Abstract

Stabilizing reagents that can be deposited onto paper is an important issue for researchers who depend on paper-based analytical devices (PADs), because long-term stability of the devices is essential in point-of-care testing. Here, we found that poly(vinyl alcohol) (PVA) would stabilize hydrogen peroxide placed on a paper substrate following exposure to air. Horseradish peroxidase was employed as a sample in colorimetric measurements of PADs after hydrogen peroxide and 3,3′,5,5′-tetramethylbenzidine were deposited as substrates in an enzymatic reaction. The addition of PVA to hydrogen peroxide significantly suppressed its degradation. Concentrations of PVA that ranged from 0.5 to 2%, increased the duration of the stability of hydrogen peroxide, and the results for a PVA concentration of 1% approximated those of 2% PVA. Storage of the PADs at 4 °C in a refrigerator extended the stability of the hydrogen peroxide containing 2% PVA by as much as 30 days. The stability of hydrogen peroxide without PVA was degraded after one day under room temperature.

Similar content being viewed by others

Introduction

Portability and ease of operation are the qualities that allow miniaturized analytical devices to satisfy the requirements of chemical analyses outside sophisticated laboratories. Over the past decade, paper-based analytical devices (PADs) have been used to achieve point-of-care testing. PADs were first reported in 2007 by the Whitesides’ group who demonstrated paper bioassay determinations of glucose and protein that were inexpensive, low-volume and portable1. Since that first report, the use of PADs has grown rapidly, as described in many review articles2,3,4,5,6,7.

The most popular detection scheme of PADs has been colorimetry, which quantifies an analyte by color intensity of the product produced in a chemical reaction with reagents deposited on a paper substrate. Selective and specific quantification of analytes is accomplished by several chemical reactions that include complex formation between metal ions and chelate reagents8,9,10, aggregation of nanoparticles11,12,13,14 and enzymatic reactions15,16,17,18. In the colorimetric measurements, the reagents involved in the chemical reactions are deposited and dried in a specified zone of the PADs. Technicians simply add a sample into a channel or a zone to react an analyte with deposited reagents.

An important issue for PADs is the development of simple detection schemes that promote instrument-free detection. In general, colorimetry can be achieved by taking images of the PADs, which is followed by image processing to measure the color intensity or hue19,20,21. Obviously, judgment of the concentrations using only the naked eye would be an attractive option in terms of portability and ease of operation. Several groups have reported instrument-free detection using distance-readout22,23,24,25,26,27,28, time-readout29,30,31 and counting of the zones colored by a chemical reaction32,33,34. These detection schemes are promising for analyses outside of a laboratory, which is often required in developing countries and in poorly equipped laboratories.

Another issue to be resolved is the stabilization of reagents on the paper substrate, which amounts to the stability of the PADs themselves during storage. When we need chemical analyses out of the laboratory, the PADs must be stable during transport and storage. Despite the recognition of its importance by researchers, only a few studies have focused on the stability of enzymes35,36,37 and antibodies38 on paper substrates. The stabilization of horseradish peroxidase (HRP) was achieved by trehalose and SU-8 epoxy novolac resin35 whereas poly(vinyl alcohol) (PVA) has also been used as a reagent for stabilization of enzymes in the PADs39,40,41. However, to the best of our knowledge, no other successful stabilization of chemical reagents in PADs has yet been achieved, which is unfortunate.

In this study, we stabilized hydrogen peroxide deposited on a paper substrate using PVA. Hydrogen peroxide is a useful reagent in enzyme assays42,43 and chemiluminescence measurements44,45. The use of hydrogen peroxide, however, requires either a fresh solution or the preparation of PADs just prior to measurement. Ramachandran et al. employed sodium percarbonate as a source of hydrogen peroxide for ELISA in point-of-care devices. However, a fresh solution of sodium percarbonate was added in the study46. This implies that sodium percarbonate would also be unstable when deposited onto a paper substrate. In this study, we found that PVA can stabilize hydrogen peroxide deposited onto a paper substrate for at least 30 days with storage in a refrigerator whereas the deposited hydrogen peroxide immediately degraded without PVA at room temperature. The stability of hydrogen peroxide was evaluated in a reaction of HRP and 3, 3′, 5, 5′-tetramethylbenzidine as enzyme and substrate, respectively, using PADs prepared with different concentrations of PVA and stored under different temperatures.

