logic SAS) with an Ag/AgCl/Sat. KCl electrode, and a Pt gauze, as well as glassy carbon electrode with 5 mm in diameter with respect to a reference electrode and the counter electrode as well as a working electrode, were used for investigating all electrochemical tests. The electrocatalytic activity towards methanol electro-oxidation reaction (MOR) and ethanol electro-oxidation reaction (EOR) of the as-obtained catalysts was recorded at a scan rate of 50 mV/s in N2-statured 10 v/v % CH3OH/0.5 M H2SO4 solution and N2-statured 10 v/v % C2H5OH/0.5 M H2SO4 solution, respectively. Furthermore, the ADT test was performed in the range of 0 V to 1.0 V (vs. NHE) for 5000 cycles at a scan rate of 50 mV/s at room temperature in N2-purged 10 v/v% CH3OH/0.5 M H2SO4 and in N2-purged 10 v/v% C2H5OH/0.5 M H2SO4 for methanol electro-oxidation reaction (MOR) and ethanol electro-oxidation reaction (EOR), respectively. All potential ranges in this work were reported with the normal hydrogen electrode (NHE) scale. The catalyst ink preparation: the catalyst powder was ultrasonicated in a solution comprising ethanol absolute and 0.5% Nafion within 30 min. Before the catalyst ink placement, the surface of the glassy carbon disk was polished with 0.5 µm BAS and then washed with ethanol as well as purified water. To start with, the catalyst electrode was activated by 100 cycles at a scan rate of 50 mV/s. In this work, the Pt loading onto the glassy carbon electrode was maintained at 0.13 mg/cm2 in all electrochemical tests.

References

Huang, H., Hu, X., Zhang, J., Su, N. & Cheng, J. Facile Fabrication of Platinum-Cobalt Alloy Nanoparticles with Enhanced Electrocatalytic Activity for a Methanol Oxidation Reaction. Sci Rep 7, 45555 (2017).

Thanh Ho, V. T. et al. Robust non-carbon Ti0.7Ru0.3O2 support with co-catalytic functionality for Pt: enhances catalytic activity and durability for fuel cells. Energy & Environmental Science, 4(10) (2011).

Kim, M., Kwon, C., Eom, K., Kim, J. & Cho, E. Electrospun Nb-doped TiO2 nanofiber support for Pt nanoparticles with high electrocatalytic activity and durability. Sci Rep 7, 44411 (2017).

Wang, R. et al. Controlled growth of platinum nanowire arrays on sulfur doped graphene as high performance electrocatalyst. Sci Rep 3, 2431 (2013).

Zhang, C., Xu, L., Yan, Y. & Chen, J. Controlled Synthesis of Pt Nanowires with Ordered Large Mesopores for Methanol Oxidation Reaction. Scientific Reports, 6(1) (2016).

Ho, V. T., Pan, C. J., Rick, J., Su, W. N. & Hwang, B. J. Nanostructured Ti0.7Mo0.3O2 support enhances electron transfer to Pt: high-performance catalyst for oxygen reduction reaction. J Am Chem Soc 133(30), 11716 (2011).

Huynh, T. T. et al. High conductivity of novel Ti0.9Ir0.1O2 support for Pt as a promising catalyst for low-temperature fuel cell applications. International Journal of Hydrogen Energy (2018).

Huynh, T. T. et al. High conductivity and surface area of Ti0.7W0.3O2 mesoporous nanostructures support for Pt toward enhanced methanol oxidation in DMFCs. International Journal of Hydrogen Energy (2018).

Nguyen, A. V. et al. Novel nanorod Ti0.7Ir0.3O2 prepared by facile hydrothermal process: A promising non-carbon support for Pt in PEMFCs. International Journal of Hydrogen Energy (2018).

Huynh, T. T., Pham, H. Q., Nguyen, A. V., Bach, L. G. & Ho, V. T. T. Advanced Nanoelectrocatalyst of Pt Nanoparticles Supported on Robust Ti0.7Ir0.3O2 as a Promising Catalyst for Fuel Cells. Industrial & Engineering Chemistry Research 58(2), 675–684 (2019).

Valério Neto, E. S., Gomes, M. A., Salazar-Banda, G. R. & Eguiluz, K. I. B. Pt and Pt–Rh nanowires supported on carbon and SnO2:Sb nanoparticles for ethanol electrochemical oxidation in acidic media. International Journal of Hydrogen Energy 43(1), 178–188 (2018).

Zhou, W.-P. et al. Morphology-dependent activity of Pt nanocatalysts for ethanol oxidation in acidic media: Nanowires versus nanoparticles. Electrochimica Acta 56(27), 9824–9830 (2011).

Bu, L. et al. Surface engineering of hierarchical platinum-cobalt nanowires for efficient electrocatalysis. Nat Commun 7, 11850 (2016).

Ho, V. T. T. et al. Advanced nanoelectrocatalyst for methanol oxidation and oxygen reduction reaction, fabricated as one-dimensional pt nanowires on nanostructured robust Ti0.7Ru0.3O2 support. Nano Energy 1(5), 687–695 (2012).

Sun, S. et al. A highly durable platinum nanocatalyst for proton exchange membrane fuel cells: multiarmed starlike nanowire single crystal. Angew Chem Int Ed Engl 50(2), 422–6 (2011).

Xia, Y., Xiong, Y., Lim, B. & Skrabalak, S. E. Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics? Angew Chem Int Ed Engl 48(1), 60–103 (2009).

Sun, S., Jaouen, F. & Dodelet, J.-P. Controlled Growth of Pt Nanowires on Carbon Nanospheres and Their Enhanced Performance as Electrocatalysts in PEM Fuel Cells. Advanced Materials 20(20), 3900–3904 (2008).

Sun, S. et al. Direct growth of single-crystal Pt nanowires on Sn@CNT Nanocable: 3D electrodes for highly active electrocatalysts. Chemistry 16(3), 829–35 (2010).

Sun, S., Yang, D., Zhang, G., Sacher, E. & Dodelet, J.-P. Synthesis and Characterization of Platinum Nanowire–Carbon Nanotube Heterostructures. Chemistry of Materials 19(26), 6376–6378 (2007).

Zheng, L. et al. Facile preparation of rutile Ti0.7W0.3O2 with high conductivity and its effect on enhanced electrocatalytic activity of Pt as catalyst support. Electrochimica Acta 150, 197–204 (2014).

Guo, G. et al. Synthesis of Platinum Nanoparticles Supported on Poly(acrylic acid) Grafted MWNTs and Their Hydrogenation of Citral. Chemistry of Materials 20(6), 2291 (2008).

Kumar, A. & Ramani, V. Strong Metal–Support Interactions Enhance the Activity and Durability of Platinum Supported on Tantalum-Modified Titanium Dioxide Electrocatalysts. ACS. Catalysis 4(5), 1516–1525 (2014).

Lv, H. et al. Carbon-supported Pt-Co Nanowires as a Novel Cathode Catalyst for Proton Exchange Membrane Fuel Cells. Fuel Cells 17(5), 635–642 (2017).

Zhao, X. et al. Recent advances in catalysts for direct methanol fuel cells. Energy & Environmental Science, 4(8) (2011).

Yoo, E. et al. Enhanced Electrocatalytic Activity of Pt Subnanoclusters on Graphene Nanosheet Surface. Nano Letters 9(6), 2255–2259 (2009).

Pan, C.-J. et al. Tuning/exploiting Strong Metal-Support Interaction (SMSI) in Heterogeneous Catalysis. Journal of the Taiwan Institute of Chemical Engineers 74, 154–186 (2017).

Choi, S. M., Kim, J. H., Jung, J. Y., Yoon, E. Y. & Kim, W. B. Pt nanowires prepared via a polymer template method: Its promise toward high Pt-loaded electrocatalysts for methanol oxidation. Electrochimica Acta 53(19), 5804–5811 (2008).

Lee, E. P. et al. Electrocatalytic Properties of Pt Nanowires Supported on Pt and W Gauzes. ACS Nano 2(10), 2167–2173 (2008).

Ganesan, R. & Lee, J. S. An electrocatalyst for methanol oxidation based on tungsten trioxide microspheres and platinum. Journal of Power Sources 157(1), 217–221 (2006).