Experimental Section

Materials. All chemicals were of analytical reagent grade. Reagent solutions were prepared using deionized water (18.2 MΩ·cm) purified using a Milli-Q System from Merck Millipore (Millipore Co. Ltd., Molsheim, France). Horseradish peroxidase (HRP), 3, 3′, 5, 5′-tetramethylbenzidine (TMB) and poly(ethylene oxide) (average molecular weight, 100,000) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Bovine serum albumin (BSA), PVA ([-CH(OH)CH2-]n, n = 1,500–1,800), sodium dihydrogen phosphate and disodium hydrogen phosphate were purchased from Wako Pure Chemical Industries (Osaka, Japan). Poly(vinyl pyrrolidone) (molecular weight, 1,000,000) was purchased from Polysciences, Inc. (Warrington, PA, USA). Polyethylene glycol #6,000 (average molecular weight, 7,800–9,000) and two different PVAs with n = 500 and n = 2,000 were obtained from Nacalai Tesque (Kyoto, Japan). The PVAs with n = 500, 1,500–1,800 and 2,000 were assigned as P500, P1650 and P2000, respectively. Hydrogen peroxide (H2O2) was acquired from Kanto Chemical (Tokyo, Japan). Preparation of a solution of TMB involved dissolving it in ethanol with the addition of 0.1 mL of 0.1 M hydrochloric acid.

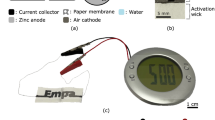

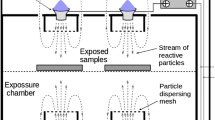

Fabrication of PADs. The PADs had reaction wells arranged in 7 mm-diameter circles that were designed using Microsoft Office Power Point 2013. The PADs were printed on a sheet of filter paper (200 × 200 mm, Chromatography Paper 1CHR, WhatmanTM, GE Healthcare Lifesciences, United Kingdom) using a wax printer (ColorQube 8580 N, Xerox, CT), which was followed by heating at 120 °C for 2 min in a drying machine (ONW-300S, AS ONE Corp., Osaka, Japan). Reagent solutions were added to each well in the following order after drying: 5 µL of 35.7 mM TMB, 5 µL of 1.0 mg mL−1 BSA (to block the adsorption of HRP onto paper)44, 5 µL of 1.0 M phosphate buffer (pH 6.5) and 5 µL of 0.01% H2O2 solution without or with PVA (10 µL of 1% H2O2 was added to 1 mL of a PVA solution with 0.5, 1.0 or 2.0 w/v%). The PADs were stored in opaque boxes with moisture absorbers (silica gel) after drying completely (Supplementary Information, Fig. S1). Then, 5 µL of a 1 mg mL−1 HRP solution was employed as a sample. The images of the PADs were captured by a scanner (CanoScan LiDE 500 F, Canon, Tokyo, Japan) and processed using Image J software according to a procedure established in the literature8.

Results and Discussion

TMB is known to be a good colorimetric reagent that changes to a blue color in the presence of H2O2 and HRP47. When all the reagent solutions, TMB, BSA, phosphate buffer and H2O2, were deposited in the wells of the PADs and stored at room temperature, the color intensity had reduced after one day. We assumed this could have been caused by degradation of the TMB and/or the H2O2, so we prepared two types of PADs, one without TMB and another without H2O2. After storage at room temperature for one day, the TMB and H2O2 were added to different reaction wells just before the introduction of HRP. Figure 1(a) shows the immediate results using a freshly prepared PAD containing both TMB and H2O2. The PAD was prepared by adding TMB, BSA, phosphate buffer and H2O2, and then HRP was added immediately after the PAD had dried completely. The PADs, on which H2O2 was pre-deposited with the reagents, except for TMB, were stored for one day at room temperature and exhibited significantly lower levels of color intensity, which indicated a degradation of the H2O2 (Fig. 1(b)). No degradation of the TMB appears in Fig. 1(c) where the PAD was prepared by pre-depositing the reagents, and H2O2 was added with HRP after one day. Here the PAD shows the same color intensity as that displayed in Fig. 1(a), which suggests the H2O2 had rapidly decomposed during storage at room temperature.