Zhu, Y., Liu, D. & Meng, M. H2 spillover enhanced hydrogenation capability of TiO2 used for photocatalytic splitting of water: a traditional phenomenon for new applications. Chem Commun (Camb) 50(45), 6049–51 (2014).

Prins, R. Hydrogen spillover. Facts and fiction. Chem Rev 112(5), 2714–38 (2012).

Micoud, F., Maillard, F., Bonnefont, A., Job, N. & Chatenet, M. The role of the support in CO(ads) monolayer electrooxidation on Pt nanoparticles: Pt/WO(x)vs. Pt/C. Phys Chem Chem Phys 12(5), 1182–93 (2010).

Wang, D. et al. Highly Stable and CO-Tolerant Pt/Ti0.7W0.3O2 Electrocatalyst for Proton-Exchange Membrane Fuel Cells. Journal of the American Chemical Society 132(30), 10218–10220 (2010).

Liao, Y. et al. Composition-Tunable PtCu Alloy Nanowires and Electrocatalytic Synergy for Methanol Oxidation Reaction. The Journal of Physical Chemistry C 120(19), 10476–10484 (2016).

Luo, Z. et al. One-pot, low-temperature synthesis of branched platinum nanowires/reduced graphene oxide (BPtNW/RGO) hybrids for fuel cells. Journal of Materials Chemistry 22, 16 (2012).

Li, C., Malgras, V., Alshehri, S. M., Kim, J. H. & Yamauchi, Y. Electrochemical Synthesis of Mesoporous Pt Nanowires with Highly Electrocatalytic Activity toward Methanol Oxidation Reaction. Electrochimica Acta 183, 107–111 (2015).

Fan, Y. et al. Bi-functional porous carbon spheres derived from pectin as electrode material for supercapacitors and support material for Pt nanowires towards electrocatalytic methanol and ethanol oxidation. Electrochimica Acta 163, 140–148 (2015).

Wang, P., Wen, Y., Yin, S., Wang, N. & Shen, P. K. PtRh alloys on hybrid TiO2 – Carbon support as high efficiency catalyst for ethanol oxidation. International Journal of Hydrogen Energy 42(39), 24689–24696 (2017).

Junjie Mao, W. C. et al. Design of ultrathin Pt-Mo-Ni nanowire catalysts for ethanol electrooxidation. Sci. Adv. (3), e1603068 (2017).

Li, F.-M., Gao, X.-Q., Li, S.-N., Chen, Y. & Lee, J.-M. Thermal decomposition synthesis of functionalized PdPt alloy nanodendrites with high selectivity for oxygen reduction reaction. NPG Asia. Materials 7(10), e219–e219 (2015).

Wang, H. et al. Platinum-Tin Nanowires Anchored on a Nitrogen-Doped Nanotube Composite Embedded with Iron/Iron Carbide Particles as an Ethanol Oxidation Electrocatalyst. Journal of The Electrochemical Society 162(1), H79–H85 (2014).

Wu, F. et al. Microfluidic Synthesis Enables Dense and Uniform Loading of Surfactant-Free PtSn Nanocrystals on Carbon Supports for Enhanced Ethanol Oxidation. Angew Chem Int Ed Engl 55(16), 4952–6 (2016).

Acknowledgements

This research is funded by Ho Chi Minh City University of Technology, VNU-HCM, under grant number BK-SDH-2019-1880699.

Author information

Authors and Affiliations

Contributions

Van Thi Thanh Ho proposed and Giang Long Bach co-supervised the project. Hau Quoc Pham designed and performed experiments under the support of Tai Thien Huynh, Anh Tram Ngoc Mai. Hau Quoc Pham analyzed and wrote the manuscript. All author participated in discussions of the research.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pham, H.Q., Huynh, T.T., Mai, A.T.N. et al. Wire-like Pt on mesoporous Ti0.7W0.3O2 Nanomaterial with Compelling Electro-Activity for Effective Alcohol Electro-Oxidation. Sci Rep 9, 14791 (2019). https://doi.org/10.1038/s41598-019-51235-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-51235-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.