Stability of the enzyme substrates. (a) Freshly prepared PAD containing TMB and H2O2, (b) PAD prepared without TMB and stored one day at room temperature, (c) PAD prepared without H2O2 and stored one day at room temperature. In (a), HRP was added. In (b), TMB and HRP were added successively, and in (c) H2O2 and HRP were added successively.

The degradation of H2O2 would be attributed to OH− generated from water adsorbed on the paper because OH− catalyzes the decomposition of H2O2, although the catalytic reaction described in the literature was performed in an alkaline medium48. Therefore, to confirm the degradation of H2O2 by OH− at a neutral pH, H2O2 solutions were prepared with 1 mM borate buffer (pH 9) and 1 mM phosphate buffer (pH 7) and stored at room temperature. The PADs without H2O2 were prepared by adding TMB, 1 M phosphate buffer (pH 6.5) and BSA. The color intensities were 98.7 ± 1.3 for pH 7 and 69.5 ± 3.5% for pH 9 when adding the H2O2 solution and HRP to the PADs immediately after drying. Therefore, H2O2 is decomposed rapidly in a solution of at least pH 9. After storing the H2O2 solutions for one day at room temperature, the color intensities for pH 7 and 9 exhibited 55.1 ± 0.8% and 28.7 ± 0.8%, respectively (Supplementary Information, Fig. S2). The results obviously suggested that H2O2 is decomposed even at pH 7 in an aqueous solution.

To prevent the degradation of H2O2 during the storage of the PADs, we employed PVA to prevent the exposure of H2O2 to air, water in particular, because dry PVA has excellent barrier properties against permanent gases49,50. Fig. 2 shows the stability of PADs with the addition of different concentrations of PVA (P1650). The relative color intensities are expressed as the ratios of the one-day results to those obtained using a freshly prepared PAD. It should be noted that the standard deviations for all data were less than 1.3%, and smaller, than the size of the marker in the figure. Without PVA, the color intensity was immediately decreased daily and fell to less than 30%. Conversely, the color intensity was constant for 10 days with the addition of 2% PVA to H2O2. The stability depended on whether the concentration of PVA was 0.5 or 2% while no difference was detected for concentrations between 1 and 2% with storage at room temperature. These results obviously indicate that PVA suppresses the degradation of H2O2.

Three types of PVAs with different degrees of polymerization were examined for the stabilization of H2O2, as shown in Fig. 3. The PVA with n = 2,000 (P2000) shows that the stabilization of H2O2 was comparable to that with n = 1,500–1,800 (P1650) whereas the PVA with n = 500 (P500) deteriorated H2O2 in two days. A feasible reason for the poor stabilization effect of P500 would be the existence of carboxyl groups in the molecule because carboxylate may catalyze the decomposition of H2O2 as well as that of OH−. This assumption is supported by the fact that the infrared spectrum of P500 showed an extremely intensive peak of acetate groups at 1732 cm−1 compared with those of P1650 and P2000 (Supplementary Information, Fig. S3)51. Furthermore, to clarify the effect of carboxylate on the decomposition of H2O2, the pH of the phosphate buffer solutions was adjusted to 6.5 after adding 10 mM or 100 mM sodium acetate, and these were added to the PADs. The results are shown in the Supplementary Information (Fig. S4). The color intensity for both the PADs containing 10 mM and 100 mM sodium acetate gradually reduced daily whereas the phosphate buffer without sodium acetate showed no decrease in the color intensity for four days. Therefore, it is reasonable to attribute the early degradation of P500 to the carboxylate groups. Conversely, the influence of the chain length would be insignificant because P1650 exhibited stability that was longer than that of P2000. Stability of P2000 that was slightly lower than that of P1650 was attributed to reasons other than the content of carboxylate and the chain length. It should be noted that the supplier of P1650 was different from that of P500 and P2000. This implies that P1650 could have functional groups and/or a conformation that is different from that of P500 and P2000 although this remains unclear.

Ten days, however, is a short period for the storage of PADs in general use. Therefore, we attempted to extend the period of stability via storage at 4 °C in a refrigerator. As the results in Fig. 3 demonstrate, H2O2 remained stable for 30 days at a low temperature in the presence of P1650 and P2000 although the PADs without PVA and with P500 were degraded rapidly and gradually, respectively, even at 4 °C. There was no difference between a 1 and 2% concentration of PVA (P1650), and it would be difficult to further increase the concentration of PVA due to high viscosity of the solution. As shown in Fig. 4, stability was significantly improved via the addition of PVA even at a concentration as low as 2% with storage at a low temperature.

For the PADs prepared with 2% PVA, the standard deviations of intra-day measurements ranged from 0.2 to 1.1% during 45 days of storage (n = 5 for each day). The inter-day precision during 30 days was 0.6% with excellent reproducibility. Therefore, PVA proved to be an efficient stabilizer of H2O2 for deposition on a paper substrate.

We also investigated the effect of Fe(III) ion, which is known to catalyze the decomposition of H2O2. The PADs were prepared by adding all the reagents followed by 5 µL of 100 µM FeCl3 and were stored in a refrigerator. As expected, Fe(III) ions played the role of catalyst for the decomposition of H2O2. Surprisingly, PVA inhibited the catalytic reaction in the presence of 100 µM Fe(III) (99.9%) whereas the color intensity was decreased to 17.9% without PVA (Supplementary Information, Fig. S5). This implies that PVA prevents the contact of H2O2 with Fe(III).

It is known that several polymers prevent gas permeation as well as PVA, but among them only PVA is hydrophilic52. Conversely, some hydrophilic polymers possibly suppress the decomposition of H2O2 if they prevent H2O2 from contacting OH− and H2O. Therefore, we examined three hydrophilic polymers, poly(ethylene oxide), poly(ethylene glycol) and poly(vinyl pyrrolidone), as candidates of substituent chemicals for PVA. Interestingly, these polymers also suppressed the degradation of H2O2 as well. The color intensities were 99.6% for poly(ethylene oxide) and 98.9% for poly(ethylene glycol) after 10 days storage at room temperature while poly(vinyl pyrrolidone) showed a slightly weak color intensity after 10 days (98.9% after 7days and 84.3% after 10 days). Therefore, these hydrophilic polymers can also be employed to stabilize H2O2 deposited on paper substrates.

Conclusions

We mixed PVA with H2O2 before addition to the reaction wells of a PAD, and the degradation of H2O2 was suppressed. The method was quite simple and significantly improved the stability of the H2O2 deposited on a PAD. The H2O2 on a PAD had degraded in only one day without the addition of PVA at room temperature, whereas with the addition of 1 and 2% PVA, the H2O2 deposited on a PAD was stabilized for at least 30 days when stored at 4 °C in a refrigerator. Improving the stability of enzyme substrates for PADs is important for achieving point-of-care testing. Therefore, PVA is expected to be a useful stabilizer for other enzyme substrates. Even for use in developing countries where no refrigerator is available, the PADs can be transported with PVA under cooled conditions, although the PADs without PVA degrade immediately. Therefore, the PADs will work well in developing countries with poorly equipped laboratories when they are used immediately after transport. Other water-soluble polymers, such as poly(ethylene oxide), poly(ethylene glycol), and poly(vinyl pyrrolidone), would also improve the stability of enzyme substrates and other molecules such as enzymes, antibodies and nucleic acids. Thus, further investigation to explore a more effective stabilizer is expected to improve the practicality of PADs.

Data Availability

All data generated or analysed during this study are included in this article (and its Supplementary Information files).

References

Martinez, A. W., Phillips, S. T., Butte, M. J. & Whitesides, G. M. Patterned paper as a platform for inexpensive, low-volume, portable bioassays. Angew. Chem., Int. Ed. 46, 1318–1320 (2007).

Yang, Y. et al. Paper-based microfluidic devices: emerging themes and applications. Anal. Chem. 89, 71–91 (2017).

Yamada, K., Shibata, H., Suzuki, K. & Citterio, D. Toward practical application of paper-based microfluidics for medical diagnostics: state-of-the-art and challenges. Lab. Chip 17, 1206–1249 (2017).

Smith, S., Korvink, J. G., Mager, D. & Land, K. The potential of paper-based diagnostics to meet the ASSURED criteria. RSC Adv. 8, 34012–34034 (2018).

Lee, V. B. C., Mohd-Naim, N. F., Tamiya, E. & Ahmed, M. U. Trends in paper-based electrochemical biosensors: from design to application. Anal. Sci. 34, 7–18 (2018).

Tian, T., Bi, Y., Xu, X., Zhua, Z. & Yang, C. Integrated paper-based microfluidic devices for point-of-care testing. Anal. Methods 10, 3567–3581 (2018).

Kaneta, T., Alahmad, W. & Varanusupakul, P. Microfluidic paper-based analytical devices with instrument-free detection and miniaturized portable detectors. Appl. Spectrosc. Rev. 54, 117–141 (2018).

Mentele, M. M., Cunningham, J., Koehler, K., Volckens, J. & Henry, C. S. Microfluidic paper-based analytical device for particulate metals. Anal. Chem. 84, 4474–4480 (2012).

Cate, D. M. et al. Rapid detection of transition metals in welding fumes using paper-based analytical devices. Ann. Occup. Hyg. 58, 413–423 (2014).

Ogawa, K. & Kaneta, T. Determination of iron ion in the water of a natural hot spring using microfluidic paper-based analytical devices. Anal. Sci. 32, 31–34 (2016).

Dungchai, W., Sameenoi, Y., Chailapakul, O., Volckens, J. & Henry, C. S. Determination of aerosol oxidative activity using silver nanoparticle aggregation on paper-based analytical devices. Analyst 138, 6766–6773 (2013).

Tsai, T.-T., Shen, S.-W., Cheng, C.-M. & Chen, C.-F. Paper-based tuberculosis diagnostic devices with colorimetric gold nanoparticles. Sci. Technol. Adv. Mater. 14, 044404 (2013).

Chen, G. H. et al. Detection of mercury(II) ions using colorimetric gold nanoparticles on paper-based analytical devices. Anal. Chem. 86, 6843–6849 (2014).

Tsai, T.-T. et al. Diagnosis of tuberculosis using colorimetric gold nanoparticles on a paper-based analytical device. ACS Sens. 2, 1345–1354 (2017).

Lee, S., Park, J. & Park, J.-K. Foldable paper-based analytical device for the detection of an acetylcholinesterase inhibitor using an angle-based readout. Sens. Actuators B 273, 322–327 (2018).

Wu, Y., Sun, Y., Xiao, F., Wu, Z. & Yu, R. Sensitive inkjet printing paper-based colormetric strips for acetylcholinesterase inhibitors with indoxyl acetate substrate. Talanta 162, 174–179 (2017).

Böhm, A., Trosien, S., Avrutina, O., Kolmar, H. & Biesalski, M. Covalent attachment of enzymes to paper fibers for paper-based analytical devices. Front. Chem. 6, 214 (2018).

Wei, X. et al. Microfluidic distance readout sweet hydrogel integrated paper-based analytical device (μDiSH-PAD) for visual quantitative point-of-care testing. Anal. Chem. 88, 2345–2352 (2016).

Li, X., Tian, J. & Shen, W. Quantitative biomarker assay with microfluidic paper-based analytical devices. Anal. Bioanal. Chem. 396, 495–501 (2010).

Jokerst, J. C. et al. Development of a paper-based analytical device for colorimetric detection of select foodborne pathogens. Anal. Chem. 84, 2900–2907 (2012).

Ferguson, S. A., Wang, X., Mahoney, M. & Meyerhoff, M. E. Detection and quantification of polyquaterniums via polyion-sensitive ion-selective optodes inkjet printed on cellulose paper. Anal. Sci. 34, 45–50 (2018).

Cate, D. M., Dungchai, W., Cunningham, J. C., Volckens, J. & Henry, C. S. Simple, distance-based measurement for paper analytical devices. Lab Chip 13, 2397–2404 (2013).

Cate, D. M., Noblitt, S. D., Volckens, J. & Henry, C. S. Multiplexed paper analytical device for quantification of metals using distance-based detection. Lab Chip 15, 2808–2818 (2015).

Yamada, K., Henares, T. G., Suzuki, K. & Citterio, D. Distance-based tear lactoferrin assay on microfluidic paper device using interfacial interactions on surface-modified cellulose. ACS Appl. Mater. Interfaces 7, 24864–24875 (2015).

Buking, S. et al. Microfluidic paper-based analytical device for quantification of lead using reaction band-length for identification of bullet hole and its potential for estimating firing distance. Anal. Sci. 34, 83–89 (2018).

Piyanan, T., Athipornchai, A., Henry, C. S. & Sameenoi, Y. An instrument-free detection of antioxidant activity using paper-based analytical devices coated with nanoceria. Anal. Sci. 34, 97–102 (2018).

Shimada, Y. & Kaneta, T. Highly sensitive paper-based analytical devices with the introduction of a large-volume sample via continuous flow. Anal. Sci. 34, 65–70 (2018).

Hashimoto, Y. & Kaneta, T. Chromatographic paper-based analytical devices using an oxidized paper substrate. Anal. Methods 11, 179–184 (2019).

Lewis, G. G., Robbins, J. S. & Phillips, S. T. Point-of-care assay platform for quantifying active enzymes to femtomolar levels using measurements of time as the readout. Anal. Chem. 85, 10432–10439 (2013).

Lewis, G. G., Robbins, J. S. & Phillips, S. T. A prototype point-of-use assay for measuring heavy metal contamination in water using time as a quantitative readout. Chem. Commun. 50, 5352–5354 (2014).

Zhang, Y. et al. Timing readout in paper device for quantitative point-of-use hemin/G-quadruplex DNAzyme-based bioassays. Biosens. Bioelectron. 73, 13–18 (2015).

Zhang, Y. et al. Equipment-free quantitative measurement for microfluidic paper-based analytical devices fabricated using the principles of movable-type printing. Anal. Chem. 86, 2005–2012 (2014).

Karita, S. & Kaneta, T. Acid-base titrations using microfluidic paper-based analytical devices. Anal. Chem. 86, 12108–12114 (2014).

Karita, S. & Kaneta, T. Chelate titrations of Ca2+ and Mg2+ using microfluidic paper-based analytical devices. Anal. Chim. Acta 924, 60–67 (2016).

Ganaja, K. A., Chaplan, C. A., Zhang, J., Martinez, N. W. & Martinez, A. W. Paper microzone plates as analytical tools for studying enzyme stability: a case study on the stabilization of horseradish peroxidase using trehalose and SU-8 epoxy novolac resin. Anal. Chem. 89, 5333–5341 (2017).

Yu, J., Ge, L., Huang, J., Wang, S. & Ge, S. Microfluidic paper-based chemiluminescence biosensor for simultaneous determination of glucose and uric acid. Lab Chip 11, 1286–1291 (2011).

Ilacas, G. & Gomez, F. A. Microfluidic paper-based analytical devices (μPADs): miniaturization and enzyme storage studies. Anal. Sci. 35, 379–384 (2019).

Wu, G., Srivastava, J. & Zaman, M. H. Stability measurements of antibodies stored on paper. Anal. Biochem. 449, 147–154 (2014).

Olkkonen, J., Lehtinen, K. & Erho, T. Flexographically printed fluidic structures in paper. Anal. Chem. 82, 10246–10250 (2010).

Seok, Y. et al. A paper-based device for performing loop-mediated isothermal amplification with real-time simultaneous detection of multiple DNA targets. Theranostics 7, 2220–2230 (2017).

Nery, E. W. & Kubota, L. T. Evaluation of enzyme immobilization methods for paper-based devices–a glucose oxidase study. J. Pharm. Biomed. Anal. 117, 551–559 (2016).

Busa, L. S. et al. 3,3′,5,5′-Tetramethylbenzidine oxidation on paper devices for horseradish peroxidase-based assays. Anal. Sci. 32, 815–818 (2016).

Talalak, K., Noiphung, J., Songjaroen, T., Chailapakul, O. & Laiwattanapaisal, W. A facile low-cost enzymatic paper-based assay for the determination of urine creatinine. Talanta 144, 915–921 (2015).

Ge, L., Wang, S., Song, X., Ge, S. & Yu, J. 3D origami-based multifunction-integrated immunodevice: low-cost and multiplexed sandwich chemiluminescence immunoassay on microfluidic paper-based analytical device. Lab Chip 12, 3150–3158 (2012).

Alahmad, W., Uraisin, K., Nacapricha, D. & Kaneta, T. A miniaturized chemiluminescence detection system for a microfluidic paper-based analytical device and its application to the determination of chromium(III). Anal. Methods 8, 5414–5420 (2016).

Ramachandran, S., Fu, E., Lutz, B. & Yager, P. Long-term dry storage of an enzyme-based reagent system for ELISA in point-of-care devices. Analyst 139, 1456–1462 (2014).

Busa, L. S. A., Maeki, M., Ishida, A., Tani, H. & Tokeshi, M. Simple and sensitive colorimetric assay system for horseradish peroxidase using microfluidic paper-based devices. Sens. Actuators B 236, 433–441 (2016).

Duke, F. R. & Haas, T. W. The homogeneous base-catalyzed decomposition of hydrogen peroxide. J. Pys. Chem. 65, 304–306 (1961).

Johansson, C. & Clegg, F. Hydrophobically modified poly(vinyl alcohol) and bentonite nanocomposites thereof: Barrier, mechanical, and aesthetic properties. J. Appl. Polym. Sci. 132, 41737 (2015).

Karlsson, G. E., Gedde, U. W. & Hedenqvist, M. S. Molecular dynamics simulation of oxygen diffusion in dry and water-containing poly(vinyl alcohol). Polymer 45, 3893–3900 (2004).

Lee, H. W. et al. Electrospinning fabrication and characterization of poly(vinyl alcohol)/montmorillonite nanofiber mats. J. Appl. Polym. Sci. 113, 1860–1867 (2009).

Hammon, H. G., Ernst, K. & Newton, J. C. Noble-gas permeability of polymer-films and coatings. J. Appl. Polym. Sci. 21, 1989–1997 (1977).

Acknowledgements

This research was supported by JSPS KAKENHI Grant Number JP17H05465 and JP19H04675.

Author information

Authors and Affiliations

Contributions

T.B. and T.K. performed the experiments. T.K. planned and designed the experiment. W.W. and T.K. supervised the experiment. T.B., W.W. and T.K. interpreted the results. T.B. and T.K. analysed the data. T.K. wrote the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Boonpoempoon, T., Wonsawat, W. & Kaneta, T. Long-term stabilization of hydrogen peroxide by poly(vinyl alcohol) on paper-based analytical devices. Sci Rep 9, 12951 (2019). https://doi.org/10.1038/s41598-019-49393-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-49393-6

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.